Types of bases

There are several types of foundations. The choice of design, methods of creating a foundation, depth of laying and other parameters are determined by a number of factors:

- type, size, weight of the building, as well as the presence of a cellar or underground garage;

- composition and characteristics of the soil at the site;

- the level of occurrence of groundwater and, in general, the presence of such on the site.

Platen

In modern construction, this type of foundation is used in the construction of large and heavy houses, the material of which is timber, brick or building blocks. A base of this type can be shallow or buried.

The main positive quality of the slab foundation is the strength of the entire structure, regardless of the characteristics of the soil. With high groundwater, this option will be one of the most preferable. The downside is the high cost and the need to attract special equipment.

Pile

It is used on sandy and clayey soils, as well as in the construction of buildings on a site with a slope. The installation of piles is also carried out using special equipment and is not cheap.

Columnar

This type of foundation stands out for its simplicity of arrangement and low cost. However, it should be used for structures with low weight, for example, for panel structures or outbuildings.

Tape

It looks like a single concrete structure with mandatory reinforcement. It is laid to a certain depth in the ground and equips itself under all the load-bearing walls of the house. Today, the strip foundation is one of the most common, since special equipment is not needed, and with the right approach and adherence to technology, it is quite possible for everyone to fill in such a foundation.

Do I need to use a special technique?

For the construction of large cottages, more and more professional equipment is used, such as a concrete mixer and a concrete pump. These units greatly facilitate and speed up the pouring of the foundation.

Concrete mixer

Concrete delivery can be ordered from a construction company. One concrete mixer can deliver about 6-8 cubic meters of the finished mixture, so it is inappropriate to use such a technique in the case of pouring a columnar foundation, you will not need such a large amount of material.

It is necessary that the concrete mixer drives up to the place of pouring the foundation from at least several sides, since concrete has the property of stratifying into water and solid materials. If you pour the mixture on only one side, its liquid part will quickly spread along its entire length, and the thicker and more stony part will remain in one place.

Concrete pump

This machine has an extendable concrete pipe boom up to 50 meters long. With the help of it, concrete can be poured from several different points, while the unit itself will remain in one position.

Household concrete mixers

In one batch, such a machine can prepare up to 200 kg of concrete. Since this volume is not enough to completely fill the strip or monolithic foundation, you will have to repeat the cycle several times. Of course, it will take longer than using industrial machines, but it will still be faster than stirring concrete by hand.

Is it possible to pour the foundation in the winter

It is far from always possible to follow the recommendations for arranging the foundation and carry out its construction by heat. There are situations when work has to be carried out at subzero temperatures. In winter, concrete can also be poured, but you should use special additives and resort to heating the mortar. In addition, it is recommended to mount a tent above the foundation, inside which they maintain a positive temperature using heat guns.

To maintain thermal conductivity in winter, you can use expanded polystyrene formwork, which will exclude the rapid solidification of the solution. The concrete should be poured in 20 cm layers and a vibrator should be used to remove the air. The upper level of the solution should correspond to the tensioned cord.

When the pouring is completed, the formwork is tapped from the outside with a hammer, and the concrete itself is leveled and covered with foil. Polyethylene is periodically removed and the foundation is spilled with water, which prevents the formation of cracks.

2 weeks after pouring, the formwork is dismantled. Directly building a house can begin a month after the foundation is poured.

Having familiarized yourself with the technology, how to properly fill the foundation under the house with your own hands and having considered step-by-step instructions with photos of the stages of construction, the arrangement of the foundation will become easier and more understandable. By strictly following the project documentation and following the recommendations, you can even independently build a high-quality foundation for future housing.

Finishing stage - pouring the foundation of the house

After installing the reinforcing cage, the formwork is loosened. The formwork is fastened with vertically arranged rods - bars, which are simply nailed to both sides of the formwork sides. The lower board is fixed with the help of racks - supports (beams, racks - jacks), with reliable fixation, completely excluding the mobility of the formwork.

The formwork is unfastened, the reinforcement cage is assembled - we proceed to pouring the concrete. For the foundation of a residential building, it is best to order concrete, produced at a special plant, of the desired brand. The concrete grade is indicated in the project or calculated separately.

With a small volume, concrete is poured directly from mixer machines.

If the volume of concrete to be poured is large, it is better to use a concrete pump installed on a construction equipment. When pouring concrete into the foundation for a house, it is imperative to seal it using electric vibrators, the mace of which must reach the bottom of the trench.

The foundation is of a tape type, it is poured at a time, without technological interruptions. If the pouring is carried out in the cold season (up to -5C), special additives are added to the concrete to prevent it from freezing.

