Recommendations

To reduce the construction time, work is not carried out in very rainy weather: the wood may get wet and the drying of the material will give a slight cracking. When installing the frame, it is necessary to make a roof or temporary overlap in case of rain.

If you have chosen a two-story frame house, the construction project can be anything, it is better to use a frame option. The building is assembled directly on the site: the "skeleton" is made of wood, the gaps are filled with brick, stone or adobe material. This option is cheaper than the frame-panel construction.

When using SIP panels, their main drawback is taken into account - it is impossible to replace the insulation layer during operation. For a frame house, the device of natural ventilation of the walls is of great importance.

If the frame is assembled from boards, then they are impregnated with an antiseptic before assembly. In this case, the wood will absorb the solution better. In sunny weather, the material is dried for 24 hours.

Frame houses are suitable for seasonal and permanent residence. An alternative to these structures can be buildings made of glued or profiled beams, or rounded logs. But these options add to the cost of construction.

Step-by-step instruction

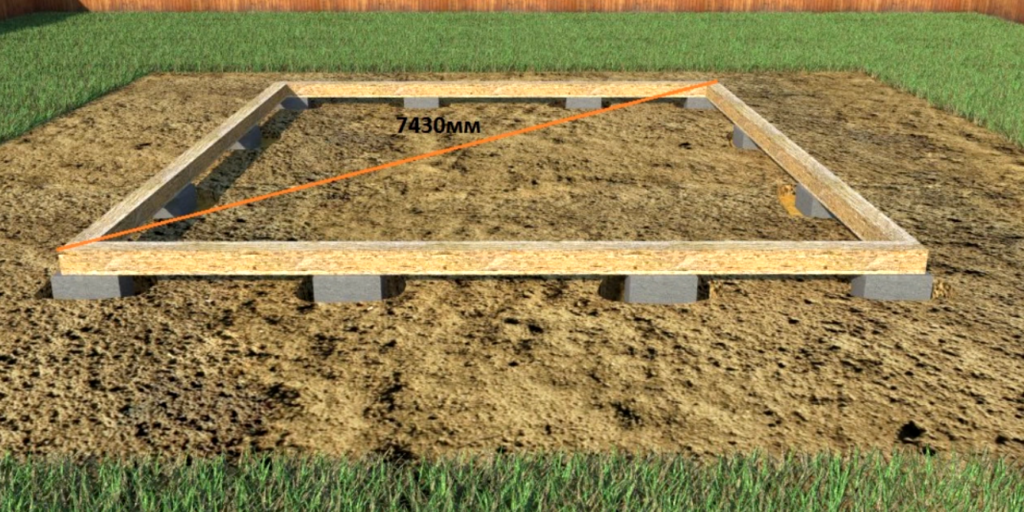

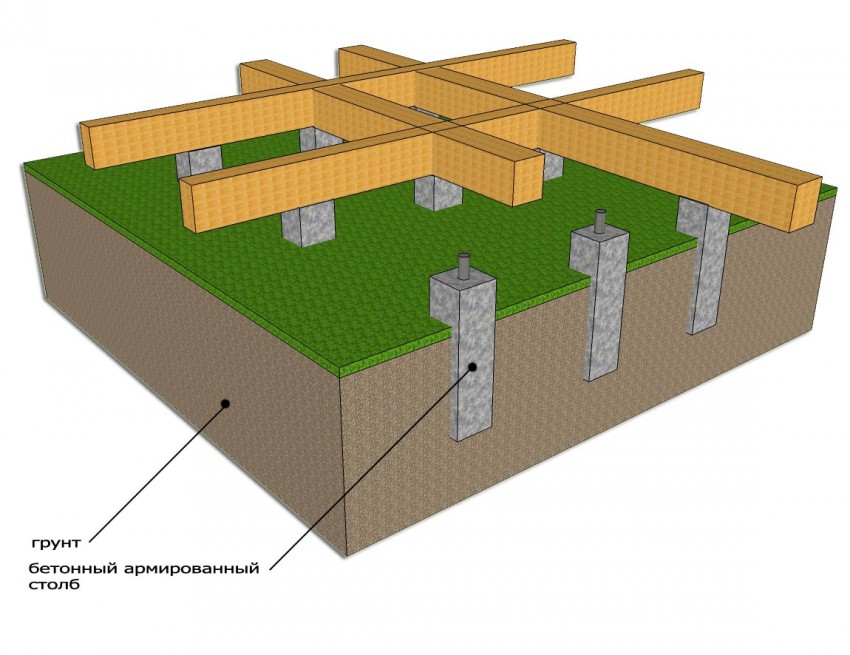

First of all, markings are made on the cleared area. Pegs are driven in according to the location of the corners of the future house, on which the cord is pulled

It is important to check by measuring the diagonals between the corners for distortions. Two diagonals are measured using cords - the difference in their length should be no more than 3 cm

And the upper marks of the future supports should be the same - a difference in their height of no more than 1 cm is allowed (checked by the level).

