Features of products for drainage of various companies

Before buying drainage pipes, you should get acquainted with the features of products from leading manufacturers. In their catalogs, products of various standard sizes are presented, which make it possible to form a water drainage system of the desired configuration. We suggest that you familiarize yourself with the features and benefits of products manufactured under well-known brands.

Drainage pipes Perfocor

The manufacturer offers high-quality perforated polyethylene products to ensure timely water drainage for a long time. The presence of two layers increases the resistance of products to atmospheric precipitation. The rigidity of the products is SN4-SN8.

Perfokor drainage pipes produced in Russia fully meet the requirements of TU 2248-004-73011750-2007. Allows connection by means of a coupling and an O-ring or by welding. For the formation of the drainage system of the required configuration, shaped parts "Korsis" can be used. To connect drains with a diameter of 110–160 mm, it is worth purchasing ECOPAL couplings.

"Perfakor" - quality you should trust

Products "Korsis"

The manufacturer specializes in the production of products intended for the installation of storm water and gravity sewers. High quality polyethylene is used for the production of drains. The pipes have a double wall, consisting of an outer black corrugation and a smooth inner surface. For contours PR-2 and PR-3, the inner layer is yellow.

To connect the elements, the manufacturer offers shaped components "Korsis". For large diameters (250-1200 mm), a welded socket is provided, which allows the connection of drainage pipes to each other using one O-ring. The connection of elements of a smaller diameter is made using a coupling and two rubber O-rings.

"Korsis" - quality products

Products "Pragma"

PipiLife under the Pragma trademark produces quality drainage made of a special type of polypropylene (PP-b). The special structure made it possible to give the material sufficient impact resistance and resistance to large temperature fluctuations (from -60 ° C to + 100 ° C).

Due to the high ring stiffness (8 kN / m²), installation in difficult conditions is permissible. The advantages of Pragma products include:

- Ease of installation.

- The ability to fit the elements to the desired size.

- Admissibility of connection with concrete and polymer wells.

Installation work can be carried out without the involvement of special equipment.

"Pragma" - the basis of high-quality drainage for groundwater

Features of "Softrock"

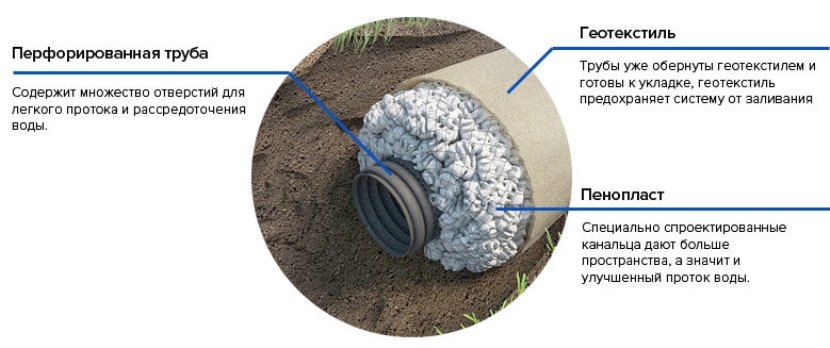

SoftRock technology is used for the production of SoftRock groundwater drainage pipes. Can be used for closed drainage devices. The system consists of flexible perforated pipes filled with polystyrene foam. The shape of the latter depends on the manufacturer. This design makes it possible to abandon the use of crushed stone and increases the efficiency of the system by 20-50%.

SoftRock design

Uponor: wide range of sizes

The company offers products designed for drainage around buildings, on agricultural land and on roads. They are manufactured in various standard sizes. Pipes can be:

- Single-layer corrugated PVC. They have a characteristic ivory color;

- Double-layer made of durable polyethylene. They are black and brown. The latter are provided with a coconut coating.

Uponor - the solution for various drainage structures

Design features of drainage pipes

Drainage pipes are made of different materials:

• ceramics;

• asbestos cement;

• plastic.

• high strength;

• long service life;

• the material is not subject to corrosion and decay processes;

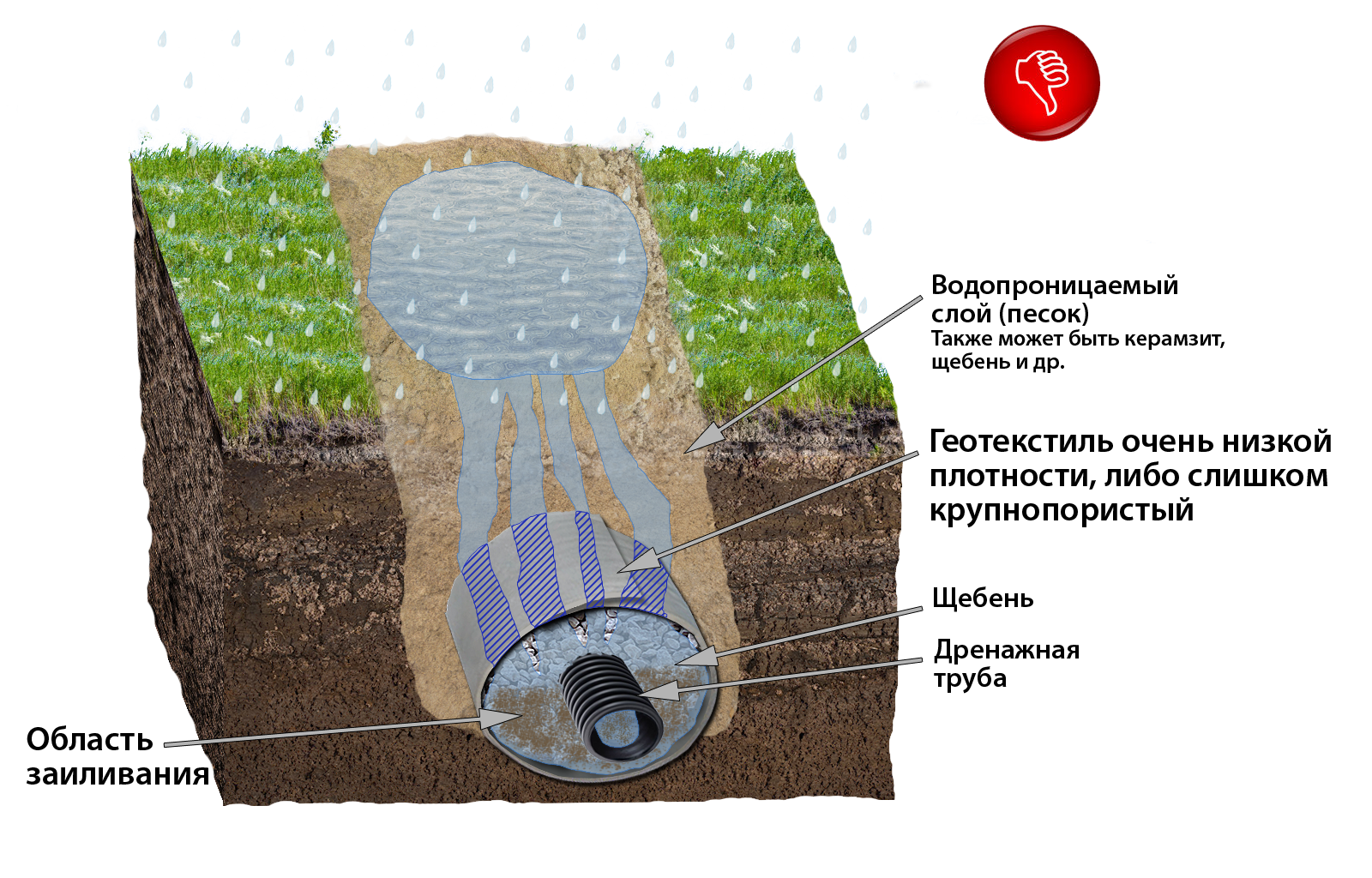

• in combination with geotextiles, it is possible to prevent siltation, which saves money and effort on regular cleaning;

• low weight excludes the involvement of special equipment for installation;

• installation of the system is carried out quickly due to the use of various fittings and tees.

• polypropylene;

• polyvinyl chloride;

• polyethylene.

The most popular are PVC products.

Why do we need drainage pipes - nuances, principle of operation

The main purpose of drainage is to remove excess moisture that forms after:

- precipitation;

- the appearance of melt water;

- outlet of ground (ground) waters;

- glaze.

