Pillow for the foundation of the house

Pillow for the foundation of the house.

When building a house, a very important element is the soil on which it is erected. All loads from the building are transferred to the ground. But often, on which it is planned to erect a building, they cannot ensure the maximum stability and reliability of the site for the supporting structures, which means that problems with the shrinkage of the foundation may arise.

The solution to this problem is to make a pillow to support the house. In the construction of buildings, three types of foundation pillows are used. The material for the pillow is:

- sand;

- crushed stone;

- concrete.

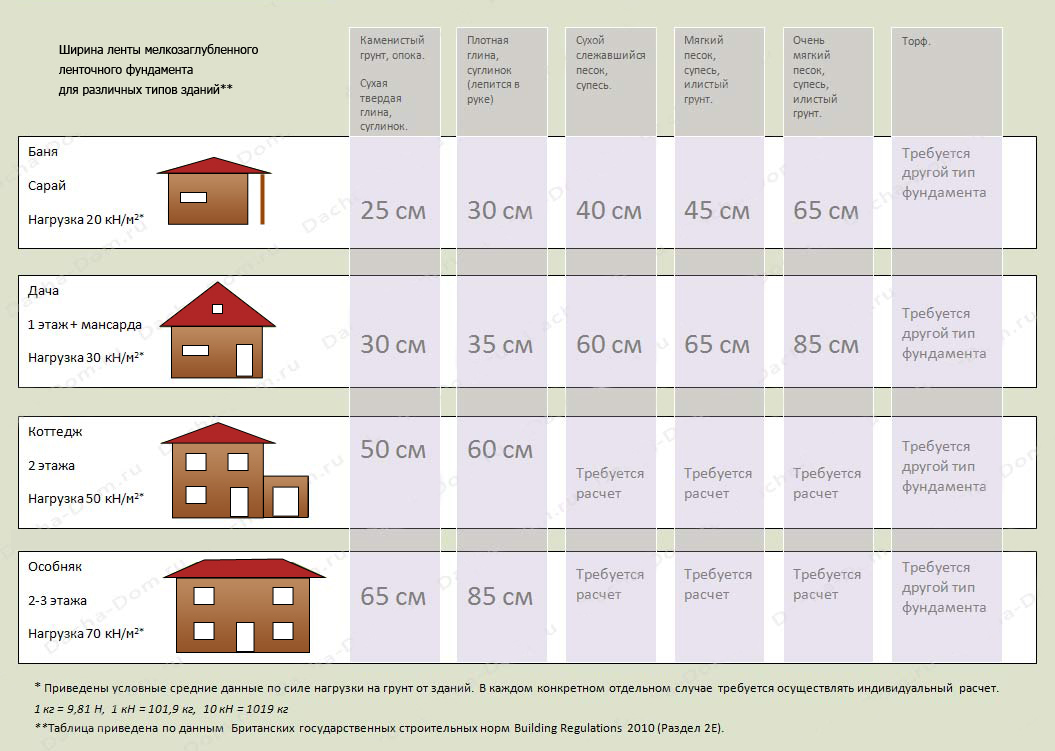

The choice of material for arranging the pillow depends on the type of soil, the number of floors in the house, the climate of the region, the level of groundwater, the building materials from which the house is built.

Sand pillow

The advantages of this type of pillow include:

- cheapness of the material;

- ensuring the optimal level of load on the bottom of the foundation;

- simplicity of the device.

The disadvantage of this foundation is that the sand bed is not suitable for the construction of buildings with heavy materials.

The sandy base is made with a thickness of 20-25 cm. It is carefully leveled and tamped, while the sand must be moistened in order to achieve the maximum density of the pillow.