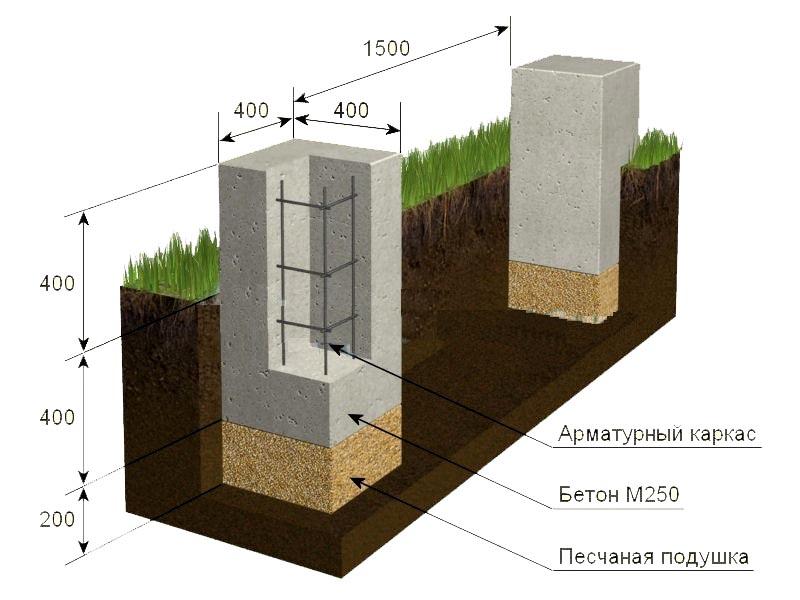

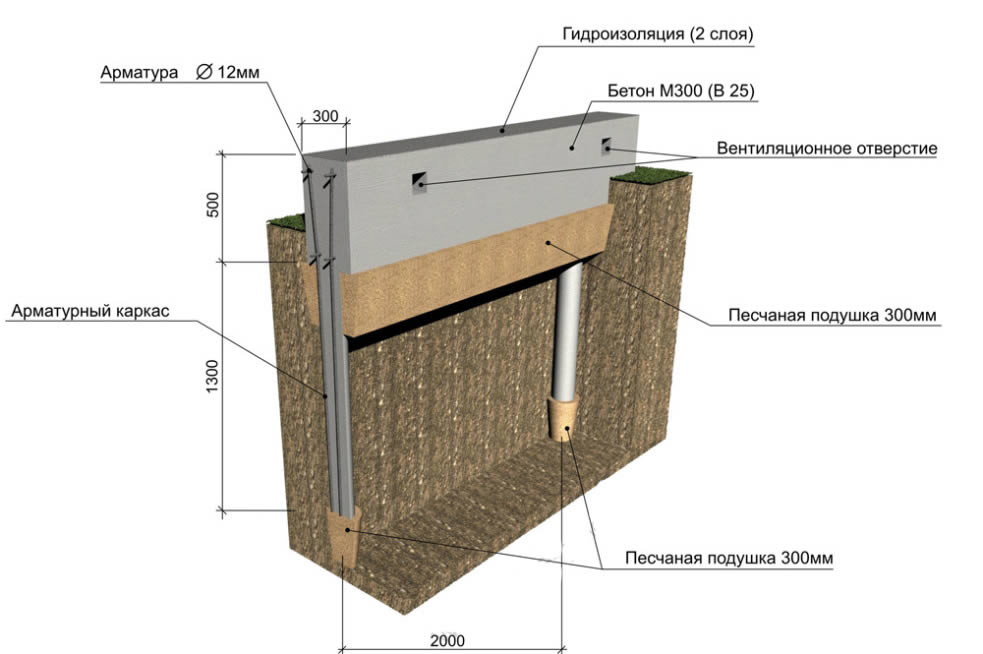

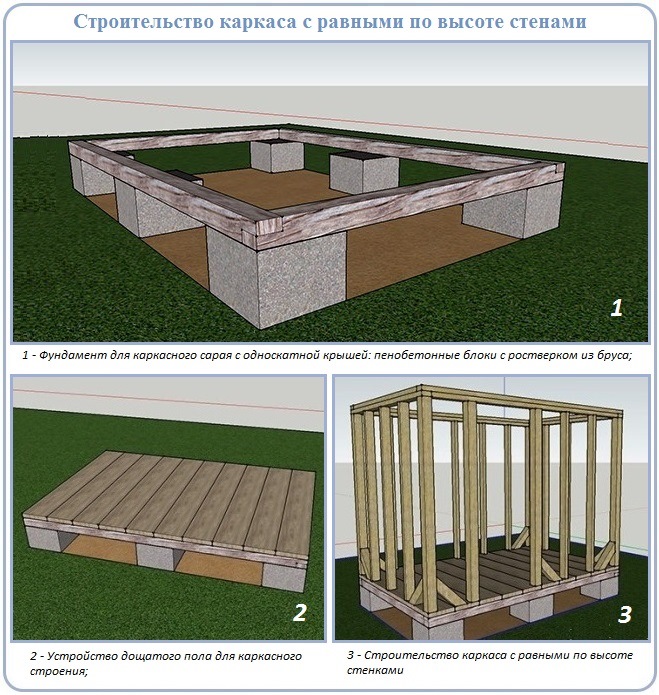

Pit preparation and waterproofing

Earthwork is carried out without the use of special equipment. Square holes are dug at the designated points. Their width should be 20-40 cm more than the supports, so that it is convenient to carry out the installation of the formwork. This work is best done with a shovel to make the holes even, or with a hand drill. A pillow of sand and fine gravel is placed on the bottom, compacted tightly. Its height depends on the level of the underground part of the base. For a deepened layer of the pillow, a thickness of 50 cm is needed, for a shallow one - 25 cm. After it is tamped, roofing material is placed on top.

