Payment

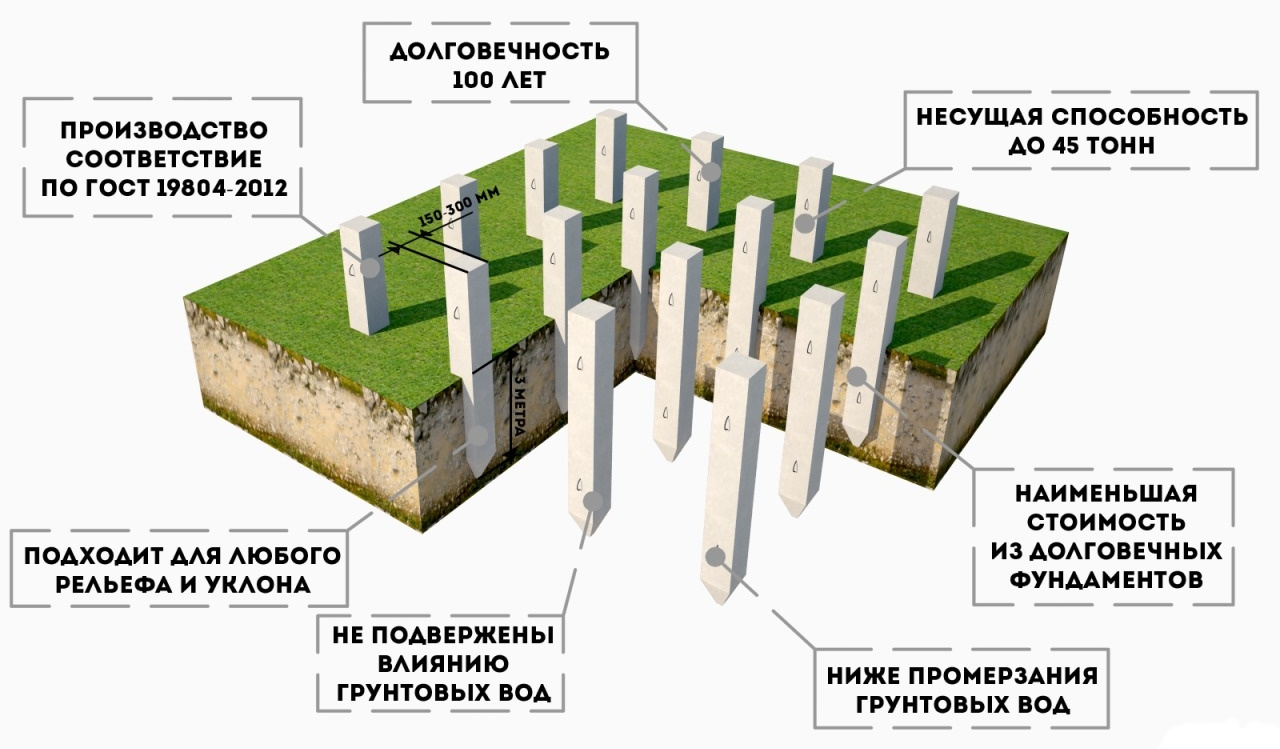

it is necessary to correctly calculate the number of piles and the depth of their driving

Depending on the type of soil, during the construction of a frame house, the pile driving depth can vary from three to ten meters, and the section size can vary from 150 to 250 mm.

Important: you can find out exactly the type of soil prevailing in a particular area using specialized reference books, or a special organization can do it. Here is an example of calculating a pile driven foundation for the construction of a two-story frame house on loamy soils, which occupy about 80 percent of the territory of our country.

Let us give an example of calculating a pile driven foundation for the construction of a two-story frame house on loamy soils, which occupy about 80 percent of the territory of our country.

First you need to calculate the total weight of the house. This is easy to do if you estimate how many materials will be spent on construction and their weight in cubic meters. Any data on the mass of materials is freely available.

For example, it took 60 cubic meters of larch timber to build a house. The mass of one cubic meter of semi-dry (namely, this is suitable for construction) larch is about 800 kg. By simple multiplication, we find out that the total mass of the log house will be about 50 tons.

Let's add here a lot of ceilings, roofs, finishing materials and don't forget about the concrete grillage. By the same calculation in terms of volume, we find out that this is still about 80 tons. And, last but not least, there is a lot of furniture, and everything that will be in the house. We get about 10 tons.

Summing up the results, we get the total weight of the finished building in the region of 140 tons. Add 30 percent of the stock for reliability and get 182 tons.

The pressure held by one 4-meter-long reinforced concrete pile ranges from 10 to 40 tons, depending on the soil, according to all engineering handbooks. Taking an average load of 20 tons per pile, it is easy to calculate that in this case only 9 piles will be needed, driven in compliance with all standards.

In practice, for the construction of a frame house, reinforced concrete piles for the foundation are driven in with a distance of no more than 2.5 meters for a more uniform load of the structure on the grillage.

For your information: in a similar way, you can carry out the calculation for any terrain and any type of pile.

Pile deepening technique

The wide geographical ranges of construction, mastered in modern times, allow us to talk about several methods of installing a pile foundation. Each of them has its own advantages and disadvantages and is distinguished by the special equipment used for this. Among the many ways, 4 main ones can be distinguished:

The wide geographical ranges of construction, mastered in modern times, allow us to talk about several methods of installing a pile foundation. Each of them has its own advantages and disadvantages and is distinguished by the special equipment used for this. Among the many ways, 4 main ones can be distinguished:

- shock;

- indentation;

- vibration pressure;

- leader drilling.

