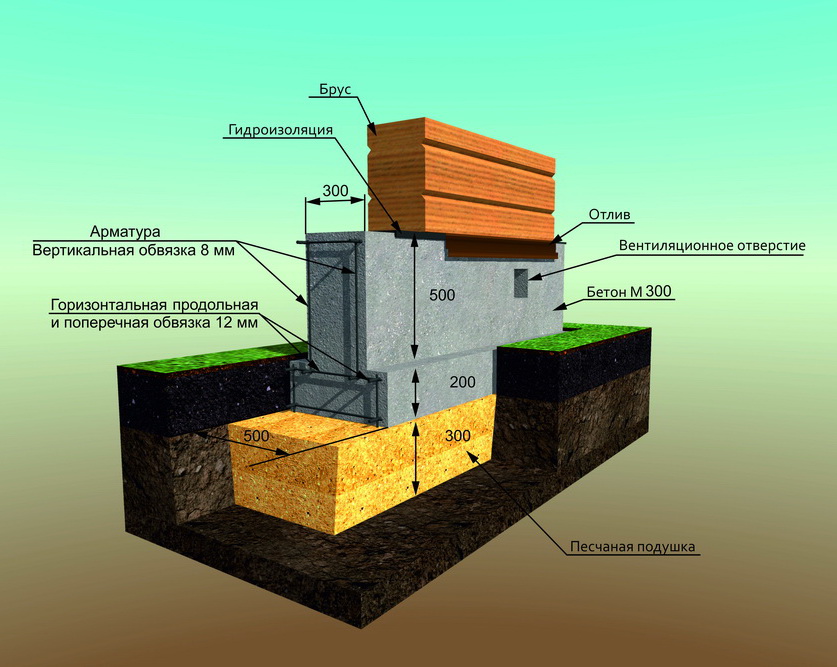

Plinth finish

The outer part of the foundation protruding above the soil level is the basement.

To complete the foundation, it is worth mentioning the finishing of the basement:

- thermal insulation, will allow you to keep warm in the basement even in the harshest winter, for this, mineral wool or rigid polystyrene plates are used;

- waterproofing, especially important in low places with high humidity, swampy soil and the risk of flooding, the easiest way is to use a coating waterproofing;

- decorative finishing, expanded clay plaster or decorative panels;

- the obligatory ebb tide on the plinth will not allow water to leak under the foundation.

A correctly selected base / plinth finish can give the house a unique flavor. Ensure the long-term operation of the building. One of the simple and effective finishes is clay plaster, on which you can create imitation of masonry using a stencil. With low money and labor costs, the plastered base is original and memorable.

