Materials and methods of insulation outside the foundation

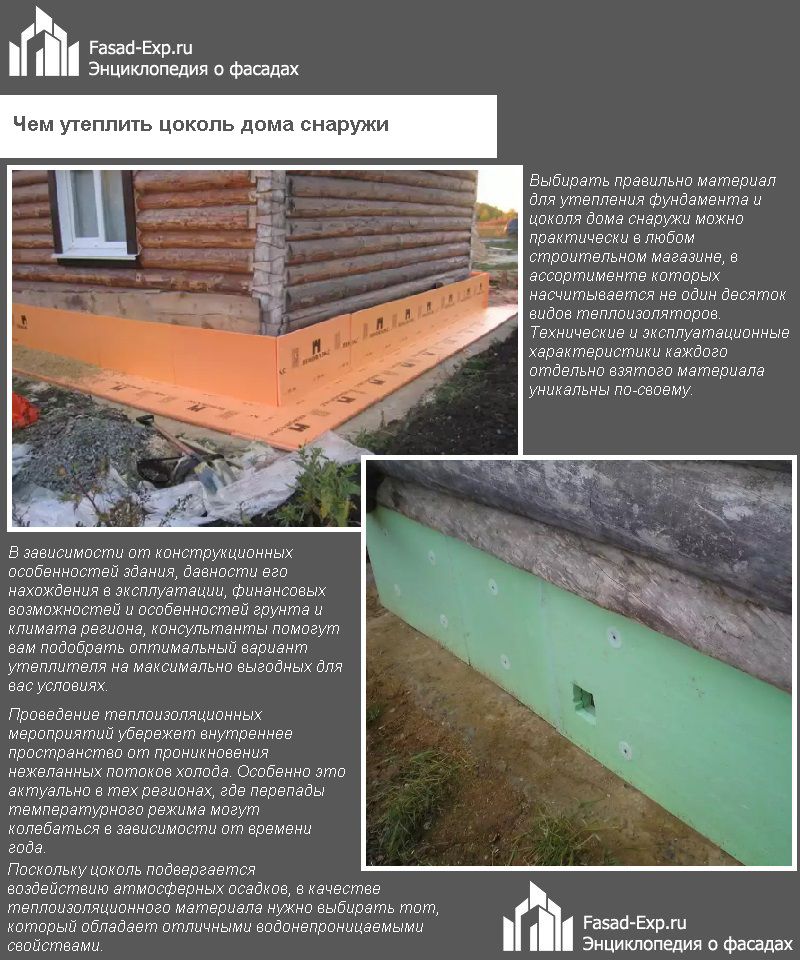

In this case, polystyrene, expanded polystyrene and polyurethane foam can be used as heat-insulating materials. The latter is applied in the same way as when insulating the foundation from the inside, only before spraying polyurethane foam, it will be necessary to carry out some preparatory work to expose the lower part of the base of the house.