Impact method

The technology is considered one of the most common. It is used in both industrial and private construction.

The technology is considered one of the most common. It is used in both industrial and private construction.

The pile is deepened by means of amplitude impacts with a hammer (headstock).

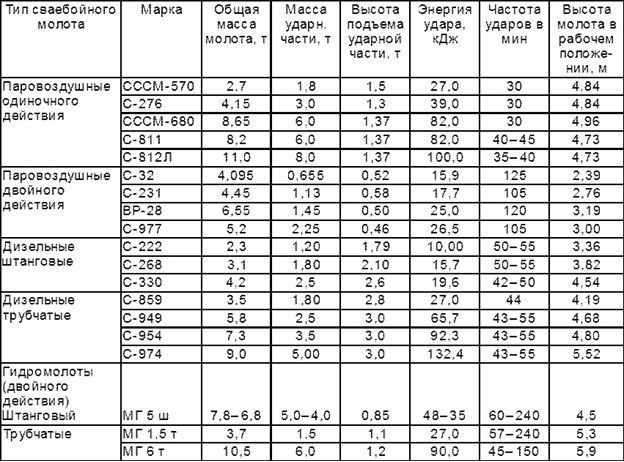

Currently, there is a wide selection of machines for performing work in this direction, differing in their characteristics. You can familiarize yourself with some of them in the table below.

Do-it-yourself pile driving

In addition, the impact technology is the only one of its kind that can be used without the use of special equipment. Making a simple device that will hit the pile is not that difficult. It looks like this:

- The tripod is going. The material of its manufacture is not fundamental, it can be logs, pipes, timber.

- 2 - 3 metal or concrete blocks are suspended on it, acting as a counterweight.

- Heavy steel rectangle - hammer. One side of it should be flat.

- 2 ropes are thrown over the blocks and are used to raise the metal beam.

The technique is simple, the hammer is raised to the maximum height and fixed. A pile is installed at the bottom, which is stretched in a vertical position. The cable holding the beam is released, the load in free fall strikes the pile, which, in turn, enters the ground. For information on how to hammer piles with your own hands, see this video:

The procedure is repeated until the desired result is achieved.

Indentation

Pressing piles is the most expensive method of deepening

Pressing piles is the most expensive method of deepening

This method of deepening foundation piles is considered one of the rarest and most expensive.

Its uniqueness lies in the fact that multi-ton special equipment is used, which fixes the element in the lock, and, transferring its weight to it, sticks it into the ground.

It is mainly used with relative proximity to other buildings and during building renovations, when it is not possible to use another type of pile technology.

Vibration pressure

This technique is performed using a vibratory hammer. Spring units are the most popular, the principle of their operation is as follows. Unbalanced shafts rotate in the free direction. At the same time, the vibration exciter oscillates at regular intervals. Having reached the minimum gap between the pile and the hammer, the latter strikes the tip, driving the product into the ground. For information on how the piles are driven in this way, see this interesting video:

The uniqueness of the machines lies in the fact that it is possible to adjust the impact force of the vibratory hammer and a corresponding increase in the amount of indentation of the support. At the same time, it is necessary to comply with strict requirements, namely, that the weight of the hammer is at least 2 times less than the weight of the pile.

The uniqueness of the machines lies in the fact that it is possible to adjust the impact force of the vibratory hammer and a corresponding increase in the amount of indentation of the support. At the same time, it is necessary to comply with strict requirements, namely, that the weight of the hammer is at least 2 times less than the weight of the pile.

The second method using vibration is based on interaction with a static load. The machine is conventionally divided into 2 halves: the rear one with a generator and a double-drum winch, and the front one with a guide boom and blocks through which the cable runs from the hammer to the winch. Being in working position, the hammer goes down and connects to the pile, capturing it in the lock. When the mechanism is turned on, the fastened elements fall down under their own weight and the influence of a vibrator.

Leader drilling

If the soil is sufficiently hard and hammering the piles by the percussion method will not bring results, leader drilling is used. The technique consists in the fact that at predetermined places, wells are drilled, which are somewhat narrower in diameter than the piles.

If the soil is sufficiently hard and hammering the piles by the percussion method will not bring results, leader drilling is used. The technique consists in the fact that at predetermined places, wells are drilled, which are somewhat narrower in diameter than the piles.

After that, with the help of copra, products are driven into them, which serve as the basis for the foundation.

