What do you need to know about your site before starting construction?

First, the bearing capacity of the soil. Secondly, its types and characteristics. Despite the fact that the frame frames are light enough, the load on the foundation is still palpable.

Assembly diagram of frame walls of a frame house.

The rule is that the area of the foundation directly depends on this characteristic of the soil. The lower its bearing capacity, the more extensive the support for the building should be.

Three indicators play the main role for calculating the foundation: soil type, its density and moisture

The latter characteristic is the most important and is determined by the height of the groundwater level. If the soil on the site is waterlogged, then its bearing capacity is low

And in this case, you should opt for either a foundation made of screw piles, or on a monolithic slab with good waterproofing.

How to determine the level of moisture and density of the soil?

For this purpose, you need to use a drill or a shovel and dig a hole about 2 m deep. After the hole is dug, you should wait a little and see if water accumulates at the bottom. If so, then the groundwater is close. The bottom is dry, which means that the soil on the site is not wet. Any type of foundation is suitable for a frame house here.

The diagram of the unfolding of the wall frame.

The calculation of the moisture saturation of the clay is as follows: if the shovel easily enters the layer and pieces of soil do not stick to it, then the clay is dry. When they stick - plastic and waterlogged. The density of the soil can be found out as follows: roll a ball out of clay and squeeze it between your fingers. If no cracks appear at the edges and moisture appears, the density is low. The same applies to loams: when the soil is wet, then cracks will appear along the edges of the cake, and if dry, then it will simply crumble.

With regard to sandy soils, here the conclusion about the density is made by the size of the grains of sand. The larger it is, the greater the density. But in this case, do not forget that humidity is always a lowering indicator. The sand can be considered coarse if the diameter of the grains is 3-5 mm. Based on the conclusions made regarding the characteristics of the soil, a calculation is made of its bearing capacity. The goal is to find out how much area support is required for the foundations for a frame house.

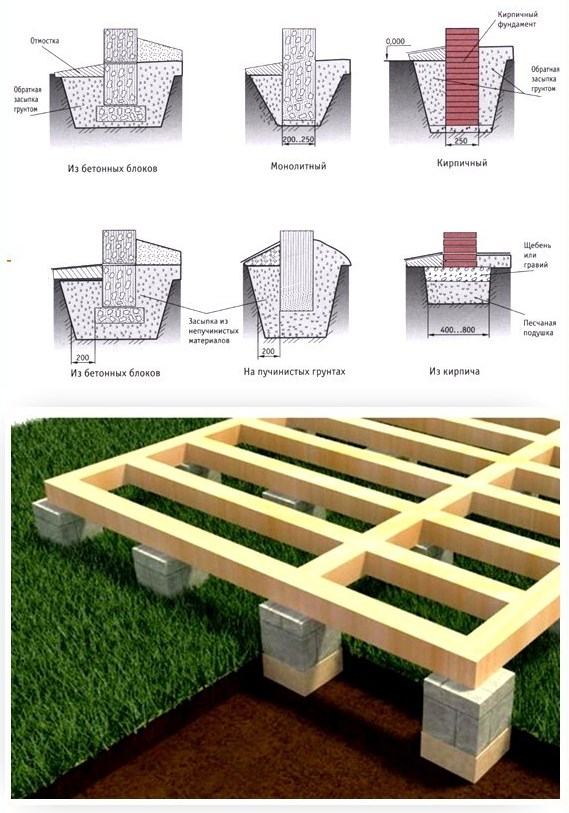

Materials for the construction of a columnar foundation

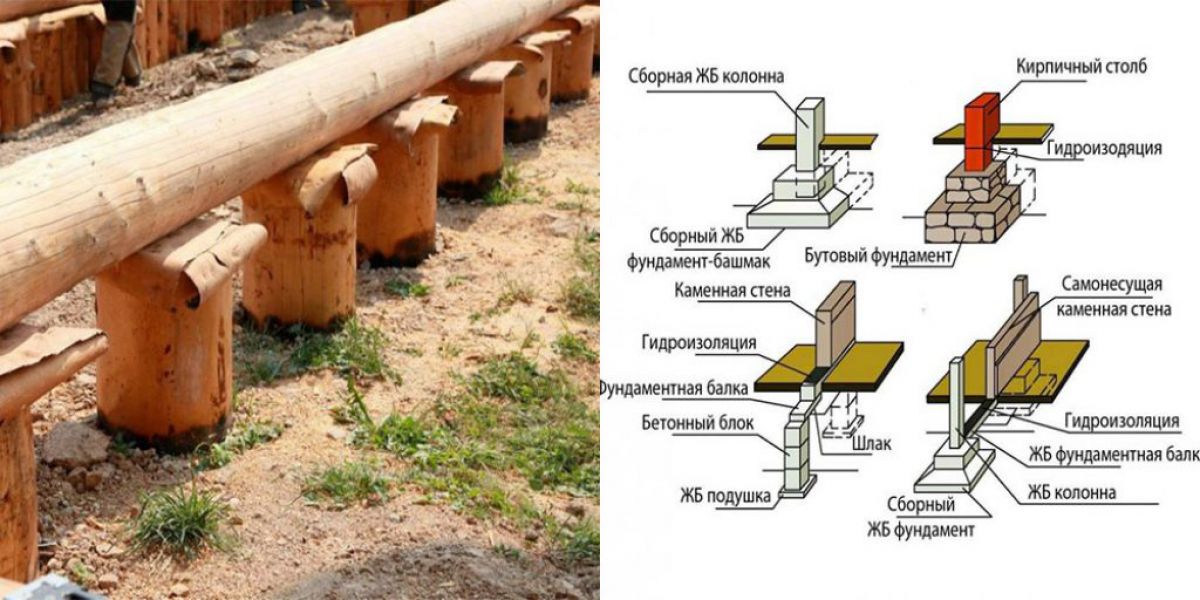

The materials used for the construction of the pillars of this foundation are very diverse. For a columnar base of a house, you can use:

- asbestos-cement or metal pipes;

- Red brick;

- rubble or other natural stone;

- concrete;

- wood;

- building blocks or other reinforced concrete products and other materials.

But giving preference to one or another material, you should correctly calculate its bearing capacity, which determines the section of the column.

For example, for concrete or block structures, 0.4 m is quite enough, and for rubble stone, you will need to make a support with a diameter of at least 0.6 m.

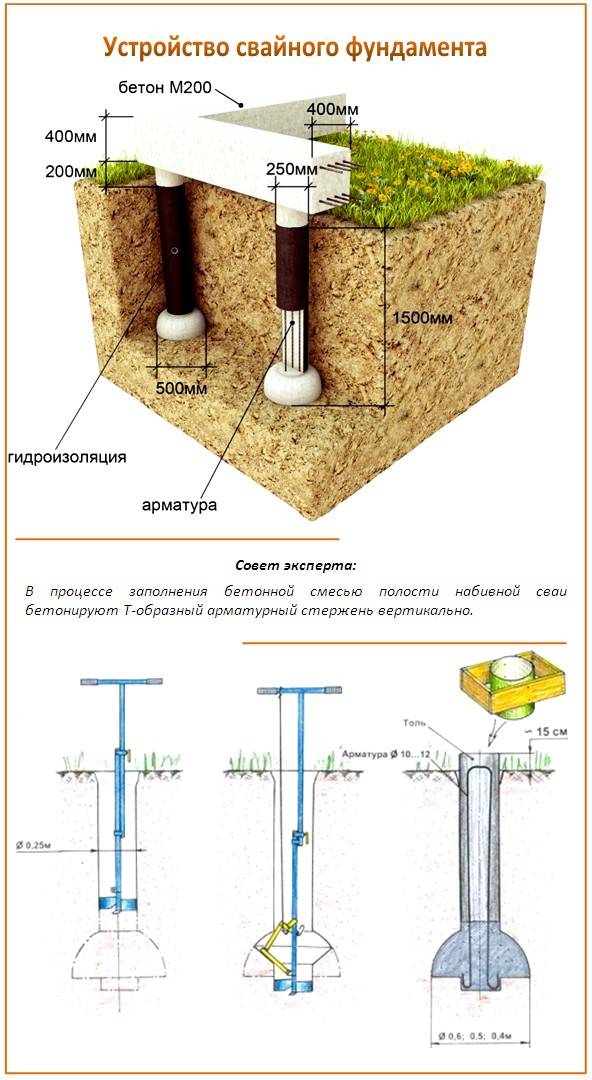

The diameter of the pipe used for the foundation is only 0.2-0.3 m - this is quite enough, provided that a reinforced frame is installed in its cavity.

