Floating foundation

Such a foundation can be laid for any home in any conditions, but it is especially in demand on moving soils that are prone to swelling. The technology involves the creation of a concrete base without burying it into the soil. Thanks to this, the foundation can move, carrying the entire structure, and after a decrease in mobility, return to its original position. This type of classification includes:

-

Swedish plate.

-

Monolithic slab.

-

Strip foundation.

-

Columnar foundation.

The Swedish slab is a structure of several layers, including a sand cushion, a waterproofing coating, thermal insulating polystyrene foam and a concrete reinforced block itself. Thanks to this multi-layer "cake", the ground floor retains heat and does not accumulate condensation inside the foundation.

Laying the Swedish slab does not require much time, and its flat surface makes it easier to install the floor. However, a monolithic movable foundation cannot be made on soft soils. This type increases financial costs due to the large amount of heat and waterproofing materials and complicates the repair of engineering communications.

A monolithic slab “afloat” does not have hydro and thermal insulation. This significantly reduces its cost, reduces the time and labor costs during installation. Before pouring, only a gravel-sand cushion is poured, and additional stiffeners are installed under the load-bearing walls. The concrete layer is calculated individually for each building. More detailed instructions for creating a floating monolithic slab are presented in the video:

When building one-story light houses made of wood, foam concrete, lightweight bricks, a movable strip type of foundation is allowed. There is a sand or sand and gravel layer under the concrete belt. It is she who creates the buoyancy effect. Such a base can be insulated by laying polystyrene tiles on the sides of the tape.

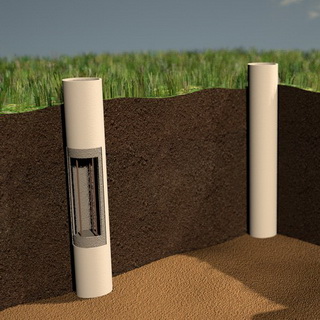

If the building is planned to be built on sandy or rocky areas, then a columnar floating foundation is the best choice. It is united with the previous types by the presence of a gravel cushion and a waterproofing layer. If the pillars are monolithic, then they are reinforced with a reinforcing skeleton. The optimal distance at which the supports are placed is 2.5 meters or slightly less.

A floating foundation has several advantages over other types. First, it does not require geological research. Secondly, it allows construction on complex semi-movable substrates. Thirdly, it creates a safe environment for the house with vibrations and ground movements. The disadvantages include the financial costs of materials and work.

Knowing what types of foundations are, what are the requirements for their construction, you can avoid mistakes in design and construction. Correct consideration of climatic and geological conditions, accurate calculation of the building load allow you to choose the appropriate type of foundation for the house and ensure a long period of trouble-free operation.

Slab (floating) foundation technology

This type of foundation is a kind of monolithic foundation, the base of which can also act as the floor of the future structure. Foundations of this type are also very costly, therefore they are used mainly for small houses in private construction. The slab foundation has all the positive properties of a monolithic base.

The order of work

Slab foundation device.

Foundations of this type are installed, as a rule, on heaving, sandy and weak soils, where the water table is high. If the foundation is laid to a depth less than the depth of freezing of the soil, this type is called. When constructing such a foundation, from 20 to 50 cm of soil is removed from the base. A layer of gravel or crushed stone up to 10 cm high is poured onto a well-leveled bottom. The layer is carefully rammed, after which a layer of sand is poured, which will wedge the crushed stone and exclude its further movement. The sand is highly frost-resistant, which will prevent crushing of the finished foundation.

A layer of waterproofing is placed on top of a carefully tamped pillow to prevent moisture loss from the foundation. Plastic wrap or any other similar material can be used. This will help prevent moisture from entering the finished substrate.

Then proceed to the installation of the formwork. If the foundation is immersed in the ground, the walls of the pit can play the role of formwork, but if it is outside, you cannot do without it. It is better to secure the formwork as carefully as possible.