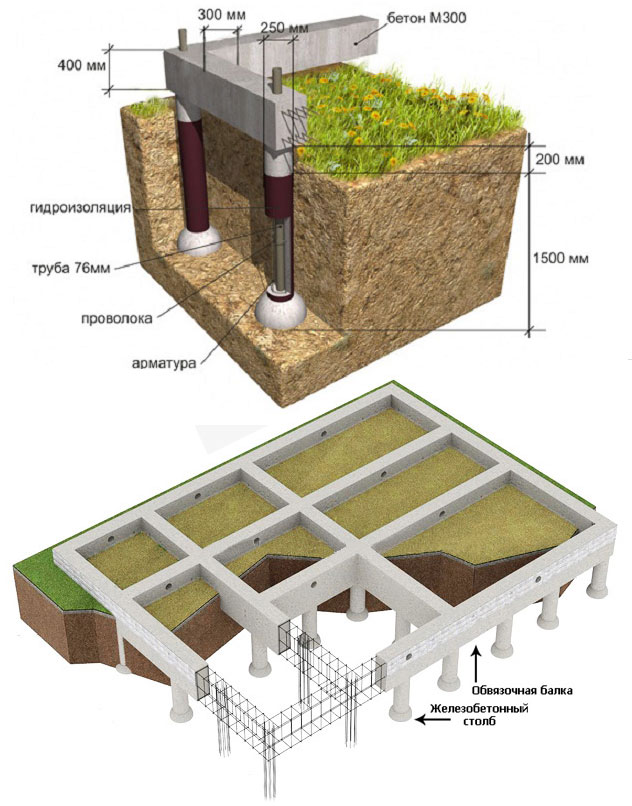

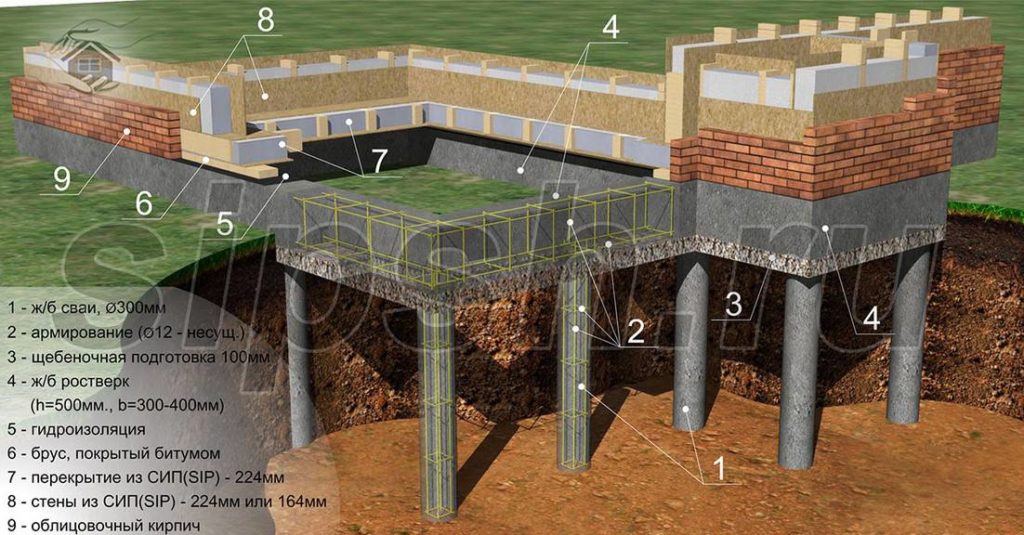

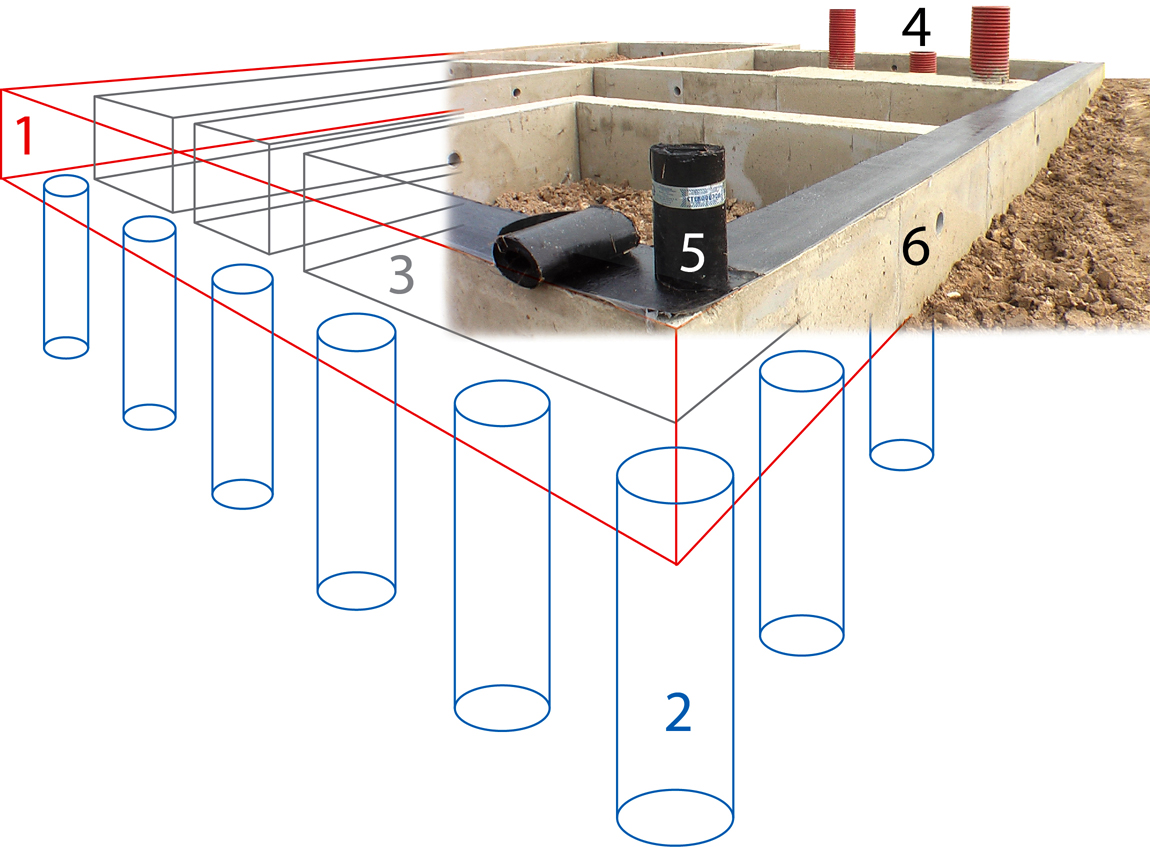

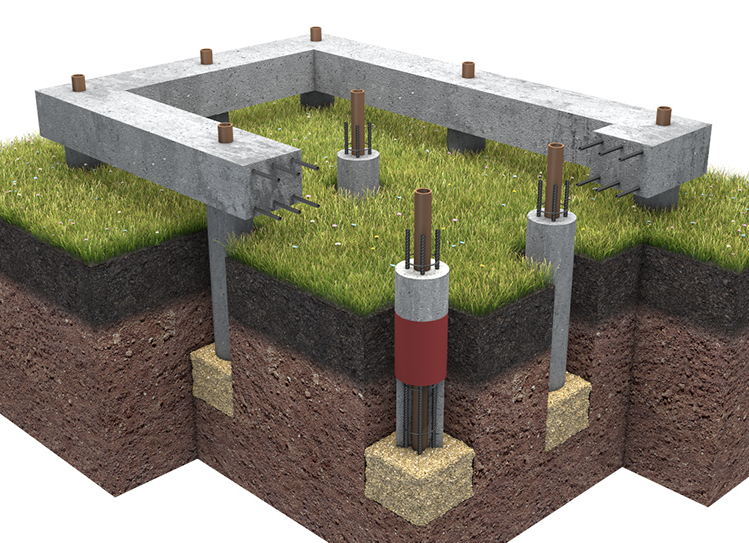

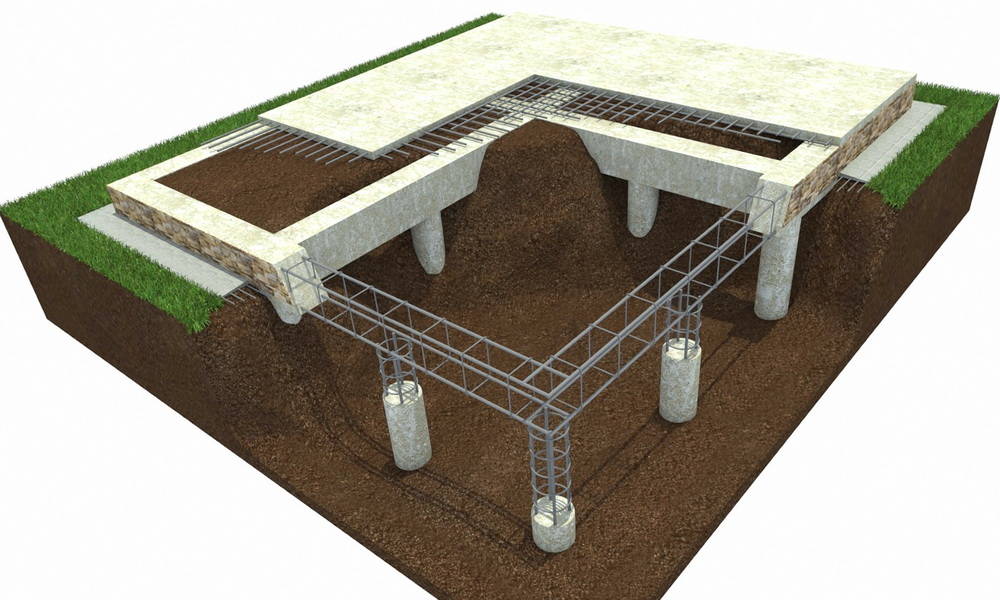

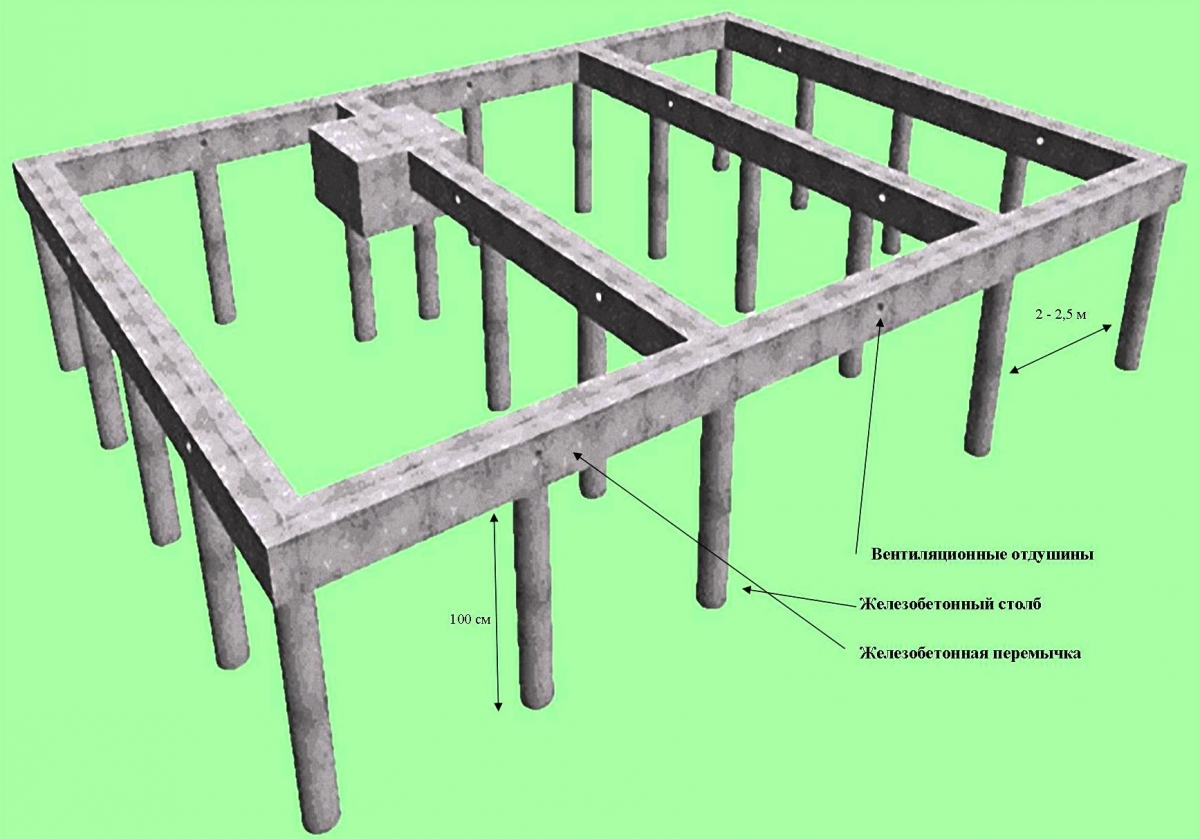

Technology for the construction of pile-grillage foundations

-

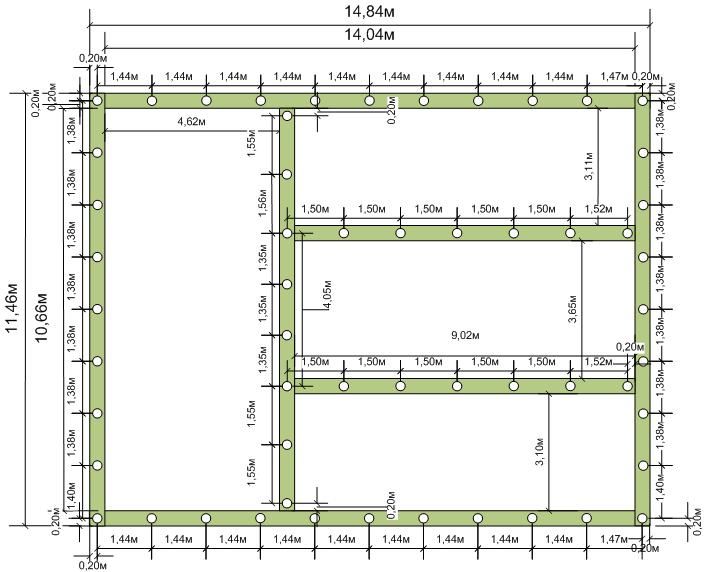

Carrying out detailed survey work, as a result of which you need to obtain detailed information about the type of soil and the depth of the water horizons;

- Development of a foundation project, where calculations of permissible loads on each support, the depth of their placement, as well as the type of grillage will be immediately provided;

- Installation of supports. If the project clearly indicates what type of supports should be used, then the technology for their installation is already provided. It happens that when erecting small buildings on piles, only the calculation of the loads is made. Then the builder himself determines the type of piles and often screw or injection supports are used, which are easier to install.