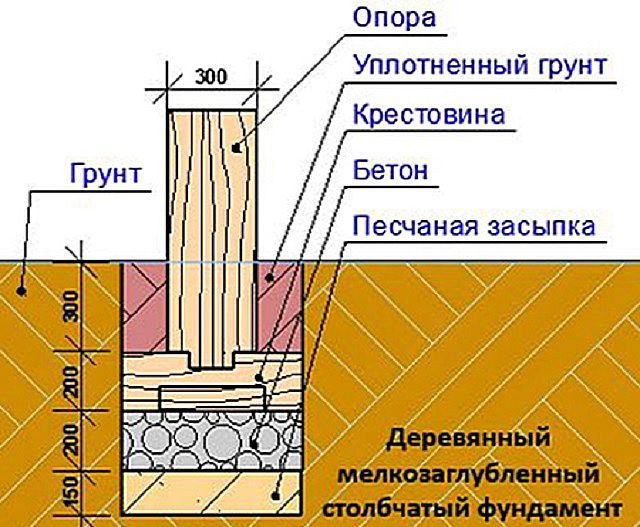

Log foundation

Wooden posts made of logs, due to their fragility and low bearing capacity, are rarely used, but they are quite rational for arranging a foundation for a country house, a gazebo, a bathhouse, a garage, or other outbuilding.

Logs with a diameter of 150 mm and more should be pre-treated with antiseptics and antipyrites, it is also important to protect them with waterproofing compounds, for this you can even use inexpensive and affordable tar

Brick posts

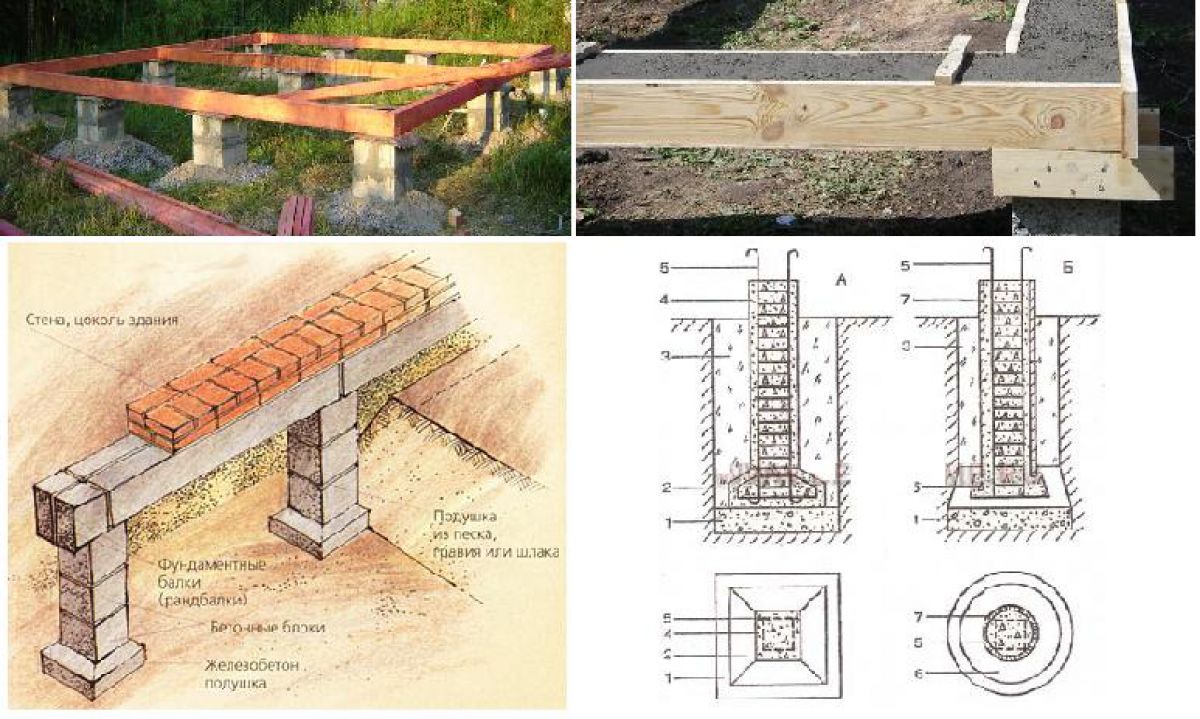

A more popular and widespread material for the construction of a columnar foundation is a brick, which has sufficient bearing capacity in order to erect a capital structure on such a basis in one or two floors using frame technology or from wood. Also suitable for small brick buildings with low wall thickness.

But it should be borne in mind that you can use exclusively corpulent red fired brick, which has a minimum moisture absorption capacity and high density. Silicate material is not suitable for the construction of the foundation.