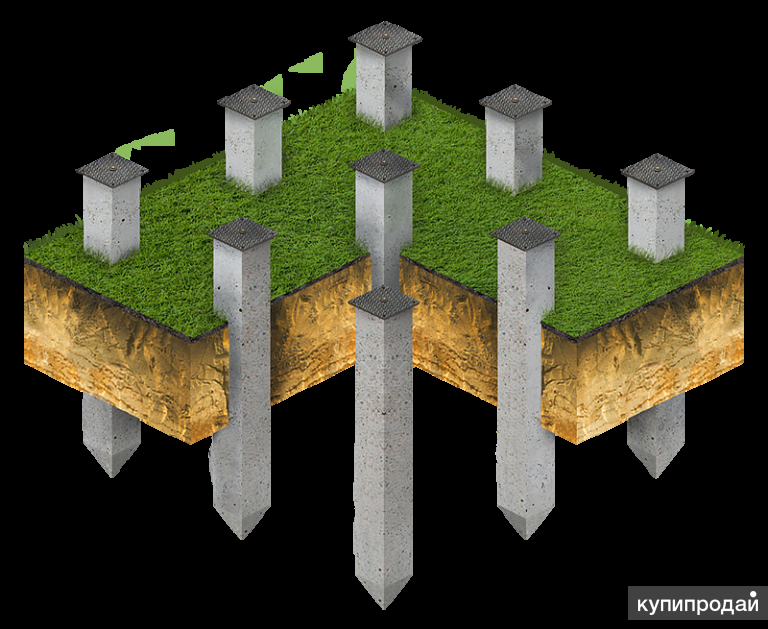

What is a pile foundation

Diagram of the device of the bored pile foundation.

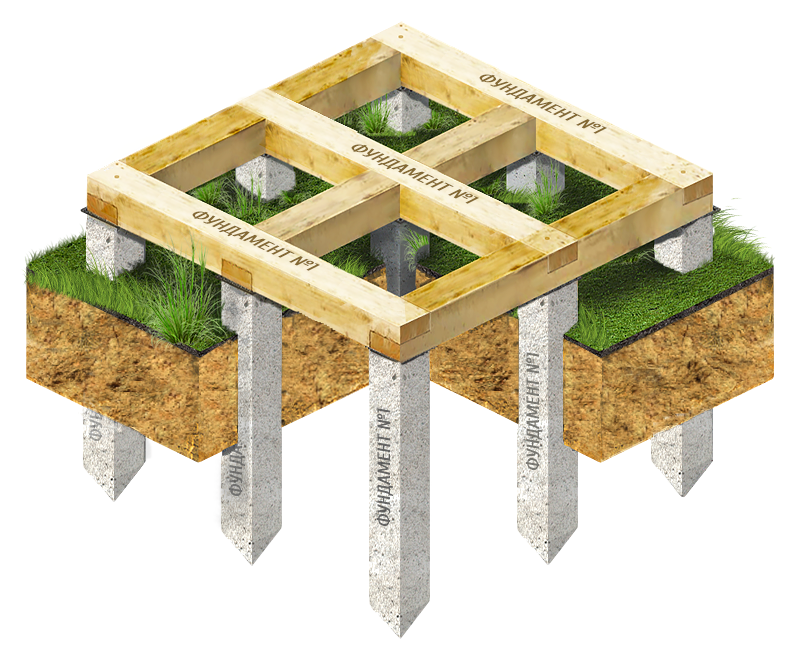

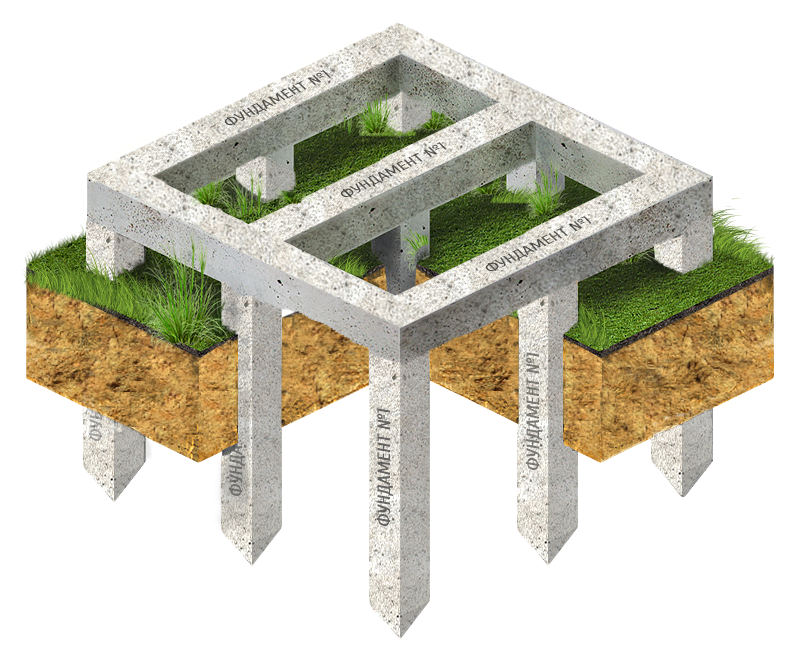

A pile foundation is a structure that is designed to transfer all the load from the structure standing on it through the piles to the ground. Such a house foundation is erected in cases where incompressible soil layers are deep. This happens on weak peaty or boggy soils. Any foundation must rest on a layer of solid ground to withstand the pressure of the house's weight. The larger the area of the base of the building, the less pressure it exerts on the ground.

The largest area has a foundation on slab-type driven piles. It rests on the ground with the entire area of the building. The belt structure has a significant area. The pile structure rests on solid ground with the ends of the piles, so the area of its support is somewhat less than that of a slab and tape structure.

Piles under the foundation can be hanging. Their lower ends do not rest against a solid layer of soil. The friction force generated between the soil and the surfaces of the supports holds them and ensures stability. Another type is rack piles. They abut their lower end against a solid layer of soil. Such foundation piles are the most reliable and stable.

When designing a foundation on piles, the weight of the entire house is calculated and divided by the number of racks. The result is the load on each support. Piles under the foundation are usually driven in with the load that they will have to withstand. When they stop and do not go deep into the soil, this is a sign that a hard layer has been reached that can withstand the given load. It can lie at different depths and consist of different rocks.

