The process of warming the foundation with polystyrene

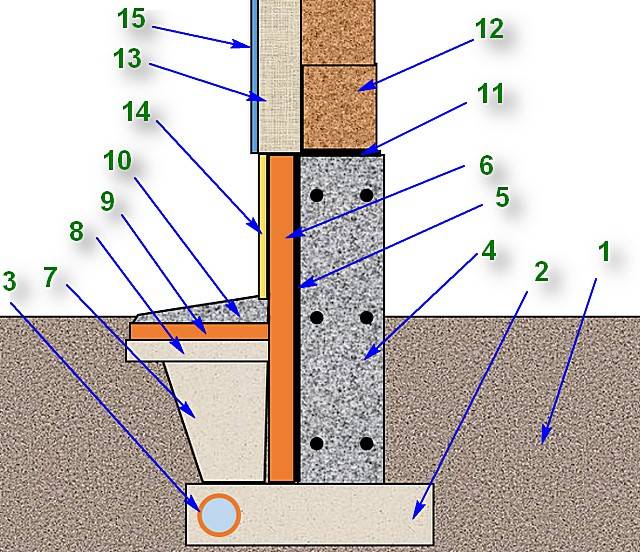

It is best to insulate the load-bearing structures of a building during the construction phase. However, if the house has already been built, then first you need to dig up the entire foundation and carefully carry out waterproofing work. Various bituminous materials can be used, which should be glued by heating to the outer parts of the foundation.

Waterproofing, in addition to eliminating problems with excessive moisture, together with polystyrene plates will give a good effect on warming the foundation.

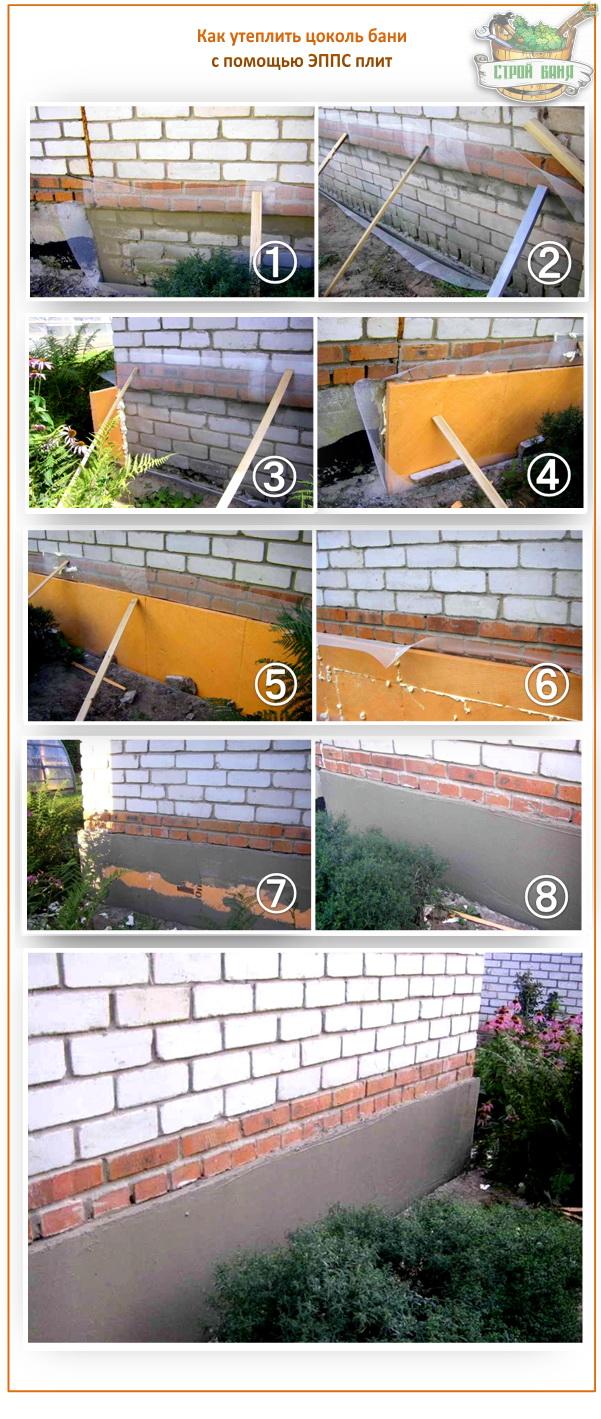

For insulation, it is advisable to invite workers of construction organizations, but if there is a desire, all the work can be done by hand. For this, slabs of material should be laid from the corner of the foundation in the direction from bottom to top.

