Curing conditions

The characteristics of cement mixtures are significantly improved with the organization of the correct hardening regime. Therefore, high-quality concreting implies taking into account all factors that affect the setting time:

- average daily temperature;

- air humidity;

- type of construction.

The colder the environment, the longer the interval must be waited before removing the formwork.

For the high-quality hardening of concrete, it is important to ensure normal air humidity: an excess or lack of water leads to a violation of the cement hydration process. That is, in the heat, the required strength is achieved as soon as possible, but the internal structure is disturbed and fragility increases.

That is why early autumn is considered the ideal time for concreting.

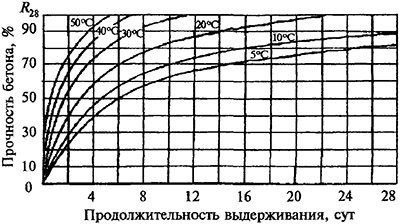

When determining the required period for removing the shields, the dependence on the average daily air temperature, associated with the brand strength, is taken into account. So, for the demanded grades of concrete М200-300, made on the basis of Portland cement М500, the graph is as follows:

| Average daily temperature, ° C | Time elapsed since the start of filling: | ||||||

| 1 | 2 | 3 | 5 | 7 | 14 | 28 | |

| Concrete strength, in% of the brand standard | |||||||

| 5 | 12 | 18 | 28 | 35 | 50 | 65 | |

| 5 | 9 | 19 | 27 | 38 | 48 | 62 | 77 |

| 10 | 12 | 25 | 37 | 50 | 58 | 72 | 85 |

| 20 | 23 | 40 | 50 | 55 | 75 | 90 | 100 |

| 30 | 35 | 55 | 65 | 80 | 90 | 100 |

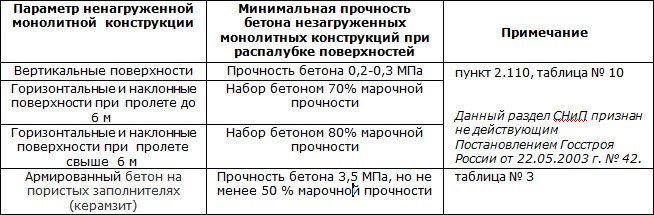

The expected bearing load on the concrete structure is considered an important factor. Vertical formworks are removed earlier than horizontal ones, their critical strength is 20% less. The same is true for porous concrete, in comparison with heavy grades.

Ways to accelerate hardening

There are two options for influencing the hardening time of the concrete mixture: autoclaving and the introduction of special admixtures. The first is difficult to implement at home: the stove or fill is placed in a special chamber with a humid environment. After treatment with hot steam under high pressure, the strength characteristics of concrete in a time from 15 to 24 hours reach similar to the annual exposure.

In private construction, there is no such equipment, therefore, for the high-speed setting of the solution, a specialized formwork with electric heating is used and conditions for minimal evaporation or crystallization of the liquid are created. It is easier to organize it indoors: a thermal gun is installed and humidity is controlled, the outer surfaces are covered with film and moistened.

The second way to accelerate the time of concrete hardening is available under any conditions, up to field conditions. In the last minutes of mixing, modifying additives are introduced into the solution, affecting its physical and mechanical characteristics (the curing time is significantly reduced). Despite its clear advantages, this method is rarely used in individual construction due to the high cost of the additives.

Strict adherence to the proportions is required, no more than 4% of nitric acid salts, 3 - sodium chloride, 2 - sodium sulfates are introduced into concrete. If the recommended ratio is exceeded, the plasticity of the solution deteriorates, which affects the final quality of the pour, the use of some modifiers is limited due to strong corrosive properties (they are not suitable for reinforced concrete). It is also possible to accelerate hardening by adding dry or wet vibratory grinder to Portland cement of significant strength (M400 or M500).

Terms for removing shields

Taking into account the above and the type of building structure, the minimum residence time of concrete in the formwork at an average daily temperature of +10 ° C is:

- For monolithic foundations and vertical reinforced products with a porous filler - 5 days.

- For horizontal slabs and small openings - 14.

- For stairways with a length of 6 m - 28.

These curing times are relevant for concrete, which includes M500 Portland cement.When using a lower quality solution, other indicators of the brand strength will act. If construction work is carried out in the cold season, then the hardening time increases by 2-3 days. The same is true if there are frequent changes in temperature or humidity during pouring and setting.