Insulation of the foundation outside the house with polyurethane foam

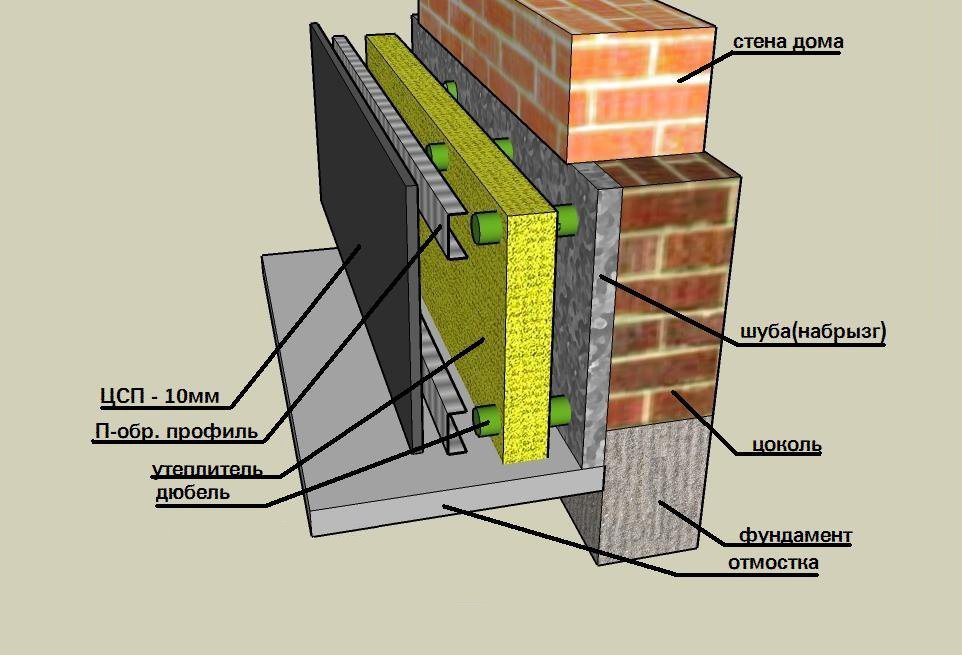

Operational method - insulation with expanded polystyrene

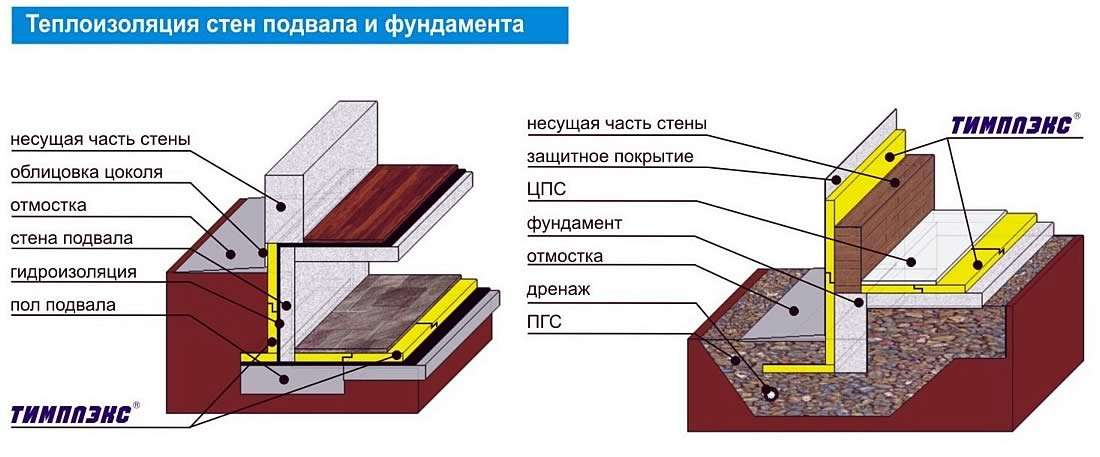

For insulation with polystyrene or expanded polystyrene, it will be necessary to free the entire foundation from the ground. To do this, a trench is dug around the perimeter of the house to the depth of the foundation, approximately 40-50 centimeters wide. Then the surface is carefully cleaned from the remnants of the earth and leveled (if necessary, of course). Waterproofing is applied to clean, dry walls, and then to a special adhesive composition or bituminous mastic insulation sheets are attached. The joints between them are filled with polyurethane foam (this technique will protect the foundation from moisture penetration).

Insulation of the foundation with expanded polystyrene outside the building

After all the work on gluing sheets of expanded polystyrene or polystyrene is completed, you can start backfilling the trench. A layer of sand (10 - 12 cm) is poured at its bottom, then you can put sheets of insulation (or you can not put it), after - a layer of gravel (60 - 70 cm), and then you can fill it with concrete, you can fill it with the same sand, but you can roll up the asphalt. If you are a creative person and love everything original and unusual, then you can decorate everything with stone or tiles.

The technology for performing thermal insulation using thermal insulation boards can be viewed in the video:

Providing thermal insulation with expanded clay

Another way to insulate the foundation from the outside is the use of expanded clay. True, this method is already partially disappearing into oblivion, since it is quite costly and ineffective, although our parents used it when building houses.

The process of thermal insulation with expanded clay is in many ways similar to foam insulation. We dig a trench at least 1 meter wide to the entire depth of the foundation. A waterproofing material is laid at the bottom of the trench, and expanded clay granules are poured on top. The layer should be thick enough, because expanded clay has very weak thermal insulation properties. Roofing material is laid on top of expanded clay and sand or earth is poured.

If you decide to save money on workers and carry out insulation of the foundation with your own hands, then you can use for these purposes not only modern materials, but also those that were used by our ancestors. True, there will be little sense from straw, peat, leaves or needles, because if these affordable, natural "heaters" really helped in the fight against cold and frost, would a person look for a replacement for them?