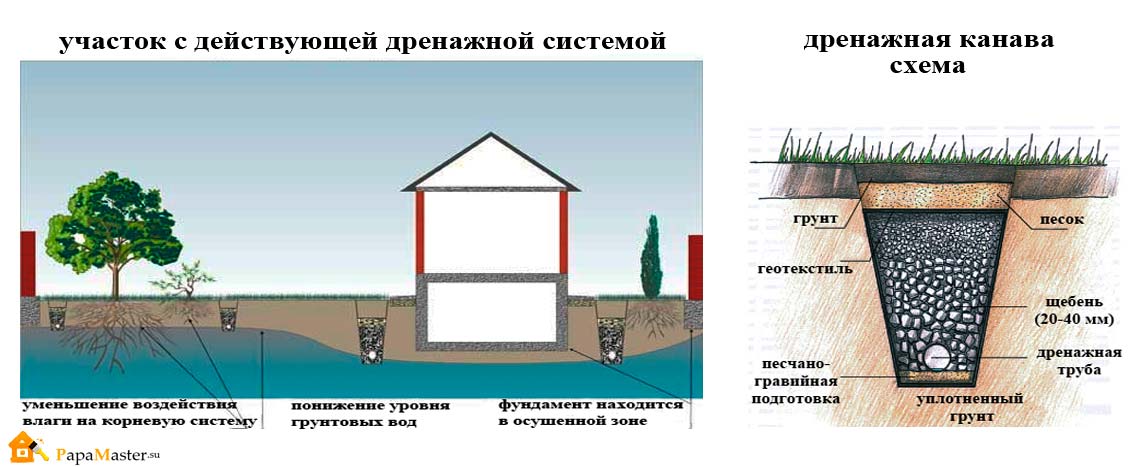

Drainage pipes are located throughout the entire area of the site

Drainage pipes are located throughout the entire area of the site

Untimely drainage of excess groundwater can cause:

- plant death, as excess moisture washes away nutrients necessary for crop growth, and also reduces the amount of oxygen in the soil;

- subsidence of buildings located on the site;

- deformation of beds and paths.

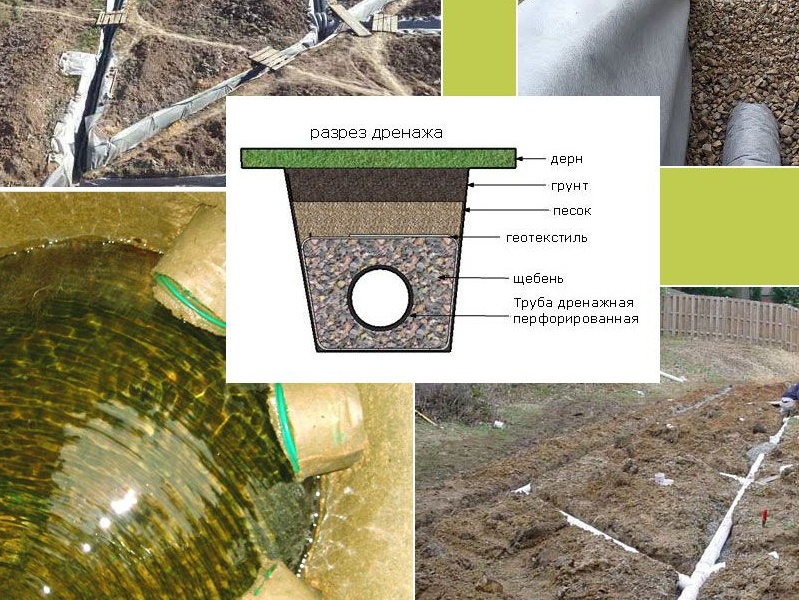

To achieve this goal, drainage pipes, unlike conventional products, are manufactured with a large number of holes located at a given interval. Due to their presence, the excess groundwater contained in the soil flows into the drain, and then is discharged through the drain to a predetermined place. Most often in a special well.

There are special holes in the drains

There are special holes in the drains

Related article:

Drainage at a summer cottage is the easiest way to do it with step-by-step instructions, what it is, photo examples, useful tips and recommendations of specialists - you will find all this and much more in our material.

For the manufacture of drainage pipes, plastic is used, which gives them high performance. Thanks to this, high-quality pipes for water drainage can serve for decades without any additional maintenance and replacement. Low weight makes installation and transportation much easier. The special structure of the material prevents the formation of mechanical deposits. The accumulation of dirt in the drainage holes is prevented by the geotextile fabric used during installation work, which filters out particles present in the groundwater.

Attention! Manufacturers offer a large assortment, and therefore it is easy to choose the best option for a specific drainage structure.

Geotextile prevents dirt from entering the drain

Geotextile prevents dirt from entering the drain

Drainage pipe slope by 1 meter

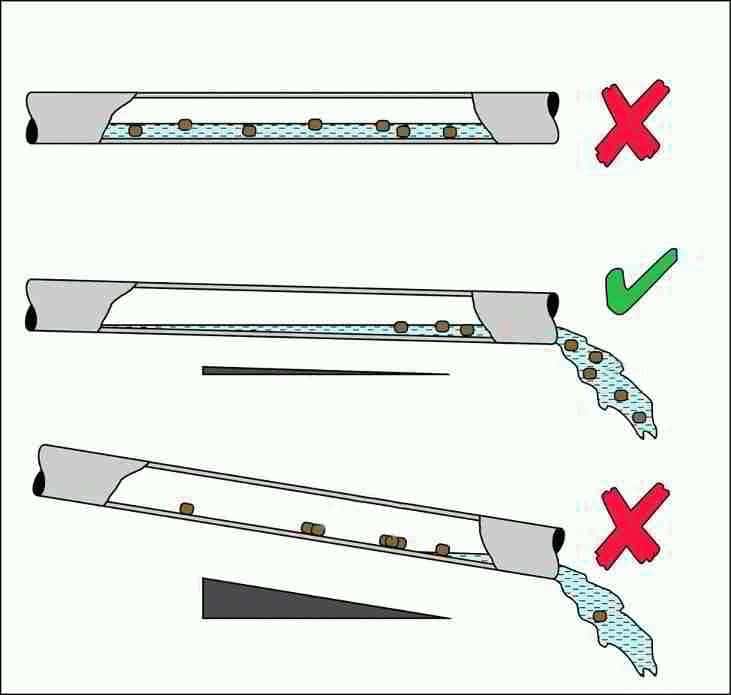

What is the correct slope for a drainage pipe? The slope of a drainage pipe is usually measured in centimeters per linear meter, not degrees. This makes it easier to determine how much one section with a length of 1 m is lower or higher than the neighboring one.

If the slope of the pipe is insufficient, then the water flows slowly. A weak head of the drain is not able to push through the formed waste, which settles and silts up on the walls of the drain. Blockages occur, the system cannot cope with the drainage system.

On the other hand, an overly steep slope leads to a rapid flow of water. In this case, fragments of large waste under the pressure of the flow are pressed against the walls of the pipes and get stuck. In addition, there is a huge load on the connecting nodes of communication.

Correct slope of the drainage pipe.

Correct slope of the drainage pipe.

The drainage pipes are cleaned through drainage and inspection wells in two ways:

- mechanical - with the help of a device for passing drains and removing deposits, it is carried out every 3-4 years;

- hydrodynamic - with the involvement of pumping equipment and a compressor, clean every 10-15 years.

The drainage system will function properly and efficiently only if the correct angle of inclination of the pipe by 1 meter is observed, according to SNiP. The installation of a drainage system requires a professional, balanced approach.

It is necessary to calculate the depth and level of inclination of the pipes so that they are not subject to blockages, and effectively cope with the drainage of wastewater. Experts will help to avoid technical errors in calculations.

Types and technical characteristics

Drainage pipes differ in material of manufacture, size and design.

Concrete drains

Massive concrete pipes are used only in municipal services and industrial construction for the removal of large volumes of water. They have a diameter of 200 mm or more and are not suitable for private drainage systems.

Asbestos-cement

Previously, asbestos-cement pipes were used in drainage systems. But they were fragile and heavy. Today they have been almost completely replaced by pipes made of polymer materials. In addition, the service life of asbestos-cement products is almost two times less than that of plastic counterparts.

Metallic

Metal is not the best material for a drainage system. Even pipes treated with a special coating under constant contact with moisture and its chemical impurities are subject to corrosion. Their maximum service life is about 40 years. The only advantage of metal drains is their durability.

