Application area

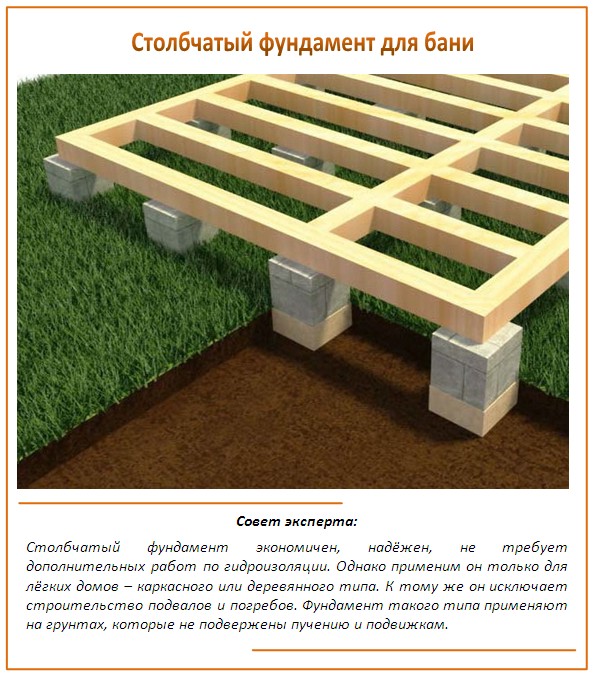

As already mentioned, a columnar foundation is also called a pillar foundation or on poles) behaves normally on soils with normal bearing capacity. They are not used on loose sands, peat bogs and other unstable substrates. Its main features are that it is impossible to organize a basement and a blown gap between the ground level and the subfloor. They also need to be borne in mind when choosing.

They are suitable for the following cases:

- for houses made of light materials - wooden, frame, panel board;

- under heavy walls, if you want to bury the foundation deeper than 1.8-2 meters and the tape becomes very expensive;

-

on highly heaving soils - less forces act on the pillars than on the tape.

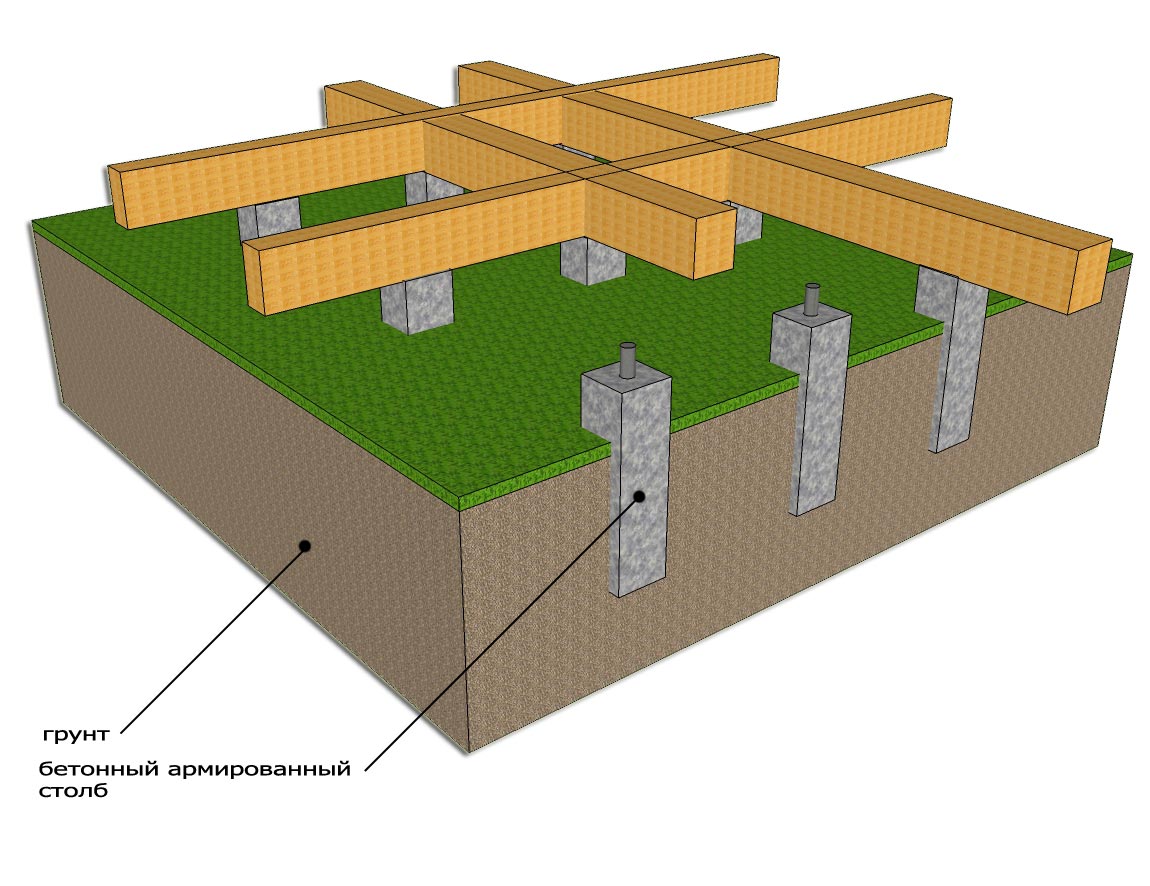

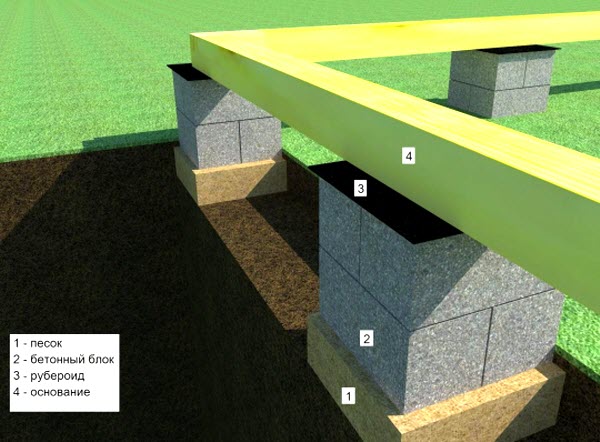

One of the columnar foundations - bottom view

At the same time, there are a number of situations (except for weak soils) when the use of foundations on pillars is not recommended:

- with a large difference in heights on the building site - more than 2 m;

- with complex geology with possible displacement of layers.

Otherwise, they can be used.

Tools and materials

During construction work, from the tools we need:

- tape measure, pegs and cord for marking the site, building level;

- garden drill (the diameter of the auger should be 10 cm larger than the diameter of the selected pipe);

- bayonet shovel and wheelbarrow for soil removal;

- grinder with a stone circle / hacksaw / circular saw or any other tool for cutting asbestos-cement pipes;

From the materials you need to prepare the following:

- asbestos-cement pipes;

- cement grade M200, mortar container and funnel;

- reinforcing bars (read how to choose reinforcement for the foundation here);

- wooden slats;

- personal protective equipment (respirator, gloves, glasses).

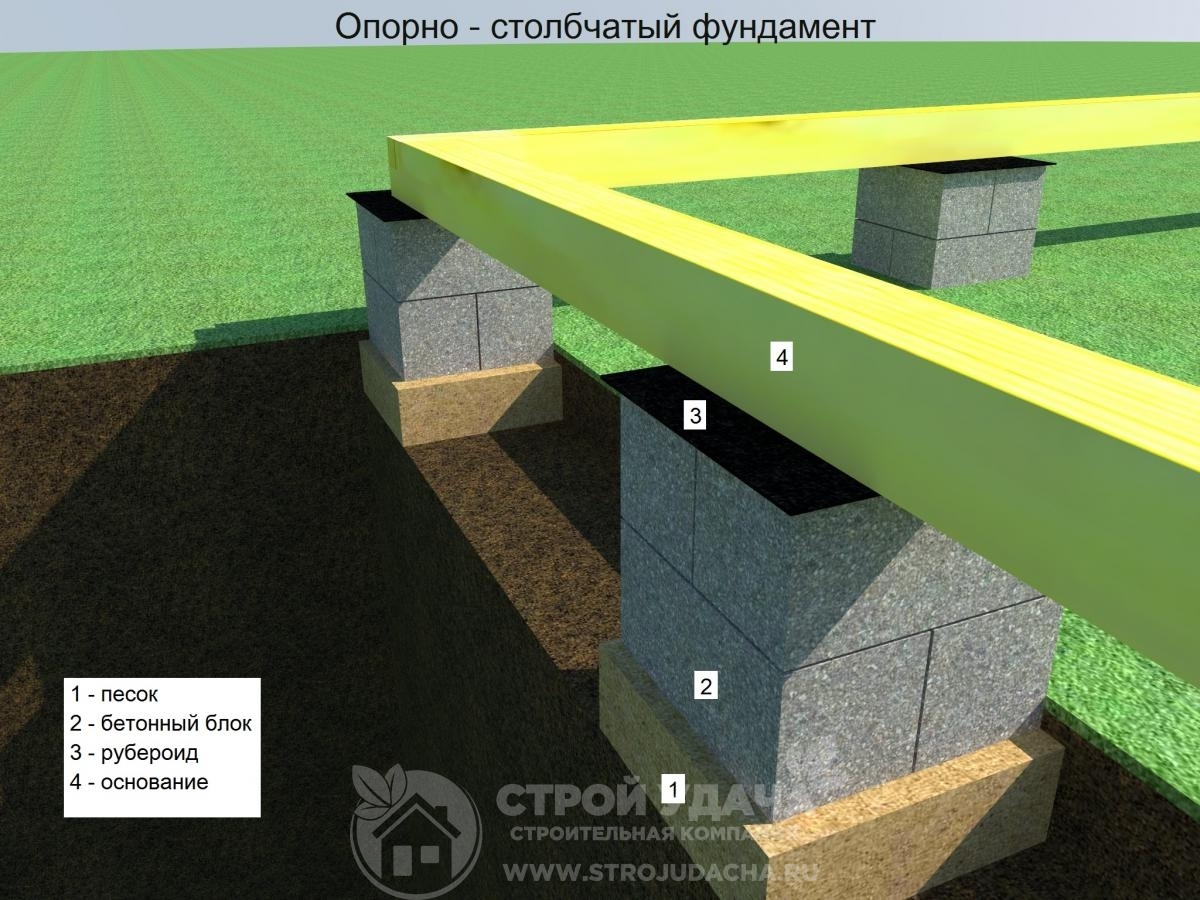

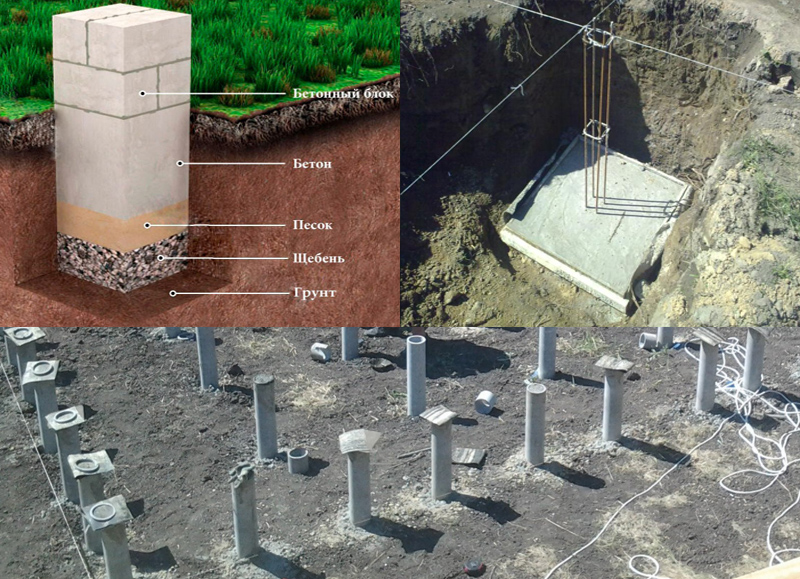

Shallow columnar foundation made of concrete blocks

For the construction of small and relatively light structures made of wood, a block columnar base is the best option. Such a foundation is also ideal for a frame house. Moreover, all the work can be done without much difficulty by yourself.

Installation of the base from blocks 20x20x40 is carried out as follows:

- The construction site is cleared of debris, turf, plantings, existing buildings, then the top fertile soil layer is removed. Sometimes, sand backfilling of the site is made or geotextiles are laid to prevent the emergence of vegetation in the future.

- The territory is marked and the places for the installation of supports are determined. On the inner and outer sides of the future foundation, cords are pulled on the pillars. Tying them to the pegs inserted into the ground, you should use a level or a building level to control that the entire contour is in one horizontal plane. It is to this level that each support will rise. The pillars are installed both at the corners of the future structure, and every 1 - 2 meters around the perimeter. It is necessary to take into account the obligatory presence of supports under the floor slabs, as well as at the intersection of the walls.