Mortar preparation, concrete pouring

Step one. When buying concrete, give preference to the M-200, M-250 and M-300 brands. Usually the construction of private houses and structures implies such volumes that a small concrete mixer is enough. In it, the concrete mix acquires the necessary mobility (in other words, consistency). The poured mass is easily distributed inside the formwork, thoroughly fills the smallest air cavities.

M-300 concrete

The composition of the mortar is best coordinated with specialists with experience in construction in your area, well versed in the characteristics of dry concrete. There is an easy way to check the viscosity of concrete (its mobility) by hand: scoop up a handful of mortar and squeeze it tightly in a fist, then unclench your hand. If all the water has come out, the concrete solution is not entirely successful - it has low mobility, and when solidified, there is a high probability of the formation of small cracks inside the foundation. If concrete milk (gruel) remains on your hand, the mixture is prepared wonderfully! The foundation of such concrete will turn out to be dense, plastic, long-lasting.

Concrete mixer

Step two. It is undesirable to pour during rain and snow (sometimes construction is carried out in spring or autumn, when there is little rainfall - at this time it is better to cover the formwork, wait for the weather to clear). Pour concrete in such portions that in one cycle the entire area at the bottom of the formwork is filled. On the good, you need to start work in the morning, so that somewhere by lunchtime or in the evening, layer by layer, fill the entire box.

Step three. In hot weather (temperatures above + 19 ... + 22 ° C), it is necessary to periodically pour water over the foundation. This will improve its strength when setting concrete.When the formwork box is completely filled with mortar, wait 25-30 days for the concrete to gain maximum strength.

However, the first construction work around the house without serious weight loads is allowed to begin as early as 10-15 days after the foundation is poured. At this stage, concrete has gained about 75% of its strength, and there is no point in wasting time.

Pouring strip foundation

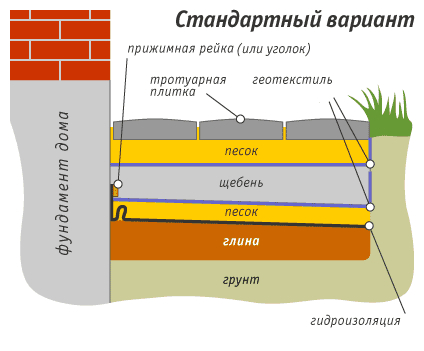

Step four. After the foundation concrete has finally hardened, the formwork can be removed, this is not the end of the foundation creation process. Be sure to create a concrete area around the outer perimeter of the house.

The meaning of the blind area:

- prevent contact of the foundation with rain and melt water;

- protect the basement soil from moisture accumulation;

- move the winter freezing zone away from the house.

Monolithic reinforced blind area

The blind area of the strip foundation

Do not forget to also build drainage structures on the roof and along the walls of the house. After all, even the strongest foundation is not immune from decomposition processes that can appear over time if water and humid vapors are allowed to freely affect the concrete.

Peculiarities

For the manufacture of concrete, cement and auxiliary components (gravel, expanded clay, sand) are used. Water helps to improve the fluidity of the solution, and plasticizers and additives are added to the mixture to protect against severe frosts. Pouring a liquid mixture into a mold (formwork) involves the onset of irreversible processes in concrete, namely: setting, hardening.

During the first process, the solution turns into a solid state, because water and its constituent components interact with each other. But the connection between the components is still not strong enough, and if a load acts on the building material, it can collapse, and the mixture will not re-set.

The second working process is hardening. This procedure is quite lengthy. On the first day, concrete hardens faster, and on the following days, the hardening rate decreases.

You can fill the foundation with your own hands in parts, but you must follow certain recommendations:

- Consecutive mixing of concrete mix. If the interval between pouring does not exceed 2 hours in the summer and 4 hours in cool weather, no joints will form, the concrete becomes as strong as with a continuous pour.

- During temporary interruptions in work, it is allowed to fill in no more than 64 hours. In this case, the surface must be cleaned of dust and debris, cleaned with a brush, thanks to this, the best adhesion is ensured.

If you take into account all the features of the ripening of the concrete mixture and follow important rules, then pouring the foundation in parts will not cause much trouble. The second layer of concrete is poured without exceeding the time interval:

- 2-3 hours in summer;

- 4 hours if the work is performed in the off-season (spring, autumn);

- 8 hours when pouring occurs in winter.

By filling the foundation in parts during the liquid setting phase, the cement bonds are not broken, and, having completely hardened, the concrete turns into a monolithic stone structure.