Ceramic

Ceramic pipes are practically not used in private construction for the same reason as asbestos-cement pipes. Today they are used for agricultural drainage systems.

Drains made of polymeric materials

On individual sites, plastic pipes are most in demand. They have undeniable advantages:

- light weight;

- long-term operation - 50-60 years;

- they are not afraid of aggressive chemical impurities and temperature drops;

- convenience and ease of assembly;

- low price.

Several types of plastic are used for manufacturing - polypropylene, polyvinyl chloride (PVC), high and low pressure polyethylene (LDPE and HDPE). The last two types of plastic are used for the production of two-layer pipes - the upper shell is made of HDPE, the inner layer is made of LDPE.

Corrugated HDPE pipes with a high strength index are used for deep drainage systems. PVC pipes are less resistant to increased loads, therefore they are more suitable for surface drainage.

Structural and design features of polymer pipes

Plastic products vary in structure and design. Existing varieties:

- Single-layer drainage pipes are either corrugated or smooth, with or without holes. Such drains are used to drain storm water.

- Double wall perforated drainage pipes are most suitable for groundwater drainage. A two-layer drainage pipe without perforation is designed to discharge the collected wastewater into the collector.

- Flexible are used to mount the system without the use of connecting elements.

- Rigid pipes, in turn, are divided into thin-walled and thick-walled. The former have a small diameter and do not have a large margin of safety. Thick-walled ones are used to drain large volumes of water in places where soil displacement is possible.

- HDPE flat drainage pipes have a rectangular cross-section and a number of advantages over the traditional round shape. They are economical, have good throughput, are easier to transport and quicker to assemble. Internal stiffening ribs provide them with strength. Flat pipes are used for deep and surface drainage.

The vertical installation of the flat pipe avoids deformation. It can be laid in trenches of any configuration in continuous sections up to 50 m.

Drainage pipes differ in stiffness classes and are marked with indices SN 2, 4, 6, 8, 16. The higher the numerical value, the stronger the pipe.

Dimensions (edit)

Drainage pipes with a diameter of 110 mm - 160 mm are used for storm sewers in private areas. For municipal needs and large areas, pipes with a diameter of 200 mm are produced. Sizes from 200 to 700 mm are used in industrial, residential and road construction, as well as for inspection drainage wells.

Flexible polyethylene pipes are produced with a diameter from 50 mm to 150 mm, rigid - from 50 mm to 700 mm. The diameter of PVC products is from 50 mm to 300 mm.

The exact size range depends on the manufacturer. Flexible pipes are sold in coils of 40-50 m, rigid pipes - in lengths from 6 to 12 m.

Drainage types

Site drainage is a complex system with many nuances and features. By structure, it can be local (local) - to solve a problem at a specific site. Most often, this is the drainage of the foundation, basement and semi-basement (basement) floors. Also, water drainage systems at the site are common - to drain the entire site or a significant part of it.

Soft drainage without pipe. Suitable when it is necessary to drain a small amount of water at a summer cottage or near a house

By installation method

By the way of installation, the drainage system can be:

Open. Concrete or stone trays are used, ditches are dug around the site. They remain open, but can be covered with decorative grilles to protect the system from large debris. If you need a simple solution for draining surface water in the country, these are ditches around the perimeter of the site or in the lowest zone. Their depth should be sufficient so that the water does not overflow at maximum flow. So that the unreinforced walls of the drainage ditches do not collapse, they are made at an angle of 30 °,

So that the walls of open drainage ditches do not crumble, ground cover plants are planted on the slopes or they are laid out with cobblestones Open drainage near the driveway, parking lot, does not spoil the picture at all Drainage option for a summer cottage is cheap and cheerful From the drainage ditch, you can decorate the site from the drainage ditch and so can drain a significant amount of water