Planks with a thickness of 20-25 mm are taken and shields are made from them, the width of each of which is 0.5-1 m higher than the planned base structure for foundations. After being attached to the pit walls, the shields are sealed with paper, cardboard or tar paper.

A frame made of reinforcement is installed on the waterproofing.

The foundation is made of deep sleepers.

Since the structure of this foundation experiences bending loads, the requirements for the reinforcement cage are serious. The armature is used only with a variable cross-section with a diameter of at least 12-16 mm.

The reinforcement is tied into a frame with a wire. It is strongly not recommended to use the welding machine in this situation. When welding, metal changes its qualities, becomes brittle and is more susceptible to corrosion. The reinforcement cage consists of upper and lower meshes, rigidly connected to each other, with a distance between the rods of 20-40 cm. The consumption of reinforcement for this type of foundation is higher in comparison with the others.

The slab foundation can be either smooth or ribbed. Stiffeners are provided at the bottom of the slab, buried in the ground. This prevents the structure from moving in the vertical direction.

Foundation layout.

Concreting is carried out in layers of no more than 15 cm, each of the layers is carefully leveled and rammed with bayonet. Pouring the entire slab should not take more than an hour. The concrete is rammed until a wet shine appears on its surface. The top layer is then leveled with a wooden strip.

On the first day after pouring, the base is moistened with water every 4-5 hours or covered with polyethylene. If not taken care of, the stove will most likely crack. On the third day, it is enough to moisten 3 times, on the third - in the morning and in the evening. The formwork can be removed after drying, but complete solidification will occur only after a month.

To resist frost heaving, soil insulation is installed around the foundation. In this case, the insulation is laid along the perimeter of the house around the foundation by 1-1.5 m, the outer part of the foundation must also be insulated. Most often, expanded polystyrene, foam glass or foam is used for these purposes.

Types of foundations

There are several types of foundations and foundations for a home with basements. Consider how to make a foundation with a basement, decide on the choice of the most suitable options.

Tape

A strip foundation for a house with a basement is the best option. Allows you to evenly distribute the load from the building. It is a tape of concrete 450-700 mm wide, the depth depends on the height of the basement. Before construction, we study the geological properties of the site.

Dig a trench under the base to a depth of 200 mm below the freezing point of the soil. If there is weak soil, the pit is dug in the form of a trapezoid, taking into account the angle of the soil shear.

- the best option for economic indicators for housing construction with a basement;

- the vertical parts of the foundation serve as the walls of the basement;

- the ability to do work with your own hands;

- the service life is 50-70 years with an accurate calculation of all influencing factors. But for this it is imperative to study the properties of the soil on the site.

Deeply buried slab base

A slab foundation for a building with a basement is suitable if it is laid to a depth equal to the height of the basement walls.

We arrange a monolithic slab foundation:

- on wetlands of soil, peat bogs;

- at a great depth of freezing;

- in areas prone to earthquakes;

- at a high level of location of underground sources;

- on unstable soil prone to heaving.

This type of foundations is called floating due to the fact that when the ground vibrates, vibrations diverge along the surface of the slab, protecting the building from cracking and uneven shrinkage.

The presented foundation consists of a reinforced concrete structure and is located under the entire area of the house.

- one of the most reliable types due to the large support area;

- service life 150 years;

- at the same time serves as a basement floor.

Block base

A foundation is being erected from ready-made reinforced concrete blocks that will serve as the basement walls. Difficulties arise with the laying of concrete elements at the level and with the density of joining to each other.

Fill the joints of the blocks with high-quality concrete mortar.

Do-it-yourself installation is impossible due to the large weight of the blocks. They are installed with a crane, which increases the cost of construction work.

If you do not close the seams at the joints with waterproofing material, they will quickly become unusable.

Waterproofing device

The monolithic base has pores that act as capillaries in the presence of even low humidity. An unprotected base in this case will absorb moisture, which will lead to negative consequences:

- decrease in strength;

- moisture will crystallize in the pores, which will lead to an increase in its volume;

- there will be dampness in the building, mold.