Laying the slabs of material must be done strictly according to the level, so that in the future there are no discrepancies and large gaps.

If you do your own foundation insulation, extruded polystyrene foam is the best choice. This insulation is made from polystyrene granules, which are mixed at high pressure and a foaming additive is added. The material is obtained with a uniform structure consisting of small closed cells, in addition, it has excellent thermal conductivity characteristics.

It has special grooves around the perimeter for better fastening, and after the installation process, a monolithic single layer of insulation is obtained. This design of material slabs provides better thermal insulation and greatly simplifies installation work.

It is necessary to glue the insulation plates using a special melted  mastic, which is applied to the foundation, and then a polystyrene plate is tightly pressed against it.

mastic, which is applied to the foundation, and then a polystyrene plate is tightly pressed against it.

It must be remembered that the insulation boards must be glued without cracks and gaps.

If protruding ridges have formed at the joints, then they must be cut off with a knife, and the resulting space must be filled with polyurethane foam.

As the installation progresses, the lower slabs of the material should be covered with soil, which will provide a more tight pressing to the parts of the foundation and facilitate installation work.

If the material is located above the soil level, then the sheets of expanded polystyrene must be additionally fastened using special mounting dowels with a wide head. The dowels must be nailed in the center of the slabs and at the joints.

When these simple requirements and rules are fulfilled, the basement insulation with polystyrene will be of high quality and will extend the life of the supporting structure, and therefore the whole house.