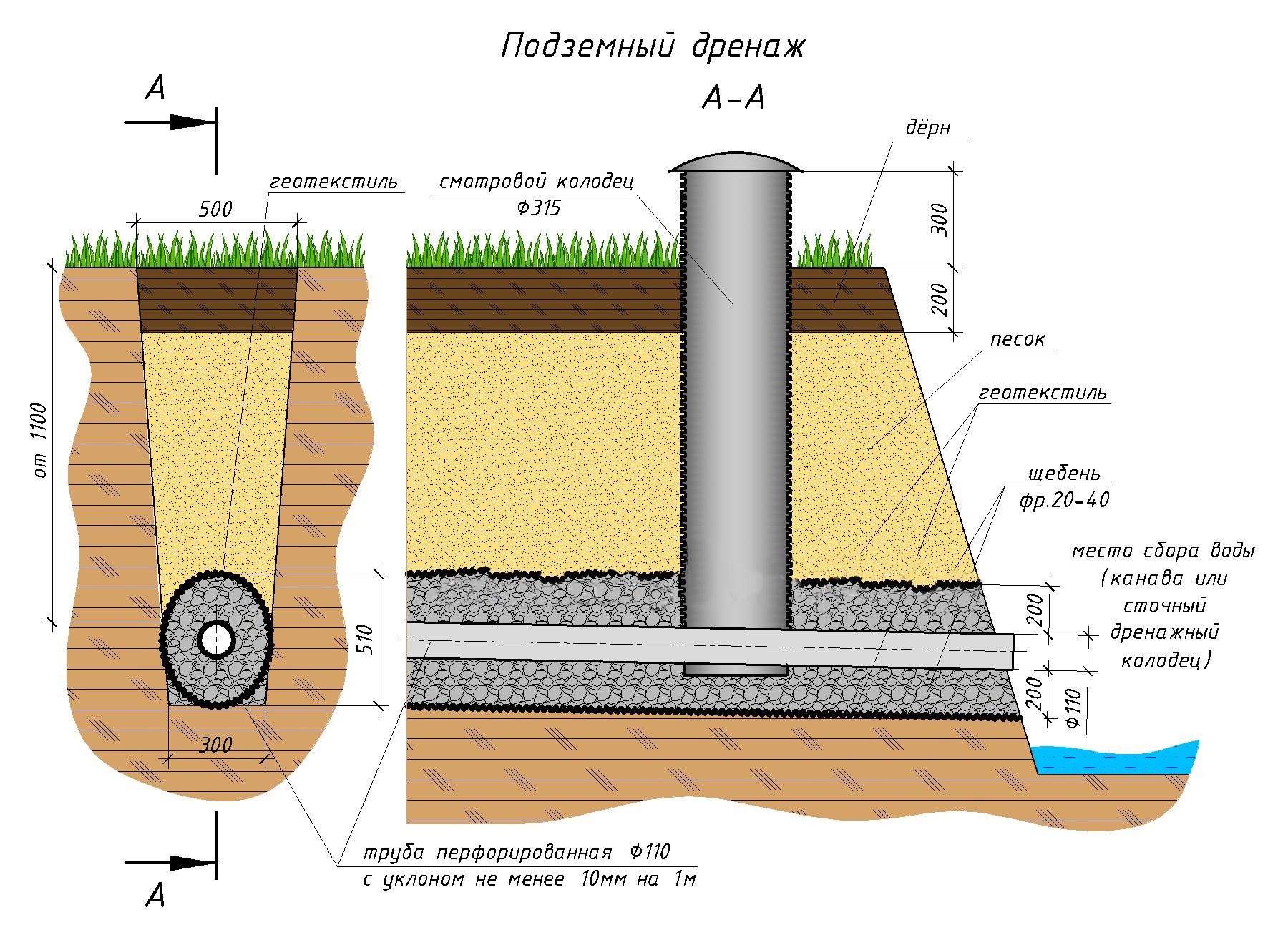

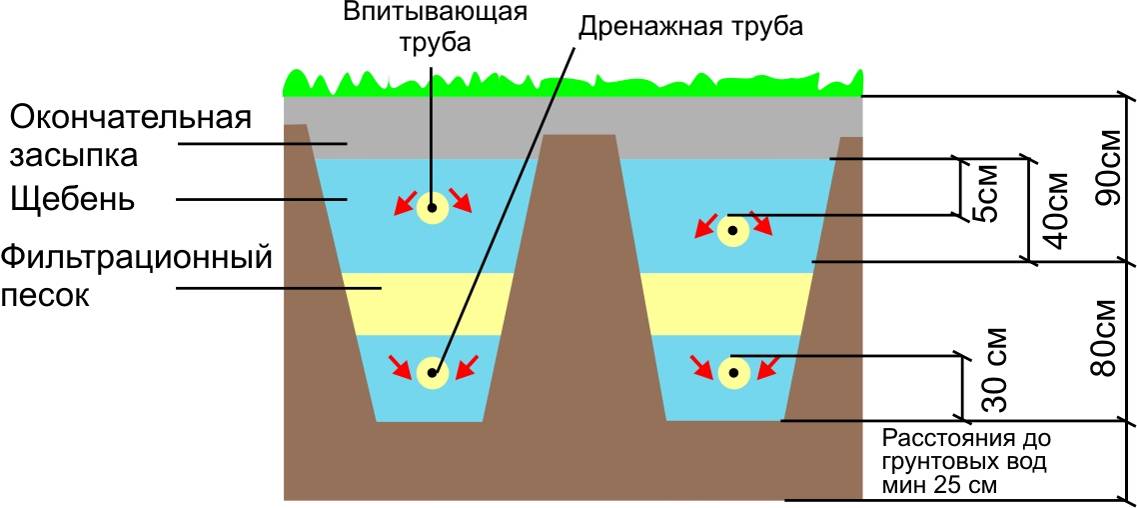

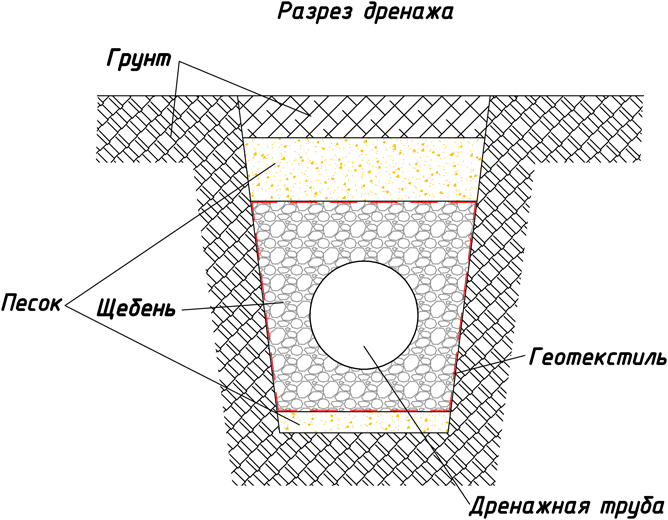

- Closed. The water is captured by the laid special water-permeable - drainage - pipes. The pipes are discharged into a storage well, into a drain, a ravine, a nearby reservoir. This type of site drainage is good for permeable soils (sandy).