Formwork assembly and reinforcement installation

In the next step, the formwork is installed and firmly fixed according to the size of the future pillars. Inside it, you need to lay roofing material so that the concrete mixture does not seep through the cracks during pouring. Then it can be left in the finished base to protect it from moisture destruction.

Cement with a thickness of 20 cm is poured to the bottom, and when it has not yet completely hardened, reinforcement is placed. Vertical metal rods (at least 4) are installed in each pillar next to the formwork (at a distance of 2 cm from it), vertically they are fixed every 25 cm with a metal wire by twisting (welding cannot be used).

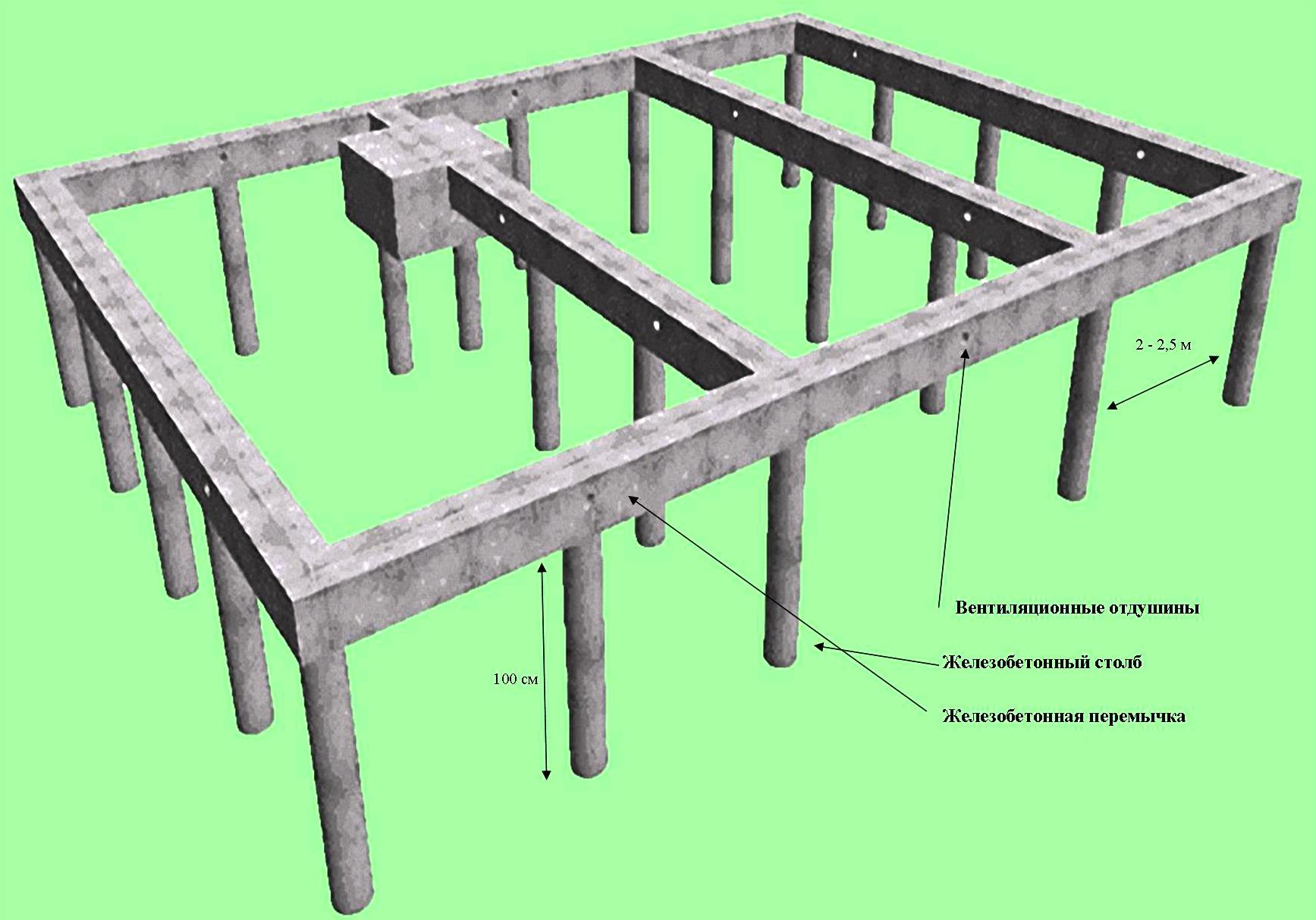

Pouring with concrete and grillage

Concrete mortar (crushed stone, cement, water) is poured in several steps of 30 cm each, each time it must be tamped by bayonet method with a metal rod. After the end of the pouring, check the level of the mounting horizon. It is leveled in height with a mixture of cement and sand.