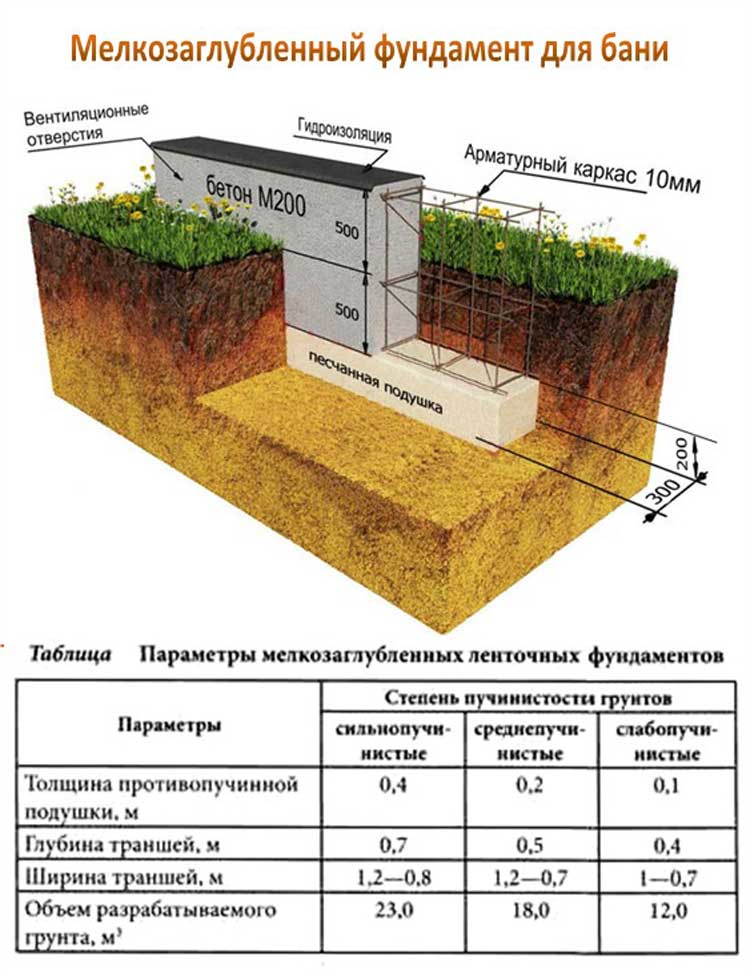

Reinforcement scheme for a buried strip foundation.

The following tools are used to construct a sand cushion:

- shovel;

- hose or bucket for water;

- vibrating plate.

In areas with a sand base, drainage is arranged. A sand cushion is more often performed under the foundation of one-story buildings made of light building materials, which are built on soils with a low level of groundwater.

Rubble pillow

For the arrangement of this type of base, crushed stone of 20/40 mm fraction is used. When making a cushion from crushed stone, a layer of 10-15 cm of coarse sand is first poured. This layer is carefully leveled and tamped. A layer of crushed stone is poured over the prepared layer of sand. Layer thickness - 20-25 cm. Crushed stone is carefully leveled and compacted as much as possible. As for a sandy base, a vibrating plate is used to tamp crushed stone cushions. The upper layer of the crushed stone base is the beginning of the foundation of the structure.

The base is larger in size than the area of the foundation itself. It protrudes 15-20 cm from both sides of the house support tape along the entire perimeter of the building. A crushed stone pillow is reliable, suitable for the construction of houses of any height and number of storeys, made of a variety of materials. This is an inexpensive and inexpensive type of foundation.

Concrete base

The most reliable and strongest type of base is a concrete pad. It can withstand any load and is suitable for any building. There is only one drawback of this type of base - the high cost.

Equip it in stages as follows:

- level and compact the soil under the base;

- a layer of crushed stone 10 cm thick is poured over the ground;

- with the help of a vibrating plate, the crushed stone is compacted;

- formwork is installed, the material for it is wooden boards or plastic plates;

- the height of the formwork is equal to the thickness of the concrete base, it cannot be higher than 30 cm and the concrete is poured exactly at the level of the top of the formwork. The foundation starts at the top of the concrete base;

- the concrete pad is reinforced with metal rods with a cross section of 8-12 mm to improve its strength properties;

- concrete is poured and compacted with a deep vibrator.

The concrete base must have an area larger than the area of the supporting structure and protrude 15 cm from under it. The connection between them is performed using metal rods.

Minimum curing time

It is in no way possible to neglect the technology of arranging the foundation. This is especially true for the construction of houses on several floors. If the supporting structure does not stand up properly, it is likely that the building will not withstand even moderate winds.

