Scope of use

Basalt plastic, carbon fiber, combined and glass reinforcement are used for various purposes:

production of composite types of concrete intended for the construction of monolithic walls of residential and industrial buildings;

Today, in private housing construction, plastic reinforcement for the foundation is increasingly used.

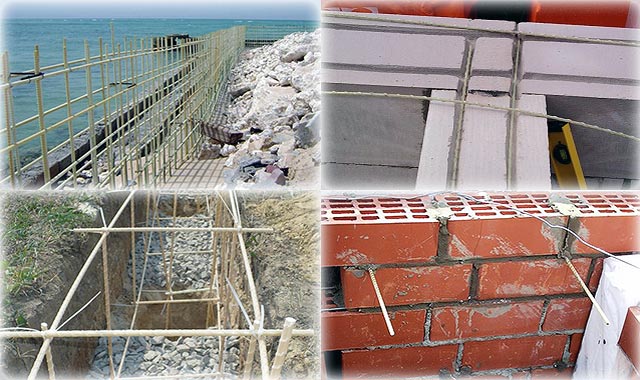

- construction of foundations and production of foundation slabs;

- reinforcement of brickwork in low-rise construction;

- erection of port facilities, shore protection structures, offshore facilities;

- arrangement of road surfaces and strengthening of slopes;

- construction of fences for railways and highways;

- manufacture of concrete products requiring prestressed reinforcement (pillars, slabs, sleepers, traverse);

- construction of flyovers, bridge structures, overpasses;

- creation of earthquake-resistant contours of reinforcement of various structures.

Advantages and disadvantages of fiberglass reinforcement

Reinforcement cages, made not of traditional metal, but of fiberglass elements, have the following advantages.

- Unlike metal structures, they are lightweight structures that do not create a significant load on the foundation of the structure, which makes it possible to extend its service life.

- Fiberglass elements of reinforcing cages, unlike their metal counterparts, better withstand tensile loads, which makes it possible to use them when strengthening the most critical concrete structures. Fiberglass reinforcing cages are characterized by the optimal ratio of their light weight and high strength, which allows them to be attributed to a separate group of building materials that are gaining more and more popularity every year.

- Unlike metal reinforcement, which is susceptible to oxidative processes and over time reduces the strength of foundation structures, frames made of fiberglass elements do not lend themselves to the influence of such negative environmental factors.

- Parts of reinforcement systems made of fiberglass are dielectric and do not conduct electric current, which also affects their durability. Metal reinforcing structures used as grounding elements oxidize much faster under the influence of electric current, which cannot be said about bars made of composite materials. Naturally, fiberglass reinforcement cannot be used as a grounding element, but this only has a positive effect on its durability.

- The wear resistance of the fiberglass reinforcing structure, like that of steel, is also at a fairly high level.

- The coefficient of thermal expansion of the reinforcement cage made of fiberglass elements is very close to that of concrete structures, which significantly reduces the risk of cracking in them when using such a material.

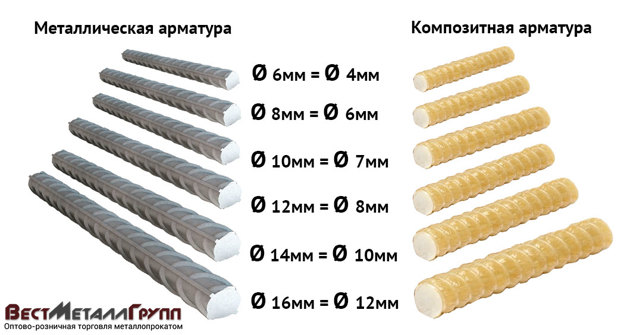

The ratio of the diameters of the rods when constructing the reinforcing frame of the foundation

Judging by the reviews, the following disadvantages of fiberglass reinforcement can be distinguished.