- Installation of a grillage with its further reinforcement;

- Arrangement of the basement, carrying out waterproofing and thermal insulation work on the inside of the floor.

As a rule, the key factor in choosing the type and length of the foundation will be the depth of the bottom edge of the foundation.

When calculating loads, the mass of the bearing walls and floors, the mass of possible seasonal loads, payloads from furniture are taken into account and the result is multiplied by a factor of 1.3.

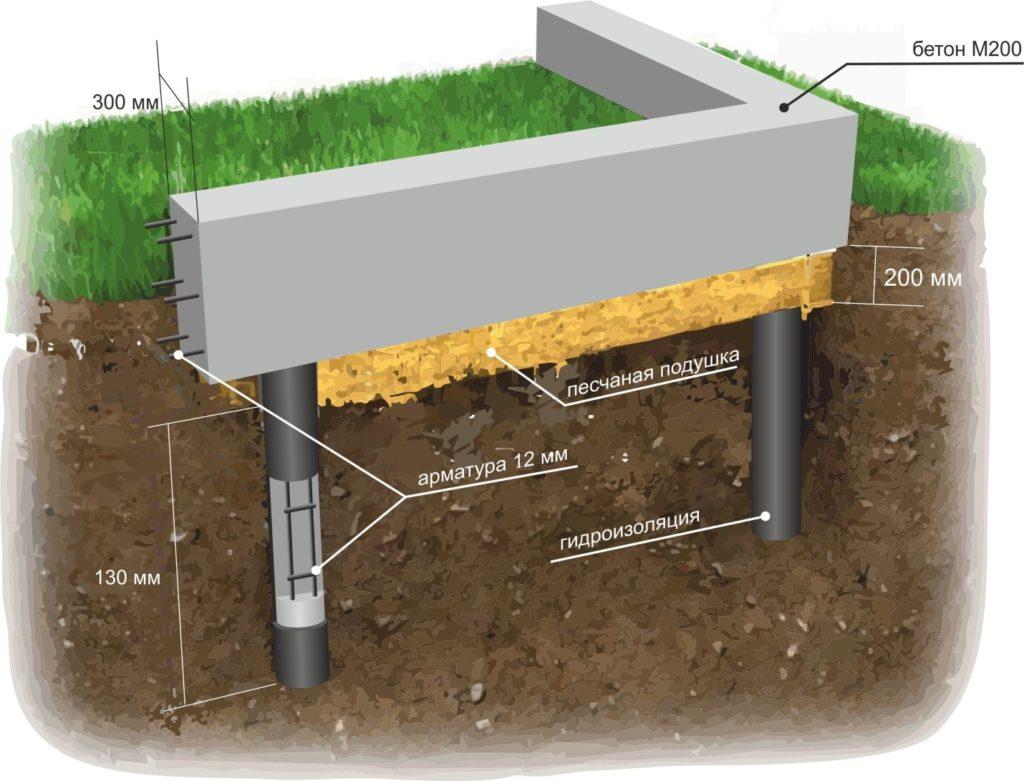

All about pouring the foundation

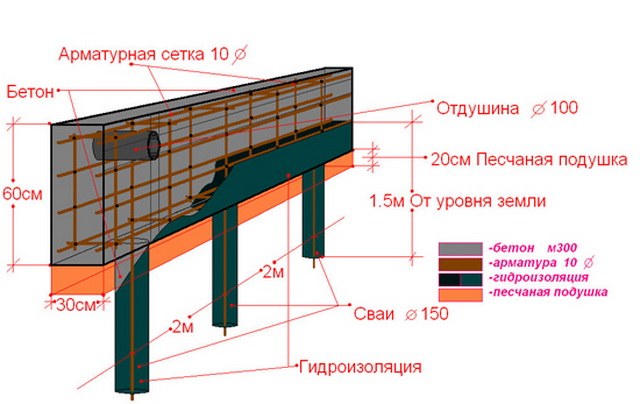

The best material for filling is considered to be Portland cement M 200 - M 500

The best material for filling is considered to be Portland cement M 200 - M 500

The best material for filling is considered to be Portland cement M 200 - M 500.

There are some rules for getting the best results from these jobs. Their step-by-step diligence is encouraged:

- It is necessary to use cement not lower than M 200 grade;

- Making a solution is preferable to medium density;

- Filling is performed with the shortest time interval for all wells;

- After its completion, you can perform reinforcement;

- It is better to fill in the supporting elements first and leave to dry for two days;

- After that, you can fill the grillage, also at the same time.

Nuances when performing work

Creating this type of foundation, the choice of technology plays a major role

Creating this type of foundation, the choice of technology plays a major role

When performing these works, such nuances may appear, without which it will be impossible to fill:

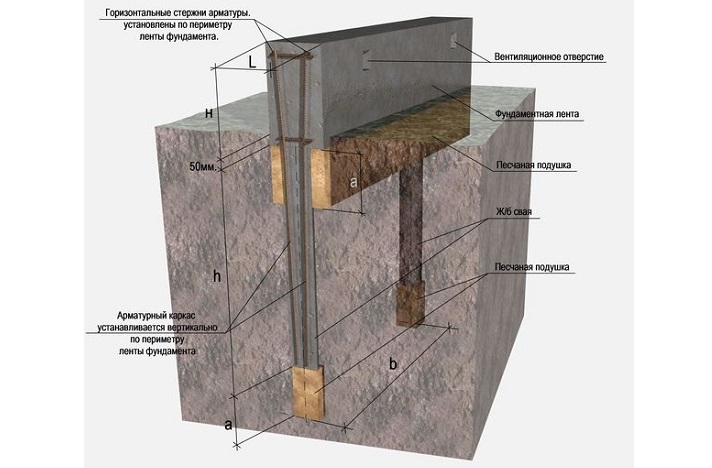

- First, we fill in the piles, and only then we can proceed to the territory of the foundation made of tapes;

- The fittings must be completely filled;

- The thickness of the solution should be of medium consistency;

It is forbidden to fill the foundation in wet weather, because the foundation will lose percent of its strength.

So, creating this type of foundation, the choice of technology plays a major role. We do not recommend using the type of piles with filler, this can be allowed in the base of strips.Remember that only compliance with all construction standards and the correct composition of the solution can really build a strong and stable structure.

