Universal foundation - monolithic slab

Any non-professional who decides to build a garage with his own hands is faced with the difficulty of choosing a foundation. Almost everyone asked the question: "Is there really no universal foundation?" In fact, in this situation, it is rather difficult to talk about universality. But the least problems, in the presence of negative factors, will be caused by the foundation slab, in other words, the floating foundation.

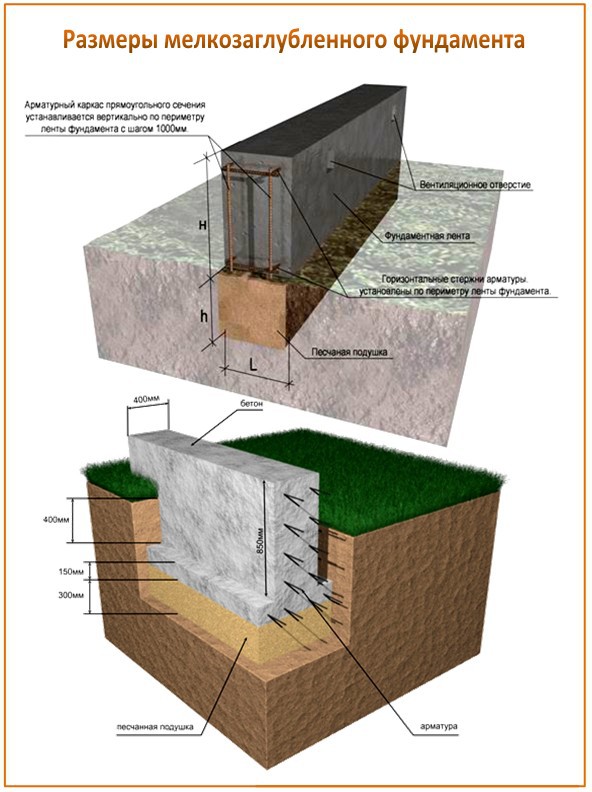

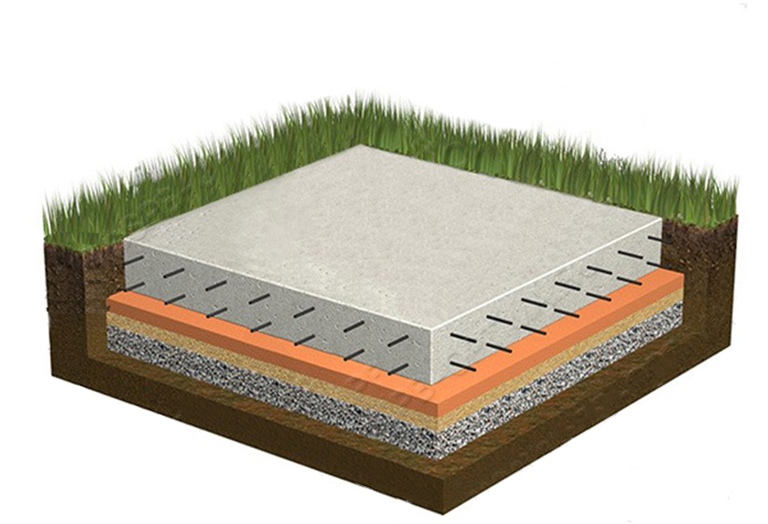

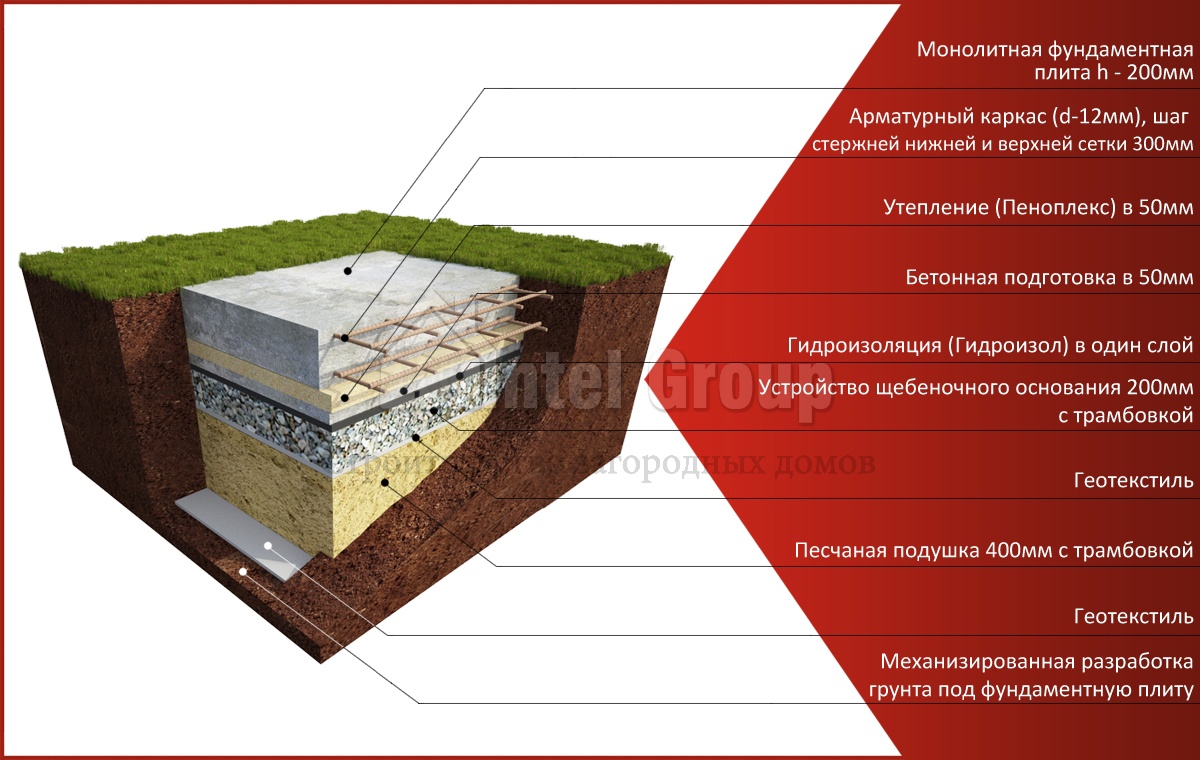

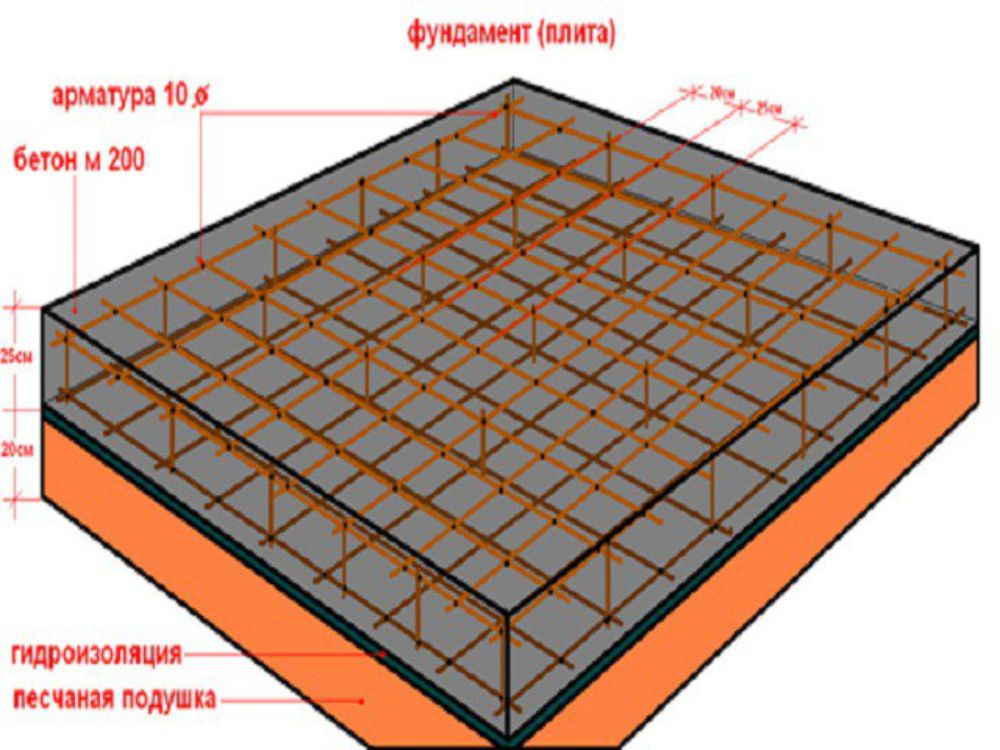

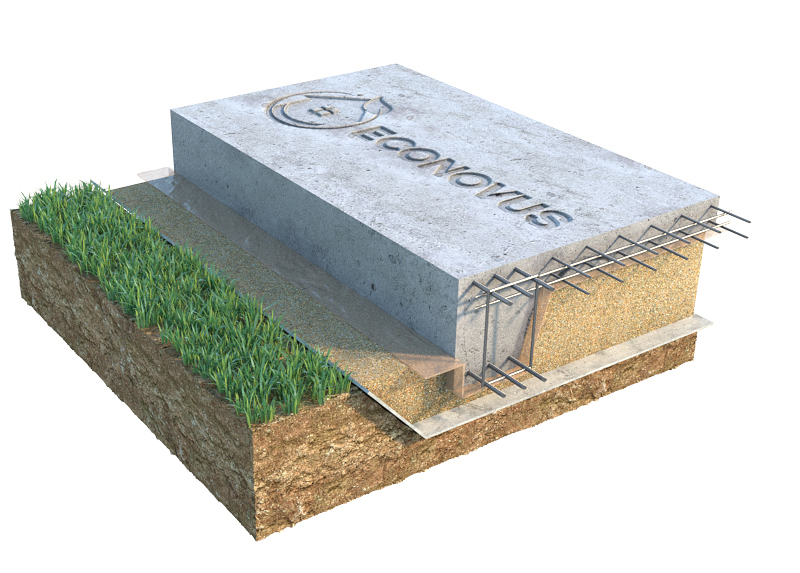

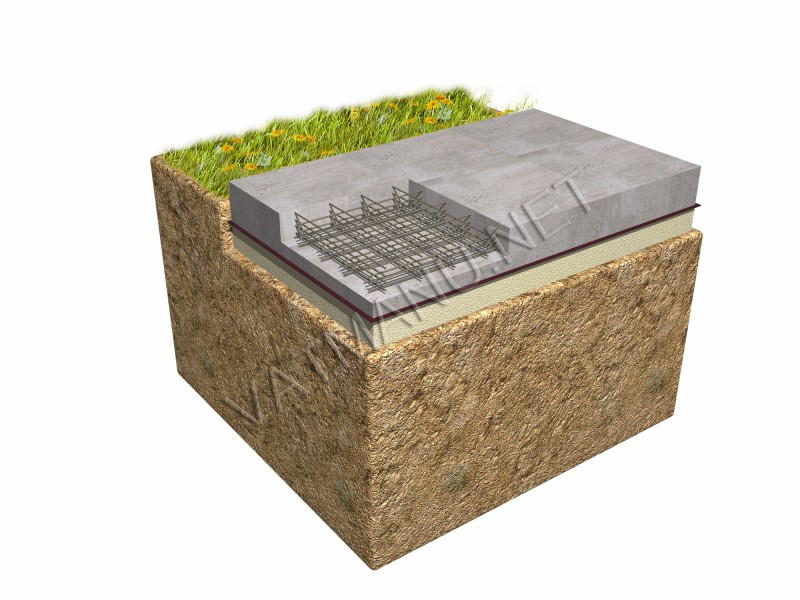

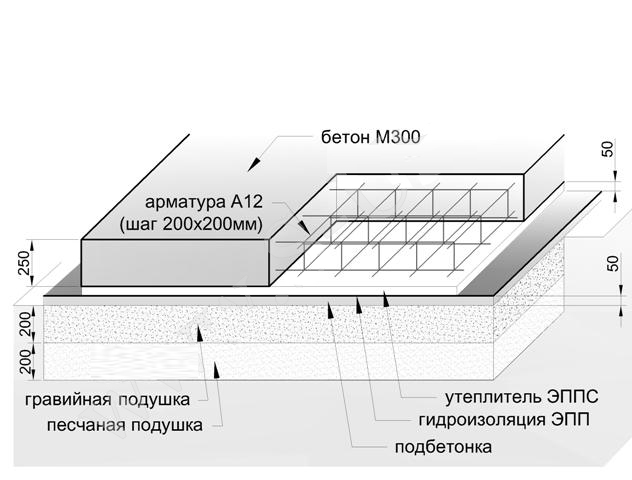

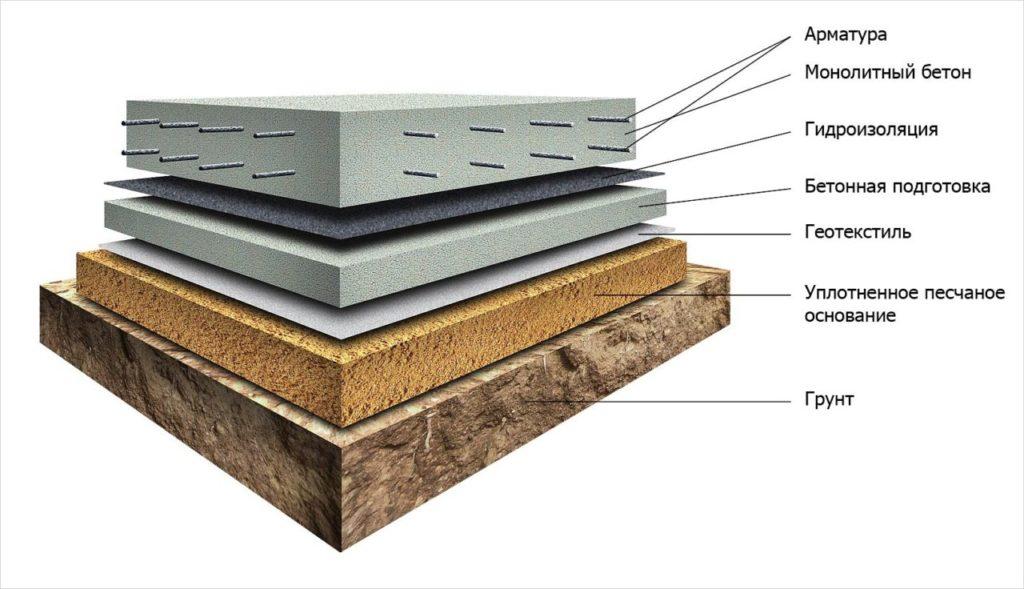

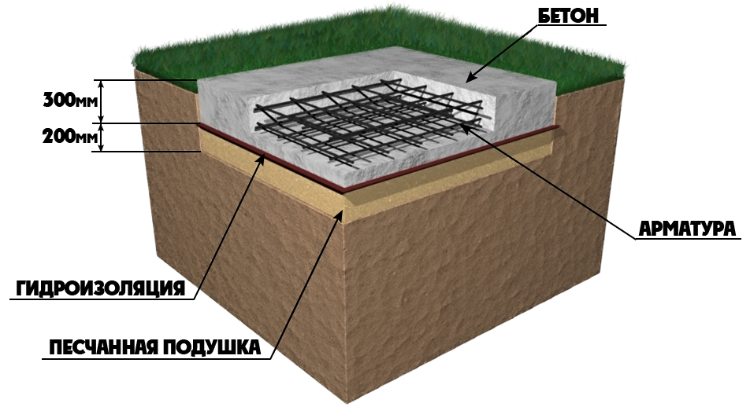

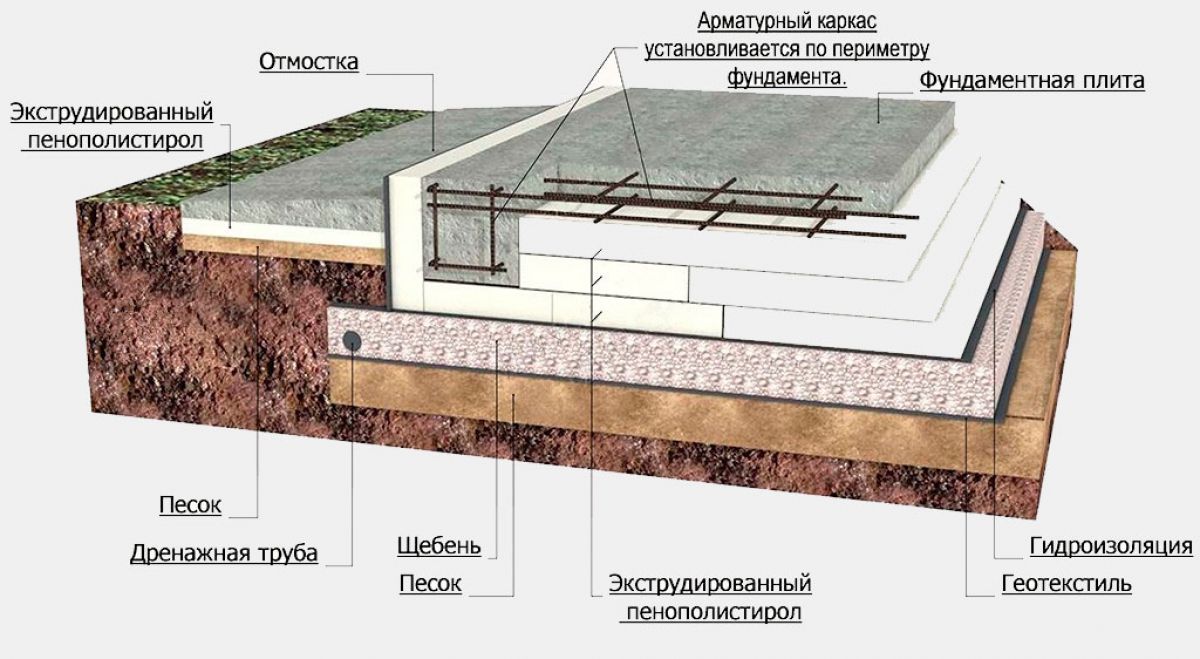

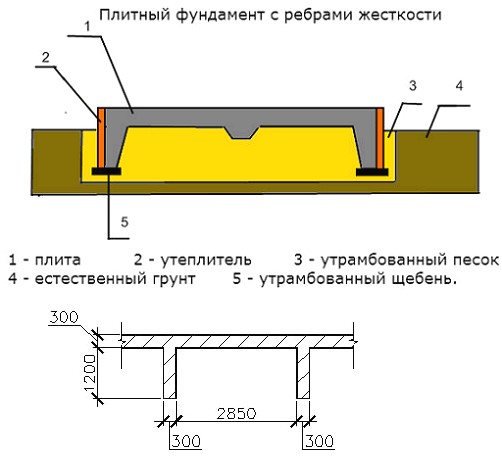

The floating foundation is a monolithic reinforced concrete slab that is placed under the building. This design distributes loads well and is optimal for a one-story garage without additional recesses (inspection pit, cellar). The slab foundation can even be used as a floor, but it is better to insulate and make additional coverage.

The monolithic slab is called "floating foundation" for a reason. It is directly related to its properties: when the soil settles or cracks from severe frosts, deformation of the foundation and the building does not occur. The structure, together with the slab, shrinks smoothly, which ensures the durability and practicality of the structure.

Pros and cons of a floating foundation

A monolithic slab for a garage has many positive aspects due to which its use is so widespread.