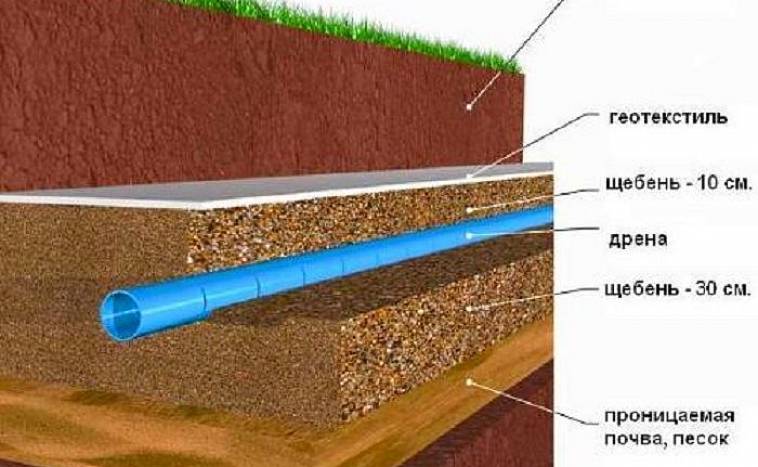

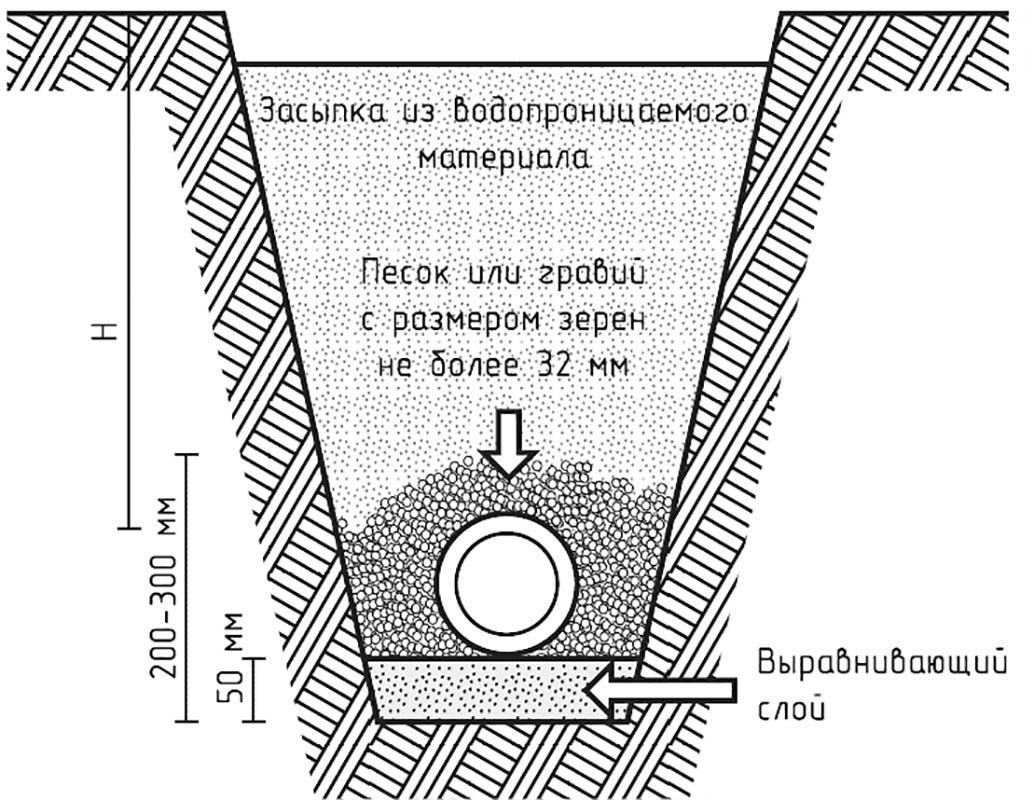

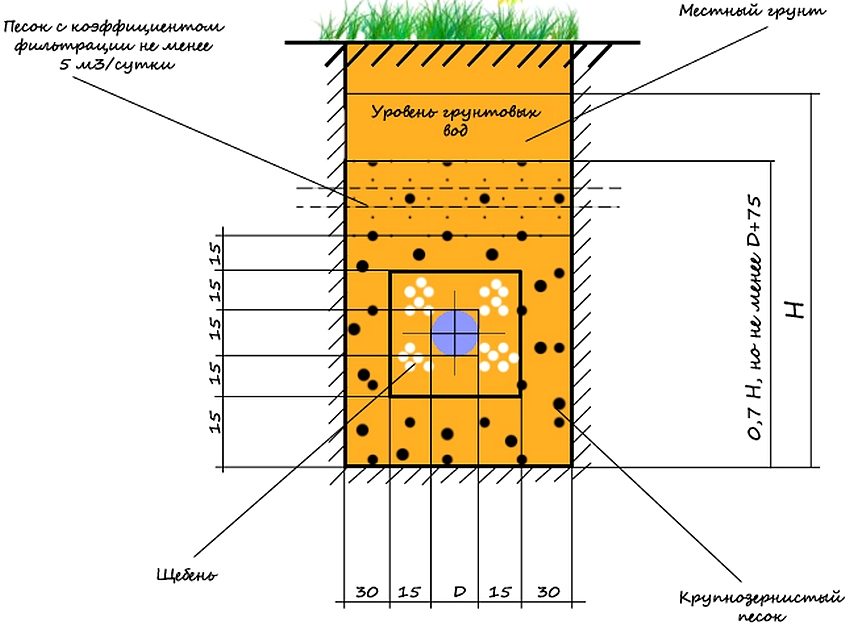

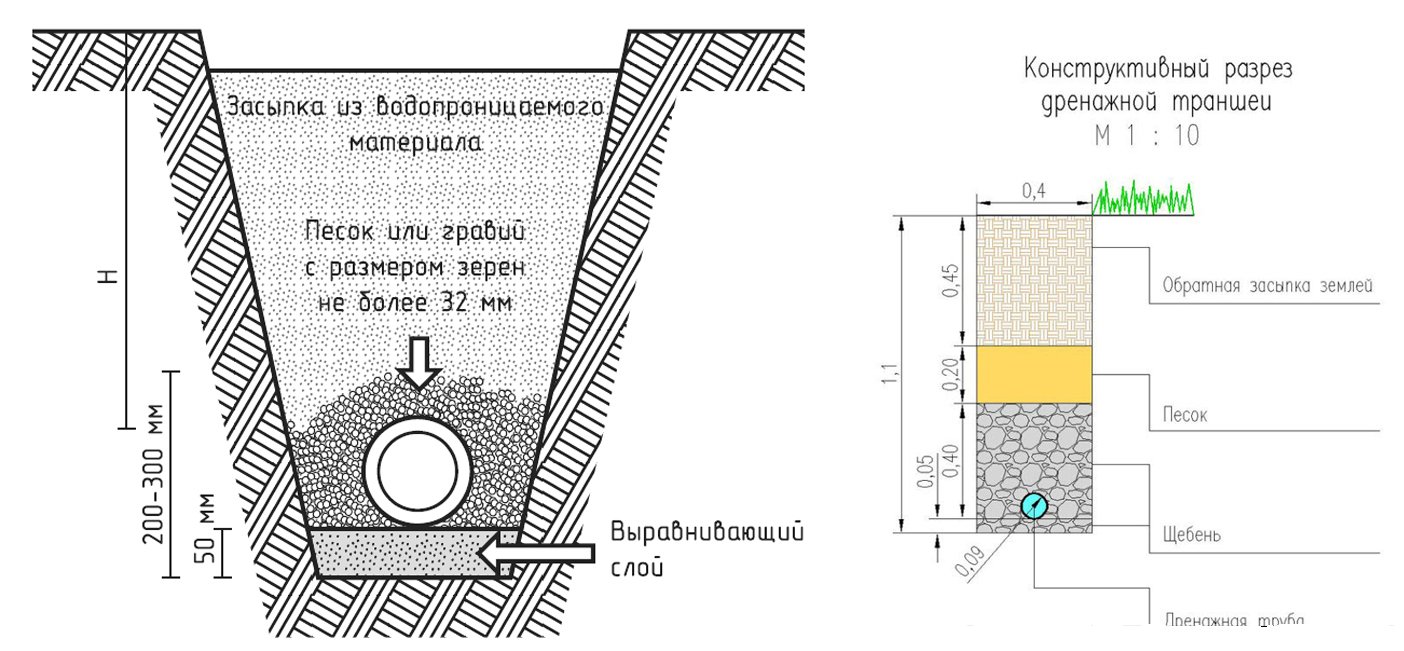

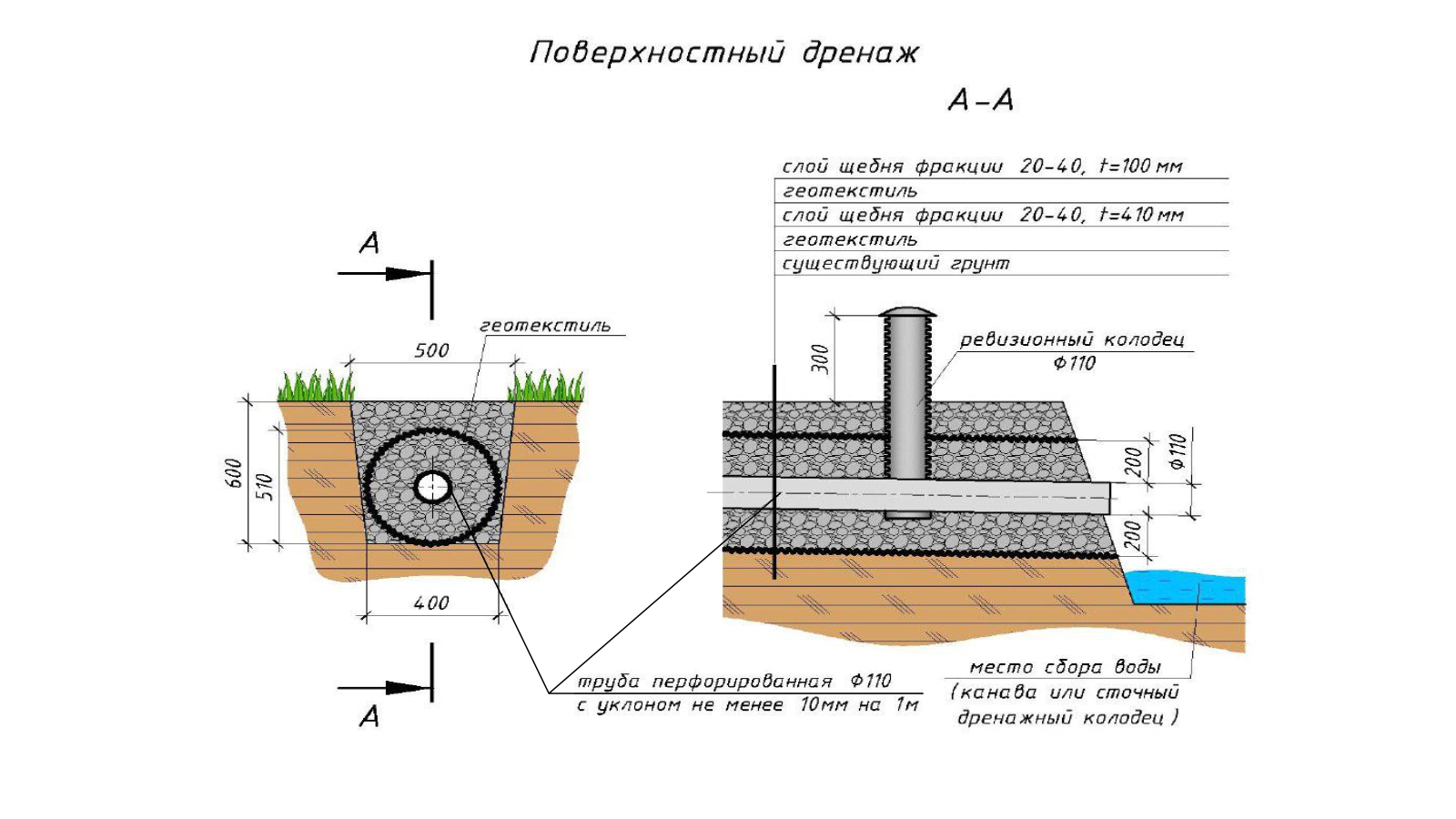

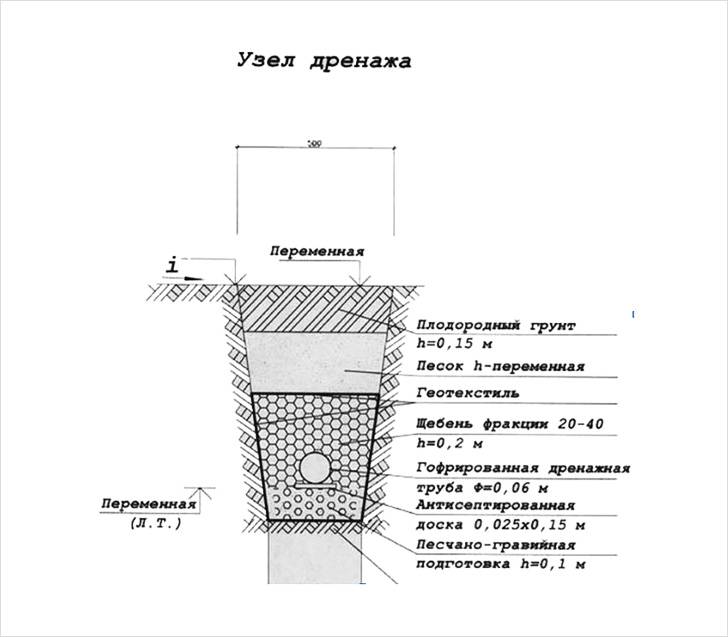

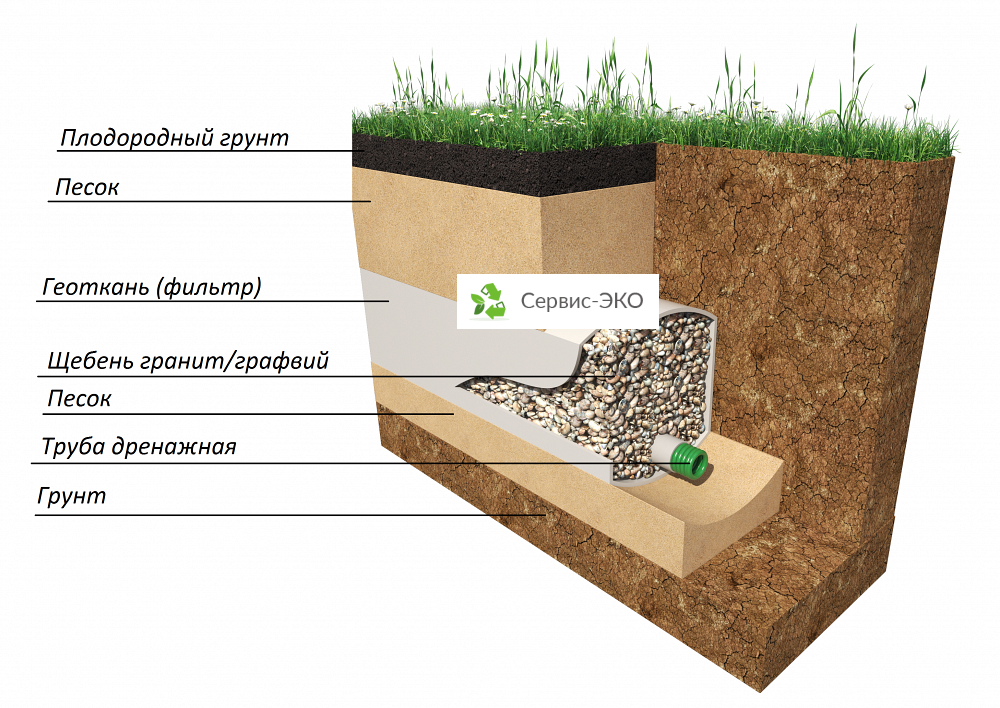

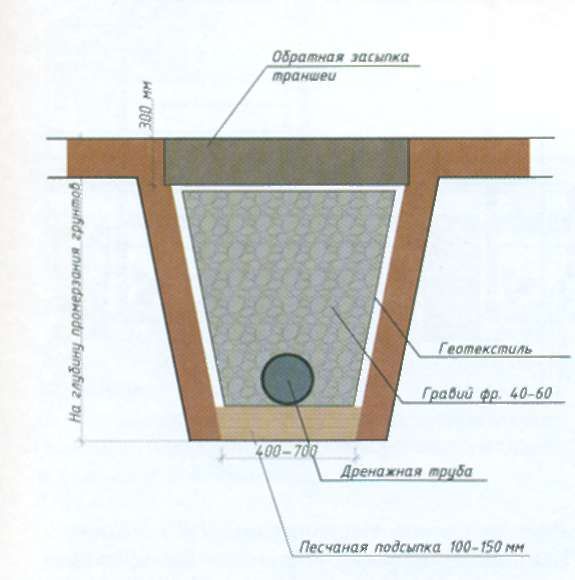

- Backfill. Drainage of this type of site is usually used on clayey soils or loams. In this case, the pipes are also laid in ditches, but a layer-by-layer sand and gravel backfill is arranged in them, which collects water from the surrounding soils. The worse the soil conducts moisture, the more powerful backfill is required.

Drainage pipe in gravel backfill

The specific type of site drainage is selected based on the site conditions. On clays and loams, an extensive gravel-sandy zone is required, into which water will flow from the surrounding soil areas. On sands and sandy