There is one more nuance: these terms determine the moment of removing the formwork, and not permission for the next stage of work. In the practice of individual construction, shields and fasteners are necessary to fill the adjacent section of the foundation or floor, but this does not mean that the freed surface is suitable for processing.

According to the norms, concrete must gain at least another 20% strength. At the same time, it continues to release moisture, which is also taken into account when choosing a stage of work. Inspection of surfaces and elimination of defects is allowed, but not waterproofing (with the exception of special water-based mastics or special mixtures for ironing) or the load of the structure.

How is the formwork dismantled

It is necessary to start disassembling the wooden frame from the corners, as well as protruding parts of the fundamental base. It is in these areas that concrete hardens most intensively. In addition, while you are removing parts of the formwork from the corners, the middle part of the foundation will continue to build up strength.

Shields must be dismantled very carefully so as not to violate the integrity of the entire structure. Therefore, it is not worthwhile to abruptly tear or break the boards with the help of tools.

It is necessary to remove the formwork from top to bottom, observing the following sequence of actions:

- Loosen the bolts and remove the upper metal ties.

- Remove the bolts of the lower screeds (the screeds must be left in the concrete).

- Carefully move the shields away from the posts.

- Remove the props.

- Remove the wooden frame.

The formwork must be removed, even if you temporarily "froze" the construction site until next summer. There are several reasons for this:

- If you leave a structure made of wood in the rain and snow, then the wood will quickly absorb moisture.

- It is better to dismantle the formwork and waterproof the foundation before the wooden frame bursts, when all the moisture absorbed into it melts in the fall.

Leaving the foundation itself for the winter is also not worth it, despite the statements of "would-be advisers" who are confident that the overwintered foundation will only become stronger from this. If you leave an unloaded concrete base for the winter, then the structure can simply be pushed out of the ground (especially if the soil is heaving). In addition, it will be very difficult to assess the foundation that has undergone wintering without waterproofing - to determine whether it has been damaged by the expansion of water inside the mass.

In turn, loading the foundation ahead of schedule is also not worth it. The best option is to calculate the work in such a way that the concrete base has time to gain the necessary strength (after 4 weeks) and you have time to load the base.

After how many days do you need to remove the formwork from the foundation?

Panel formwork scheme.

There is no definite answer to this question yet, because it depends on many things. For example, the fact that the foundation of a building has several functional tasks in addition to installing and holding walls and floors on it. This will also affect the requirements that apply to one type or another. It must be made from safe, durable and reliable materials. They must meet the standards and requirements that apply to any construction site. The foundation structure is usually made of a heavy-duty metal frame and a plywood plane made of several panels. The main load that occurs during the laying of the foundation is directed to them.

The constantly improving technological process allows the use of all modern technologies during the manufacture of shields.This is how they create a formwork that can withstand any pressure of concrete and reinforced concrete structures without subsequent deformation and fracture of both the foundation and the whole building. When a building is built on its own, several questions arise. For example, how to organize such a process as the removal of the formwork, and after how many days it will be possible to remove this structure? Finding the answers requires the most careful approach, since there is no one unique solution. According to the norms accepted and approved in construction theory and practice, a material such as concrete reaches its maximum strength level in about 28 days. Moreover, it should be watered in the first two days after pouring. But even this number of days cannot mean that during this entire period the foundation must be inside the formwork. Here, the most important thing will be to monitor indicators such as temperature, humidity, etc. At the same time, it is absolutely not necessary to rush in this matter. It is best, according to experts, to dismantle the temporary structure around the foundation 10 days after the foundation is completely filled with concrete.

How the formwork is removed from the tape base

The formwork is ready for dismantling when the strength is 50%. It is necessary to disassemble the formwork carefully, otherwise you can seriously damage the structure.

Strip foundation

Strip foundation

The concrete is not yet strong enough to withstand severe mechanical stress; chips may form on the surface.

The formwork can be reused. When removing, it is necessary to monitor the integrity of the material.

Instructions:

- You need to start from the least loaded place. These areas include open edges, corner joints. The setting of the solution is faster than in other places.

- We have to act in the "from top to bottom" technique. The most important thing is to be able to remove the parts that are used for support.

- Dismantle metal brackets, studs - the elements pull together opposite shields. The technique of cutting, unscrewing is suitable. If the formwork panels were pre-treated with an oil composition, covered with a polyethylene film, it is necessary to remove the fasteners before disassembling the structure.