- Compared to metal products, fiberglass reinforcement has a significantly higher modulus of elasticity, which is approximately 4 times higher than that of steel products. This fact means that fiberglass elements, in comparison with metal ones, will bend much better under the influence of mechanical loads.When using these elements to reinforce the roadway and foundation, this characteristic is not critical, but to strengthen floor slabs it is better to use metal structures or make additional calculations.

- Reinforcing elements made of fiberglass have the property of strongly softening and losing their elasticity when heated to a temperature of 600 degrees. Therefore, when using fiberglass parts, it is better to take care of reliable thermal insulation of the frame made of composite materials.

- Reinforcing bars made of fiberglass cannot be welded, unlike metal ones, so if there is a need for such an operation, it is better to use products, into the inside of which a steel tube is mounted at the stage of their production.

- It is better not to bend the reinforcement made of composite materials on the construction site, as this may damage it. Such an operation, guided by the drawings of the reinforcement cage, is best performed at the production site.

- The complexity and installation technology unusual for modern builders is another drawback of reinforcing elements made of fiberglass. Meanwhile, such a disadvantage cannot be considered too significant, given the reliability and durability of fiberglass structures.

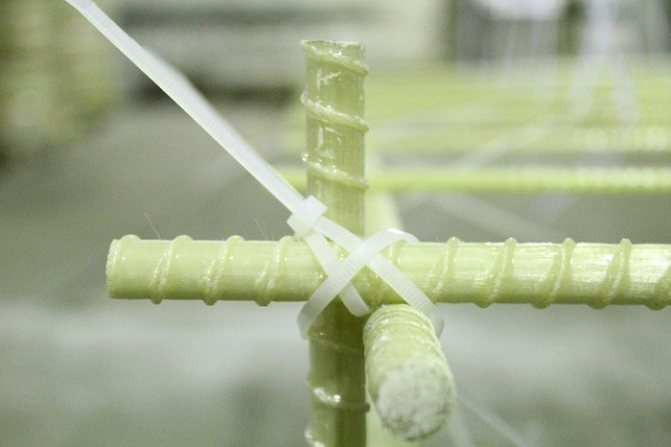

Fastening fiberglass reinforcement using clamps and clamps

Materials for making

Today the market for composite reinforcement is represented by three types:

-

fiberglass

; -

basalt-plastic

th; -

carbon fiber

.

Fiberglass reinforcement

The first type of reinforcement is made of fiberglass. This technology appeared in the USSR about 50 years ago. Then printed wiring began to gain momentum in electronics, and textolite began to be used as a material for boards, when the basis was fabric, and the bonding compound was artificial resin. Later, fiberglass was used instead of conventional fabric, and this expanded the use of fiberglass.

The first type of reinforcement is made of fiberglass. This technology appeared in the USSR about 50 years ago. Then printed wiring began to gain momentum in electronics, and textolite began to be used as a material for boards, when the basis was fabric, and the bonding compound was artificial resin. Later, fiberglass was used instead of conventional fabric, and this expanded the use of fiberglass.

He took his place in the aircraft industry, furniture and household goods, and sometimes even in the military industry. Gradually, it began to be used in construction, and fiberglass reinforcement became an excellent option for foundation frames operating in aggressive conditions - for example, in water.

The materials for fiberglass are glass and epoxy.

This material does not contain fiberglass, but basalt. Its manufacturing technology is simpler than that of glass, because glass production requires several types of raw materials, and for basalt plastic

This material does not contain fiberglass, but basalt. Its manufacturing technology is simpler than that of glass, because glass production requires several types of raw materials, and for basalt plastic

- only basalt.

Compared with the previous composite, basalt-plastic has a higher modulus of elasticity and ultimate strength, has a lower thermal conductivity, but somewhat greater weight.

Carbon Fiber CFRP

It is made from carbon fiber and the same resins, but this material is expensive. This is due to the technology for the production of carbon fiber - the basis of such materials. Technological process

It is made from carbon fiber and the same resins, but this material is expensive. This is due to the technology for the production of carbon fiber - the basis of such materials. Technological process

requires strict adherence to the parameters of temperature and processing time, since organic fibers serve as the raw material for them.