loams, there is no need for such a pillow - the soils themselves drain water well, but only a specialist can say specifically based on the results of geological studies.

By type of implementation

There are several types (schemes) of drainage devices on the site:

- Annular. The pipes are closed in a ring around the object. Usually it is the house. It is rarely used, since it is necessary to deeply deepen the drainage pipes - the pipe itself must be laid 20-30 cm below the groundwater level. It is expensive and difficult to implement.

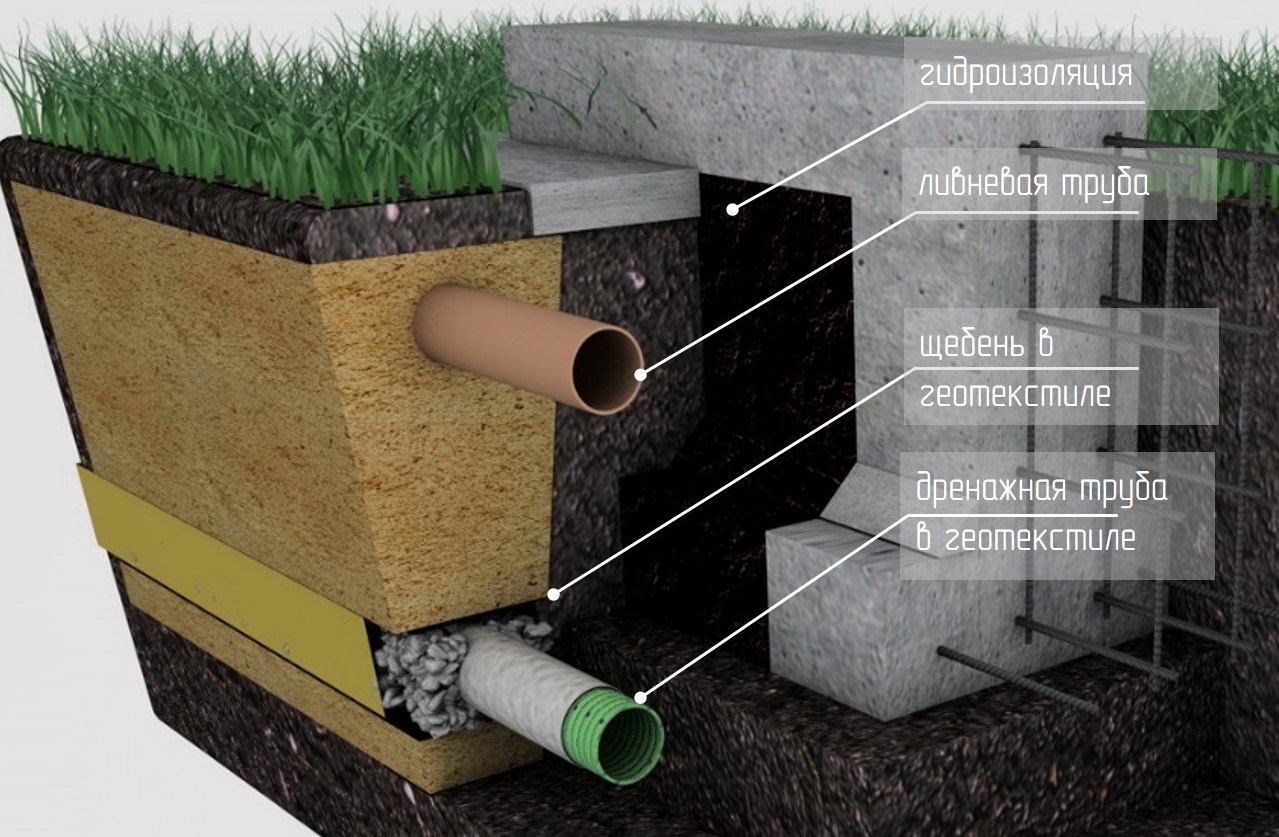

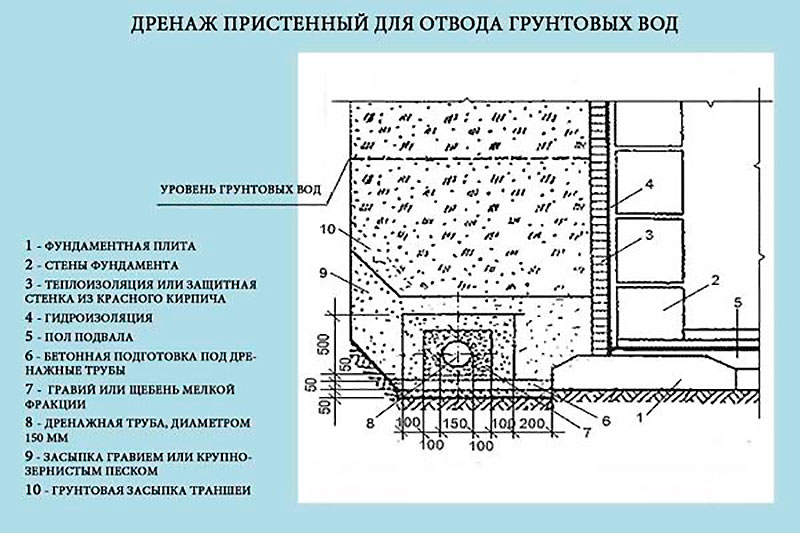

- Wall drainage - to drain water away from the walls. It is located at a distance of 1.6-2.4 m from the walls (in no case close). In this case, the drain is located 5-10 cm below the basement floor. If the floor is poured over a large crushed stone cushion, the drain is laid 5-10 cm below this level.