- Remove the longitudinal connecting bars when they connect the panels. The operation facilitates the dismantling of the long formwork.

In places where channels for communications are laid, you need to be careful - if damaged, it takes a lot of time to repair. Usually, it is impossible to make repairs on your own - you have to invite builders

Dismantling tips

When installing the formwork, it is required to ensure the integrity of the structure so that the mortar does not pour out of it. It can be removed after reaching 50-80% of the brand strength of concrete, depending on the type of construction. At large facilities, it is done in stages, in the reverse order relative to the installation. In private construction, it is removed simultaneously from the entire monolith.

The dismantling of the formwork is done carefully so as not to subject the cast structure to unnecessary stress. Do not use heavy equipment as it can severely damage the surface. When removing, it is necessary to follow simple rules that will help preserve the surface of the poured solution, having received a strong durable structure:

- Lubricate all elements in contact with the monolith with materials that reduce adhesion or lay a plastic wrap.

- The formwork should be removed manually so as not to damage the casting and to be able to reuse it. If difficulties arise, a wooden wedge is carefully driven between the monolith and the shield.

- The solution grasps better in the corners, so it is better to start work with them, shoot from top to bottom.

- Supporting elements, columns, towers are released from the formwork last.

The lumber formwork does not need to be left for a long time in the autumn-winter period, since they begin to swell, they warp, which leads to surface deformation.

The most suitable time for work is the end of autumn. The air at this time becomes humid, and the difference between day and night temperatures decreases. If the foundation is cast, after removal it must stand all winter in order to compact and gain the required strength.

It is possible to remove the formwork only after the mortar has set and hardens, so that the structure does not lose its shape and cracks do not appear on it. Compliance with the rules for dismantling will allow you to get an ideal monolith, with almost unlimited service life.

When to remove the formwork from the foundation and how?

There is an opinion that the dismantling of the supporting structures can begin as soon as the foundation can withstand the weight of a person and can be walked on. This advice is given by experienced builders, but you should not use it at home. Firstly, there is a chance that the mortar has not set, and we will deform the top layer. Secondly, when building a house for yourself, there is no need to rush.

The ideal option is to cast the structure in late summer or early autumn, at which time there is sufficient humidity and there is no intense heat, which is ideal for such work. In addition, the cast foundation must overwinter. Winter frosts and spring streams will test the entire structure for strength, the possibility of soil subsidence under load and other parameters. If there are flaws in the casting, then in the spring all of them "will be on the surface."

However, you should not leave the casting in the formwork for the winter, the wooden sheets will begin to swell in winter, and there are already few options - they will either move the props apart or start checking the foundation for strength. Steel sheets are simpler, but here the problem lies in the national mentality and the desire for profit, they can simply be stolen. The removal of structural elements of the formwork should be started with corner or protruding elements, it is these parts of the casting that solidify the fastest. This means that while they are being dismantled, the main concrete casting will dry out and harden a little more.

It is necessary to shoot as carefully as possible, in no case should the sheets be ripped off with lifters or a car. Otherwise, you can damage not only the formwork itself, but also the hardened concrete. After the corner parts, we proceed to the main spans. The supporting piles are removed from the ground, and after them the sheets adjacent to the concrete. If, before installation, the sheets were not soaked in oil, a special liquid, wrapped in polyethylene or paper, then it will be more difficult to tear them off, especially if they are wooden.

Formwork dismantling works

The formwork structure is disassembled carefully so that it can be reused and the possibility of damage to the concrete monolith is excluded.

From the foundation

How long does it take to remove the formwork after pouring concrete into the foundation?

The workflow requires caution. The fact is that concrete at this moment does not have sufficient resistance to damage of a mechanical nature, and there is a possibility that chips will appear on its surface

In addition, the formwork is often planned to be reused, and the shield material can be damaged by forceful methods of dismantling.

The algorithm of actions is as follows:

- work should be carried out from the least stressful areas - corners and open edges, since here the concrete hardens faster;

- after that, the dismantling process continues from top to bottom - stops, brace elements and other parts that served as support are removed;

- it is the turn of the shield ties located on the opposite side - studs and steel brackets, which are unscrewed or neatly cut off.

If the formwork panels were pre-treated with oil or lined with foil before installation, then the structure can be removed without much difficulty.

From the overlap

Now let's figure out how long it takes to disassemble the formwork on such structures.