- A monolithic slab is not afraid of geological problems. Such a foundation is not afraid of shrinkage, swelling and washing away.

- High groundwater is not a hindrance for a garage built on a monolithic slab. Providing proper waterproofing and compliance with technical standards, the garage will always be dry.

- The slab foundation can act as a floor, which will simplify the work and save a little. As a rule, insulation is done on top of the floating foundation and the main covering is laid.

- The design of the reinforced concrete slab allows you to make a warm floor in the garage. It is a great alternative to uneven and wasteful heating.

- The solid construction provides 100% protection against rodents and insects that can penetrate the ground and floor.

Well, the main advantage, of course, is the simplicity of the design itself. Even if you have never done anything like this, having carefully studied the issue, you can make a reliable floating foundation for a garage with your own hands, which will serve you for many years without complaints.

Although there are few shortcomings of this design, it still has them. Firstly, such a foundation excludes the arrangement of a viewing pit or cellar. But not everyone needs them. Secondly, the installation of a monolithic slab implies a large consumption of reinforcement and concrete, which is quite costly. Again, reliability and durability are well worth the expense.

Summarizing an overview of the main qualities and properties of a floating foundation, we can say that this is the most practical and simple solution for problem areas.

Design options

A monolithic slab for a garage is universal in that there are several design options. You can use the one that best suits your requirements and financial capabilities.