Insulation outside and inside the foundation

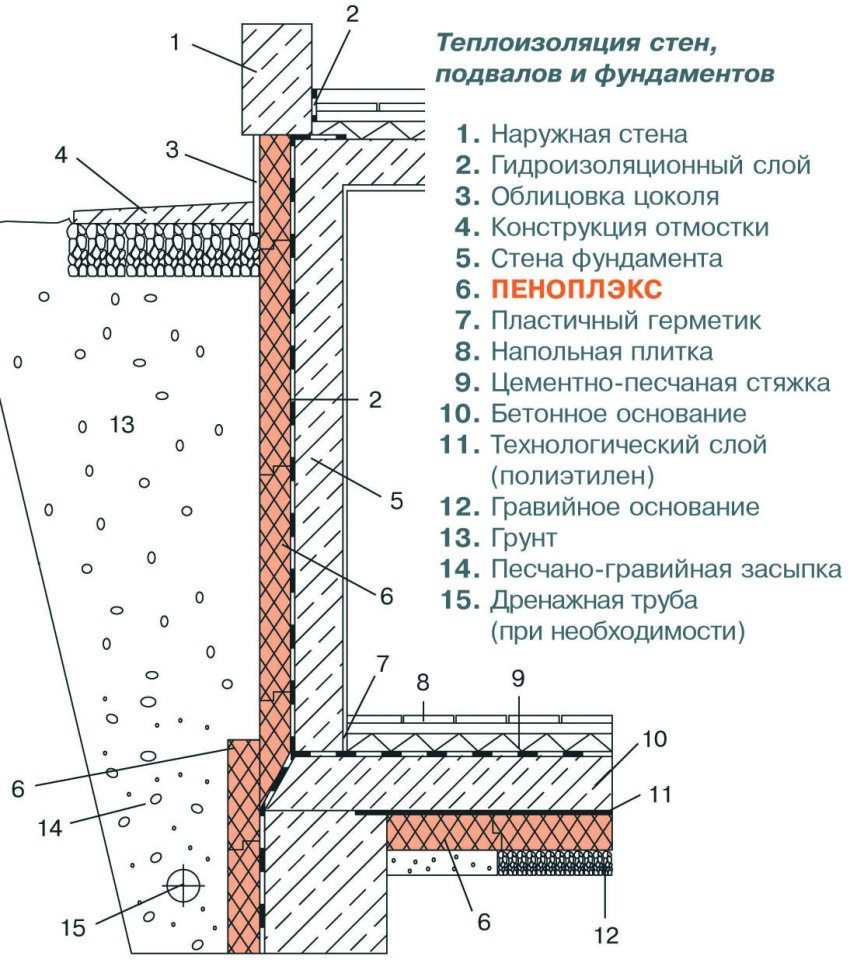

In most cases, the insulation is carried out outside the supporting structure, since this achieves the best thermal insulation effect. It is also necessary to take into account the presence of foundation drainage. In this case, it is necessary to use a special material that does not allow moisture to pass through - geotextile. It needs to be fastened with an overlap of up to fifteen centimeters.

In some cases, it is not possible to insulate the foundation from the outside, because these works are associated with a large volume of excavation.

Fastening plates with dowels

There are two ways to insulate the inner walls of the basement with polystyrene foam:

- gluing with a special heated mastic,

- using fasteners - dowels.

Many experts argue which is better - external or internal insulation of the foundation. Both methods allow high-quality thermal insulation of the supporting structure. When working inside, you can easily do the insulation of the foundation with polystyrene foam with your own hands.In this case, there is no need for time-consuming earthworks, there is no need to dig numerous trenches and holes, which will significantly reduce the time and resources of a private homeowner.

All work comes down to the usual insulation of the basement walls. This does not require the use of complex tools and knowledge. As a result, the necessary layer of expanded polystyrene will be obtained, which will insulate the supporting structure and create a favorable atmosphere in the basement. The use of heaters such as mineral wool in this case is not recommended, as it will absorb moisture over time, which will nullify efforts.

Installation of the blind area

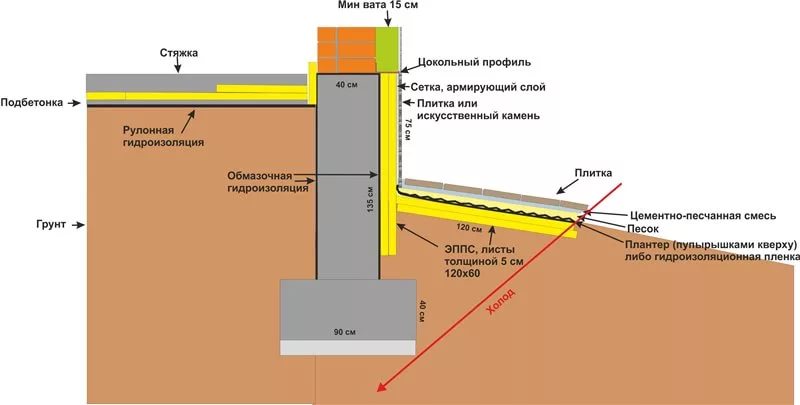

Insulation of the foundation cannot be considered complete without the final insulation of the basement and the arrangement of the blind area. The latter is a narrow path along the perimeter of the building, concreted or covered with asphalt. Its width varies depending on the roof overhang, the minimum is 600 mm. The sloping surface protects the foundation from rain and melt water flows

In addition, the blind area insulates the soil along the house, which is especially important for regions with a cold climate.

Insulation of the blind area

In frosty winters and clayey soil, prone to uneven freezing, for additional insulation, it is advisable to complete the construction of the blind area with plates of extruded polystyrene foam. The strength and elasticity of this material is consistent with the functions assigned to the blind area.

Work order

To install the blind area, first of all, fill the residual trench with sand with a layer of about 100 mm thick, compact it and cover it with roofing material. On top of the roofing material, a timber formwork is installed, into which the insulation is tightly packed. This is followed by a layer of waterproofing film (in this case, it is permissible to use polyethylene), a layer of fiberglass mesh and, finally, concrete or asphalt.

Why Styrofoam?

Expanded polystyrene board insulation is divided into two main types - EPS and foam. Polyfoam is made from the same raw materials as extruded insulation, but does not undergo pressure treatment, and therefore has less outstanding characteristics, but more attractive cost.

