The foundation has been completed. Building walls?

Most likely, those who have undertaken the construction of a house know or have heard that immediately after laying the foundation, a pause should be made before continuing construction. But not everyone understands why it is necessary to defend the strip foundation.

According to building codes, any type of foundation, before continuing the construction of a building on its basis, must be defended (with the exception of the pile-screw). This is necessary so that the concrete is completely dry, so that the structure does not sag in the future, does not crack, for example, in the wall. In a word, it was not deformed.

Why can this happen? The reasons for various kinds of defects are very diverse:

- incorrect depth of the trench for laying the foundation;

- low quality of the prepared concrete mixture;

- high moisture content of the soil where the foundation was laid;

- the season of the year and the temperature regime of the air when laying the foundation and other reasons.

Why does the foundation have to stand?

The concrete used to fill the foundation consists of several ingredients. These are pure river sand, gravel or crushed stone with a fraction of 40-60 mm, Portland cement of the M200-M300 brand and water without oil or gasoline impurities. The brand of cement that is chosen for concreting depends on what loads the foundation will bear. The larger they are, the higher the grade of cement you need to choose.

Depending on the type of soil on which the construction is being carried out, on the weight of the future structure, the type of foundation laid under it is chosen. A light one-story structure can be based on a columnar foundation. A two-story brick house requires laying a solid strip foundation or a monolithic slab if there will be a garage under the house or a basement with a swimming pool.

At the same time, there is no interdependence between the type of support for the structure being erected and how much the foundation should stand after pouring. Many builders believe that concrete foundation posts harden faster than a monolithic slab. This means that you can put a load on them literally in a few days. This misconception leads to the appearance of cracks, distortions and even faults in structures built on insufficiently stable foundations. After all, concrete tends to gain strength over a period of time. If you give a load to it earlier, then you should not ask why it cracked.

Minimum curing time

Foundation insulation diagram.

The foundation of the house is one of its most important components. A house will not be able to withstand even moderate wind strength if it does not have a foundation. An important question is how long the foundation should stand after pouring it. One of the most common types when building a house is a strip foundation. After it was poured, at least three weeks should pass, provided that the weather was sunny outside, the humidity was low, and everything contributed to the rapid solidification of the base. There must be a foundation without any intrusion into it. The whole structure is a single whole, and if you decide to fix something "along the way", then it is better to wait until the concrete mixture hardens. And it takes about a month for this, this is how much the foundation of the house needs to withstand. In addition, the depth of the base of the house will help determine the amount of time it takes for the foundation to stand. The deeper the foundation, the more time you need to give it to stand.

Experienced builders testify that in the first month after pouring there is shrinkage and solidification, these two processes go through 70% of the possible, the remaining 30% occur in the first year of the building.

Even if, when building a house, withstand a month, provided that there is dry, sunny weather and low humidity, the concrete mixture will harden well, the foundation will get stronger, its sediment will continue for the next year. The foundation of the house can be completely defended only when all the remaining materials have been installed on it, when the construction of the house is completed. It is not for nothing that it is recommended to move into the house only a year after the completion of the building.

If you have time, the deadlines are not running out, then use the maximum time intervals, which according to the technique should be allocated to each stage of construction. If you are in a hurry, then the time frame can be shortened. However, in less than two weeks, the foundation cannot stand. Otherwise, the concrete mix will not get stronger, and further construction will be meaningless. Even if it is possible to erect a structure, in the near future the house will squint, crack, or, worst of all, it may collapse altogether. The fragile concrete mixture will be pressed not only by the weight of the materials, but also by the weight of the entire structure as a whole, the foundation will begin to "play", that is, move, settle, bend, and the whole structure will "play" with it. If a building is being built for public use, where a large number of people are expected, then this factor must also be taken into account. It is categorically impossible to admit movements of the base or its incomplete solidification, because the consequences can be irreversible.

It is advisable to pour the base on sunny dry days, since the additional moisture will add time to the foundation.

Stages of train readiness

Determination of the degree of hardening of concrete using a special device

Determination of the degree of hardening of concrete using a special device

If a developer wonders how long to wait for the concrete to fully harden, then they will have to be disappointed. External factors have little effect on the solidification rate, because this is a chemical exothermic reaction.

Moreover, it begins already at the moment of mixing the solution, because the mixture heats up sharply. But, as a rule, there is a clear time frame while concrete is gaining its strength, namely:

- Primary casting into forms. Concrete gains 30% strength in the first day;

- Three days after pouring. Strength is set by half;

- After a week, its strength can reach about 70%;

- In three to four weeks, the strength gain reaches almost 100%.

