Formwork calculation for the foundation

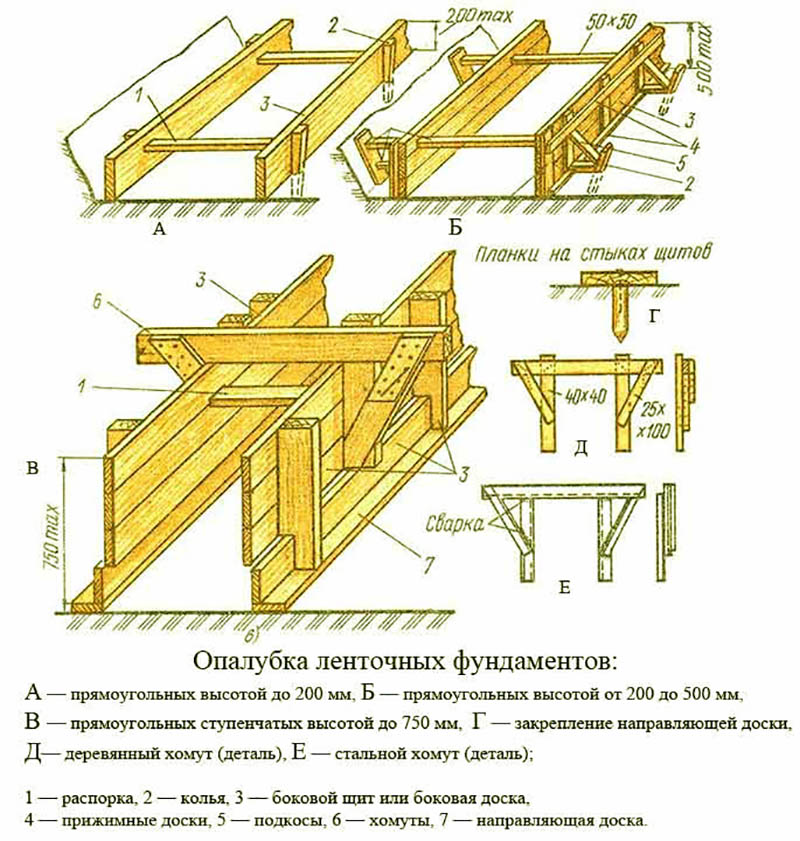

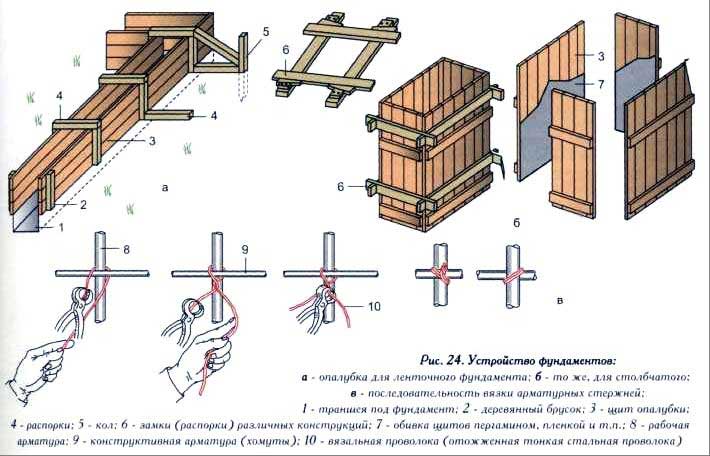

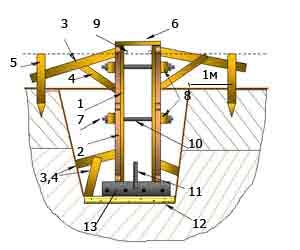

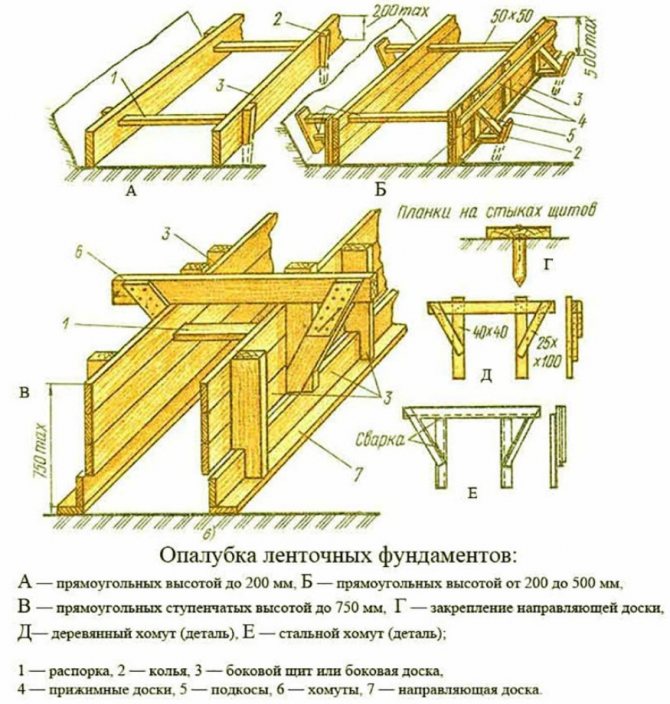

In this case, a calculation means the calculation of the required thickness of panels or boards of a structure, taking into account the distance between the supports, the specific gravity of the mixture to be poured and the ability to resist the form material. The traditional, simplest formwork design consists of shields installed at the bottom of a pre-dug trench, held in a vertical position by special supports.