CFRPs are actively used in the automotive industry, the production of sporting goods, aircraft and shipbuilding, and science.

Carbon fiber reinforcement is stronger than fiberglass and has a higher modulus of elasticity, but it is not without its drawbacks. So, the fragility of this material is great, which does not allow its use in long stressed structures like floor slabs.

Reinforcement of the foundation

To determine if fiberglass reinforcement can be used for strip foundations and how to knit fiberglass rods with such a base, you need to take into account that there are two types of base with tape:

- Rectangular.

- T-shaped.

In the second type, the installation of reinforcement is carried out without preliminary calculations, and the sole is designed to absorb bending loads. The material can be sewn into the wall, but extra care must be taken when installing into the sole.

If the foundation has a rectangular cross-section, the use of fiberglass reinforcement is justified, since this structure can take compressive loads.

Tools and materials

Before you start knitting a strip foundation, you need to prepare the following tools and materials:

- Measuring device - tape measure.

- A device for fitting and processing rods - a grinder.

- Personal protective equipment.

- Water level.

- Plastic clamps for fastening rods.

Excavation

Before starting the reinforcement, you need to prepare a recess, guided by the layout of the future building. The bottom surface must be leveled and tamped, then a layer of sand (10-15 cm) should be poured, poured with liquid and compacted. The next layer will be crushed stone with a similar thickness. After the top cover is compacted, a firm cushion with a flat surface is formed at the bottom.

Formwork construction

For arranging the formwork, boards are used, which are connected into shields using nails or self-tapping screws. The hats of the fasteners must be installed from the inside, and the structure must be additionally reinforced with spacers.

The surface of the walls is covered with parchment, which is fixed with a stapler. The task of this material is to keep the planks clean and to prevent the leakage of liquid from the concrete screed.

Further on the walls are placed marks that will determine the level of concrete pouring. It is worth guiding along this line when installing reinforced elements. For a more accurate performance of the work, a water level should be applied.

Knitting technology

To understand the knitting technology, you should take into account the simple advice of experienced specialists and adhere to the following algorithm of actions:

Before starting knitting, you need to prepare the drawings of the frame and cut all the elements, adhering to the calculations.

Clamps are used to position the cross wires in the lower layers. They are fixed both before starting the installation of the fittings and after completing the assembly.

The diameter of the cells is determined by the parameters of the tape, which is reinforced. In most cases, it varies from 15 to 30 cm.

Before connecting the longitudinal rods, they must be laid out on the ground and marked on them at the points of attachment of the transverse parts. In the process of knitting, a right angle must be observed.

The cross members are fixed with the longitudinal ones from the bottom. To ensure reliable reinforcement, plastic clamps or wire are knitted as tightly as possible.

First of all, it is necessary to prepare the horizontal layers of reinforcement, and then start fixing the vertical

Fixation is carried out from the inside of the cells to increase the reliability of the structure.

The corners need to be given special attention. Experts recommend not to bend them by temperature exposure, as this can worsen the strength properties.

After completing the binding of the reinforcement structure, it must be placed inside the formwork.

If fiberglass reinforcement is knitted with wire, then, in order to facilitate the work, it is better to use a crochet hook. An old screwdriver can play its role.

Reinforcement cage construction

When arranging the frame, you must adhere to the key requirement - the product must be completely filled with concrete, maintaining a distance between the walls of the formwork of at least 5 cm.To prevent the reinforced elements from being placed at the bottom of the recess, bricks should be fixed, and longitudinal rods and horizontal crossbars should be placed on top of them.These elements are connected using plastic clamps.

Pouring the foundation

At the last stage, you need to pour concrete into the formwork with a frame

It is important to carry out this action with extreme caution, placing it in the free cavities between the parts of the frame. It is also necessary to periodically pierce the concrete with rods to remove air bubbles.