The correct solution for drainage from the foundation is a storm sewer system and drainage - Reservoir drainage.It is used when constructing slab foundations in difficult situations. It is necessary for the drainage of the top water, it is usually used in conjunction with a wall drainage of water. Reservoir drainage is the layers poured into the pit - sand, crushed stone, waterproofing (as they are poured from bottom to top). On top of this cushion, the reinforcement is already laid and the foundation slab is poured.

- Systematic and radial. Used to drain areas. They differ in the way the drains are located relative to the central pipe. With a beam scheme, the system is similar to a herringbone (already existing plants can be taken into account), with a systematic scheme, the drains are laid with a calculated step (usually arranged when planning a site).

Radiation drainage of the site

When draining a site, a central drain or a collector is made of pipes of a larger diameter (130-150 mm versus 90-100 mm for conventional drains) - the volume of water here is usually larger. The specific type of drainage system is selected based on the tasks that need to be solved. Sometimes you have to use combinations of different schemes.

Selection of materials for creating drainage

The selection of the necessary equipment and materials depends on the type of drainage selected for the site. For wall or ring, gratings and trays are widely used, for surface or deep - geotextiles.

Regardless of the drainage system used, the main elements for it are pipes and wells. The first ones perform the tasks of withdrawing and concentrating water flows. The latter are based on accumulation.

The general list of equipment and materials consists of the following elements:

- trays;

- sand traps;

- pipes;

- geotextile;

- wells;

- consumable and connecting components: couplings, rings, plugs, cuffs.

Trays

They serve to direct water flows and remove moisture from the soil. When creating drainage, trays are selected based on their throughput, depending on the material used and dimensions. Calculations are made during the preparation of the project based on data on the condition of the site and the level of water intake.

Trays with galvanized steel grating, withstand the pressure of water flow up to one and a half tons. The trays with a cast iron lattice have increased stability - up to 25 tons. The main materials used in the manufacture of drainage trays:

- Cink Steel;

- cast iron;

- plastic;

- concrete;

- polymer concrete;

- reinforced concrete.

An addition to the trays is a filtering system: sand traps, garbage collection grates, siphons-partitions.

Sand traps

When creating several types of drainage systems at the same time, it is necessary to install sand traps.

The connection of drainage systems is possible when each of them performs different tasks: wall-to-wall - drainage of water from the roof of the house, deep - removal of excess moisture from the ground.

Sand traps prevent blockages in the final stages of water withdrawal. Sediments of heavy mineral particles remain in the pipes if the system is not equipped with sand traps. The accumulation of precipitation leads to a decrease in the throughput of the pipe and a subsequent decrease in the volume of water withdrawal, which leads to flooding.

Pipes

Like gutters, drain pipes direct water flows to drainage points. The throughput depends on the diameter of the pipes, they are chosen in the range of 75-200 mm. The service life of the pipes depends on the material used. The following materials and combinations are used:

- asbestos-cement;

- ceramic;

- polymer (high and low pressure);

- porous.

The ingress of water into the pipes occurs through drainage holes or pores on the surface. It will be correct to use pipes in conjunction with the geotextile covering of the territory. Pipes are great for do-it-yourself drainage of a site on clay soils.

Pipes are laid with a slight slope - at least 2-3 mm per meter. Numerous additional elements are used to connect and install pipes: couplings, fittings.There are drainage methods without pipes.

Geotextile

When installing deep drainage, the surface above the pipes is covered with geotextiles. This layer allows you to strengthen the soil, and also prevents the penetration of unwanted particles: grains of sand, silt, small pieces of soil.

The geotextile cover protects the drainage system from the formation of mold, fungi, a favorable environment for insects and rodents. The material is made of polyester or polypropylene, and a canvas with a density of 150-300 g / m is used for drainage. The lower the density, the lower the wear resistance, which will lead to a partial violation of the properties of the drainage system.

Wells

The place where excess water is sent is a drainage well. Two types of wells are used according to the type of material:

- concrete;

- plastic or fiberglass.

Drainage wells usually have a diameter of up to 1 meter and a depth of up to 6 meters, where the pipes of the system are led out. 3 types of construction are used:

- swivel - at the pipe turning point;

- absorption - underground without an outer part;

- water intake - for the accumulation of large volumes of water.

The choice of a well depends on the remoteness of the place of water discharge, the volume of flow. Previously, concrete rings were common in the construction of wells, but they were replaced by lighter and easier to install plastic and fiberglass structures. The joint with the pipes is made at least 20 cm from the bottom - this protects against blockages due to subsidence at the specified height.

Next, we will take a closer look at how to make drainage on the site with your own hands, step by step. Examples of several types of systems: wall, ring and surface.

What is drainage for?

Having settled in a private house, sooner or later it becomes necessary to drain the site in order to save oneself from the problem of excessive waterlogging of the territory and the consequences associated with it.

Prudent people, planning the construction of their own home, order the drafting of a drainage system in advance. At the same time, they build a house and drainage - as a result, they get ideal conditions for life.

Living in a country house, a cottage gives the owner the opportunity to arrange the adjoining territory to his liking. It can be a garden, a lawn, lawns, paths, a pool, an alpine slide, everything that pleases the eye and makes life more comfortable.

A solid foundation of the house, strong walls, a dry basement, an ideal lawn, a fruitful garden, durable buildings on the territory of the estate are possible provided that the water balance in the soil is maintained.

It is regulated by a competent drainage system, which serves to collect and drain rain and melt water outside the site, as well as maintain a given level of groundwater. Surplus groundwater is also removed from the site through drainage.

Selection Tips

Material

The optimal material for drains is plastic. Exceptions: if you live in an area of seismic activity; the house stands on soils with the danger of landslides, movements. In this case, you will have to use metal structures.

It is better to buy the material in building hypermarkets, certified. The approximate price of materials is much less than the cost of the work, and the quality is more dependent on the material. For the same reason, you should not use used materials.

If it is necessary to deepen the drainage system by more than two meters, we recommend choosing two-layer pipes - they have greater rigidity; a smooth inner surface allows them to be laid with a lower slope and not to bury the trench "to the center of the earth", which is important when the distance to the collector well is large

Diameter

When choosing the diameter of the drains, it is necessary to take into account all the factors affecting the amount of groundwater: the amount of precipitation, its distribution by seasons and months; the height of the groundwater relative to the bottom of the foundation, the size of the house; the slope of the soil surface (slope, lowland, elevation), the seasonality of the rise of groundwater.

If the groundwater rises above the level of the bottom of the foundation 1-2 times a year (mainly when snow melts), you can choose for ring drainage around the house:

- with a house area of up to 70 m² - diameter 100 mm;

- 100-120 m² - 150 mm;

- 120-150 m² - a diameter of 150-200 mm is desirable.

If the house is in a swamp or the groundwater level is above the foot of the foundation, the house is on a steep slope or in a beam, the house has a building area of 200 m2 or more - do not experiment with your own home, contact the specialists and make a project - it will come out safer and cheaper than to redo the sewage system that cannot cope with the volume of the discharged water, to repair the basement and to repair cracks in the walls.

Soil type

Clay and loamy soils retain water. In chernozems and sandy loam soils, water usually drains quickly and without problems. All other things being equal, when installing drainage pipes in loam and clay, you should choose a larger pipe diameter.

