Instructions - how to equip the foundation yourself

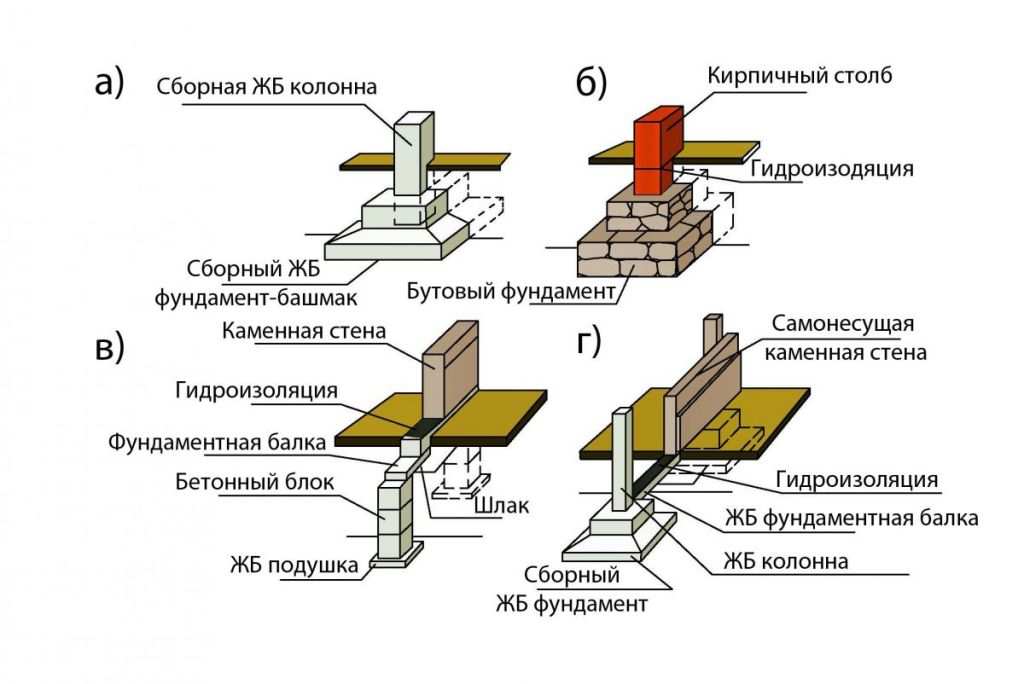

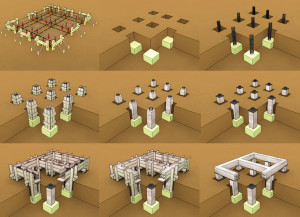

Columnar foundations are being erected using the technology in four stages:

-

Excavation work with drilling holes under the support pillars and installing sand cushions at their bottom.

-

Installation of permanent formwork for foundation supports, followed by pouring concrete or laying them out of bricks or concrete blocks.

-

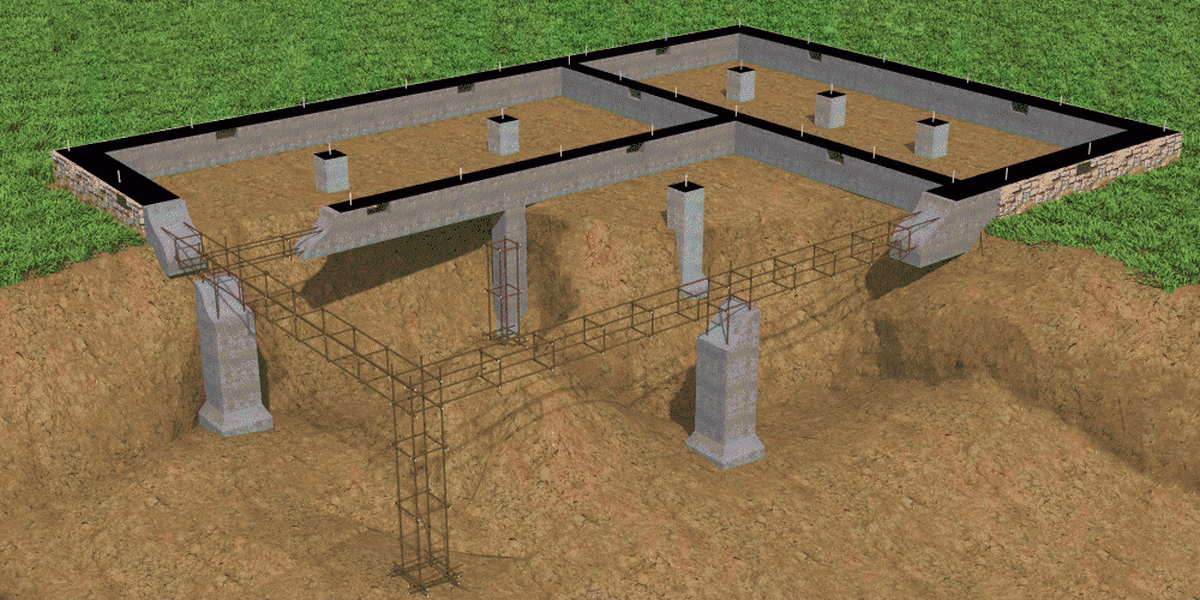

A device for this type of pile-grillage foundation of the upper load-distributing part made of reinforced concrete, steel channel or wood.

-

Waterproofing of the entire structure and cladding of supports along the perimeter of the building with siding or profiled sheet.

Everything is quite simple, but there are a number of nuances in this process. The first of them - regardless of the level of the grillage, the retaining piles of the columnar version of the foundation for a private low-rise building should be immersed deeper than the freezing point. To speed up the work, in some cases it will be best to involve specialized equipment with a drill.

The base supports themselves can be made from:

-

Reinforced concrete poured into an asbestos-cement pipe;

-

Brick;

-

FBS (reinforced concrete blocks for foundations manufactured at the plant);

-

Natural stone.

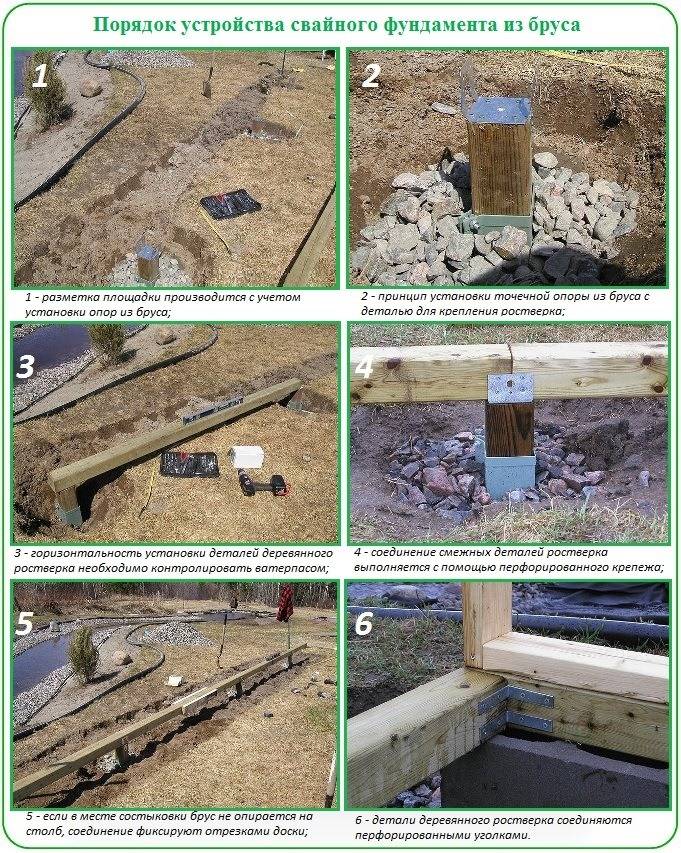

Below is a step-by-step photo-instruction of a columnar foundation on foam blocks:

We transfer the foundation plan to the terrain - mark the future borders with pegs

Digging holes

We fill the pits with rubble, sand on top and spill it several times and repeat the procedure for filling with sand

We put the first 4 blocks on the pillow in the corners and align with the lace and size

Substitute the second block and level it

We measure the zero level of the foundation with the hydraulic level - its height