The most popular type of foundation is strip. For him, the minimum time for strengthening should be at least 3 weeks under the following conditions:

- It is sunny outside (meaning in summer, it will take more time in spring).

- Low humidity.

- The absence of any external influences.

In this case, the foundation will quickly solidify and will be ready for further construction work.

Once the support structure is already poured, do not try to fix anything on the fly. Wait until it is completely dry, and only then carry out the modifications.

Ideally, it is better for the foundation for a serious building to stand for a month in good weather.

Please note: if you have a deep structure, then you need to be prepared for the fact that in the summer it will dry for 1.5-2 months. During the hardening of concrete, shrinkage and hardening of the solution occurs.

At this stage, the process is 70% complete. The remaining 30% occurs during the first year of construction

During the hardening of concrete, the mortar shrinks and hardens. At this stage, the process is 70% complete. The remaining 30% occurs during the first year of construction.

Even with the correct timing for standing the base for the house, be prepared for slight shrinkage over the next year.

But if the time frame is very limited, then be guided by the fact that the foundation cannot stand for less than two weeks. Otherwise, all subsequent construction will already be meaningless. If the deadlines for drying the foundation are not met, the risk that the walls may simply collapse increases significantly. Over time, the unfinished foundation will simply "play", which will entail instability of the building itself.

Foundation conservation

If, nevertheless, there is a need to "winterize" the structure, then you need to take care of its competent insulation. You can preserve the foundation for the winter or another period by taking care of the following measures:

- waterproofing with bituminous materials;

- thermal insulation with extruded polystyrene foam (penoplex);

- prevention of damage to the structure by groundwater, especially in the spring.

It is important to note that conservation is a necessary measure when it is impossible to continue work, and not a necessary stage. It often happens that having started construction, the owner cannot finish it for personal reasons.

Probably, this is where the myth of maintaining a support under the structure of buildings came about.

In conclusion, it should be repeated that how much the monolith should stand after pouring depends only on temperature conditions and concrete. After gaining 100% compressive strength, you can safely proceed to the "zero" cycle.

The drying time of the foundation is an important point when building a house. Although the term "drying" is not entirely appropriate in this case, concrete requires a lot of moisture to cure. About how time affects the strength of the foundation, let's try to understand this material.

How the drying time affects the foundation can only be understood by knowing the characteristics of the concrete. Here it is necessary to distinguish between the concepts of "drying" of concrete and "strength" of concrete.

Drying of concrete is the process of moisture loss in concrete. A kind of dehydration. Concrete gains strength within 30 days from the moment of pouring.

Compressive strength is the main characteristic of concrete. And, as already mentioned, concrete is gaining it gradually. Concrete gains the first 70% of its brand strength within 7 days. Therefore, it is recommended to disassemble the formwork not earlier than this time.

The drying time of the foundation can negatively affect the strength of the entire structure.After all, water is actively involved in the processes of strength gain. Since the process of curing takes a long time - up to 30 days, it constantly evaporates. And so that the foundation does not lose strength, it must be watered.

In addition to directly watering the foundation with water, it is necessary to ensure that water does not evaporate from the foundation tape. For this, the foundation is covered with roofing material or plastic wrap.

How to determine when shrinkage is over

All processes associated with soil compaction occur so slowly that it is impossible to visually determine their completion. Therefore, the end of shrinkage is determined on the basis of calculations, in which all factors are taken into account.

If an error appears in one of the values that are used for such calculations, then there is a high probability that the whole process will go wrong.

There are cases when a team of builders erected a house, but incorrectly determined the characteristics and properties of the soil.

This increases the duration of the installation of the house, but greatly reduces the likelihood of improper shrinkage of the base and subsidence of the walls.

Professional advice

In the question of how long the foundations should stand after pouring, you should be especially careful. It will not be superfluous to read the advice of professionals.

Many people recommend that you completely tamp the sand pad before you start pouring. It is best to fill in several stages - this will increase the term and quality of the base.

After the first floor of the structure is erected, it is best to wait 7-10 days. This time will be enough for the foundation to adapt to the loads. It will also be easier to remove cracks and damage at this stage.