1 Regular

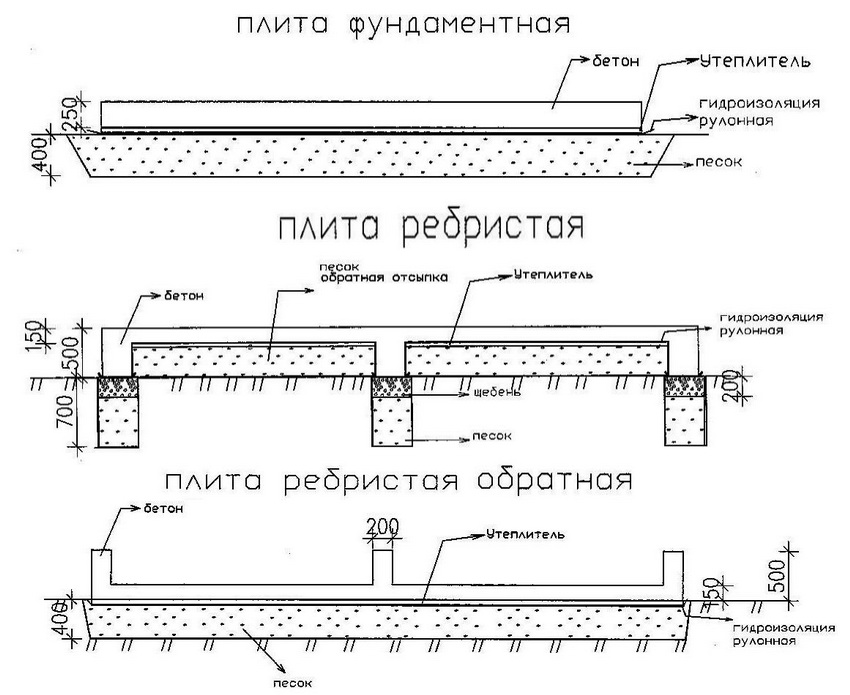

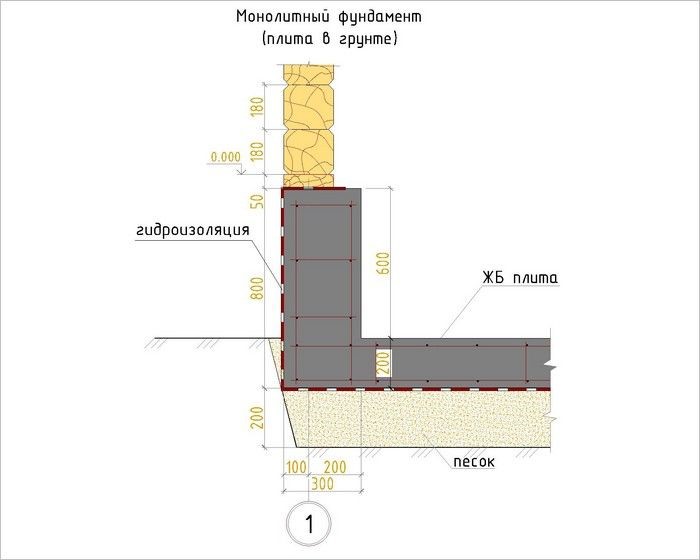

An ordinary slab is a solid base, 10 to 60 cm thick, located in a recess or on the surface.

2. Reinforced at the edges

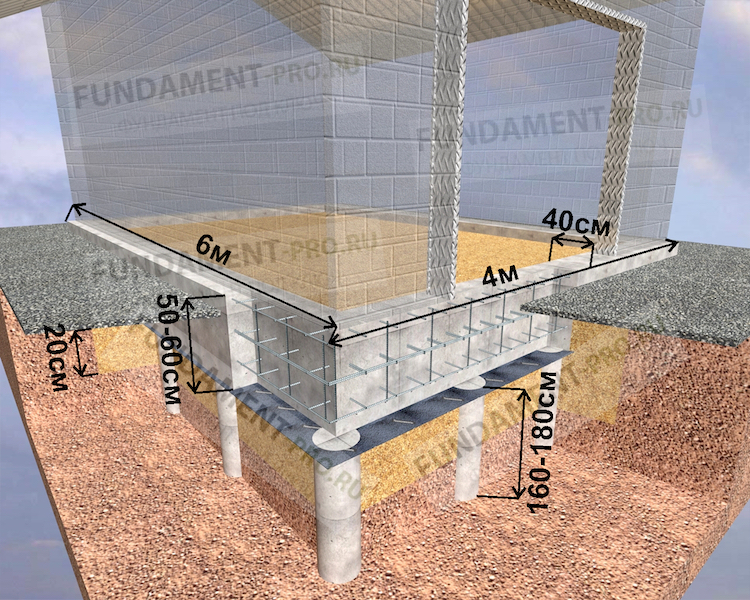

This design can be located at any convenient depth (1.5-2.5 m). The monolithic slab, reinforced at the edges, is a flat base with stiffeners placed around the perimeter. With the help of formwork, the ribs are also poured with concrete, forming walls. Another reinforced concrete slab is formed on top of the reinforcement.As a result, we get a solid foundation with a basement room that can be used as a basement or cellar. Due to the complexity and high cost in private garages, such a design is not used very often, but almost all high-rise buildings are built according to this principle.

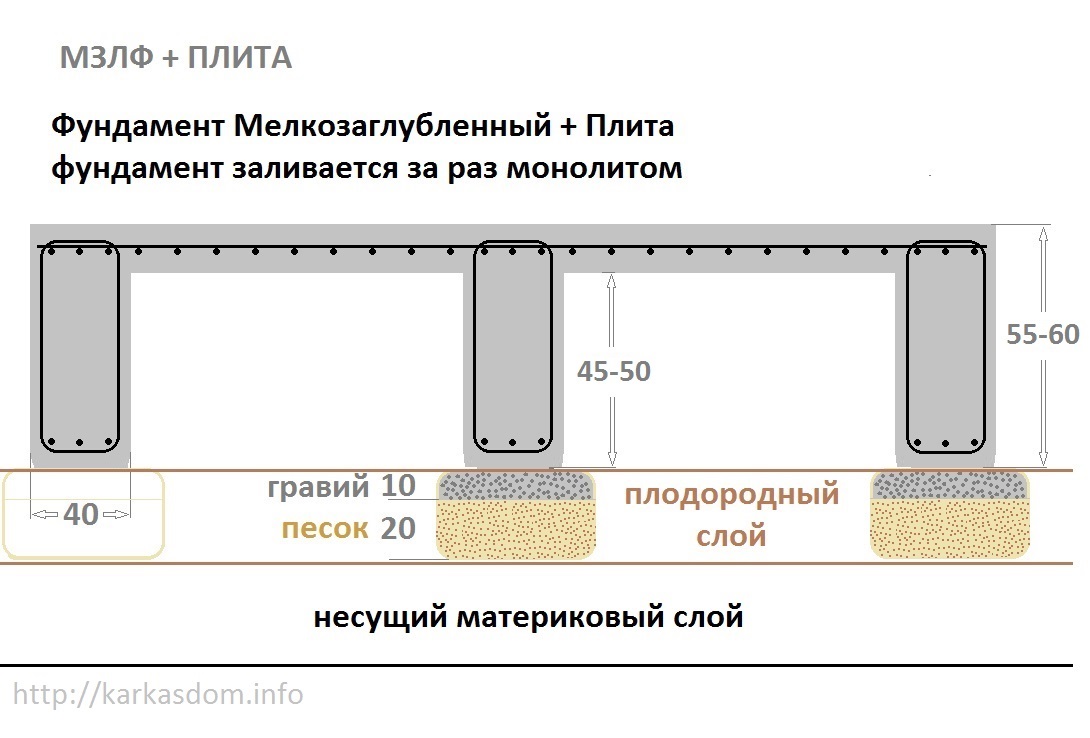

3. Lightweight (lattice)

This design allows you to save a little on materials, although it is only suitable for garages made of lightweight materials (wood, foam blocks). The lightweight foundation is not a solid slab, but a lattice with cells (from 1 to 1.5 m). Such a foundation can be called monolithic at a stretch, it is more like a strip foundation. But nevertheless, with such a foundation, the load is distributed much more evenly, and the building structure itself is more stable.