We expose the following levels of blocks of our base

We make all the other pillars by level

We spread the roofing material on the posts for waterproofing

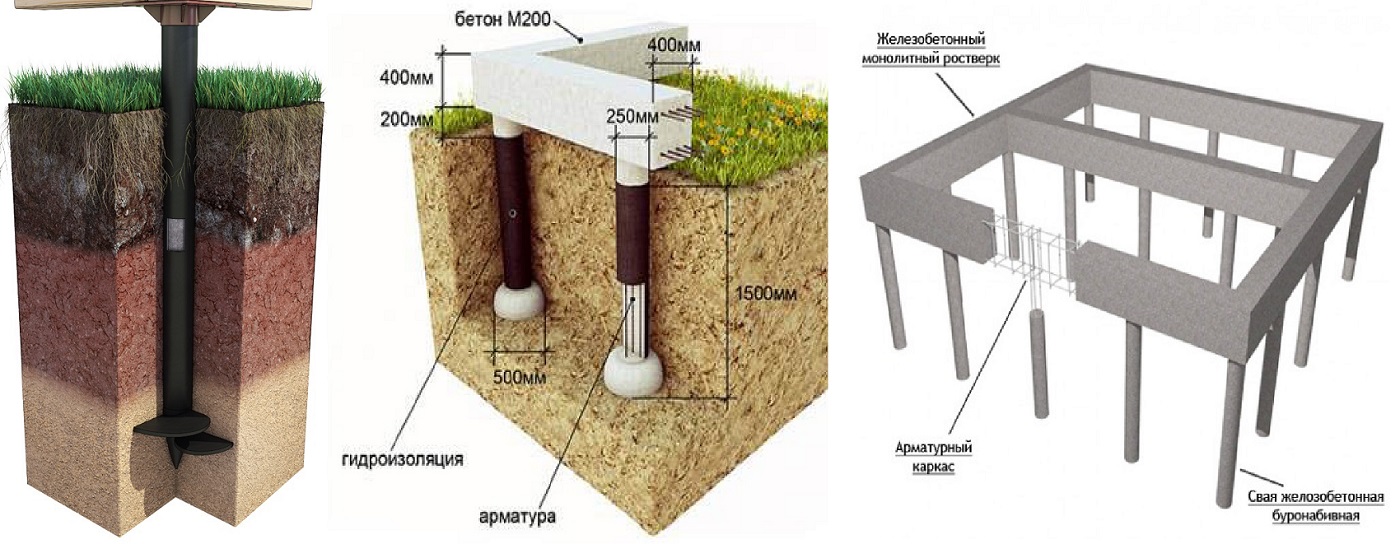

It is also possible to use steel screw piles. But this will already be more of one of the variations of the pile-screw foundation. Previously, supports were even made of moisture-resistant larch. However, today most private developers prefer to put something more durable and concrete under their house.

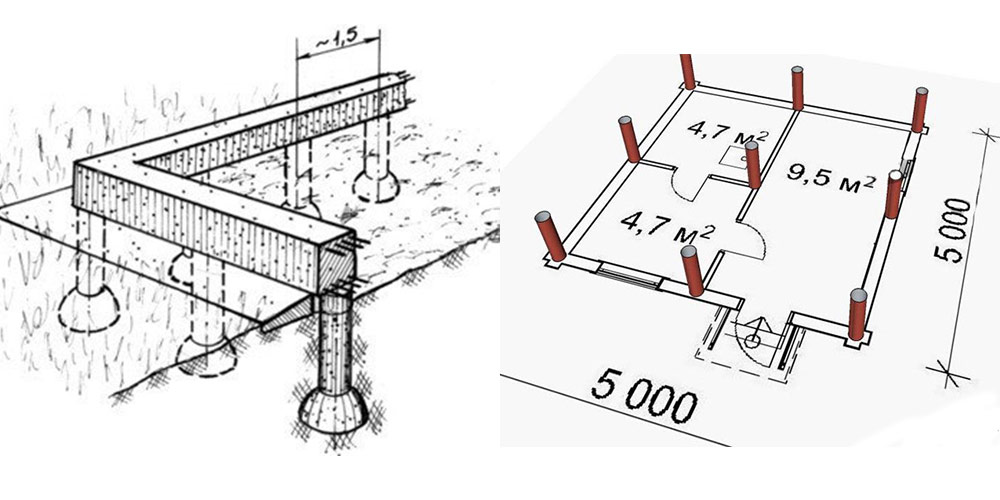

Supports are placed at intervals of 1.5–2.5 meters so that they are located at the corners of the structure, at the intersection of internal walls and the laying of load-bearing beams, as well as under stoves and fireplaces. These are the main load points. Some of them are quite capable of distributing the grillage throughout the structure. But ideally, the bulk of the weight should fall just on the support piles on which the columnar-strip foundation rests.

When choosing a brick, you should immediately exclude its silicate variety. And ceramic should be taken with the highest frost resistance. In general, if you do not want to mix and pour concrete, then it is best to prefer FBS. These blocks are originally intended for the construction of foundations for various buildings.