If you do not first waterproof the base, over time it will become unusable, which will affect the general condition of the building. In modern construction, different methods of protection are used:

- the coating is characterized by high efficiency, simple arrangement and provision of high-quality protection from moisture. A mastic or a specially designed emulsion is applied to the foundation. It is necessary to take into account the manufacturer's recommendations for application, the composition can be used in normal or in a heated state;

- modern and quite effective waterproofing option - penetrating, provides a high depth of penetration into concrete. The mixture crystallizes in the pores, making it difficult to get moisture inside;

- the roll method is the most popular. In this case, moisture-resistant materials in rolls are used.

A decision is made on the choice of one or another waterproofing option, taking into account the location of the aquifers, the amount of precipitation in a particular area, the presence of drainage systems near the structure, the design features of the base and the customer's financial capabilities.

Foundation classification

Support aboveground base administrative building, Glendale (California)

- Depth

- on natural or artificial bases;

- ;

- By appointment

- Carrier;

- Combined, that is, capable, in addition to carrying functions, also perform the functions of seismic protection;

- Special, for example, experimental anti-seismic "swinging" foundations; "Floating" foundations, the pressure of which is equal to the pressure of the excavated soil, and others.

- By material

-

stone:

- from natural stones (quarrystone): rubble, rubble concrete;

- from artificial stones: ceramic bricks, concrete block.

- reinforced concrete:

- concrete;

- cellular concrete;

- wood.

- By construction type

The foundation of the administrative building on the r. blocks FBS}

In engineering practice, several basic types of foundations have become widespread:

- Columnar - monolithic made of concrete, rubble concrete or masonry.

- directly columnar

- "Glass type"

-

Tape (prefabricated or monolithic):

- buried (below the freezing depth);

- shallow (above the freezing depth);

- Pile (prefabricated or monolithic):

- on driven, pipe-concrete, bored, rammed, screw and other piles.

- Pile-grillage

- Platen

- Combined pile-slab (KSPF)

Continuous foundation is a very voluminous, large, most often close to the shape of a circle or square, which cannot be considered as a free-standing columnar, slab, strip or pile foundation. Typically these are:, silos, bunkers, etc. See also sinkhole.

Calculation of foundations

Theories for calculating the settlement of foundations

To calculate the calculated settlement of the foundations of buildings and structures, a calculation scheme of the foundation is selected based on the nature of the bedding of soils, the structural features of the structure and the size of the foundation. There are more than two hundred methods (theories) for calculating base deformations, they all have their advantages and disadvantages, here are some of them:

- linear deformable half-space method with conditional limitation of the depth of the compressible strata Hwith;

-

method of linearly deformable layer of finite thickness (Egorova K.E.), applies in the following cases:

- if within the compressible thickness Hc, defined as for a linearly deformable half-space, there is a soil layer with a deformation modulus E1 ≥ 100 MPa and thickness h1 ≥ Hwith (1 — (E2/E1) ^ 1/3), where E2 - modulus of deformation of the underlying soil layer with modulus E1 (pp. 7, 8);

- width (diameter) of the foundation b ≥ 10 m and the modulus of deformation of the base soils E1 ≥ 10 MPa.

- Note. According to the scheme of the linearly deformable space, the foundation settlement can also be determined by the method of the equivalent layer according to N.A.Tsytovich

- method of equivalent soil layer (Tsytovich N.A.)

- layer-by-layer summation method - the accuracy of the forecast of the settlement decreases with an increase in the area of the foundations and the depth of the torn-off pit.

