Varieties of permanent formwork

There are several options for arranging such a structure. Consider those used in the construction of foundations.

Expanded polystyrene

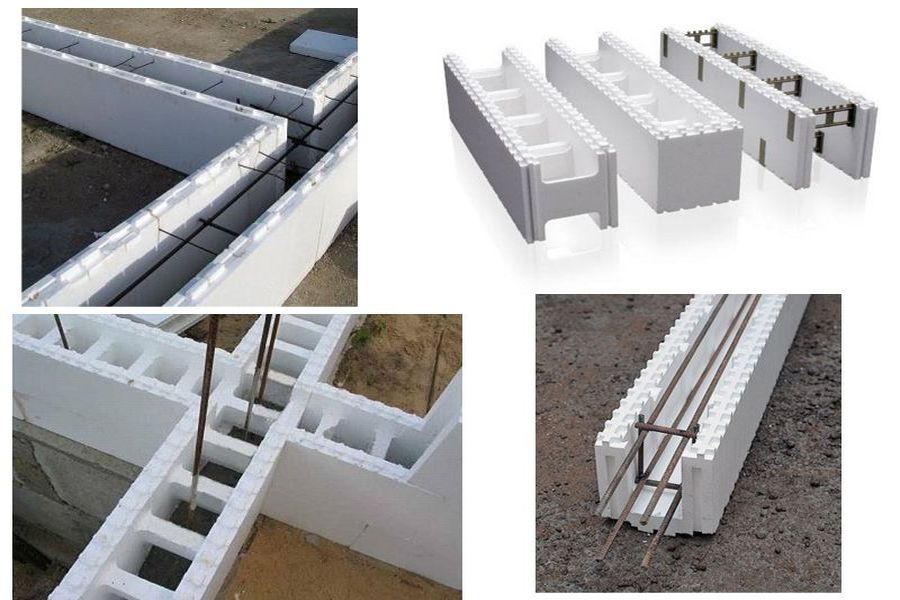

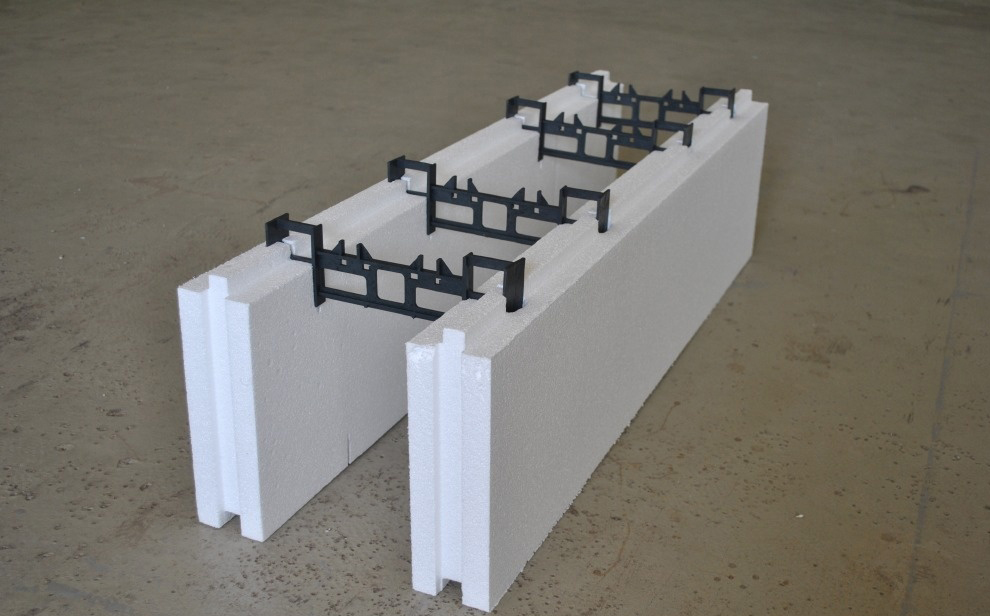

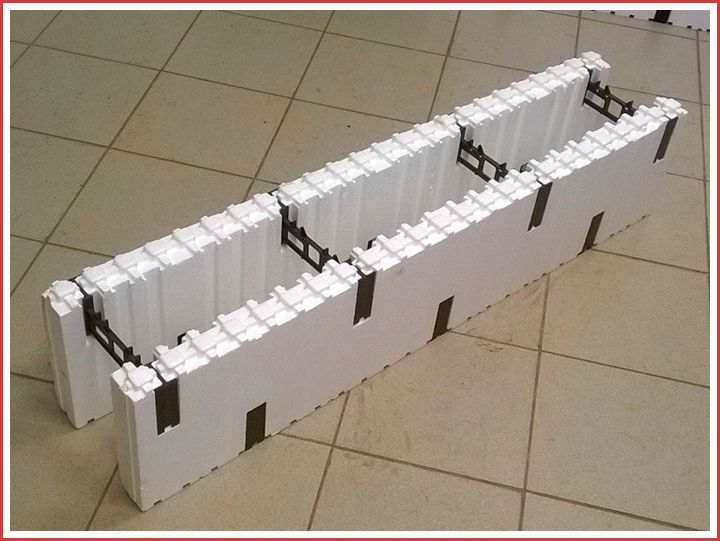

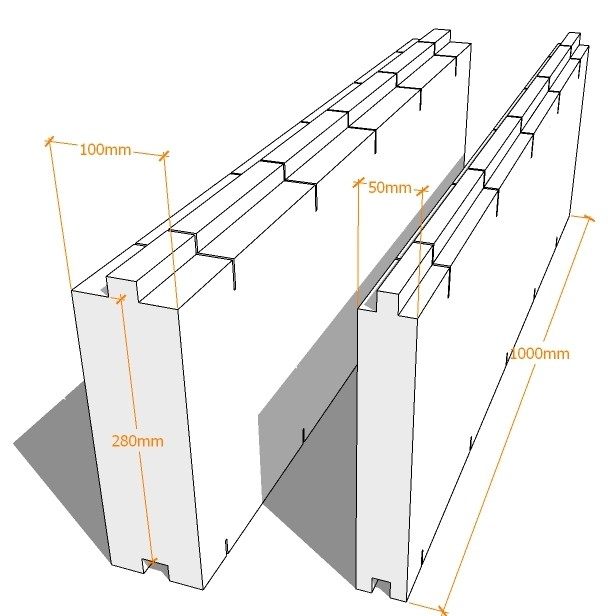

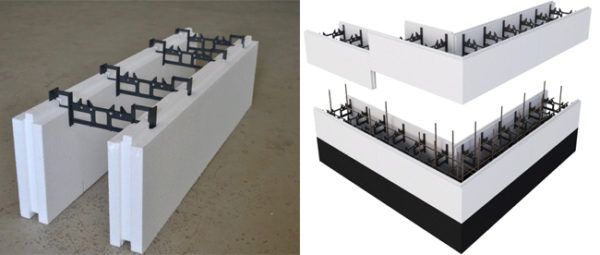

Such structures can be mounted in two systems. The most popular and relatively inexpensive of them assumes that the insulation is located outside, that is, slabs, modules or hollow blocks are installed on both sides, between which concrete is poured. In this case, expanded polystyrene is attached using steel or plastic jumpers. Reinforcement is installed inside the slabs and the stage-by-stage formation of the foundation wall begins. As soon as the concrete hardens (even before the full set of strength), you can start facing.

As a rule, for such a stacking scheme, blocks with a length of 1000-1500 mm and a width of 200-300 mm are used. This type of formwork is suitable for the construction of monolithic buildings up to 5 floors high.

There is also a system in which the insulation is located inside. In this case, a reinforcing mesh is laid on both sides of expanded polystyrene with a thickness of up to 250 mm. After that, concrete is applied by gunning (spraying under high pressure). A similar method is used if it is necessary to reduce the construction time by another 20-30%. In addition, with such a scheme, much less concrete is required. For the foundation, it will need almost 45% less.

Healthy! It should be noted that expanded polystyrene is not an environmentally friendly material; it can be dangerous in the event of a fire. In addition, this material does not withstand frost, so it is only suitable for regions with a warm climate.