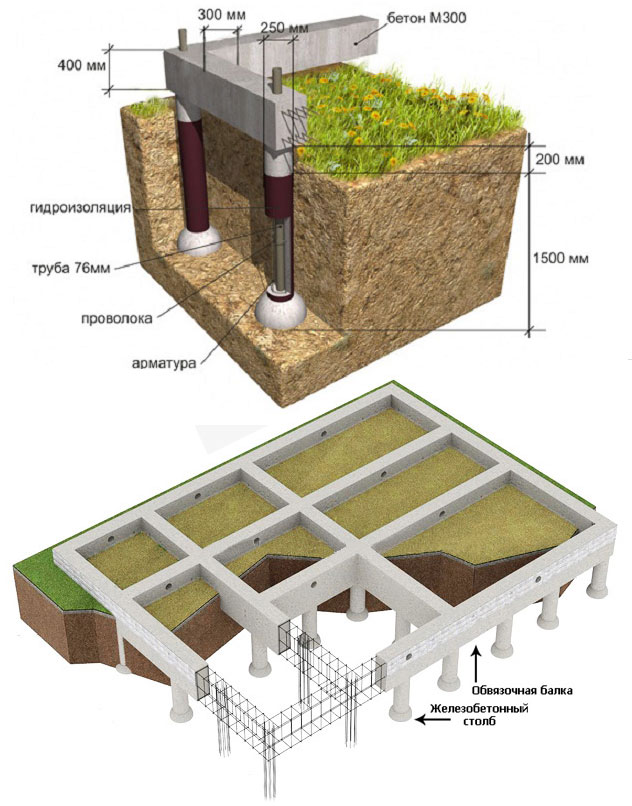

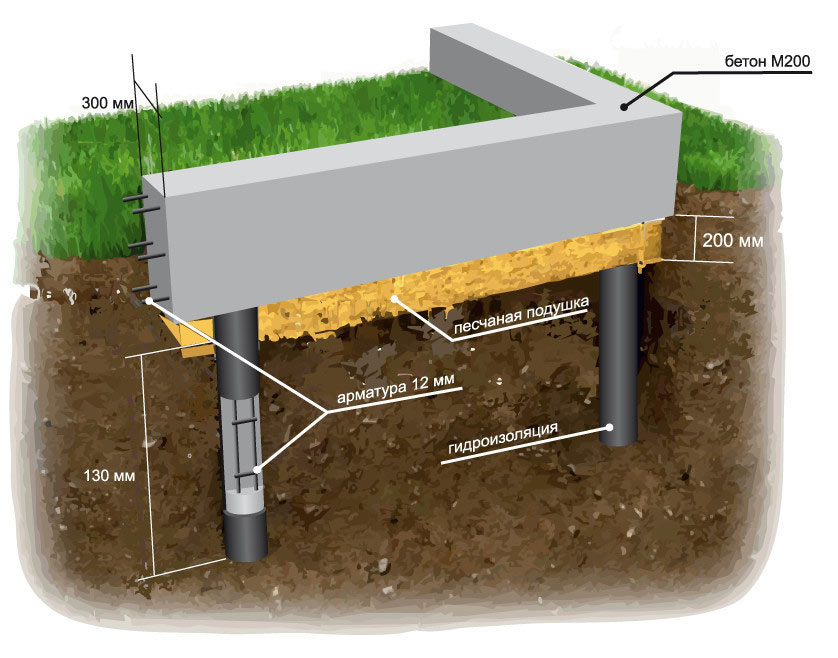

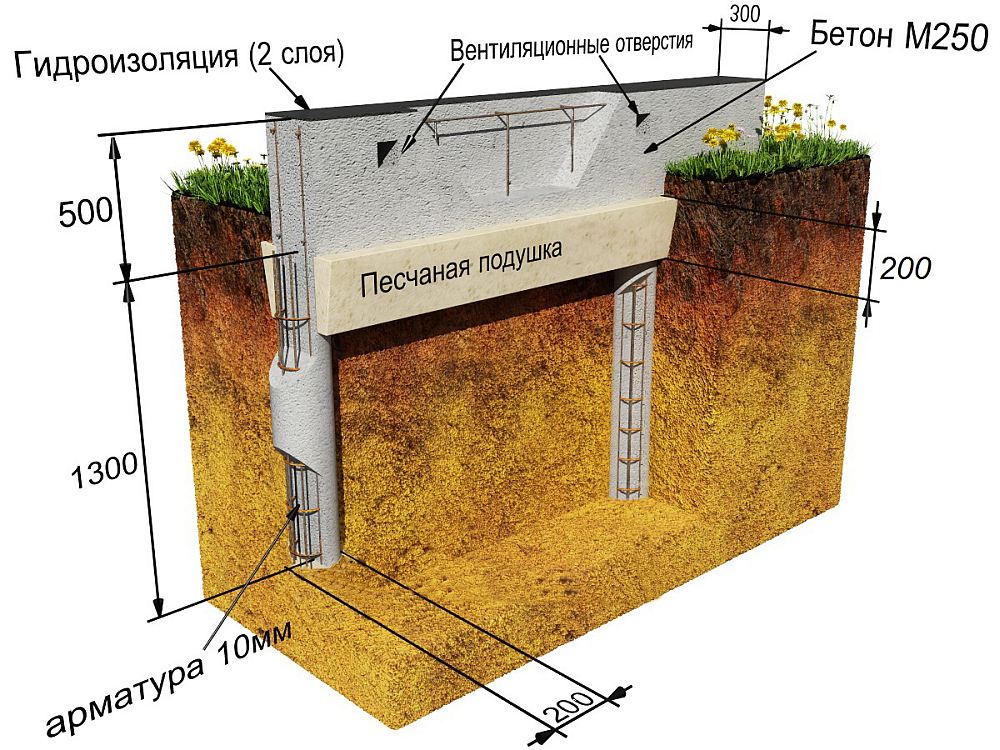

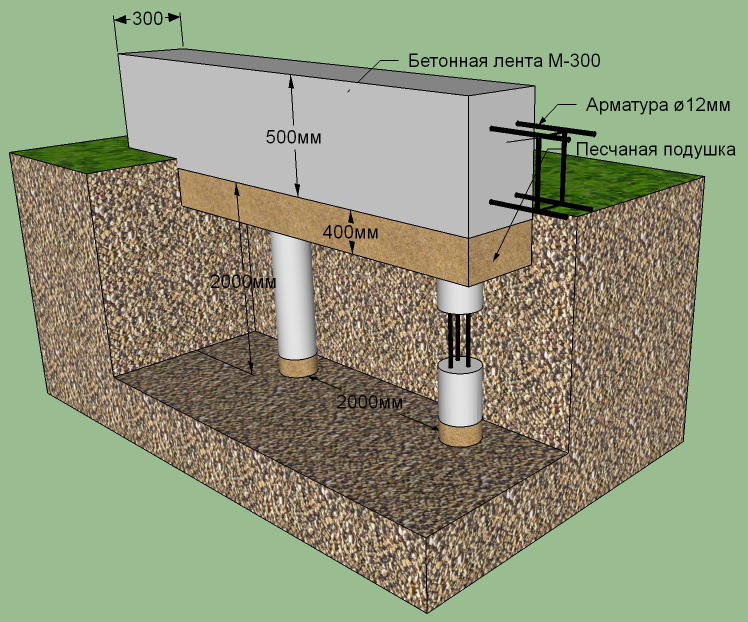

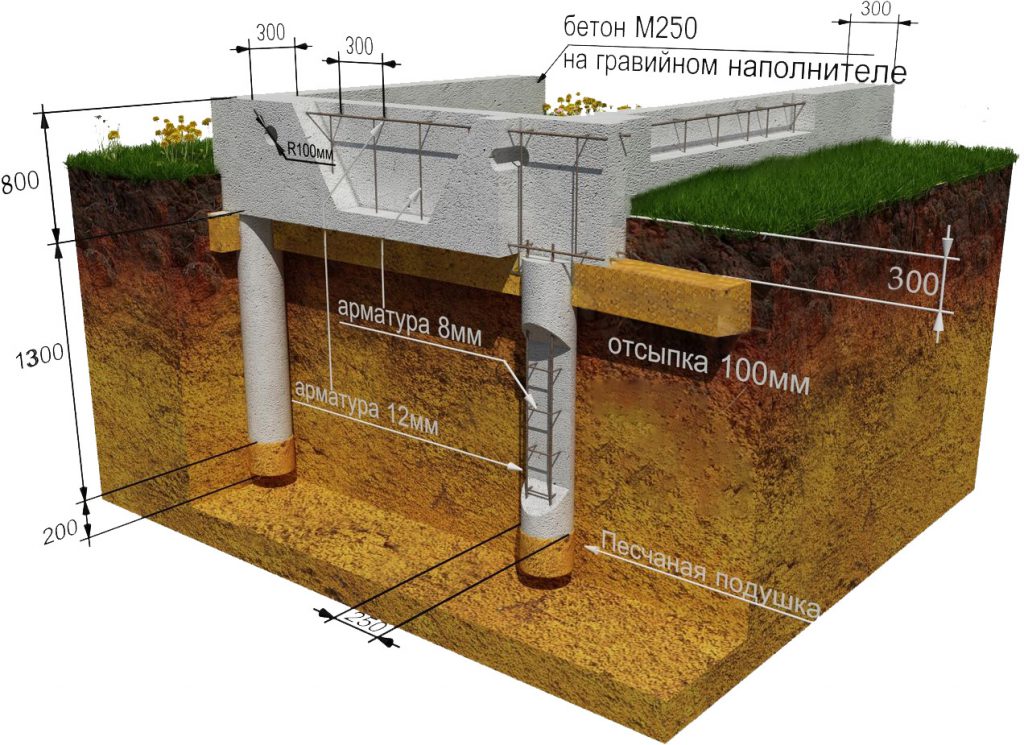

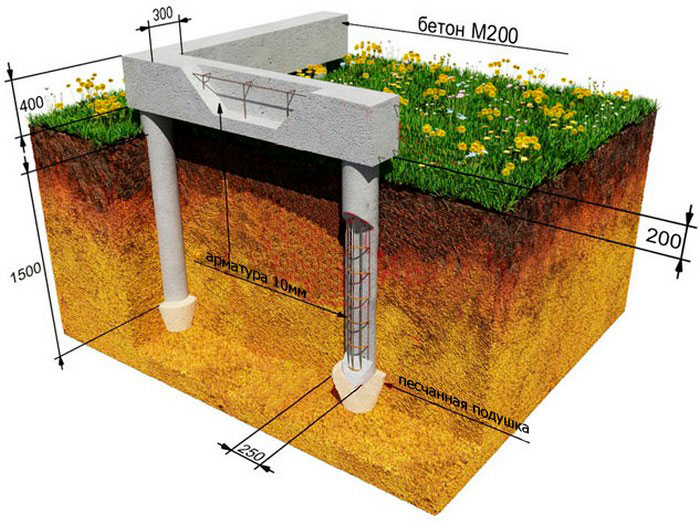

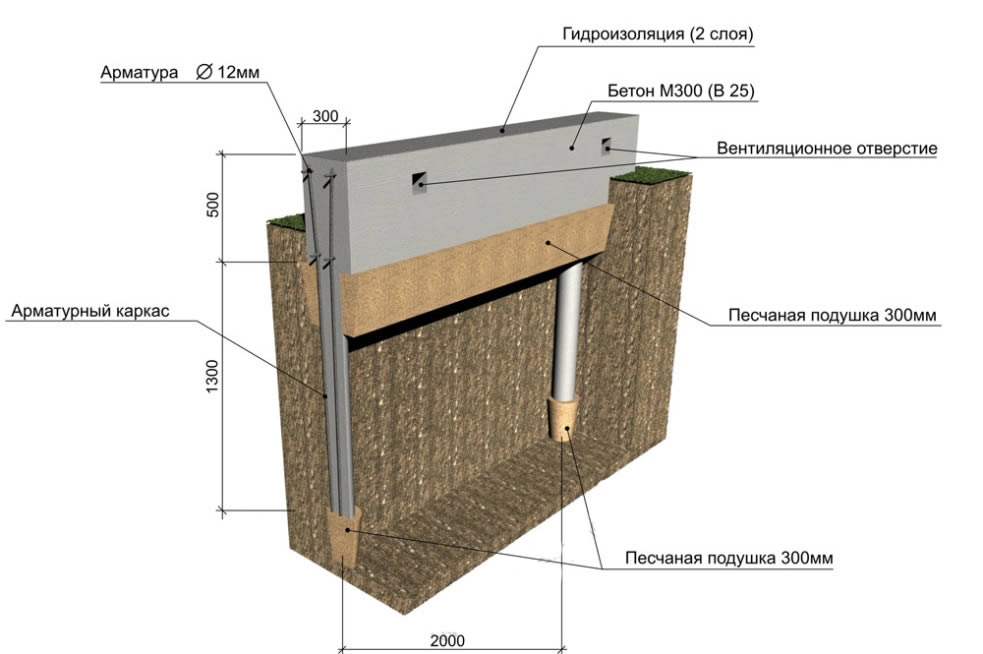

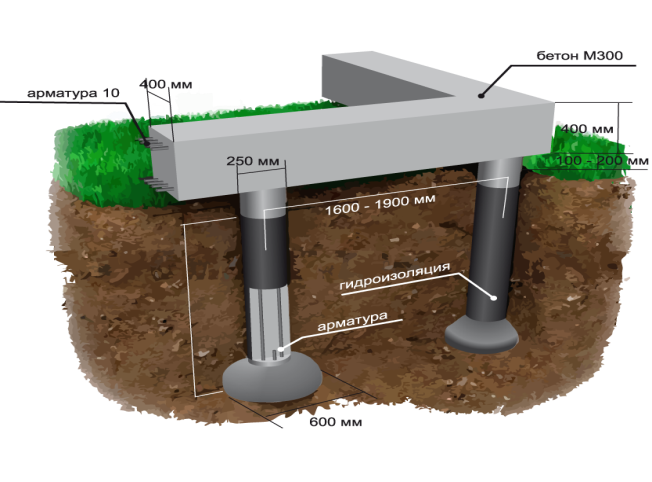

By design, the concrete grillage on top of the pillars is a small strip foundation. A separate formwork is assembled for it, with reinforcement from steel rods of 10–12 mm being placed in it. After their bundle, the finished reinforcing belt will only have to be poured with concrete mortar with a brand not lower than M-300. At the same time, for wooden structures, the grillage part is often made entirely of timber. In many cases, it is quite enough for redistribution of loads.

For waterproofing elements of a columnar base, you can use roofing material or liquid bitumen mastic. Even soft tiles are suitable if they remain unused when covering the roof of an already built building.

Recommendations for the construction of a foundation from asbestos pipes

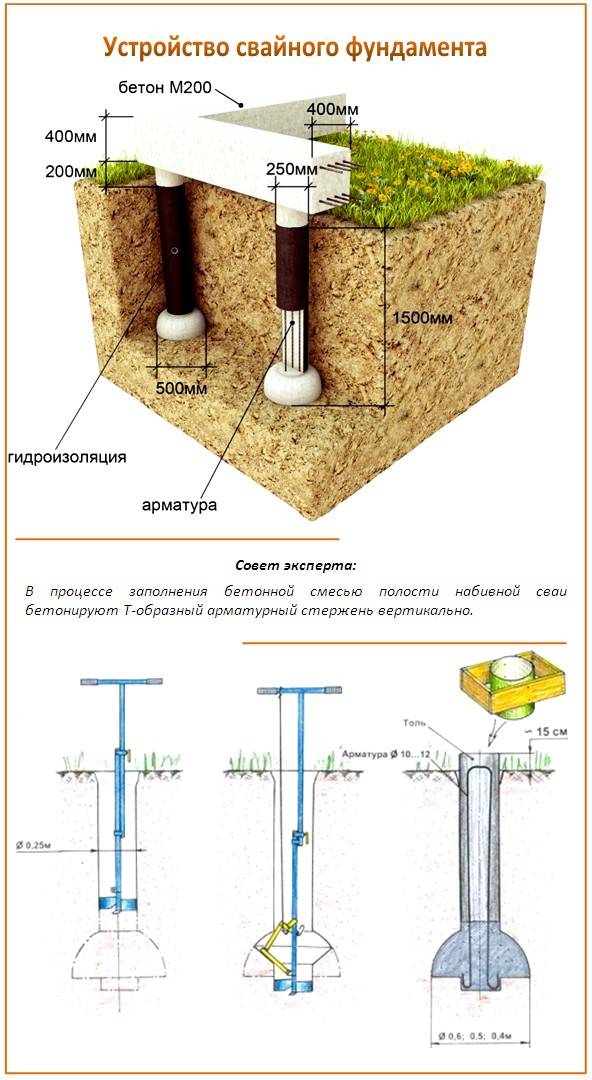

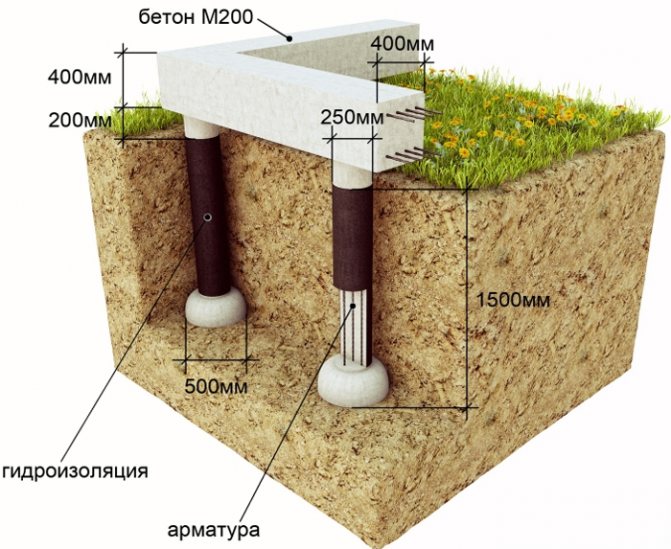

Another equally popular and relatively cheap option for building a foundation for a bathhouse, a terrace or a light structure of a house is pouring pillars, for which asbestos pipes are used as formwork. Their diameter is selected depending on the required bearing capacity. So, if about 15 cm is enough for the construction of light buildings, then for the construction of a house from a bar or log it is necessary to make more massive supports - up to 30 cm.

A brief instruction on the construction of a columnar foundation made of asbestos pipes with your own hands is as follows:

As in the case described above, first of all, the site is cleared of debris, all sod, all kinds of plantings are removed, and the foundations of old buildings, if any, are removed.

The contour of the base is marked