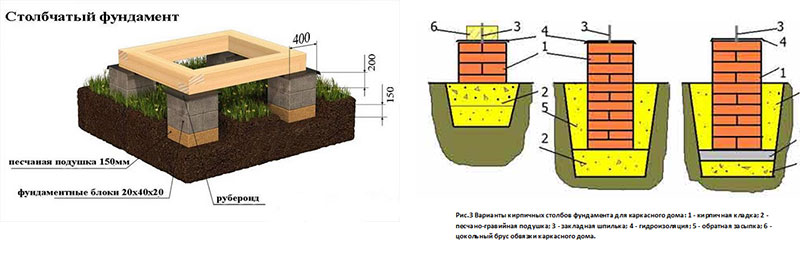

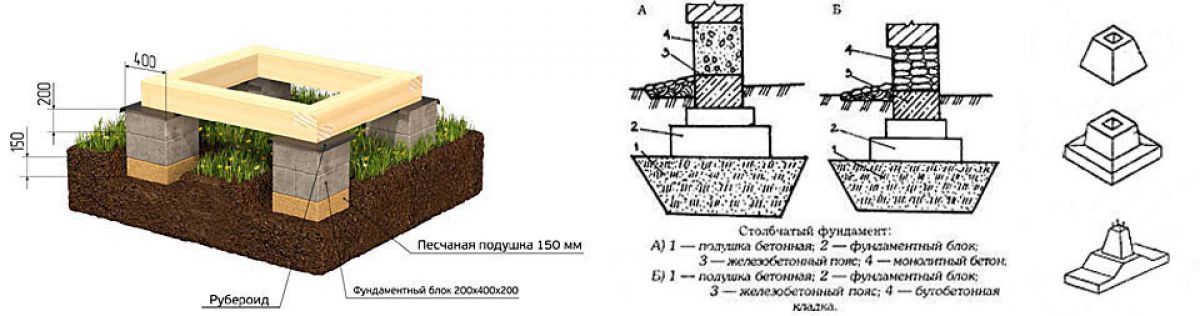

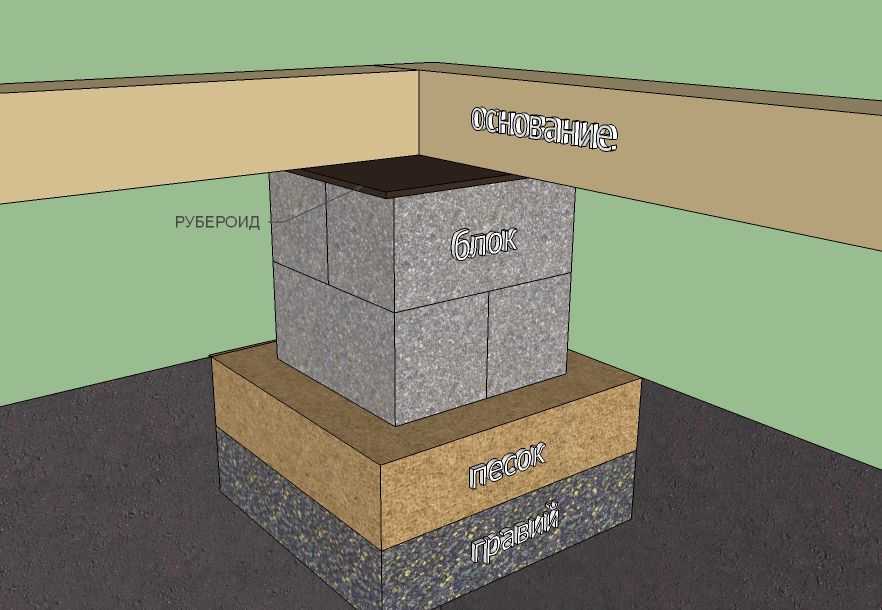

As a rule, the area of the post is formed from 4 bricks, and the dressing of the masonry is performed with an offset - this increases the bearing capacity. The pillars are laid to a depth of 0.5 to 0.7 m.

Before laying the first row, a sand and gravel pad with a thickness of up to 20 cm must be laid, spilled with cement milk - a liquid cement-sand mortar.

After laying the foundation of brick pillars, you can start building walls in 2-3 weeks - this time is necessary for the cement mortar not only to dry out, but also to gain strength.

Support block foundation, video:

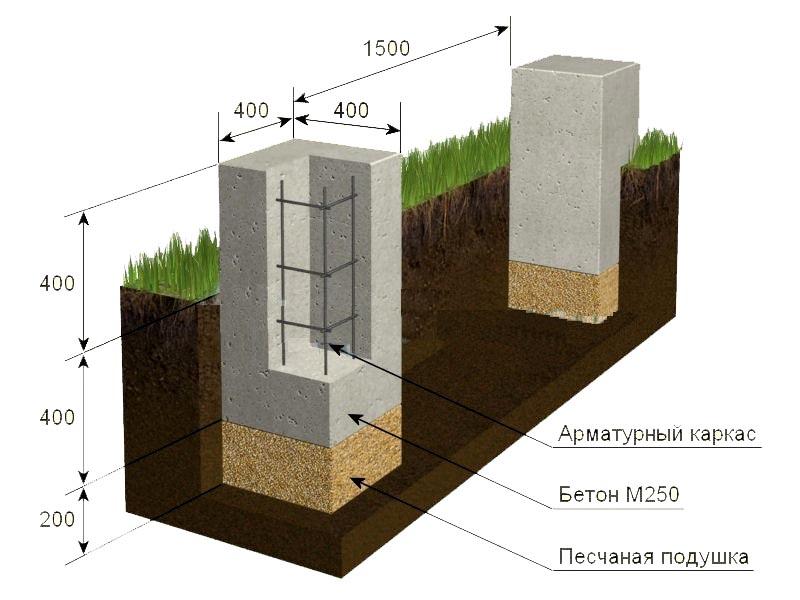

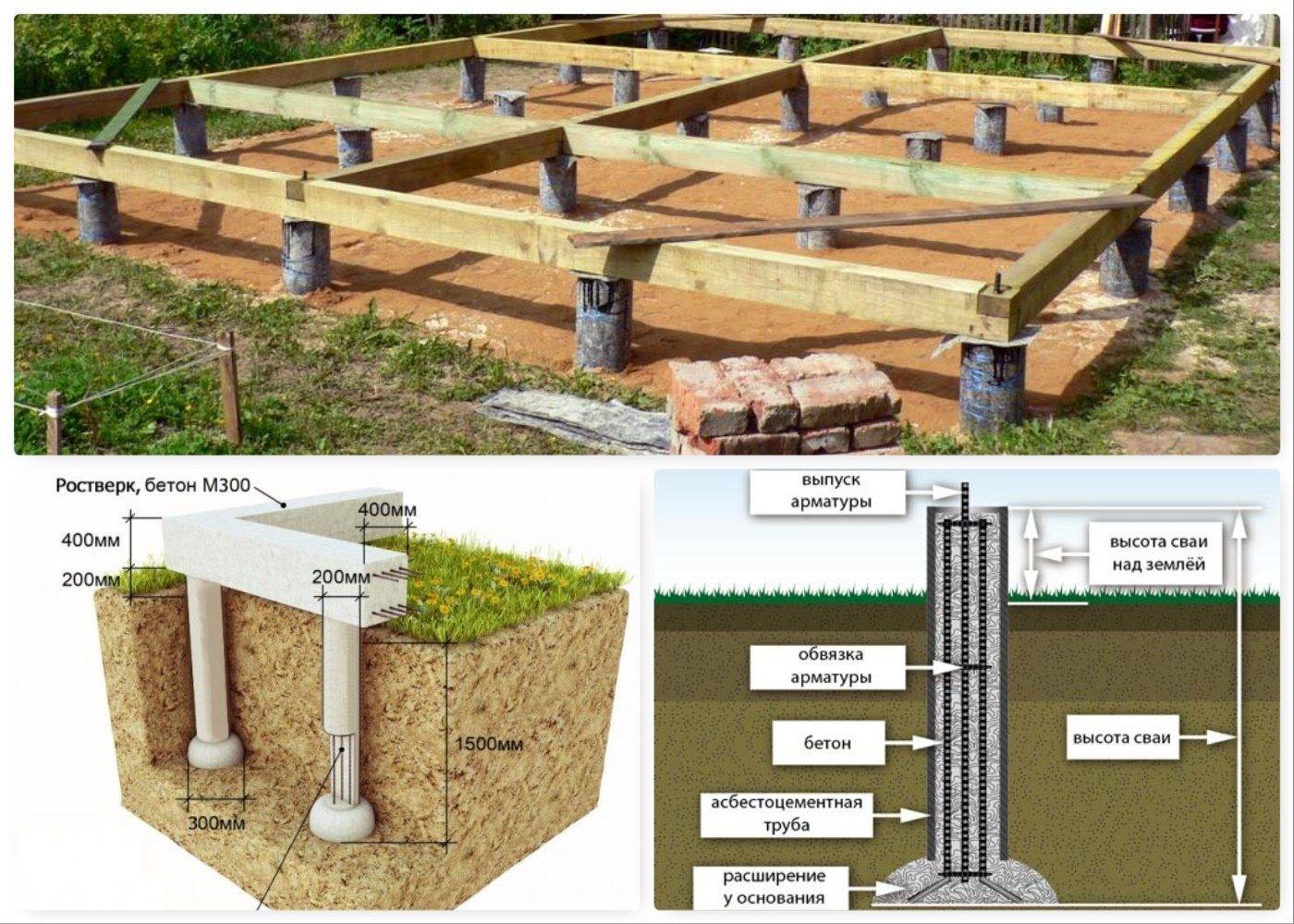

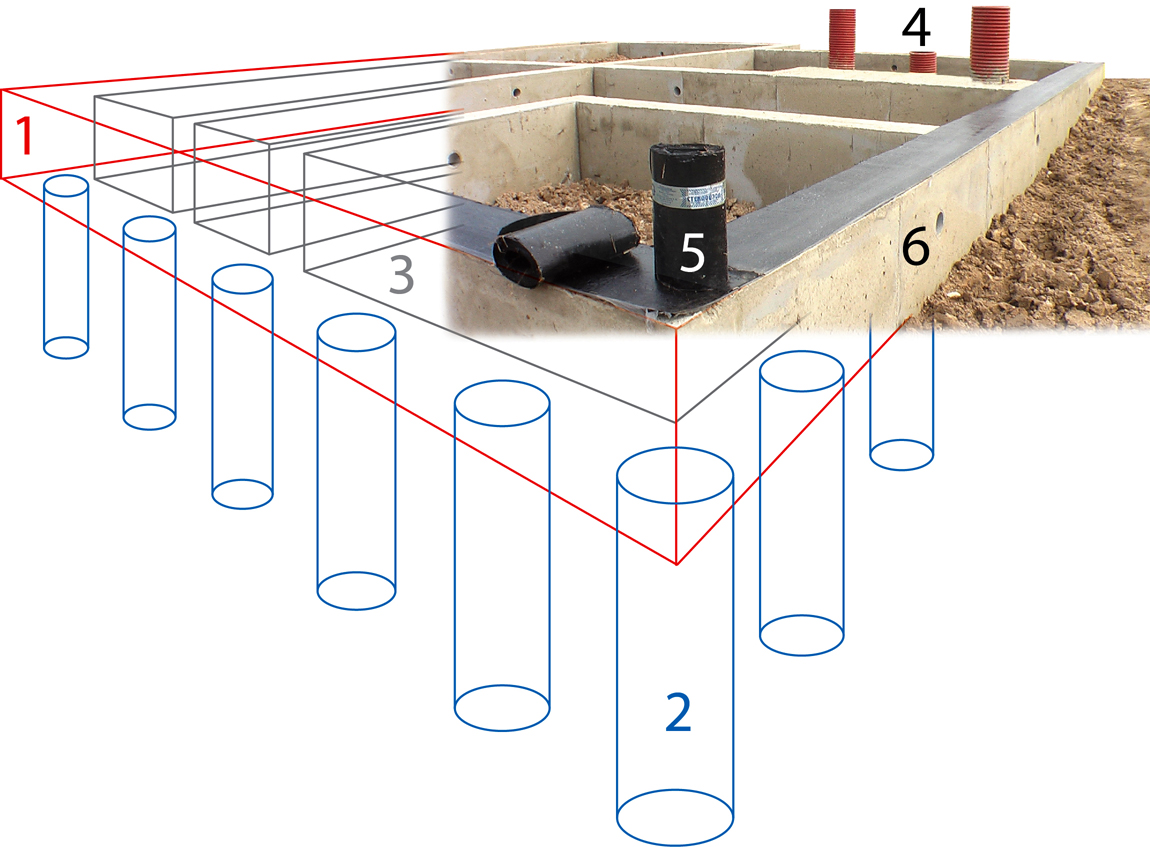

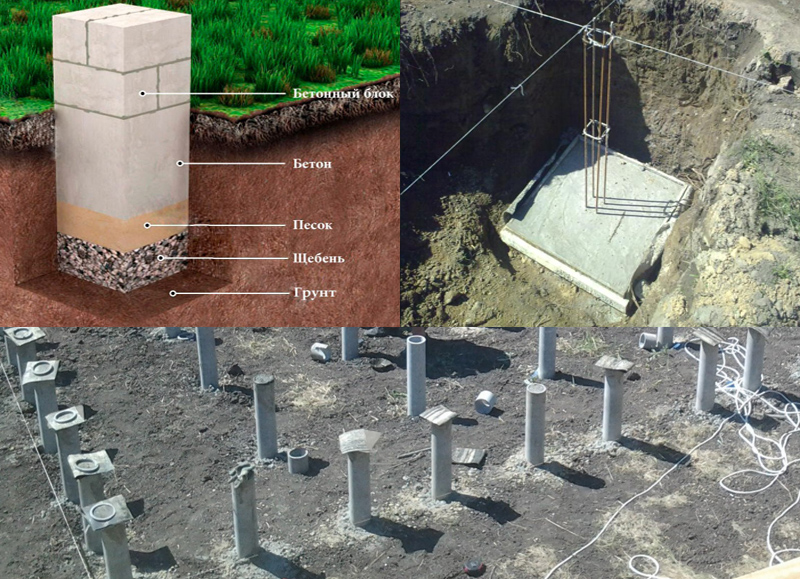

Monolithic reinforced concrete and pipe column foundations

The device of a columnar foundation using concrete is characterized by greater strength and high bearing capacity. A simpler option is the use of asbestos or metal pipes, which are installed in pre-prepared wells with a mandatory sand cushion at the bottom.

Such a do-it-yourself pillar foundation for a frame house is a completely rational and reliable option, and its construction will take no more than a month - until concrete gains full strength.

A large bearing capacity is provided by reinforcement, for which reinforcement rods or a pre-fabricated frame are used, installed directly into the pipe before concreting.

A concrete post can be made without using pipes - for this, formwork (removable or non-removable) and a reinforced frame are installed in the prepared pits.

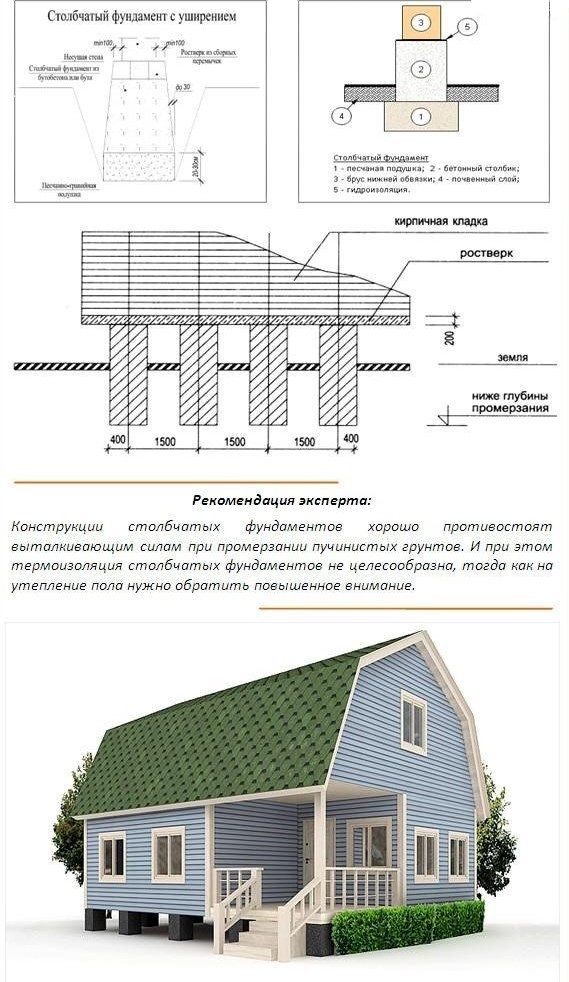

In some cases, especially on difficult soils or under a capital structure with a rather large weight, it is recommended to install a so-called "sole" or "heel" - a special widening in the lower part of the pillar.

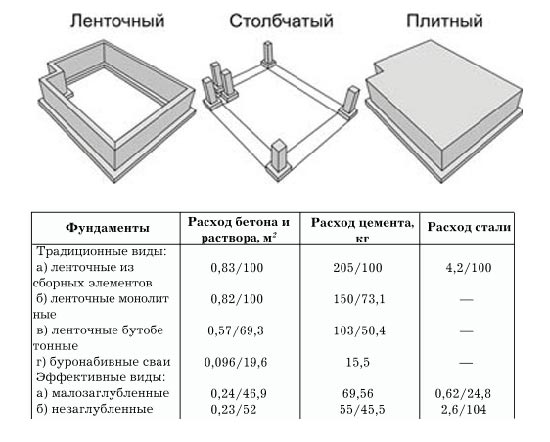

Types of foundations for frame houses

Before determining the parameters of the foundation that are optimal for a frame house, you need to choose the type of foundation in accordance with the type of soil of the site. Consider the pros and cons of each.