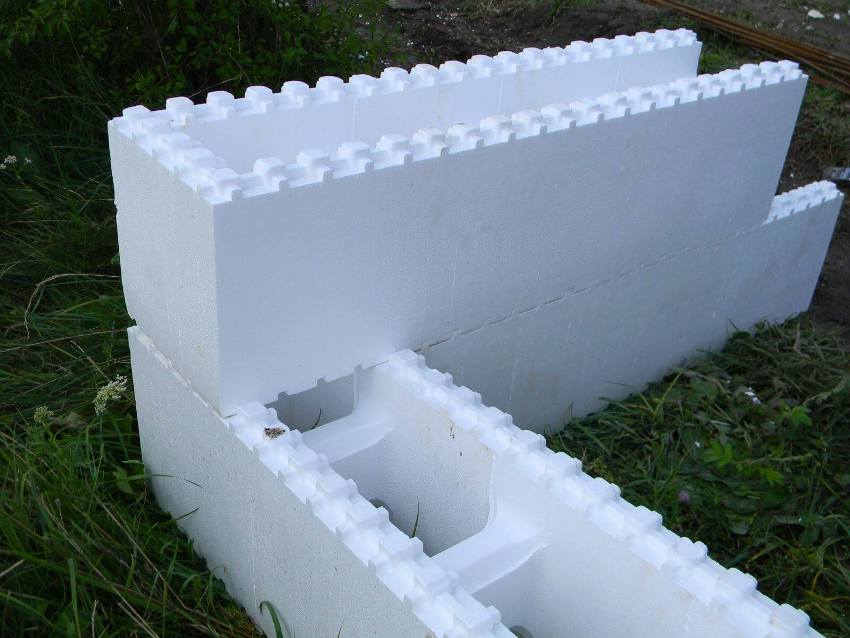

However, it is more convenient and quickest to work with ready-made polystyrene foam blocks. They are sold in different shapes and are fastened in a groove-ridge pattern. In essence, you are assembling a Lego constructor. Since the blocks themselves are much larger and lighter than concrete ones, they are laid several times faster.

From extruded polystyrene foam

Many people confuse this type of construction with the usual "foam" one. But, it is worth noting that extruded foam is characterized by increased strength. It burns much worse and does not react to frost at all, therefore it is suitable for laying in any region.

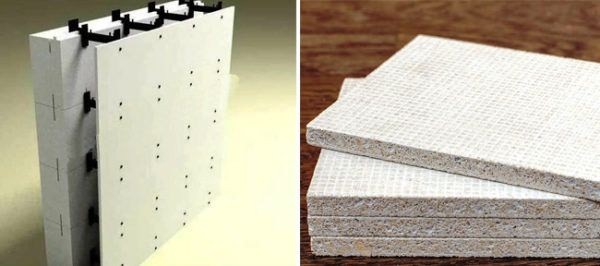

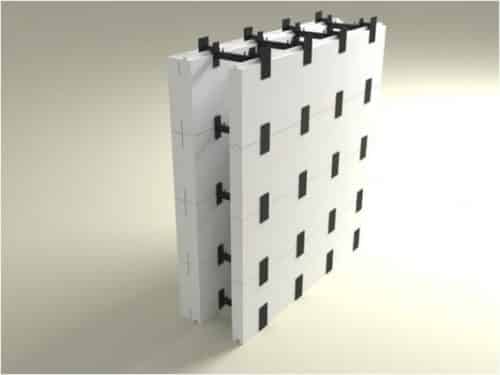

The design of such a formwork is slightly different from the first option. In this case, adjustable metal pins are used. It is more difficult to work with them, but the finished structure turns out to be much stronger and precisely meets the requirements of the project.

Glass-magnesite

We are talking about LSU sheets, which began to be used for non-removable formwork structures in the middle of the 20th century. This material is a mixture of oxide, sodium chloride, fiberglass, sawdust and polypropylene particles. This is a composition of natural origin that is completely safe for humans.

Magnesia glass formwork is used for so-called weak foundations. The sheets themselves are lightweight, so they are often used for walls, so as not to load the finished building. It is a multifunctional, fireproof, moisture resistant, elastic material that has high thermal insulation values.

Arbolitovaya

For this construction, hollow wood-concrete blocks or panels are used. 90% of the total volume of such blocks is wood chips, so the material can rightfully be called the most inexpensive and environmentally friendly. The only drawback is the rather large thickness of the resulting walls.

Compared to concrete blocks, which today are practically not used for such formwork structures, arbolite is lighter in weight (does not require the use of construction equipment), it is easier to cut. Also, this material is resistant to fire (withstands up to 90 degrees of heat) and does not freeze.