At the same time, it is important to control the perpendicularity of adjacent sides - as a rule, all buildings are rectangular. For this purpose, it is enough to check the equality of the diagonals with the help of a rope

All cords are fixed on pegs at the level to which the supports will rise. The entire contour should form one horizontal plane, which can be easily checked with a building level or using a level.

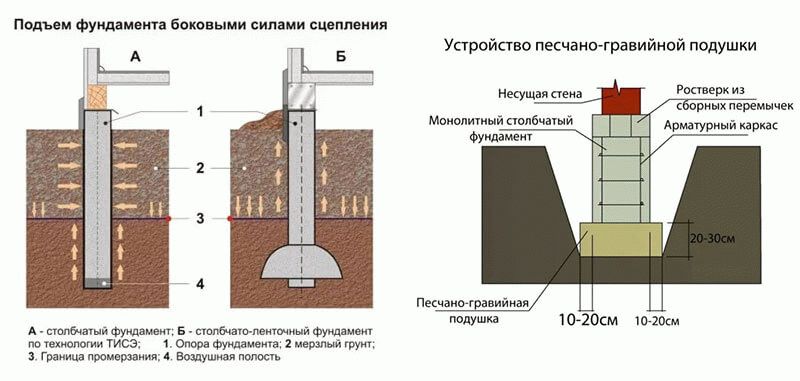

With the help of a hand drill, holes are made in the places where the posts are installed. In cases where it is necessary to install supports below the depth of soil freezing, use special equipment. At the bottom of the well, widening is often done using a special TISE drill. The diameter of the holes should be slightly larger than the size of the asbestos pipes. The depth is calculated taking into account the implementation of a cushion of sand and gravel - its height should be about 20.

After the holes for the base pillars are ready, the sand cushion is backfilled and compacted, which is abundantly moistened with water during the ramming process.

Next, a layer of roll waterproofing is laid on the bottom, preventing water leakage into the sand from the poured solution.

Pipes are installed strictly vertically to a height slightly higher than the filling level. In this position, they should be securely fixed, for example, using bars. To ensure reliable waterproofing at a high level of groundwater, it is important to treat part of the pipes that are in the ground with a polymer or bitumen composition.

The pre-prepared solution is poured to a third of the height of the pipes, after which they are raised by 10 cm so that the cement spreads along the bottom of the holes. At this point, work is suspended until the mixture is completely solidified. Such foundations are created with the aim that the future columnar foundation could withstand the buoyancy forces from the soil during seasonal heaving.

After the concrete base has completely hardened, which will take about 3 weeks, the pipes are filled with sand round and round. It must be thoroughly tamped, moistened with abundant water.