When planning a foundation for a residential or administrative building, then a number of points must be taken into account. For example, the brand of cement used, the date of its packaging or production, storage conditions, as well as how many ingredients are needed for the solution and in what proportions to mix it. Also, a lot depends on the type of base chosen and the specifics of a particular soil.

When choosing a structure, you need to focus on the type of soil, the complexity and mass of the future structure, the depth of the groundwater, possible horizontal and vertical loads. Concrete must be poured at an ambient temperature of +5 degrees, if the temperature is lower, then electric heating is used, because then it will not be possible to achieve the optimal rate of curing.

Strength set with concrete

The concrete mixture dries and receives the necessary and sufficient strength values in the process of passing through two successive interconnected stages:

Setting stage. The preliminary setting of the concrete mortar laid in the formwork in summer at an ambient temperature of about 20 ° C takes place during the day. In cold seasonal periods, it is necessary to use available heating means and use heat-insulating structures. It should be borne in mind that the setting processes begin to occur already within the first two hours from the moment the concrete mixture is mixed with water. That is why the operations of mixing the mixture and placing concrete in the formwork should be as close as possible to each other in time intervals.

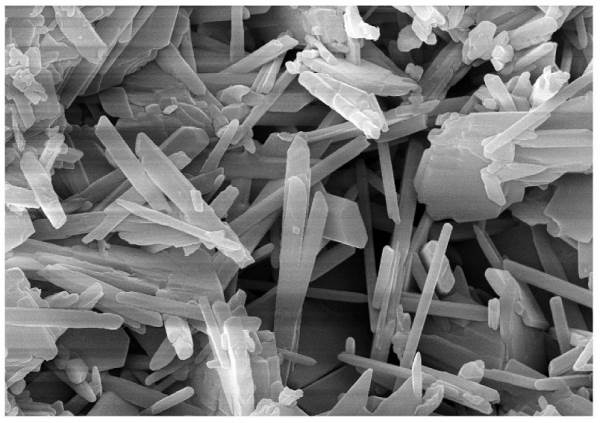

Concrete hardening. The concrete gains strength occurs in the process of hydration - the formation of molecular bonds of water particles with the substances that make up the mixture. Hydration takes place in a narrow range of temperature and humidity, which must be provided with concrete care measures

The importance of careful control of the course of the physical and chemical process in the mass of a reinforced concrete structure is explained by the complete dependence of the quality of the structure.