It will not be possible to drive reinforced concrete piles under the foundation manually; you need a pneumatic hammer. Therefore, independent construction of the foundation on driven reinforced concrete piles is not possible. Drop-in supports for the foundation are installed under the walls of the future building, in the corners and at the intersections of the walls. The number and distance between them depends on the total weight of the building. The pile heads are cut at the same height. The building will be mounted on them in the future.

Technology features

In the construction of bored foundation is becoming more and more popular. This is due to the advantages of this technology, which makes it possible to erect structures on almost any soil. The features of bored piles include:

- A wide range of applications, the ability to use both on dense and unstable soils (heaving or loose soils, near water bodies).

- Fast foundation erection. The technology with the use of bored piles allows you to do all the work faster than pouring a strip base or.

- Built in compliance with all standards, the foundation on bored piles will last at least 150 years.

- The simplicity of the design due to the relatively small amount of earthwork, it is enough to drill wells.

- The ability to independently select the diameter and height of the supports, the type of reinforcement, depending on the properties of the soil and the structural features of the building.

- Increased load-bearing capacity. Such a foundation can support the weight of multi-storey, industrial buildings, massive reinforced concrete structures.

The pile diameter is selected according to the current SNiP after geodetic surveys, taking into account climatic and geological features. Directly during the design, the mass of the building, the number of supports are calculated and the type of soil is determined. Information on the bearing capacity of bored piles on different soils can be found in the table:

The technology of the bored foundation has disadvantages, which include:

- the use of heavy equipment for drilling, installing casing pipes, reinforcement at large construction sites;

- the relative complexity of technological processes;

- the need for calculations.

Drilling piles

Bored pile technology

Drill piles are classified according to the method of the device.

- bored, concreted in wells drilled in silty-clayey soils above the groundwater level without fixing the walls of the wells,

- bored, arranged in wells drilled in any soil below the groundwater level - with fastening the walls of the wells with clay solution or inventory casing pipes,

- drilling injection with a diameter of 150-250 mm, arranged by injecting fine-grained concrete mortar into drilled wells,

- drilling piles, arranged by lowering a reinforced concrete pile into the well and filling the gap with a concrete mixture.

The types of bored piles differ in the method of construction and purpose. Actually, the main view is performed directly at the location by drilling a well, filling it with concrete solution and reinforcing it with a frame pre-prepared for the entire or partial depth of the well from iron rods and wire.

In difficult soil conditions, quicksand, sandy and soils at the level of underground aquifers, the installation of bored piles (BPS) is performed protected by recoverable inventory casing or protected by a clay (bentonite) solution.It is permissible to leave casing pipes in the ground if the filtration of groundwater exceeds 200 meters per day. Usually this becomes known from the results of engineering and geological surveys, and cheaper pipes are used for the BNS device.

BNS device with casing pipes

The diameter of the bored piles is determined by the calculation of the bearing capacity and can be in the range of 300-2000 mm, and the depth can also be up to 76 m. The purpose of the bored piles is to provide a solid foundation for massive buildings and structures due to the large diameter and depth of immersion, allowing to achieve low-compressive bearing strata and provide a support foot of a large area.

In simple soil conditions, a less costly method of installing bored piles with a continuous hollow auger is used. The essence of the method lies in the fact that concreting is carried out not with the help of a separate concrete-cast pipe, but directly through the cavity of the drill auger. When the drill reaches the design depth, concrete is pumped into its cavity under pressure, and as it rises, the well is filled with concrete. At the last stage, the reinforcement cage is immersed. After the concrete has set and cured, the pile is ready.

Installation of piles for the oil reservoir foundation

Bored piles (BIS) have a special application: strengthening old, dilapidated foundations of buildings, as well as in case of danger of subsidence and movement of the ground. Drilling with a diameter of 150-250 mm occurs in the immediate vicinity or through the massif of the foundation structure. LSI reinforcement in these cases may not be performed.

Boring piles are intended for the construction of a solid concrete wall, capable of carrying the function of a sheet piling of a pit, serving as a foundation and a wall of the basement of a building. They are carried out by the method of sequential drilling and concreting, first of odd wells, and then even ones, ensuring their engagement.

Calculation of piles

Calculation of foundation piles is performed:

- According to the bearing capacity of the soil under the heel of the pile,

- By the strength of the pile structure,

- According to the existing horizontal loads.

The sequence of selection, manufacturing, deepening, quality control, testing of piles is regulated by SNiP 2.02.03-85 "Pile foundations".

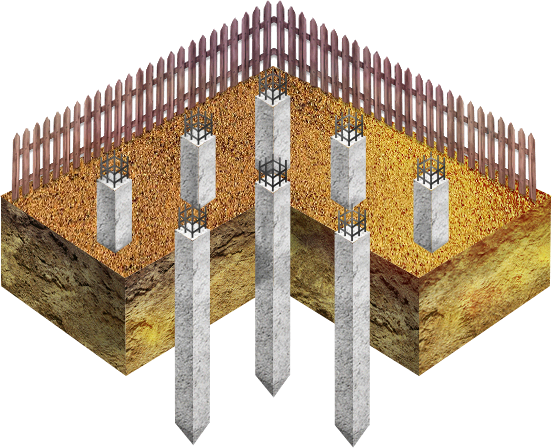

Features of the installation of the fence

The sheet-mounted material, intended for installation on driven piles, is attached to square or round posts. This type of support is specially designed for this type of pipe. The special shape and size is ideal for fast column installation. Watch a video on how to mount a fence on screw piles.

