At the final stage of the construction of a summer house or a country house, an external staircase is being built. Outwardly, such structures are no different from those used to connect floors, however, higher requirements are imposed on them in terms of strength. Such structures must withstand well temperature changes, the influence of atmospheric precipitation, etc.

It is pleasant to consider the most durable and reliable stairs made of concrete, which are made directly at the construction site. However, metal and wooden structures are often used.

The device of a street staircase should be thought out even at the stage of building a house. Thanks to this approach, you can not only correctly calculate and position the staircase, but also provide it with maximum protection from environmental conditions.

Purpose of street stairs

Outdoor stairs are very important in the household. Through their construction, the house is connected with the adjacent territory, that is, the connection of two sites located at different levels.

To date, there are several options for the device of external stairs:

- Entrance steps (porch) are the most common option. In the event that the territory is located at an angle, you may even need a whole flight of stairs.

- Connection of the upper landing with the terrace.

- In the presence of a high basement floor.

- A staircase from the street to the second floor, through which an additional entrance to the room is created, which can be accessed from inside the building.

- If we are talking about resorts, then in this case, two-storey cottages are often used, in which there is a separate living room on each floor, not communicated with the other by a common corridor. In this case, a street staircase to the second floor is a very convenient option.

- Firefighters street stairs to the second floor, intended for evacuation, are also not uncommon.

- Many home craftsmen are interested in how to make a staircase to the attic from the street, since this option saves the interior space of a private house allocated for arranging a manhole.

Ladder construction

Street stairs to the house are of the following types:

- Vertical position for quick access to roof or attic.

- Spiral staircases.

- Conventional marching structures, both straight and curved, which can be located parallel, perpendicular or at an angle relative to the wall.

- In the event that the relief is characterized by large differences in height, you can arrange garden steps on the slope.

They are of two types:- Cut into the slope, resting on tightly compacted soil.

- Protruding, resting on specially equipped retaining walls.

Planks, limestone, gravel, logs, paving slabs, sandstone can be used to decorate garden steps of stairs - in general, any materials that will be at your fingertips. The intervals between such steps are on average 3-7 cm, that is, such stairs are "small".

Advice!

In order to avoid the development of the root system, the fertile soil must be removed by sprinkling the area with sand, which is compacted tightly.

A lawn is usually arranged on the sides of such paths, which gives the steps a spectacular appearance.

Choosing a material

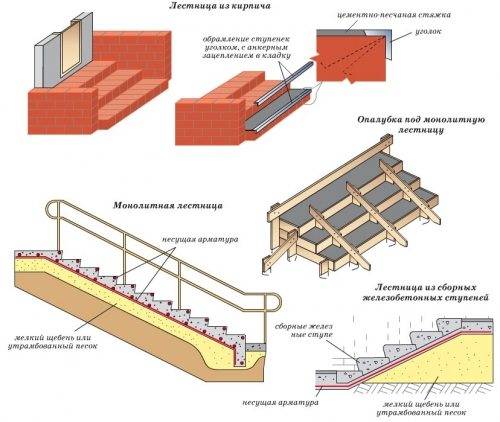

- Reinforced concrete... Both the entrance steps of the porch and additional staircases for the second floor are often made of reinforced concrete.This material is very durable and reliable, characterized by high resistance to weathering. The reinforced steel frame only adds strength to the structure.

Such stairs can be either monolithic or made of ready-made blocks. In the case of a monolith, concrete is poured into the formwork with pre-installed steel reinforcement.

Advice!

On hard soils, reinforced concrete structures can be poured without reinforcement.

- Ceramic brick... Very often, ordinary, facing or clinker bricks are used for steps. At the same time, clinker is the most advantageous option, since it is specially designed for paving paths.

Very often, when using brick blocks, certain difficulties arise when laying. It is very important here to choose the relative position of the bricks, so as not to go beyond the established dimensions. The best option is to stack two pastel blocks on top of each other.

Advice! In order not to go beyond the calculations, you can use a brick of non-standard shapes (typical for clinker), or cut some blocks to the desired size.

Such structures are usually installed on a concrete or gravel-cement foundation.

- Street metal stairs are no less common than concrete ones.... Metal allows you to embody any design solutions, therefore among such products there are both cheap attic stairs and premium constructions, the price of which will not be affordable for many owners of private houses.

As a rule, household, evacuation and additional stairs are made of metal. Such structures can be assembled from fittings, profiles, angles or pipes of various diameters, connected by means of welding or screws.

Advice!

To protect metal steps from corrosion, it is advisable to paint them.

If we talk about forged models, then they are very strong and durable, while differing in their original and attractive design. However, they are quite expensive and very massive.

- Wood... Wooden outdoor stairs are also not uncommon. Most of them are made for wooden houses. To protect it from decay, the tree is treated with an antiseptic and covered with waterproof paint.

Advice!

To ensure fire safety, wood must be treated with fire retardants.

Making a reinforced concrete staircase

Since reinforced concrete stairs are one of the most popular today, we will figure out how to properly fill such a structure with our own hands.

The instruction provides several stages:

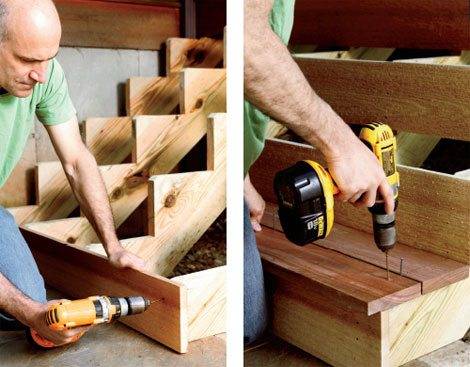

- At the first stage of work, the formwork is made. You must prepare in advance all the materials that are needed for this stage - bars, boards, nails, plywood boards. Boards and plywood boards will be nailed to the bars. When creating the formwork, care must be taken to ensure that no cracks or gaps arise.

Advice!

For formwork, it is best to use moisture resistant plywood sheets, 2-2.5 cm thick.

It is advisable, in addition to plywood, to also use boards fitted to each other, which will simplify further finishing work.

The formwork itself can be of two types:

- General, that is, you make the frame for the entire staircase by pouring it with concrete in one go.

- A new formwork is installed for each step. To achieve the most even steps in height and size, it would be better to use this option.

- We pour a drainage layer on the bottom of the formwork, which consists of brick chips and gravel in a 1: 1 ratio.

- We create a reinforced frame. Before filling the formwork with concrete, it is advisable to lay a reinforcing cage in it. Steel bars are placed along the flight of stairs.Their diameter is 10 mm. They are firmly connected to each other by wire or electric welding.

A mesh with mesh sizes of 150 by 150 mm is also excellent for reinforcing stairs. It is advisable to strengthen the front edges of the steps with transverse reinforcement, which will prevent crumbling.

Advice!

Before pouring the cement mortar, the formwork should be moistened with water.

- Now you can go directly to pouring the concrete solution. It is kneaded in a concrete mixer made of cement, crushed stone and sand in proportions of 1: 3: 3. The solution should be thick.

After pouring each step, a break of about five minutes should be taken so that the pressure exerted by the next step is better held. Also, each step should be leveled using special tools.

Two days after pouring the concrete, the formwork can be removed. After that, you can start facing. Reinforced concrete stairs will look great with ceramic tiles, wood or natural stone.

Conclusion

It just so happened that even in a one-story house there is a staircase located outside the building. It must be reliable and durable, while having an attractive appearance, and therefore requires careful calculation. In the video presented in this article, you will find additional information on this topic.