Warming the foundation, no matter what you are told, is necessary in any case, because the weather conditions in Russia are so unpredictable that even the forecasters themselves are not able to answer the question of what awaits us tomorrow. Even if you live in Sochi or the Krasnodar Territory, where the temperature is usually stable around zero, do not risk it, but take care of your home, otherwise it will be too late later.

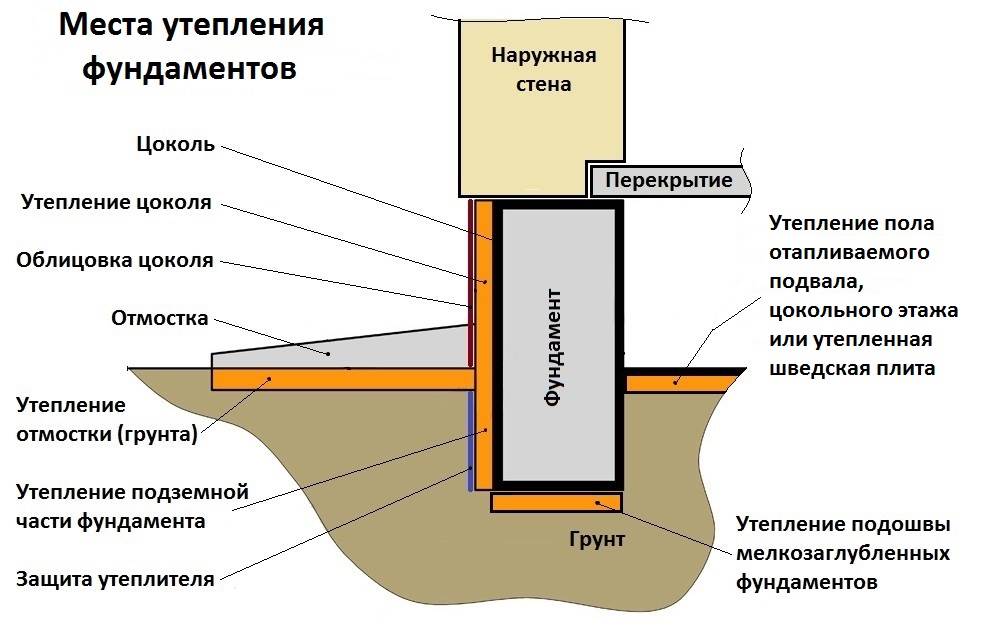

Exists several types of foundation insulation

:

- internal;

- combined.

The advantage is of course for combined insulation

... Only it guarantees complete isolation of the basement part of the house from freezing in the winter months, when, under the influence of frozen moisture, the soil swells, which can push the foundation blocks to the surface.

It is more convenient to do external insulation, given the freedom of access to the basement of the house.But in some cases, the only possible way to insulate the lower part of the structure is internal insulation.

Warming with expanded polystyrene plates

Consider the option of building a strip foundation with wooden formwork. Insulation work begins after the removal of the formwork.

Strip foundation. Photo. The work will be carried out after the dismantling of the formwork

Step 1. Check the linearity of the side of the foundation. In most cases, it will need to be leveled. Between the joints of the shields and the loosely knocked down boards, concrete seams will certainly appear, they need to be cut down. In addition, large bumps should be corrected, the dimensions of the bumps cannot exceed 0.5 cm per linear meter. Such irregularities allow the boards to bend without mechanical damage and are partially eliminated by changing the thickness of the adhesive. Large irregularities become the reason for a significant increase in material consumption, and it is quite expensive. Check the linearity of the surfaces with a flat rod or a rope stretched at the corners.

Step 2. Take measurements of the foundation and draw up an approximate plan for cutting materials. This is a very important operation, consider several options and choose the best one. The nesting plan will help you to significantly reduce the amount of irrecoverable waste, reduce the number of seams and speed up the work.

Take measurements

Step 3. Laying polystyrene foam boards.

Here it is already more difficult, it is very difficult to give general universal advice. The fact is that the slabs must adhere to the foundation over the entire area; air pockets must not be left. This is in the case of insulation of ceilings or walls, the glue can not be applied to the entire surface of the expanded polystyrene, it will hold on and so it will, and the finishing sheathing will protect it from mechanical damage.

During the insulation of the foundation, this method is ineffective. There are two ways to level the foundation surfaces: by additional plastering or by increasing the thickness of the glue. The first method is more laborious, but less expensive. The second method, on the contrary, requires less time, but more money to purchase expensive glue. Make a decision on the spot, taking into account both the condition of the foundation surfaces, and your professionalism and the thickness of the wallet.