When the concrete hardens, the formwork is removed, waterproofing is done. It is necessary because the base of the building (especially the recessed part) is always exposed to the destructive effects of moisture. For this, roofing material, liquid glass, fiberglass, hot resin are used.It is better to cover the gaps between the soil and the pillars with clay, tamping it tightly at small intervals.

To give the base rigidity and strength, a grillage is installed. It is made of wood, metal profiles, reinforced concrete. For the manufacture of a concrete grillage, formwork is installed on top of the pillars, metal reinforcement is placed and concrete is poured. In light frame houses, it is not necessary to make a reinforced grillage.

Pile-screw foundation for a frame house

Screw piles will help out where other foundations are useless. This type of base can be mounted in any area with any relief. Even if the soil is waterlogged, screw piles make it possible to build a frame house. This metal support is made from hollow tubes with a wall thickness of at least 4 mm.

It has a pointed tip on one side, and a head on the other. This part of the pile is of two types: welded and removable. For those developers who decide to independently mount the pile-screw foundation, it is better to buy supports with a removable head.

Installation diagram of the pile for the foundation.

Not far from the tip there are blades and a disc, which comes in the following diameters: 150 mm, 200 mm and 250 mm. The thickness of the trunk (pipe) is also different. For light houses, a pile with a diameter of 89 mm is suitable. To make the correct calculation of the foundation of screw piles, you should do the following:

- calculate the total weight of the house together with furniture, household appliances and residents;

- find out the snow load in a given region per 1 m²;

- calculate the wind load;

- calculate the dynamic load using the formula: the area of the building is multiplied by 350;

- add up all the indicators obtained and round the amount up. This figure will mean the number of piles for the foundation of this frame house;

Stages of installation of the pile-screw foundation

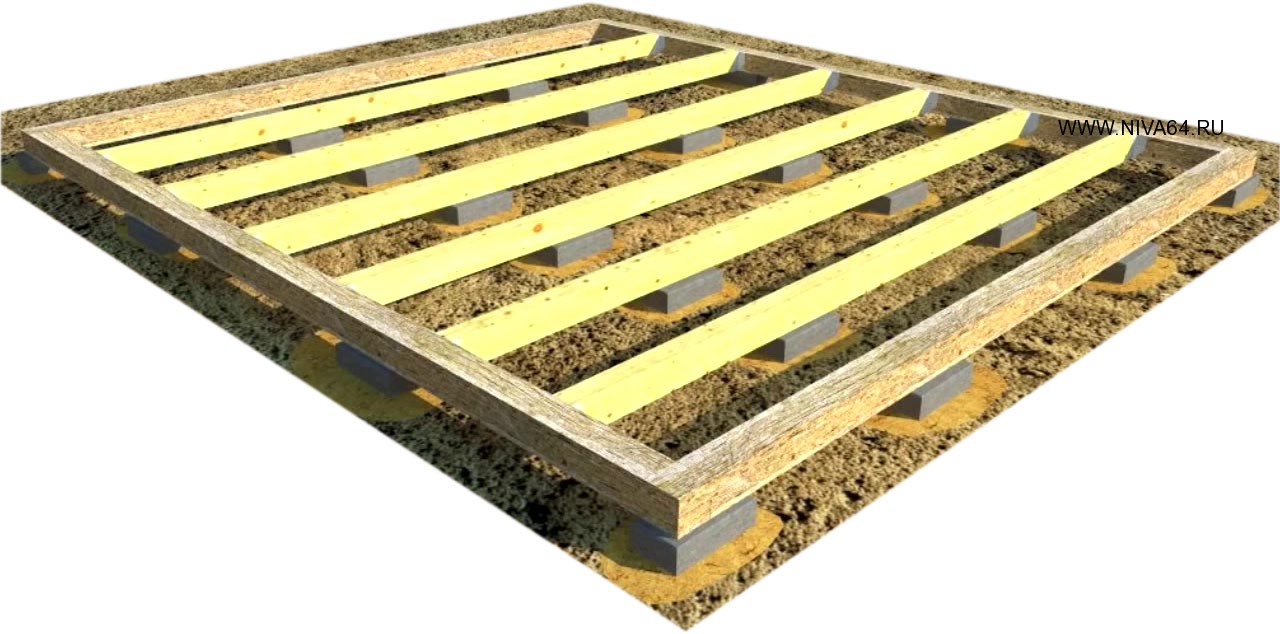

Overlapping scheme of a frame house.

- A scrap, a shovel, a garden drill and 2 pieces of thick-walled pipes 2.5 m long are prepared.

- Marking is made and the places for the installation of supports are marked with pegs.

- In the upper part of the screw pile with a removable head there are lugs through which you need to thread the scrap.

- With the help of a drill, a hole is formed of such a width that it is narrower than the pile shaft.

- They begin to twist the supports. To avoid vertical deviations, a level with a magnetic stripe is connected to the pipe and the correct installation is checked on it.

- When it becomes impossible to twist the pile with the help of a scrap, its ends are built up with pipes prepared in advance. They continue to work.

- After all the piles are installed, the trunks are cut with the help of the grinder, bringing the foundation into a single plane.

- A channel or beam is laid on top of the supports. Thus, the foundation strapping is mounted.