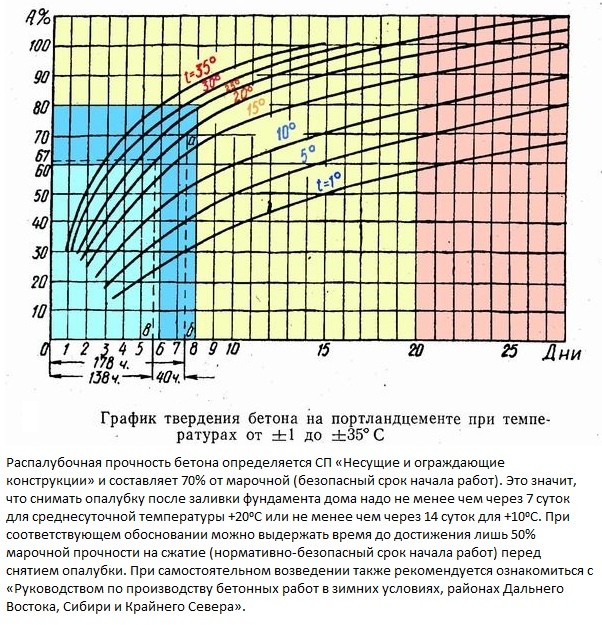

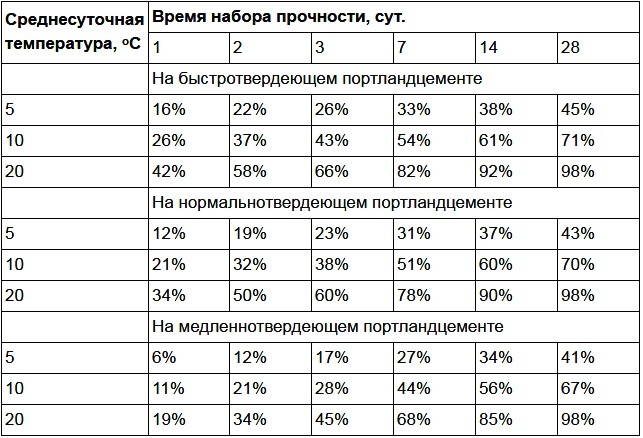

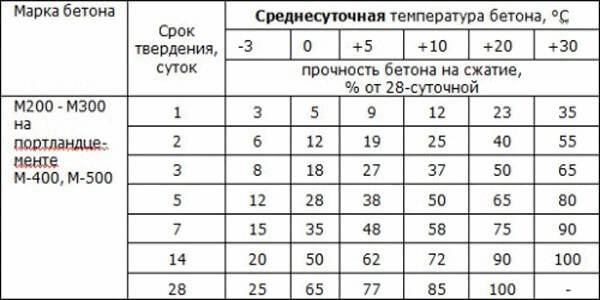

It is natural to assume that the period during which the foundation must be defended is directly related to the strength gain of the concrete that constitutes its basis. Ready-mixed concrete of grades M-200 and M-300, which is made on the basis of Portland cement M-400 and M-500, respectively, gains 70% strength required before the start of construction and standardized by SP 70.13330.2012 in 28 days at an average daily temperature of 20оС. A change in the average daily temperature inevitably leads to other indicators of strength. The dependence of the gained strength is clearly visible from the table:

It is natural to assume that the period during which the foundation must be defended is directly related to the strength gain of the concrete that constitutes its basis. Ready-mixed concrete of grades M-200 and M-300, which is made on the basis of Portland cement M-400 and M-500, respectively, gains 70% strength required before the start of construction and standardized by SP 70.13330.2012 in 28 days at an average daily temperature of 20оС. A change in the average daily temperature inevitably leads to other indicators of strength. The dependence of the gained strength is clearly visible from the table:

| Concrete grade | Standing time (days) | Concrete strength (% of the standardized) depending on the average daily temperature (оС) of the concrete mass | |||||

| -3 | +5 | +10 | +20 | +30 | |||

| M-200, M-300 | 1 | 3 | 5 | 9 | 12 | 23 | 35 |

| 2 | 6 | 12 | 19 | 25 | 40 | 55* | |

| 3 | 8 | 18 | 27 | 37 | 50 | 65 | |

| 5 | 12 | 28 | 38 | 50 | 65 | 80 | |

| 7 | 15 | 35 | 48 | 58 | 75 | 90 | |

| 14 | 20 | 50 | 62 | 72 | 90 | 100 | |

| 28 | 25 | 65 | 77 | 85 | 100 | – |

The composition of the mixture

When we hear or say "concrete", we rarely think about what this material is. And, of course, we do not at all think about why all the instructions for the care of freshly poured concrete structures state that it is necessary to water the concrete. If we try to bring all the definitions found in the special literature into one, then we get a definition that explains that concrete is an artificial stone material that forms a rationally selected, thoroughly mixed and compacted, hardened mixture.

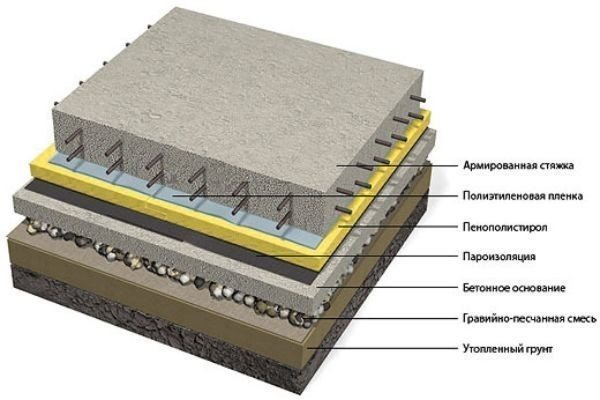

Concrete floor scheme.

The composition of the concrete mixture includes: a binder (cement), coarse and fine aggregates (gravel or crushed stone and sand, respectively), water and special additives (if needed). The density of concrete in the hardened state should be 2200-2500 kg / m³.

Water and binder are the active components of the concrete mixture, which envelop the grains of the passive element of the concrete mixture - the aggregate - in a thin film. Over time, the water softening the binder evaporates, the binder hardens and binds the enveloped aggregate grains, turning the mixture into a durable monolithic artificial stone - concrete.