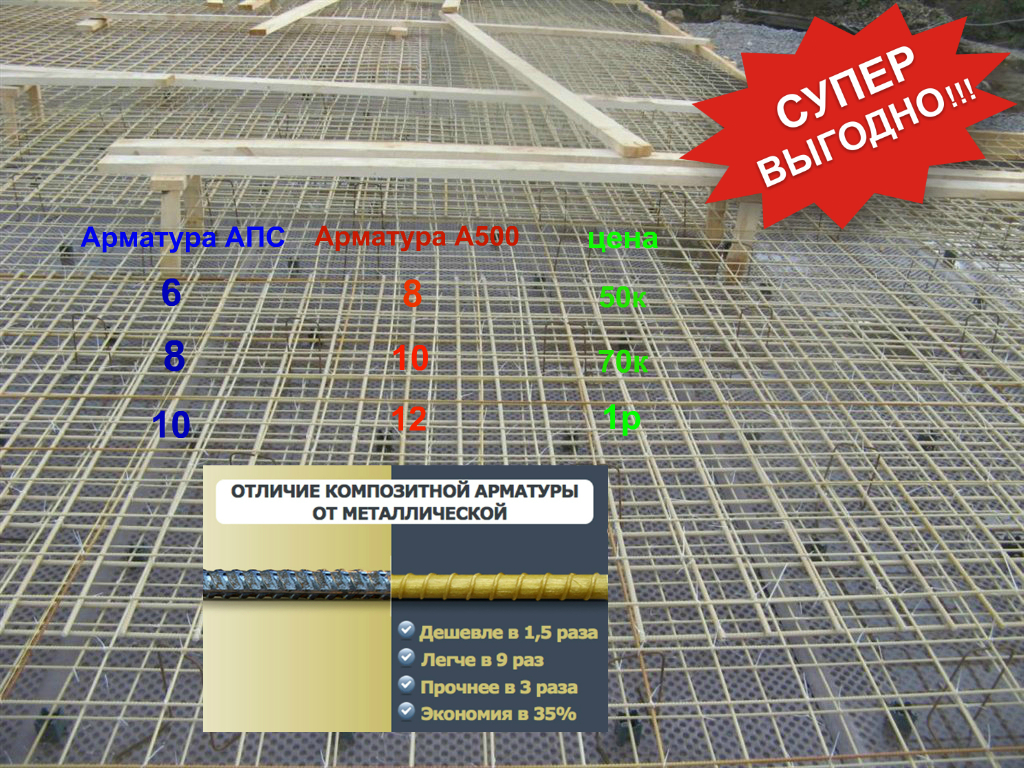

Advantages and Disadvantages of Using Composite Reinforcement

The wide popularity of composite types of reinforcement was provided by the following properties:

- The weight of composite reinforcement is an order of magnitude less than the weight of steel analogs, however, this advantage can hardly be considered significant, since the concrete mixture itself has a large specific gravity, so that a fundamental change in the mass of the structure will not occur;

- The use of fiberglass reinforcement eliminates the formation of cold bridges, which has a positive effect on the energy efficiency of the building as a whole. Steel fittings do not have such an advantage;

- The possibility of delivery in coils allows the use of rods of the required length without resorting to splicing of reinforcement, which not only saves material, but also increases the efficiency of reinforcement;

- Inertness to aggressive media and moisture is a very dubious advantage, since metal analogs, isolated from the effects of the environment by a layer of concrete, practically do not collapse;

- Composite reinforcement is dielectric, which significantly reduces radio interference and increases the service life of the frame;

- Inertness to aggressive chemical compounds of polymer reinforcing elements is of particular importance at subzero temperatures, since concrete mixtures during this period include additional components that prevent mortar freezing;

When choosing a reinforcement option, it is necessary to have an idea not only about the advantages, but also about the disadvantages of fiberglass, which, unfortunately, also take place:

- It is undesirable to use composite reinforcement at elevated temperatures. On the other hand, it is very problematic to heat a crate filled with a concrete composition to 200C, even if we take into account the good thermal conductivity of concrete;

- The high price of the composite. This disadvantage is partially offset by high strength, which allows the use of rods of a smaller diameter;

- The plasticity characteristics of carbon fiber reinforcing elements are far from perfect, which limits the possibility of its use in complex architectural structures;

- The rigidity of reinforcing cages, assembled from composite elements, is significantly lower than that of the lathing. Made using a metal rod. There have been cases where the polymer reinforcing structure failed during the pouring phase.