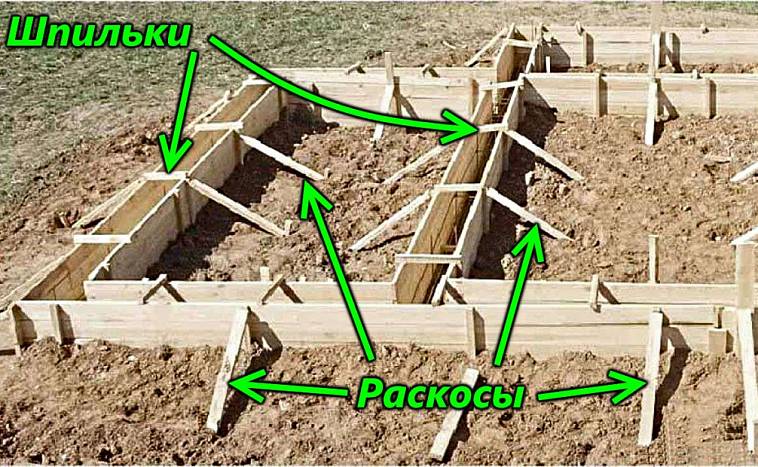

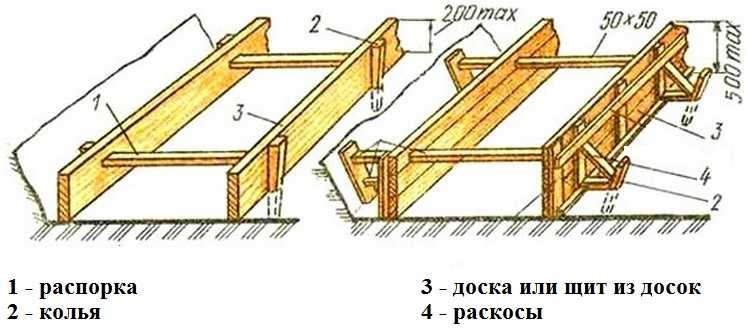

The choice between stakes or braces depends on the volume of the mixture to be poured and the type of soil: for small foundation strips (250 ... 400 mm) and dense, not prone to crumbling or creeping of the soil, stakes are sufficient. If in doubt, it is better to give preference to braces, since they are able to hold the shields in place even with increased load.

Formula for calculating the thickness of the panels (minimum)

Here

- G - the load of the liquid mixture on the formwork, it is assumed to be maximum and is determined as the product of the specific gravity of concrete and the thickness of the poured layer G = q x H. The specific gravity is q = 2500 kg / cubic meter, H is the height of the foundation strip in meters;

- n is the coefficient of compaction of the concrete mixture. If vibration compaction is not used, the coefficient is equal to one;

- l is the distance between the shield supports, in meters;

- T is the resistance of the board material to the load, for wood it is taken equal to 8 x 105 kg / sq.

Taking into account the difficulty of independently determining the grade of concrete, respectively, its density, as well as the lack of accurate data on the resistance of the material of the panels for the formwork, the calculations are carried out approximately, for averaged values. Usually, the thickness of the board is taken equal to 25 mm.

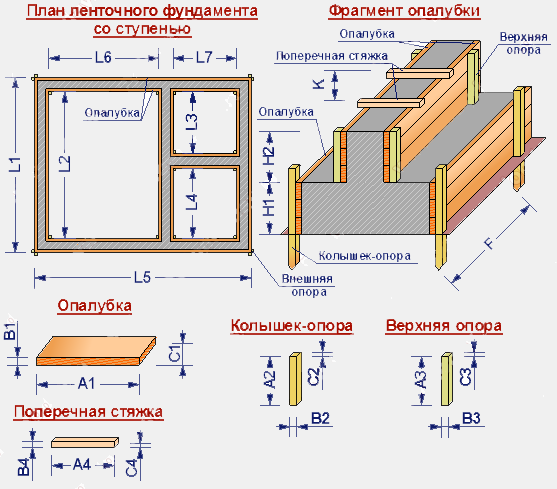

The second part of the calculation is to determine the required number of boards of a given thickness, the number of fasteners. For these calculations, you need to know the length of the foundation tape, the height of the fill. The length of the tape is multiplied by two since the shields are on both sides. When installing a strip foundation with a step, the calculation is carried out twice - for the first and second stages of pouring. The amount of lumber is determined based on the data on which board will be used for the foundation formwork (dimensions).

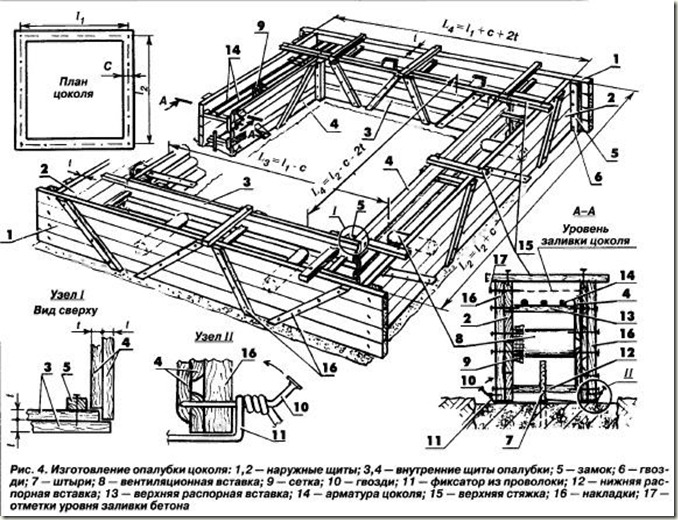

Drawing up a plan similar to that shown in the illustration will help you navigate in a more accurate calculation of the required shape length, the number of connecting and supporting parts.

What materials can formwork be made from?

Formwork can be made from various materials. Among them are:

- Metal. This type of material is very expensive, but at the same time the most versatile. It is made from steel sheets with a thickness of about 1-2 mm. The main disadvantage of this material is its high cost, therefore it is used extremely rarely.

- Reinforced concrete. This type of formwork is also expensive. It is made from concrete slabs of various thicknesses. When using it, the consumption of concrete for pouring is significantly reduced. However, the main disadvantage of this material is its high weight, which requires the use of special heavy equipment.

- Expanded polystyrene. This type of formwork is also not cheap, but it does not need to be removed after the concrete has gained strength. It is made from ready-made blocks of expanded polystyrene, it is quite easy to install it. The main disadvantage of this material is its high cost and possible difficulties in the process of selecting some complex elements.