Preparation for work

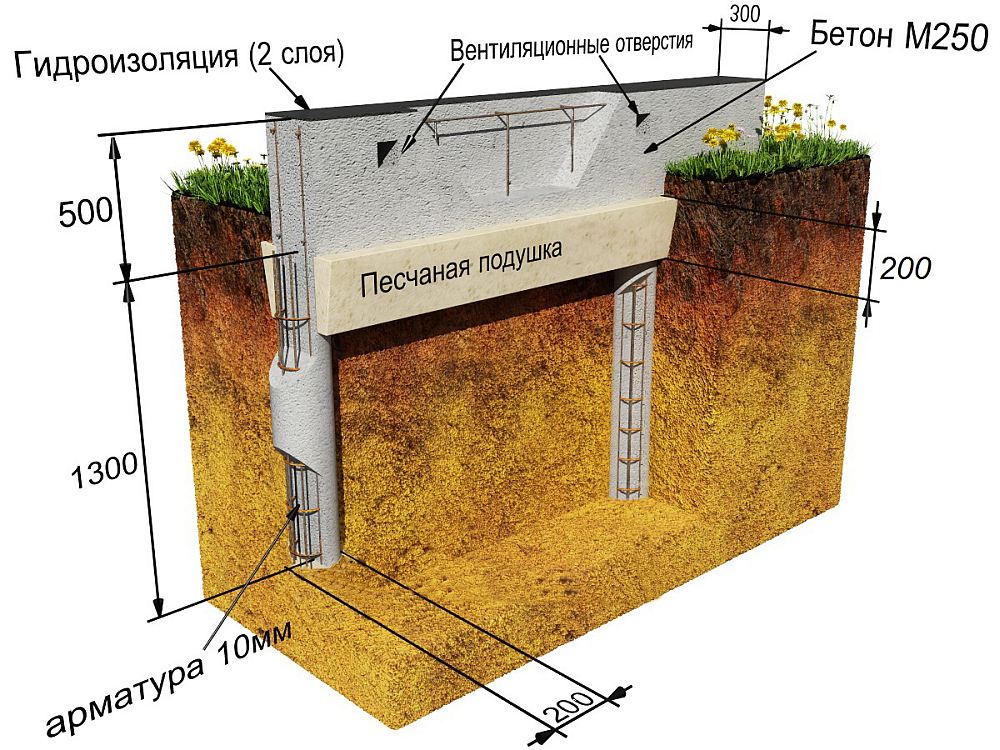

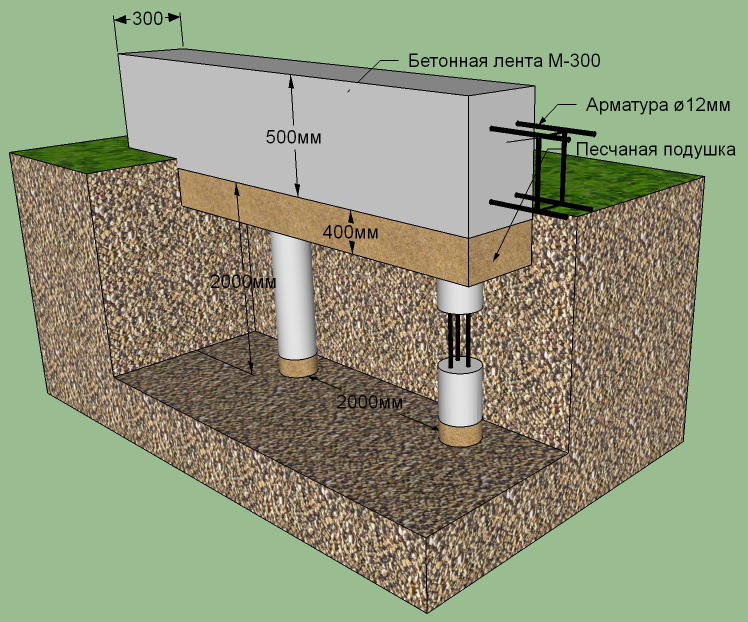

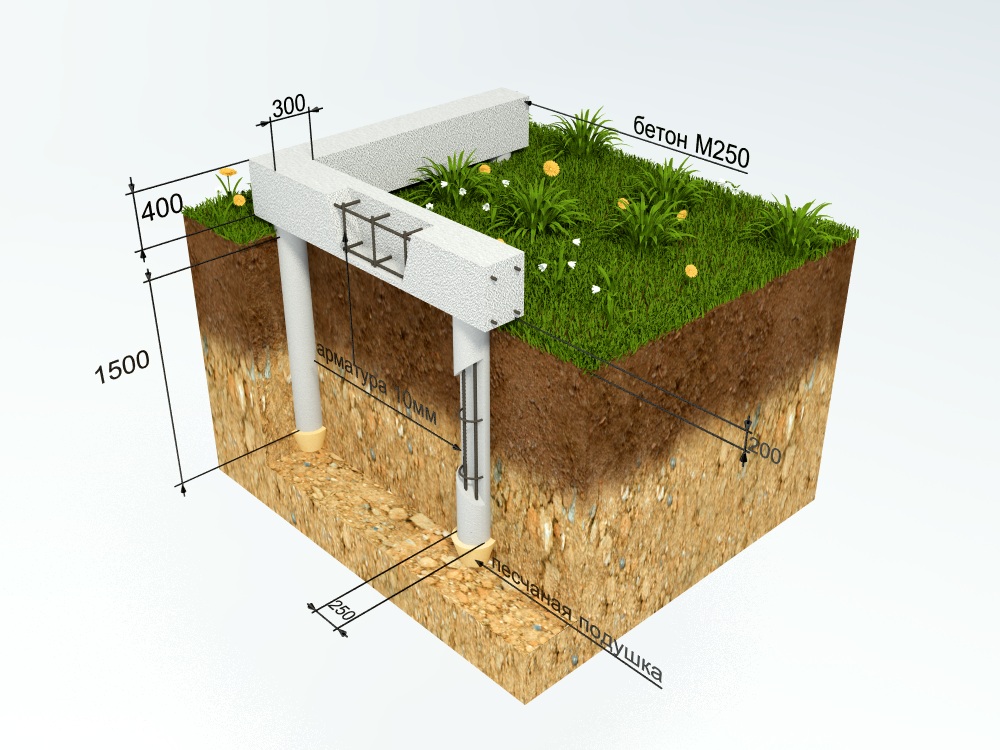

Having chosen the type of foundation, the owner of the house is faced with the task of correctly calculating the parameters of the strip foundation, if it is done without the services of a construction company, but only with his own hands, using step-by-step instructions.

Let's decide what parameters we will have to face when deciding how to make a foundation for a house:

The deepening of the foundation into the ground, here it is important to know exactly the depth of soil freezing in the region of work and lay 300-500 mm below this border, in addition, the weight of the future house will be important in the calculation, the higher the house and the heavier materials are used, the deeper you need a foundation pit.

The width of the concrete belt, here the dimensions of the building will also be the determining factor, but usually the thickness is designed in the range from 300 to 500 mm.

The brand strength of concrete, it makes no sense to use concrete with a strength less than M250 for the foundation of a residential building, this is a limiting value, if it is underestimated, there is a risk that the house will collapse even before the completion of construction.

The project of the foundation must accurately correlate with the project of the house, it will be a stone capital house made of cinder blocks or a gas silicate summer cottage option, if it is planned to install a brick oven, garage sliding gates or other heavy structures, the embedded elements of the foundation should be drawn up with this calculation.

Pros and cons of strip foundation with piles

When we talk about the general advantages of a pile foundation, regardless of the specific production technology, they are as follows:

- Simple construction.

- Material consumption is lower than, for example, when using a strip foundation.

- Can be used on soft soils.

- Suitable for a variety of buildings.

- Great stability, good load carrying capacity, floor movement.

- Almost all work can be performed independently and without the use of special equipment.

This is also a bug:

- No matter how good the piles are, they also have a bearing capacity. For particularly heavy buildings, a different type of foundation should be chosen.

- There is practically no way to equip a basement.

- Difficulties in calculating the properties of the base. Online calculators, which can be found on the Internet, help to partially solve this problem.

Geological surveys

Not only the calculation of the foundation is important for the construction of a stable frame house, the characteristics of the soil and geological features are important. Specialists who design structures carry out complex geological surveys - drilling and studying material in the laboratory.

If the frame building will be erected on its own, then a visual study is often sufficient. For this purpose, drilling is carried out to a depth below the base of the foundation by about 50-100 cm. This will help determine the type of soil and exclude the presence of water-saturated layers. It is recommended that this check be done in several places, since unstable soil may be nearby, within the building.