Monolithic slab - an excellent foundation for a garage

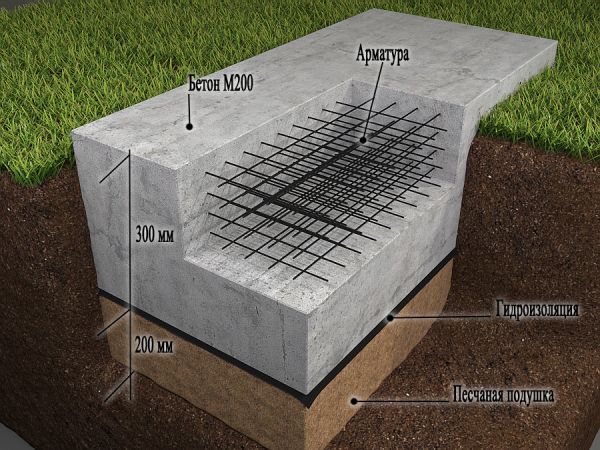

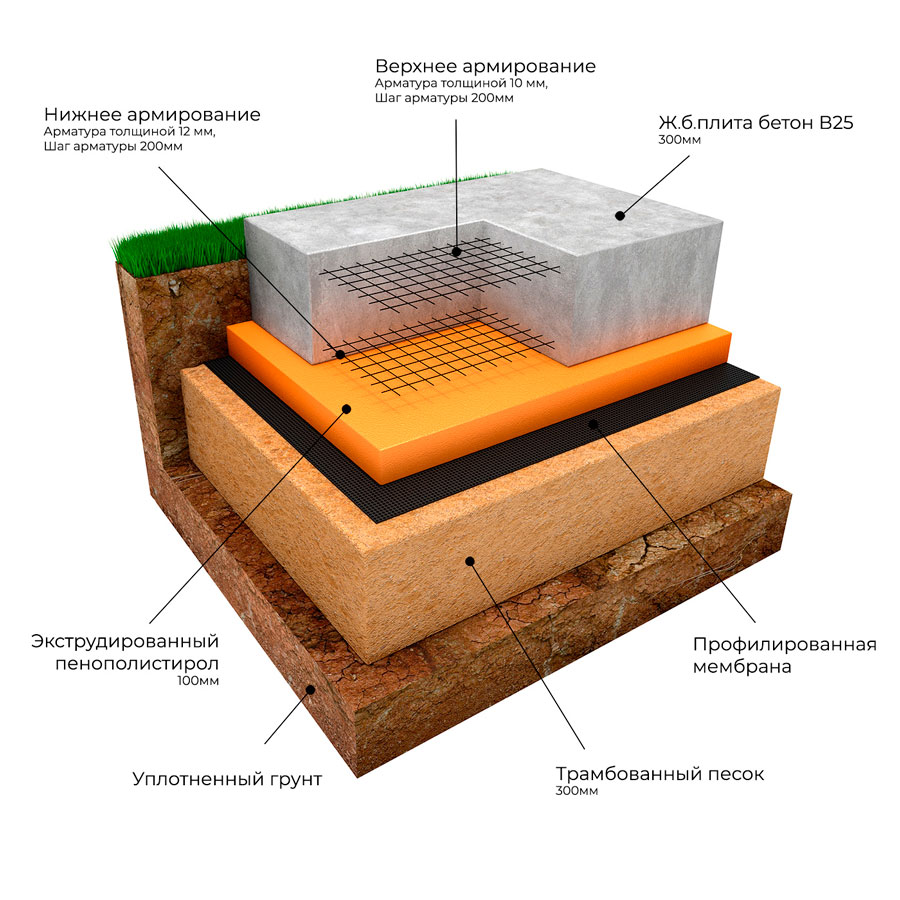

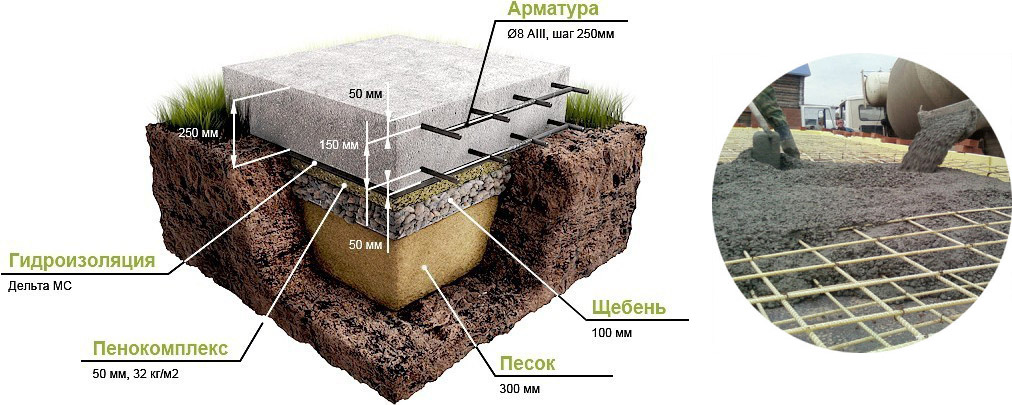

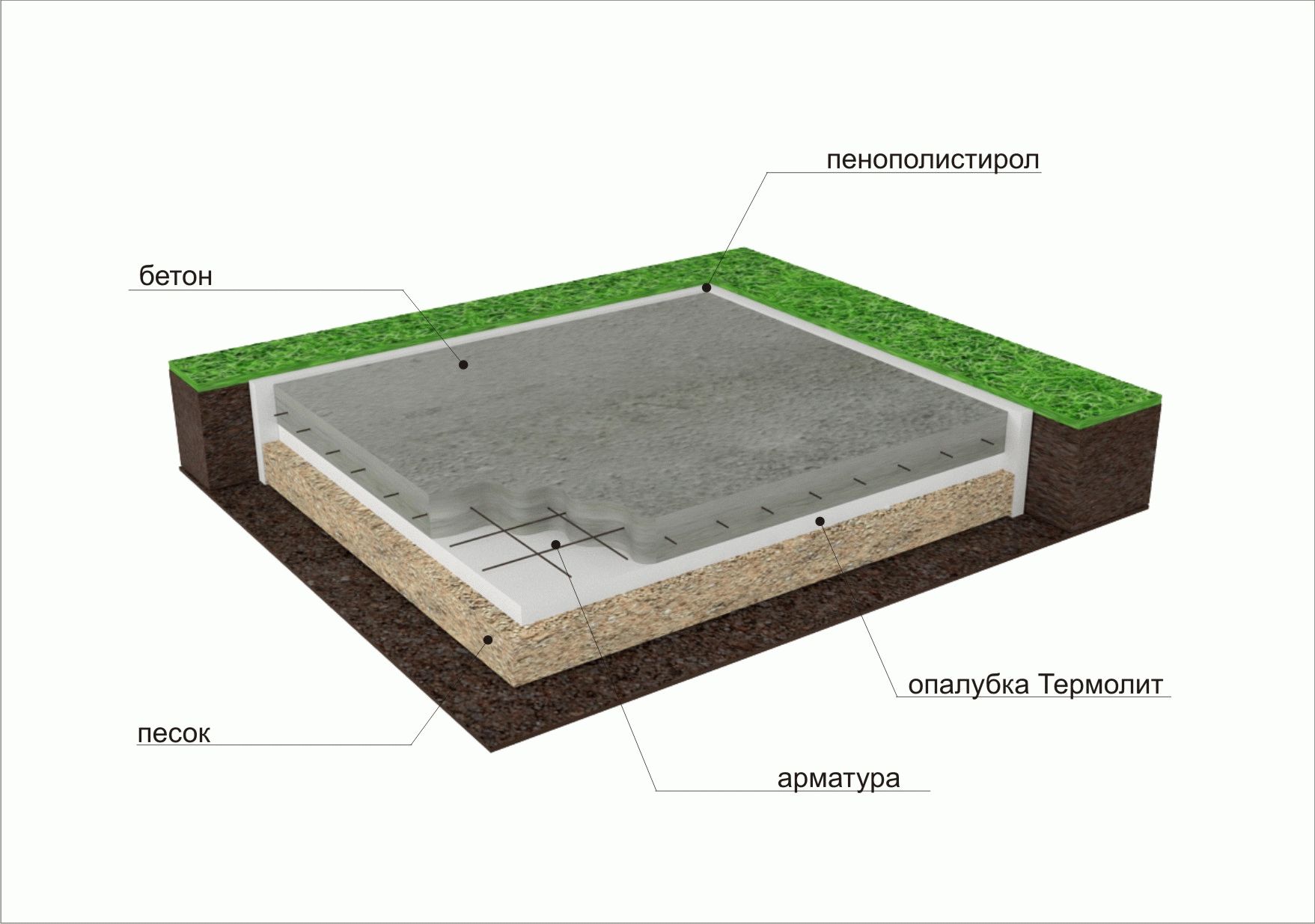

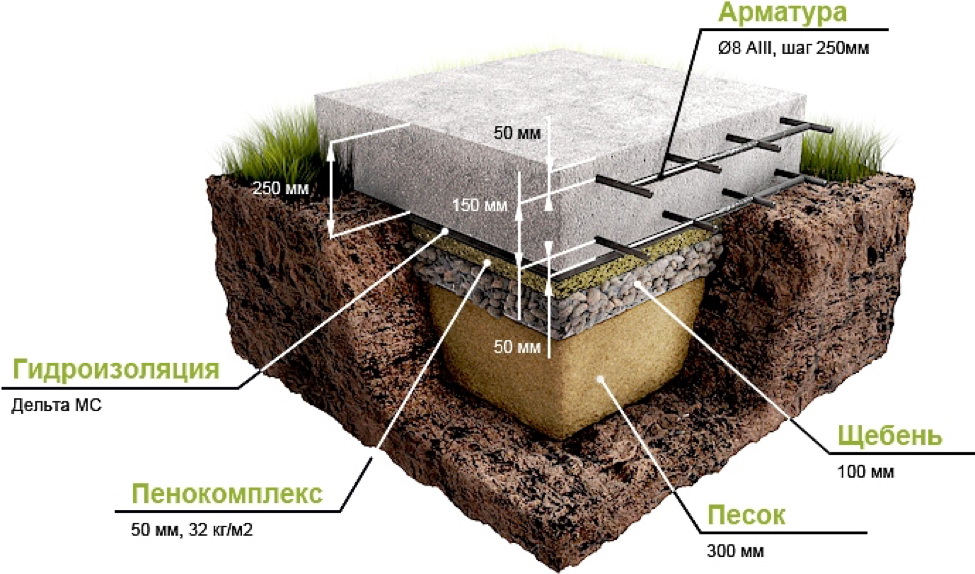

The slab foundation is suitable for low-rise buildings, which include garages. A monolithic slab is erected on a bulk cushion of crushed stone or sand, the strength of the base structure is given by a reinforcing cage laid in the body of the foundation. A monolithic base can serve as a garage floor, only in this case it is required to carry out additional insulation and provide for reliable waterproofing.

The slab base is called "floating" - when the soil bulges or settles, the building smoothly moves with the slab, which excludes the occurrence of deforming moments and uneven shrinkage.

The disadvantages of a slab foundation include the impossibility of building a basement, which is necessary when building a garage.

On swampy and watered soils, it is best to build a garage on piles.

Installation of a slab under a garage

There is nothing difficult in performing work on the construction of a monolithic slab for a garage box on your own, you only need to have minimal construction skills and sufficient funds (a slab of monolithic concrete is a rather expensive type of foundation).

Preparatory work, site planning

Before starting concrete work on pouring the slab base under the foundation, it is important to carry out preparatory planning work with special care. The site should be cleaned of debris and large stones, uproot tree stumps, remove overgrowth of trees and shrubs, and plan the territory