Preparation

The technology of pouring the foundation under the house requires careful preparation. Before starting construction work, markings are performed. The limits of the future foundation are determined by means of improvised means: reinforcement, rope, pegs, twine. By means of a plumb line, 1 angle is determined, after which the remaining angles are determined perpendicular to it. Using a square, you can set the 4th angle.

Pegs are driven in at the marked corners, between which the rope is pulled and the placement of the axis of the room is determined.

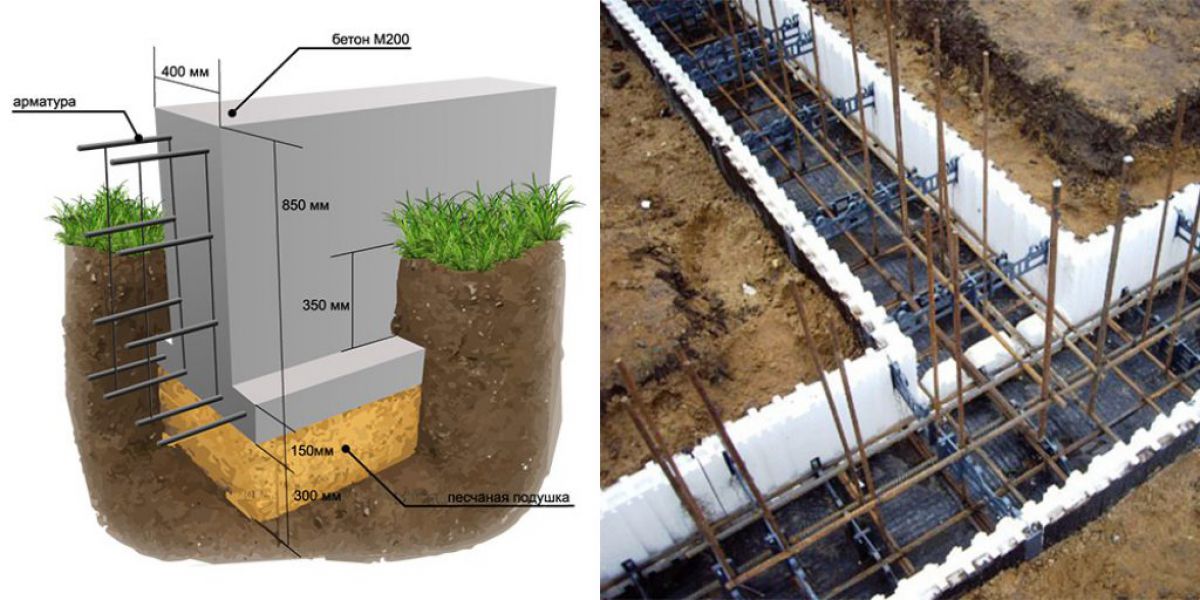

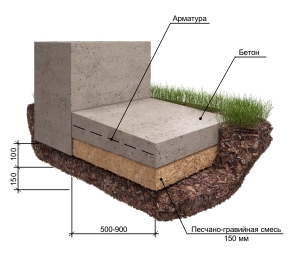

When the markup is completed, you can begin to determine the difference in elevated surfaces on the site. To measure the depth of the foundation, you need to start from the lowest point of the entire territory of the future pouring. For a small private room, a depth of 40 centimeters is suitable.After the pit is ready, you can start preparing it.