Aggregates in a concrete mix occupy 80-85% of the concrete volume. It is clear that what the concrete will be in the future in terms of its physical and mechanical characteristics directly depends on the properties of the aggregate. It is easy to calculate that for the two active components of the concrete mixture - cement and water - 15-20% remains in the volume of the concrete mixture. With the generally accepted ratio of cement to water 2: 1, cement takes 10-13%, and water, respectively, 5-7% of the volume. For most brands of concrete, this figure becomes 190-200 liters per 1 m³ of concrete mixture.

How long does it take to solidify?

An uncured or poorly hardened foundation will not be able to withstand the loads of the house and the wind, therefore it is important that it hardens well. Let's look at a few examples

For strip foundations, the minimum recommended curing time is 20 days. In this case, the following conditions must be met: during this time, the weather should have been sunny, with low humidity. Immediately after pouring (after 12-15 hours), all types of bases should be watered from above with water - this is necessary so that the top layer, which dries up the fastest, does not crack. The surfaces of the bases are watered every 2-3 hours for 3-5 days after pouring. Other manipulations with the base are strictly prohibited, since it is a single array, and in the event of any violation of integrity, the strength of the base can be deteriorated.

Professional builders almost always give at least a month to solidify the base of the house and only then process it. At this time, the building subsides by about 75% of the final subsidence (the remaining 25% falls on the first 2-3 years). At the same time, in the case of high-quality concreting, favorable weather and exposure for a whole month to dry, the structure will still sag for some time. The base will completely stand up only after a year and a half after the completion of the construction completely (including the rough finishing of the premises). Therefore, it is recommended to settle in the house only some time after construction.

Thus, during construction, it is important to carefully allocate time so that all the minimum necessary terms for the construction of the building are adhered to. Shorter build times are possible, but within reason

If construction begins earlier than the minimum permissible period, then the walls of the house may crack literally immediately after construction, the building may tilt or collapse. At the same time, not only its own weight will act on the base, but also the weight of walls, roofing, finishing materials (and it is not small and cannot be underestimated).

In no way can the specified period be violated, since this can lead to movements of the foundation and soil, which will cause the complete destruction of the building in the future, moreover, with possible human casualties. At the same time, both the filling and sludge of the base should be carried out in warm and sunny seasons.

Components of standard concrete

Concrete dough is important for the construction of a belt, monolithic or columnar foundation.

Grout components

A common concrete mass consists of the following raw materials:

- cement - has astringent properties that ensure the combination of ingredients into a single solution. To prepare a high-quality mass, you will need material labeled M500;

- sand is one of the aggregates in the mixture. Only free-flowing raw materials with uniform fractions from 1.5 to 5 mm are used. Impurities are sieved through a fine sieve. To make the composition durable, use the river type of sand;

- crushed stone is the main filler. In the conditions of home construction, crushed stone or gravel materials with fractions of 8 - 35 mm are purchased. For a snug fit of the particles, small and large raw materials are mixed.

To prevent debris from entering the mixture, the components are poured onto a clean tarp. The binder of the solution is water. The liquid is filtered before adding to the rest of the ingredients.

Do I need to add plasticizers?

Experts recommend choosing additives to improve the workability of the mix. Manufacturers of modern building materials produce the following products:

- ready-made slaked lime, which ensures the strength of the composition;

- plasticizers that give the solution fluidity or viscosity;

- reinforcing components - needed to strengthen the foundation in conditions of unstable soil.

Before buying, it is important to study the technical characteristics and technology of the use of auxiliary components.

Solution calculation technology

At home, it is advisable to prepare the concrete mix by hand. You will need 1 part cement mix, 2 parts sand, 3 parts gravel, additives, and water. Consider the difference in the bulk density of the material and calculate in buckets: a bucket of sand will weigh 19 kg, cement - 15 kg, and crushed stone - 17.5 kg. Water is added to the ingredients and the solution is kneaded until smooth.

After the foundation is poured, a technologically complex physicochemical reaction follows - the release of heat and evaporation of water, as a result of which an artificial stone is formed.

Consequences of premature removal of the formwork

To understand the entirety of the process, you need to know its scale, and also calculate how much concrete is needed.For laying a strip type of foundation, a concrete solution of a mushy state must be used. After penetrating the formwork, the hydration and hardening procedure begins. This is called the holding period.