As a rule, horizontal cast ceilings are rare, because they are more often poured on the ground, and only then they are mounted in the necessary places. To fill the floor, you will need a reliable formwork with powerful supporting elements.

In accordance with the SNiP technology, the dismantling of the floor formwork should be performed when the concrete reaches at least seventy percent of its strength. Here you have to take into account certain points:

- with a thermal mode of air from 30 to 35 degrees, stripping is allowed to be performed after five days;

- if the average daily rate is 20 - 25 degrees, the concrete floor will gain strength by the end of the seventh day.

- if the thermometer does not exceed a division of 10, then the structure is dismantled after fifteen days;

- at a zero mark, stripping is carried out after a month.

It turns out that in the worst case, you can remove the formwork from the floor in twenty-eight days, to which it is best to add a few more days

This is especially important if, during the period of concrete hardening, the temperature regime or the level of air humidity has changed.

How to properly remove the formwork from the floor? First of all, you will have to lower the structure of the load-bearing nature. The process will be simplified if racks with lowering heads were used, because it is forbidden to sharply knock out the elements. When releasing large-sized boards, it is recommended to use bolts, due to the rotation of which the boards themselves will move away from the concrete base, making it easier to dismantle.

After concreting

When can the formwork be removed after the concrete has been poured? The norms governing when to start this type of work have been determined. But who gives permission to dismantle the formwork? For this purpose, special laboratories have been created, issuing conclusions based on studies of samples submitted for verification.

Pouring process

How to pour concrete into the formwork? Given the construction conditions, concrete can be prepared in a variety of ways.

Solution node

During the construction of a large facility that constantly needs concrete, a mobile workshop for its production is installed. The necessary material is sent to the mixer by batchers, water is added in portions, the finished mixture is fed into the bodies of the freight transport, which delivers the concrete to the place of pouring.

Automixer

This is a machine equipped with a special drum. The necessary ingredients are put into it, and while transportation to the construction site is being carried out, due to the rotation of the drum, the raw materials are mixed until fully ready for pouring.

Concrete mixer

An excellent solution for the construction of small structures, containing up to one hundred and fifty liters of the mixture in its rotating pear. All components are loaded according to established standards with a shovel, water is added and mixing is carried out until fully cooked.

Manual method

For small amounts of work related to concreting, it is enough to perform several batches on our own. In this case, concrete is prepared in a container of a suitable size.

Removing plywood formwork

The rules and terms for removing the formwork from construction plywood are similar to the conditions for dismantling wooden and metal formwork. Dismantling of plywood panels is carried out from top to bottom. In places where plywood is subject to sharp collapse, the shields are temporarily fixed. After removing the formwork fasteners, you can start disassembling the plywood fences.

We recommend watching a video about the complete process of dismantling the formwork.

Construction plywood, like metal panels, is a reusable building material

Therefore, the removal of plywood panels should be treated with care and should not be hit on its surface.

The quality of the foundation surface, its durability and reliability depend on how professionally the dismantling of formwork structures is performed.

Preparatory work

Before pouring concrete into the formwork, preparatory measures are taken related to the selection of the necessary tools, the preparation of the concrete mixture and the arrangement of the site.

The concrete is selected taking into account the required characteristics and weather conditions, the characteristics of the soil composition. To increase the strength index of the finished structure, a steel reinforcement cage is installed.

Concrete for pouring into the formwork can be prepared independently by mixing sand, cement material, crushed stone and water in the required proportions, or you can purchase a ready-made mixture.

For such work you will need:

- shovels are different;

- buckets, mixing container or concrete mixer;

- measured container.

In addition, a formwork system is being prepared that meets certain requirements:

- the material of the shields must be strong in order to reliably protect the reinforced concrete structure from deformation;

- internal surfaces should be smooth in order to ensure easy dismantling and evenness of the poured surface;

- the whole structure should not have gaps.

Plumb lines and levels are required to accurately position the formwork. Clamps, spacers and retaining elements are used for fastenings.

First of all, the formwork is mounted for pouring concrete. The shuttering boards should stand upright, not create gaps through which the concrete mixture will begin to flow. Diagonals of opposite angles can have a maximum divergence of no more than three centimeters.

Following the installation of the formwork, its internal surfaces are cleaned, and the reinforcement cage is installed. The metal structure is necessarily equipped with retaining elements that prevent the rods from contacting the earthen and formwork surfaces.