- Materials at hand. Formwork can also be made from slate, profiled sheets and other suitable materials.The advantage of such formwork is its low price, however, among the disadvantages is the complexity of assembling the structure, there is a risk of leakage of concrete solution through the cracks formed, it is necessary to use additional wedges and supports.

- Wood. This type of formwork material is widespread and not expensive. Most often, cut boards or sheet plywood are used to create formwork. It is easy to assemble, but additional reinforcement elements must be installed. It is this type of formwork that is best used for beginners in construction.

Formwork structure made of boards and plywood

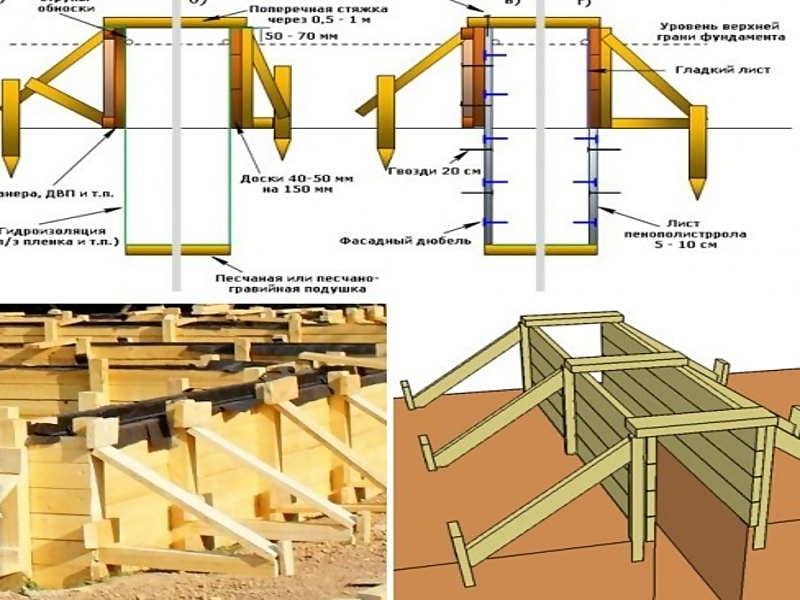

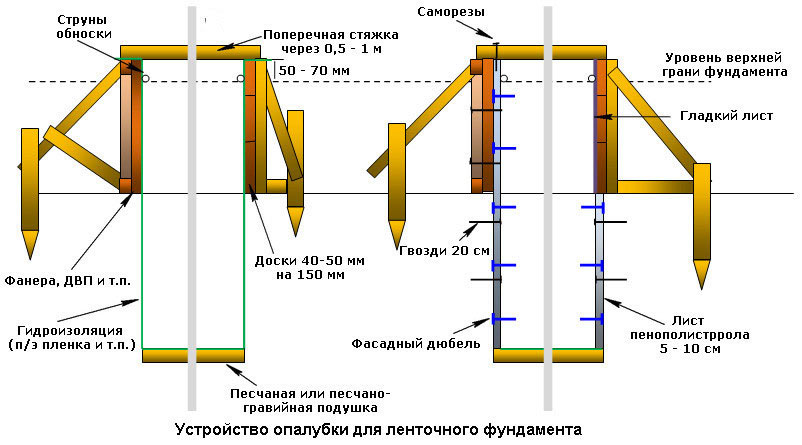

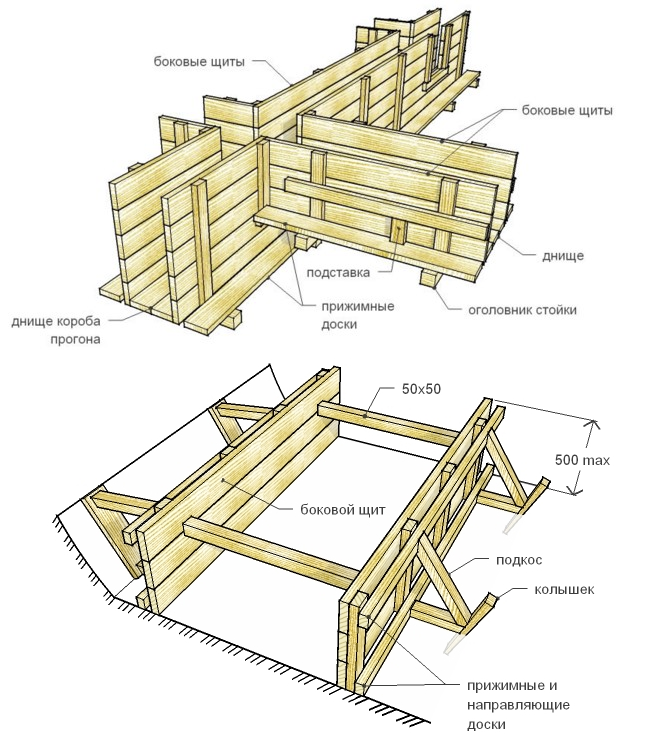

Correctly connected in shields should not have gaps between them. For fastening wooden panels, a system of ties, spacers, slopes, clamps and stops is installed.

The installation of the formwork structure should be carried out in such a way that its inner surface does not have any protrusions, but is smooth and even. The developed standard technologies for assembling plank or plywood formwork for foundations recommend using boards and plywood with a thickness of at least 10 mm for boards.

Plywood with a thickness of at least 10 mm is attached to the frame from a bar

Plywood with a thickness of at least 10 mm is attached to the frame from a bar

If the foundation has a large width, then the lateral pressure of concrete can withstand boards made of boards with a thickness of 30 to 40 mm. The framing of the boards and the stiffening ribs are prepared from a wooden bar with a section of 40X60 mm. Fasteners for enclosing structures are made from the remains of boards and timber. Other suitable materials are also used.

After installing wooden or plywood panels, carefully check the surface of the formwork for cracks and irregularities. If you find any, you need to eliminate them.

First, the boards and plywood are cut to the size of the boards. Planks or sheets of plywood are laid out on the laid out bars. Then all the elements are connected with nails or self-tapping screws. The finished planes are framed with a bar and the ribs of rigidity are attached to them.