Strip foundation - a classic of private housing construction

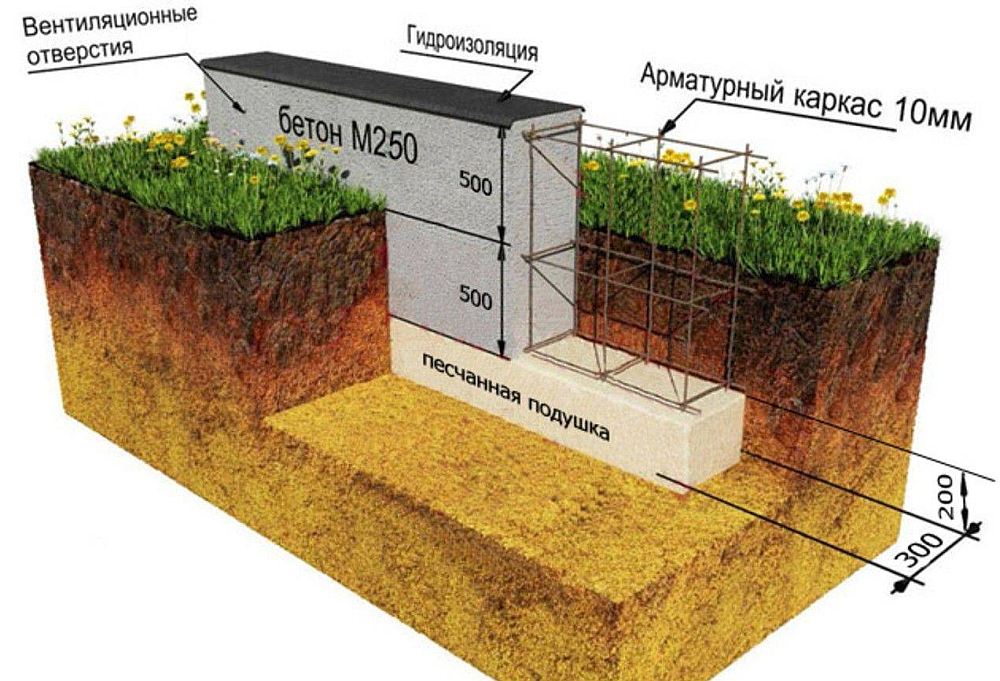

The strip foundation can withstand significant loads, including on moving ground. A monolithic or prefabricated finely coarse foundation, which has a depth of about 0.5 m and rises above the ground about 20-30 cm, is best suited for a frame house.

The disadvantage of the strip foundation is the impossibility of redeveloping the house

Therefore, during design, it is very important to correctly make all the calculations of a residential object, since then nothing can be corrected.

Stilt house

The pile-screw foundation can be used for any site, while most often it is relevant on difficult soils. Despite the fact that the piles are located at a great depth, there is no need to attract special equipment, installation is possible at any time of the year and does not require much time and financial costs.

The pile structure has good bearing capacity and, if necessary, allows for repair work. The piles are resistant to groundwater and soil freezing.Ideal for a small frame house.

Monolithic slab

The slab foundation is based on a flat reinforced concrete support. Foundations of this type are being erected on weak, heaving and heterogeneous soils that contain groundwater.

The foundation is reliable, easy to install, stable on sliding soil. For a frame house, it is used very rarely, since it is characterized by high cost and the need to install a subfloor.