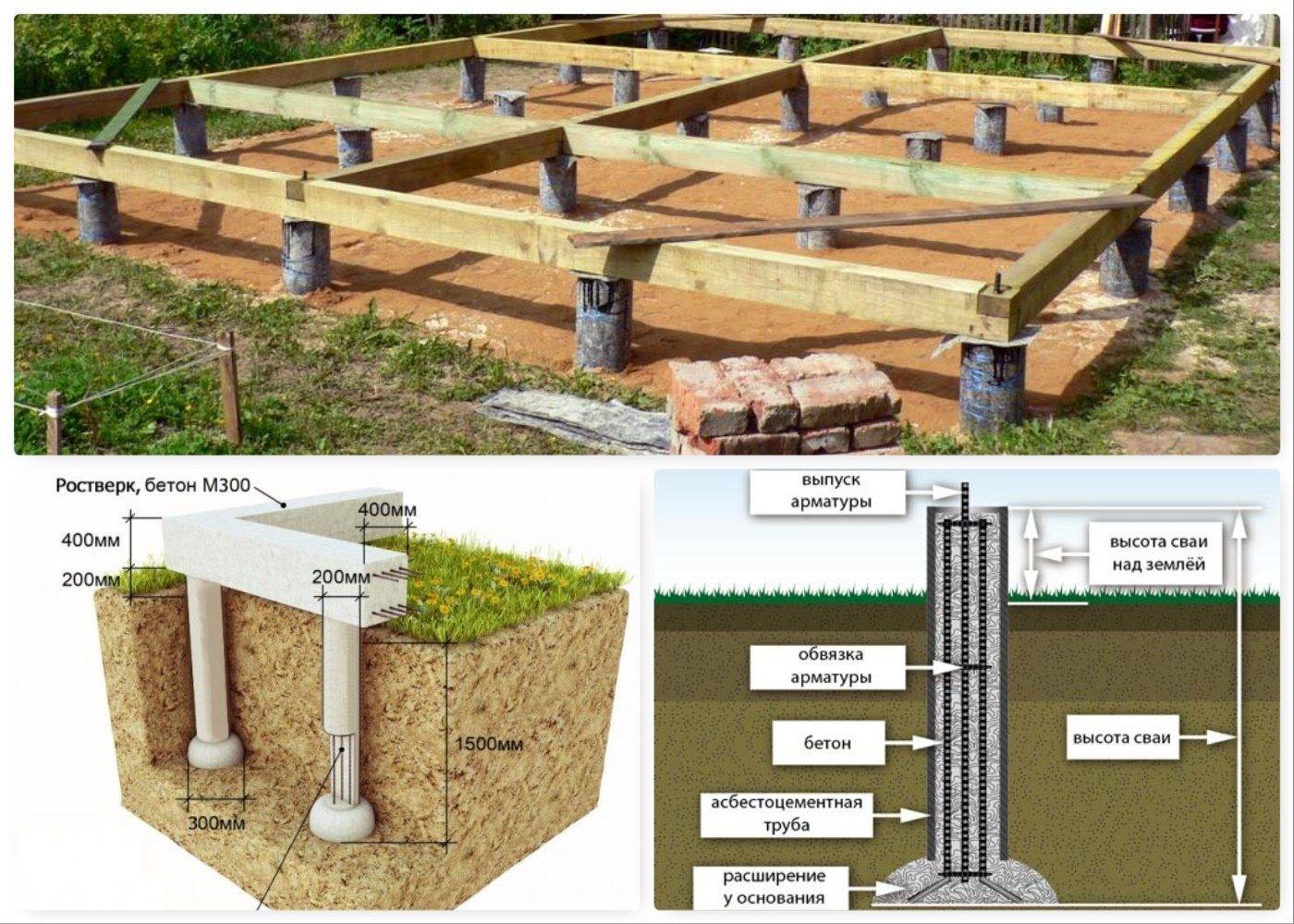

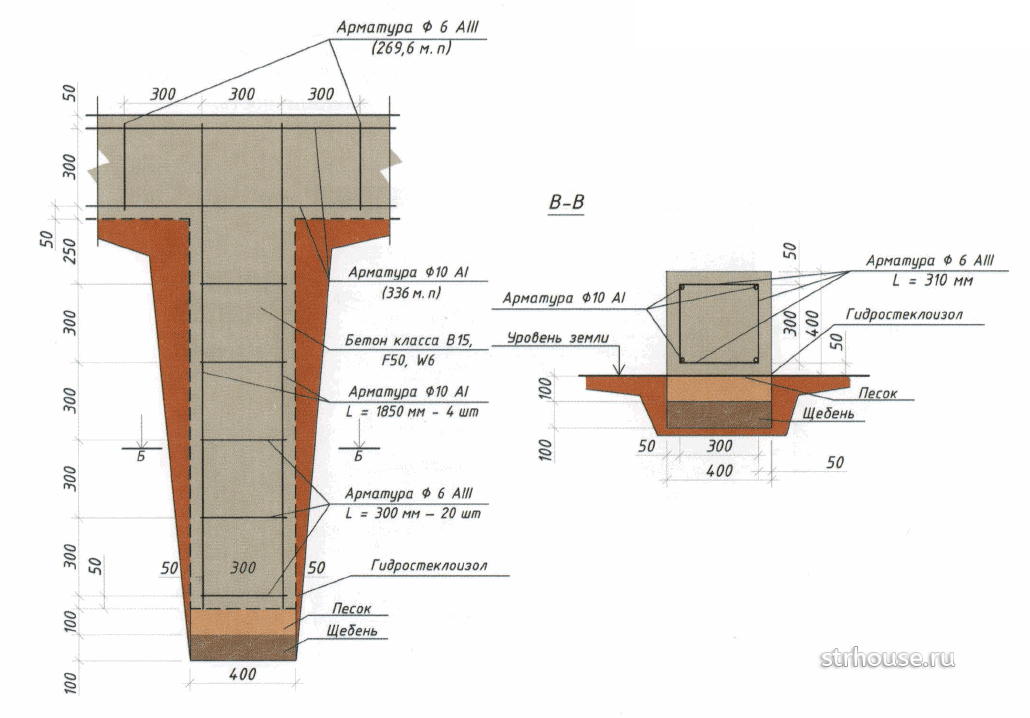

All pipes are cut to the desired level. Then, frames are inserted inside the formwork, fastened with a knitting wire and consisting of 4 vertical bars of reinforcement with a diameter of 10 to 14 mm. It is advisable to bend the lower ends with the letter G in order to form the heel. When erecting a pile-grillage structure of the foundation, it is necessary that the frames protrude about 10 cm above the level of the posts.

At the final stage, the asbestos pipes cut to the required height are filled to the brim with mortar. In this case, the mixture should be pressed periodically every 15 - 20 cm of height to remove air bubbles.

After pouring, the columnar foundation should stand for at least a couple of days, after which it will be possible to start building the walls. It is not recommended to leave the foundation for a long period without load.After the soil swells, the pillars can be crooked or raised, as a result of which a lot of time will have to be spent on correcting the situation.

Base device

In order to competently build a columnar foundation with your own hands for a frame house, it is important to clearly understand the device and the process of its construction

Work with soil

- To start work, it is necessary to prepare a site for the construction of the base.

- Complete debris removal and sod removal by about 15-20 cm.

- Leveling the ground.

- Marking the site with pegs according to the plan. The pegs are installed at the corner points of the future foundation, connected with a cord, after which the marking accuracy is checked along the perimeter.

- The marking of the installation points of the pillars is carried out.

- Digging grooves.