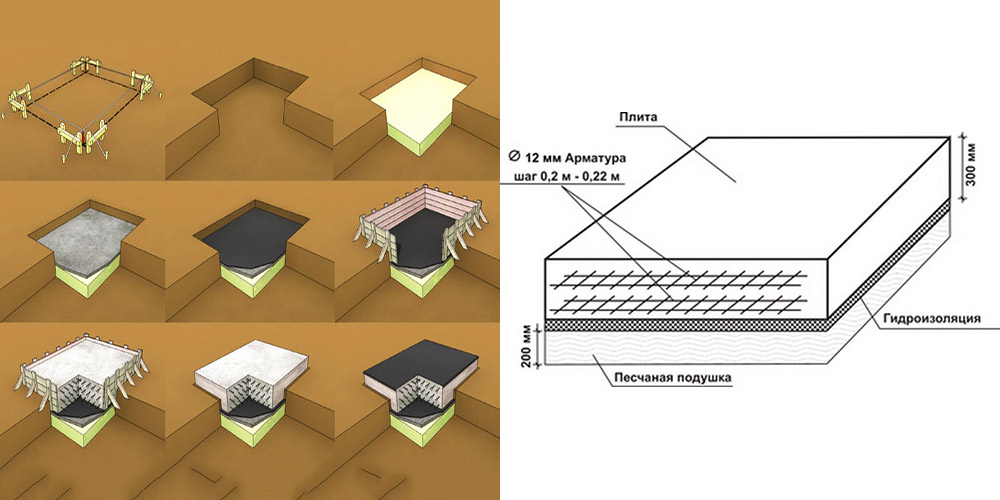

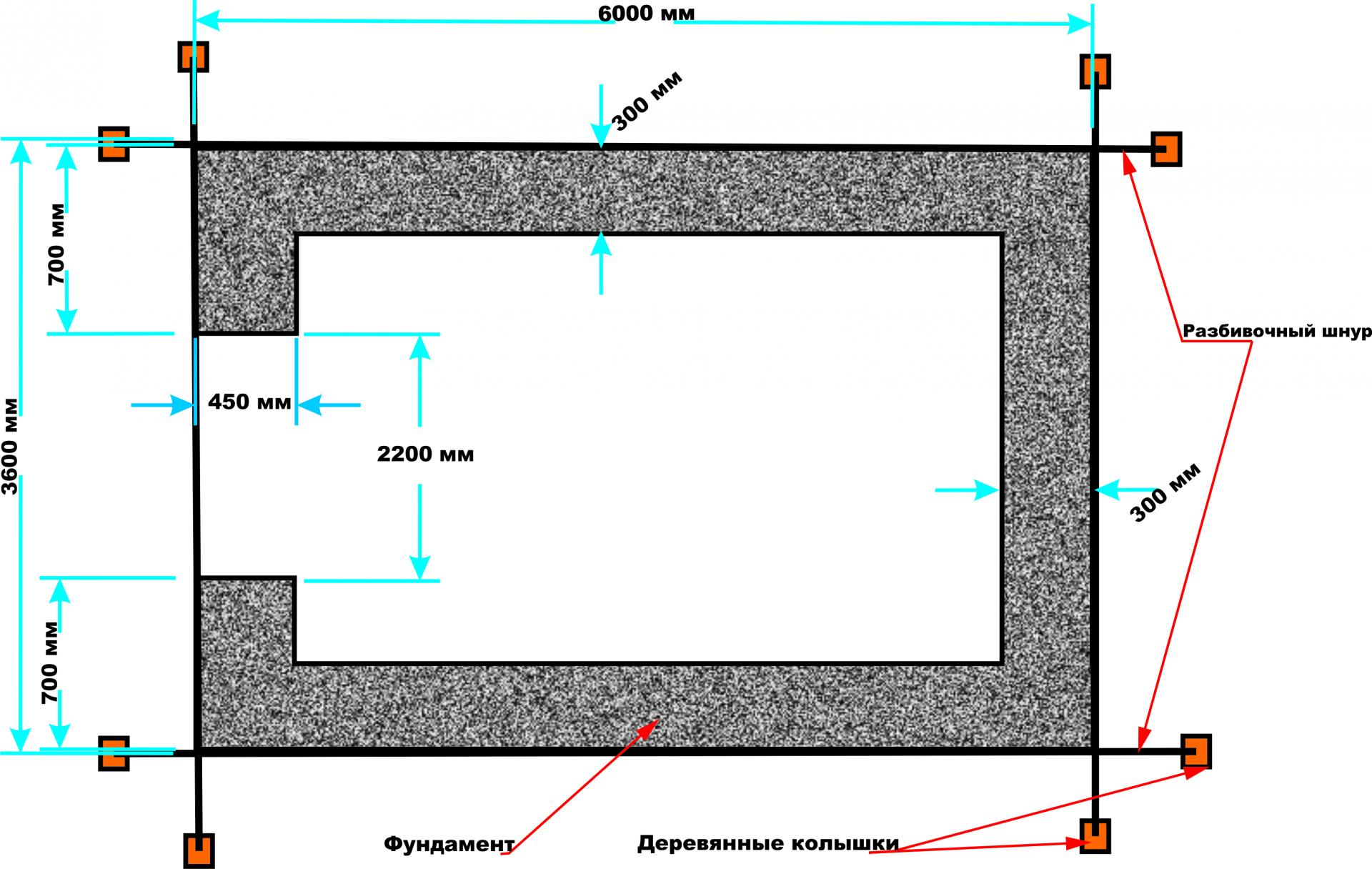

The marking of the future foundation is carried out directly on the construction site after planning work. The corners of the building are marked with pegs, between which twines are stretched. The length and width of the slab are measured with great care - any discrepancy in size can cause a skew of the foundation structure and the garage building erected on the slab.

In order to check the conformity of the dimensions, it is worth pulling the twine along the diagonal of the site - the measurement results should be exactly the same.

Excavation work on the device of a monolithic slab

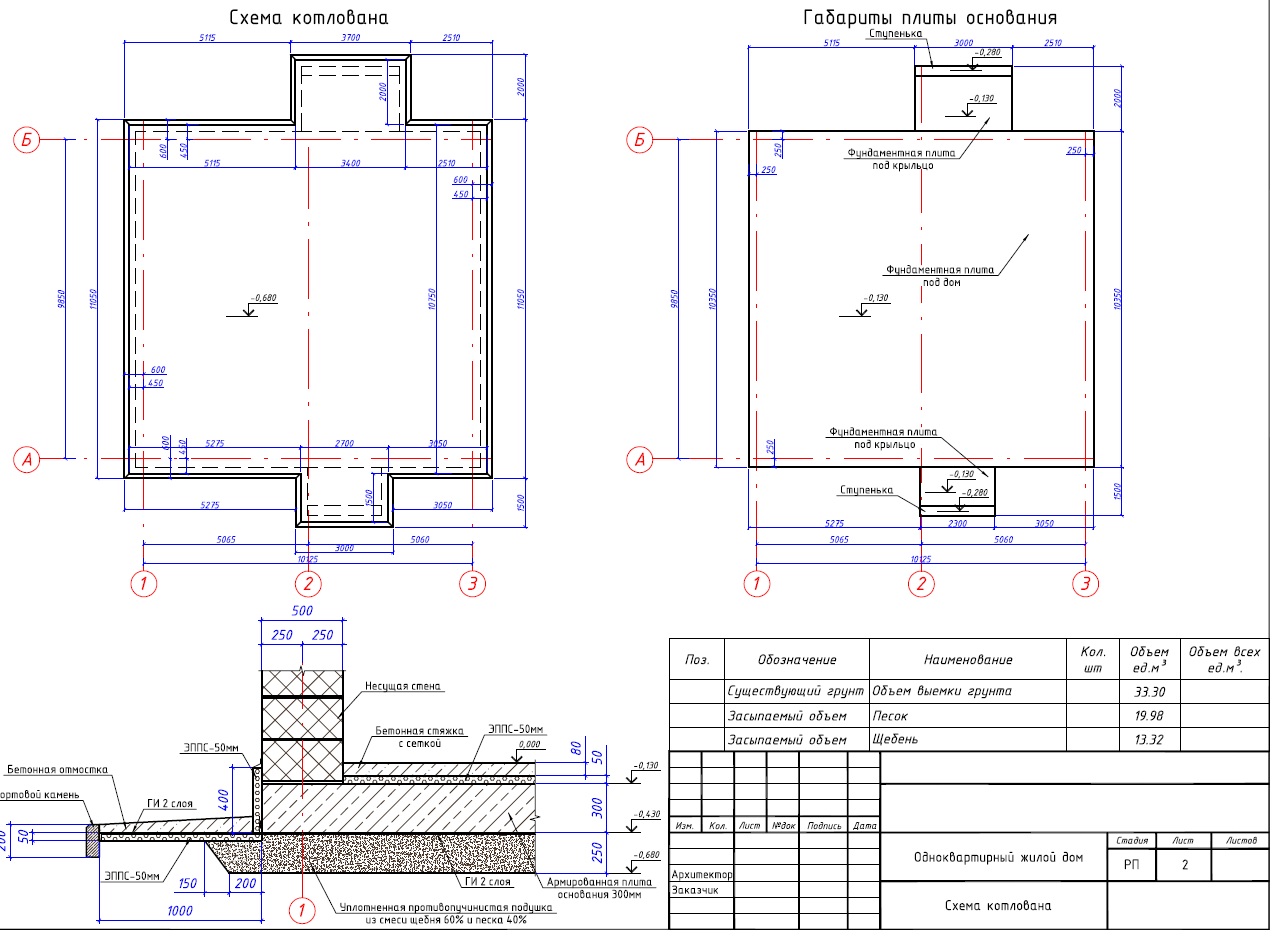

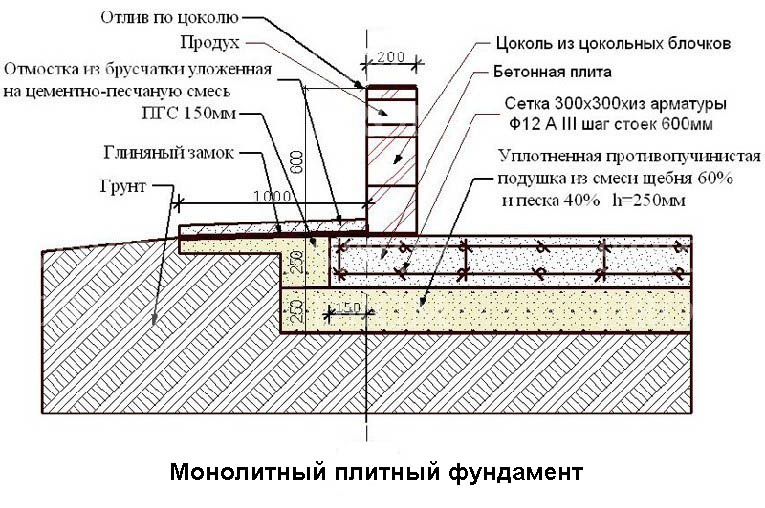

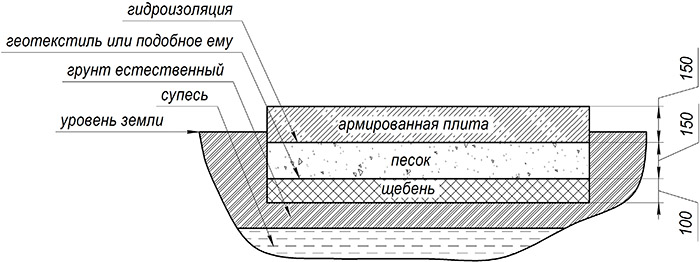

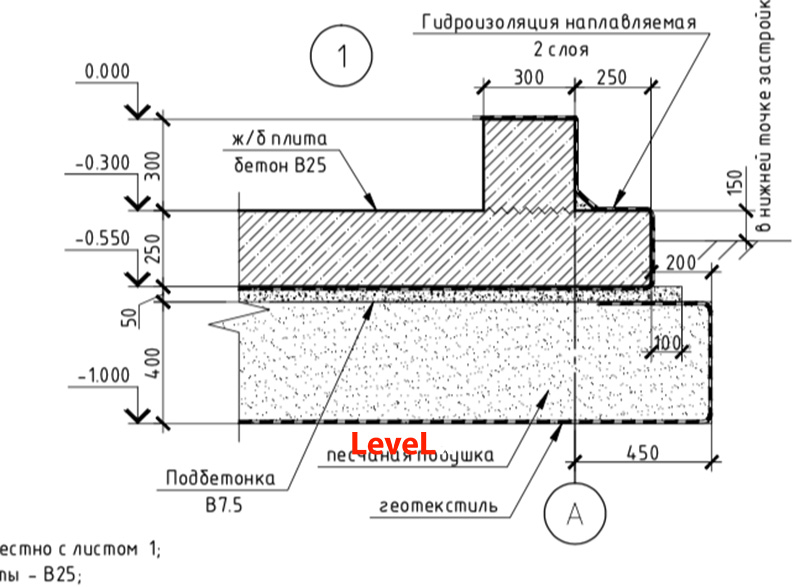

For the construction of a concrete cushion, it is necessary to dig a pit, which usually has a depth of 30 to 50 cm. In some cases, the thickness of the slab has to be made more, but it should be remembered that the cost of such a foundation increases sharply.