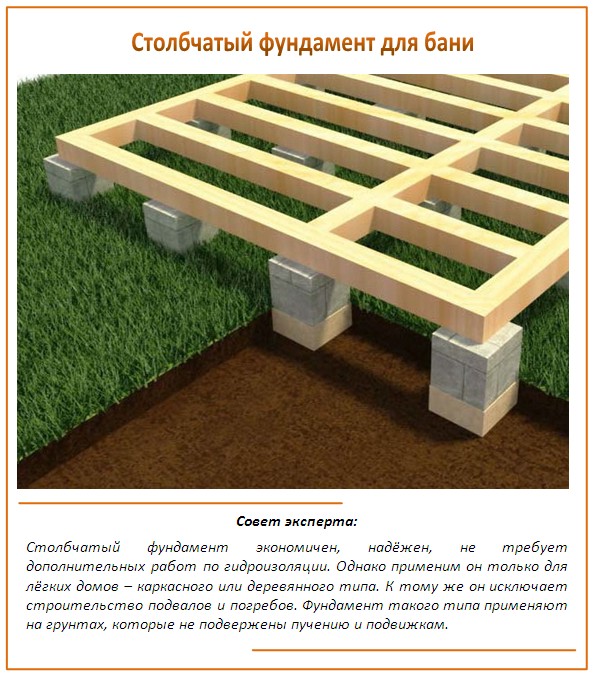

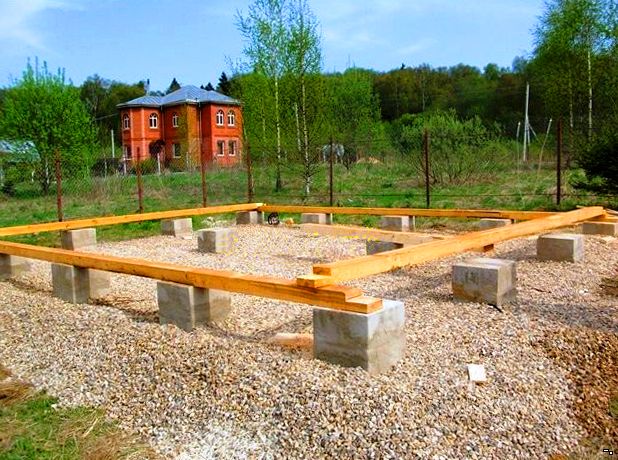

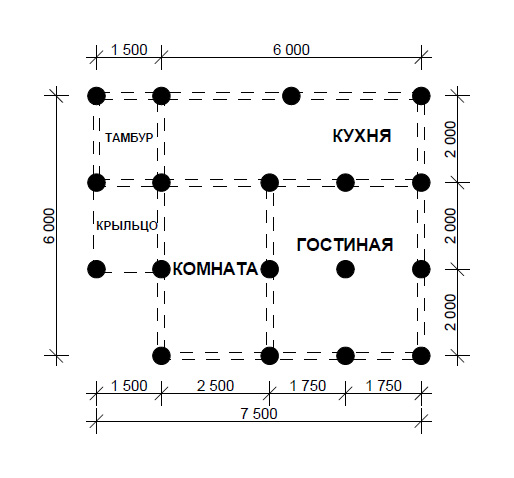

Simple columnar foundation

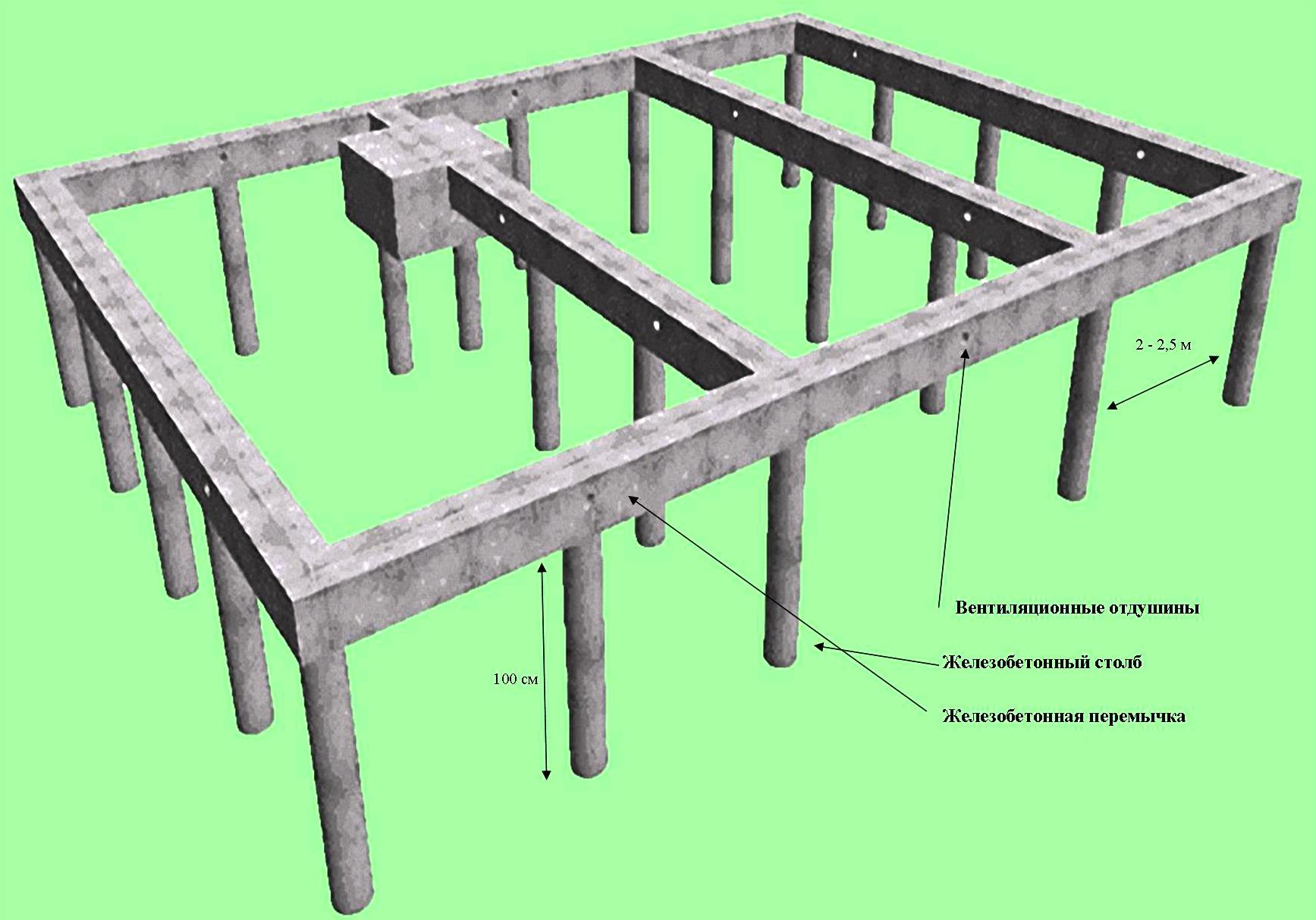

The columnar foundation consists of free-standing concrete pillars. The top of the structure is called the head and the bottom is called the base. The columns are located in places where the load is concentrated, in particular along the perimeter of the frame house and under the intersection of the walls. Their height is usually equal to the height of the floor on the ground floor, that is, about 50-60 cm above the ground.

Foundation insulation methods

Methods for insulating and isolating the foundation of a house from dampness and cold from the ground are divided into the following groups:

- Insulation and insulation along the outer walls;

- Thermal insulation and insulation along the inner walls.

Insulation and insulation of the foundation

Insulation and insulation of the foundation

A more effective option is to insulate the foundation along the outer walls. This is best done immediately after the foundation is erected, before the installation of the frame of the house begins. Insulation of the foundation along the outer walls is carried out in the following ways:

- Zasypny. It is carried out by filling loose building absorbent materials (crushed stone, expanded clay, sand, etc.) into a trench made from all outer sides of the foundation. These materials wick away moisture well, thereby preventing the destruction of the foundation, and are a good barrier against cold.

- Fastening foam plates. It is carried out with plates of expanded polystyrene (polystyrene), which are attached to the foundation with glue or mastic. Polyfoam, which has the property of retaining heat, provides a fairly high thermal insulation. But it has one significant drawback - it is eaten by rodents. To protect against them, a mesh should be placed on top of the foam.

- Fastening foam boards. Penoplex is a material similar to polystyrene, but more environmentally friendly and strong. It does not deform and is not eaten by rodents. Penoplex with special glue or bitumen mastic can be glued directly to the foundation.

This method allows you to raise the temperature in the basement and remove excess moisture. But internal insulation does not protect the foundation from water in the ground and temperature changes.

Recommendations

- How to properly reinforce the corners of the strip foundation? The most common mistake is simply crossing wire reinforcement bars. Correct reinforcement of the corners is done by bending the anchors with L-shaped and U-shaped shapes.

- How to properly fill the foundation for the garage? It is necessary to take into account the parameters of the garage and the adjectives to it. It is advisable to draw up a project plan for the garage and get good theoretical training.

- The foundation for yise technology is slightly different from the traditional construction. According to this method, the piles are not driven into the ground, but grow out of it - the technology of "hammered nails" only with the hat down.

- Can foundation fittings be welded? For welding, choose fittings with markings that allow you to connect the rods with a welding machine. Please note that the material has been treated with a special anti-corrosion compound. Such welded fittings will last a long time and will strengthen the base of the house.

Slab foundation pros and cons:

- suitable for different types of houses;

- can be installed on any type of soil;

- withstands a high level of groundwater;

- long term of work performance;

- produced only on a flat piece of land;

- high cost of materials.

Pillow under the foundation slab. It is best to fill a layer of river sand under the slab, and then lay a layer of rubble.A 30 cm thick sand cushion is able to strengthen weak soil, increase the bearing capacity of the base and provide good drainage. For a crushed stone pillow, crushed stone of a fraction of 20 mm is used. It will reduce the risk of deformation during slab base shrinkage.

It is possible to carry out a foundation for an aerated concrete house using a strip and some types of columnar foundations, taking into account the external conditions and the type of soil.

We strengthen the base on the pillars

If a mistake was made in the calculations, or the peculiarities of the work were not observed, after a few years you will encounter a problem - the supports will deviate from the vertical level or sink into the ground. The building seems to hang in the air, cracks form along its walls.

The main reasons for such phenomena can be not only your erroneous actions, but also seasonal weather conditions, as well as the construction of larger objects in the immediate vicinity. It also happens that the owner of the house wants to increase the area by erecting extensions or second floors, but such additional loads were not calculated in the project. In any case, the foundation has to be repaired.

In this case, the easiest way is to replace the piles with bored supports. The main difficulty is that the object will have to be lifted and temporarily fixed. The damaged pillars are removed, the freed pits deepen by thirty to fifty centimeters. After that, new supports are erected.

Preparation

Construction begins with choosing a location. Stony soil is suitable. The building will have a strong support, water can easily go into the ground. Nice to use in sandy soil. However, such bases are less stable and do not withstand heavy loads. Elevated places are less susceptible to flooding and experience high wind loads.

Drilling with a hand drill

Drilling with a hand drill

The approximate composition of the soil can be found from geodetic maps, from local residents, exploration drilling. The latter method is more reliable, but expensive. After determining the place, registration, they begin to collect the necessary tools and materials. You may need to put outbuildings, fence off the site.

Instruments

Construction tools can be divided into three categories:

- measuring;

- for earthworks;

- for the construction of the foundation.

Some of them are universal. The first category includes:

- roulette;

- level;

- square;

- plumb line.

Laser equipment is more convenient, but more expensive, wasteful for a single action. If you need to dig holes for the posts, you will need a hand drill. On stony ground, you may need a crowbar, a pickaxe. For square holes, you need a bayonet, a shovel. You can carry out the soil outside the area on a stretcher. More tools will be required to cast the foundation:

- concrete mixer;

- Master OK;

- jigsaw for metal;

- vibrator;

- hammer;

- nail puller;

- hacksaw for wood;

- Bulgarian.

Measuring instruments, shovel, stretcher, buckets are required. When using imported concrete, a concrete mixer is not required. Can be replaced with a mixing container, if there is no electricity, the mixing will have to be done manually.

Drill with nozzles

Drill with nozzles

List of materials, how to calculate consumption

In addition to the tool, it is necessary to prepare devices, calculate the material. First, you need to decide what will be used for the formwork. If wooden boards - boards are required, you can not planed. When the foundation is columnar, it is necessary to determine the material of the pipes: metal, asbestos cement. For metal pipes, an additional coating will be required to protect against corrosion.

The volume consumption of concrete is calculated first for one support, then multiplied by the amount. The volume for a rectangular foundation is determined by the formula: abh, where a is the length of one side of the formwork, b is the length of the other side, h is the height. For a circular section, a different formula is used: h, where r is the inner radius of the pipe; h - height.