Support device

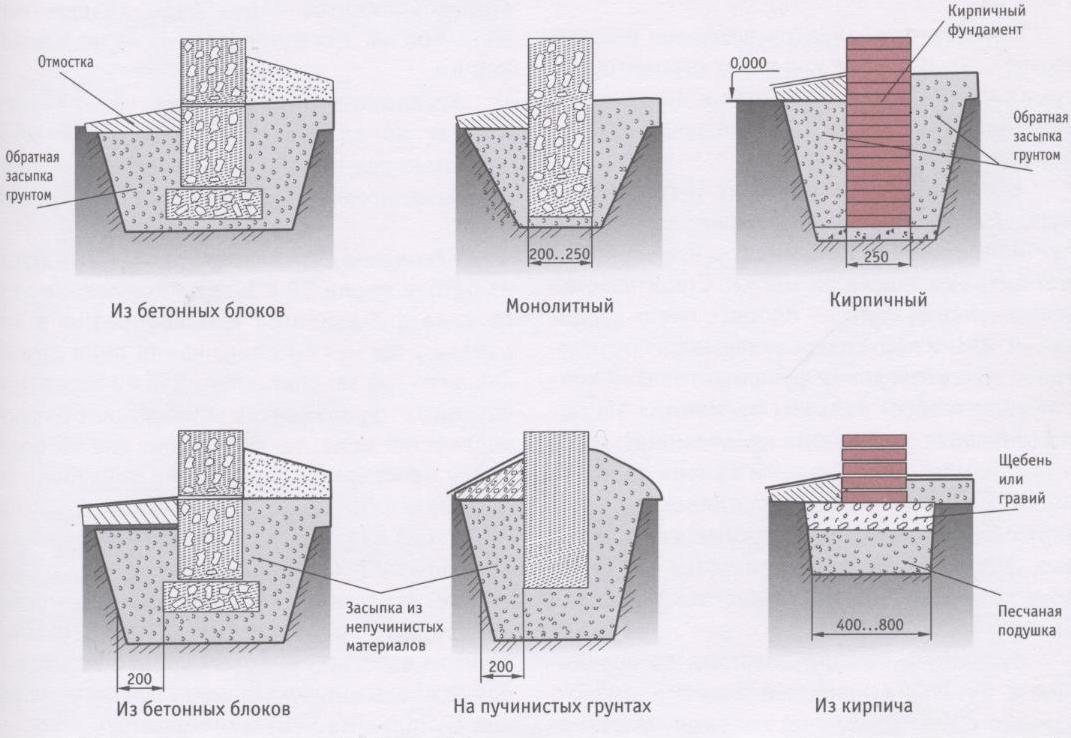

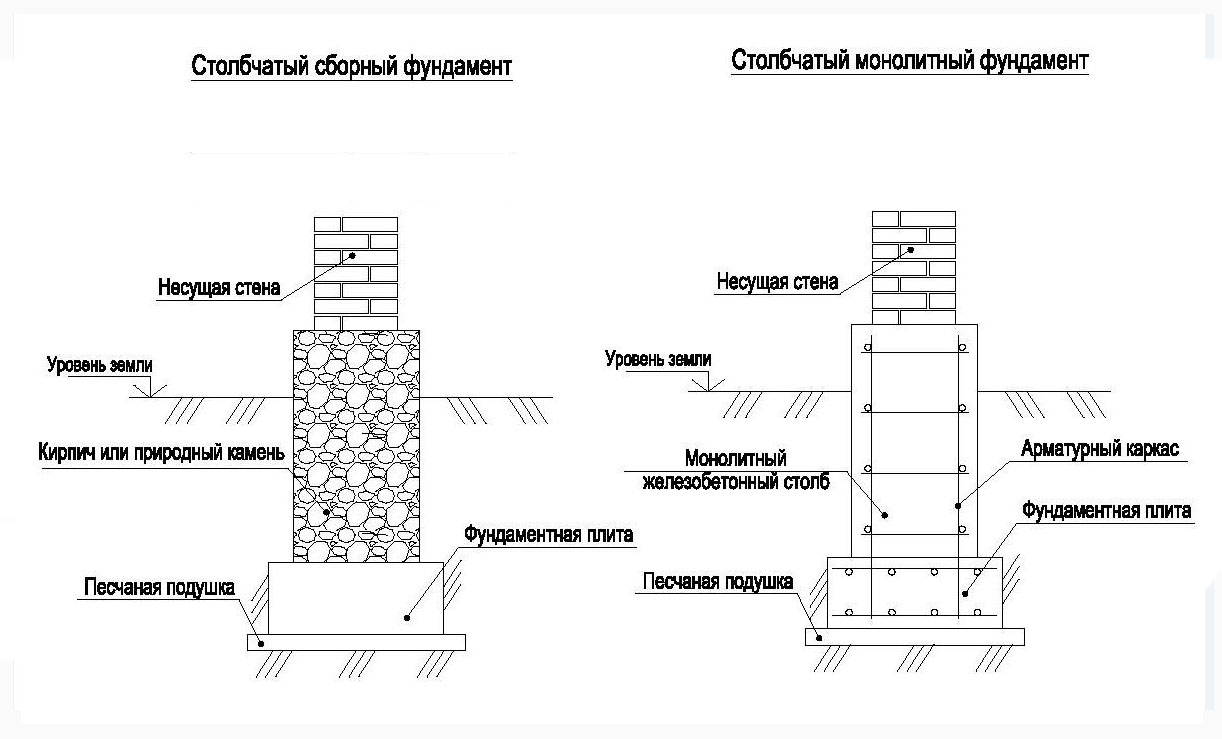

1. Brick supports. Some situations make it possible to make support posts from bricks, which is advisable to do on stable soils and in places of deep groundwater.

Laying is possible in two ways:

- laying on a sand pillow;

- construction of a concrete shoe, then brickwork on a hardened base.

Most often, supports are prepared 25 by 25 cm (a row of 2 bricks). If the construction of a large building is planned, then 4 bricks can be laid - 38 by 38 cm with additional installation of reinforcement inside the column.

It is important to maintain an exclusively vertical position of the supports with regular checks with a plumb line or level. 2

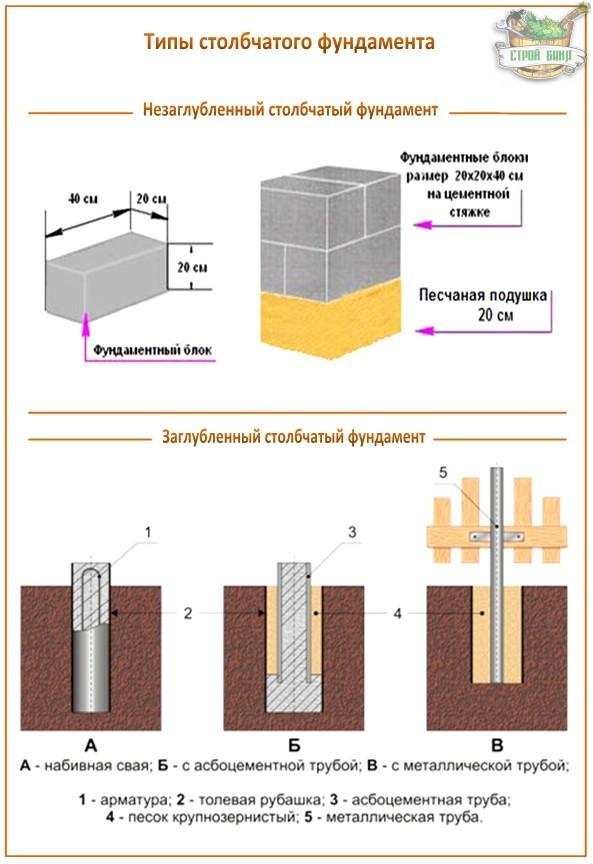

Blocky. An alternative option is wall or shoe (pillow) rectangular concrete blocks measuring 20 by 20 by 40 cm.The latter should be mounted on top of a sand pillow at the base of the supports, the shape of the racks is trapezoidal. Most often erected as shallow or shallow supports

2. Blocky. An alternative option is wall or shoe (pillow) rectangular concrete blocks measuring 20 by 20 by 40 cm.The latter should be mounted on top of a sand pillow at the base of the supports, the shape of the racks is trapezoidal. Most often they are erected as shallow or not buried supports.

The use of concrete pillars is recommended for low groundwater levels and for stationary soils.

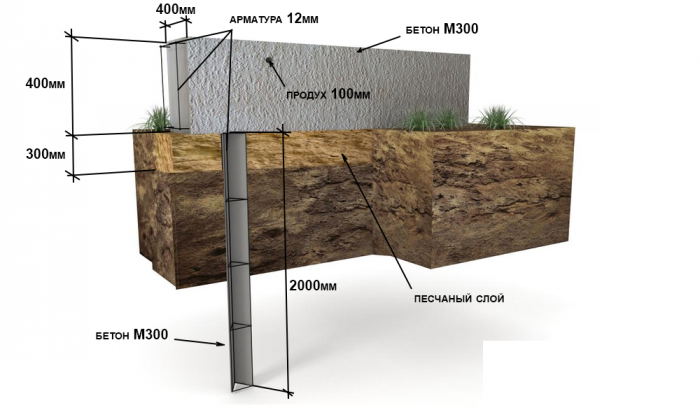

3. Monolithic. Such supports are made by pouring concrete mortar into a pre-installed formwork, round or rectangular in cross-section, additionally reinforced with steel rods.

4. Rectangular supports. The formwork for such supports is constructed from plywood or edged boards. If the construction takes place on stable ground, then the formwork is created naturally from the walls of the recesses. Before pouring the mortar, it is necessary to cover the pit walls with a waterproofing material.

When mounting racks in loose soils, formwork must be erected along the entire height of the future pillar, the recesses are dug out in such a way that it can be installed and fixed without problems.

5. Round pillars. It is allowed to erect supports round in cross-section. For manufacturing, wells are drilled 20 - 25 cm in diameter. The construction technology coincides with the manufacture of rectangular supports, instead of formwork, roofing material, plastic or asbestos pipes are used.

In some cases, the TISE technology is permissible, when specialized drills with a plow are used for wells with an extension at the bottom in order to increase the support area.

6. Combined supports. In some cases, a do-it-yourself columnar foundation for a frame house is erected not from one material, but from two. For example, first the concreting of the recessed part of the support is carried out, after which the ground part is erected, but already with the use of bricks.