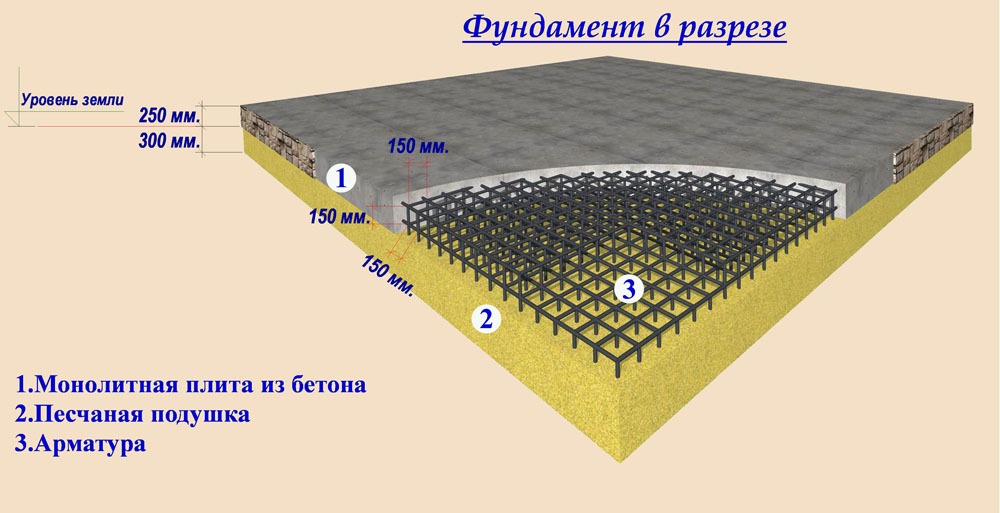

The bottom of the dug pit is filled with rubble, which is laid out in an even layer on the ground and carefully tamped. The height of the crushed stone base can be from 10 cm.

The preparatory layer of crushed stone is filled with coarse quartz sand, which is leveled over the area of the pit and in height must correspond to the thickness of the crushed stone preparation. The sand layer must be tamped, if tamping causes difficulty - pour water, and then repeat the operation.

Formwork and fabrication of the reinforcement cage

A wooden formwork is erected along the perimeter of the pit, the height of which should be slightly higher than the thickness of the supporting monolithic slab. The formwork device starts from one corner into which the first support peg is driven

The pegs are placed along the entire perimeter at equal distances, while it is very important to ensure that the vertical position is observed. The formwork boards are fastened with self-tapping screws, during their installation it is important to fix the boards with the smallest gap between them

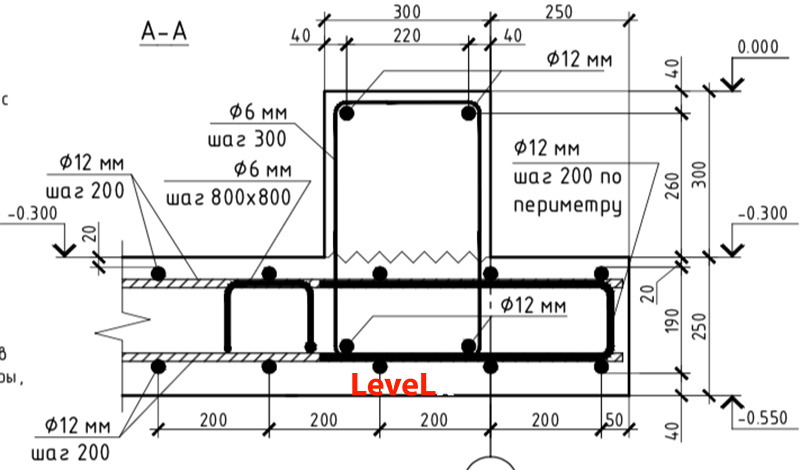

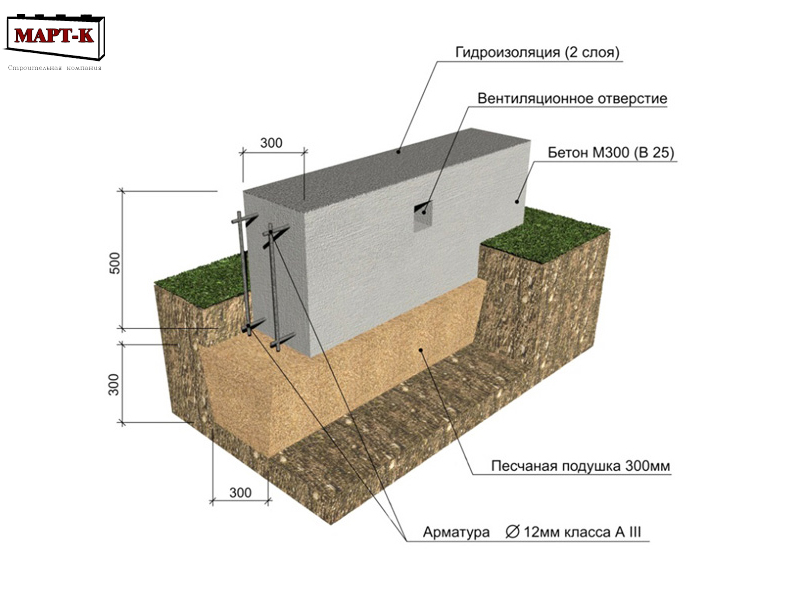

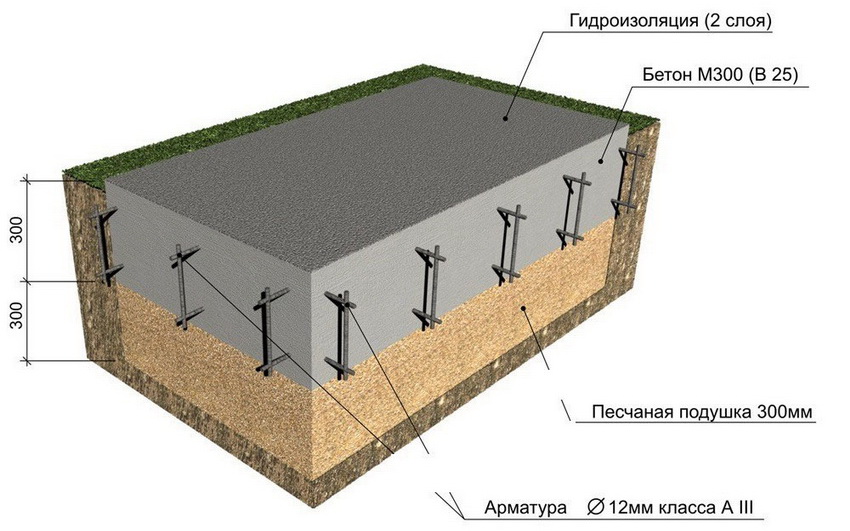

After installing the formwork, you should proceed with the construction of the frame from the reinforcement. It is allowed to use reinforcement with a diameter of at least 12 mm for reinforcing a monolithic slab foundation. The frame is knitted using knitting wire or welding. The cell size should not exceed 20 cm.

Choosing between a welded method of manufacturing a reinforcing cage and a method using a knitting wire, it is worth noting that both methods have their own advantages and advantages, but the second is more reliable.

Pouring concrete mix

The quality of the foundation largely depends on adherence to the technological process of pouring concrete. It is allowed to use concrete not lower than M-250, the ideal option is M-350. It is best if the process of filling the prepared formwork with concrete is continuous - thus, it is possible to avoid uneven setting of the concrete mixture and the formation of cold bridges.

It is best to order a concrete mix that is supplied in special mixers. The filling of the formwork starts from one corner, the concrete mix is distributed throughout the structure, with constant compaction with vibrators

It is very important to avoid voids when pouring the slab base, their presence will significantly weaken the bearing capacity of the foundation pad

When making concrete mix by hand, it is important to place concrete mixers on different sides of the foundation, filling the formwork from opposite corners, while it is very important to thoroughly compact the concrete mix with vibrators. Watch a video on how to properly mount a slab under a garage:

Watch a video on how to properly mount a slab under a garage:

Foundation cushion device

Before starting construction, trenches for a tape base or a foundation pit for a monolithic base are dug on a cleaned and marked area. All loose soil is removed and the bottom of the trench is leveled. Then a layer is formed underneath, sand, gravel or concrete.

Sand cushion for strip foundation

Diagram of a sand cushion device for a strip foundation.

To create a sandy layer under the base, you will need:

- Sand with coarse to medium grain without various inclusions (especially clayey).

- Geotextile or roofing material - will serve as a barrier against groundwater.

- Level, pegs and rope.

- Vibratory plate or homemade rammer.

Before starting the device of the interlayer, all loose soil is removed from the bottom of the trench. Geotextiles or roofing felt with an overlap (10 cm) are laid on its bottom. These materials will prevent the sand from mixing with the soil. Also, when backfilling, an important point is the observance of the horizon line. To do this, use pegs and a rope to set the desired level.

Sand is poured over the laid material.

Then each layer is compacted using a vibrating plate. Tamping is carried out until traces remain on the surface. Each layer should be approximately 10 cm high.

Forming, usually its height is in the norm of 20-30 cm. To calculate the maximum permissible height, you need to triple the width of the tape. The created interlayer should resemble a trapezoid in its section. Its narrowest part should be located at the bottom (an angle of inclination of 30 degrees is desirable).

The organization of this variant of the interlayer is relevant:

- If leveling of the bottom of a trench or excavation is required.

- If it is required to replace the soil with strong heaving with sand.

Rubble pillow

For arranging a crushed stone pillow under the strip foundation, the following material is required:

Construction of rubble concrete foundation.

- River sand with coarse grains.

- Crushed stone or gravel 20-40 mm in size.