For fastening the formwork, it is necessary to choose only high-quality reinforcement

For fastening the formwork, it is necessary to choose only high-quality reinforcement

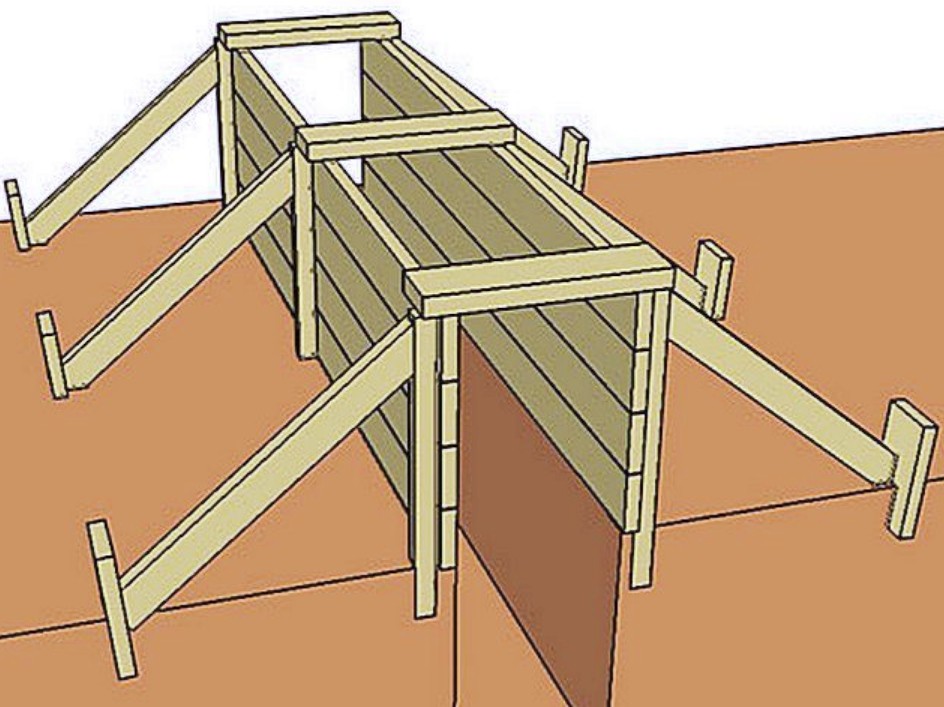

After that, the enlarged elements are installed in the design position and proceed to the installation of fasteners. Support boards are placed along the formwork installation line, the pointed lower ends of the support beams abut against the ground, and the upper ends hold the formwork.

The walls of the fence are placed along the entire perimeter of the marking, fixing them with evenly distributed fasteners. The shields are interconnected by pieces of timber using nails or self-tapping screws. The opposite walls of the fence are connected with U-shaped clamps. Clamps are made from boards and beams.

Such structures do not allow the walls of the formwork to disperse under the pressure of the poured concrete mixture. From the outside, slopes are installed from a bar, which with its pointed part rests against the ground, and with the other end supports the upper part of the shield.

The removed plank boards can be disassembled into planks and beams, then they are used in other works. The dismantled plywood sheets can be used again for the foundation at another site.

Basic information about strip foundations

Strip foundations can be used in the construction of houses with or without basements. In any case, you get significant savings when choosing this type of foundation.

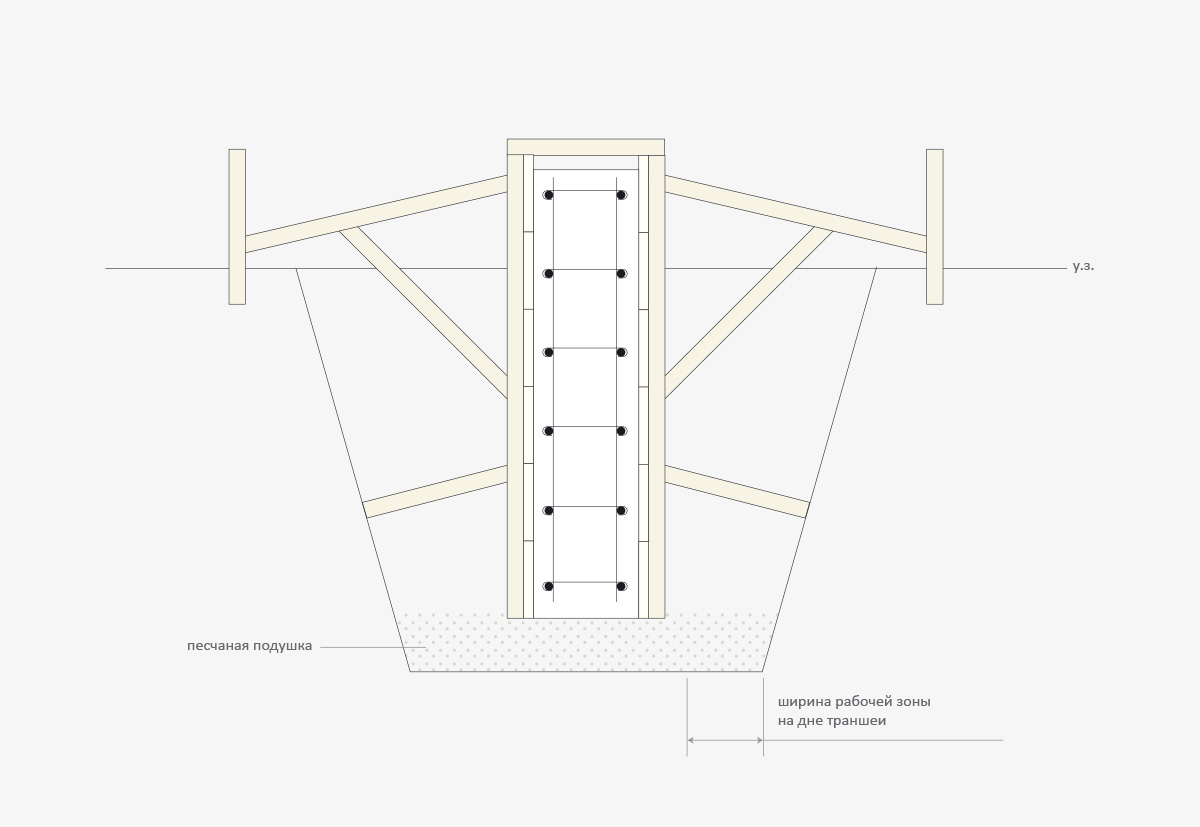

When arranging a basement, it is advisable to erect a foundation in an already finished pit using double-sided formwork, in this case the foundation will play the role of basement walls.