It remains to check the evenness with the help of the building level, pull the marking cord and fill it.

Building codes

If the process is carried out at home, then it is unrealistic to measure this factor, therefore, they are guided by the time allotted for the solidification process and the air temperature. After removal, you can continue to work and load the concrete base. It is advisable to start work in a warm period, when the amount of precipitation is low.

Most often this is early autumn, spring, summer, at this time the weather and ambient temperature are most suitable for high-quality styling and quick drying of the base. In construction, there is a term stripping strength, which indicates the time of removal of protection from concrete and the further continuation of the process.

Most often this is early autumn, spring, summer, at this time the weather and ambient temperature are most suitable for high-quality styling and quick drying of the base. In construction, there is a term stripping strength, which indicates the time of removal of protection from concrete and the further continuation of the process.

This value depends on the type of construction. For reinforced tape and slab bases, blind area and armored belt, it is 50% of the brand design strength. In this case, you can quickly continue working and erect the building. When pillars, columns and vertical products harden, the stripping strength is about 30% of the total strength. For monolithic floors and concrete stairs, the indicator should be about 70%, since strong pressure will be applied to the base. This can affect the surface and, if hardened insufficiently, will lead to destruction.

The exception is reinforced concrete staircases, which are installed on a base that has solidified up to 70%. In order for the base to be of high quality and withstand mechanical loads well, it is necessary to accurately determine the time after which it is necessary to disassemble the formwork.

Important question

Although the chemical reaction of crystallization of material particles and their bonding with each other occurs in a standard mode, environmental factors still have an influence on this process.The procedure takes place in two stages. First, it sets under optimal conditions, which takes several hours.

Initial hardening cannot be the basis for the continuation of work, but is an indicator of the quality of the concrete, the level of mixing of the mixture and the ability to take the form that the formwork gives. This is an important element as you can see if the foundation is firm enough and add density with cement.

Initial hardening cannot be the basis for the continuation of work, but is an indicator of the quality of the concrete, the level of mixing of the mixture and the ability to take the form that the formwork gives. This is an important element as you can see if the foundation is firm enough and add density with cement.

The second factor is a set of brand strength. It occurs after 90% of the expected hardness is obtained, the rest of the percentage depends on how the surrounding conditions affect. This process can be completed within a few years after construction. Therefore, formwork removal is not a standard process for all types of work, depending on the following:

- type of material;

- environmental factors;

- the amount of moisture;

- temperature regime.

In order to slow down the drying process, the "stirring" method is used. It is relevant when transporting concrete with special mixers. If we talk about standard conditions, with a sufficient level of humidity in the air, the concrete mixture can reach the required strength in about three days, and harden by 75-80% in a week.

If the air temperature is different, there is a lot of moisture in it, then the curing time may increase or decrease. Builders advise using a table that reads the air temperature and indicates the strength of the concrete. The average daily air temperature is taken as a basis. Thanks to the calculations, you can find out after how many days you can remove the formwork from a strip foundation or other type of foundation.

Factors affecting strength

The influence of the environment must not be overlooked. The moisture regime plays an important role in the set of strength of the base. In hot weather, the open hardening monolith succumbs to the influence of the environment. The first sun warms the concrete surface strongly and quickly evaporates moisture. The surface hardens faster, the moisture in the base concentrates, as a result of which a crack appears on the surface.

- Therefore, during the drying process, builders are advised to moisten the surface.

- The chemical reaction is accelerated, but because of this, the hardening is uneven. The concrete becomes covered with cracks and irregularities, the upper part begins to crumble and crumble. Masters advise to add water to the surface using sprays to avoid destructive processes.

- After that, it is necessary to cover the surface to create a greenhouse effect, so that moisture evenly evaporates from the inside, but at the same time the surface does not dry out.

When can the formwork be removed?

When it will be possible to remove the formwork from the strip foundation, the following factors influence:

- base height and thickness;

- climatic conditions;

- temperature and humidity;

- concrete composition.

Whatever may be said, but in the conditions of a summer cottage, few people will ask the "competent" authorities after how long it is possible to remove the formwork from the foundation. Mostly word of mouth is working, which brings different advice from different neighbors. But do not blindly trust the docks, because this is still not their home. Therefore, let us turn to time-tested knowledge. One of the factors affecting the hardening of concrete, which means after how many days to remove the formwork from the foundation, is the temperature. Moreover, it is not the daily maximum that is taken into account, but the daily average. For example, daytime plus 30, nighttime - plus 15. Average daily - plus 22.5. The following table shows the average daily temperatures and on which day the withdrawal can be made.