General theories

Calculation of foundations for buildings and structures, it begins with the choice of the type of foundations. First of all, it is required to determine the geometry (dimensions) of the foundations, based on their stability and strength of the materials used; for this, the following conditions must be met:

Establish the depth of the foundation sole, depending on the following factors:

- estimated depth of soil freezing;

- technological solutions;

- design solutions (design features of the underground part of the structure: the presence or absence of a basement; separate foundations for columns, tape for walls or a solid monolithic slab for the entire structure; monolithic or prefabricated foundations, etc.);

- geological surveys (the nature of bedding and the state of soils: subsidence, heaving, etc.);

- hydrogeological surveys (groundwater level - GWL);

- the massiveness of the building being erected (two or twenty floors);

- special conditions of the construction site - the seismicity of the area (in seismic regions, it is customary to deepen on average up to 10% of the entire building based on design experience and instructions from state standards);

- the presence of constructed buildings and structures nearby, underground utilities, etc .;

- terrain (mountainous area or flat plain).

Note... The minimum depth of the foundations is 0.5 m from the level of the planning, in the bearing engineering-geological element - IGE - 0.2 m. It is advisable to install the foundations above the GWL, if possible, at the same elevation, especially in earthquake-prone areas, and at the same IGE.

Determine the dimensions of the foundation:

- collect loads on the foundations and on the base under them - N (vertical load), M (overturning moment), Q (shear force);

- take the preliminary area of the foot of the foundation A and its dimensions in plan (b×l) based on the accepted value R (see clause 5.6.7 SP 22.13330.2011), having determined the pressure along the base of the foundation ρ (p = N / A) and comparing it with the real value R for the selected dimensions of the foundation;

calculation of the strength of the foundation material

- to perform the calculation of foundations for punching (calculate the thickness of the foundation cushion);

calculation of the basis, if necessary

- calculation of a sand cushion (for an artificial foundation);

- deep compaction calculation, etc .;

- check the strength of the weak underlying layer, if required by the results of the assessment of engineering and geological conditions;

calculation of the final settlement of the foundation

- calculate the final draft s foundation (and compare it with the maximum permissible absolute draft smaxU);

- calculation of the settlement of two closely spaced foundations.

- calculation of absolute precipitation;

- calculation of the average draft;

- calculation of the relative draft.

Note... Comparison of the settlement obtained by calculation with the limiting ones given in SNiP, and solving the issue of the need to install sedimentary joints, or changing the type and design of foundations.

Calculate the values of various types of deformations of the foundations (calculation of the stability of the foundation)

- calculation of foundations for overturning (tearing off the base of the foundation is usually allowed no more than 1/4 of the area, depending on each specific case, for example, for the foundations of overpasses, tearing off the base of the foundation is not allowed);

- calculation of foundations for shear;

- calculation of foundations for the relative difference in settlement, relative deflection, deflection, roll of the foundation or structure, twisting.

Foundation for walls

The basic rule for pouring this category of foundations is that they must be monolithic. In this case, the pressure on a separate section of soil is distributed over the entire length.

Strip foundation

Strip foundation

Strip foundation

This is the most common type of foundation for industrial buildings. It has the following device. A cushion block is used as a sole. A wall block is installed on it (marking - SP). This element has standard dimensions: 600 mm high, 300-600 mm thick and 2.4 meters long. It should not have voids. For ligation of blocks, SPD models with a length of 80 centimeters are used. This option of foundations is poured under load-bearing walls made of bricks or blocks.

In the case of concrete panels, a monolithic structure is used. At the same time, an armored belt is mounted in the trench twice as wide as the foundation itself. Then the main part of the structure is poured. To reduce the cost of concrete work, the pad can be made in the form of separate thick plates. For this, an additional recess is made in the trench, into which a metal frame is installed. The distance between these elements is 20 to 90 centimeters. If the soil has a high shrinkage factor, then the pad should be solid. The strip foundation provides maximum dimensional stability.

Column foundation

The main reason for using a columnar foundation for industrial buildings is in the case of dense soil that does not significantly shrink. The device of such a base consists of a monolithic shoe and a concrete pillar, which is installed in a special groove, so that it does not move when vibrations occur. It is used if the load on the walls is insignificant.

Vibrating paw for compaction of soil

Vibrating paw for compaction of soil

The maximum distance between these elements should not exceed six meters. They must necessarily communicate with the main parts of the structure using concrete lintels.