- Pits are drilled or dug for the installation of pillars. The depth of the holes is determined depending on a number of parameters, the main of which are the weight of the building and the type of soil. If the soil is stable, then the depth of the foundation should be about 50 cm. It should be borne in mind that any support is mounted on a sand and gravel cushion with a height of at least 30 cm, which is spilled with water and carefully compacted. Before installing the pillars, roll waterproofing, for example, roofing felt, is covered on the sand.

- A thick cement slurry is prepared.When using the M400 grade, about 3 parts of sand are needed for 1 part of cement.

- The foundation supports are being installed. When erecting pillars from blocks of 20x20x40 cm, masonry is performed, consisting of at least two rows. Thus, at least 4 blocks are required for one support - at least two for each row. The layer of solution for level dressing should be about 10 mm. To prevent possible distortions, it is advisable to put trims of reinforcement or the corresponding thickness of the rail along the contour of the previous row, which can be removed in the future.

- When the mortar has completely hardened, waterproofing is performed: concrete supports, in accordance with the technology, are primed with a special primer, then covered with bitumen mastic.

- At the final stage, roll waterproofing is laid on the upper surface of the supports, which will directly contact the walls of the future structure. Roofing material, roofing felt or glass insulation are glued directly to the mastic layer.

Differences in the installation of a columnar foundation for a bath and a house

However, you should not save and lay this type of foundation for the construction of heavy brick or block structures of houses, and even more so for cottages of several floors. Such a building can be torn apart at any moment. Even screw piles are not always able to withstand excessively high loads.

Currently, the columnar-tape type of foundation is very popular, which is able to withstand the extremely large weight of the structure. In this case, the depth of the supports is located below the freezing level, and the pillars are connected from above with a tape. However, independently, without the use of special equipment, it is almost impossible to build such a combined foundation. In addition, the cost of materials will be rather big. After pouring such a foundation, further construction work can be carried out no earlier than a month later - this period is necessary for the complete hardening of the cement.