After analyzing the above information, we can come to the conclusion that there is no definite answer which fittings are better. In some cases, it is advisable to use combined frames made of metal and composite elements.

Required materials and tools

Before knitting fiberglass reinforcement for the foundation, you need to purchase materials and prepare tools for work.

Usually, to strengthen monolithic structures, horizontal flat meshes are used, connected by spatial links into a single whole. This scheme is suitable for laying strip and slab foundations under a building, or for preparing a frame for pouring a foundation for a fence.

Individual rods are tied together with metal wire using special hooks or a gun (material on the topic of knitting reinforcement is presented here).

They can also be connected with clamps.

Before starting work, the following materials are purchased:

- fiberglass rods (diameter must correspond to the design documentation);

- metal wire or plastic clamps.

Plastic fittings are supplied in coils, therefore, before starting work, they must be cut to size. You can cut the reinforcement with an ordinary hacksaw for metal or a cutting disc of an angle grinder (the material for cutting fiberglass reinforcement is posted here). It will be convenient to mark the rods into separate pieces with a marker.

For knitting, choose a metal wire with a diameter of 1 mm. This size allows you to create a reliable knot that will hold the intersection of individual rods without differences in height.

To cut the wire into separate pieces, it will be enough to cut the coil with wire into 3 parts with an angle grinder.

To give the wire more elasticity, it is recommended to anneal it at the stake. After heat treatment, the wire is easily bent and tightened with a knot at the junction of the reinforcing rods. Untreated wire tightens worse and does not grip the joint tightly, and also breaks more often.

As a tool for knitting wire can be used:

- pliers;

- crochet hooks;

- knitting guns.

It is inconvenient to work with pliers. It takes a lot of effort to get the right knot, and the speed of work will be several times lower than when using other tools. Most often, builders use crochet hooks.

Hooks are of two types:

- Manual. Such a tool will need to be rotated by hand.

- Semi-automatic. They are internally threaded, and when the handle is pulled back, the hook turns, tightening the knot.

A regular hook can be purchased at a hardware store, but it is also easy to make it yourself from thick steel wire (read about this in this material).

A knitting gun significantly speeds up the process of preparing the frame, but this is a rather expensive tool. In addition, the dimensions of the pistol do not allow for the seizure of the connection of rods in hard-to-reach places - there you still have to work with an ordinary hook.

Benefits and where it is used

The popularity of using fiberglass is associated with a host of advantages, including:

- No vulnerability to corrosive processes. Due to this property, fiberglass can be used in environments with high humidity or other aggressive influences.

- Small size and weight. This contributes to comfortable transportation and use of the material. The reinforcement process does not require large expenditures of human strength. The material is easily coiled and easily delivered to the construction site.

- Affordable cost. Composite products are much cheaper than steel counterparts.

- Increased strength properties. Fiberglass reinforcement is characterized by high strength, which is 2-2.5 times higher than the strength of metal rods with the same cross-section.

- Low thermal conductivity, resistance to electric current. Concrete structures are not able to protect the building from heat loss, and they are additionally insulated with insulating material, so the low thermal conductivity properties of the composite do not play a big role. The non-conductivity of electricity is an important point that protects the building from discharges.

However, in addition to positive features, the reinforcement of the strip foundation with fiberglass reinforcement also has disadvantages:

- The structure is not flexible and therefore cannot absorb tensile loads. Since the reinforcement is laid on a concrete surface, it is already undergoing ultimate tensile stress.

- The areas of use of the material are limited as it can only be installed taut.