If the structure of the base of the formwork is dismantled before the moment the cement sets, there is a high probability of collapse of the structure, the appearance of cracks, and crumbling. An exhausted structure will not be able to withstand not only third-party weight, but also its own. This is especially dangerous if there is an underground part of a capital structure, basements, and other premises.

How much the foundation should stand after pouring, there is no answer, since in each situation the numbers are different. The average is 29 - 30 days. Often there are exceptions in the form of 17 - 23 days, in difficult circumstances or weather conditions, the period is extended. Most experts defend the point of view that it should dry for one calendar month.

Factors affecting the drying rate:

- Minimum and maximum ambient temperature;

- moisture indicator;

- frequency and amount of precipitation;

- seasonality of the season;

- soil quality;

- general relief of the horizon;

- dimensions;

- type of base;

- concrete strength according to design data;

- the qualitative composition of materials for the building;

- the height of the groundwater;

- type of construction technology;

- value, loads that correspond to the calculation.

Sometimes it happens that the foundation is defended for several months. For example, it was flooded in the fall, left for the winter, and only in the spring the construction of load-bearing walls begins. This is done in order to timely identify defects and cracks in the structure after thawing of the soil base. In this case, the entire monolithic frame must be tightly covered and moisture penetration. How much insulation is needed is decided individually in each case.

When calculating the timing, most often, the worst conditions for a given region are taken. So the called stock will play into our hands afterwards.

How to work with concrete correctly

Vibration compaction of concrete

The most responsible and troublesome is the moment of pouring the foundation of the building. Those people who are going to build a house with their own hands need to learn that any work with concrete consists of three components:

- The stage of preparing a mixture of concrete.

- Pouring concrete mix.

- Fresh concrete care.

These stages are directly related to each other. With the slightest, even insignificant error, you can forget about the strength and quality of the foundation under the structure. Therefore, each of the work included in the general process of erecting the foundation must be performed by a specialist with certain skills, knowledge, and also in compliance with the rules. In addition, each stage must be approached with special responsibility. Only in this case you will get a reliable base that does not undergo destruction and cracking during operation.

Chemical processes

In the manufacture of concrete, cement is used, which is designed to connect the components of the concrete. Cement, entering into a chemical reaction with water, forms a solid rocky substance that connects sand and crushed stone.

The chemical processes occurring at the initial stage are called setting, while the first bonds between the filler are formed in concrete, and the set of strength consists in strengthening these bonds.

For the normal course of chemical reactions in concrete, the presence of water is necessary. The process of concrete maturation is long, and the water contained in the solution initially evaporates quickly, therefore, the concrete is protected from the rapid drying of moisture, and for this it is covered with roofing material or plastic wrap, or periodically moistened abundantly

To obtain a high-quality foundation, it is important to ensure that the concrete dries evenly.

Is it possible to make a foundation in winter?

When the foundation is poured in the winter, the maturation of the concrete is suspended, as the water required for chemical processes freezes. But these are not all the disadvantages of such an installation, the water in the solution, freezing, will expand, and at the same time tear the concrete from the inside. Practice and research show that already at minus 10 ° C, chemical processes in concrete slow down, and along with them, the process of strength gain slows down.

Therefore, when making a foundation in winter, after pouring, the concrete mixture must be heated throughout the entire period of maturation. With individual construction, it is difficult to heat the foundation and this will entail additional costs, therefore it is advisable to make the foundation in the summer, at an average air temperature of 20 to 25 ° C.

How to shorten the curing time of concrete?

Modern materials allow you to change the maturation of concrete, it is enough to use special additives. The use of additives allows you to get durable concrete in two weeks. Such additives have one significant drawback, which does not allow their use for individual construction. Additives reduce not only the maturation time, but also the setting time, and therefore, when using them, there is little time for pouring the foundation.

Another way to shorten the ripening period is to increase the ambient temperature, which is also problematic for individual construction.

Compliance with the maturation of concrete will allow you to get a solid foundation.

What factors affect solidification and pouring?

The foundation is called the base of the house, which must evenly distribute the load of the building on the ground to prevent subsidence or collapse of the structure. The strength of the foundation is determined by its type and the materials used for pouring. The durability of the walls and the building as a whole depends on this. It also depends on the time given for the foundation to settle after pouring.

At the moment, the required amount of time allotted for the concrete to settle is determined by SNiP, however, SNiP indicates only the required period for certain standards, which do not always coincide with the real conditions for a particular object. The following factors affect the period for settling the solution after:

- Ambient temperature and humidity.

- Presence / absence of precipitation.