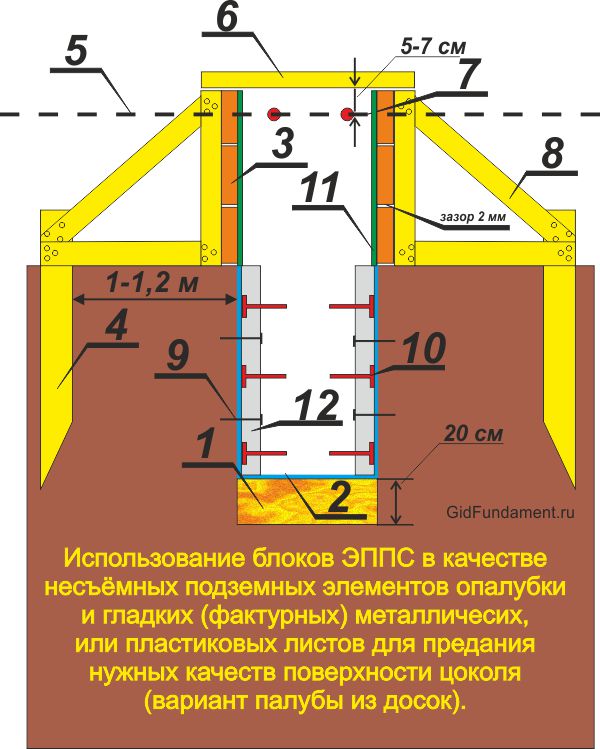

A simpler method is to pour the structure into specially prepared trenches. In this case, you can save on the cost of the formwork, because it is enough to install only its outer part, which, when using modern materials (formwork using extruded foam), will also become a reliable element of insulation and waterproofing.

A simpler method is to pour the structure into specially prepared trenches. In this case, you can save on the cost of the formwork, because it is enough to install only its outer part, which, when using modern materials (formwork using extruded foam), will also become a reliable element of insulation and waterproofing.

The calculation of the parameters of the foundation should be carried out by a civil engineer who can calculate all the parameters of the structure, depending on the condition of the soil, the presence of groundwater and other factors.

The entire technology of casting a strip foundation can be divided into several stages:

- Preparatory and earthworks

- Preparation of the base, installation of formwork

- Reinforcing frame manufacturing

- Pouring concrete mix

Let's take a closer look at all of these steps.

Preparatory and earthworks

The main issue of preparation is the calculation and purchase of the necessary materials. If you decide to prepare the concrete mixture yourself, which will help to somewhat reduce the cost of pouring the strip foundation, but will significantly increase the time of its construction, you need to bring the required amount of crushed stone, sand, cement to the construction site.

In addition, before starting work, it is necessary to purchase formwork material, reinforcement, all this can be imported in the process of performing earthworks. In addition, for the preparation of concrete, you need to take care of the presence of a concrete mixer, which, as a last resort, can be rented. But we would still recommend using ready-made concrete mixes, which will greatly simplify the work.

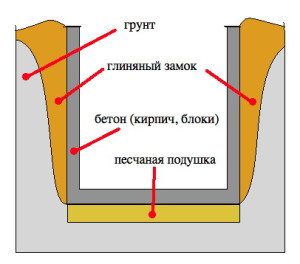

Clay castle device

As already mentioned, concrete can be laid either in trenches or in a foundation pit. In addition to the fact that the foundation pit will simplify the work on arranging the basement, in this case it is possible to arrange additional waterproofing of the building by arranging a clay castle over the entire area, which will significantly reduce the access of groundwater to the building.

When carrying out earthworks, it is necessary to constantly monitor the elevation, this will be the basis for the stability of the entire building.

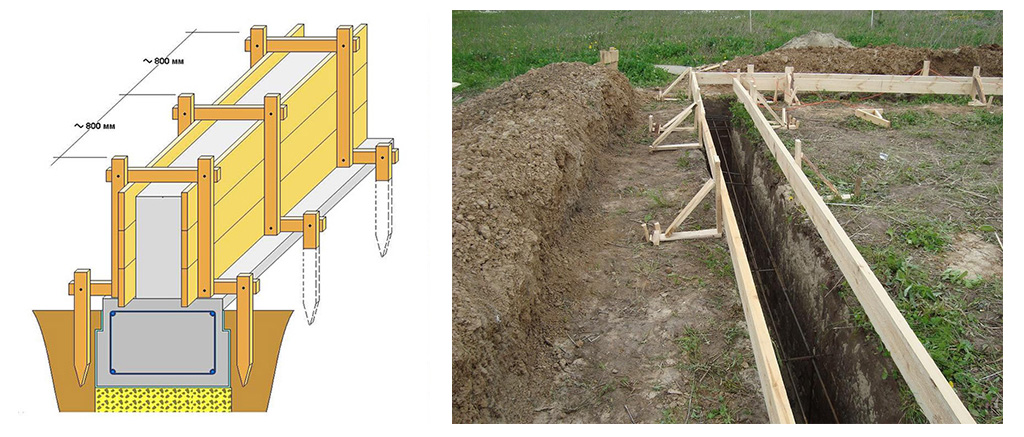

In addition, control of trenches along the axes of the building should be carried out. To do this, they resort to the so-called cast-off, it is performed as follows. 2 m recede from the lines of future walls, supports are mounted to which the boards are attached. Thus, we get a structure that follows the entire contour of the building, which makes it easier to carry out earthworks.