- For the construction of large-sized and multi-storey buildings, fiberglass is not suitable. Therefore, most often it is in demand when solving simple problems by beginners.

- The inability to use welding equipment to connect the elements.In most cases, welding is involved in the construction of large-sized frames. For arranging the foundation of a private house, the method of step-by-step knitting of rods is suitable.

The material appeared relatively recently and is considered not fully understood.

Applications include both residential and industrial construction. The use of fiberglass reinforcement in the foundation is in great demand, which is associated with a number of advantages over concrete structures.

Today, such reinforcement is used to strengthen the banks of reservoirs and road surfaces located in problem areas with constant aggressive influences.

In private construction, products are necessary to strengthen:

- Concrete structures that perform enclosing functions. At the same time, it is prohibited to use material for reinforcing load-bearing structures.

- Foundations of a tape or other type.

- Foam concrete or aerated concrete masonry.

What are the fittings

Long gone are the days when fittings were only metal. Now in hardware stores, the assortment of material is much wider.

Plastic reinforcement for the foundation

The plastic type appeared on the domestic market relatively recently and has already managed to achieve a certain popularity due to its good technical characteristics.

Rods with a diameter of 6, 8, 10 mm are produced. The maximum temperature for their use is 60 °, so they are just perfect for the foundation. This also applies to strength characteristics. When stretched, fiberglass reinforcement can withstand a pressure of 1400 MPa or more, and when compressed, 350 MPa or more.

Plastic fittings are easier to install than metal fittings

Advantages of fiberglass reinforcement:

- corrosion resistance;

- low thermal conductivity, lack of prerequisites for the formation of cold bridges;

- does not conduct electricity, is impervious to electromagnetic waves;

- small weight;

- seamless (the rod is supplied in coils, so there is no need to cut into pieces);

- there is no need to use a welding machine during installation;

- ease of transportation and installation.

However, there is also a disadvantage, which is quite significant - low fracture strength. Fiberglass reinforcement resembles rubber in its strength properties - it stretches easily, which means that concrete will have to work in tension, but it does not know how to do this.

Fiberglass reinforcement is supplied in coils

There are some peculiarities of laying fiberglass reinforcement into the foundation. Firstly, this can only be done on a brick, and there must be an indent from the edges of the formwork. Secondly, the bundle of rods must be carried out with plastic clamps.

Steel reinforcement

Steel is more familiar to people with experience. As a result of using steel reinforcement, a reinforced concrete structure is obtained, the strength of which is much higher than concrete.

It has a ribbed surface, due to which good adhesion of the rods and concrete mortar is ensured.

Steel reinforcement in concrete works is most often used

The range of steel profiles is much higher (6 to 80 mm). They are supplied in the form of rods 6 or 12 meters long.

There are several types of steel reinforcement:

- non-spinning (the number of wires can be 3, 7 or 19, which is indicated in the reinforcement class, for example, P-7);

- steel ropes;

- welded reinforcing mesh;

- woven welded or wire mesh.

Composite

A fairly new type of fittings with many advantages:

- high specific strength;

- corrosion resistance;

- lack of heat and electrical conductivity;

- ecological cleanliness;

- convenient transportation and easy installation.

At the same time, the material does not have plasticity and rigidity. When cutting it, dust is formed, which can not only contaminate the workplace and tools, but also damage the respiratory tract, eyes, and skin.Therefore, it is possible to work with composite reinforcement only in protective clothing.

Composite rebar is more commonly used for wall reinforcement

Composite reinforcement is rarely used for foundations. More often it is a component of the walls of residential and industrial buildings, and is also used in the repair of reinforced concrete structures, especially in winter.

Advantages and disadvantages

Fastening of carbon fiber rods is carried out with special clamps, for fastening there is no need to use welding

The advantages of composite reinforcement include:

- light weight;

- the cost is lower than that of metal;

- strength;

- resistance to aggressive environments;

- excellent thermal insulation properties, which is the main advantage in the construction of a bath;

- is not a conductor, and therefore does not interfere with radio waves;

- service life can be 80 years;

- fittings are sold in coils, and therefore the length of the rod is unlimited.