Extruded polystyrene foam is a popular and economical material for basement insulation

Speaking about the properties of various types of thermal insulation, it is important to understand that these materials have universal and specific characteristics (from the point of view of application specifically for foundations). Consider the parameters of expanded polystyrene insulation, simultaneously clarifying their differences for EPS and foam

Universal:

- Thermal conductivity. The lower this indicator, the higher the heat-insulating properties of the material. For EPS and foams, thermal conductivity is in the range of 0.029 - 0.034 W / (m * K). At the same density, the energy efficiency of EPS is higher than that of foam. There is only one type of building insulation with less thermal conductivity than polystyrene foam - this is polyurethane foam (PPU), which is applied by spray.

- Combustion resistance (fire hazard class). Styrofoam is a combustible material. Depending on the use of fire-fighting additives (fire retardants), EPSP boards have a class G3 - G4. Foam plastics can be less fire hazardous (up to G1 for PSB-S slabs). Perhaps this is their only superiority over extruded insulation. In terms of combustion resistance, polystyrene foam insulation is inferior to mineral wool.

Specific:

Strength test of expanded polystyrene

- Compressive strength. Reaches 400 kPa or more for extruded boards. The strongest grade of polystyrene PSB-S-50 has an indicator of 160 - 250 kPa.

- Frost resistance. All polystyrene foam retains its properties in the temperature range from -70 ° C to + 70 ° C.

- Hygroscopicity.EPPS practically does not absorb moisture in direct contact (no more than 0.02%). The indicators of foam plastics are much worse - up to 2% and higher. Although, even they are much more hygroscopic than mineral wool.

- Biostability. EPPS is not subject to biological types of destruction. Foams can be destroyed by rodents. On their unprotected surfaces, under favorable conditions, colonies of algae, mold, and other fungi and bacteria are formed.

- Life time. Manufacturers declare 40, 50, 60 and even 80 years of operation of extruded polystyrene foam without loss of insulating properties. For foams, the resource largely depends on the humidity of the environment.

Being one of the most effective heat insulators, EPPS is ideal for insulating foundations, primarily due to its unique strength and high hygroscopicity. The strength allows it to work in compression, withstanding concrete foundations of small thickness. Hygroscopicity is important, since we are dealing with external insulation and direct contact with the ground.

Insulation laying works

When the preparation of the base is completed, they begin the insulation work on laying the plates.

Adhere to the following technology:

- Fastening of expanded polystyrene to the foundation is carried out using adhesive mixtures that do not contain organic solvents. The glue is applied in several places pointwise to the slab, then tightly applied to the waterproofing material and pressed, keeping the slab in this state for the time specified in the instructions for the adhesive mixture.

- Laying work begins from the bottom of the foundation from the corner, laying in levels. The first and subsequent layers should be staggered. After completing the work, foam all joints with polyurethane foam or putty with an adhesive mixture.

- Insulation of the foundation from the outside with expanded polystyrene requires laying an additional layer at the corners of the building with a length of at least 1 m from the corner in both directions.

- It is required to strengthen and protect polystyrene foam from possible mechanical damage. For these purposes, a reinforcing mesh or wooden shields are used, which are fastened with dowels.

- The process is completed with the laying of drainage material, through which a perforated pipe is drawn, brought into a well to drain water. Fill the trench with sand and soil.