Since there is no need for additional fastening structures, the process of installing a fence on driven piles is somewhat simplified and has specific features.

The installation process is slightly different for square and round pipes. To fix vertical square pipes in the nest of driven piles, you will need:

- a square pipe with dimensions of 40 or 50 mm, depending on the size of the nest in the pile head;

- screwdriver or electric drill;

- level, plumb line and marking cable;

- engraving screws;

- mark;

- drill for metal corresponding to the section of the self-tapping screw.

Installation of a fence on piles

Installation of a fence on piles

There are special holes in the side face of the nesting column head, according to which the base of the pipe should be marked and the bait passages for the self-tapping screw should be drilled. This must be done, since usually the strength of the self-tapping screw is not enough to pass through the dense metal of the pipe. In addition, before installation, holes should be made for fastening the horizontal guides, if a solid sheet hanging material is selected.

To install round pipes in the corresponding sockets of the round heads, you just need to insert the pipe into the socket and secure the sliding mechanism with a special locking ring, which is included with the pile. The most convenient way to do this is with a special pipe hammer, which exerts uniform pressure on the surface of the ring. Regardless of the type, driven piles for the fence provide good structural stability, and all rumors about the unreliability of such a foundation are the result of poorly performed work.

Driving technical process

The very procedure for installing piles is quite clearly described in one word - "driving". It takes place through the use of pile hammers, which are mounted on heavy vehicles such as a crawler crane, cable excavator and hydraulic excavator.

Driving piles on site

The grooves are immersed in the soil vertically, but there are options for inclined plugging. At the construction site, there is a basic machine that is needed to engage, lift and insert the pile into the hammer, which moves in the indicated direction. After that, the discharge of the hammer striking part sends the pile into the soil surface.

Some builders immerse these structures using the indentation method. Naturally, with this method, more bulky equipment is used, and the production is not too large, but in some cases this is simply an irreplaceable action.

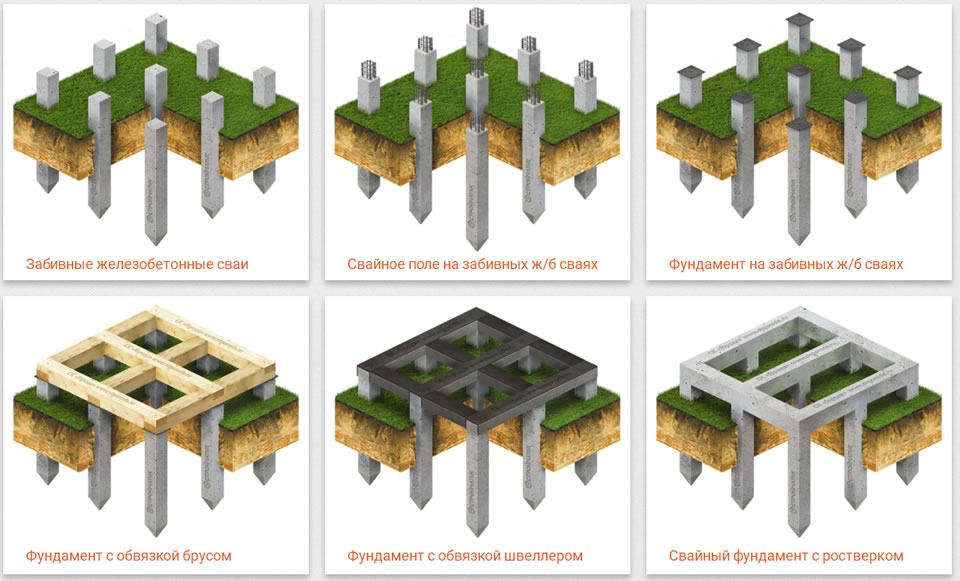

Foundations, in the construction of which driven piles are used, are arranged in the following forms:

- Single - for separately located columns;

- Belt, which are located under the wall structures of buildings;

- Shrubbery, for the placement of supports, where the sheet piles are installed in accordance with the development project, depending on what dimensions the base has;

- Solid pile fields, which are designed to better perceive the entire load from the house.

The purpose of the stud piles is to break through the weak topsoil and transfer the entire weight of the structure to the lower layers, which have greater density and strength.

Driven-type sheet piles can be made of metal, reinforced concrete material or wood. For the latter type, coniferous trees are most often taken, for example, pine, larch or cedar. You can also use oak. The thin end must be larger than 18 centimeters. The pile is sharpened from below, and a steel tip is attached to it, which protects the sharp edge from breakage during the process of driving it into the soil. A ring is attached to the top of the pile to protect the tree from splitting when it is hit with a hammer.

Installing piles in water

Reinforced concrete tongue and groove usually have a square section and a sharp end. There is also a steel guard on the other end.

Metal structures are made from various types of rolled metal - pipe, channel, I-beam and others. Pipe grooves for greater stability and strength are sometimes poured with concrete mortar. In this case, such piles are called pipe concrete.

Pipe piles have more advantages over all others. They are much lighter and can be driven to any depth, since it is possible to increase the length to the desired size. As a kind of pipe piles, there are screw grooves. They are screwed into the soil, thereby increasing their carrying capacity.