And yet, composite reinforcement has disadvantages:

- it cannot be operated at temperatures above 200 ° C;

- not too elastic. However, the last drawback is important only in the construction of high-rise buildings. Elasticity does not play any role in the foundation of the bath.

If you are not going to heat the bath foundation to too high temperatures, then the best choice is to use composite reinforcement. Strong and lightweight material, which can be cut into pieces of any length, has excellent reinforcing properties.

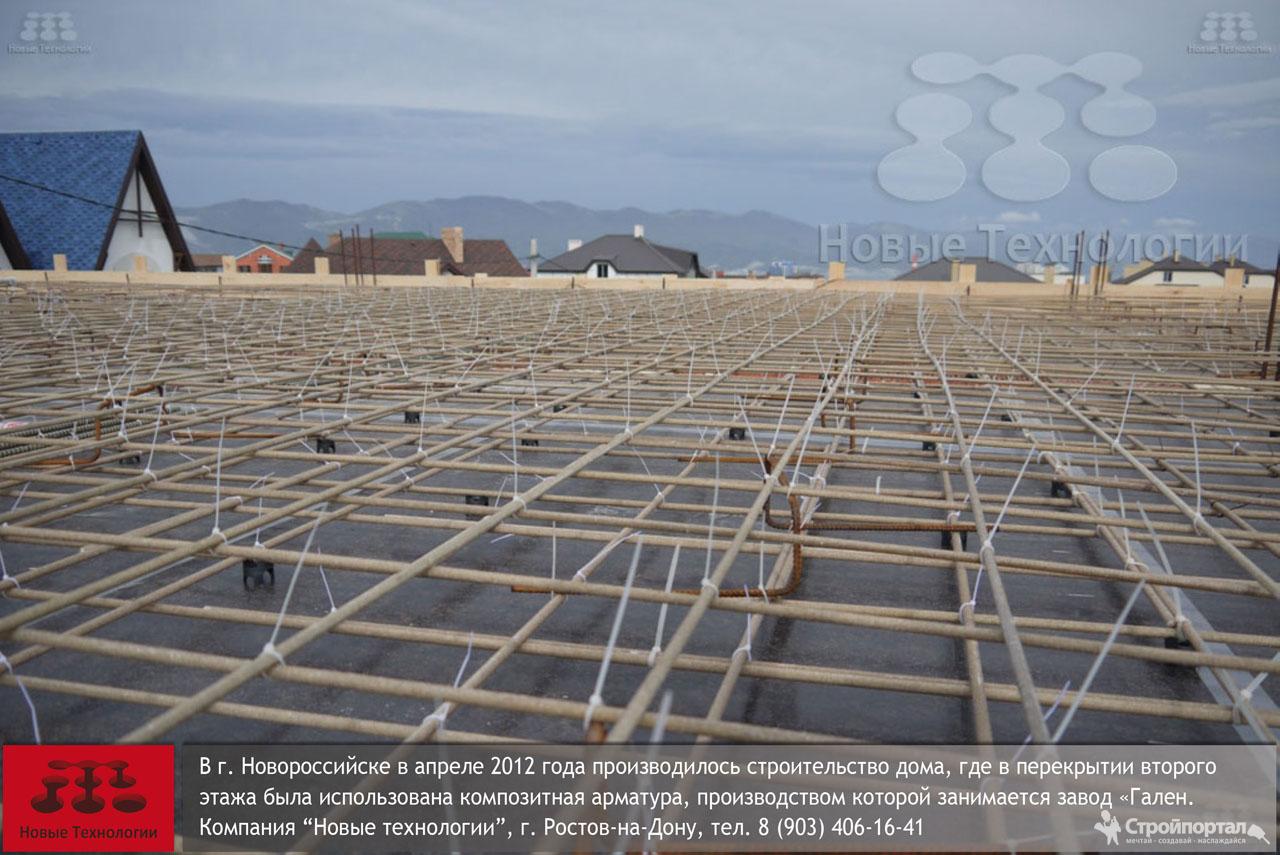

Reinforcement of concrete monolithic structures with plastic materials is increasingly used in construction. This is due to such performance characteristics as high strength, durability and absence of corrosion. The latter circumstance is especially important in the construction of hydraulic structures, bridges and foundation foundations.