The foundation is the basis of the entire structure, therefore, during the construction of this part, you should be especially careful.

To get acquainted with the possible types of base for a house and the timing of their exposure, watch the video: It is imperative to give time for the base to solidify, so that it can further safely withstand the weight of the structure. Otherwise, poorly frozen formwork in the future can lead to serious consequences in the form of distortions and destruction of the whole house.

How to properly harden the structure

As already mentioned, a concrete surface becomes more or less hard from a viscous one in about one week - and it is during this period that it acquires more than half of its strength indicators, but this is far from the limit and should not stop there. That is, after just a seven-day wait, you cannot try the concrete with your finger and, after making sure of its hardness, happily start erecting floors, walls and ceilings.

It is important to cancel that concrete cannot be simply left alone - otherwise it will dry out greatly and may crack: throughout the drying period, paradoxically, it needs to be slightly moistened. Do not pour water from a watering can, like a flower bed - namely, moisten a little - and this is done throughout the entire period, how long the foundation dries under a bath or under a country house

At first glance, such a strange event is being performed, if only so that the concrete does not dry out and does not crack, and the chemical reactions at the moment of setting the foundation proceed correctly and evenly. In the end, potassium hydrosilicates are formed precisely from the mineral compounds of cement mortar and water, more precisely, from their interaction and fusion into one single substance.

It is important to cancel that the direct process of increasing the strength characteristics can last for several years - but this no longer affects the construction (if we are not talking about massive dams and bridges), but only gives an additional guarantee of quality. If the foundation can withstand the load now and distribute it correctly, then everything will only get better - it already inspires some hope in the future.

There is a more or less average period after which construction usually begins: this is due to the same rather tight deadlines for the construction of a building so that the construction of a summer cottage does not stretch out for decades. Concrete, which dries and hardens in natural conditions without additional influence from the outside or inside and without any catalysts, takes an average of a month in order to fully react with water and enter a state where it can already be exposed to various loads.

How the time required for proper shrinkage is determined

To determine how long the foundation must stand before the walls are erected, the following factors must be carefully analyzed:

- results of geodetic and engineering studies;

- average annual rainfall;

- soil freezing temperature;

- deepening the foundation;

- type of foundation;

- materials from which the foundation is made;

- the mass of the finished structure.

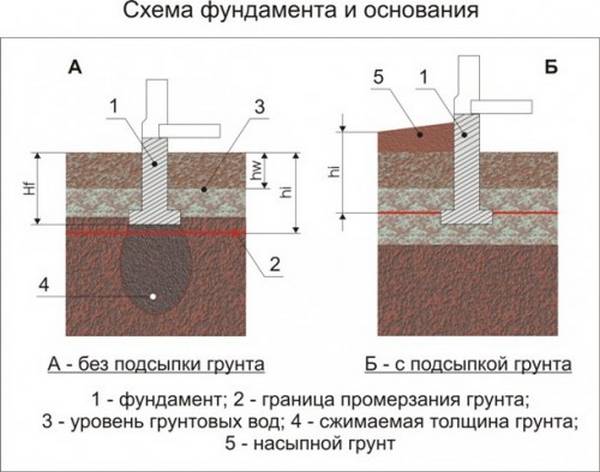

As a result of geodetic research and engineering surveys, the structure of the soil and its characteristics are determined. These data allow you to determine how the soil will behave under the influence of the base and the entire structure and how long it will take to compact it.

An incorrect determination of the characteristics of the earth will lead to the fact that in winter or after heavy rains it will sag and the wall of the house will be covered with cracks. All these parameters determine how much time is needed for the correct shrinkage of the foundation, without which it makes no sense to proceed with further construction.