What materials may be needed

Before starting work, you should calculate the amount of required building materials. This does not apply to bulk substances (gravel, crushed stone, sand), but to specialized parts and assemblies.

If you decide to do-it-yourself foundation drainage, mistakes can lead to unnecessary costs and a decrease in the efficiency of the system. To avoid these troubles, specialists should be involved in the calculation. For example, you can contact the Vodolov company.

To equip a drainage system, you will need: a drainage project or scheme, drainage pipes, geotextiles, drainage wells, free time or a team of builders.

Drainage pipes

The use of high-tech plastics has practically supplanted metal products for the formation of drainage systems. Modern materials have a number of undeniable advantages:

- small specific gravity;

- ease of installation and connection;

- resistance to corrosion;

- low cost;

- good strength properties - the possible depth of laying in the ground is 6-7 m.

The construction market offers specialized drains made of corrugated plastic pipes of various (100 - 200 mm) diameters. Perforation for water entering the pipe is applied by the factory. Thanks to the stiffening ribs, they perfectly withstand mechanical stress, the inner surface is smooth, which promotes self-cleaning, and the flexibility allows you to lay the product at any angle. Drains are offered ready-to-use in a geotextile braid, coconut fiber is used for filtration. The drainage system of the foundation, made of such materials, will serve for many years.

Instead of specialized pipes, you can use sewer pipes, but you will have to drill the perforations yourself, which takes additional time, and the connection with fittings is not always convenient.

The diameter is selected based on the length of the structure and the volume of incoming water. The carrying capacity of the drains must ensure the flow of any power.

Plastic wells

Ring or wall drainage for any foundation is not complete without wells. You will need two types of products - revision and accumulative.

- Revision - designed to control the system. When a blockage is detected in a certain area, the pump is lowered inward, the pipes are washed. Such nodes are installed at every turn or every 50 meters on straight sections. The standard product diameter is 600 mm.

- All the collected water will enter the reservoir. If there is a lot of it, additional capacity can be provided. Water is used for irrigation and technical needs.

To connect the system, you will need plugs, fittings, adapters and other small parts. The connections are carried out over the sealing gaskets, which ensure that there are no leaks. All these elements are always available in Irkutsk in the Vodolov company.

Device technology

Any blind area consists of an underlay and a protective coating.

Backfill: what materials to use

The task of the underlay is to create a level base for laying the sheeting. Its thickness is about 20 cm. Sand and crushed stone are often used for these purposes, but native soil or clay can also be used.

The simplest clay paving design

Sand and crushed stone are used on well-draining soils. In this case, sand is first laid, spilled and rammed. Then - a layer of crushed stone, which is also compacted.

If the soil on the site is clay or loam, then it is better to use native soil. If, with such soils, rubble or sand is laid around the foundation, then water will certainly be present near the house. Because it turns out that the density of the soil outside the underlying layer will be higher. This will lead to the fact that water will accumulate under the blind area. If, with such a design, a drainage pipe is laid around the perimeter of the bedding, the problem will be solved. Moreover, it is effective. But there will be more work, and the cost of the blind area with drainage is higher.

Types of protective coating

The covering for the blind area must meet many requirements:

- should not leak water;

- must be frost-resistant;

- have increased abrasion resistance;

- should not be destroyed by water.

It can be paving slabs or paving stones. The shape and color can be very different - you select it based on the general design of the territory, houses of nearby buildings. The thickness of these materials is at least 6 cm, only in this case they will withstand the harsh operating conditions.

The protective coating can be made of natural or artificial stone

You can use slabs or tiles made of natural or artificial stone, you can lay out the paths with large pebbles, or sprinkle gravel on top of all layers.

There is another type that is becoming more and more popular - this is a soft blind area. It has few layers, but it works effectively. There may not be any solid and waterproofing layer on top: you can pour soil and plant grass or flowers. An interesting solution for a summer residence or a country cottage.

The principle of a soft blind area

All these options are not bad, but the cost of their arrangement is quite high. If there is a need or desire to make it cheap and cheerful - your choice is a concrete blind area. There will be a lot of work, but the total cost is low.

General principles

Depending on the soil on the site and the purpose of the building, different materials and layer structure can be used, but there are some points that are always present:

- the blind area has a general slope "from the house", its minimum value is 3% (3 cm per meter);

- there must be a 1-2 cm expansion joint between the protective coating and the foundation (lay roofing material in two layers, foam or EPS, fill with sand, fill with sealant);

- when waterproofing and warming the foundation, the material rises to the level of the blind area;

-

the plinth should hang over the expansion joint and it should not be joined to the protective coating (a gap of 1-2 cm is left).

How to make a blind area at home with your own hands

First, markings are made around the perimeter of the building using pegs and laces. Further, the order of work is as follows:

- The vegetation layer and some soil are removed. The depth of the trench depends on the size of the sub-base and the thickness of the protective cover. Usually 25-30 cm.

- The bottom is treated with herbicides. This is necessary so that plants do not grow on this site. They are able to destroy even concrete and asphalt, and grow instantly between tiles or paving stones.

- The bottom of the trench is leveled, forming the required slope and compacted.

- The underlying layer is laid, rammed, keeping the slope. Compaction is desirable with a vibrating platform. Manual ramming is ineffective. Density is especially important when laying concrete, but it is advisable to compact well under tiles or paving stones: it will not fall through and warp.

- A protective covering is laid.

- A drainage groove is formed.

This is very short and schematic. Each coating has its own characteristics, and each should be discussed separately.

Drainage pipes for groundwater disposal: complete product classification

This article discusses drainage pipes for groundwater drainage: a complete classification of drainage products, their advantages, characteristics and main parameters is presented. With this information, you will learn how to select the appropriate types of pipes for certain types of discharge systems in accordance with their requirements, soil characteristics, etc.

Corrugated pipe walls are highly resistant to any deformation changes under the influence of loads

Drainage pipes for groundwater disposal: an introduction to the topic

The drainage pipe acts as the main building element, on the basis of which a drainage system is formed, designed to drain the areas. This element is responsible for collecting and discharging underground, melt and rainwater outside the territory with their preliminary filtration.

Note! A large volume of melt and storm water can provoke a rise in the level of groundwater. The emergence of such a situation is extremely undesirable, since as a result, the destructive effect on the foundation part of the building, as well as all the elements of landscape design located on the site, increases. The drainage system helps to get rid of excess water in the area

The drainage system helps to get rid of excess water in the area

The installation of large diameter drainage pipes allows you to cope with such problems as:

- increased soil moisture,

- mold formation,

- flooding of the site, the foundation of a residential building and utility buildings, as well as cellars,

- formation of permafrost,

- the appearance of puddles on paved surfaces,

- formation of ice on footpaths,

- decay of the roots of garden flowers, vegetables and other vegetation due to an excess of moisture in the garden and summer cottages.

Features of drainage pipes with partial perforation, complete or lack thereof

If we talk about the general classification of products for drainage systems, the assortment is represented by the following types of pipes (by type of material):

- asbestos-cement,

- ceramic,

- plastic drainage pipes with and without perforation, as well as with its partial presence.

On the building materials market, drainage pipes are presented in a wide variety of types and sizes.

However, most construction companies have already abandoned the use of pipes made of ceramics or asbestos cement due to the numerous disadvantages inherent in them:

- Large weight, requiring significant costs for transportation and installation, because the installation of such bulky products cannot do without the use of specialized construction equipment.

- The slow process of installing a drainage system, which can only be carried out by the hands of professionals.

- Poor performance. Drainage pipes are usually on sale without perforation, so the holes are made by hand. Because of this, during operation, the pipeline becomes clogged faster, so frequent cleaning is required, and in some cases, complete replacement of elements.

- The construction of systems based on them is much more expensive than in the case of using plastic elements.

Installation of a water drainage system on a land plot using corrugated plastic pipes with perforation

Note! The table shows the average price of drainage pipes 200 mm from various materials. There are other diameter options, however, in products made of ceramics, asbestos cement and plastic, the standard dimensional parameters do not coincide. Therefore, for comparison, the diameter of the drainage pipe is 200 mm, which is present in the range of all these products.

Therefore, for comparison, the diameter of the drainage pipe is 200 mm, which is present in the range of all these products.

Comparative pricing table:

Drainage pipes for groundwater disposal: complete product classification Drainage pipes for the removal of groundwater from a suburban area: types of products, their characteristics, prices and features of application in drainage systems.