Features of the soil, design and size of buildings

Regardless of the material of the building, when choosing the types of foundation, you need to take into account the presence of a basement or basement floor, its dimensions

Regardless of the material of the building, when choosing the types of foundation, you need to take into account the presence of a basement or basement floor, its dimensions

- sandy;

- rocky;

- gravel;

- sandy-stony without the presence of clay.

The latter is considered the best due to the timely release of moisture, non-swelling at low temperatures and having the property of compressing under the load mass. The peculiarity of the base for the frame structure is that in the presence of a sufficiently dense and stable sandy-rocky soil, you can not do the foundation, just level the surface.

Clay soils have the ability to freeze through, retain moisture and, therefore, swell. Sandy soils are a good option, but they need additional strengthening of the pit walls, but the sand does not freeze, does not swell and easily compresses.

Freezing of soils also affects the type of substrate. Rocky soils are considered the most resistant to freezing, they do not contain water, slightly change their characteristics at low temperatures.The rest of the soils can begin to swell when freezing, which means that the base can burst under the influence of soils or be pushed out of the ground.

The type of building to be erected affects the mass of the foundation. The frame house is lightweight, so professionals often advise to do with shallow foundations or not to deepen the foundation at all.

Base materials are also selected based on the needs of the developer:

- As a rule, concrete is used on rocky, sandy soils, however, it can crack on clay soils.

- Reinforced concrete has excellent strength and with its help you can quickly build a cheap foundation of any configuration.

- As for the brick, it does not fit the foundation for a frame house, at best, only for the part that is above the ground level. It is impossible to deepen the brick due to its high hygroscopicity and susceptibility to destruction from frost.

Remember that the construction of a frame house allows any kind of foundation due to the insignificant mass of the structure, therefore the selection is carried out only by the indications of soils and other features.

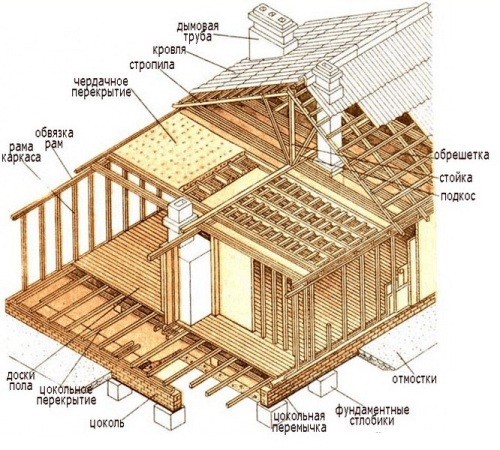

Frame construction theory

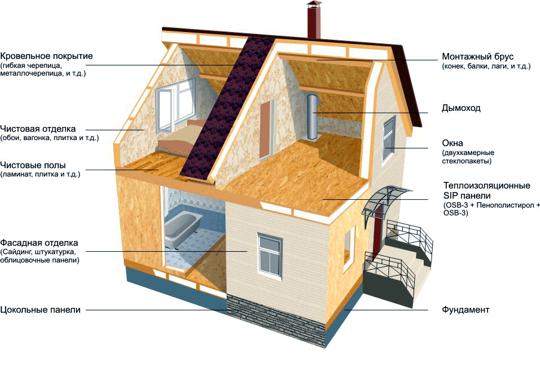

The composition of the main elements of a frame house

The composition of the main elements of a frame house

The construction of houses always begins with preparatory steps:

- analysis of the site - the structure of the soil and the characteristics of the behavior of the soil;

- design of the building - the foundation, the calculation of the structures themselves that make up the elements of the future house;

- formation of the necessary documentation - drawings, technological maps;

- approval of papers before the start of construction in the permitting authorities.

The main feature of frame housing construction is the use for the base of the elements of walls and ceilings - a bar and a metal profile. As filling - different insulation (mineral wool, polystyrene), which are closed from the inside and outside by various panels - wood, metal, plastic or combined. The structure is gradually mounted on the foundation and sheathed in parallel - from the inside and from the outside. This allows small teams of workers to erect buildings - from two people, and also not to use construction equipment - everything is done by hand.

An example of a two-story house 6x6

An example of a two-story house 6x6

As a result, the owner can get a unique building with the properties he needs, which depends on the purpose of the building, the local climate and financial capabilities.

Pros and cons of frame houses

In most countries of the world, frame construction is becoming more and more popular every year. There are several reasons for this:

- the total cost per square meter is the lowest among all other construction methods. Only cardboard houses or tents are cheaper;

- versatility: the ability to adapt the building to a hot and cold climate, as well as to build simple farm houses;

- ease of maintenance - frequent refurbishment of facades is not required, and repairs are made as easy as construction;

- high speed of construction - even a small team of 2-4 people can create a standard house in 3-6 months;

- low heat capacity of walls and horizontal partitions - simplifies the heating process, the cost of which will be minimal;

- good sound insulation - provided that proper insulation materials are used;

- frame houses are the safest - this applies to both ecology and earthquake resistance. The buildings are able to withstand tremors up to 8-9 points.

Separately, it should be clarified that, if necessary, you can build a house that can be quickly disassembled, transported to a new location and reassembled. Such mobility is provided only by frame and frame-modular construction schemes.