Continuous glue application

Step 4. Lay the expanded polystyrene boards in rows according to the previously drawn cutting chart. Control their position with a long spirit level or a flat rod. The technology of gluing the plates itself should not create difficulties, these are not ceramic tiles, millimeter precision is not needed. Follow the recommendations of the manufacturer of the glue exactly, its consistency should not be too liquid or too thick.

Leveling the adhesive layer with a spatula

You need to press the plates only with your hands. In order to slightly correct their position, you need to make small rhythmic movements with the plate up / down or left / right. Plates should fit as tightly as possible to each other.

Press the stove with your hands

In most cases, the height of the underground part of the foundation is not the same, this is due to the peculiarities of the landscape. It is desirable that the visible upper sheets of insulation are even; it is recommended to align the first bottom row. To do this, before starting the work, beat off the horizontal line at the bottom edge of the foundation, cut each slab at the required angle. Thus, you will be able to bring the edge of the insulation through the row to a horizontal position.

Step 5. Glue the slabs around the entire perimeter of the foundation, check the adhesion strength.

Glue the slabs around the entire perimeter of the foundation

All wide joints between the boards must be sealed with polyurethane foam or construction foam. There will be seams, it is unlikely that you will be able to make the surface of the foundation absolutely flat. But this is not considered a marriage, construction foam has excellent performance.

Example of sealing joints with foam

Step 6

Carefully backfill the trench with pitch. If the soils are sandy loam on your site, you can not pour sand

If, for one reason or another, there are difficulties with the delivery of sand, this is not a problem. Take a metal mesh with a mesh size of about 1 ÷ 2 centimeters and sift through the available soil. Large stones will be removed, and the sifted earth will not damage the insulation.

Surface preparation

Primer application

Primer TechnoNIKOL

Waterproofing

Mastic for gluing boards

Expanded polystyrene for basement insulation

Fixed Styrofoam Plates

Geotextiles are fixed on top of the slabs

Drainage pipe laid and soil filled

An example of the effect of moisture on a foundation

High strength sealed board with PU foam

Polyurethane foam or polyurethane foam is a modern building material with many advantages. It is characterized by low thermal conductivity, strength, durability and environmental friendliness. It is easy to work with polyurethane foam - no additional fasteners are required for installation, its application to the surface is quick. PPU has high waterproofing properties that prevent moisture from entering, thereby protecting the building.

The main advantage of using polyurethane foam as insulation is the impossibility of spoiling the result - the final coating is always obtained without cracks, irregularities and joints.

How to work with polyurethane foam?

Warming of the foundation with polyurethane foam occurs by spraying insulation on the surface using special installations. The resulting foam is firmly connected to the base of the structure, filling all cavities. The result is a high-strength slab, very hard and tight. Since the material has a closed structure and there is no air gap, condensation cannot appear in such a product.

Thermal insulation of the foundation with polyurethane foam is the most effective method. It is suitable both for new buildings and for thermal protection of an old house. But the cost of such insulation is high and it is impossible to carry out the work on your own, since special equipment is required.

There are many options for waterproofing and insulation of the foundation, it remains only to choose which one is most suitable.

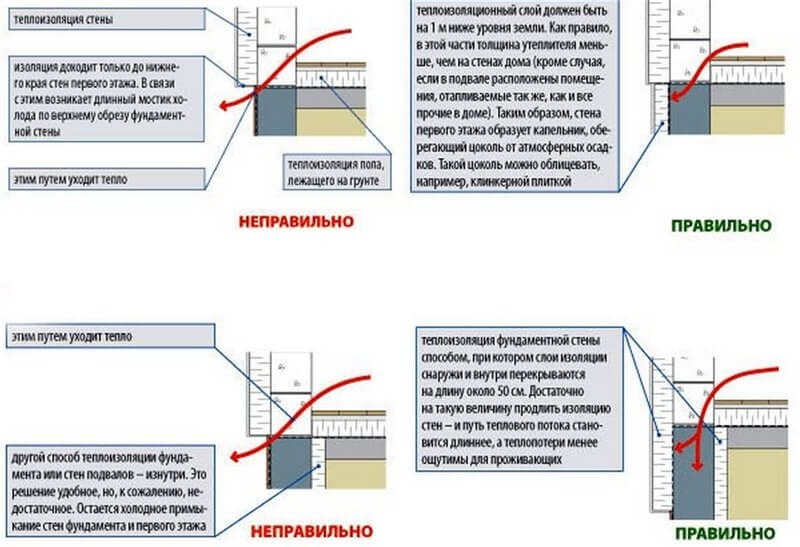

Is it possible to insulate from the inside

In the recommendations (albums of technical solutions) of the leading manufacturers of extruded polystyrene foam, there are options for buildings for seasonal residence, which are erected by their own hands, mainly in gardens. If the building does not have heating, the basement, together with the underground part of the MZLF, is pasted over with EPSP from the inside. Vertical insulation is connected to a horizontal layer of polystyrene foam under the floor along the ground.