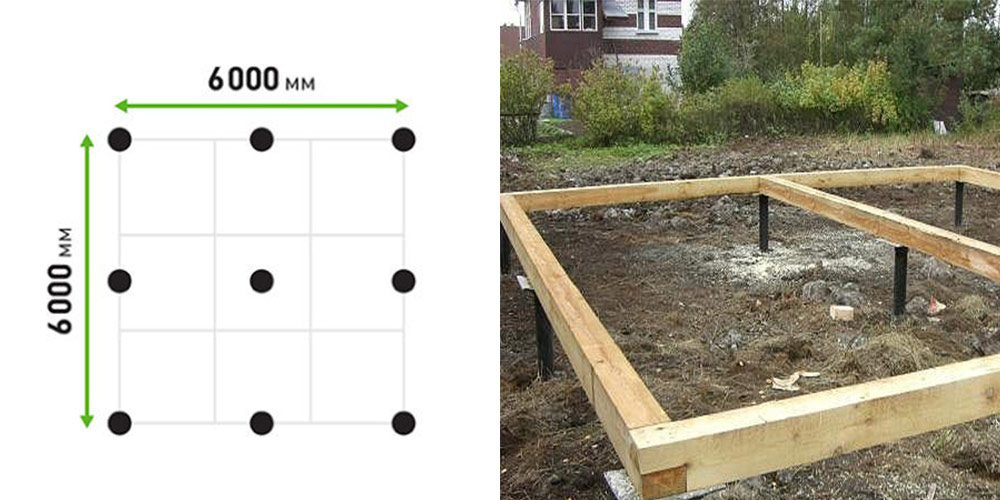

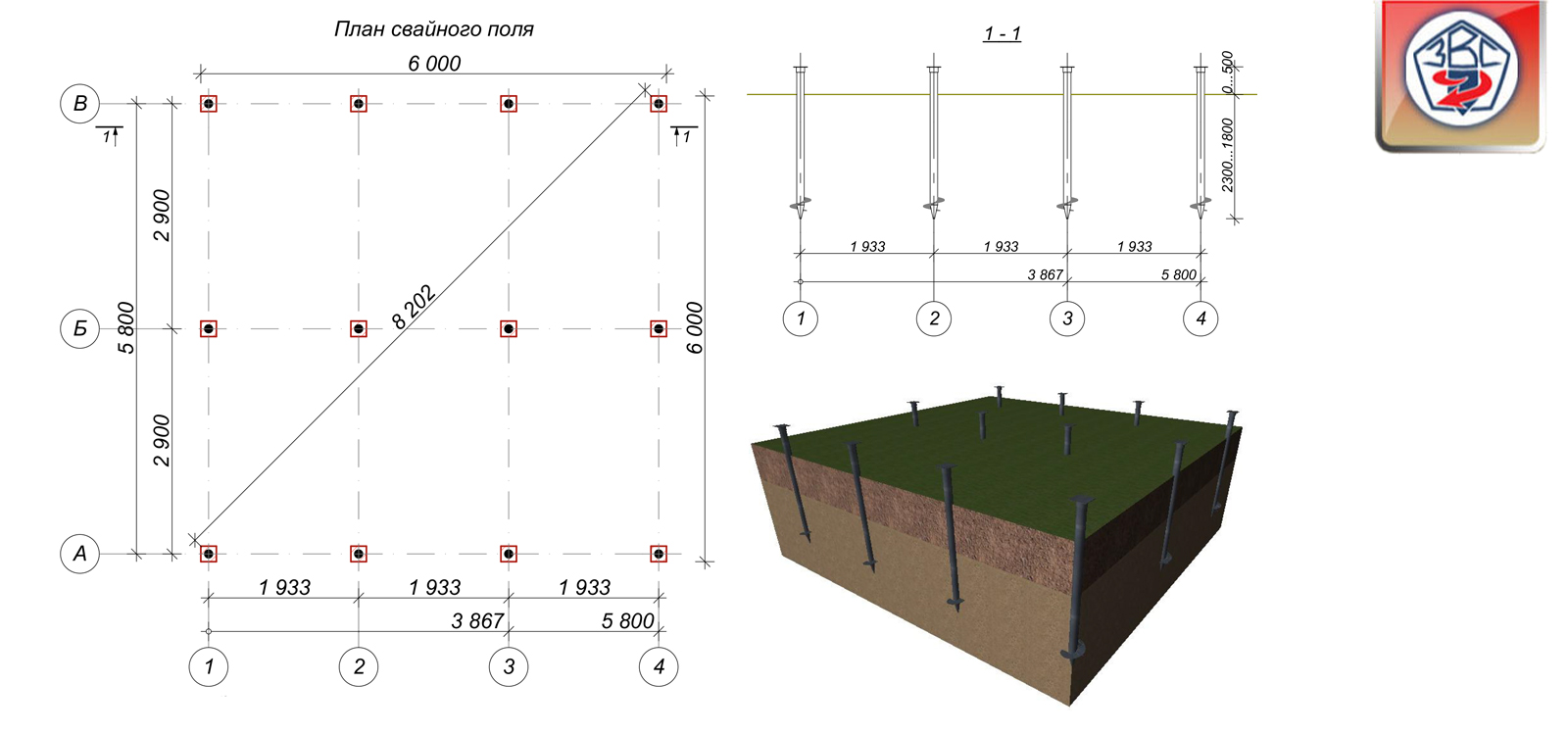

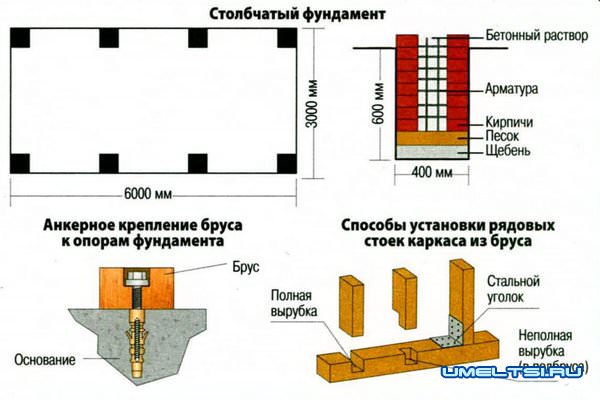

Calculating the depth of the foundation, determining the number of pillars

The purpose of the foundation is to evenly transfer the load from the structure to the foundation (ground). For light buildings, shallow foundations are used that lie above the freezing point of the soil. Not suitable for a frame house. The depth of freezing can be determined using geological maps, which provide readings for soil without snow cover. You can determine the depth of heaving soils by drilling in early spring when the ground freezes over.

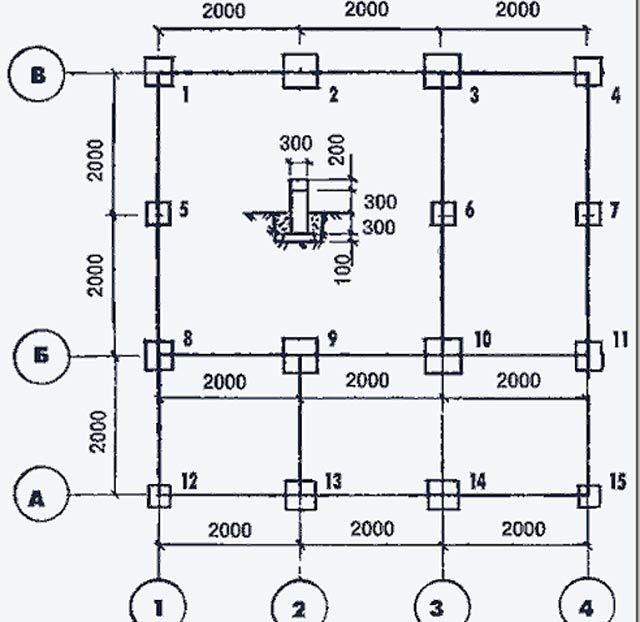

Calculation of the number of pillars:

- the support is installed at each corner of the building;

- at the junction of the walls;

- under each load-bearing wall;

- the rest of the pipes, approximately every 1 m.