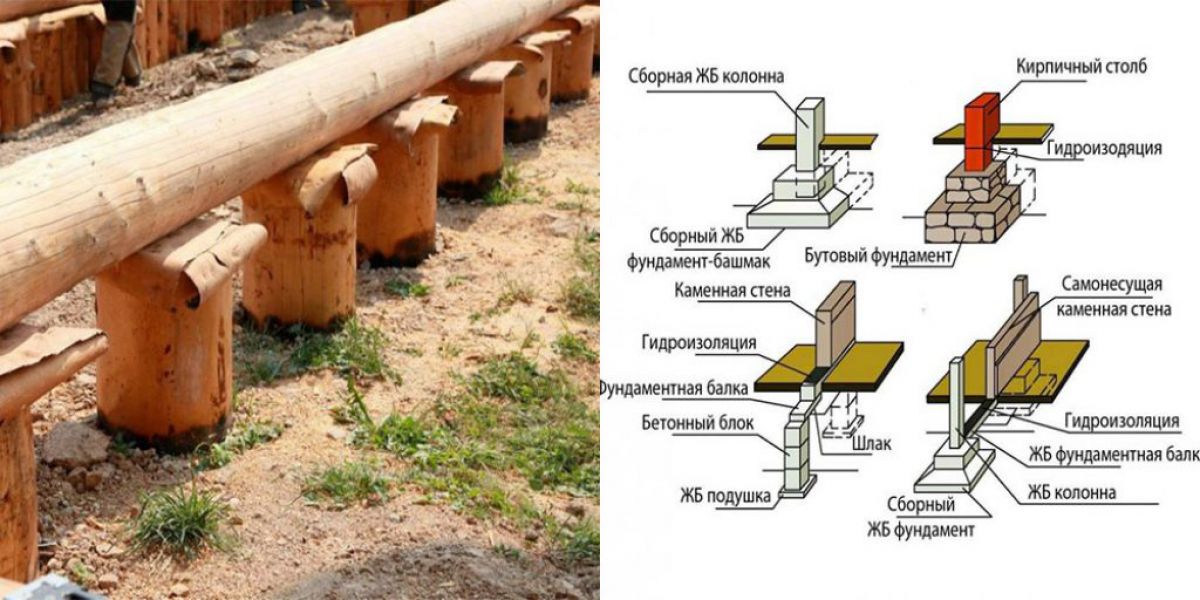

What is a support-columnar foundation and its difference from other types

Columnar foundation - a number of concrete pillars buried in the ground to a certain depth (what should be the depth of the foundation and how many pillars - we will talk about this a little further). From above, these pillars are rigidly connected by a grillage. As a grillage, as a rule, concrete or wooden beams are used, in some cases the grillage is poured with concrete and is a monolithic rigid reinforced concrete structure. As mentioned above, the support-column foundation has a very low bearing capacity, even in comparison with such as shallow and not buried strip foundation, not to mention a monolithic slab. But despite this, with a technically correct approach, it will be a fairly durable, reliable and very inexpensive solution for some types of houses, especially since it will not be so difficult to lay it with your own hands.

Where and how is the support-column foundation used

Due to its design features, the pillar-support foundation is not suitable for all types of houses. Due to its low bearing capacity, the main condition for building a house on such a foundation is light weight. And because of the low stability - the house must be built from a material that is resistant to tearing. Also, a support-column foundation is not suitable for those houses in which a basement is planned, since you most likely will not be able to arrange it.

After we have decided for which houses this type of foundation is suitable, let's figure out in which soil it can be laid, and in which not.

Materials for work

Another huge advantage of such bases is the ability to choose different materials.

Another huge advantage of such bases is the ability to choose a variety of materials.Based on video recommendations and literature, we have highlighted for you the most popular variations of such a construction:

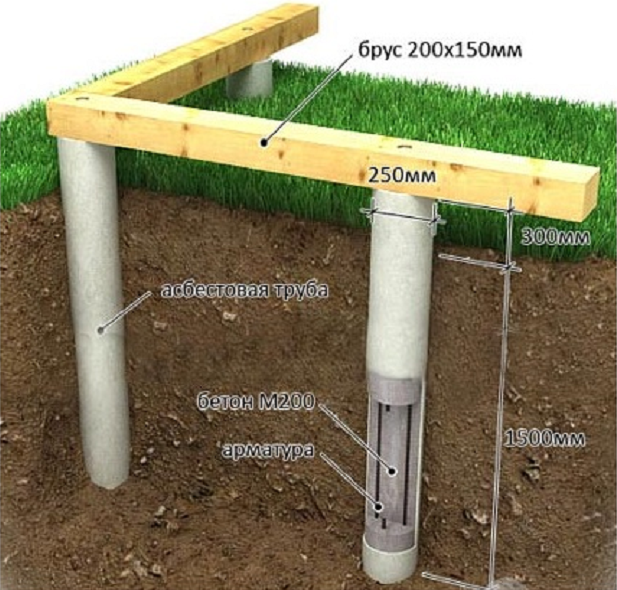

- Asbestos pipes. This material has a fairly high strength, efficiency and ease of installation.

- Brick. This is one of the most requested bookmarking options. Although it is worth noting that of its advantages, only a long service life and strength can be distinguished. Moreover, such a material has a number of disadvantages, such as the complexity of the installation, the high cost of materials and the susceptibility to heaving of the earth, which leads to the appearance of deformations.

- Logs made of wood. This option is the most economical, and is used in construction projects for light types of buildings. Also, the ease of installation work of the object should be attributed to the pluses. Among the disadvantages are such negative characteristics as fragility and the mandatory need for waterproofing and treatment with a special septic tank.

- Reinforced concrete material. Concrete has a very high level of strength and a long service life. It is worth noting that this is exactly the option when quality is equated to price. But, there is also a drawback that manifests itself in the complexity of the installation work.

It is worth noting that it is better to give your choice in the direction of a monolithic base, since the kit includes it and reinforcement, which increases the foundation's ability to withstand the load. If you choose a prefabricated type of building, then poles can be pushed out during the winter season, which will lead to numerous repairs. It is for this reason that we still recommend choosing a monolith.

What are the pillars made of?

Before proceeding with the independent arrangement of the columnar-tape base, you must choose the optimal material for the manufacture of supports. Available solutions include timber, concrete blocks, bricks, asbestos-cement and metal pipes. Check out the specifics of each option and choose the solution that best suits your situation.

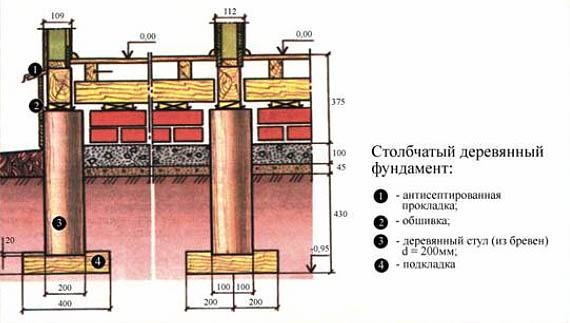

Wooden supports

Wooden supports

They are used extremely rarely due to their relatively low durability. Wood pillars are only suitable for arranging a foundation intended for installing a terrace or other similar structure.