Types of support-columnar bases

The main criterion that allows you to use various versions of this type of foundation is the variety of building materials used in the production of work. When planning an object, it is necessary to choose the best type of materials based on a number of parameters:

- Operating conditions.

- Construction time.

- The parameters of the future structure.

- The financial capabilities of the owner.

Consult with an architect - based on the pre-design studies, he will be able to recommend you the best project option and type of materials.

The support-column foundation consists of a series of pillars, which are made of:

- bricks,

- foundation blocks,

- steel pipes of the calculated diameter,

- asbestos pipes,

- concrete,

- natural stone,

- wooden logs.

Before planning such a foundation, it is necessary to carry out detailed engineering-geological and engineering-geodetic surveys. Without this complex of works, it is difficult to choose the optimal type of structure and lay the foundation for the required strength. The soil should consist of sand or sandy loam, and the groundwater level should be of sufficient depth. Otherwise, the pits for the supports should be buried well below the waters.

Each material imposes its own characteristics on the production of works.

Various versions of the supporting columnar base

Steel pipes are durable and resistant to stress. But they have one main drawback - they are susceptible to corrosion and can gradually deteriorate under the influence of negative environmental factors. Before laying the supports, you must:

- thoroughly treat the pipe surface with special anti-corrosion agents,

- the tube thickness must be at least 4 mm,

- the use of used materials is not allowed - only new pipes.

Asbestos poles are not susceptible to such problems. They are also resistant to water and can be used on loose soils. But it is necessary to observe the technology of laying and monitor the quality of the material.

Concrete allows medium-weight structures to be erected on a foundation. At the same time, the construction process is simple and can be performed even by non-professionals.

Natural stone is the "ancestor" of the columnar base. It occupies a large area and is able to withstand heavy loads

But when laying the foundation, it is important to have the skills of laying natural stone - there are peculiarities here that require special knowledge

The tree is destroyed by moisture and insects. It has a number of advantages (resistance to deformation and soil movements, cost), but requires close attention when choosing wood and performing work on laying the foundation. In addition, it is necessary to process the logs with special means to ensure the safety of its structure.

The columnar foundation has its pros and cons. But, if the conditions allow laying just such a foundation, it is worth giving preference to it. This will significantly reduce construction costs.

Columnar foundation made of concrete blocks

Columnar foundations made of concrete blocks are the most common type of foundation in this category. It is actively used in the construction of frame houses and various household and household buildings.

Supporting columnar base made of concrete blocks

When constructing small buildings, the order of work is as follows:

- Determine the number of posts on the perimeter of the building. Be sure to place supports at the corners of the building and at the intersection of the walls. Next, you need to put poles every 3 meters, no less.

- Next, make an accurate breakdown of the foundation on the site with the fastening of each support.

- Pits are made at the points of the pillars. The depth ranges from 15 to 30 cm. Determined from the relief of the site and the characteristics of the soil.

- Sand pillows are poured into each pit, with a capacity of 15 cm. After sprinkling with water, they are thoroughly rammed.

- After that, support platforms are made to increase the support area of each pillar.

After creating the bottom platform, they begin to place the concrete blocks. It is better to use solid blocks with greater strength. A masonry mixture is used to fasten the blocks.

A surface columnar foundation made of concrete blocks, if done correctly, can serve for a long time and withstand heavy loads.

Construction stages

Preparation of the base for the building is carried out in several stages.

Marking the territory for the foundation

In accordance with the plan of the house, the territory is marked out. All garbage and plants are preliminarily removed, bushes and trees are uprooted. It is advisable to remove about 10 cm of the top soil layer.

With the help of pegs and a stretched rope, the boundaries of the house and all internal load-bearing walls are marked. It should be checked that the angle between the walls is strictly 90 °, unless the project involves a complex wall configuration.

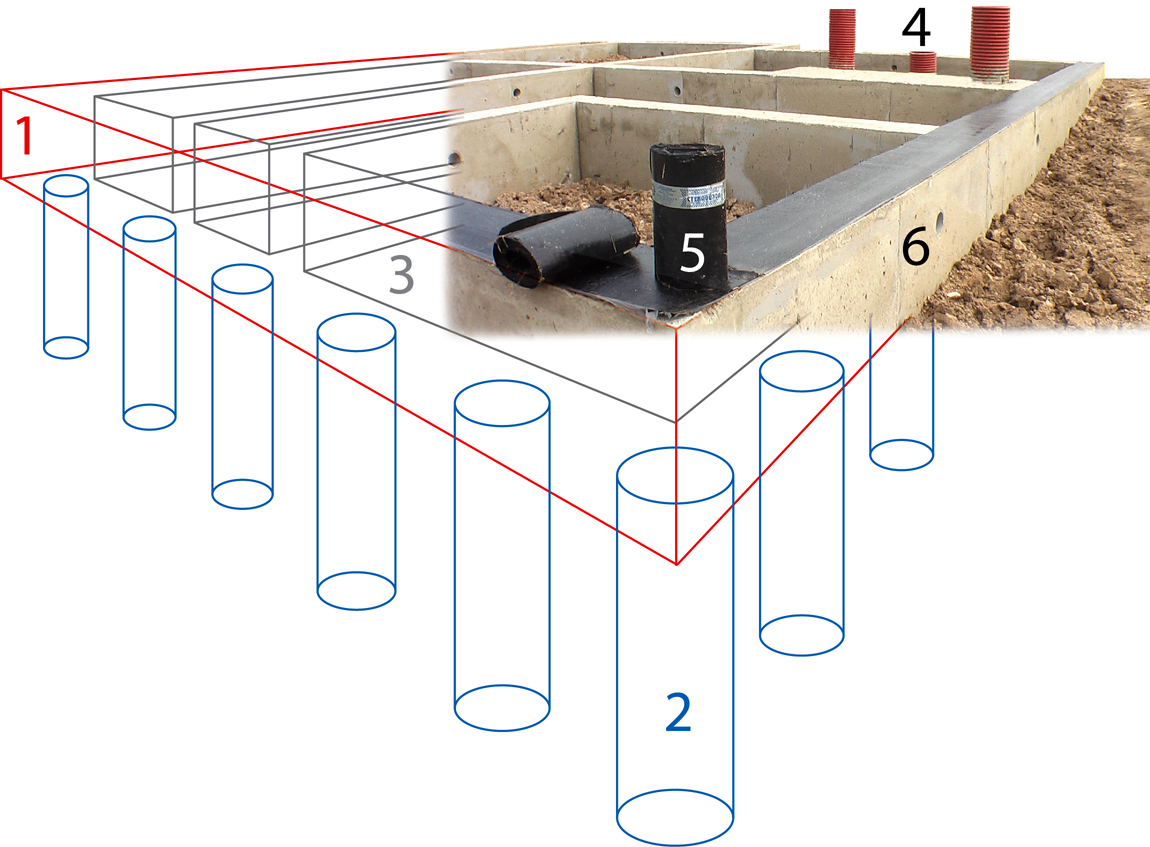

Trench

In this case, the trench serves for the convenient formation of piles. It is dug to a depth of no more than 40 cm and of the width that will allow you to install wooden formwork and start digging holes for piles without any problems.