Foundation stripping

Types and types of strip foundation

The concrete-strip foundation is divided into 3 groups by type:

- Shallow. It is located at ground level on a crushed stone and sand cushion.

- Shallow. Designed for panel, frame, foam block or wooden houses. The depth of penetration is 50-70 cm.

- Recessed. It is used for houses with basements, buildings with heavy weight, in areas with heaving soil. The depth of the bookmark is below 50 cm of the level of soil freezing.

The recessed version is rarely used - the amount of concrete for the foundation is very large. In places with a cold climate, the laying depth can be more than 2 m.

When deciding which type to choose for construction, they pay attention to 4 indicators:

- the load that the foundation will experience;

- the required height of the base;

- ground water level;

- the depth of soil freezing.

By type, the concrete-strip foundation is divided into prefabricated and monolithic. The first is the individual elements produced in the factory, from which the structure of the desired configuration is assembled. With an equal thickness with a monolithic, it is inferior to it in strength by almost a third. Among the advantages of this option is the absence of the need to independently calculate the quantity concrete on tape foundation, ease of assembly and the ability to install blocks at intervals to save money.

Monolithic is made directly at the construction site: the cement mortar is mixed and the formwork of the strip foundation is concreted. The device of this option is more laborious, but it is stronger than the prefabricated one and is cheaper.

If there is a choice between different types of foundation, you can determine which will be better by comparing the characteristics and features of each

So, when choosing between a strip foundation or a monolithic slab, several parameters are taken into account:

- Soil type. For weak and non-porous soils, the belt is optimal. On heaving it is more advisable to use a plate.

- Time. Installation of the slab is possible at any time of the year, after installation, you can continue construction. It is necessary to pour the strip foundation at positive temperatures, after which it is required to wait until the concrete gains strength.

- Life time. The service life of the plate declared by the manufacturers is up to 100 years, however, it can be reduced due to high load, unfavorable operating conditions and under the influence of other factors. The prefabricated strip foundation retains its integrity for an average of 50-75 years, monolithic - up to 150.

- Budget. Which will cost less - a strip foundation or a monolithic slab? The cost of the tape is several times lower than the plate.

It is impossible to answer unequivocally which is better - a strip foundation or a monolithic slab. For the construction of a house on heaving soils in a short time, the second option will be preferable. On weak soil, tape is used, which is cheaper and easier, since no special equipment is required for installation.

The construction process consists of 5 main stages - preparatory work, formwork installation, reinforcement and concreting and concrete maintenance

In order for the resulting structure to have the required strength, it is important to know what grade of concrete can be used for the strip foundation, as well as to comply with the construction technology