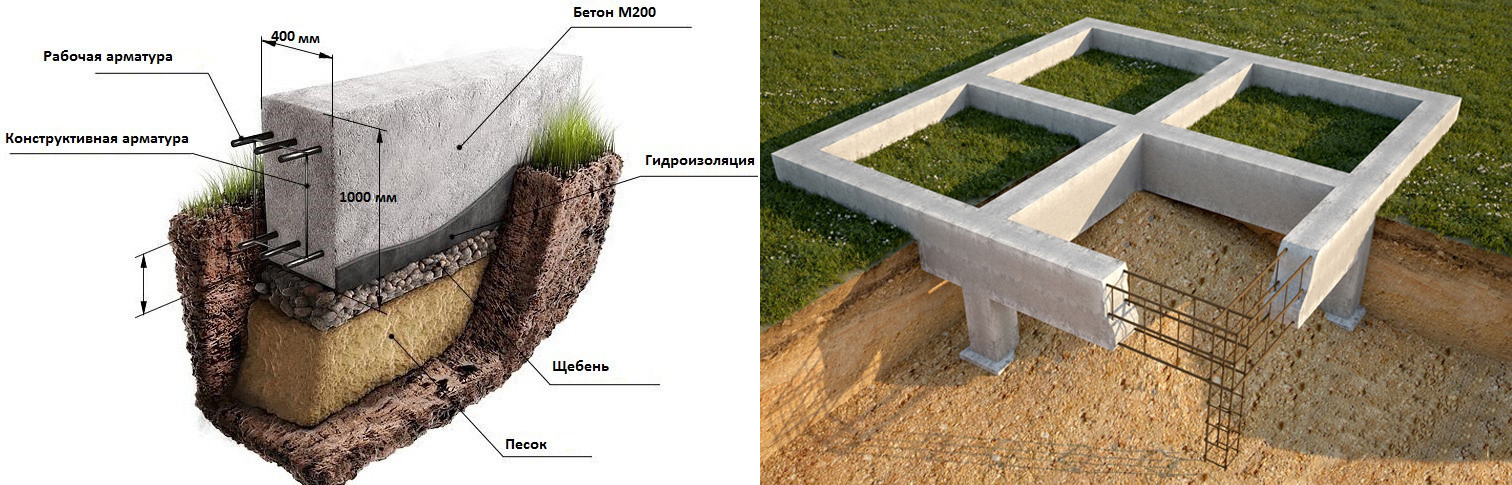

Strip foundation

The strip foundation is known for its massiveness, but, at the same time, for its ease of construction. It is this type that is most often used when it comes to individual construction projects. The strip base is a strip of reinforced concrete that runs along the entire perimeter of the structure being erected. In addition, it passes under all the walls of the building, including the inner ones. The cross-section of this strip remains the same anywhere on the base.

This is what a strip foundation for a house looks like.

The strip foundation is used, as a rule, in the construction of brick and stone houses, buildings with heavy ceilings, as well as cottages, in the layout of which there is a basement.

Strip foundation device

The depth of the foundation device directly depends on the depth of soil freezing. The foundation is laid 20 cm deeper than the level of freezing of the earth, but at the same time its depth should not be more than 50-70 cm. The thickness of the foundation, in turn, directly depends on various features of the future structure.

Drawings for laying various types of strip foundations on different soils and for different buildings

Shallow and buried strip foundations

A shallow strip foundation is erected, as a rule, during the construction of small stone houses, as well as wooden houses on slightly weeping soils. It is laid to a depth of about 50-70 cm.

Drawing of laying a shallow strip foundation

Recessed strip foundations are used in the construction of houses with heavy ceilings or thick walls, in houses with basements and garages. This type of foundation is laid at a depth of about 20-30 cm below the level of the soil freezing depth. The construction of such a foundation requires a lot of materials.

The deepened strip foundation is much stronger and more reliable, but also requires large capital investments

How to calculate the number of piles for a foundation

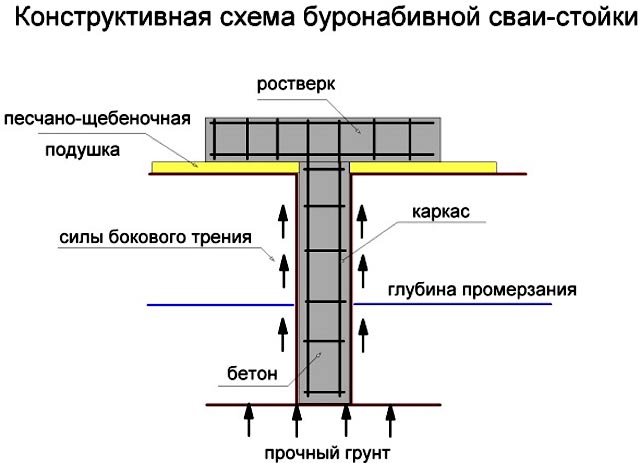

The correct calculation of the number of piles used requires preliminary geodetic exploration. First of all, it is necessary to calculate the level of soil freezing in winter, given that this indicator differs in different regions. For a solid installation of the pile, its lower end must be below this level.

And also it is necessary to find out the degree of density of the soil layers. The higher the density, the shallower the pile depth should be laid at the design stage. For example, for semi-rocky and large-block rocks, it will be minimal (but not less than 0.5 meters), and for sandy and clayey soils, it will have to go deeper to the maximum.

1. Calculation of the potential ultimate load on piles

Before calculating the number of piles for a foundation, you should find out the bearing capacity of an individual pile. The general view of the formula is as follows:

In this case, W is the required actual bearing force, Q is the calculated value of the bearing force, calculated for an individual pile according to the material, dimensions and characteristics of the soil; k is an additional "safety factor" that expands the operational reserve of the foundation.

2. Calculation of the design load on the piles

Next, we need to find the parameter Q, without which calculation of the pile foundation impossible. The design load is determined by the formula:

Where S is equal to the cross-sectional area of the pile blades, and Ro is an indicator of soil resistance at the depth of placement of the blades. Soil resistance can be taken from a ready-made table:

table 2

table 2

As for the "safety factor" of the conditional foundation, its value can vary within 1.2-1.7. It is logical that the lower the coefficient, the lower the cost of the foundation at the design stage, since it will not be necessary to use a large number of piles to achieve a given value of the bearing force. To reduce the coefficient, a high-quality and reliable soil analysis should be carried out at the construction site, involving specialists.

3. Calculation of the load from the building structure

At the final stage of the design of the pile foundation, the number of piles is calculated. To do this, you will need to sum up all the elements of the building structure: from the main walls and floors, to the rafter system and the roof. It is quite difficult to accurately calculate all the components, so we recommend using one of the specialized calculators. And also, operational loads are entered into the calculation calculator, including interior items, furniture, household appliances and even people living in the house.

4. Counting the required number of piles

Before calculating the number of piles involved, we need to obtain at the previous stages two values: the total mass of the building (M) and the bearing capacity of the pile (W) multiplied by the "safety factor". The value of the bearing capacity can be taken from Table 1. So, if the mass is 58 tons, and the corrected bearing capacity of the SVS-108 pile is 3.9 tons, then:

As the calculation example showed, for a house weighing 58 tons, 15 SVS-180 piles will be required. It should be noted that this value is approximate and does not take into account the rules for the exact distribution of piles according to SNiP:

- The former should be installed at the intersection points of the supporting structures;

- The rest are mounted evenly between the designated corners;

- The minimum distance between individual piles is 3 meters;

5. Installation depth piles and distance between them

The base value of the pile installation depth is calculated based on the depth of soil freezing in a particular region, plus 25 centimeters. And also, before calculating the pile foundation, you need to find out:

- The level of pile strength in terms of material and construction;

- The bearing capacity of the soil;

- Calculate the settlement of the pile foundation, which occurs over time under the load of the building;

- Additional parameters (temperature regime throughout the year, amount of precipitation, wind loads, etc.).

Project: to order or not

Building a house requires a lot of money. Naturally, there is a desire to save money. But the foundation is not the stage at which it is worth saving, because its incorrect construction will lead to problems, the elimination of which will require much more money. Therefore, it is advisable to order a project, as well as a geological survey.

This stage can be dispensed with only when building small houses, baths, temporary or outbuildings. If a capital house is being built, moreover, from heavy materials, then the risks are too great. But it's up to you to decide.

Actually, there is enough information for independent design of foundations, especially belt foundations. But a lack of knowledge and experience often leads to two opposite results:

- The foundation was made with an excessive margin of safety for the given conditions. This is good from an operational standpoint, but leads to increased costs, often exceeding the design cost.

- Insufficient safety factor or improper design resulting in uneven soil settlement. The result is cracks in the walls of the house.

As you can see, both options lead to cost overruns: under construction or for restoration and repair. And it's not a fact that design work will cost more. Rather, the opposite is true. The calculation of the foundation can cost about $ 100-250, but it requires geological data on the site, and these studies cost around $ 1000. For a small building, you can conduct research on your own, but for a solid one, it is probably better to trust the professionals.