Metal

This is the most expensive material for the manufacture of permanent formwork, therefore, it is most often used in the construction of industrial facilities.Such structures are made of steel or aluminum sheets with a thickness of 1-2 mm, which are mounted on a metal frame

At the same time, it is important to correctly calculate how many clamps are required so that the metal sheets do not bend after pouring the concrete mixture

Each type of formwork is more or less suitable for different projects.

Formwork cost and average market prices

| Appearance | Name | Dimensions, mm. | Thermal insulation thickness, mm. | Price (per sq. M.) |

| Series 25 (one-piece) | ||||

| Main wall block | Length - 1250 Width - 250 Height - 250 | internal - 50 external - 50 | From 490 rub. | |

| Wall end block | From 500 rubles. | |||

| Corner wall block (left / right) | Length - 700/450 Width - 250 Height - 250 | From 500 rubles. | ||

| Wall swivel block | Length - 700 Width - 250 Height - 250 | From 500 rubles. | ||

| Series 30 (one-piece) | ||||

| Main wall block | Length - 1250 Width - 300 Height - 250 | internal - 50 external - 100 | From 560 rub. | |

| Wall end block | From 570 rub. | |||

| Corner wall block (left / right) | Length - 1250/500 Width - 300 | From 570 rub. |

Comparative cost per m2

Let's consider it in more detail using the example of popular manufacturers. First, let's find out: what explains this cheapness? First of all, the production process is not associated with special costs, because of which the price may rise slightly only due to increased demand in a particular region of the country.

Thus, the Mosstroy company produces a wide range of expanded polystyrene blocks at the following prices:

- straight blocks - from 490 rubles;

- straight blocks 5 cm thick - about 800 rubles;

- 10 cm corner products - the same amount;

- jumpers and all sorts of plugs - somewhere around 25 rubles.

Note! These are Moscow prices. If we take, for example, Blagoveshchensk, then there such blocks will generally cost about 300-350 rubles apiece.

Fixed formwork made of expanded polystyrene is often constructed from blocks produced by the Samara company "Thermomonolit". The cost of its products starts at 780 rubles; products are distinguished not only by high quality, but also by the ideal combination of foam and plastic.

The most expensive blocks are products from Technoblok, faced with artificial stone. They cost about 1800-2500 rubles per square. Be that as it may, the costs will still be less than if any other building material was used.

The technology of laying fixed polystyrene foam formwork

In order to correctly place non-removable blocks of expanded polystyrene before pouring liquid concrete, special skills are not needed. Observing the requirements, the structure can be assembled without problems.

The walls of the house can be assembled from ordinary wall, as well as from rotary and corner blocks of expanded polystyrene

How to install an auxiliary structure

When starting the construction of formwork from blocks of expanded polystyrene, you need to understand that the process resembles the assembly of a designer. Each part of the structure made of artificial raw materials has grooves at the bottom, and spikes at the top. Therefore, the blocks are connected tightly and tightly and easily assembled into the desired structure.

Slots and ledges make it easy to assemble the formwork

The expanded polystyrene formwork is mounted by performing the following steps:

- The foundation of the house is covered with a canvas that serves as a moisture barrier. The first line of expanded polystyrene blocks is placed on the waterproofing material. Reinforcement elements are threaded inside them (vertically), providing a reliable connection between all fragments of the structure. When placing the blocks, they look to see if the dimensions correspond to the specified parameters, monitor the form of the formwork and leave voids for outlets for internal partitions.

-

The next lines of the blocks are set so that they overlap the joints of the structural elements laid earlier.

-

The structure is reinforced around the perimeter, that is, two metal rods are inserted into each line of blocks.The armature is immersed in the material exclusively in the horizontal direction. To facilitate this task, small protrusions are created on the lintels on the inner side of the blocks. Metal elements are laid, making overlaps, and fastened to each other with steel wire. In addition, the armature is connected in the same way to the pins inserted vertically into the base.

- The necessary communications are carried out through the created structure. Then, mounting holes are made in the formwork. It will not be possible to do this later: the poured and already hardened concrete will become a serious obstacle.

-

For pouring, take a composition devoid of large crushed stone, since it is capable of deforming the walls of a structure made of expanded polystyrene. The formwork is filled with mortar in layers of one meter. The penultimate layer of concrete is pressed and leveled. When it completely hardens, the last layer of the solution is poured.