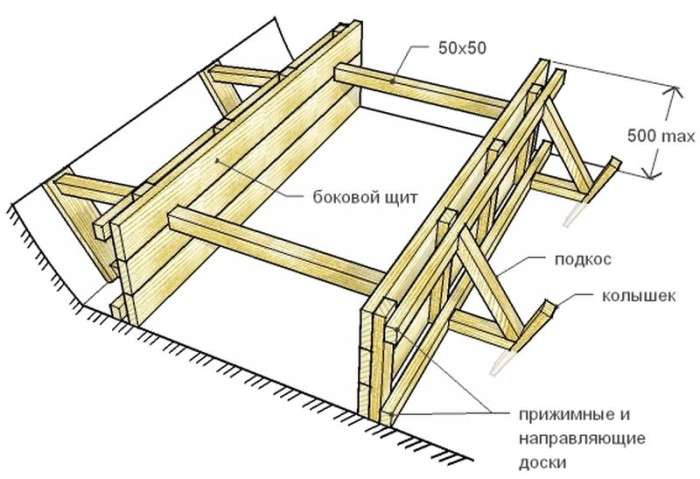

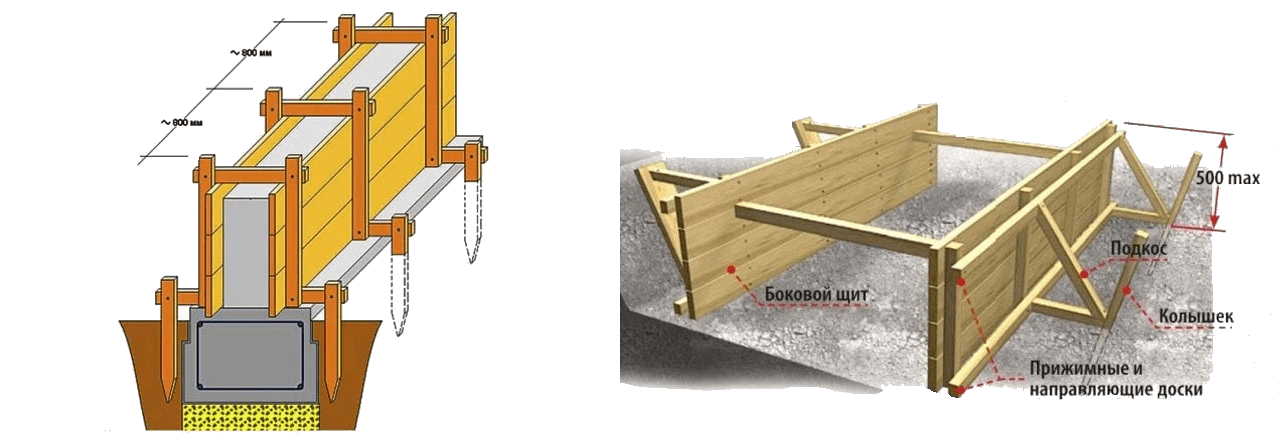

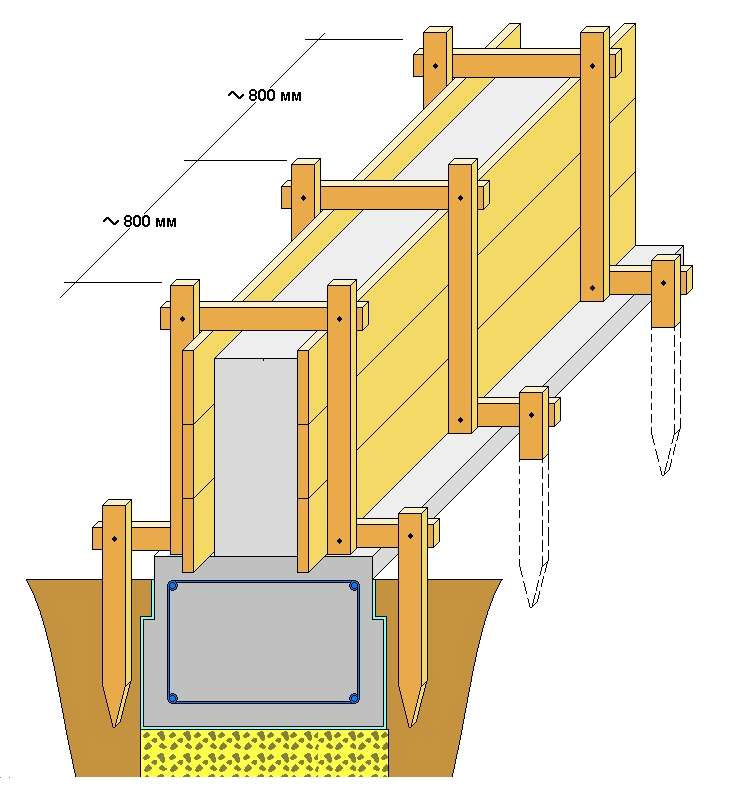

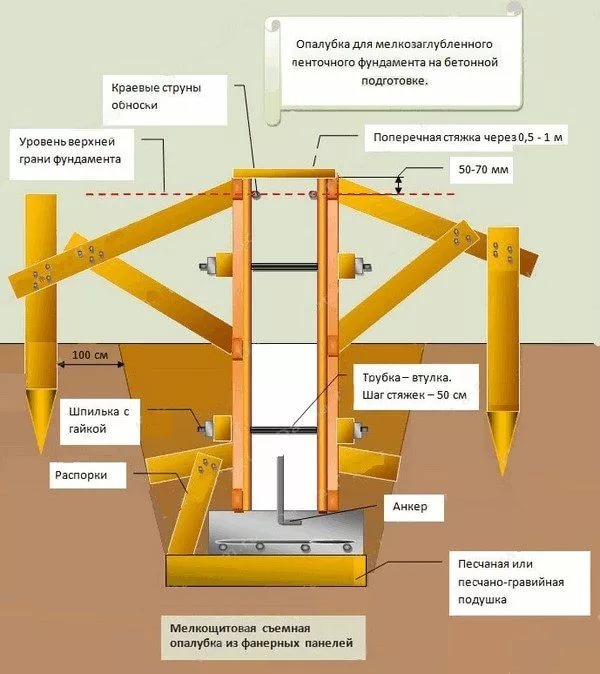

Installation of wooden formwork under the strip base on stable soil

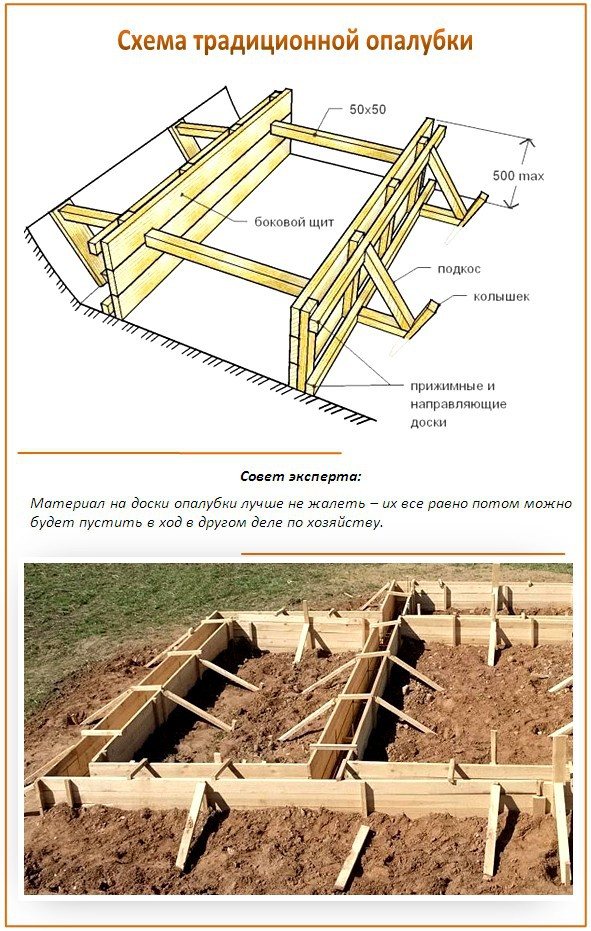

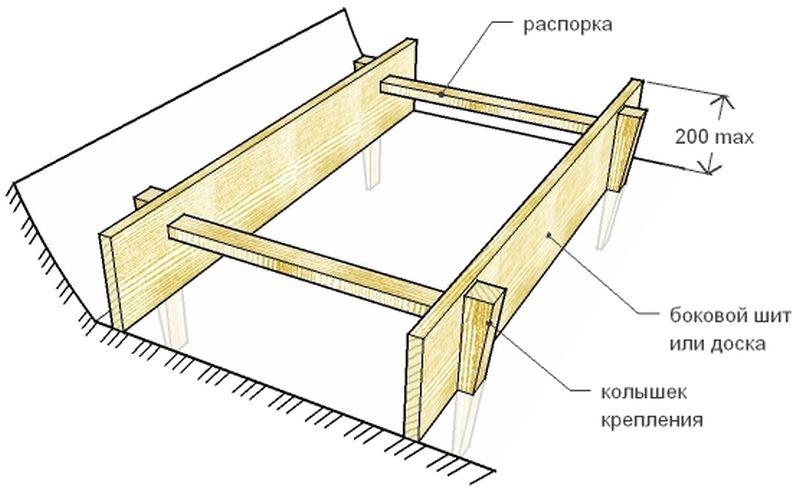

For the installation of such a structure, an edged board 3-4 cm thick and 10-15 cm wide is used, plywood with a thickness of 0.5-1.5 cm can also be used.