The amount depends on the base, the softer, the larger the area of the supports.

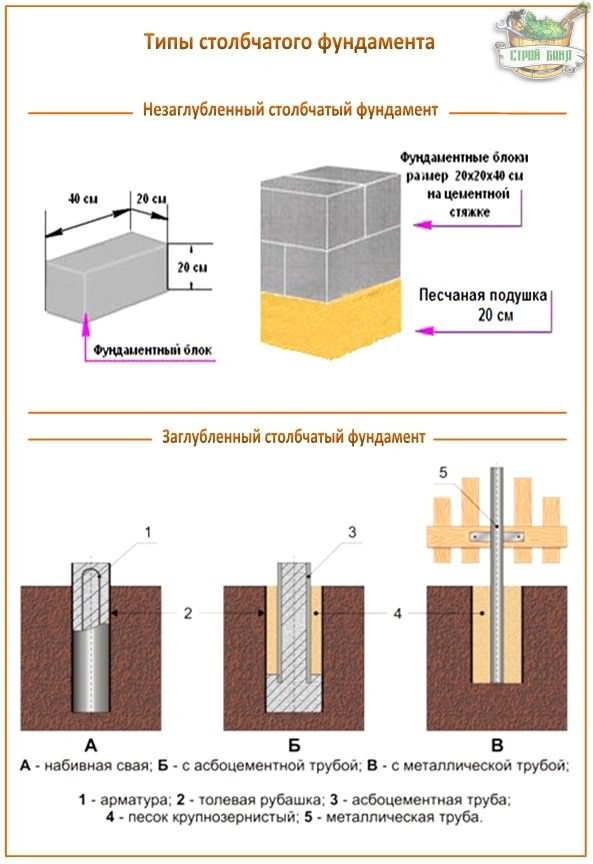

Columnar foundation technology

Different technologies are used depending on the design and depth of the columnar foundation. The easiest way is to masonry from concrete wall blocks 20 x 20 x 40 cm or ceramic bricks. If the frame house is being erected on heaving ground, it is preferable to concreting monolithic pillars, on which the lower trim with a bar will be rigidly fixed.

The depth of the laying significantly affects the construction budget. Therefore, it is preferable to shallow and non-buried structures with the organization of drainage, insulation, the use of nonmetallic materials.

Pouring a monolithic columnar foundation

After marking the axes of the walls, excavating the soil from the trenches under the outer and inner bearing walls, the centers of the pillars at the bottom of the pits are marked with a plumb line. Further, the columnar foundation of the frame house is made according to the technology:

- the underlying layer - 40 cm of crushed stone or sand is compacted with a vibrating plate in layers (15-20 cm each), the size is 50 cm larger along the perimeter than the cross-section of the widening plate;

- drainage - corrugated pipes perforated with slots are laid between vertical wells on a layer of crushed stone on top of a geotextile fabric, covered with the same inert material, closed in a common contour, have a slope of 4 - 7 degrees;

- insulation of the sole - plates of extruded high-density polystyrene foam (modifications of EPS, XPS from different manufacturers) are laid on top of a sand or crushed stone foundation cushion, the width is equal to the size of the underlying layer;

- waterproofing of the sole - 2 layers of roll waterproofing are laid on top of the thermal insulation material, the edges are launched beyond the perimeter of the pillar widening plate, so that after stripping they can be glued to the side edges from the outside;

-

reinforcement - for the slab, a reinforcing mesh of bars of a periodic profile of 8 - 14 mm is used, a frame made of vertical bars of the same diameter, tied with square or ring clamps from reinforcement 6 - 8 mm with a frequency of 30 - 60 cm, is tied to it in the center;

- formwork - for the widening slab, 4 boards with a height of 30 cm or more are mounted, 4 boards are installed on them on the edge, to which the pillar formwork boards are attached, which allows the structure to be cast in one step without technological seams. Read more about formwork here;

- concreting - laying the mixture in layers of 40 - 60 cm, compaction with a deep vibrator of the columnar foundation until the formwork is completely filled;

- waterproofing - after 70% of the strength gain, it is possible to make stripping for waterproofing concrete surfaces with coating, pasting, plastering materials.

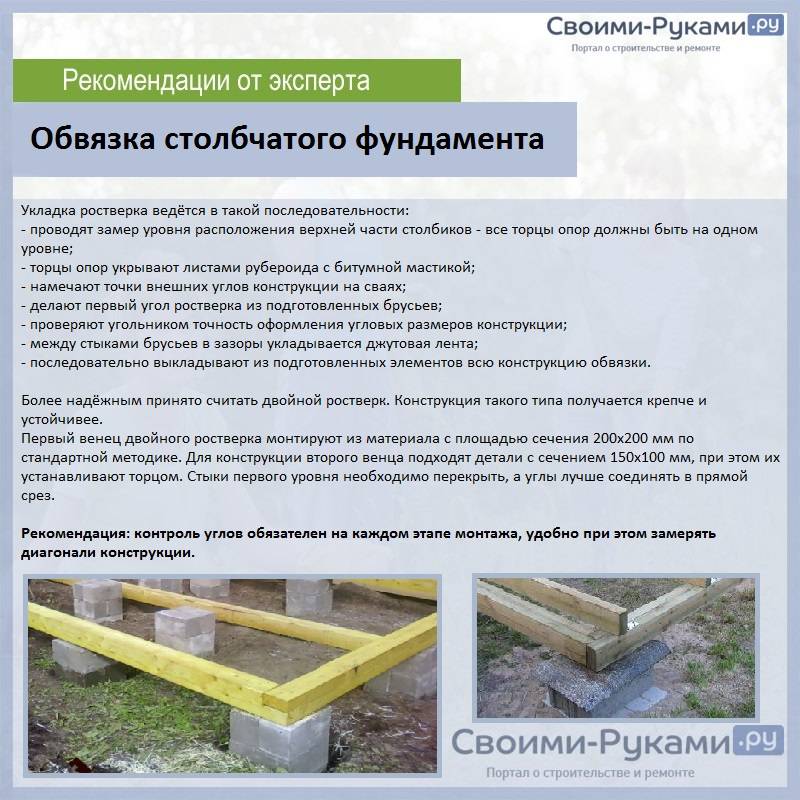

Pillars can be tied with a bar after 28 days, since anchors are usually used that are anchored into concrete through lumber. When placing the reinforcing mesh of the frames, a protective layer of concrete should be observed - 4 - 7 cm in the sole, 2 - 4 cm on top, on the sides.

Due to the fact that the frame house has low prefabricated loads, it is not necessary to additionally distribute them to the posts with a reinforced concrete grillage. The lower timber strapping is quite suitable for the role of lattice grillage beams.

If you need information on the construction of a columnar foundation with a monolithic grillage, read the article: Columnar foundation with a monolithic grillage.

Production of prefabricated pillar foundations from bricks or blocks

A budget option for a prefabricated columnar foundation for a one-story frame house with an attic is brickwork or blocks on a cement-sand mortar. The features of the technology are:

- work to ensure the absence of swelling is similar to the above (drainage, backfilling, insulation of the sole, underlayment);

- widening of the foot of the pillar is created by a monolithic slab;

- waterproofing of prefabricated structures is much more difficult than monolithic concrete, therefore it is recommended to add Admix or other additives with water-repellent properties to the solution;

- the section of brick pillars usually corresponds to 38 x 38 cm, concrete structures 40 x 40 cm;

- every 3 - 5 rows in the columnar foundation of a frame house, it is advisable to lay a masonry mesh.

If necessary, the masonry can be reinforced with corner frames to increase the strength of the uprights. On the outer edges of the pillars, to which the filling material will be attached, you can leave mortgages in order to also maintain the strength of the structure.

Read more here: Brick Column Foundations and Block Column Foundations.

Thus, a columnar foundation can be made for a frame house yourself. In clay soil, it is better to use monolithic pillars, on soils with a high bearing capacity, not prone to frost swelling for a one-story house, you can do with brick or block masonry.

Good publicity