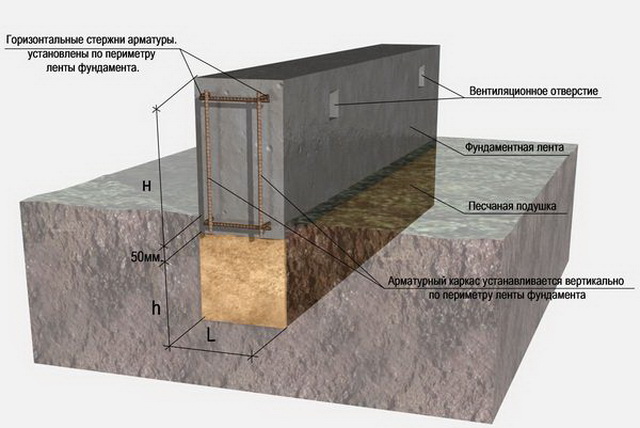

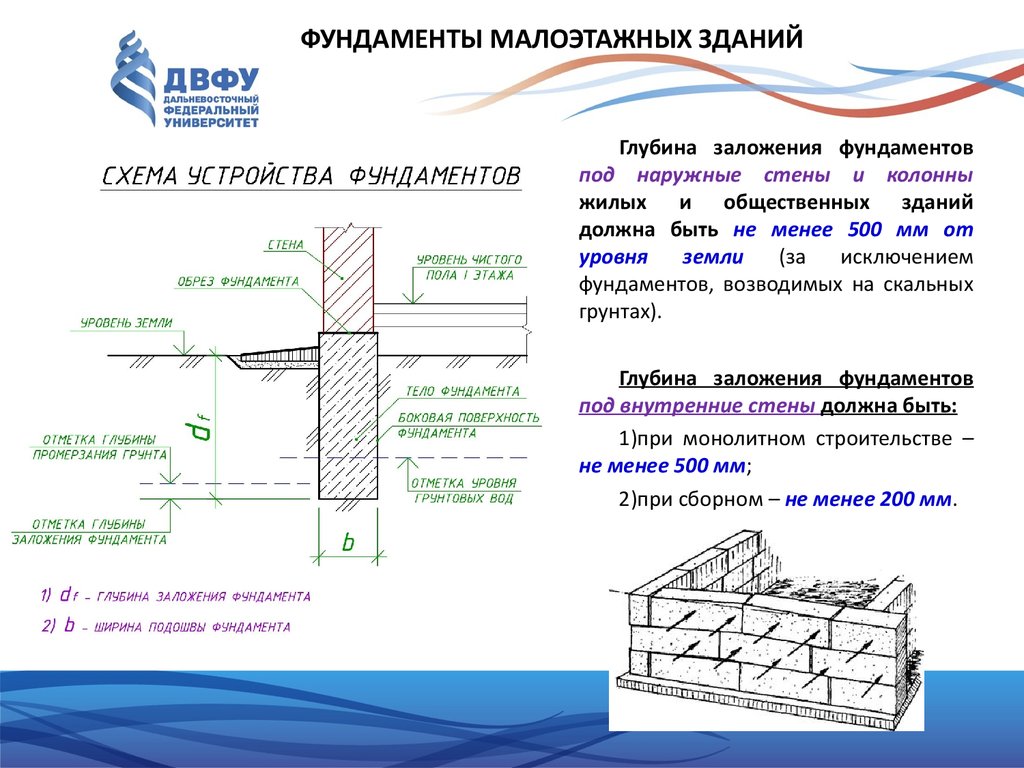

Features of the arrangement of the strip foundation

Among all types of foundations, most often in the construction of private houses or cottages, the option of a strip foundation is chosen. It is characterized by convenience, strength and durability.

The device of the strip foundation.

The strip foundation is equipped using two construction technologies:

- the monolithic version is a one-piece reinforced concrete structure made directly at the facility;

- the prefabricated version is a structure made of reinforced concrete blocks, which are attached to each other with cement mortar with reinforcement.

The strip foundation, erected using any technology, is a closed loop made of reinforced concrete. It is carried out under all load-bearing walls to distribute the weight of the building along the perimeter.