The formation of a crushed stone base begins with an embankment of a layer of sand.Its thickness is 10-15 cm. The resulting layer is necessarily wetted and the compaction process is carried out using the same devices as in the previous version.

Crushed stone with a thickness of about 20 cm is poured onto the compacted layer. In total, the height of crushed stone and sand should be 30-40 cm. The crushed stone is compacted. As a result, the crushed stone must lie strictly in the horizontal plane. The width of the interlayer is equal to the width of the planned base tape with the addition of 15-20 cm on one and the second side.

Such a simple version of the base for a strip foundation will withstand the load from a structure of several floors.

Concrete foundation pillow

This version of the device is more expensive, but also justified. When properly formed, the foundation with a concrete cushion will become a solid foundation for the future structure. For its construction you will need:

- Concrete.

- Crushed stone or gravel.

- Boards.

- Vibratory plate or homemade rammer.

- Metal rods.

To begin with, crushed stone with a height of 10 cm is laid on the bottom of a leveled trench under the strip foundation.It is tamped using a homemade device or a vibrating plate. Then a formwork from boards is mounted on a crushed stone substrate. Its height should be equal to the height of the future pillow (up to 30 cm). The width of the interlayer is plus 15 cm on both sides.

To increase the strength, reinforcement (strengthening) of the pillow is carried out using metal rods with a diameter of 8-12 mm. A frame is created from the material for reinforcement by welding or bundling structural elements together.

Concrete is poured into the formwork with a metal frame. The grade of this material will depend on the weight of the future structure. After the pouring process, the concrete is compacted using a deep vibrator. In the prepared base for further adhesion of the concrete sole to the foundation, rods 40-60 cm long are inserted.They should look out above the surface by half their length.

When forming a concrete preparation for the construction of a lighter structure, crushed stone can be replaced with sand. Form a 10 cm layer and sprinkle with water to seal. The following manipulations are identical to the above described variant of the device.

For a strip foundation, a concrete cushion will become a solid base with a fairly long period of use. With its correct organization, it will withstand the significant weight of the structure and will serve as an excellent foundation.

Each type of pillow has a right to exist. Despite the fact that the formation can be carried out from different materials, with the correct process, any of the above options will be a reliable support for the future structure.

Depth of laying

does not affect so much

However, the determination of the depth of shallow and deep slab foundations can vary depending on several factors:

- from the depth of soil freezing;

- on the type of soil;

- from the total load on the ground;

- from the groundwater level.

The height of the pit and the thickness of the monolithic foundation slab for various types of soils is indicated in the relevant regulatory documents, for example, SNiP 2.02.01-83 and SNiP IIB.1-62.

Below are approximate recommendations for installation:

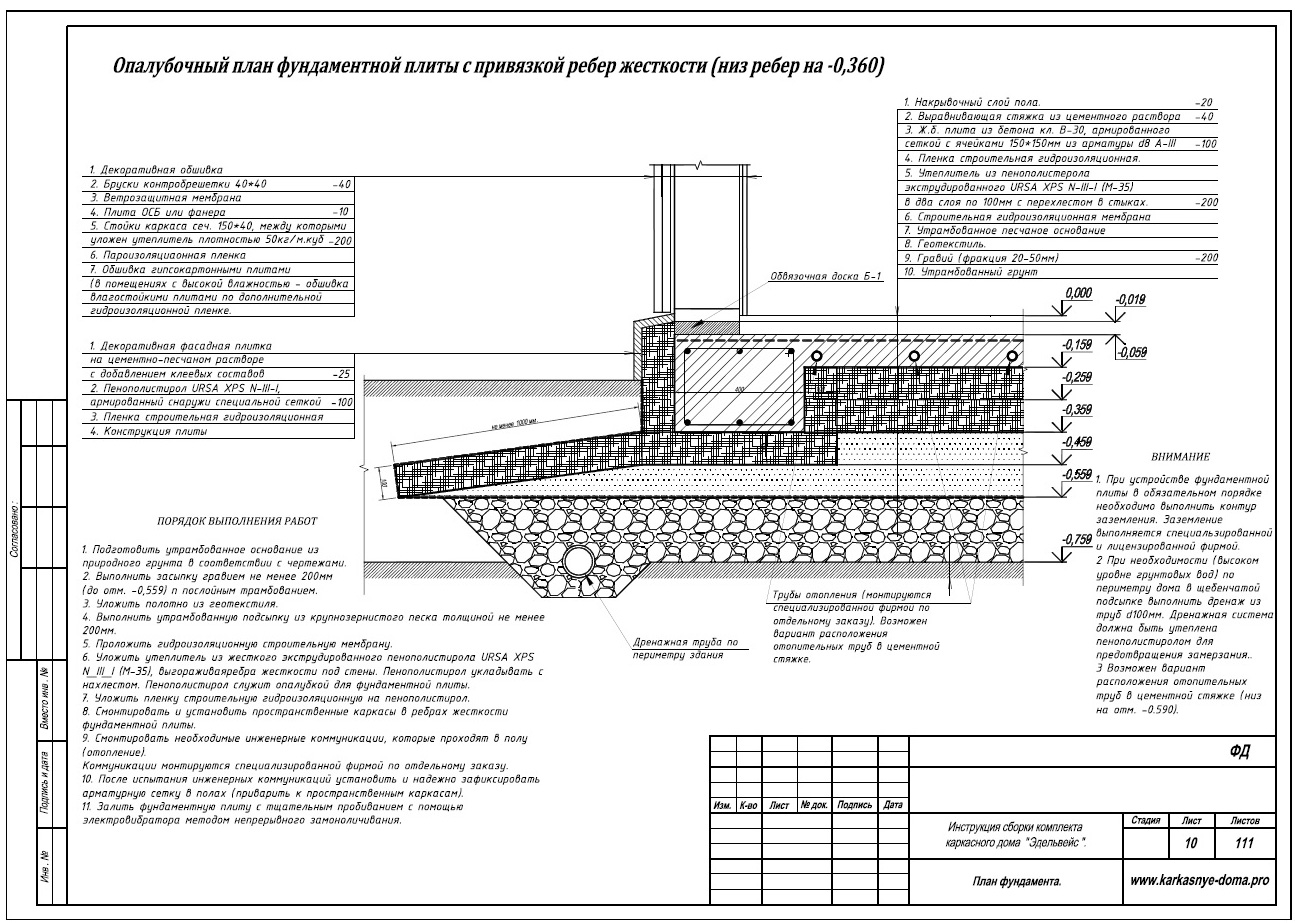

- The height of the crushed-stone cushion. The thickness can vary from 15 to 60 cm and depends on the depth of soil freezing in a given area and the type of soil. If the depth of soil freezing is more than one meter, it is recommended to pour 40–45 cm of sand and 15–20 cm of crushed stone. The total thickness will be 60 cm. If the freezing depth is from 50 to 100 cm, a pillow with a total thickness of 30–40 cm is sufficient.

- The thickness of the thermal insulation layer should be at least 10 cm in warm regions and 15 cm in northern ones. Here it must be borne in mind that the higher the soil moisture, the thicker the heat-insulating layer should be.

- The height of the reinforced concrete base should not be less than 15 cm.Such a layer is used in the construction of one-story frame houses or outbuildings. When erecting a brick or monolithic concrete structure, it is recommended to make a layer thickness of 25-30 cm.

Thus, the calculation of the burial depth and thickness is carried out individually on a specifically selected area. For northern regions with unstable soils, a foundation pit 80–100 cm deep with a total base thickness of 100–120 cm is required; for construction on stable soils in warm or moderate climatic conditions, a depth of 30–40 cm is sufficient with a “cake” thickness of 50–60 cm ...