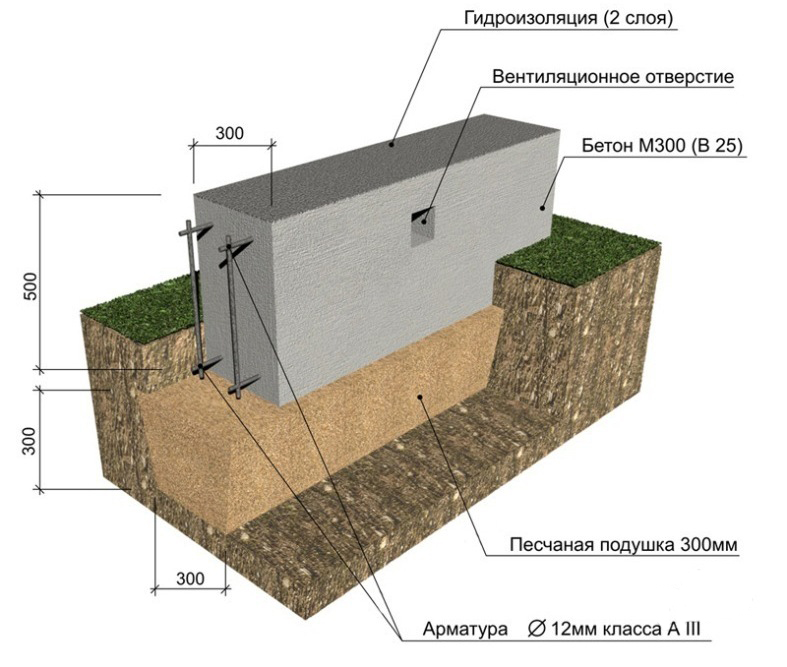

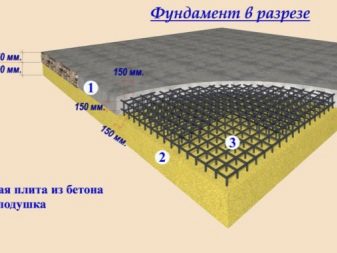

Before pouring the foundation, a sand cushion is placed on the bottom of the excavated pit, which is designed to reduce the load. It is distributed over the entire area of the site with a thickness of at least 15 cm. Sand is poured in layers, each layer is tamped and filled with water. Crushed stone can be used as a pillow, but its layer should be 2 times less. After that, the bottom of the pit is covered with waterproofing building material (polyethylene, roofing material).

Now you can start installing the formwork and fittings. This is necessary for greater strength of the base of the room and additional protection against crumbling of the trench walls.

The installed fittings must not come into contact with the ground, otherwise rust will appear.

Shields are installed at the very edge of the contour and connected with jumpers made of timber. These lintels hold the formwork upright. The bottom edge of the beams must be firmly attached to the ground so that the mixture does not leak out. From the outside, the shields are propped up with supports made of beams, boards, reinforcing rods. But first you need to make sure that the walls of the formwork are in a vertical position.

The armature is a large lattice with rectangular cells (30x40 cm). It is necessary to connect the reinforcing bars with wire, not welding. The latter option can lead to rust at the joints. If the foundation is composite, you first need to fill in the holes for the support posts and insert 3-4 reinforcement rods inside, which are interconnected.

How to choose the right type of foundation?

Speaking about how to fill the foundation, you must first of all decide on its type. If you need a foundation for a bath made of a bar or a rounded log, you can stop at a shallow tapered one. This approach is optimal in terms of financial, time and labor costs. A strip foundation can become a reliable and solid foundation for a building.

However, if the soil in your area is unstable, highly mobile, swelling during the flood period, a strip foundation is unlikely to work. For a structure to stand firmly, its base must "cling" to the deep layers of the soil, which have high rates of density and immobility. In such cases, the ideal solution would be a pile foundation - the base of the building on reinforced concrete or metal supports, which go deep into the ground at a distance of up to 2 meters.

So, summing up the results of this part of the conversation about the independent pouring of the foundations of buildings, we note that a strip foundation is excellent for construction on dry flat areas, and for the construction of buildings on swampy soils, on soil prone to swelling, as well as on slopes, it is better to choose pile structures ...

We propose to talk in more detail about how to fill the foundation for a tape-type cinder block on your own site without the involvement of specialists.

Is it allowed to fill the foundation in layers

To obtain a monolithic base under the building, it is necessary to pour the concrete mixture continuously, avoiding hardening.

When the available stock of the solution was not enough, it is permissible to make a foundation from several successively poured portions. The resulting structure is not worse in strength than a monolithic one, if you follow a few rules:

- The foundation should be poured with reinforcement fastened with vertical and horizontal ties made of special plastic or annealed soft wire. This will distribute the load evenly over the entire volume of the foundation. The reinforcement itself should be knitted, not welded.

- Filling is carried out sequentially, taking into account the ambient temperature. The colder it is, the later it is allowed to add the next portion of the mixture.The previous concrete has already set - it must be left without touching for at least three days.

- If the construction site has stopped, the place of work is covered with a film, before feeding the mixture, the substrate is thoroughly cleaned of dust, dirt, moisture using metal brushes. Instead of mechanical removal, chemical removal can be used (acid etching of the surface) - but the method is more often used by professional concrete workers.

Installation of reinforcement with formwork

Scheme of the formwork of the strip foundation.

A sand cushion is placed in the prepared trench. This will reduce the potential load by distributing it evenly across the foundation. In addition, it will save a significant part of your finances on materials.

The minimum sand layer should be 15 mm. After laying, it is leveled, moistened with water and compacted. Crushed stone is laid on the pillow, then roofing material: this makes the foundation for the house even more solid.

Before pouring, it is required to make a formwork, which can be of any materials: plywood, wooden boards, metal tiles. To fasten it, screws or self-tapping screws are used, however, the caps should be on the inside for easier disassembly. Thus, the walls of the formwork will be smoother. During installation, the formwork must be at least 30 cm above the ground, and a rope must be stretched inside it at the level of the casting.