Seasonal use (garden house)

The basement is pasted over with a heat insulator from the inside in the only case - if there is no heating in the dwelling. The thermal insulation scheme is as follows:

- expanded polystyrene is laid under the floors on the ground;

- fixed outside on the entire vertical surface of the MZLF;

- continues horizontally at the bottom of the trench along the perimeter of the dwelling (width 0.6 - 1.2 m).

Thermal insulation of MZLF during seasonal operation.

An additional layer in the corners is not needed, as is the launch on the upper edge of the base. Cold bridges are inevitable here, the walls are usually not insulated.

Periodic operation (summer residence)

When building a dwelling in which heating is switched on periodically (for example, a summer residence), a special insulation scheme is used:

- horizontal layer - under the floor along the ground in all rooms + under a blind area 60 - 120 cm wide from the walls of the building;

- vertical contour - basement + underground part of the MZLF outside to the insulation of the blind area.

From the inside, you do not need to glue polystyrene foam to the tape, since reinforced concrete freezes from the street. Unlike the warm blind area of houses with constant heating, there is no need to increase the thickness of the EPS in the corners.Occasional heat loss in this case can be ignored.

Frequent mistakes when insulating the foundation.

Thus, all options have been considered when do-it-yourself insulation is used from the outside and from the inside. This will help to reduce the construction budget without compromising the efficiency of the building's thermal circuit.

The maximum heat loss in any building is carried out through the ceiling and floor

It is for this reason that special attention should be paid to the issue of thermal insulation of the room. Before insulating the foundation of a wooden house, it is necessary to choose the correct insulating materials.

Why is additional thermal insulation needed?

Insulation of the foundation can be carried out from the outside and from the inside. In the first case, we can talk about preventing the penetration of cold air masses. In addition, do-it-yourself thermal insulation of the base of a wooden building excludes the possibility of freezing of the foundation. This increases the overall life of the building. Among the advantages of this procedure, the following points should also be noted:

- increase in the service life of elements of communication systems;

- savings on heating the house;

- protection from the influence of groundwater;

- prevention of condensation;

- the formation of a favorable indoor climate.

In order for the implemented thermal insulation layer to provide reliable protection, you must first select the most suitable insulation materials correctly.