The optimal diameter of wooden posts is 150-200 cm.

Bitumen-based mastics are ideal for waterproofing wood.

Wooden supports

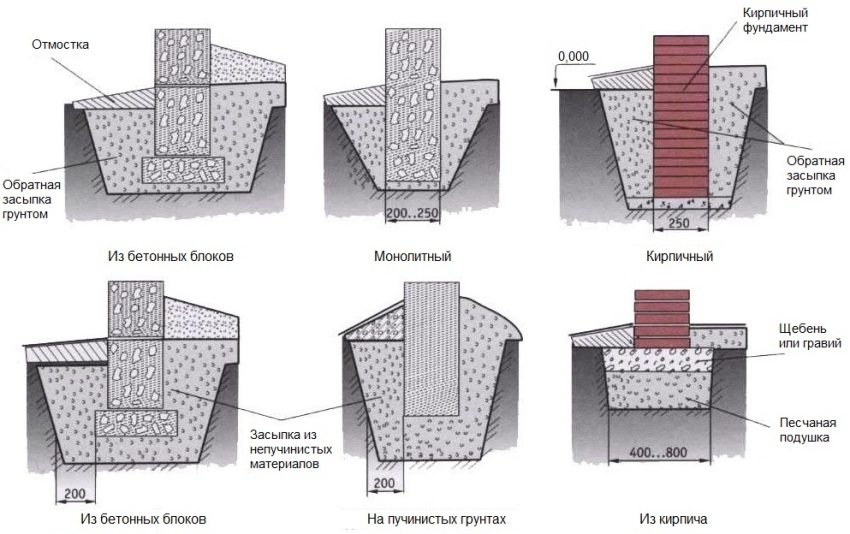

Brick supports

For arranging a columnar-tape structure, iron ore brick is well suited. With its use, shallow-buried columnar foundations are also being erected.

Brick supports

Professionals recommend equipping brick supports with a width of about 40-50 cm.

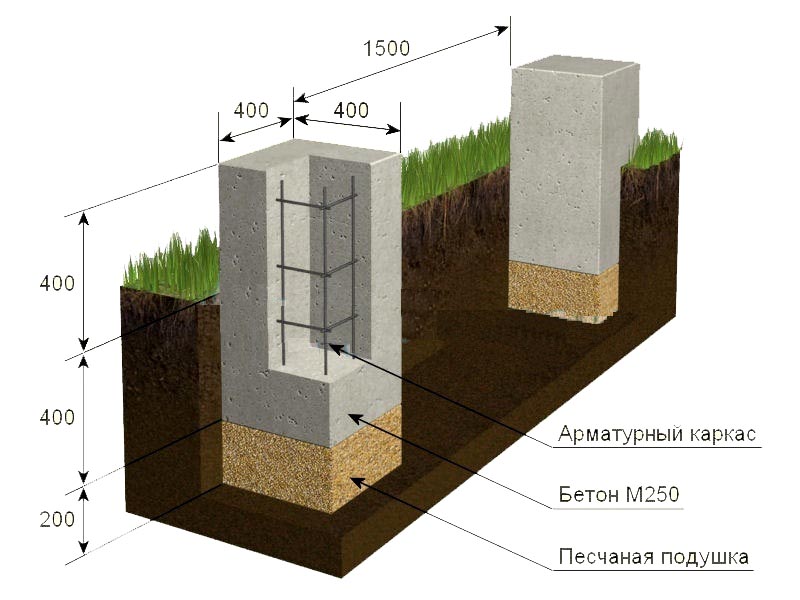

Concrete supports

Supports in the form of concrete pillars, additionally reinforced with reinforcement, are considered the most reliable. In view of this, it is precisely such supports that are most popular.

Concrete supports

Concrete pillars can be either one-piece (monolithic) structure, or consist of several blocks.

Tubular base

Tubular base

Pipes made of asbestos cement or metal are very easy to install. Installation is reduced to placing hollow pipes in pre-prepared recesses, installing reinforcement rods inside the pipes and finishing the cavity with concrete.

The work is done extremely quickly and easily. The optimal pipe diameter is selected individually, taking into account the expected load on the base being erected.

Formwork installation

Consider how to make a semicircular formwork yourself. To cope with the task, you will need a detailed and drawn project, as well as basic skills in the construction business.

For rings

How to make a round formwork for a well with your own hands? Such a system, by its definition, is a variety of forms that are used in the construction of wells.The variant of the sliding formwork is especially popular among private owners.

To prepare the formwork for the concrete rings, we need sheets of metal that are no more than two millimeters thick. The length of the inner strip is taken as 2.6 m, the outer one - 2.86 m.The height will be standard, as the sheet itself is 1 m.

From the parameters of the steel sheet, it is clear that the structure will turn out to be solid. Note that summer residents often stop at 1.5 m for the outer diameter and 1.3 m for the inner diameter. In this case, sheets are selected 1.5 mm thick and 0.62 m high, which greatly lightens the weight of the structure.

These parameters are considered satisfactory because one can make a solid reinforced concrete pipe, so that rings are not even required. Holes are drilled at the ends of each strip for five bolts.

Having built such a formwork for concrete rings, you can independently dig and equip a well.

For the foundation

Rounded foundations are now being poured by many. Private traders try to perform such work on their own, since everything turns out to be quite simple.

First of all, a construction site is being prepared for laying the foundation. A layer of vegetative soil is removed, the points at which the trench will be prepared are determined.