Wood formwork assembly process

Wood formwork assembly process

Do-it-yourself installation of this structure occurs in this way: first, guide boards are placed in the pit from the side of the ground and fixed with pegs driven into the ground, then shields are attached so that their ends coincide with the edges of the guide boards. It is necessary to arrange shields using a level or plumb line. Shields are fixed with wooden slopes from the inside of the formwork.

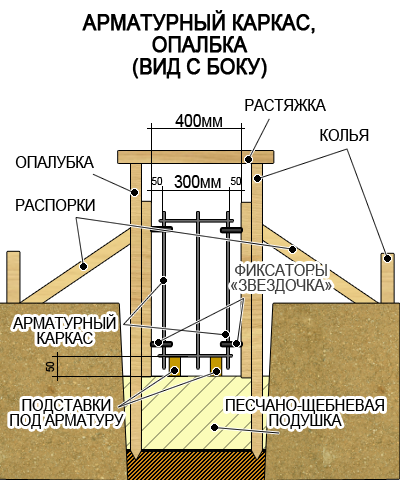

When assembling the specified structure with your own hands, it is necessary to take into account that a similar structure will be on the other side, so you need to strictly adhere to the dimensions of the foundation tape. Such actions will make it possible to avoid cracks in the docking points. To maintain the same width of the tape around the entire perimeter, you need to use spacers in increments of 0.5 m.

There is a second option for formwork installation in stable ground. It assumes the construction of the specified building structure only for the above-ground part of the foundation. The underground part of the form for pouring the foundation in this version will serve as the walls of the trench, which must be covered with a waterproofing material

It is important that they are dug up strictly in compliance with the vertical level.

Form shields for the base are fixed along the edges of the trench using braces from the remains of the boards. The braces can be nailed to stakes made of wood or driven into the soil with an indentation of at least 1 m from the formwork panels. They are attached to the shields with self-tapping screws, in places where the transverse bars are located. When fixing the shields, you need to adhere to the level so that the shields do not deviate vertically. To control the degree of deviation, use a level or rule. The deviation of the boards from the vertical is not more than 0.5 cm per 1 m of its height.

Watch a video on how to use a fixed timber structure.

After the installation of this structure, its inner walls are covered with a waterproofing material so that an overlap is formed at the bottom of the trench. It will prevent the waterproofing material from tearing when pouring the concrete mixture.

The procedure for performing the reinforcement of the strip foundation

The existing scheme for reinforcing the strip base for building a house implies following several mandatory rules:

- Application when carrying out reinforcement of bars of class A400

- Minimization of the use of welding when joining the rods, as this technology contributes to the weakening of the sections

- At the corners, the frame can only be tied, the use of welding at the corners is not recommended

- The protective laid layer of concrete used in a particular situation must be at least 4 centimeters to protect metal elements from the negative effects of the environment, corrosion

- The use of smooth reinforcement is not recommended.

- When laying concrete, it must not be able to get stuck between the rods, which will eliminate control over failure, for too frequent arrangement of metal rods

Detailed step-by-step instructions with photos and videos given for clarity will help to create a reinforcing cage. A significant advantage of reinforced strip foundations is the combination of high reliability and affordable cost. Steel and concrete are high strength materials.

This is important for creating a foundation for construction on any soil, except for the already naturally stable and reliable rocks. In other situations, any foundation reinforcement will save you from damage caused by stress.

How is formed

When carrying out work such as strip foundation reinforcement, drawings include three groups of rods:

- Used for laying along the belt, used working rods

- Horizontal elements located transversely

- Vertical options, transverse

The task of the transverse reinforcement is to connect all working elements into a stable in use, a single unit of reliable, innovative working rods. They are often called clamps.

An important feature of the work is the use of SNIP and other regulatory specialized documents in activities such as reinforcement of the strip foundation. The calculation uses SNiP 52-01-2203

In this regulatory document, it is easy to find all the necessary calculations to create the reinforcement of the strip foundation of a small country house.

What are the requirements for concrete determined by regulatory documents?

If you maintain the order of creating reinforcement, it is important to comply with the mandatory requirements for the concrete used in a particular job. When creating a strip foundation with your own hands at the site of future construction, it should be borne in mind that among the main characteristics of the strength of concrete structures is an indicator of resistance to axial compression, readiness to resist stretching and not respond to transverse fracture

Correction factors for reliability can vary from 1 to 1.5

When creating a strip foundation with your own hands at the site of future construction, it should be borne in mind that among the main characteristics of the strength of concrete structures is the indicator of resistance to axial compression, the readiness to resist stretching and not respond to transverse fracture. Correction factors for reliability can vary from 1 to 1.5.

Requirements for fittings

These indicators are determined by regulations and standards. Reliable foundation reinforcement uses bar-based:

- hot-rolled rebars,

- mechanically hardened fittings

- heat treated reinforcement

It is GOST that allows you to calculate the indices of the limiting submerged states, which are strictly divided into groups in it. Indicators are determined on the basis of the requirements specified in state standards, which are determined on test benches. Any regulatory and technical documentation that is used to determine the reliability of reinforcement must be approved by the official regulatory authorities.

What basic rules are important to consider when performing work?

As a rule, reinforcement during suburban and construction is carried out independently. In this case, the requirements of SNiP and GOST are not always followed so carefully.

For this reason, when considering how to reinforce a strip foundation with your own hands, it is important to adhere to some mandatory rules:

- When performing the reinforcement of the strip foundation of the future structure, including 1-2 floors, rods with a diameter of 10-24 mm are used.

- The use of welded joints is not recommended

- When creating a strip foundation with your rivers, it will be necessary to create a formwork