Video: how to connect the walls from the fixed formwork to the roof

Is it possible to make a fixed structure of expanded polystyrene on your own?

At the plant, expanded polystyrene blocks are produced using a complex technology in several stages:

- Construction raw materials are treated with steam, which is called pre-foaming in production. As a result, the pores of the material become wider, and the material acquires a different density - 35 kg / m³.

- The expanded polystyrene foam is kept in the hopper, waiting for it to be ready for further processing. After a day, the state of the granules in the material is normalized and excess liquid comes out of them.

- Blocks are formed from expanded polystyrene. For this, the material is enclosed in special forms and foamed again.

- Finished blocks are cooled with water and removed. After that, a break is made in production for about 24 hours. The exact downtime depends on the humidity and temperature of the room where the formwork is being manufactured.

- Waste from production is crushed and converted into a storage device. The leftover material can be used again.

The expanded polystyrene formwork block is the result of multi-stage material processing

It is very difficult to repeat all the above steps at home. In addition, the production of polystyrene foam blocks involves the use of a steam generator - an expensive apparatus.

The steam accumulator for the production of permanent formwork must have certain characteristics:

- foaming temperature - from 100 to 115 degrees;

- forming temperature - from 130 to 140 degrees;

- steam pressure during foaming of the material - from 1 to 1, 5 atm;

- steam pressure during forming - 4–5 atm;

- steam consumption during foaming of raw materials - from 50 to 100 kg / h;

- steam consumption during molding - from 25 to 50 kg / h.

Styrofoam blocks are manufactured at the factory, it is better not to tackle them at home

In addition to the steam generator, for the production of polystyrene foam blocks, pneumatic transport, a residue crusher, a receiving hopper and accessories are needed.

It turns out that making blocks of expanded polystyrene with your own hands is unreasonable. It is easier and cheaper to purchase ready-made permanent formwork.

Arrangement of the foundation of the building without the use of formwork

In some cases, it makes sense to make a foundation without using any formwork. For example, in the construction of a small building, some overconsumption of concrete is compensated by the simplicity and speed of casting a concrete base. Of course, such a foundation is not suitable for a house with a basement floor. Moreover, without the use of formwork, the foundation can be equipped on soil that does not crumble, that is, with a certain clay content.

Filling the strip foundation without the use of formwork

Filling the strip foundation without the use of formwork

To equip the strip foundation, a trench is dug under it in accordance with the contours of the building and up to 1m deep. A sand pillow with a layer of 10-15 cm is laid on its bottom. The sand is moistened and thoroughly rammed.To improve the performance of the concrete, it is recommended to cover the side walls of the trench with roofing felt or thick polyethylene. Next, the frame is equipped with reinforcement, and concrete is poured.

This is interesting: Windows to the floor on the balcony: we will write the main thing

Making permanent formwork with your own hands

Let's consider the process of creating a permanent formwork from sheet materials with self-cutting using the example of EPS (extruded polystyrene foam).

Fold the sheets into pieces corresponding to the width and length of the tamped trench. From the remains, cut out strips for the sides with a height of 20-25 cm. The total length of the sides should correspond to the double perimeter of the trench + 20% for overlapping at the corner points.

Place the sheets in the trench so that the sides are on the XPS layer and not touching the ground. Fasten the sheets in the corners by piercing the material with the plastic ties of the SVT system.

Place the halves of the plastic ties between the vertical sheets and fasten them together. If the system does not snap tight enough, tighten the connections with pliers.

Install reinforcing bars above and below the horizontal braces. To keep the metal in the thickness of the concrete, place pieces of expanded polystyrene under the rods. Special grooves on plastic ties will help maintain the same distance between the reinforcement bars throughout the entire foundation.

Tie the twigs together with a thin wire folded 2-3 times. In the same way, the reinforcement can be tied to plastic ties.

Build up the foundation with whole sheets of EPS, having previously attached narrow strips of the same material to them using plastic clips. Place the prepared sheets as shown in the figure

When installing, pay attention to the location of the grooves and ridges on the sheet.

Attach vertical sheets to each other with ties, install and tie the reinforcement using the technology described above. You should get at least two plastic-reinforcing belts, approximately at a distance of 10 cm from the top and bottom edges of the sheet.