Shockless methods

Shock-free methods are based on achieving soil softening, using a special design of supports, or simplifying the immersion of piles. These methods make it possible to significantly simplify the labor costs of immersing foundation supports by an average of 20-40%.

Screwing method

The screwing technology is used for deepening screw piles. Their blade design allows, when transmitting a torque, to deepen the pile supports into the ground even without the use of special equipment and tractors.

Watch a video on how the support installation process takes place by screwing it into the ground.

The method is used in cases where it is required to erect a low-rise building, masts, power lines and other structures in conditions of loose or flooded soils. The technology is relatively simple and can be applied in any climate.

Screw piles are usually made of steel or reinforced concrete. The lower part has widening due to the installed blades, which gives the screwed support additional resistance to shear and pull-out forces. Piles can be screwed in without problems even in dense buildings, without worrying about possible subsidence of the soil under the erected objects.

Soil erosion method

The installation of piles using the soil erosion method is used to deepen supports in loose and loose layers. The greatest efficiency is achieved when it is necessary to immerse pile structures with a large diameter and / or length.

Soil washing scheme

Soil washing scheme

The technology consists in erosion of the soil under a high pressure of water supplied through pipes with a diameter of 38-62 mm in the direction of burying the pile. The density of the soil is reduced due to loosening and leaching, and the water rising to the surface erodes the walls and reduces the lateral friction of the submerged structure against the passable soil layers. The pile path is freed by its own weight, and the soil is washed out to the surface.

The water supply pipes can be located on the side or in the center of the pile. The lateral water jet is the most advantageous, as it significantly facilitates the penetration process by reducing the effect of lateral friction. The pipes are fastened so that their ends are above the tip of the pile supports by 300-400 mm. The minimum water pressure is 500 kPa.

During the water supply, the bearing capacity of the dense layer may deteriorate; therefore, soil washout is stopped 50-200 cm before the specified design depth is reached.

Electroosmosis method

The technology for installing piles using the electroosmosis method is based on the immersion of two piles with one connected to the negative pole of the power grid, and the other to the positive. As a result of this connection, moisture begins to accumulate near the negatively charged support, making it easier to dive. Additionally, to accelerate the penetration, you can use a drive unit.

After switching off the current, the bearing capacity of the soil is fully restored. The humidity level is leveled out to the previous state.

Indentation method

The pile indentation technology is effectively used for supports of small lengths from 3 to 5 m and with a tubular section. The piles are immersed by means of a static load.

Watch a video of how the process of pressing reinforced concrete supports takes place.

First, the support is installed in the desired position, the head is fixed to the upper part, and then, through the action of the boom of the base machine unit, a dive is made. Vibration action can be applied simultaneously with the indentation.

Before pressing into high-density soils, it is necessary to drill a small hole that sets the direction for the movement of the pile.

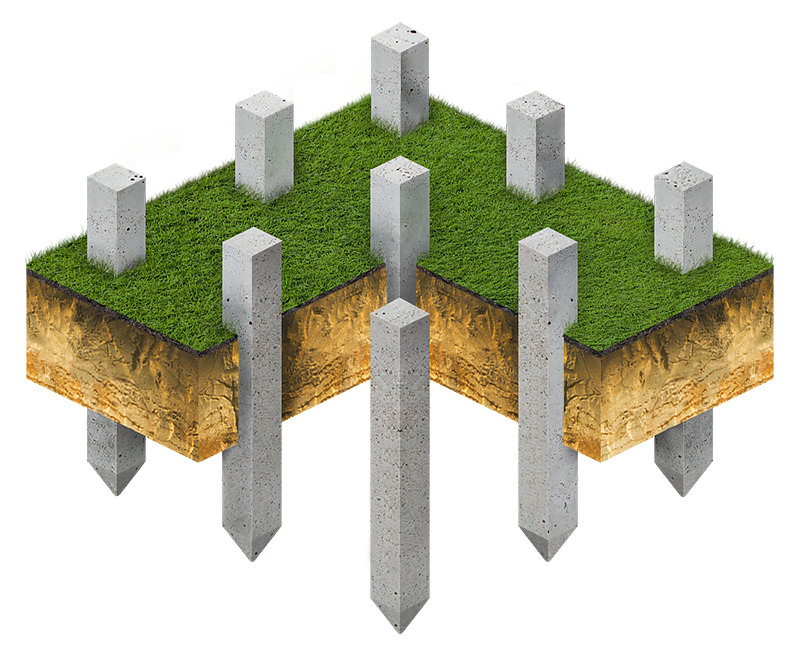

Pile field arrangement

Piles can be staggered across the territory or in parallel rows. For large buildings, it is customary to place them in a checkerboard pattern; for small buildings, placement in parallel rows is suitable.

The device of the pile field begins with its design, before which it is imperative to conduct geodetic surveys. In the course of this work, you should determine:

- The force of soil resistance.

- Density of the soil.

- The depth of freezing and the height of groundwater.

- Layering of different types of soils.

Further, based on the characteristics of the soil, the bearing capacity of the driven reinforced concrete piles is calculated, and their number is determined. Select the required type and size of support pillars.

At the end, a plan-project of the pile field is drawn up, which is coordinated with the customer.This mesh is transferred to the construction site and the work of driving in or screwing in the pile posts begins.