First, you will need to take care of the sewerage and water supply, leaving holes for this. Otherwise, they will have to be done after the concrete has dried, while violating its integrity.

Next, fittings are laid. The rods with a 12 mm cross-section are tied with a dedicated wire. As a result, each cell is obtained with sides of 30 cm. In this case, it is better not to use welding, since corrosion may appear in the connecting places.

In the case of wire, the structure will be more flexible. In order for the reinforcement to end up inside the monolith, it must be located at a distance of 5 cm from the trench wall.

Pouring concrete mortar

Pouring concrete mortar

It is necessary to fill the foundation with concrete mixture at one time. If this process is stretched, the solidity of the base will be broken, which will lead to the appearance of cracks and the gradual erosion of the concrete. Now many people prefer to order ready-made concrete mortar directly from the factory, as this saves time and effort. If this is not possible, you will definitely need a concrete mixer, since it is very difficult to make such an amount of concrete with your hands.

Pouring concrete mortar

Before you start pouring, you need to calculate the consumption of concrete mixture on the foundation. Since the base consists of several strips, it is recommended that you first find out the volume of each segment, and then add everything together. To find out the volume, the width of the tape is multiplied by its length and height. The total volume of the foundation is equal to the volume of the concrete solution. It is not worth ordering with a margin, because in the calculations each corner of the perimeter was taken into account twice, which is exactly the necessary margin.

The strength of the base largely depends on the brand of cement, as well as on the proportions of the components in the solution. For the foundation for a residential building, it is optimal to use M300 or M400 mortar. To prepare it, you will need M500 cement, sand and fine crushed stone in a ratio of 1: 3: 4. The volume of water should be half the volume of all other components of the solution.

So, first prepare the solution:

- sift sand through a mesh;

- mix sand, crushed stone and cement;

- add water in small portions;

-

thoroughly knead the components.

The finished solution has a uniform color and structure, a thick consistency, when the shovel is turned over, it slowly slides down in total mass, without splitting into pieces. When the concrete is ready, you can start pouring. It is necessary to fill the formwork in layers, distributing the mortar around the perimeter with a thickness of about 20 cm.If you immediately pour out the entire mixture, air voids form inside, which sharply reduces the density of the foundation.

Pouring the foundation formwork

After pouring the first layer, the solution is pierced in several places with a piece of reinforcement, and then compacted with a construction vibrator. If you don't have a vibrator, you can use a wooden rammer. When the concrete surface is compacted and leveled, the second layer can be poured. They pierce the solution again, releasing air bubbles, then tamp and level the surface. The last layer should be at the level of the stretched line; the walls of the formwork are tapped with a hammer, and the surface is leveled with a trowel.

Tamping concrete

The finished foundation is covered with plastic wrap on top and opened only in dry cloudy weather. To avoid cracking, the top of the base is periodically moistened with water. The formwork can be dismantled 12-14 days after pouring, but it is recommended to carry out construction work no earlier than a month later. During this time, the foundation will become sufficiently strong and compacted, so the loads will not bring harm.

Varieties of foundations

For the correct choice of the basis required for the construction of a building, you should figure out what types exist and what are their differences. According to the degree of immersion in the ground, three types of bases are distinguished:

- shallow, characterized by the location of the sole at the same level or above the ground surface;

- shallow, with the sole located above the freezing line;

- buried, in which the lower level coincides or is below the freezing point.

Under heavy concrete structures, a deep foundation is made, which is fixed 20-30 cm below the freezing mark of the earth layer

Various types of foundations are used in the construction of buildings:

- monolithic. It is a solid concrete slab reinforced with steel bars. Proven as a reliable base on quicksand or sandy soils;

- pile. It is used for the construction of buildings on soft soils, prone to frost heaving. The erection of the base of the building on piles is carried out using special equipment;

- tape. The most common and reliable option for ensuring the sustainability of buildings on various types of soil. A concrete belt embedded in the soil, reinforced with a spatial reinforcement cage, guarantees the stability of various types of buildings on all types of soil.

In most cases, when erecting private buildings, preference is given to a strip base, which guarantees the stability of the erected objects at reasonable costs for arrangement.Various materials are used for the construction of the strip base:

- stone laid in a trench and poured with mortar;

- ready-made foundation slabs or blocks, the use of which accelerates the construction of the base;

- brick that needs waterproofing and is used to a limited extent;

- reinforced concrete for maximum strength.

Let's dwell on the reinforced concrete tape base in more detail.

This type of foundation is one of the simplest and most common