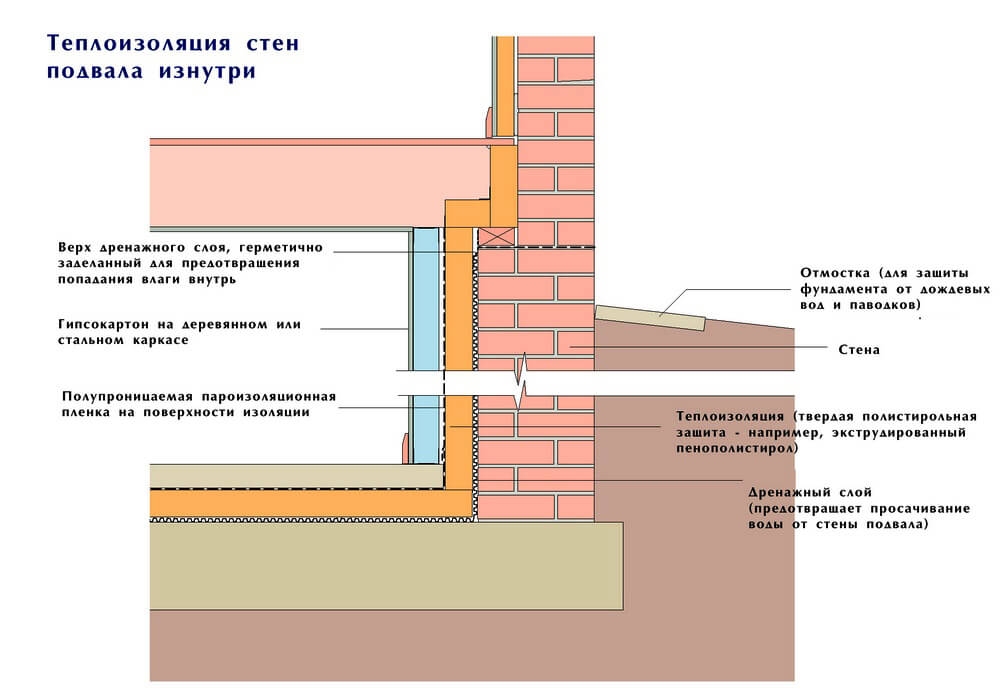

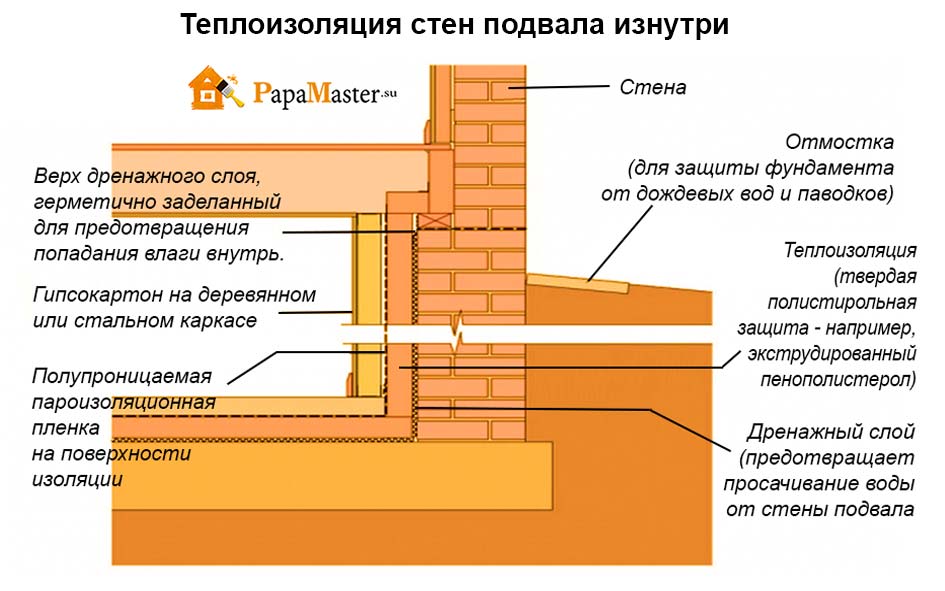

Choosing a way to insulate the foundation from the inside

When choosing a method, you need to focus on several factors:

- Building structure, basement or semi-basement dimensions;

- The presence of external insulation and temperature conditions on the outside of the foundation;

- Soil type and location of groundwater;

- The required temperature regime in the basement after insulation, the presence of heating and ventilation;

- The need for further decorative finishing.

A cheap method of internal thermal insulation of the foundation is filling the space under the floor with expanded clay. This material removes water and creates an air cushion that protects the floors of the ground floor from cooling. You can fill up both the entire space under the floor, and the formwork installed on the inside at some distance from the foundation walls.

If the basement is used to accommodate household premises, and its walls need not only insulation, but also finishing, it is advisable to use polystyrene or polystyrene foam boards, which allow you to create an even coating ready for cladding. The best quality and most durable in this case will be the insulation of the foundation, both outside and inside - by eliminating the temperature difference, you can avoid the formation of condensation on the inner walls of the basement. If insulation from the outside is not possible, it is necessary to perform penetrating waterproofing of the foundation: concrete treated in this way is not susceptible to freezing, but retains vapor permeability, reducing moisture under the insulation slabs. It is also necessary to arrange supply and exhaust ventilation, since these materials do not allow moisture to pass through.

If funds allow, you can choose thermal insulation with polyurethane foam - this method is effective and suitable for any basement.

How to organize the drainage of water from the basement?

Melt and rainwater over time lead to the destruction of the foundation. Often, even proper insulation cannot save in such a situation.

Therefore, it is important to organize the drainage of liquid from the base of the house. For this purpose, an open or closed drainage system is made.

The easiest way is to make an open drain on your own. It consists of ditches about 0.5 meters wide and 1 m deep, dug along the entire perimeter of the building. The walls of such a trench are mowed at an angle of 30 degrees for better water flow. The liquid from the pits must move to the drainage well.Therefore, the efficiency of such a system is much higher if the site has a slope.