Reinforced concrete driven piles for foundations

What you need to know about pouring such a foundation

The binding component of the mixture is ordinary Portland cement of grades M200 - M500

- The type of cement. Here you need to use Portland cement of a brand not lower than M-200. This cement is used to create mortar.

- The solution should be of medium density, but not liquid.

- Pouring must be done simultaneously or with a small time range, first of all piles. But only when all the fittings are installed and connected.

- It is recommended to first pour the supporting structures and leave for a couple of days until the concrete hardens. It is not recommended to start pouring the grillage immediately after pouring the piles for one reason: it is practically impossible to achieve the tightness of the pipe with a sand cushion and part of the concrete will leave through the lower edge.

- As soon as the concrete is fixed, the grillage is poured simultaneously in several places. It is worth using several powerful enough concrete mixers to automate the process.

- After pouring the entire grillage, leave it to dry for several days, up to a week, so that the concrete receives at least half of its strength.

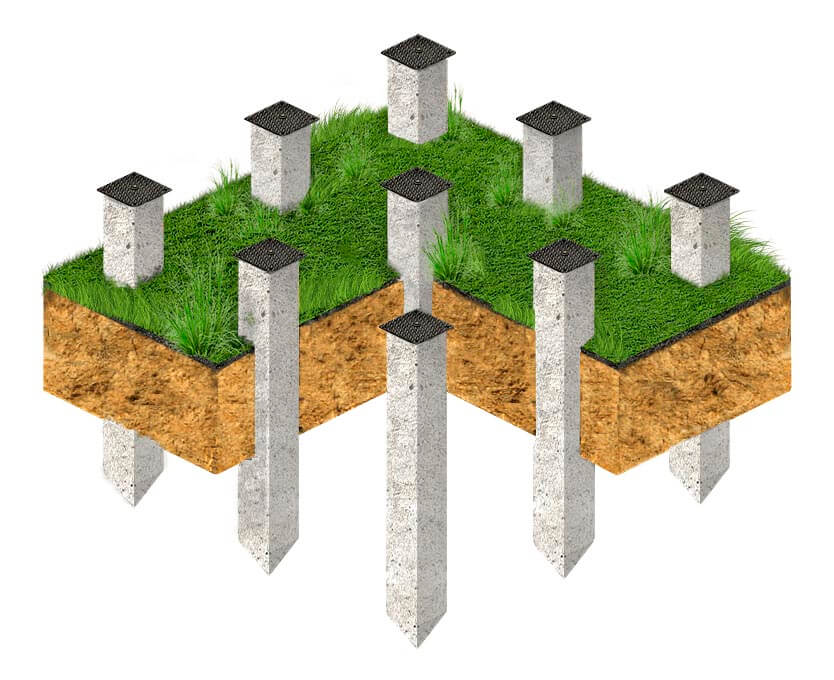

Varieties of piles

If we consider all categories of pile foundations, driven ones are considered one of the most durable and reliable. They are relatively firmly held in the ground, therefore, they are used for the installation of a heavy grillage base.

If we consider all categories of pile foundations, driven ones are considered one of the most durable and reliable. They are relatively firmly held in the ground, therefore, they are used for the installation of a heavy grillage base.