- The type and condition of the soil.

- Terrain relief and groundwater depth.

- The quality of materials and construction technology.

- Base type.

- The type to which the foundation waterproofing belongs.

Naturally, not a single regulatory act will be able to take into account all of the above conditions, therefore, to determine the period of the foundation sludge, one should be guided primarily by one's own knowledge and experience. To be sure that the foundation has settled, you should take the most negative conditions for the area in which the construction is carried out, and, based on them, calculate the period.

At the same time, it is important to plan the construction so that by the time the temperature drops below +5 degrees Celsius (i.e. before the onset of autumn), the foundation is ready

Otherwise, it will need to be closed and insulated, and the shelter for the base is a troublesome business that requires additional resources. After cold weather, many wonder why the uncovered base is cracking? The answer is simple - from moisture getting into micropores, which, when solidified, breaks the concrete.

Strip foundation: concrete shrinkage and soil settlement

Characteristics and features of the strip foundation

Strip foundation - the base of the house in the form of a strip, a strip located completely under all external walls and under some internal walls (for large structures).

The base of a reliable strip foundation must rest on the ground, where the ground temperature is always above 0 ° C.

The strip foundation can be made of a cement mixture and fine crushed stone or from rubble stone, filled with ready-made cement mortar.

- concrete and reinforcement. An iron frame made of pieces of metal reinforcement welded together is intended for use as a supporting skeleton that strengthens the concrete part of the foundation, distributing uneven loads throughout the base strip. does not need such a framework. But a tape of fine gravel and concrete, intended for a massive structure, must be reinforced with reinforcement. How long should it stand is a question that many owners who are building their own country house ask themselves. How much should the strip foundation be defended in order to withstand the weight of the structure and not crack after the construction of the structure?

Requirement for strip foundations

Installation diagram of the strip foundation.

The main requirement for the structure and materials of the base of the building is to ensure strength and durability. The foundation holds the wall, piers, roof, ceilings, floors, furniture, heating and plumbing on itself. should prevent the house from swelling during winter freezing of the soil. To do this, the base of a reliable foundation is supported on a frost-free layer of earth at a depth where the soil remains warm (above 0 ° C). Frozen ground can increase in size, rise in winter and sink in summer. The house will stand without raising and lowering with a properly built foundation. A strip foundation, resting on a frost-free layer of soil, will ensure a long service life of your structure. Is it possible in the form of a tape after its construction and under what conditions do shrinkage processes have the maximum effect on the foundation tape? How can you prevent or reduce the impact of shrinkage processes?

Shrinkage of concrete and soil settlement

Shrinkage is the process of reducing the size of a building material during its hardening and drying. It becomes noticeable some time after the completion of construction. Shrinkage of concrete occurs during its hardening, according to building codes, the size of shrinkage in concrete is 1% of the wet weight.

Draft is the process of lowering the earth after digging it up. Occurs over time, worse after rains and getting wet.

Both of these processes accompany construction.

Concrete shrinkage and soil settlement affect the possible subsidence of the strip foundation and the amount of time it takes to settle.

Dependence of the holding time of the foundation on its type

The insinuations that the finished foundation, after the set of the normalized strength of its constituent concrete components, must stand for a year or a winter, are absolutely not consistent. The widespread misconception about the need to withstand the structure until the end of the ongoing sedimentary-shrinkage processes arose as a result of the substitution of concepts. The fully erected building must be maintained before the start of finishing. This is explained simply by the example of existing varieties of the structural structure of foundations.

Video on how to accelerate the hardening of concrete

Columnar foundations

A columnar foundation is a series of individual pillars, for the arrangement of which brick or masonry is used, often the foundation pillars are made of concrete or reinforced concrete. To give the foundation elements additional stability, a grillage is set up - a reinforced concrete tape connecting the headbands of the pillars.

This type of foundation is classified as a light variety, therefore, the foundation base, unloaded by the weight of the building, is subject to increased mobility during soil movements with a heterogeneous morphology, and can be easily deformed as a result of frost heaving.The foundation of a columnar structure cannot be defended by definition, and it is necessary to start erecting walls immediately after the end of the setting of the masonry mortar or the curing of concrete.