Closed drainage has become the most popular in recent years. It consists of pipes that are dug into the ground outside the building around the perimeter. They are laid at an angle for self-drainage of water into a drainage well. Pipes must be wrapped with geotextiles.

Insulation materials

How can you insulate the foundation from the inside? We bring to your attention several types of materials and the procedure for their application.

Expanded clay

This option for insulating the strip foundation from the inside is considered the most affordable. With its help, a space is formed for the removal of moisture, the temperature of the floors is maintained. As a rule, they are filled with the formwork of the internal parts installed against the walls, and the space where the basement floor is supposed to be installed.

First, the base is prepared:

- surfaces are cleaned with a metal bristle brush;

- revealed cracks and other damages are repaired;

- the joining sections of walls and floors are treated with polyurethane foam;

- communication lines are being laid;

- a waterproofing layer is arranged;

- beacons are displayed;

- expanded clay is laid.

Minvata

As a material for insulation, it is allowed to use mineralized wool, represented by foamed fibrous mass.

The material is realized in rolls or mats, with a thickness of five centimeters, capable of creating a reliable heat-insulating layer for the inner walls of the basement.

Modern cotton wool contains special additives that allow it to be used for internal insulation of basements. The material can be easily cut into mats of the desired size, which are fixed on the walls of the recessed floor. After the completion of the insulation layer, finishing with plaster or putty solutions is mandatory.

Styrofoam

A polymer material with a fine-celled structure and low weight, with a high thermal insulation index. Easy to process, hydrophobic, resistant to organic formations.

Wall cladding from the inside is performed with slabs, the thickness of which varies from four to twelve centimeters. Foam plastic is fixed on heated bitumen, it is attached to monolithic vertical fences with special dowels.

It is best to fix the material with a cement-based adhesive. Glue is applied to the back side of the board with a trowel, the foam sheet is firmly pressed into the wall. The seam areas are filled with sealant so that cold air does not pass.

Expanded polystyrene

Insulation of the foundation from the inside is also carried out with expanded polystyrene, the thickness of the slabs of which is 5 - 10 cm.The algorithm of actions is as follows:

- the surface of the walls is pre-leveled, cracks and seams are sealed;

- waterproofing of foundation walls is carried out. If the structure is built on wet or heaving soil, penetrating waterproofing materials should be used;

- polystyrene foam boards are glued using a special composition, dotted on the surface of the insulation material;

- for tight packing, the sheets are provided with grooves that must be aligned. If the insulation is arranged in several layers, the sheets are arranged in a checkerboard pattern;

- as soon as the adhesive dries. The insulation is additionally fixed with dowels with wide caps. To do this, holes are drilled through expanded polystyrene so that the dowel goes into the concrete by five to six centimeters.

Polyurethane foam

The most effective and modern method is performed by spraying a foaming liquid composition supplied under a certain pressure. During the application, a layer of foam is created that can withstand the effects of a humid environment, which does not have joints and seams.

The material can be applied without preliminary preparation of the walls, the layer is applied quickly enough. Unfortunately, the cost of such a material is quite high, and the application process involves the work of a specialist and the appropriate equipment. True, over time, all costs will pay off due to the preservation of heat and excellent waterproofing.

It is allowed to apply any material intended for finishing work on such insulation.

Foundation insulation methods

The options for thermal insulation of the base are directly related to the type of material. Before laying them, it is worth considering the structure of the house: the presence of a basement, the number of floors, the intensity of the basement operation.

Backfill method

Inexpensive expanded clay is needed to insulate the foundation of a wooden house or a summer cottage. The work will be effective if you act step by step:

- Prepare lumber for building the frame and treat the wood with an antiseptic.

- Collect the formwork from the boards, repeating the contours of the basement.

- Make the slopes.

- Cover the soil surface with polyethylene to prevent water penetration into the expanded clay pebbles.

- Tamp the bulk material up to the upper level of the formwork.

- Close the space between the sub-floor logs with mineral wool.

The filling method will help to insulate the strip foundation with minimal financial costs and without special construction skills.

Laying polystyrene foam in the form of plates

Foam boards are durable, lightweight and inexpensive. Material 50 - 100 mm thick is used to fill voids in load-bearing structures. The thermal insulation process goes like this:

- Prepare the walls: sanding, removing irregularities, gaps, flaws.

- Waterproof the foundation.

- Using a brush, apply special dry glue around the perimeter of each sheet.

- Fix the slabs to the base in a checkerboard pattern. Styrofoam sheets have grooves that must be joined during masonry.