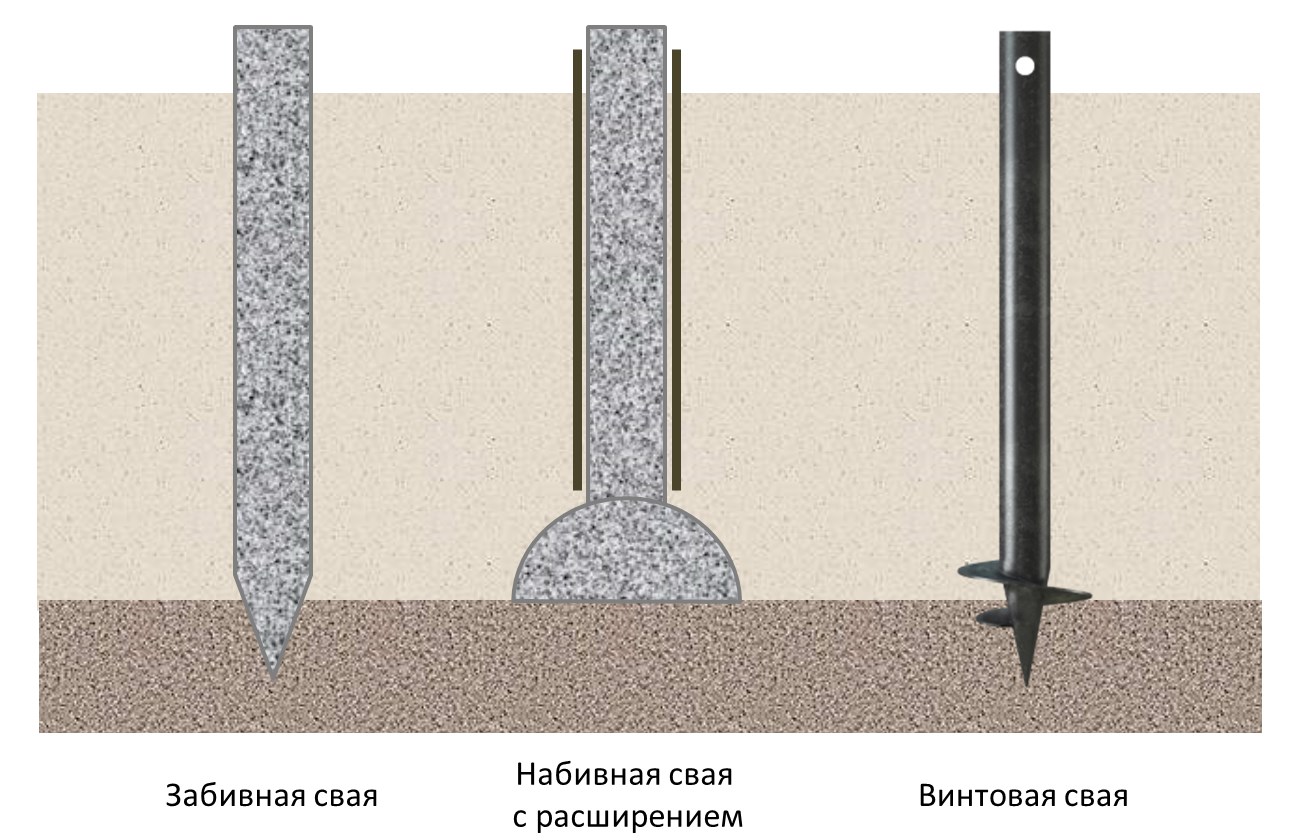

In addition, this technology is recognized as the oldest and most widespread in the whole world. At the moment, there are 3 categories of pile foundations:

- General construction. Widely used for the private sector.

- Mostovoy. Used for the construction of bridge structures.

- Electrotechnical. For the installation of the frame of hydroelectric power plants.

Square poles are very popular

Square poles are very popular

All of them differ from each other, starting from the characteristic features of the material from which they are made: reinforced concrete, metal, wood. Additionally, there is a classification by type of reinforcement (with or without stress), as well as by cross-section (round, solid, hollow or rectangular).

In this case, the technology for manufacturing can be used as a prefabricated or monolithic one. Square-section supports have become very popular. In this case, you need to make the right choice between the type of reinforcement, use elements with or without tension.

GOST requirements

The foundation is a capital structure directly responsible for the integrity of the load-bearing walls of any structure, therefore, to select the materials used for its installation, strict adherence to the official documentation characterizing the characteristics of the products is required.

The foundation is a capital structure directly responsible for the integrity of the load-bearing walls of any structure, therefore, to select the materials used for its installation, strict adherence to the official documentation characterizing the characteristics of the products is required.

Materials of wooden products are selected in accordance with GOST 9463-88. For reinforced concrete, there is a wide range of regulatory documents:

- GOST 1980479-2012 - General technical information.

- GOST 19804.4-78 - solid rectangular non-reinforced.

- GOST 19804.2-79 - rectangular solid with transverse reinforcement.

- GOST 19804.3-80 - rectangular solid with a rounded cavity and a reinforcement net.

- GOST 19804.5-83 - hollow, rounded section.

Differences in material and appearance

Metal piles are common in individual construction

Metal piles are common in individual construction

As mentioned earlier, driven piles can be made of 3 types of building material: wood, metal and reinforced concrete. The first ones are made of hard wood: cedar, oak, larch. At the end, a conical tip is installed, put on the driven end of the pile.

The upper part is pulled together with a ring that prevents the wood from cracking from hammer blows. Products of this type are found up to 15 m long and up to 0.4 m wide.If the situation requires it, sets of several wooden supports, tied together and driven into one piece, can be used.

Metal piles are the most common in modern individual construction. The uniqueness lies in the longer service life compared to wood and ease of driving in relation to reinforced concrete. Often they are made independently, and are driven into the soil using a conventional hammer.

Metal piles are the most common in modern individual construction. The uniqueness lies in the longer service life compared to wood and ease of driving in relation to reinforced concrete. Often they are made independently, and are driven into the soil using a conventional hammer.

The construction of a pile foundation using reinforced concrete products differs in external characteristics: different diameter and shape of the column: square, rectangle, round or I-beams.

Types and features of driven piles

Of all the varieties, driven piles are considered to be the most reliable support for the foundation. Due to the fact that they hold quite tightly in the ground, it is the hammering technology that is recommended for arranging heavy grillage foundations. Driving piles is the oldest and most proven method of driving them into the ground. Today this technology is widespread throughout the world, and therefore various driving techniques and special devices have been developed.

Reinforced concrete piles

Reinforced concrete piles

Modern driven piles can be of several types:

- Reinforced concrete. They have a ready-made pointed end and can be of any section - square, round, I-beam, etc. They must be made of concrete of at least 300 grade and have a reinforcing cage inside. Before driving, the cast pile should be carefully inspected - it should not have cracks, deformations or other defects. When deepening, a special steel head is put on the upper end to prevent its destruction during hammer blows.

- Wooden. They are usually made from hard trees (cedar, larch, oak) and are supplied with a conical metal point worn on the buried end. A metal hoop is put on the upper part to avoid cracking during driving. They are up to 10 meters long and up to 40 cm in diameter. In some cases, when it is necessary to achieve special strength of the pile foundation, bundles of several piles are used - "packages", driven into the ground as a whole.

- Metallic. The most common type of pile used in private construction. Steel is the most versatile material, more durable than wood and more technological than concrete. They can be made at home or driven into the ground using a hand hammer. Structurally, they consist of a pipe, a tip and a head.