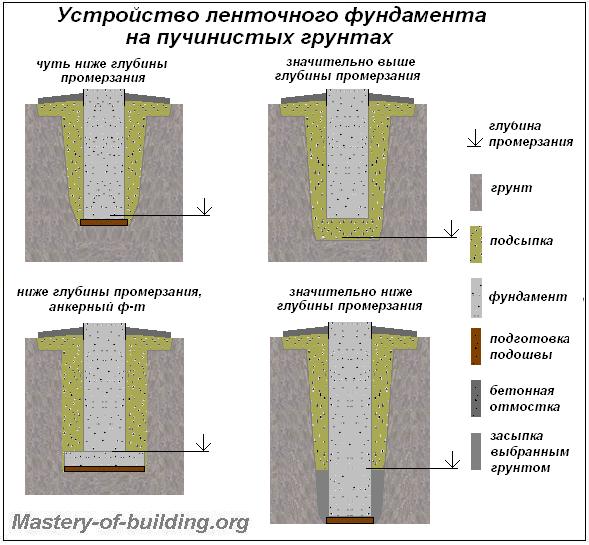

This part of the building resists the forces of soil swelling, which protects the walls of buildings from distortions and subsidence. The supporting structure is erected on a cushion under the foundation.

"Shelf life" of the foundation

How long can a foundation stand without a house? After all, one often sees such a picture: the monolith was prepared, and the further construction was frozen. After a couple of years, they decided to continue the process. But there is doubt about the safety of the structure.

If the foundation has been properly mothballed - covered with floor slabs, waterproofed, and the groundwater drainage measures are fully implemented, there is a hope that the structure has been preserved in good condition.

If none of the above has been done, invite specialists for a technical survey of the foundation. Without checking its condition, building walls is risky.

Video about how much the foundation hardens.

Construction errors

The most important myth about the strength of the foundation and the transition to the next stage of work says that the foundation must be allowed to stand (overwinter) before building a house on it. This statement is not supported by any regulatory documents and is not practiced by professional builders. This action does not bring any benefit, on the contrary, harm.

The negative consequences of the fact that the foundation is allowed to "stand" include:

- an increase in the time spent on building a house;

- uselessness of the event with high-quality compaction of the base (according to technology);

- the risk of cracks during construction on clay, loam, sandy loam, fine and dusty sand when work is stopped in winter due to the forces of frost heaving, because the unloaded foundation will be easily pushed out by the frozen ground.

Among professionals there is such a definition as "conservation" of the foundation

It is important to understand that this is not a necessary, but a forced measure, which is resorted to when the future owner cannot continue construction for his own reasons. And there is no such notion that the supports under the house must "stand"

If it is precisely the need for conservation arose, it is recommended that you familiarize yourself with additional information on this issue, since there are several nuances here.

To ensure the strength and reliability of the foundation, it is important to allow it to gain sufficient strength (dry out). Determining the time is not difficult using the information in the article

It will not take a lot of time, but it will save you nerves, time and money in the future.

Good publicity

Minimum curing time

Foundation insulation diagram.

The foundation of the house is one of its most important components. A house will not be able to withstand even moderate wind strength if it does not have a foundation. An important question is how long the foundation should stand after pouring it. One of the most common types when building a house is a strip foundation. After it was poured, at least three weeks should pass, provided that the weather was sunny outside, the humidity was low, and everything contributed to the rapid solidification of the base. There must be a foundation without any intrusion into it. The whole structure is a single whole, and if you decide to fix something "along the way", then it is better to wait until the concrete mixture hardens. And it takes about a month for this, this is how much the foundation of the house needs to withstand. In addition, the depth of the base of the house will help determine the amount of time it takes for the foundation to stand. The deeper the foundation, the more time you need to give it to stand.

Experienced builders testify that in the first month after pouring there is shrinkage and solidification, these two processes go through 70% of the possible, the remaining 30% occur in the first year of the building.

Even if, when building a house, withstand a month, provided that there is dry, sunny weather and low humidity, the concrete mixture will harden well, the foundation will get stronger, its sediment will continue for the next year. The foundation of the house can be completely defended only when all the remaining materials have been installed on it, when the construction of the house is completed. It is not for nothing that it is recommended to move into the house only a year after the completion of the building.