Staggered laying of expanded polystyrene sheets on the waterproofing layer

Staggered laying of expanded polystyrene sheets on the waterproofing layer

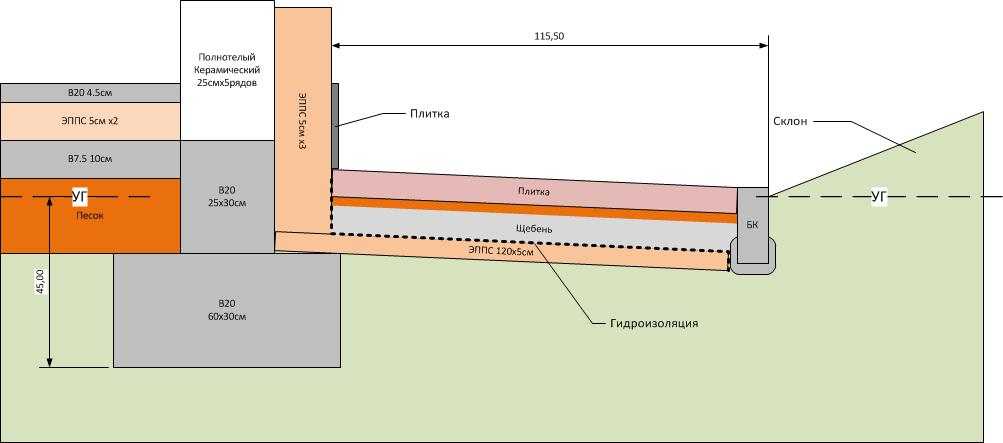

More often during construction, a strip foundation is erected. It is a monolithic reinforced concrete structure. Insulation of the strip foundation expanded polystyrene is carried out in the above described way.

Extruded polystyrene foam

The more advanced insulating material on the market is extruded polystyrene foam. In terms of chemical composition, it is not much different from expanded polystyrene. The fundamental difference is in the manufacturing technology. Unlike foam, which consists of granules, extruded polystyrene foam turns into a homogeneous viscous mass when melted.

It is preferable to use extruded polystyrene foam for the foundation due to the fact that it is more durable, practically impervious to water and its warranty period is up to 50 years. It finds its application in insulating buildings that have a deeply grounded foundation, if the groundwater at a construction site passes too high to the surface.

Extruded polystyrene foam sheet

Extruded polystyrene foam sheet

Unlike conventional expanded polystyrene, this type of material does not deteriorate from water. In ordinary foam, moisture trapped between the balls of the structure freezes under the influence of low temperatures and increases the space between the capsules.

The joints between the balls become fragile and break easily. The integrity of the insulating layer suffers and the building's protection against cold is gradually deteriorating.

Cold bridge

The thermal cold bridge is a structural element of a building with low thermal resistance.

The thermal cold bridge is a structural element of a building with low thermal resistance.

Masonry elements and monolithic structures are conductors of cold to the building, as they contain concrete, mortar and metal in their composition. These materials are cooled much faster than others, and through them, like bridges, heat leaves the building. The more such bridges are in direct contact with the external environment, the lower the thermal efficiency of the building.

The lower the energy efficiency of the structure, the more energy consumption will be. Heating costs will rise. At the same time, cold bridges contribute to the formation and accumulation of water condensation. This affects the appearance of mold and various fungi. Condensation also gradually leads to corrosion and destruction of building elements.

Foundation insulation technology

The technology of insulating the walls of the foundation with expanded polystyrene is not too complicated, but it can still be divided into several stages.

- preparatory work

The first step is to prepare the foundation for subsequent insulation. For this you need:

- Dig out the foundation around the entire perimeter, that is, make a trench around it about 1 m wide and with a depth that corresponds to the depth of the foundation.

- Further, the surface of the foundation is cleaned of all dirt and earth, substandard concrete, and, if necessary, level the surface with cement mortar so that there are no large protrusions and pits in it. If there was a need to make cosmetic repairs to the foundation, it must be allowed time to dry, after which you can proceed to the next stage.

- The thickness of the insulation should be about 10 cm, however, for a more accurate determination, it is necessary to carry out appropriate calculations, depending on weather conditions. As a rule, to achieve the required thickness of the insulation, polystyrene foam is laid in several layers.

- If the site has an elevated level of groundwater, or there is a well, it is necessary to make drainage. To do this, a layer of sand is placed on the bottom of the trench, on top of which a layer of geotextile is laid. Next, a layer of gravel and a perforated pipe filled with gravel are laid, which is additionally wrapped with geotextiles. A layer of sand is poured over the gravel and pipes. The pipe must be taken to a drainage well or to the nearest collector.

- Further, the surface of the foundation must be waterproofed using various materials. Self-adhesive insulation is most often used, which is well ironed with a roller.

Having done all the necessary manipulations, you can proceed to fixing the expanded polystyrene sheets.

- fastening of sheets

Fastening of expanded polystyrene sheets should be carried out according to the following rules:

- Sheets of material are fixed on the surface of the foundation using special adhesives, while it is highly discouraged to use organic solvents, dowels or hot fixing. This can damage both the thermal insulation and the waterproofing.