Before pouring the base for the post, the soil area under it must be compacted with a vibrating paw. Sand bedding at the bottom of the trench with a depth of 30 to 60 centimeters will ensure minimal compaction during the operation of the building. Columnar foundations of industrial buildings are complementary rather than basic elements. Most often they are used as bases for partitions indoors. They save money on filling the base for internal lintels. However, if a dimensional lift or other device is installed on the wall, which will take on additional load, then a more stable structure should be poured.

Pile foundation

The main use is in the case of soft soil with high shrinkage. The device of such a foundation consists of a pile driven into the ground, on which the monolithic base of the building is located. The piles used in this case can be round and square (in section). To avoid deformation of the element, a yoke is put on top of it, and a shoe is put on the bottom. These are steel tips. They allow the concrete structure to withstand strong hammer blows from the pile driver.

Driving in piles with a pile driver

Driving in piles with a pile driver

Less commonly, wooden piles are used. In this case, they should be made of coniferous wood (to prevent premature decay of the base). In exceptional cases, a metal analogue is used. In both cases, it should be taken into account that such a foundation has a shorter working life than a concrete pile. The installation depth of the pile depends on the characteristics of the soil, as well as the size of the building. These calculations can be made by the local design and construction organization.

The advantage of this base option is the minimum shrinkage of the overall building in areas with soft soil (sandy or swampy terrain), as well as lower costs for earthworks.

What is the foundation for

As you know, a foundation is a part of a building buried in the ground, which serves as the basis for its walls and columns. It is necessary in order to provide the building with support on a stable foundation, to which the topsoil cannot be attributed in any way. The surface of the earth seems solid and reliable only in dry summer weather, but it is worth it to pass the average force of rain, as it immediately becomes unsteady due to the abundance of moisture, turning into mud. The situation is even worse in spring, when the snow that fell during the winter melts.

Much more reliable is the so-called underlying layer, which, unlike fertile humus, is usually formed by a combination of clay and sand or rocks. It does not lie so deep - only 30–70 cm from the surface. However, in the overwhelming majority of cases, the foundation has to be immersed a little deeper. There are two reasons for this: the forces of frost heaving and the deep bedding of layers with sufficient bearing capacity.

The forces of frost heaving

As you know, water expands during freezing, and the force with which the ice tends to increase in volume is quite large. Everyone probably had to, if not personally observe, then at least hear about what happens to a glass bottle filled to the top, placed in the freezer.

The forces of frost heaving are capable of breaking a reinforced concrete tape

If the soil located under the foundation contains water, and the temperature in winter in it drops below 0 C, then the same force that breaks the bottle in the freezer will begin to act on the building from below. In construction geology, this force is called "the force of frost heaving." It is quite enough to squeeze even the largest building out of the ground a little, and due to the uneven impact, it will warp and deform.

Therefore, if the soil has an inherent ability to retain water, the foundation must be immersed below the depth to which the earth freezes in winter (it is called the depth of freezing).Such a foundation is called buried. This very ability is expressed the stronger, the greater the proportion of clay inclusions in the soil. Rocky soil, like sand, on the contrary, exhibits draining properties, that is, it does not retain water. Accordingly, on this basis it is possible to restrict oneself to a depth of 0.5–0.7 m. In this case, one speaks of a shallow foundation.

Understanding all this mechanism, it is easy to guess about ways to reduce the depth of the foundation. There are two of them:

- Remove the heaving soil to the depth of freezing and replace it with sand.

-

Insulate the perimeter adjacent to the house, thereby reducing the depth of soil freezing. How to do this will be described in the section on repairing foundations.

Deep bedding with sufficient bearing capacity

It happens that the upper layers of the soil are of very low strength. Even at relatively low loads, they are strongly compressed, which can lead to significant distortions with the subsequent destruction of the building. In such a situation, it is necessary to embed the foundation deep enough to get to the foundation with a higher bearing capacity. It depends on many parameters and is measured in kg / cm2.