But there are also negative aspects:

To reduce the echo of the entire structure, you will have to lay heavy types of insulation in the walls - for a summer residence this is not very important, but a house that is intended for permanent residence will require this to be done.

A reliable frame house can be erected only after scrupulous calculations. It is very difficult to draw up correct drawings without the appropriate education, therefore it is recommended to contact professionals. This will require the allocation of part of the budget for ordering design documentation, but it will give a guarantee that the house will not fall apart in a year or two.

What to consider when building a frame house

Frame house

Frame house

When designing a country frame house, first of all, it is necessary to correctly calculate the area of the building in order to determine the amount of materials and the total cost of construction:

- Day zone. Its area depends on the number of people living in the house. This value is approximately 40-60 m² for a family of 3-5 people.

- Sleeping area. The area of each bedroom can be from 10 to 20 m², if 3-5 people will live permanently in the house.

- In a frame house designed for more than 3 residents, it is worth planning 2 bathrooms with an area of 5-10 m².

- A terrace or veranda will make your stay comfortable. The area of the outbuildings can be from 7 to 15 m².

- Halls, corridors, stairs, utility rooms are allocated about 20 m². Depending on the method of heating the house, it is necessary to plan a boiler room. With gas heating, this room should be at least 5-6 m² in size.

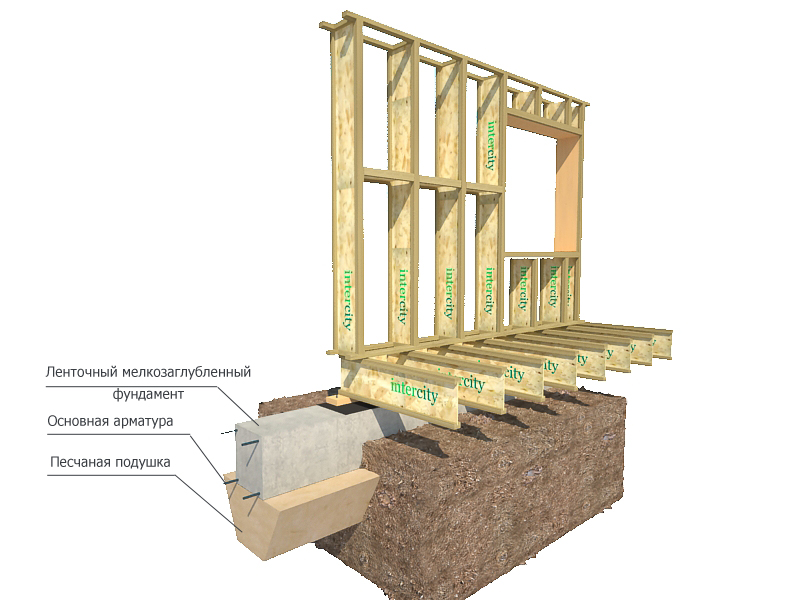

Strip foundation

Fig. 1 Strip prefabricated and monolithic foundations with a basement.

The strip foundation is most common in the construction of country houses of any type, including frame ones. It is an inseparable rigid structure, laid under all load-bearing walls of a frame house. It makes it possible to build a basement if soil is removed from a limited space. The foundation walls then serve as basement walls. If the basement is not provided, the soil is not removed.

(Fig. 1 Diagram of a strip foundation for a house with a basement)

Fig. 2. Strip foundation with rectangular cross-section without widening at the bottom.

The width of the strip base is usually 10-15 cm wider than the thickness of the walls of the house. The cross-section can be rectangular, but it is better to make it with broadening at the bottom to increase the support area of the foundation and to prevent the effects of heaving forces. The height of the tape should be at least twice the width to avoid lateral deformation.

(Fig. 2 Strip foundation with rectangular cross-section without widening at the bottom)

(Fig. 3 Strip foundations with a trapezoidal cross-section)

Rice. 3. Strip foundation with a trapezoidal cross-section.

The threat of longitudinal deformation in a strip foundation arises when the load on it is unevenly distributed and under the influence of frost heaving forces. Therefore, such a foundation must be reinforced. The main load is applied to the longitudinal bars of the reinforcement. The transverse rods only serve the function of creating a single frame. The most vulnerable point of the strip base is its corners, so they are subject to the most careful reinforcement.

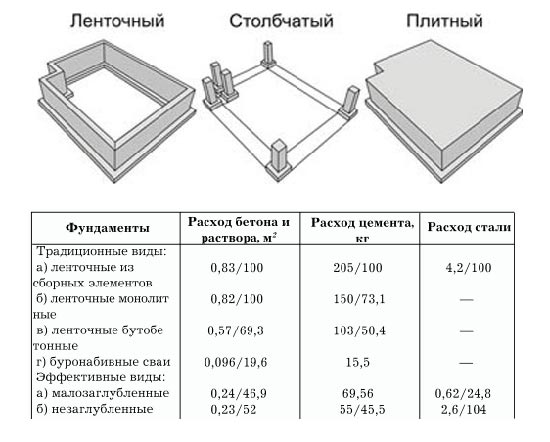

The strip foundation for a frame house is of several types:

- Precast foundation (made of concrete blocks). It is not suitable for DIY home construction due to the heavy weight of these blocks. A crane is required to install it. To avoid cracks, concrete is used to connect the blocks, the joints are reinforced.