Belt type foundations

Reinforced concrete strip foundations can be equipped in two types:

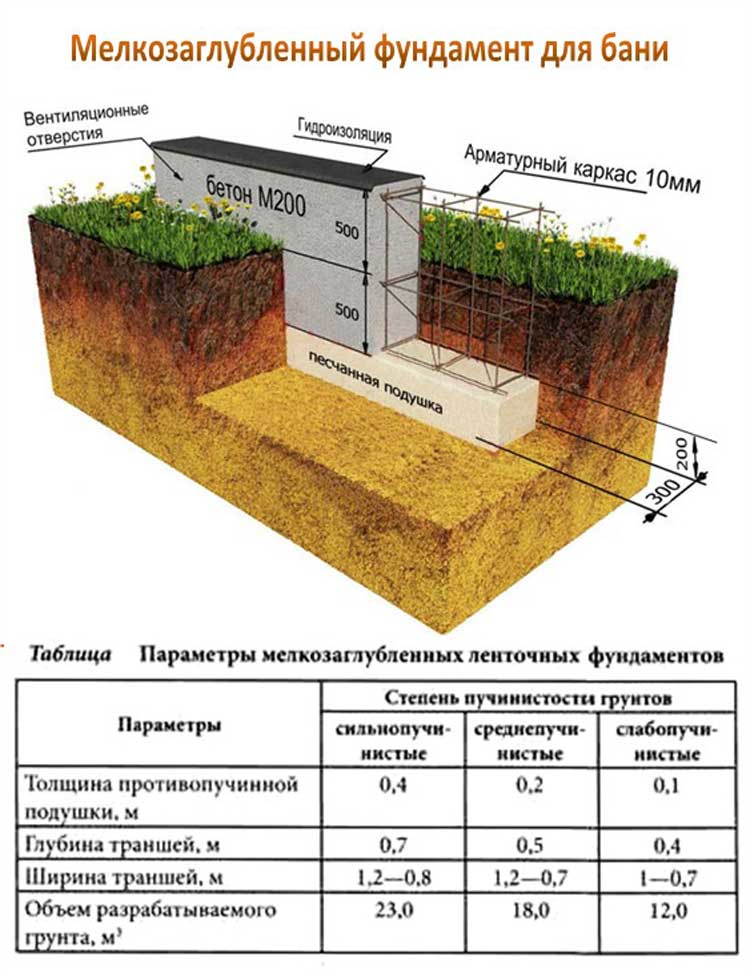

- shallow foundations are equipped for the construction of light buildings and with their soles rest on soil horizons located above the freezing level;

- deeply buried options involve the erection of bulk structures on them with a large weight, the level of occurrence of their soles exceeds the depth of freezing of the soil.

A shallow strip foundation undergoes loads that are similar in tension and strength to the impact on columnar options with a grillage. If such a foundation is allowed to stand during the period when the active heaving of soils occurs under the influence of freezing and thawing of ground moisture, the possibility of its deformation is very likely.

The foundations of the strip type of deep bedding are supported by their soles on dense horizons, are not subject to the influence of ground shifts. The shrinkage processes in the concrete mass are completely completed after reaching the standard strength, and the structure's settlement under the action of its own mass, without taking into account the weight of the building, is completely leveled by expansion joints.

Plate varieties

Monolithic foundations are easy to calculate and equip, they provide the foundation for the building being erected with sufficient strength characteristics. The even distribution of the load on the soil base due to the large supporting surface determines the minimum value of the specific pressure on the soil. Competently prepared sand or sand-crushed stone cushion under the foundation slab prevents its significant sedimentary movements.

The stability of the building erected on a slab foundation directly depends on how carefully the preliminary earthworks were carried out. The amount of time that a monolithic foundation must be defended is, again, determined only by the period necessary for concrete to cure.

Pile foundations

The foundations of buildings on piles, with any technology for their arrangement, ensure the transfer of load to deep, often primary, horizons of soil and rocks. This type of foundation construction completely eliminates the possibility of deformation of the building, regardless of how much time is allotted for their standing after the end of installation.

The determination of the time for how long the foundation should stand after pouring should be correlated with the time period for which the ready-mixed concrete will gain the strength specified by SP 70.13330.2012. Additional curing is not advisable, and in cases of using columnar structures and shallow strip foundations, it is even contraindicated.

Strength gain

Concrete in a cured state is an artificial stone obtained from a solution composed in certain proportions of cement, sand, gravel and water (composition of concrete for the foundation, proportions in buckets and kilograms). There is no unequivocal answer to the question: how long the foundation should stand after pouring. Although any builder can name the average figure - 28 days.