In addition to the depth of the foundation, there is another important characteristic - the foot area. The larger it is, the lower the specific pressure on the ground will be, that is, the load per unit area. As it was said, the soil has one or another bearing capacity, and the foundation must be designed in such a way that the specific pressure produced by it does not exceed this capacity.

For example, if a building weighs 5 tons, and the bearing capacity of the soil is 2.5 kg / cm2, then the area of the base of the foundation must be at least Smin = 5000 / 2.5 = 2000 cm2.

Of course, the foundation material must also have sufficient strength to support the weight of all building structures supported by it. The compressive strength of building materials such as brick and concrete is indicated on their grade. For example, the concrete grade M150 indicates that it is capable of withstanding a compressive force of up to 131 kg / cm2.

The technology of the device of a columnar foundation on piles and wooden chairs

When are columnar foundations erected in the construction of houses?

Columnar foundations are in the form of separate supports, arranged under walls, pillars or columns. They are used for insignificant loads on the foundation, when the pressure on the ground is less than the standard (in the construction of light low-rise buildings). Columnar foundations can be wooden, brick, concrete, buto-concrete or reinforced concrete. When installing a columnar foundation, the pillars are placed at a distance of 1.5-2.5 m from each other. It is obligatory to install pillars at intersections of walls, in the corners of the house, along heavy walls and where the greatest load is concentrated. Foundation pillars made of concrete or reinforced concrete are covered with reinforced concrete foundation beams on which the wall is being erected.

How to lay out the posts made of bricks or rubble concrete?

Pillars made of bricks or rubble concrete are arranged as follows. First, a 1x1x1 m hole is dug. A sand pillow is placed on the bottom. If the bottom is sandy, then gravel or gravel is immediately poured, which it is desirable to spill with bitumen or cover with roofing material in one layer. Then a layer of concrete is laid and leveled. About a day later, when the concrete "grabs", a brick pillar is laid out on this base, bringing it 25-50 cm above the ground. The use of silicate bricks for posts is unacceptable. Before backfilling, the pillar is coated with bitumen.

How are concrete pillars erected?

The most reliable are concrete pillars. According to the technology of the device of the columnar foundation, before the erection of the pillars, 3-4 reinforcing rods, pieces of thick wire or metal pins are embedded in the center of the concrete pad.As soon as the concrete pad hardens, the formwork is installed on top of it. When knocking off the formwork panels, the connecting bars are not cut off, but a so-called lock is made of them at 1/3 of the height from the base. It is necessary to lay concrete so that there are no voids or sinks. For this purpose, it is rammed with a crowbar or a pole. A cord is used to determine the height of the post. At the required level, a nail is driven in (through and through), after which the required amount of concrete is poured. Columnar rubble foundations are most effective under geotechnical conditions that require the laying of the base to a depth of 1.5 to 3 m.

How is a columnar foundation built on piles?

To erect a columnar foundation on this pile, you need to dig a pit 50 cm deep and use an ordinary garden drill (18-20 cm in diameter) to drill a well 1 m down. Then twist the sleeve from the roofing material and lower it into the drilled hole. Thus, you get a kind of formwork, into which concrete is laid. After that, the external formwork is installed. It is best to make the formwork in the form of a truncated pyramid, no more than 1 m in height.In this case, it does not have to be disassembled, since it can be easily removed in a day. It must be made strong enough to be used when casting all posts. Boards should be planed from the inside. Then the pillars will turn out to be smooth, and it will be easier to clean the formwork before reinstalling.

How are wooden chair foundations installed?

Wooden chair foundations are installed under light frame and wooden buildings. It is advisable to take wood for them butt (pine or oak) with a diameter of at least 20 cm and antiseptic (coated with bitumen or burnt). Wooden chairs are installed on special pads made of plates or beams 10 thick, 20 wide and 40-50 cm long. They increase the stability of the foundation and increase the area of transfer of pressure to the ground. The chairs are deepened into the ground by at least 125 cm, installing them around the entire perimeter of the building at a distance of 1-2 m from one another. At the same time, a chair must be at every angle. After installing them, you need to fill the pits in layers of 15-20 cm with careful tamping. It is recommended to add crushed stone or coarse gravel to the top two layers. Foundations made from pine chairs last 6-7 years on average, and from oak ones - 12-15 years. Antiseptic treatment or firing lengthens this period by 1.5-2 times.