- A monolithic foundation is more reliable and durable than a prefabricated one. It is quite possible to build such a foundation for a frame house with your own hands.

- Shallow foundations are used in the construction of light timber frame houses.

- A deep foundation is suitable for the construction of heavy brick or concrete houses.It is laid to a depth below the freezing depth in order to lean on dense soil with a high bearing capacity. Such a foundation makes it possible to make a basement.

The advantage of the strip foundation is that it can withstand high loads and can be used even on moving ground. Most of it (about 0.5 m) is underground, and the height above the ground is 20-30 cm. The disadvantage is the lack of redevelopment and high cost.

Calculation of individual building structures

It is clear that before you build a frame house with your own hands, first of all it is necessary to include in the estimate the cost of material for the construction of the roof and foundation.

Wiring diagram of a frame house

Insulation of a frame house, both internal and external, is also an extremely important event, with the exception of cases when houses are being built using Canadian technology, using pre-insulated sandwich panels. Insulation of a frame house at a cost will be up to about 20% of the total estimate, provided that no factory insulation was used in the house kit, and up to 10% - if one was used

Insulation of a frame house at a cost will be about 20% of the total estimate, provided that no factory insulation was used in the house kit, and up to 10% if one was used.

If you build a frame house with your own hands, then the consumption of lumber will also be of great importance, and not even so much for the walls, but for the roof. The same attic beams in cost can be almost half of the price of the entire box of a panel house.

We have already disassembled the calculation of lumber for the walls of a panel house, so attention should be paid to the roof. Of course, if you buy ready-made house kits, then there will be no more difficulty: the manufacturer calculated everything in advance

But how much lumber will be needed for a panel house and its cladding, provided that a frame house is being built with your own hands - this is already much more difficult. The insulation of a frame house has already been described above.

Roof

When designing the roof of a house, it is necessary to take into account not only the total weight and load of attic floors and beams, but also the weight and characteristics of the roofing material itself.

An example of a cost estimate for the construction of a frame house

Particular attention should also be paid to the construction of the roof, during the construction of which it is necessary to take into account the wind rose in a certain area (that is, from which side the wind will blow more often - from that side there will be a large load). Materials for construction are also selected taking into account these criteria.

In fact, these are very important criteria for choosing materials and calculating their cost. If you do not take into account the same wind rose, then the roof on one side can leak, leak out, roofing material without proper reinforcement and fastening can simply be blown away by a strong wind, not to mention hurricanes and other natural troubles.

The nuances that must be taken into account before starting the construction of the roof of a frame house:

- a high and acute-angled roof is not recommended to be mounted on a house in an area where excessively strong winds prevail (otherwise, you will have to calculate the roof with a rather large margin of safety, which will inevitably lead to a significant increase in the entire construction estimate);

- the roof sheathing should be installed with more frequent steps to increase the safety margin;

- for the rafter system, it is necessary to choose a more durable beam (the thicker the roofing beam, the stronger it is, everything is extremely simple here);

- it is better to choose a harder roof covering, as it will be stronger (slate instead of metal or corrugated board, for example).