One of the factors affecting the hardening of concrete, which means after how many days to remove the formwork from the foundation, is the temperature. Moreover, it is not the daily maximum that is taken into account, but the daily average. For example, daytime plus 30, nighttime - plus 15. Average daily - plus 22.5. The following table shows the average daily temperatures and on which day the withdrawal can be made.

| Temperature (˚С) | Number of days |

| +1 | 15 |

| +5 | 10 |

| +10 | 7 |

| +15 | 5 |

| +20 | 4 |

| +25 | 3 |

| +30 | 2,5 |

| +35 | 2 |

The table shows the data after how many days you can remove the formwork, and not carry out construction work. For the construction of walls, the minimum sufficient period for the maturation of the foundation is 28 days. Until this time, waterproofing work can be carried out. In nomenclature terms, this is the time required for the concrete to gain 50% of the brand strength, sufficient to painlessly remove the formwork. However, some experts say that for a strip foundation under ideal ripening conditions (+ 20 ° C, relative humidity 100%), four days are enough for the foundation to gain the necessary strength and it would be possible to walk on it.

In nomenclature terms, this is the time required for the concrete to gain 50% of the brand strength, sufficient to painlessly remove the formwork. However, some experts say that for a strip foundation under ideal ripening conditions (+ 20 ° C, relative humidity 100%), four days are enough for the foundation to gain the necessary strength and it would be possible to walk on it.

The time of concrete curing is greatly influenced by the relative humidity of the air: the lower it is, the worse the quality of the finished monolith will be. Therefore, "young" concrete structures are periodically watered.

For filling the strip foundation, the end of summer - the beginning of autumn is considered ideal. The temperature at this time decreases, and the humidity rises. That is, all favorable conditions are created for good maturation of concrete. If there is no particular rush in the construction of the walls, then it will be better if the concrete structure overwinters, but then the formwork must be removed. By absorbing moisture, the tree swells, and this can lead to various negative consequences. This is on the one hand.

On the other hand, if the task is to build a house in a season, then the best time is the middle of spring. Then it is not very hot yet and the humidity is high. In addition, you can find out how high the groundwater level is in order to determine the type of foundation and subsequently develop a construction project and purchase materials with an eye to this nuance. Here it will be possible to say with absolute certainty that the cellar will be dry next spring.

How many days to remove the formwork

Concrete hardening is a chemical reaction of crystallization of cement powder particles after contact with water. The process takes place in 2 stages:

- The initial setting takes several hours under optimal conditions. The concrete mix loses its mobility and takes the form given by the formwork.

- A set of brand strength. The monolith hardens to 97-98% of theoretical hardness, the remaining 2-3% can be added over decades (if external conditions are favorable).

Any chemical reaction fits into the framework of Van't Hoff's law: when a substance is heated by 10 degrees, the process is accelerated 2-4 times. Conversely, cooling slows down the reaction in a similar way. That is, the hardening time of concrete in the formwork to gain 50% strength strongly depends on the ambient temperature.

Under normal conditions (t = +20 ° C), a concrete mixture made from the common grades of Portland cement M400 and M500 reaches a stripping strength of 50% in 3 days, 75% in a week. If the air temperature differs from the optimum, the curing time increases or decreases. Curing times at different temperatures are shown in the table.

An example of using the table. The formwork is removed from the foundation or blind area after 5 days if the average daily temperature does not exceed 10 degrees. Shields are dismantled from the floor and staircase, solidified in similar conditions, after 2 weeks.

Humidity plays an important role in the strength of concrete. What happens to an open solidifying monolith at the height of summer:

- The sun heats up the concrete surface strongly, evaporating moisture from the structure.

- The chemical reaction is accelerated, but the hardening is uneven, especially in the surface layers.

- The massif is cracked, the upper part crumbles and crumbles.

To exclude destructive processes that occur during the hot period, the concrete surface should be abundantly moistened from sprayers, and then covered with burlap and other similar materials that do not let the sun's rays through. When the fabric and surface are dry, it needs to be moistened again.

Hypothermia of hardening concrete at night frosts is just as destructive. We suggest that you familiarize yourself with a separate instruction on how to properly do concreting in winter.

This is interesting: Column foundation made of blocks