If you have time, the deadlines are not running out, then use the maximum time intervals, which according to the technique should be allocated to each stage of construction. If you are in a hurry, then the time frame can be shortened. However, in less than two weeks, the foundation cannot stand. Otherwise, the concrete mix will not get stronger, and further construction will be meaningless. Even if it is possible to erect a structure, in the near future the house will squint, crack, or, worst of all, it may collapse altogether. The fragile concrete mixture will be pressed not only by the weight of the materials, but also by the weight of the entire structure as a whole, the foundation will begin to "play", that is, move, settle, bend, and the whole structure will "play" with it. If a building is being built for public use, where a large number of people are expected, then this factor must also be taken into account. It is categorically impossible to admit movements of the base or its incomplete solidification, because the consequences can be irreversible.

It is advisable to pour the base on sunny dry days, since the additional moisture will add time to the foundation.

Views

There are many types of formwork.For heavy structures, a strip foundation is used. This is a structure that looks like a dug-in wall into the ground.

For light structures without basements, columnar structures are used. Support pillars are installed at the corners of the structure and at the intersection of wall partitions.

Plates are also used, but this is a less durable base. Due to the influence of external factors, the plate loses its quality over time and collapses.

Another type is pile formwork. This is a very expensive structure and is used for the construction of large buildings.

What happens during shrinkage

After the concrete is poured, several parallel processes take place. The strength of concrete increases and after 12-18 months reaches values close to the maximum. The mass of the slab compresses the soil by squeezing particles of clay, sand and other substances. Along with the seasons, soil characteristics such as moisture and mobility also change.

The slab pushes the ground until it reaches the point where the influence of other factors becomes too insignificant. How long these processes take is impossible to determine. Therefore, the time that the foundation should stand is determined on the basis of geodetic studies.

In regions where the temperature in winter drops below minus 10 degrees Celsius, the depth of the pit should be below the freezing depth. Therefore, the finished base should stand longer, because the temperature at such a depth never drops below 0.3 and does not rise above 5 degrees Celsius.

At such a distance from the surface, the influence of rain runoff is too little, therefore the shrinkage process occurs under the influence of groundwater. When determining how long the foundation should sag, the depth of freezing must be taken into account. Otherwise, there is a high probability of damage to the base and the walls of the house located on it.

A few general tips

To determine how much the strip foundation should be defended in your particular case, it is worthwhile to familiarize yourself with some recommendations that will help you better navigate this issue. Already at the stage of preparatory work and laying the foundation of the future building, you should strictly follow the regulatory recommendations. For example, before pouring, make sure that the sand cushion is carefully compacted, and the construction work itself is carried out in several stages, this will increase the quality of the foundation and reduce the likelihood of its deformation.

If a building is being erected in 2-3 floors, then according to the standard, the time for complete hardening of concrete is 46 days. For complete confidence, when carrying out work in the autumn-winter period or due to the not entirely satisfactory quality of concrete or cement grade, the curing time can be extended to 60 days.

When the first floor is erected, work is suspended for 7-10 days, allowing the foundation to adapt to the load. With the sudden appearance of cracks, the situation at this stage is much easier to correct, preventing its consequences, than after the complete completion of the work.

You can often see how the foundation is being laid even in the fall, guided by the idea that after the end of winter frosts, melting snow and melting melt water, it will be precisely established how well it was laid. Of course, this is reasonable. But there are also some objections here: first, this technique requires a significant time interval; secondly, autumn bad weather and spring melting of snow can excessively saturate the strip foundation with water, and this is undesirable.

Therefore, when using this construction technique, in the fall along the foundation in a circle, both from the outside and from the inside, a drainage trench is dug for rain and melt water. Moreover, it is necessary to dig at some distance from the base of the foundation in order to protect not only it, but also the adjacent soil.This will prevent the movement of the soil under the foundation and its deformation.

How to care for concrete

The basic rules for carrying out demoulding are clearly written out in the construction rules of the joint venture and SNiP. Thus, paragraph 5.4.1. the same rules states that the surface must be reliably protected from moisture in the solution itself. In addition, it is necessary to protect the surface from the penetration of atmospheric precipitation. A similar procedure should be carried out throughout the entire period of preservation of the foundation, but not less than 75% of the total period when it should stand.