Manufacturers of building materials produce 5 types of composite plastic reinforcement:

- fiberglass or fiberglass - ASK;

- carbon composite - AUK;

- basalt composite - ABK;

- aramid composite - AAK;

- combined - AKK.

From the name you can understand what material is the basic basis for the manufacture of plastic fittings.

Technology of reinforcement of foundations with composite materials

The light weight of the plastic reinforcement for the foundation simplifies the process of assembling the reinforcement cage of any design. At the same time, due to the increased strength of the material, the cross-sectional diameter is taken one number less than for metal counterparts.

The technological process of installing concrete monolithic structures using polymer rods consists of the following stages:

- installation of formwork and marking the level of pouring concrete mixture;

- assembly and installation of the reinforcing frame;

- pouring concrete into the formwork;

- removal of formwork panels.

Work on the installation of reinforced monolithic structures must be carried out in accordance with the adopted design decisions. The configuration of the deck must fully match the size and shape of the foundation. As a formwork material, you can use factory-made standard shields, boards, moisture-resistant plywood or chipboard. For permanent formwork, sheet polystyrene foam is most often used.

After assembling and fixing the formwork panels, on their inner side, using a water level, marks the upper limit of pouring the concrete mixture. This will shorten the turnaround time and help spread the concrete more evenly.

Spatial reinforcing frame for strip foundations

The foundation reinforcement scheme, laying and the diameter of the rods are always indicated in the project. The use of composite reinforcement, especially based on carbon fiber, allows the diameter of the rods to be reduced by one size. The laying of the material must exactly match the calculated data. The frame is assembled on a flat area.

Work begins with cutting blanks. To do this, pieces of the required length are unwound from the bay and installed on supports at a height of 35-50 mm above the support cushion or ground. After that, the transverse jumpers are laid, according to the drawing, and at the intersections they are tied with wire or ties. Thus, the bottom row of the spatial reinforcement cage will be assembled.

At the next stage, it is necessary to assemble a lattice, completely similar to the first, lay it on top and then cut the vertical posts of the projected length. The first post is tied at the corner of flat gratings, the second - at the adjacent intersection, as a result, a spatial structure is gradually formed in this way. If there are more horizontal rows, then the second lattice is fixed at the required height, and then the next one is fixed. In this case, the vertical stand is one whole segment.

At the bottom of the trench, it is necessary to pour a sand-crushed stone pillow and tamp it well. After that, it is recommended to cover the sand layer with geotextile or waterproofing material. This will prevent moisture from entering the concrete and the germination of weeds.

Horizontal reinforcement of slab foundations

When pouring slab-type foundations, horizontal reinforcement technology is used. Its main feature is the absence of turning and adjoining sections. Usually these are two nets, located one above the other from long straight rods and vertical posts.

All work is done locally. First, according to the design drawing, the lower mesh is knitted, and the upper mesh is laid on top of it. After that, vertical racks are installed, as described for tape structures. The lower net must be installed on the stands.

Pouring concrete onto a plastic reinforcement cage

Technologically, pouring a concrete mixture is no different from work using steel reinforcement

However, given the lower strength of the material with lateral radial action, the compaction with a vibrator should be done carefully so as not to violate the integrity of the plastic rods.

The construction industry is constantly evolving. New materials appear on the market that meet high requirements. Residential and industrial buildings are built in a short time. During their construction, various modern materials and innovative technologies are used. Recently, the developers were presented with fiberglass reinforcement, which began to compete with the time-tested steel rods.