- It is necessary to apply the adhesive composition to the sheets of material pointwise, that is, in the corners and in several places in the center of the sheet. After applying the glue, the sheet must be well pressed against the foundation surface and held in this position for a while. As a rule, the instructions for the adhesive composition indicate the retention time of the board.

- It is recommended to start gluing the sheets, starting from any lower corner of the foundation, gradually passing along the base, and then moving to the next row in a checkerboard pattern.

- All gaps that arise between the plates of the material must be carefully foamed or filled with glue.

- When the first row of insulation is laid, it can be covered with half of the soil, which will simplify further work.

- The corners of the foundation must be insulated with an additional layer of slabs, since they are the weakest point.

- It is necessary to insulate the basement of the foundation in exactly the same way as the rest of the part, the only thing is that special disc dowels can be used to fix it. As a rule, 3-5 umbrellas will be enough to secure one plate.

- plastering and backfilling of the foundation

At the end of the work, the insulation must be completely plastered with glue for finishing work. In addition, to give greater strength, they additionally use a reinforcing mesh for external work, which is embedded in the applied plaster.

The part of the foundation, which is below the ground level, is poured back. It is also recommended to perform a blind area. This will give more protection to the foundation from the effects of climatic conditions.

In conclusion, I would like to say that observing fairly simple rules for warming the foundation, you can achieve high-quality thermal insulation of the foundation, which, in turn, will reduce the cost of heating the premises in the winter. In addition, expanded polystyrene is a durable, durable and affordable material that will significantly increase the service life of both the foundation and the house as a whole. Therefore, the question of how and why to insulate the foundation with expanded polystyrene is fully disclosed.

Extruded polystyrene foam for self-insulation of the foundation

Thermal insulation of the basement of the old building with expanded polystyrene

It is possible to insulate the foundation with extruded polystyrene foam even for those who do it for the first time.

- A trench is being pulled out.

- At its bottom, clean sand of medium grain size is poured into a layer of 15 cm. The sand embankment is made at a slight slope (about 5 °) in order to avoid the accumulation of water in the trench. With soils saturated with groundwater, drainage should be performed to remove them from the foundation. For this, crushed stone of the middle fraction is used, it is poured to the bottom. A geotextile sheet is laid on top. On top of the canvas is a perforated pipe, into which water will collect through the material.

- The outflow of water is carried out, the ditch is dried.

- The foundation must be prepared before insulation. To knock off all growths, adhered earth. Remove peeling layers. Align the surface so that no air pockets form between the insulation plates and the foundation wall.

- For better adhesion, prime the treatment site with a deep penetration compound or special mastic.

- You need to start warming the foundation with your own hands from the bottom corner of the base. This is where the first sheet of extruded polystyrene foam is attached. Further work is carried out, going up.

- For a firm hold, you need a good adhesive solution, such as Knauf or Polimin, for example. It is prepared according to the instructions and applied with point touches, either around the entire perimeter of the slab, or over its entire area, spreading with a spatula. Instead of a solution, Ceresit adhesive foam or another is also used.

- In cold climatic zones, a thicker layer of insulation can be formed by gluing 2 layers of polystyrene foam. The seams of the bottom and top layers must not match.

- Provides protection of sheets from rodents and accidental damage by a fine-mesh reinforcing mesh stretched over the slabs. It can be made of metal or polymers.

- Backfilling of the trench is carried out after expanded clay previously poured onto its bottom. This will create a drainage outlet for water and provide additional insulation.

You can strengthen the thermal insulation material with special fasteners.

Fastening technology

To insulate a shallow strip base, the insulation sheets are fastened to a special glue. It should not contain organic solvents. The layer of bitumen mastic applied for waterproofing must cool down before installing the expanded polystyrene. The adhesive composition is applied pointwise to the plate, 7-8 strokes are required in the corners and in the middle.Having pressed the material to the wall with your own hands, you need to hold it for some time to fix the glue.

Laying insulation outside starts from the corner of the house. To avoid distortions, the correct installation is checked by the building level. Each next row of plates is fixed with an offset of half the sheet. Ease of installation is facilitated by the locking system of the tongue-and-groove material. The gaps remaining between the plates are blown out with polyurethane foam. Even if the thermal insulation technology does not require laying the EPSP in two layers, it is better to perform double protection at the corners, taking out 1 meter in each direction.