Calculation of the area of the base of the foundation

An important place in the design of the base for future construction is occupied by the calculation of the area of the base of the foundation. This stage of work is carried out according to the formula shown in the figure below.

The value obtained as a result of the calculations is the approximate total area of the base of the foundation, necessary in order not to literally push the soil under load. If we are talking about the construction of the most expensive - slab monolithic foundation (in the article, the calculation of reinforcement for the foundation, you will appreciate how "economical" this solution is), then you can completely avoid these calculations, because it is enough to fill the slab under the entire area of the house, and such a sole with an excess is enough to prevent all the surprises that the soil presents.

Each type of soil, depending on the depth, density and porosity, has its own load resistance.It goes without saying that soil layers at great depths as a result of natural compaction are characterized by high values of resistance. So, if you plan to build a foundation to a depth of less than 1.5 m, then the calculated soil resistance will take on a slightly different value. In this case, it will be calculated according to the formula: R = 0.005R0 (100 + h / 3), where R0 is the tabular value of the design resistance, h is the depth of the foundation relative to the zero mark, see. In turn, a lot depends on groundwater, because increased soil moisture reduces its resistance to load.

Naturally, when calculating the foundation for a house on your own, you will have to tinker with calculating the load from the structure being erected, which will be on the soil layers under the base of the foundation. This includes:

- the total load from the structure, including the approximate one - from the foundation (data from the table presented in the figure below are used);

- load from objects that will be placed in the building (fireplaces, furniture, people);

- weight of seasonal snow loads. For the middle lane, it is taken equal to 100 kg per sq. m of roof, for the south - 50 kg, for the north - 190 kg.

The value of the basement foot area obtained as a result of calculations is used when drawing up the foundation project: choosing the width of the tape (for a strip monolithic base) or the support area (for columnar, pile types of foundations). Consider a specific example of calculating the foundation for a stone house 6? 8 m. How the reinforcement for the foundation is selected will be discussed in a separate article.

An example of a foundation calculation

Suppose we are building a two-story stone house 6? 8 m, the project of which includes one internal load-bearing wall. The mass of the house, taking into account all the loads, turned out to be equal to 160,000 kg. The soil is wet clay (design resistance - 6 kg / cm2). Condition factor - 1. Reliability factor - 1.2. We substitute all the values into the formula for calculating the area of the base of the foundation:

S = 1.2? 160,000 / (1? 6) = 32,000 cm2 = 3.2 m2

For strip foundations: with a total strip length of approximately (6 + 8)? 2 + 6 (inner wall) = 34 m the minimum tape width is 3.2 / 34 = 0.1 m. This is the minimum value!

If we consider the foundation for a light wooden house, provided that the minimum foot area is equal to 1 m2, then for the construction of a pile foundation (the base area of each pile is taken equal to 0.07 m2, provided that the lower part of the pile is 0.3 m in diameter ) would need:

1 / 0.07 = 15 piles

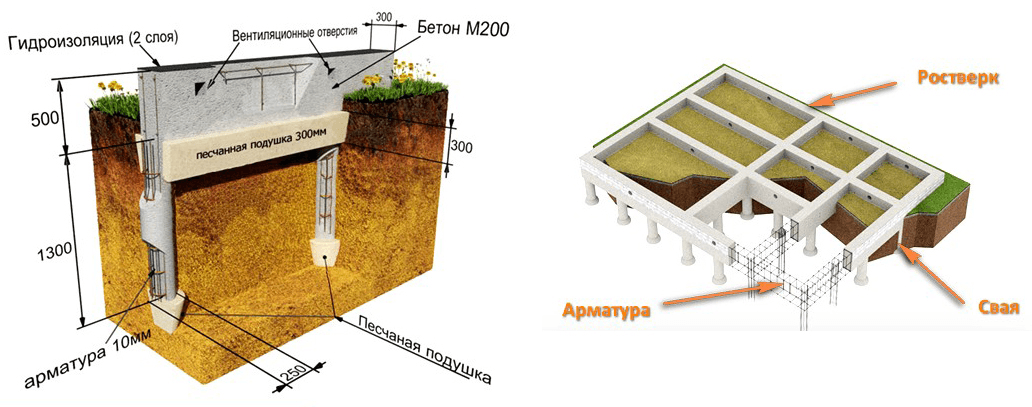

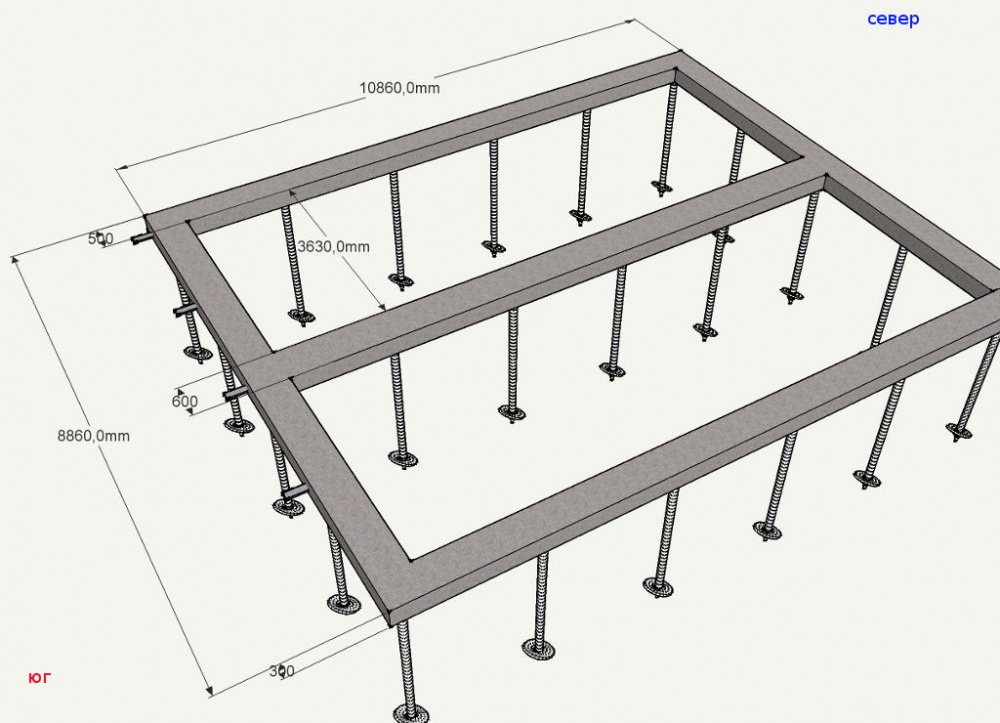

Calculation and preliminary preparation

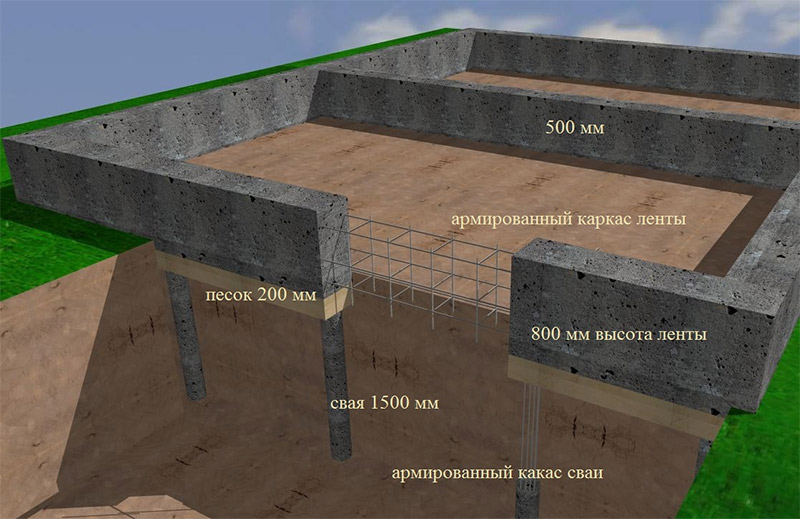

When creating a foundation, one of the most important points is to calculate its depth and conduct a general marking of the territory.

First you need to find out how much the soil can freeze in the selected area. After the parameter of the soil freezing depth becomes known, the depth is calculated to which the pile slab will subsequently be immersed.