Installation processes of types of bases

Construction of a strip base

The installation of the foundation in the form of a reinforced concrete tape is performed in several stages. First, they clear the site of debris and mark it with pegs and a cord, fixing the location of the main axes of the base.

It is quite simple to make a tape base with your own hands from formwork to pouring concrete mortar

It is quite simple to make a tape base with your own hands from formwork to pouring concrete mortar

Then they dig a trench with their own hands or with the assistance of special equipment and perform the following work:

- clean up and compact the bottom of the pit;

- build a cushion of sand or coarse gravel, which is spilled with water and tamped for a better fit;

- laying waterproofing that prevents concrete dehydration during drying;

- formwork is made from boards or other materials at hand and installed around the perimeter, clearing it of shavings and debris;

- check the verticality of the walls of the formwork using a level.

For rigidity, self-made formwork elements are fixed with spacers. Can also be used for pouring concrete and ready-made structures. Then the frames are installed from the reinforcement and the formwork is filled with a concrete mixture, leaving holes for the communications of the house. To eliminate voids in the base, concrete is poured in layers of 15-20 cm, each compacted with a wooden rammer.

After 7-10 days, when the foundation is gaining up to 70% of the planned strength, the formwork is removed and waterproofing is carried out.

We recommend watching a video on how to fill the base tape with your own hands.

Installation of a columnar foundation

When constructing a columnar base with your own hands, on a prepared site, cut the soil to a depth of 10 to 30 cm, leveling the bumps and pouring soil into the formed pits. To control the horizontalness of the surface, a building level is used. Then the following operations are performed:

- mark the location of the pillars, which should be located at the intersection of the walls;

- they dig holes according to the outline and install formwork in them;

- lay the vertical reinforcement in such a way that it protrudes 10-15 cm above the posts;

- concrete is poured into the formwork, compacting each layer.

Watch a video showing in detail the installation of a columnar base.

After gaining strength, the pillars are connected with strapping. Structures made of bricks or natural stone of high strength can also be used as supports for the house. For small buildings in the form of baths, sheds and summer cottages, it is better to choose pillars made of wood, treating them with antiseptics before installing.

Erection of a monolithic foundation

Installation of the foundation in the form of a monolithic slab is carried out on a previously prepared site, which is cleaned of debris. Then, depending on the overall dimensions and configuration of the house, they mark the location of the base and dig a trench with their own hands or with the help of small-scale mechanization. The depth of the pit must match the level of the foundation.

Then do the following:

- compact the bottom of the trench;

- make a pillow of sand and tamp it, excluding voids;

- the pit is poured with a thin layer of concrete;

- laying waterproofing and reinforcement;

- concrete is poured so that the ends of the reinforcement protrude above the monolithic slab.

In order for the foundation of the house to evenly gain strength, it is better to spill it with water in dry weather and cover it during rain.

Installation of a pile foundation

Before installing the base on piles, you need to decide on the type of supports. For the construction of residential buildings in areas with difficult terrain, it is better to use screw piles, the diameter of which is selected taking into account the expected load. Wood supports can be chosen as bases for small outbuildings or enclosing structures.

Watch a video on how to assemble a pile foundation with your own hands.

How to build a foundation on screw piles? First, the location of the supports is outlined and the pegs are hammered. Then do the following:

- make small indentations along the outline;

- install screw supports, twisting them with the help of special devices or pipe sections, using them as levers;

- check the coincidence of the above-ground parts of the piles and align them, cutting off the excess with a grinder.

To ensure the stability of the supports, they are poured with concrete. In addition to screw piles, when building a base with your own hands, you can also use bored and combined ones. For tall houses with heavy floors, reinforced concrete supports are chosen.