The fixing of extruded polystyrene foam requires only an adhesive composition. It is strictly forbidden to hammer in plastic dowels in the underground part, as it will break the tightness of the waterproofing coating. When insulating the basement floor, disc dowels are hammered in 5 pieces for each plate. To mount the fasteners in the slabs and the wall of the house, holes are drilled into which plastic dowels are hammered. They start work 3 days after gluing, when the composition is dry. The base / plinth is finished with cladding material.

Some nuances

When insulating a basement with expanded polystyrene or foam with your own hands, you should take into account a whole series of facts, non-observance of which can lead to improper operation of the structure or its destruction. The main requirement is that when choosing thermal insulation, it is recommended to consult with specialists and determine the exact thickness of the slabs required for a particular region in which the property is located. For more information about insulating the basement and blind area with extruded polystyrene foam, see this video:

In addition, there are a number of important details. Some of them are presented below:

- Insulation plates located above the ground level must be additionally fixed with disc dowels.

- When installing the drainage system, be sure to tilt towards the storage wells, where moisture will drain through the pipeline.

- When insulating the corners of the foundation, it is recommended to apply a double layer of thermal insulation, since these elements are considered the most susceptible to freezing.

- Extruded polystyrene foam and foam must not be glued to a compound containing acetone, ethyl acetate, toluene and white spirit.

- The work process must be carried out at a positive ambient temperature.

- Insulation of a high foundation is carried out with a staggered arrangement of thermal insulation. The seams should not be overlapped. The use of a double layer is not recommended by professionals, explaining this by the fact that when the soil pressure as a result of its heaving, the layers can unstick and destroy the integrity of the structure. If you do use this option, make sure that the seams do not overlap with each other. This will help to avoid the formation of cold bridges.

The main mistake of home owners is the desire to insulate the walls of the building, not its foot. At the same time, not many are interested in the thermal insulation of the foundation. Therefore, this leads to significant heat loss and a decrease in the service life of the base and the entire structure.

Perimeter insulation

With the arrival of heat, cracks or distortions often appear in the walls of the basements of buildings. This is due to the deformation arising from the heaving of the soil in the cold season.

How to avoid soil swelling?

Each type of soil is subject to heaving in its own way. Clays and loams are particularly affected by this process. Initially, the soil actively absorbs water. When winter comes, moisture freezes, the volume of the soil increases. Swelling appears, sometimes capable of pushing out the foundation. With the onset of spring, the frozen water melts, the base of the house sags. The walls of the basement are warped and cracks are formed.

To reduce frost heaving make a sand pillow under the foundation... The thickness of the sand is at least 10 cm. Backfilling is also based on sand, which is sometimes called non-porous soil. But these measures do not finally solve the problem. Only the complete elimination of soil freezing helps to get rid of the pushing out of the foundation, followed by subsidence. To do this, you can perform insulation with extruded polystyrene foam around the entire perimeter.

Perimeter insulation technique

Work begins with digging a perimeter cut outside the building, the depth of which is 40–50 cm. A 20 cm thick layer of sand is poured into it. Then it is compacted with a slight slope, starting from the base of the supporting structure. Foam plates are placed on the sand. Since soils in our country freeze by 1.5–2 meters, products should have the same width.

In the corner zones, the width of the insulation is one and a half times greater, because heat is lost more strongly than on flat surfaces. From above, the materials are covered with a layer of sand 30 cm thick.

Warming the foundation with foam solves several problems at once. It prevents the ground from freezing. As a result, heaving soil loses its buoyancy force. The supporting structure remains intact, the basements keep warm.

The sequence of work on the insulation of the foundation of the house outside

Insulating the foundation of a house outside with expanded polystyrene requires some experience and special knowledge, since this is the only way to properly fix the plates and ensure the durability of the structure.

The sequence of work in this case is the same as during the use of foam, but there are still some features of insulation. First, you need to dig a trench and create a cushion for the slabs, preferably around the entire perimeter.