The slab will be 0.3-0.5 meters lower than the extreme limit of the soil freezing level. After that, the selected area is thoroughly cleaned and leveled using a level. Further, detailed marking is made using reinforcement, which is driven into the ground.

The marking is carried out both along the outer and inner perimeters. This leads to the fact that the width of the future tape becomes known.

In general, the parameter of the grillage width directly depends on the characteristics and type of material used.

If, for example, a house is built of wood, and the walls are erected using a foam block, then a tape with a width of 30 cm will be enough to support the weight of the structure.

If it is planned to build a stone or brick house, the width of the tape can be equal to 40-60 cm.The depth of the entire monolithic structure should not be less than 45 cm.

Pile-strip foundation pouring

This parameter directly depends on how much the future structure will weigh. After the first marking, the second is carried out - it is needed for the piles to be driven in. In this design, the piles are located with a pitch equal to 1.3-1.5 meters from each other.

As mentioned above, reviews of pile-tape type foundations are mostly positive.

Oleg, 53 years old, Omsk:

Sergey, 47 years old, Vologda:

Vladimir, 38 years old, Sheksna:

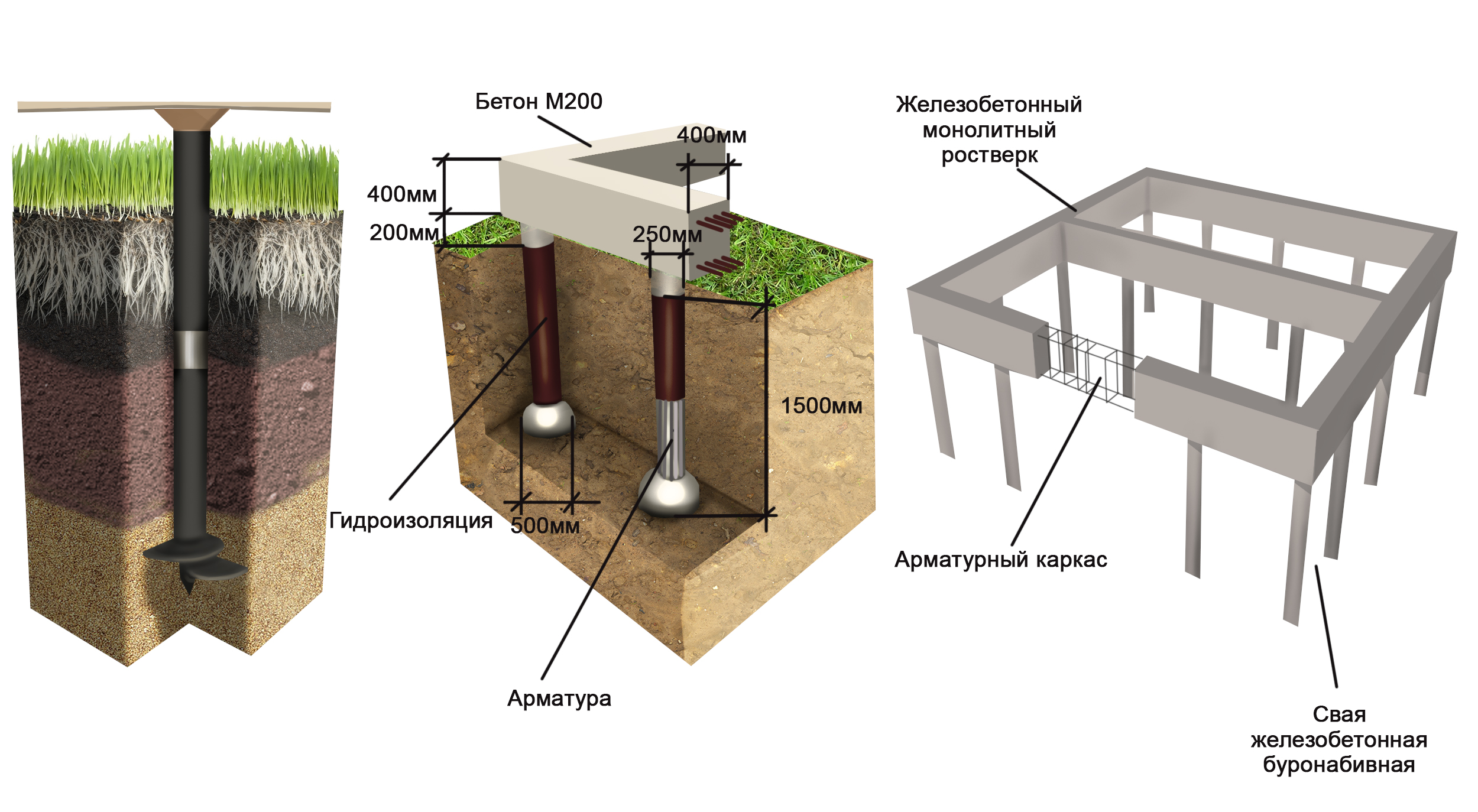

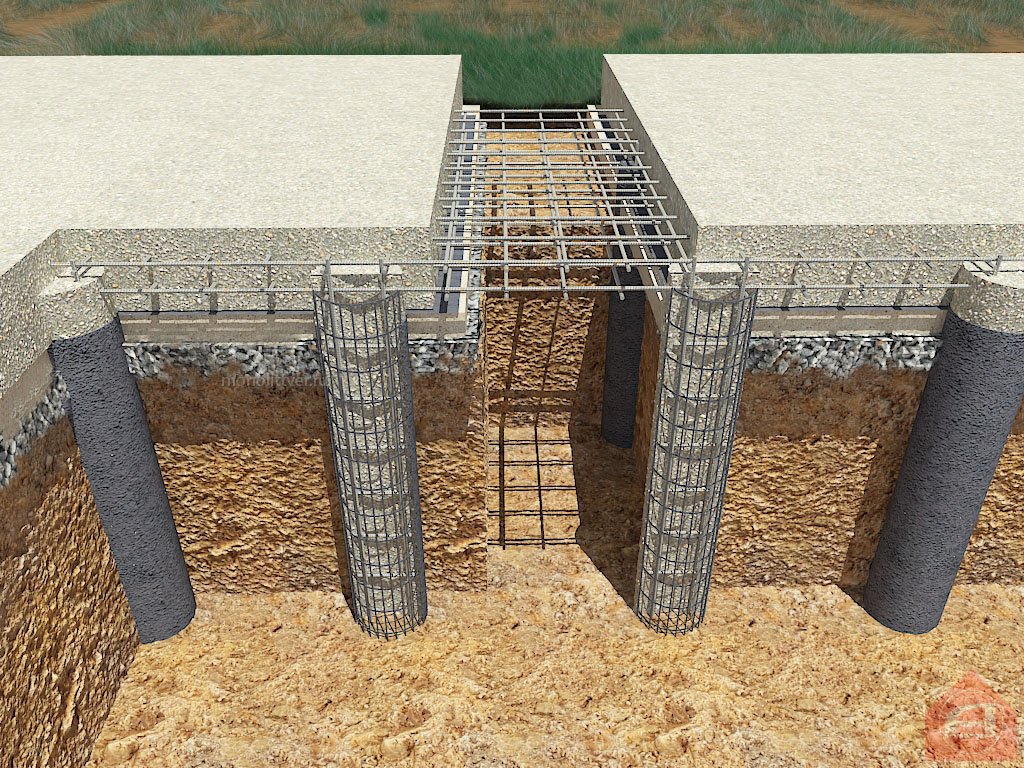

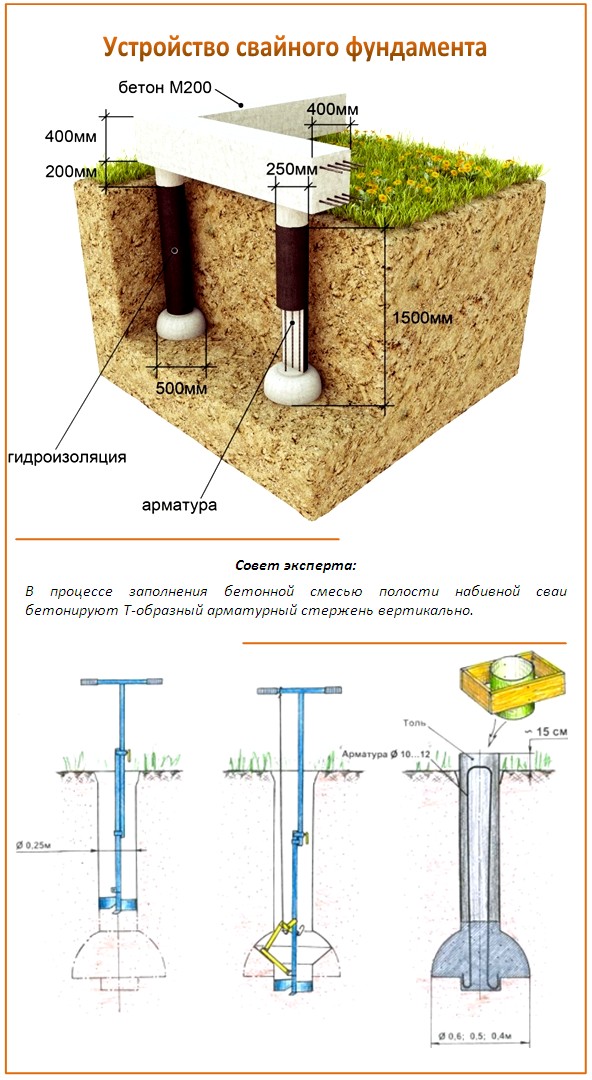

Do-it-yourself pile installation

In order to drill a well to place the future pile, you can use a hand or garden drill. There is an alternative - the purchase of ready-made piles, which are equipped with a circular cross-section.

When creating a well, it is important not to forget that an extra 30 centimeters is added to the existing pile length. They are designed for a sand cushion that is laid at the bottom of the well.

To do this, you need to fill the bottom with ordinary river sand, and then, as it should, pour plenty of water, and then tamp

They are designed for a sand cushion that is laid at the bottom of the well. To do this, you need to fill the bottom with ordinary river sand, and then, as it should, pour plenty of water, and then tamp it.

After that, you can install metal or asbestos-cement pipes and sheathe the walls with roofing felt.

For each separately taken well is provided with a sole. In order to create it, a concrete solution is poured into the pipe by 30-35 cm, and then the pipe is raised by 20-30 cm.

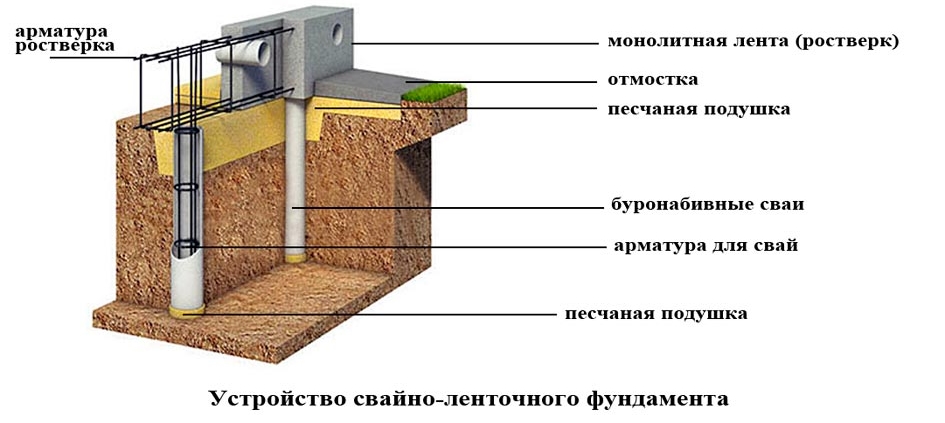

Formwork fabrication and concrete pouring

After the trench is dug, its bottom is covered with sand to create what is called a sand cushion. Its width should not exceed 150 mm.

In this case, the layer of sand should be evenly dispersed along the entire perimeter. As with piles, this slab is filled with abundant water and compacted tightly.

For additional strength, it is covered with a layer of crushed stone. The formwork is made from any materials at hand.

These can be wide boards or sheets of chipboard laid on top of each other. Further, ready-made structures are nailed to stakes driven into the ground at a distance from each other. The stakes should be placed at the top of the trench dug for the foundation.

After completion, the height of the formwork is measured, and bricks are laid on the bottom of the dug trench. After that, the piles of the entire structure are poured with concrete.

Before this, the piles are compacted tightly and checked for the presence of voids formed. In order for the concrete-poured piles not to accidentally connect to the foundation tape, you do not need to wait until the concrete has finally hardened.

For this, the formed monolithic top of the entire foundation is initially poured. All this is done in the shortest possible time period in order for the concrete to lay flat.

The evenness of the poured foundation is checked using a level placed on its upper side. After pouring, concrete hardening can last up to two weeks.

It depends on the weather conditions. If the weather is hot, it is recommended to water the foundation with cold water, and when high humidity occurs, cover it with polyethylene film.

Calculation and preliminary preparation

When creating a foundation, one of the most important points is to calculate its depth and conduct a general marking of the territory.