Attach the locking plate to the sharp ends of the plastic ties and cut off the ends that remain free.

Fill the reinforced formwork with cement-sand mortar

You can use your own concrete mixer to prepare concrete, but you will need a lot of mortar. If you doubt that you can fill the entire foundation in a day, it is better to use the services of an industrial concrete mixer tank.

Remove air bubbles with a construction vibrator and level the concrete surface. In this case, it is impossible to expel air with a reinforcing bar, since the metal will damage the formwork, easily piercing the EPSP sheet.

After the concrete of the foundation has completely solidified, you can continue pouring the walls using the same technology, but such a foundation can be used with other materials.

Video: technology for building a house with permanent formwork from chip blocks

When giving preference to one of the options for permanent formwork, consider not only your financial capabilities and labor costs, but also the purpose

For example, in areas with swampy soil, blocks based on wood chips should not be used, and in cold regions, you should pay attention to a material with a minimum coefficient of thermal conductivity. In this case, you can quickly build a warm house without unnecessary financial costs.

Popular manufacturers and prices

Prices may vary depending on the region and seasonality, but for the most popular manufacturers, the average cost will be:

A straight wall block 50 mm thick produced by Mosstroy will cost about 500 rubles, a more complex corner element - 780 rubles. Additional elements cost about 30 rubles on average.

The cost of standard blocks of the Samara "Thermomonolit" will be 750-780 rubles. The higher price is justified - in addition to polystyrene, plastic is added to the formwork blocks, which gives the product increased strength.

The most expensive blocks include the products of the Moscow plant "Technoblok" - their price reaches 2500 rubles. But this difference with standard products from other manufacturers is justified. Each element is covered with an artificial stone cladding. Additional exterior finishing is not required for this material.

The main characteristics of polystyrene foam formwork

- The formwork class is the main quality parameter and is assigned 1; 2nd or 3rd, depending on the availability of an exact fit in the manufacture of formwork parts. All deviations are regulated by standards. Example: for non-removable blocks of the 1st class, the limit of deviation of the linear dimension is no more than 0.8 mm, for the 2nd class - no more than 1.5 mm. The 3rd class of accuracy is not regulated, but is negotiated with the customer. The accuracy requirements are quite strict.

- Average density 25-30 kg / m3, increased density 47-50 kg / m3. The weight of one square. meter of wall 300 mm thick (150 mm concrete + 150 mm two layers of expanded polystyrene) is up to 350 kg without finishing layers.

- Thermal conductivity coefficient Kt = 0.036 W / m * deg K for polystyrene concrete Kt = 0.08 - 0.038 W / m * deg K

- Heat transfer resistance not less than 3.2 m2 * degree K / W

- Excellent frost resistance F300- F600, that is, up to 600 alternating freeze-thaw cycles

- Volumetric water absorption 0.1% per day

- Vapor permeability coefficient 0.032 mg / m * h * Pa

- In terms of flammability, it is classified as group G1 - slightly flammable. In terms of fire resistance, the fire resistance of a wall with a thickness of 250 mm is up to 2.5 hours. Smoke formation group D1, practically does not form smoke

- Soundproofing. The best performance of all building materials. Can be built near highways, railways. Sound absorption about 50 dB

The maximum possible number of floors in world practice is up to thirty, in our country, as a rule, the highest buildings with expanded polystyrene formwork are sixteen-story buildings

First, about the environmental friendliness of expanded polystyrene

It should be noted that expanded polystyrene with a very big stretch can be attributed to environmentally friendly materials. However, it is so often labeled. This is true, if only you do not consider it from the point of view:

Effects on humans - styrene, from which expanded polystyrene is made, is a poison for humans, in expanded polystyrene it is polymerized, but not completely, therefore, the poison is gradually released into the environment, and under the influence of light, oxygen, heat, etc. he begins to stand out more actively. In case of fire, it burns at a very high temperature of 1100 ° C, destroying even metal structures, and emitting toxic substances. Of course, modern polystyrene foam is processed with fire retardants, so they talk about fire safety, but fire retardants are also not harmless to humans.

Environmental impacts - after the end of its life, polystyrene foam is sent to landfill, but it will lie there for hundreds of years, poisoning the environment, since it has poor biodegradability properties.

The question is: is such an "environmentally friendly" material needed?