In this case, it is important to ensure that the angle of laying of the flooring is at least 50 degrees, which will avoid the accumulation of water at the foot of the slab. In those areas where the soil moisture level is increased, you should think about additional drainage of the foundation of the house .. This is the only way you will be able to insulate it with high quality and reliable, having achieved your goals

Crushed stone with an additional layer of geotextile and perforated pipes can be used as drainage. Thanks to this scheme, water will enter the pipes without leading to clogging.

Only in this way will you be able to insulate it efficiently and reliably, having achieved your goals. Crushed stone with an additional layer of geotextile and perforated pipes can be used as drainage. Thanks to this scheme, water will enter the pipes without leading to clogging.

The following stages of insulation:

- Dry the surface for a few days.

- Foundation preparation. Level the surfaces to insulate the house with high quality and glue the plates securely. Leveling is not a mandatory procedure, but it can help reduce the consumption of adhesive mixtures and prevent the formation of an air gap between the wall and expanded polystyrene.

- Treatment of the surface of the foundation of the house before the start of insulation involves the application of a layer of mastic or a primer. This is necessary so that the expanded polystyrene plate is reliably attached to the adhesive mixture applied to the thickness of the foundation of the house.

- Glue the slabs to the foundation to insulate your home with high quality and minimize the level of heat loss.

Do-it-yourself foundation insulation

To insulate the base with foam or extruded polystyrene foam, no special knowledge and skills are required. It is quite possible for an ordinary person to complete all the work. To do this, it is enough to be able to use a hand tool and have it on hand.

To insulate the base with foam or extruded polystyrene foam, no special knowledge and skills are required. It is quite possible for an ordinary person to complete all the work. To do this, it is enough to be able to use a hand tool and have it on hand.

Another recommendation is that it is not recommended to save on consumables.You should first prepare everything you need: both tools and consumables, only after that start working. To carry out the installation of insulation on the basement of the house, you will need the following:

- insulation plates;

- reinforced mesh;

- molten bitumen;

- glue for fixing insulation;

- hammer drill or hammer drill;

- drainage pipes.

Installation of thermal insulation

As mentioned earlier, it is not so difficult to make a protective facade that insulates the foundation. For more information on insulating the basement, see this video:

The whole process can be conditionally divided into several stages:

- trench preparation;

- checking the integrity of the base and its repair;

- waterproofing;

- insulation;

- drainage system installation.

Before insulating the basement, dig a trench around the perimeter

Before insulating the basement, dig a trench around the perimeter

Having prepared everything you need, you need to dig a trench. In depth, it should reach the lower level of the foundation, and in width, it should allow free movement of a person.

A ditch is being dug along the entire perimeter of the walls. It is not recommended to throw the earth far away, since in the future it will need to be covered back.

- The excavated foundation is cleaned of the soil adhering to it and inspected for damage. If there are any, you need to seal them up with cement mortar, but first clean all the delaminations with a metal brush with high quality.

- Further, the surface of the foundation is primed, and after complete drying of the solution, it is treated with bitumen mastic. It will act as the first layer of waterproofing.

- Roofing material is glued to the mastic. In this case, the overlap of adjacent strips on top of each other should be at least 10 cm. It is not recommended to glue the entire surface of the foundation at the same time. It is better to choose small areas for this. While you fumble on one side, the mastic on the other will dry out.

- The insulation is attached to the base of the house using a special glue, instructions for the use of which are printed on the packaging. The joints between the plates can be treated with mastic or foamed with polyurethane foam, then sealed with reinforcing tape.

- It is recommended to install the first row of thermal insulation on a rigid base, and best of all on a foundation ledge (if any). This will avoid possible shifts of the entire structure under the influence of soil heaving processes. If it is not possible to fulfill this requirement, you need to make a sand pillow under it with a thickness of at least 5 cm.

- Having finished fixing the insulation boards to the foundation and making sure that the glue is dry, it is recommended to plaster the surface using cement mortar and reinforcing mesh. This will increase the external strength of the erected structure.

- Having finished with the insulation of the foundation, we proceed to the installation of the drainage system. To do this, a cushion of sand mixed with gravel is poured into the dug trench. Geotextiles and pipelines are laid on it.

- After all the work has been completed, fill up the trench and make a blind area at least 80 cm wide.