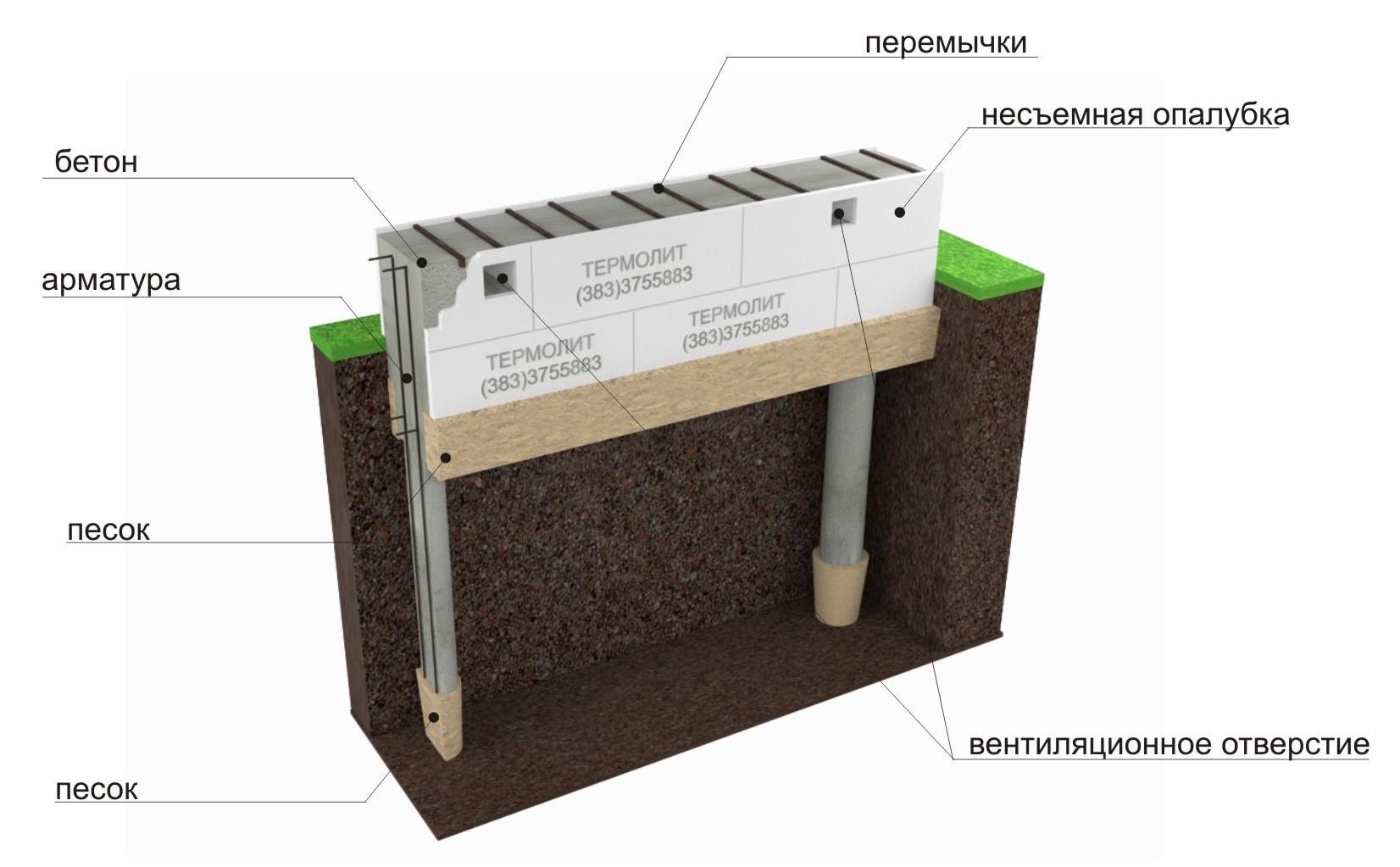

After they are formed, the trench can be buried, because the concrete tape acting as a grillage should not lie on the ground. Sand can be poured under the belt part to the desired height.

Where to dig in the pillars?

The number, diameter, depth of piles should be determined at the stage of calculation. The pillars are installed in the corners of the building, under the load-bearing walls, in the corners of the junction of these walls, as well as in those places where the installation of some kind of heavy equipment is envisaged.

For example, if you plan to install a stove, fireplace, etc., it may be necessary to strengthen the foundation in this place. In this case, it makes sense to install piles at the corners of this reinforced area.

To dig holes for piles, drills are used, which are selected in accordance with the calculated values of the pile diameter. The diameter should be slightly larger in order to be able to install the formwork and lay the waterproofing.

In order to save on the amount of concrete, it is possible to increase the area of support of the pile on the ground due to its wider base. Thus, without increasing the diameter and weight of the pile, the load on the ground is reduced due to the wider supporting surface. This can be done using a special TISE drill.

Attention! For reference, the TISE drill differs from the usual one by the presence of a folding plow, which allows you to form a cavity of a larger diameter in the desired part of the hole to be dug under the post. Sand is poured to the very bottom, possibly with the addition of crushed stone, with a layer of about 10 cm

Formwork

Before concreting, it is required to erect the formwork, as well as reinforce the hole for the pile. As formwork, boards, plywood, metal, special boards, purchased in stores, boards, etc. can be used. The holes are waterproofed with roofing material rolled into a pipe in 2 layers.

The formwork for the pile can be an asbestos-cement pipe, which then remains in the ground. Roofing material, pipes are inserted into the hole under the pile to the end. Inside, a reinforcing frame is formed from reinforcement with a diameter of 12-16 mm.

Depending on the diameter of the pile, the reinforcement can be installed in a rectangle, or have a triangle in cross-section with a central rod. Vertical sections are tied with horizontal rods and wires with a pitch of about 30 cm. The reinforcement should be located in the center of the pipe, without touching the walls.

The ends of the reinforcement should protrude 15-25 cm above the ends of the pipe, since the reinforcing base of the strip part of the foundation will be tied to them.

Pouring with concrete

The hole is ready for pouring concrete. First, a layer of 20 cm is poured, while the roofing felt pipe is lifted, which makes it possible for the solution to spread over the entire base of the pile, forming a support "shoe".

During the pouring process, air pockets can form, due to which the strength of the entire structure is significantly reduced in this place. To get rid of voids, it is better to take care of a submersible vibrator in advance.

In extreme cases, you need to pierce the freshly poured solution with a piece of reinforcement. After the support has been formed, the entire pipe can be poured. The pile must be completed in one day.

After all the piles are concreted, they begin to form the tape part.

The strip part of the foundation is not designed for contact with the ground, its task is to transfer the load to the piles. After pouring them, the formwork should be covered with sand, a waterproofing layer of material should be laid, reinforced, and the reinforcement should be attached to the rods sticking out of the poured piles and filled with mortar.

After the concrete hardens, the formwork is removed, and the sand from under the tape is removed. As a result, the pillars support the weight of the entire building, resting on the ground below the level of its freezing, and the concrete grillage tape serves as the basis for the construction of the walls.

For information on how to correctly make a columnar-tape foundation with your own hands, see the video below:

Pros and cons of columnar foundations

The main disadvantage of the columnar foundation is the impossibility of arranging a basement in the house. Therefore, if this factor is important, then you should not stop your choice on this type of basis. But in other cases, you should definitely consider all the advantages and disadvantages.

For a private developer or summer resident, the "pluses" will be the following facts and criteria:

-

cost, which is from 50 to 75% of a similar strip base;

-

significantly less excavation work, since only a few holes need to be dug, in contrast to a long and often deep ditch around the perimeter of the house;

-

it is quite possible to cope with the implementation of all stages of work on your own without attracting additional labor and special equipment;

-

the device of the foundation in parts: the posts can be made gradually and not necessarily all at once. This is very convenient for summer residents who have the opportunity to engage in construction on weekends;

-

this type of foundation has a much smaller impact on the soil, which is important in problem areas.

Among the shortcomings, attention should be focused on the non-versatility of using this type of foundation, which can only be arranged for frame, wooden houses and other buildings made of light materials. For brick walls, it can be used only under the condition of a deep, more than 1.5 m, depth of laying, but in such cases, a foundation on piles is more justified if the construction is carried out on difficult soils, as well as a belt, with the possibility of a full-fledged underground level. For brick walls, it can be used only under the condition of a deep, more than 1.5 m, depth of laying, but in such cases, a foundation on piles is more justified if construction is carried out on complex soils, as well as a belt, with the possibility of a full-fledged underground level

For brick walls, it can be used only under the condition of a deep, more than 1.5 m, depth of laying, but in such cases, a foundation on piles is more justified if the construction is carried out on difficult soils, as well as a belt, with the possibility of a full-fledged underground level.

It is not recommended for buildings made of lightweight aerated concrete because of the poor bending performance of the material, which during the first years of operation will lead to the formation of longitudinal cracks on the blocks.

In what cases is it impossible to build a columnar foundation for a house?

The columnar foundation works especially well on heaving soil, which is very dangerous for the strip one.

The forces of frost heaving in this case affect a much smaller area of the base of the house, which, as a result, does not affect the strength of the structure and its seasonal shrinkage, at least these phenomena have a less pronounced effect.

It is ideal, of course, to lay the pillars at a depth below the freezing level, but this option is not suitable for all climatic zones.

For example, for construction in regions with a large depth of soil freezing or in the permafrost zone, it is possible to make a columnar-strip foundation, which is erected using the TISE technology.

The main feature of this type of house foundation is that columns are erected in the ground at a certain depth, and as a kind of grillage, right on the surface of the earth, a full-fledged monolithic tape is arranged, the construction of which is completely identical to the construction of a strip foundation, but with one difference: all work is being carried out exclusively on the surface. Thus, the necessary protection against the influence of heaving forces on the bases is provided.

Of course, when designing a capital country cottage made of stone or brick, there is no need to think about building a columnar foundation.

You should also take into account the geological situation on the site and know that it is not suitable for weak, water-saturated, peat and clay soils, which are characterized by horizontal movements.

In some exceptional cases, their influence can be leveled, for example, with a grillage, as well as with the help of special measures aimed at reducing the frictional force of the soil against the support. For this, various mastics and lubricants are often used, with which the surfaces of the posts are treated.

It is imperative to pay attention to the relief of the site: in the presence of large differences in height, from 1.5-2 m and more, it is not only unreasonable to stop your choice on a columnar foundation, but it is also dangerous due to the insufficient stability of such a structure and its tendency to overturn