- Lubricate the joints between the plates with sealant.

- Fasten the laid sheets with dowels. For each unit of material, you will need from 4 to 6 dowels with a head with a diameter of 60 mm.

Laying the finishes and installing a reinforcing grid will increase the strength of the structure.

Heat insulator with reflective layer

It is used together with foam blocks. It helps to reduce the loss of thermal energy and reduce the level of condensation, therefore it is used to insulate the foundation of a wooden house. Sequence of work:

- The material is fixed with liquid nails on any surface with the reflective side inside the room.

- From above the wall is lined with foam.

- Cut with a hacksaw.

- The floor covering is lined with a heat insulator tape with a reflective layer and covered with expanded clay.

- Floor gypsum plasterboards are mounted.

The method of internal insulation takes square meters, therefore it is mainly used for rooms with a large area.

Polyurethane foam in cylinders

The universal agent is applied without preliminary surface treatment and is important for the insulation of the strip foundation. It is a foaming liquid with a dense structure that is not afraid of frost, precipitation, and high temperatures. After applying polyurethane foam for 2-3 days, the substance is in liquid form, filling every hole and gap. An easy-to-use product allows you to complete the work as soon as possible.

In comparison with the previous options, this one is the most costly. The high cost of the material is justified by its high operational properties.

The process of insulating the flowing foundation of the house from the inside, carried out with your own hands, seems complicated. But, if you are guided by a step-by-step instruction, difficulties should not arise in the process.

When choosing a material, you should pay attention to its coefficient of thermal conductivity, the higher it is, the more effective the thermal protection.To enhance the effect, you need to combine indoor and outdoor work.

So you can protect your home from temperature extremes, high humidity, increasing the service life.

vote

Article Rating

Insulation types

Internal insulation by materials is not so different from external insulation. As a rule, one of three basic materials is chosen.

Filling the basement with expanded clay is the cheapest and easiest of all solutions. With the help of such insulation, it will be possible to reduce the effect of cold on the flooring due to the air cushion created and to drain excess water. As a rule, the entire room under the floor is covered with expanded clay, so any other purpose of the basement becomes impossible. Alternatively, you can fill only the formwork specially installed on the inner side of the basement walls with expanded clay, but then the level of heat saving will greatly decrease. Expanded clay, in principle, cannot be called the most reliable insulation, therefore, in capital buildings it is almost never used, being limited to use in summer cottages and in summer houses.

Insulation installation methods

Penoplex is excellent for thermal insulation

Penoplex is excellent for thermal insulation

The technologies for carrying out internal work to insulate the base are similar to the external installation of heat-insulating sheets. The most common ways are:

- sprinkling with expanded clay - a lightweight porous material made by firing clay shale and clay (reduces the freezing rate of the floor of the first floors, but is an ineffective tool in houses of permanent residence);

- installation of thermal insulation boards made of polystyrene foam, polystyrene foam and polystyrene with finishing cladding (one of the most commonly used methods of installing thermal insulation, as a rule, used when jointly placing thermal insulation outside a building from a homogeneous material);

- spraying polyurethane foam (a fairly effective method of arranging thermal insulation, installed both as an additional and independent insulation, capable of creating a monolithic heat-insulating coating with high adhesion; the use of this method is implemented through the involvement of specialists with special equipment).

Reasons not to insulate the foundation from the inside

There are five good reasons why such construction work is impractical. They are presented like this:

- Freezing of the entire reinforced concrete structure of the building, even with the Izospan V. vapor barrier. In such a situation, the foundation is not protected by anything from unstable temperature jumps, which adversely affects its operational life;

- Due to the fact that the so-called "dew point" will shift to the "insulation-foundation" border, in the future it will be necessary to add an additional vapor barrier layer, which will hit the overall budget of insulation works;

- The implementation of the previous paragraph will lead to the violation of the microclimate in the basement, the humidity of the air will increase quite strongly. Therefore, in addition, it will be necessary to install effective ventilation, which will once again negatively affect the overall budget;

- Due to such a huge amount of additional equipment, the space inside the basement will be much smaller than the original one;

- In general, at the exit, the owner of the building will have huge financial costs for the construction work themselves and the acquisition of various materials, which the method of external thermal insulation is deprived of.

It is only necessary for the owner to decide whether or not to insulate the building foundation from the inside with Izospan AM, but all experts in the field of insulation definitely do not recommend this procedure.

Thus, it is much easier and more economical to make external thermal insulation.