Having finished with the markings, they choose the formwork option, determine the dimensions and material for its manufacture. A solid frame is created from individual elements, the upper edge of which is aligned with the general slope of the site.

The main feature of round formwork is the choice of the right material, which will combine flexibility and the required strength. If no large load impacts are expected on the foundation under construction, then plastic formwork, which is easy to give the required shape, will be an excellent option.

If a timber formwork is arranged, then its base is strengthened with pegs, and the joints are coated with mortar as an additional measure. Special jumpers are used to connect the elements.

Plywood material resembles plastic in its characteristics, but it lends itself less to bending. Such formwork does not withstand significant loads.

The best option for round formwork is metal. Due to its mass and strength, it is somewhat more difficult to work with it; the joints are welded or using self-tapping screws.

Round formwork tanks are most often manufactured in the factory and transported to the construction site in a folded state. There the sheets are unfolded and mounted in the required places.

For columns

If there are several round supports, then it is recommended to make a universal formwork so that the geometric shapes of the columns do not differ

Please note that a joint with a purlin can be provided on top, which will also have to be taken into account when arranging the formwork

We design the exact dimensions of the columns, prepare in advance the materials from which the surface will be formed. If you have to use the boards, then it is recommended to process the inner surfaces with a plane.

We sew the boards with a bar. Located across, it will act as a stiffener. A certain number of connected boards are assembled in the form of a pillar. There must be a strong connection at the base, since this is where the pressure from the solution will be maximum.

A steel frame is made of wire strands. It can also be made using a welding machine. A reinforcing base is laid in the wooden structure.

In order to easily dismantle the structure in the future, it is recommended to cover the inside of the shield surface with plastic wrap.

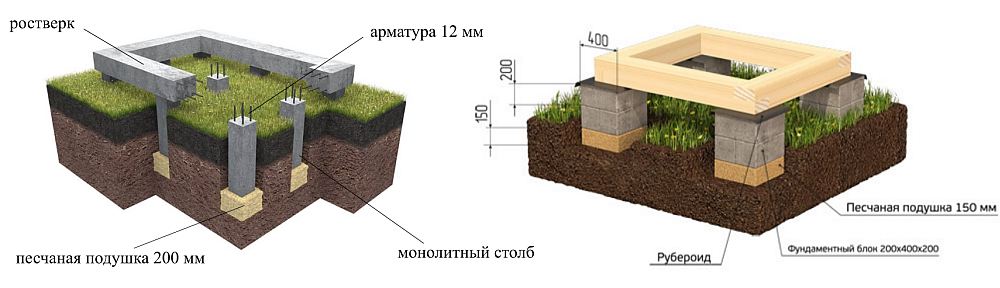

Monolithic pillar foundation: instructions

This method of erecting a pillar foundation differs little from the previous version.The difference is that vertical formwork should be provided in the dug holes.

They are of a removable type and expand between the walls. And only after that you can start making columns, for which a concrete solution is used. It is advisable to use cement of a grade not lower than M200. A prerequisite is the creation of a reinforcement strapping inside the formwork. After that, concrete mortar is poured. It should be reminded once again that the length of the rods above the ground should be at least 20 cm.

When the concrete solution hardens, the formwork is knocked off, measures are taken to waterproof the supports. In this case, it is advisable to use roofing material, with the help of which the columns are wrapped in 2 or 3 layers.

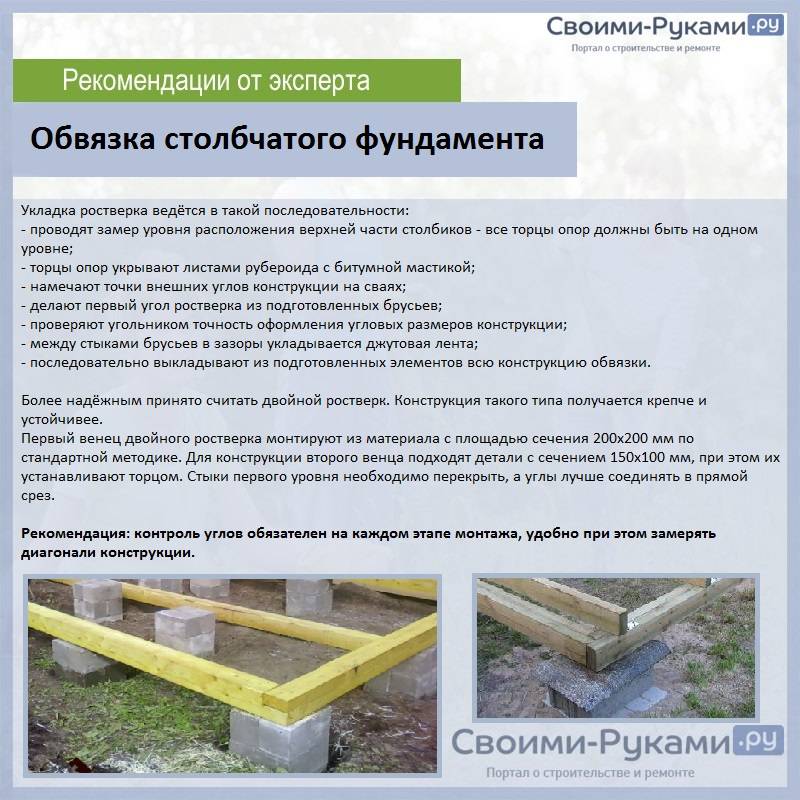

As mentioned above, the second component of this type of foundation is the grillage. After installing the formwork, the horizontal and vertical rods are tied together, then a concrete solution is poured. When the grillage hardens, it is worth starting to create waterproofing with roofing material. Floor slabs are installed on top.