Foundation

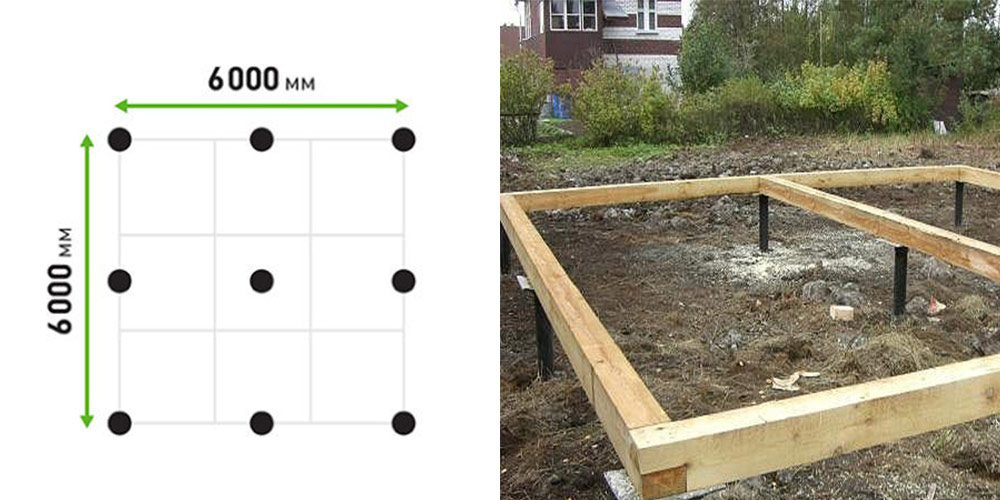

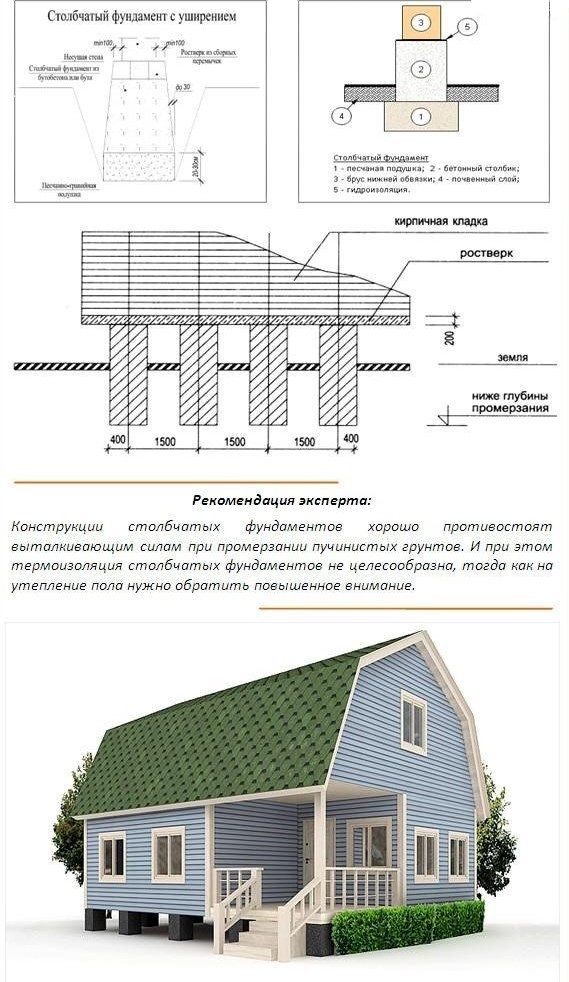

For frame shield structures, lightweight types of foundations such as shallow tape (most often monolithic), pile or even columnar foundations are usually used.True, one must take into account the fact that columnar foundations are suitable only for small frame houses, for a summer residence, for example.

General diagram of the structure of a frame house

As for pile ones, the simplest option is screw foundations. To calculate the number of piles, it will be necessary to take into account the entire mass of the house and the load per square meter of area from a solid foundation.

It will also be necessary to take into account the condition of the soil on the site that was allocated for the construction of the building. And also it is necessary to take into account the heaving of soils and the depth of groundwater.

For example, if the foundation piles are not buried deep enough, then during cold weather the foundation will simply raise the house, which will immediately lead to the appearance of cracks of various sizes and partial destruction of the frame structure.

After all, what mistake do people often make when building houses on their own? They calculate the foundation only by the weight of the house - that's all. And this cannot be done, because it is necessary to take into account many other criteria that were indicated above. But it is better that specialized specialists are engaged in this - this will definitely be more reliable.

Thermal insulation of the house: price and materials

Waterproofing

Waterproofing

Insulation of a frame house from the inside optimally protects housing from winter frosts. External insulation will create an additional load on the frame, so it is not always advisable to do it.

It is necessary to carry out waterproofing work. It is done both during construction and after the end of work.

It is important to choose the right material for house insulation

In order to save money, the installation of insulation can be done independently.

During installation, the insulation layer must have the following parameters:

- For insulation of the outer walls of the roof - more than 15 cm.

- For noise insulation of partitions, load-bearing walls and floors - 10-15 cm.

- Internal partitions can be without insulation, or this layer can be 5 cm.

Materials are used as insulation at prices in rubles:

- waterproofing (1 roll) - about 2,400;

- vapor barrier (4 rolls) - within 4,800;

- mineral wool (thickness 15 cm) 21 m³ - 37 400;

- mineral wool (thickness 10 cm) 7 m³ - 12 500.

The insulation will take at least 57,000 rubles if you do the work yourself. When hiring a contractor, the insulation will cost 72,000 rubles.

Installation of finished floors is carried out separately. The floors are assembled with a 150 mm board (25x100). The tongue-and-groove board is taken if no special floor covering will be installed. 1 m² of sheet pile flooring will cost 360, and from edged - 240 rubles. Working on your own will save 50% of your money. A finishing floor in 2 levels from a tongue-and-groove board will cost 27,000 rubles.

Ventilation installation

Supply and exhaust ventilation scheme

For frame houses, supply and exhaust ventilation is most suitable. Its main advantages are efficiency and budget.

Main elements:

- Distributor block with installed fans and cleaning filters. The mechanism consists of two parts, the first is responsible for the flow of fresh air and its distribution throughout the building, and the second for the outflow to the outside.

- Air inlet and outlet channels. Hidden in the walls and should be foreseen early in the construction phase.

Installation tips:

- ventilation ducts pass through the walls, so it is more expedient to draw up their diagram immediately in the construction project;

- the system must be installed before finishing the room;

- positioning ventilation control in an accessible and convenient place;

- so that the ducts have the same cross-section, it is necessary to use wooden or cardboard templates during the laying process;

- asbestos-cement pipes are used to lead the channel to the roof;

- the pipe outlet is reinforced with a cement compound to avoid the appearance of cracks;

- excess solution should be removed, the air duct should have a smooth surface;

- for quiet operation of ventilation, sound insulation must be provided;

- check the tightness before starting.

Building a frame house with your own hands is not as difficult as it might seem at first glance, but it guarantees high quality and reliability of future housing, and also saves a lot of money. However, this process requires a responsible approach, clear planning, strict adherence to technological instructions and performing actions in a strictly defined sequence.