After the formwork has been removed, it is not recommended, or rather not allowed, to walk, run, and stomp on the surface until it is fully ripe. The foundation must be allowed to stand. The sanitary rules say that the strength indicator should be equal to 2.5 MPa, but the data are not always kept for several reasons: the quality of the material, temperature regime, weather conditions, humidity. It is strongly not recommended to build structures from foam concrete.

When to disassemble the formwork

The formwork of the foundation for a bathhouse, garage or house is removed after seven days. Until this time, the object is examined several times. The composition is checked with a concrete strength meter. After removing the formwork, another strength check is made.

In construction, there are precedents when the formwork is removed in a day. They are guided by the fact that concrete begins to harden forty minutes after laying. A risky approach to business, and the risk is not always justified.

There is no need to rush to dismantle the formwork. It is better to make sure once again that the composition is seizing and the acquisition of stripping strength.

Maintenance of concrete structures

The main goals of surface care after the foundation is poured:

- reduction of plastic shrinkage;

- increased strength;

- drying out prevention;

- neutralization of the influence of temperature drops;

- increased service life;

- prevention of the influence of chemical and mechanical forces.

To understand how much concrete to water, you need to know about the existing rules. The methods of leaving after pouring the foundation are influenced by:

- type of cement;

- type of construction;

- climatic conditions, etc.

The period of care is influenced by the speed of hardening of the cement in the mixture:

- cement structures that harden gradually need to be moistened for 4 weeks;

- Portland cement structures - from 2 to 3 weeks;

- on fast-hardening cement - 8 days.

In hot and dry weather, a longer maintenance period is required. For slower evaporation of moisture and in order to protect against overheating after pouring, it is recommended to cover the foundation with moistened sawdust, matting, roofing material.

In hot weather or strong winds, it is recommended to start irrigating the surface 2-3 hours after the end of the work. Not everyone understands how to water properly.

If you use a jet with a strong pressure for humidification, the plane that did not have time to harden may deform. It is recommended to use a spray to simulate rain over the surface.

Watering should be carried out during the day so that the structure is constantly wet

You can understand how often you need to irrigate the surface by paying attention to the temperature and humidity of the air.

It matters how much time should elapse between waterings. In extreme heat, the breaks between humidification should not be more than 2 hours, in other cases - every 3 hours during the day, up to 3 times at night. Hissing during irrigation indicates insufficient water supply.

Requirements for irrigation water:

- must be clean flowing;

- it should not contain impurities that can have an aggressive effect on the surface;

- you can not use the groundwater located close to the surface;

- a pH level of 7 is recommended (tolerance is 1);

- must not contain pesticides or organic deposits;

- should not be in large amounts of calcium, magnesium, sodium.

On the foundation, which is in the formwork, moisture remains longer, therefore, irrigation is allowed less often. After removing the formwork, it is necessary to start watering, paying more attention to the edges of the structure, since they are more exposed to the influence of wind and temperature, therefore, moisture loss occurs faster.

Sometimes, to preserve moisture, the surface is covered with a polyethylene film. In the process of evaporation, water droplets end up on the inner side of the film, part of the moisture returns to the foundation. This technique allows you to reduce the number of irrigations, but is not able to replace them completely.

Features of the strip foundation

Foundation laying is a very time consuming stage of construction work. The strip foundation is laid under each outer wall of the building in the form of a continuous strip, as well as under the load-bearing interior walls and is, in accordance with the depth of the laying, a high or not very high half-wall. The tape option is the most popular among other types of foundation.

Depending on the method of construction and the materials used in this case, the strip foundation is prefabricated and monolithic:

- A monolithic foundation is erected directly on the construction site of the building, and there are two types of it, depending on the expected severity of the structure - shallow and buried. A shallow strip monolithic foundation is used in the construction of lightweight buildings on clay soils. A deepened monolithic foundation is erected in the case of the construction of heavy structures and buildings in which a basement, an underground garage or other basements on unstable soils is provided.

- The prefabricated strip foundation is made up of blocks based on reinforced concrete, which are manufactured at the factory, transported by special equipment to the construction site and, with the help of a crane, are installed on the construction site in the trenches. In terms of strength, the prefabricated foundation of this type is inferior to the monolithic one.