Brick support structure

Consider the instructions on how to correctly make a columnar foundation using bricks or blocks:

- Roofing material spreads on the walls of the wells; one of its features is good waterproofing.

- A reinforcement structure is mounted to the entire depth of the pit. It should not be above ground level.

- Next, a concrete solution is poured, into which gravel or crushed stone is added.

- As a result, the well must be completely filled with concrete. The setting process of concrete takes up to 10 days.

- Several layers of roofing material are laid on the surface of the concrete base, which will serve as a good waterproofing for subsequent masonry.

This is the technology of building a columnar foundation, it is much more economical in its design. You can do it yourself.

Preparation for manufacturing

At the preparatory stage, it is necessary to find out the dimensions of the future structure, the load on the foundation of the higher structures and the bearing capacity of the soil. Before erecting a frame house, you can independently carry out a soil study. To do this, you need to drill several holes in the area. The depth of the well is below 50 cm of the basement base. In this way, the type of soil and the absence of aquifers are determined.

Characteristics of soils:

- Rocky - soils with a high content of stone or gravel, are distinguished by a strong base, hold the load well, do not collect water.

- Coarse sands - represent a strong base with low heaving.

- Fine sand - poorly suited for construction, as they are highly heaving. They collect water in the upper layers and act in a pushing manner on the foundation.

Calculating the depth and number of posts

Columnar bases are buried (for water-saturated and clay soils) and shallow (for rocky and sandy soils with a low level of groundwater). The height of the buried foundation depends on the average depth of soil freezing in your area. The sole of such a foundation should be 30-50 cm below this level. Before starting work, the load of the house should be calculated, for this, the weight of the walls, floors, roofs and the mass of the foundation are summed up.

| Construction type | the weight |

| Insulated frame walls 15о mm thick | 25-50 kg / m² |

| Wooden beams with ceilings and insulation | 90-140 kg / m² |

| Roof and snow load | |

| Metal | 45-60 kg / m² |

| From flexible shingles | 45–65 kg / m² |

| Ceramic | 75-115 kg / m² |

| Snow load in different regions of Russia | |

| Middle lane | 100 kg / m² |

| Southern regions | 50 kg / m² |

| Northern part of the country | 90 kg / m² |

To determine the weight of a reinforced concrete columnar foundation, its volume must be multiplied by the specific weight of reinforced concrete (2500 kg / m³). To calculate the weight of one column, the following formula is used: V = 3.14 * G² * h.V - column volume, G - column radius, h - column height. All values are in meters. The resulting value must be multiplied by the number of pillars, and we get the total volume of the foundation.

Bearing capacity of different soils (in kg / cm²):

| Bearing capacity of soils | |

| Pebble with clay | 4,5 |

| Coarse sand | 6 |

| Medium sand | 5 |

| Fine sand | 4 |

| Gravel with clay | 4 |

| Loam | 3.5 |

| Clay | 5 |

Material selection and quantity calculation

Different materials are used for the construction of a columnar foundation:

- Wood is a very short-lived material; even when treated with protective compounds, it will last no more than 20 years.

- Stone pillars - usually built of rubble or granite stones. They are distinguished by their durability and reliability. The disadvantage is massiveness and laboriousness during construction.

- Monolithic concrete pillars.

In order to calculate the amount of concrete for a columnar foundation, you can use the following table:

| Round column radius | |

| 7.5 cm | 0.0176 m³ |

| 10 cm | 0.0314 m³ |

| 15 cm | 0.07 m³ |

| Square section | |

| 20x20 cm | 0.04 m³ |

| 30x30 cm | 0.09 m³ |

| 40x40 cm | 0.16 m³ |

The reinforcement for the columnar base is corrugated, class A, with a diameter of 10–12 mm. The metal rods are needed the same length as the supports. For a column with a diameter of 10-14 mm, you will need 4 bars of reinforcement. They are placed at a distance of 10 cm from each other and tied across half a meter with a smooth and thinner reinforcement with a diameter of 6 mm. Thus, for a two-meter post, you will need 8 m thick and 1.2 m thin reinforcement. The resulting figures are multiplied by the number of supports and we get the footage required for the columnar base of the reinforcement.

Required tools

Before starting construction, you need to prepare the following tools:

- Concrete mixer;

- Shovel;

- Roulette;

- Level;

- Nails and screws;

- Hammer;

- Cord;

- Pegs;

- Hand drill;

- Master OK;

- Formwork pipes or boards.

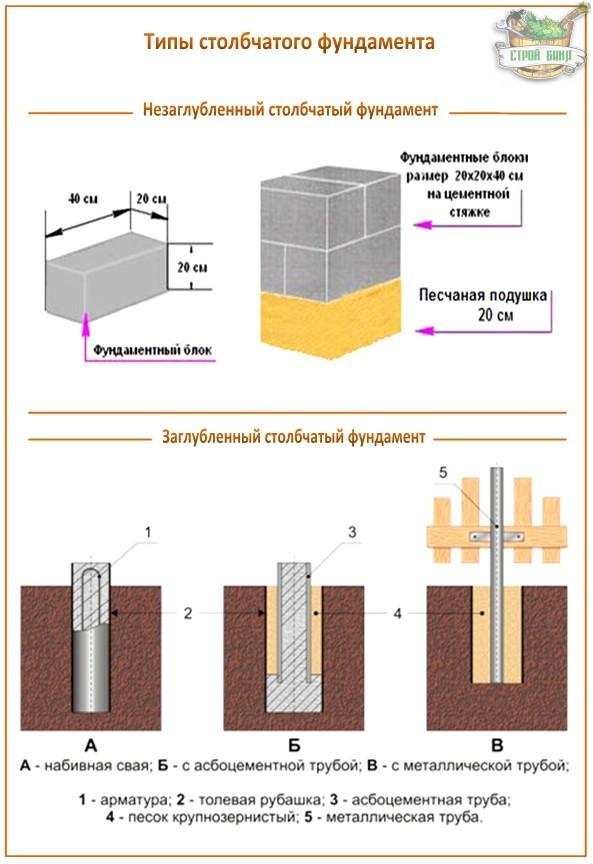

Types of columnar foundations

According to the manufacturing option, the columnar-type foundation can be divided into:

- made;

- monolithic;

- wood.