Important! On rocky stable soils, the burial depth is minimal and can be 20 cm

Arrangement of a conventional shallow foundation for a garage

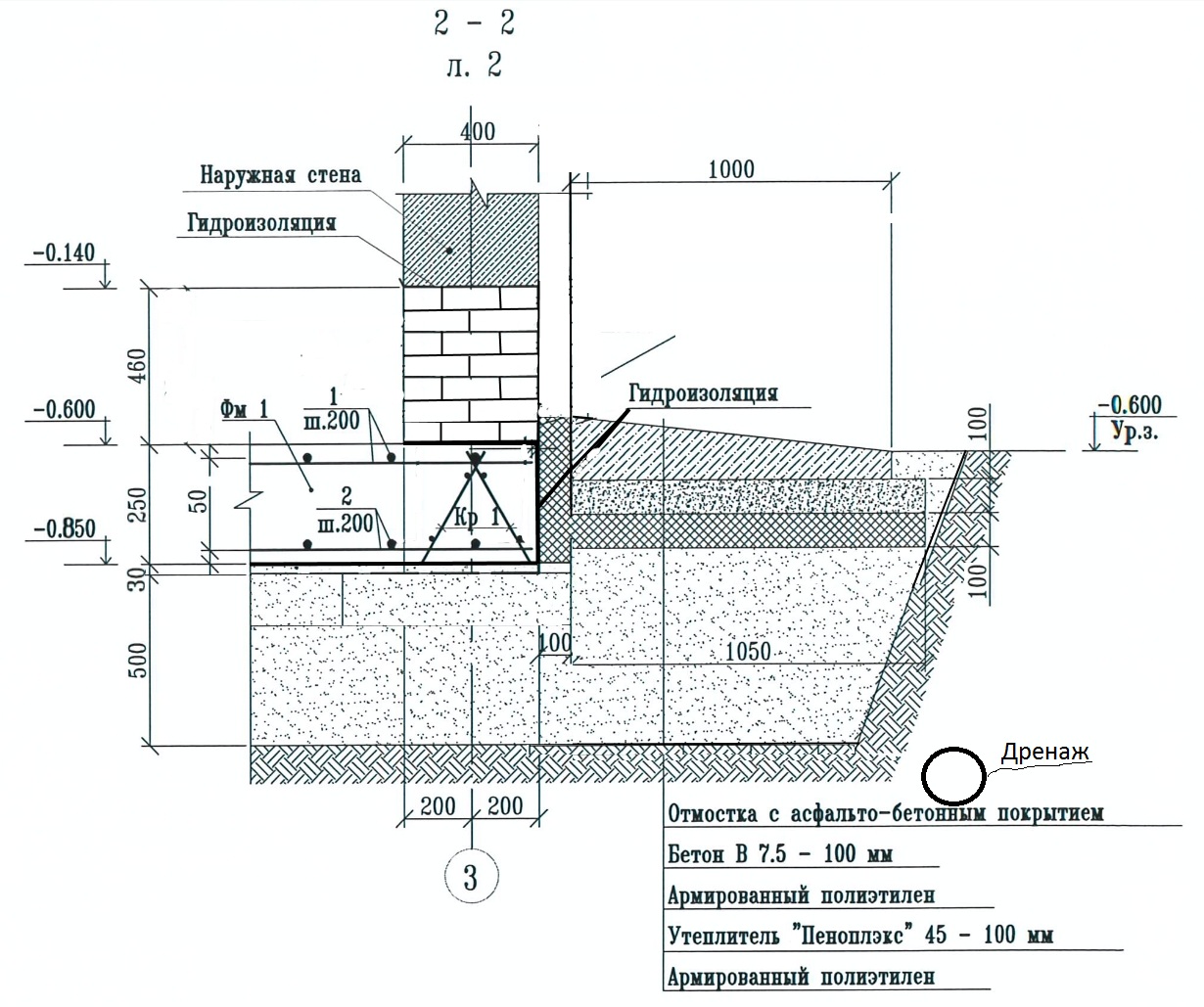

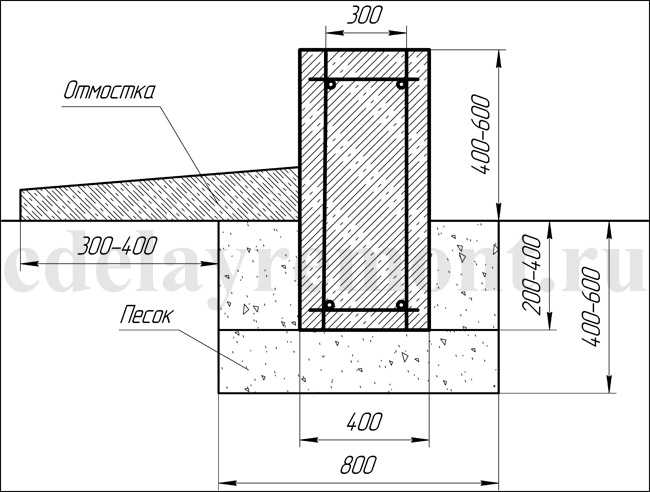

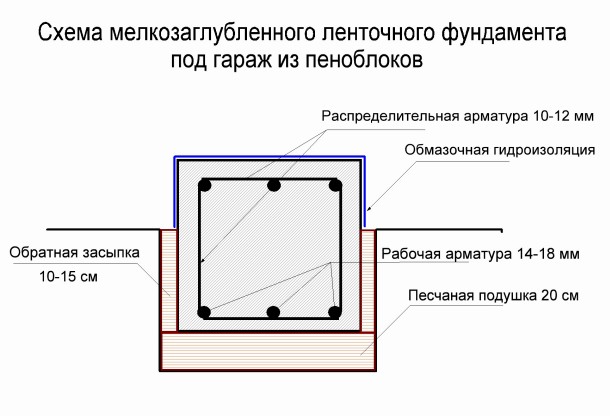

If you plan to equip a small inspection pit in the garage with your own hands, then the deepening of the foundation tape should be at least one meter. This will provide a high bearing capacity of the base and prevent deformation of the base during excavation work.

Let's dwell on the important points of construction work that will prevent the negative effect of heaving soil and moisture on the foundation tape and the walls of the building:

- it is imperative to insulate the outside of the foundation along the formwork with sheets of extruded polystyrene foam or expanded polystyrene along the entire height of the tape, including the base. We choose the thickness of the foam, focusing on the climate of the region;

- installation of a blind area (50 cm wide), with foam insulation, will prevent the soil from freezing and deformation of the brick and concrete walls of the garage;

- storm sewerage will provide water drainage from the foundation;

- additional drainage at the level of the sole is necessary when there is a high level of groundwater at the site;

- it is imperative to install high-quality waterproofing of a concrete tape using penoplex or ordinary sheets of roofing material. You can also use bituminous waterproofing.

If you do not save on waterproofing and drainage work, then the stability, strength and durability of the foundation is guaranteed.

Varieties of designs

To understand what basis to make for building a garage, you will have to familiarize yourself with their main varieties.

Not deepened

Builders advise residents of southern regions where there is no severe frost to make non-buried structures. The height of such a foundation reaches 20-25 centimeters, and the width is 12-15 centimeters. The advantages of such bases include the fact that they practically do not deform under the influence of moisture. However, they do not cope well with serious loads, and therefore such a foundation is suitable for a small garage.

Recessed

It is more difficult to make bases of this type, since when creating them you have to pull out a deep foundation pit. Recessed structures are created during the construction of garage premises, under which the basement is located. Foundations of this type are resistant to frost and high humidity. They are also distinguished by their high density and therefore they are made when building large garages.

Floating

A floating structure is rarely used in construction, as it requires serious financial costs. Experts advise making such grounds only in cases where there are no other alternatives.

Monolithic

Monolithic structures are the most common, since they are the ones that are made in the construction of premises for storing cars. When creating foundations of a monolithic type, you will have to dig a deep pit, tamp it, fill it with mortar and make a frame from reinforcement

You can also use ready-made reinforced concrete products, which will have to be carefully placed in the dug pit.

It is interesting: Which foundation is better than pile or tape

Types of foundations for a garage

The garage is a lightweight construction, therefore the most common base option is a strip foundation. Depending on the design of the garage and the type of soil, the foundation tape can be made of the following materials:

- concrete mix with reinforcement is the simplest and most affordable solution;

- cinder blocks - a reliable and solid base, quick and easy installation. Cons - a large weight of blocks and poor thermal insulation, insulation is necessary, and these are unnecessary costs;

- FBS blocks - can be installed on any type of soil. Such a tape will be durable and resistant. The only drawback is that you need to use special equipment to lay the blocks.

Important. The construction time of the FBS foundation is minimal, which significantly reduces the construction time

This justifies the cost of renting special equipment. After all, a concrete foundation must harden for at least 21 days.

- gas silicate blocks - they attract by their low price and ease of installation, the material is frost-resistant. But gas silicate materials have many disadvantages, the main ones are low strength and a high percentage of vapor permeability;

- foam blocks are an inexpensive material that can be used for lightweight prefabricated metal structures. It should be borne in mind that the foam block shrinks and often does not withstand high loads. Not the best choice for a foundation.

Formwork for strip foundations

The strip foundation can be shallow and buried. It depends on the type of soil on the site, the depth of soil freezing and on the material of the walls of the building.

On difficult problematic wet soils with high heaving, it is better to choose a more expensive, but reliable type of foundation:

- pile base - these are racks made of screw or bored metal piles tied with a reinforcing cage and fixed with a metal grillage. Installation time is minimal, high bearing capacity and relatively low cost;

- slab floating foundation is an expensive, but quickly installed structure. Recommended for areas with high groundwater levels and moist, weak clayey soils.

There is a misconception that it is easier to make an inexpensive brick pillar foundation for a garage. But such a base has a very low bearing capacity. The deepening of the pillars must be done at least a meter or more, depending on the point of freezing of the soil.

If the soil is clay, then additional insulation is needed. As a result, the ghostly cost and labor savings will cost a lot of labor and money.

If it is decided to carry out the construction of the foundation with your own hands, then the simplest option is a strip foundation. Next, we will consider the features of the device of this type of base for a garage.

Monolithic slab is an excellent foundation for a garage

And it's hard to disagree with this. Monolithic concrete slab has high operational and technical characteristics.

It has a number of significant advantages:

- Low cost in comparison with other methods of building a foundation.

- The large area of contact between the foundation and the ground creates an excellent load-bearing capacity.

- Uniform load distribution allows building on problem ground.

- Monolithic reinforced concrete is an excellent choice for building a basement floor.

But this design also has a drawback. When building a garage on such a foundation, it is impossible to equip a basement. Whether it's a serious flaw or not, it's up to you.

Column foundation for a garage

The main positive quality of a columnar foundation is the ability to install it to a depth of 3.5 m or more. This makes the foundation suitable for any type of soil.

It is problematic to install a strip foundation on clay soils. The columnar foundation is installed to a depth below freezing of the soil, reinforced with reinforcement and serves for a long time without cracking and without distorting the garage.

When using a columnar foundation, it is impossible to make a basement in the garage.

The pillars of the foundation, located in the corners of the garage, sometimes go into the ground 0.5-1 m lower than others.The pillars are located under all the walls of the building at a distance of 1.5-2 m from each other.

Columnar foundations are usually made using TISE technology. Before installing the poles, wells are drilled with a foundation drill at pre-designated points.

Most often, the pillars are made from a reinforced concrete mixture in two ways.

Easier - installation of reinforcement in a drilled well and pouring reinforced concrete mixture into it.

Another method is more expensive to manufacture, but has better bearing qualities. Roofing material is laid in an empty place, and wooden boards are horizontally attached to it with nails. A wooden formwork is being built, equal in size to the future post. The walls of the formwork are fastened with nails so that the cement mortar that has not yet taken up does not flow out. Instead of formwork, asbestos-cement or metal pipes can be used.

Reinforcement posts are installed in the formwork or pipe and a reinforced concrete mixture is poured. It is recommended to use cement grade 300 or 400 for its manufacture. The base plate is manufactured separately. Its height is not less than 10 cm, and its width depends on the diameter of the posts and the size of the step between them.

The base plate is concreted to the pillars made in the formwork, together with it, they are placed in the drilled holes using a crane. To the pillars formed by pouring concrete into the wells, the base plate is concreted after their installation.

The borehole diameter should be 3-4 cm larger than the diameter of the previously made column. After placing the pillars in the wells, the remaining empty space near them is covered with soil, which ensures reliable fixation of the foundation.

Depending on the purpose and the material from which the walls are made, a wooden, brick and stone columnar foundation is used.

A wooden garage is made, for example, for installation next to a wooden house, in this case, the foundation for it can also be made of wood. Before laying a wooden foundation, it is imperative to protect the wood from decay. First of all, you need to make sure that the wood is dry. After making or purchasing wooden poles, they are coated with a protective coating. You can coat wooden posts with bitumen. It is advisable to add 2-3 layers of roofing material to such a coating.

There are other processing options, but when they come into contact with wet soil, they are washed off and the tree quickly decays.

For processing wood in contact with moisture, organic solvents are used: solvent, white spirit. Brick and stone pillars of the foundation also need additional processing with bitumen mastic. Bearing pillars instead of brick or stone ones are always made of reinforced concrete.

Installing a columnar foundation for a garage allows you to get by with minimal costs, with the possibility of construction on almost any type of soil. If you use wood or stone instead of universal reinforced concrete, there will be additional difficulties and material costs associated with the formation of pillars and their additional coating.

How to cover the roof of the garage? You will find out the answer to this question by reading this article.

How to cover the roof of the garage? You will find out the answer to this question by reading this article.

And this article tells about the insulation of the garage roof.