First you need to find out how much the soil can freeze in the selected area. After the parameter of the soil freezing depth becomes known, the depth is calculated to which the pile slab will subsequently be immersed.

The slab will be 0.3-0.5 meters lower than the extreme limit of the soil freezing level. After that, the selected area is thoroughly cleaned and leveled using a level. Further, detailed marking is made using reinforcement, which is driven into the ground.

The marking is carried out both along the outer and inner perimeters. This leads to the fact that the width of the future tape becomes known.

In general, the parameter of the grillage width directly depends on the characteristics and type of material used.

If, for example, a house is built of wood, and the walls are erected using a foam block, then a tape with a width of 30 cm will be enough to support the weight of the structure.

If it is planned to build a stone or brick house, the width of the tape can be equal to 40-60 cm.The depth of the entire monolithic structure should not be less than 45 cm.

Pile-strip foundation pouring

This parameter directly depends on how much the future structure will weigh. After the first marking, the second is carried out - it is needed for the piles to be driven in. In this design, the piles are located with a pitch equal to 1.3-1.5 meters from each other.

As mentioned above, reviews of pile-tape type foundations are mostly positive.

Oleg, 53 years old, Omsk:

Sergey, 47 years old, Vologda:

Vladimir, 38 years old, Sheksna:

Do-it-yourself pile installation

In order to drill a well to place the future pile, you can use a hand or garden drill. There is an alternative - the purchase of ready-made piles, which are equipped with a circular cross-section.

When creating a well, it is important not to forget that an extra 30 centimeters is added to the existing pile length. They are designed for a sand cushion that is laid at the bottom of the well.

To do this, you need to fill the bottom with ordinary river sand, and then, as it should, pour plenty of water, and then tamp

They are designed for a sand cushion that is laid at the bottom of the well. To do this, you need to fill the bottom with ordinary river sand, and then, as it should, pour plenty of water, and then tamp it.

After that, you can install metal or asbestos-cement pipes and sheathe the walls with roofing felt.

For each separately taken well is provided with a sole. In order to create it, a concrete solution is poured into the pipe by 30-35 cm, and then the pipe is raised by 20-30 cm.

Formwork fabrication and concrete pouring

After the trench is dug, its bottom is covered with sand to create what is called a sand cushion. Its width should not exceed 150 mm.

In this case, the layer of sand should be evenly dispersed along the entire perimeter. As with piles, this slab is filled with abundant water and compacted tightly.

For additional strength, it is covered with a layer of crushed stone. The formwork is made from any materials at hand.

These can be wide boards or sheets of chipboard laid on top of each other. Further, ready-made structures are nailed to stakes driven into the ground at a distance from each other. The stakes should be placed at the top of the trench dug for the foundation.

After completion, the height of the formwork is measured, and bricks are laid on the bottom of the dug trench. After that, the piles of the entire structure are poured with concrete.

Before this, the piles are compacted tightly and checked for the presence of voids formed. In order for the concrete-poured piles not to accidentally connect to the foundation tape, you do not need to wait until the concrete has finally hardened.

For this, the formed monolithic top of the entire foundation is initially poured. All this is done in the shortest possible time period in order for the concrete to lay flat.

The evenness of the poured foundation is checked using a level placed on its upper side. After pouring, concrete hardening can last up to two weeks.

It depends on the weather conditions. If the weather is hot, it is recommended to water the foundation with cold water, and when high humidity occurs, cover it with polyethylene film.