The prefabricated view includes concrete blocks, bricks, and steel pipes.

The monolithic type is reinforced concrete. Building materials used for the production of individual elements must meet all the requirements, as well as provide reliability and high strength. A monolithic view is erected at the construction site by pouring concrete mortar into the completed formwork with reinforcement. With this option, the pillars can have a square as well as a rectangular cross-section.

The monolithic reinforced concrete option is the most stable when performing construction work on the construction of a structure.

The burial depth of this option usually does not exceed one and a half meters. The standard distance between the posts should be at least 1.5 meters, but not more than 2.5 meters.

By deepening, the columnar base can be divided into:

- a recessed version, which is located below the level of freezing of the soil, the depth of which is equal to one meter or more;

- a shallow view is most often deepened by 50 centimeters;

- the non-buried version is used only for light buildings, only the top fertile soil layer is removed.

The lower part of the support should be located 30 centimeters below the level of soil freezing.

The main requirement for the level of deepening is that the structure should not touch the level of groundwater.

Foundation types by section option:

- The foundation of the glass type can be erected under public as well as industrial structures. It can withstand quite heavy loads. This view has a stepped shape. The structure consists of a base, which is erected on a sandy substrate, a glass patella, on which support pillars are installed. This option ensures structural reliability as well as a longer service life of the entire building.

- Pillars of constant cross-section can be used for single-storey buildings with a small total weight, which can be made of natural timber or frame options. The base area is not able to withstand heavy loads.

If it is necessary to erect a heavier structure, as well as construction on unstable soils, builders recommend performing a combined form - a columnar-strip foundation.

It combines the advantages of two types of foundations. With this option, the pillars are buried in the ground, and the strip base evenly distributes the total load between the piles. The tape does not exert any pressure on the subgrade.

The supporting-column foundation can be made of bricks, steel or asbestos pipes, monolith, concrete blocks, and natural wood. This option allows you to complete all the work in a maximum of three days. This figure may vary depending on the area of the future building.

Instructions - how to equip the foundation yourself

Columnar foundations are being erected using the technology in four stages:

-

Excavation work with drilling holes under the support pillars and installing sand cushions at their bottom.

-

Installation of permanent formwork for foundation supports, followed by pouring concrete or laying them out of bricks or concrete blocks.

-

A device for this type of pile-grillage foundation of the upper load-distributing part made of reinforced concrete, steel channel or wood.

-

Waterproofing of the entire structure and cladding of supports along the perimeter of the building with siding or profiled sheet.

Everything is quite simple, but there are a number of nuances in this process. The first of them - regardless of the level of the grillage, the retaining piles of the columnar version of the foundation for a private low-rise building should be immersed deeper than the freezing point. To speed up the work, in some cases it will be best to involve specialized equipment with a drill.

The base supports themselves can be made from:

-

Reinforced concrete poured into an asbestos-cement pipe;

-

Brick;

-

FBS (reinforced concrete blocks for foundations manufactured at the plant);

-

Natural stone.

Below is a step-by-step photo-instruction of a columnar foundation on foam blocks:

We transfer the foundation plan to the terrain - mark the future borders with pegs

Digging holes

We fill the pits with rubble, sand on top and spill it several times and repeat the procedure for filling with sand

We put the first 4 blocks on the pillow in the corners and align with the lace and size

Substitute the second block and level it

We measure the zero level of the foundation with the hydraulic level - its height

We expose the following levels of blocks of our base

We make all the other pillars by level

We spread the roofing material on the posts for waterproofing

It is also possible to use steel screw piles. But this will already be more of one of the variations of the pile-screw foundation. Previously, supports were even made of moisture-resistant larch. However, today most private developers prefer to put something more durable and concrete under their house.

Supports are placed at intervals of 1.5–2.5 meters so that they are located at the corners of the structure, at the intersection of internal walls and the laying of load-bearing beams, as well as under stoves and fireplaces. These are the main load points. Some of them are quite capable of distributing the grillage throughout the structure. But ideally, the bulk of the weight should fall just on the support piles on which the columnar-strip foundation rests.

When choosing a brick, you should immediately exclude its silicate variety. And ceramic should be taken with the highest frost resistance. In general, if you do not want to mix and pour concrete, then it is best to prefer FBS. These blocks are originally intended for the construction of foundations for various buildings.

By design, the concrete grillage on top of the pillars is a small strip foundation.A separate formwork is assembled for it, with reinforcement from steel rods of 10–12 mm being placed in it. After their bundle, the finished reinforcing belt will only have to be poured with concrete mortar with a brand not lower than M-300. At the same time, for wooden structures, the grillage part is often made entirely of timber. In many cases, it is quite enough for redistribution of loads.

For waterproofing elements of a columnar base, you can use roofing material or liquid bitumen mastic. Even soft tiles are suitable if they remain unused when covering the roof of an already built building.