But the process of concrete curing is influenced by:

- cement grade (choice of concrete grade for the foundation of a private house);

- the percentage of cement and water in the concrete mixture;

- weather conditions and air temperature.

The process of recruiting design strength characteristics can be roughly divided into two stages:

- grasping;

- hardening.

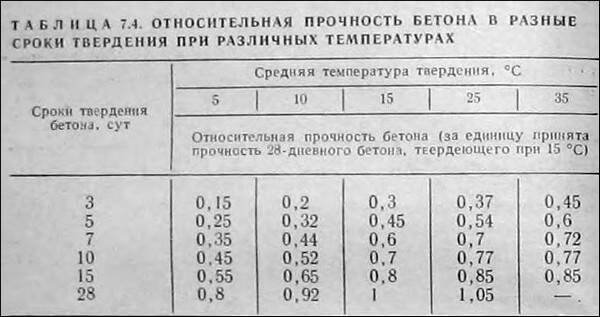

Foundation strength development table.

Grasping

The concrete mix has been in a liquid - or mobile - state for some time.This phase can be increased over time by constantly stirring the solution (on how to properly fill the foundation under the house). For this reason, concrete is delivered to construction sites in concrete mixers. Although this process has a downside: if it is in the mixer for too long, its qualities change, and for the worse.

The setting period is in direct proportion to the air temperature. For example, at zero temperature, the setting process begins in 6-10 hours, and ends in 15-20 hours after mixing the mixture.

If it is thirty-degree heat outside, then within an hour after preparation the concrete will begin to set, and this process will be completed in 1.5-2 hours.

Hardening

At this stage, in fact, a set of concrete strength characteristics occurs. If you ask a professional how much a strip foundation should be defended, he will ask you a counter question: what time of year are you going to stand for it?

If it is cold (at a temperature of 0 degrees), then after 28 days it will gain only 65% of its strength. With minus (-3 degrees Celsius) for the same period of time, this figure will be only 25%.

If the weather is moderately warm (+20 degrees) outside, then in four weeks the foundation will gain 98% strength. At 30 degrees, concrete will only take 14 days for this.

There is a parameter "stripping strength". It is stipulated in the corresponding joint venture and is 70% of the brand strength.

In accordance with this, the formwork can be removed from the foundation no earlier than after:

- 7 days - at an average daily temperature of +20 degrees;

- 14 days - at +10 degrees.

Concrete strength table depending on the time of hardening.

Construction errors

The most important myth about the strength of the foundation and the transition to the next stage of work says that the foundation must be allowed to stand (overwinter) before building a house on it. This statement is not supported by any regulatory documents and is not practiced by professional builders. This action does not bring any benefit, on the contrary, harm.

The negative consequences of the fact that the foundation is allowed to "stand" include:

- an increase in the time spent on building a house;

- uselessness of the event with high-quality compaction of the base (according to technology);

- the risk of cracks during construction on clay, loam, sandy loam, fine and dusty sand when work is stopped in winter due to the forces of frost heaving, because the unloaded foundation will be easily pushed out by the frozen ground.

Among professionals there is such a definition as "conservation" of the foundation

It is important to understand that this is not a necessary, but a forced measure, which is resorted to when the future owner cannot continue construction for his own reasons. And there is no such notion that the supports under the house must "stand"

If it is precisely the need for conservation arose, it is recommended that you familiarize yourself with additional information on this issue, since there are several nuances here.

To ensure the strength and reliability of the foundation, it is important to allow it to gain sufficient strength (dry out). Determining the time is not difficult using the information in the article

It will not take a lot of time, but it will save you nerves, time and money in the future.

Good publicity

When, after pouring the foundation, it can be treated with bitumen. Bituminous compositions

A budget and easy-to-apply method of waterproofing the foundation, which led to its popularity. It is necessary to process the walls of the foundation completely with bituminous mastic, pay special attention to the joints and possible cracks.

Advantages:

- Low cost;

- Ease of application;

- Elasticity.

Disadvantages:

- Quite a long time to complete the work (you need several layers and you need to wait for each layer to dry);

- Not the best hydraulic resistance;

- Short service life (after about 10 years, re-processing will be required).

Process applying bituminous mastic simple:

- Surface preparation. The concrete surface must be free of soil and fragile concrete layers. Caverns and crevices must be filled with cement plaster. The surface must be dry to continue working.

The moisture content of the concrete base before applying the mastic should not exceed 4%. Otherwise, the mastic will flake off. It is easy to check: we take a piece of plastic film, meter per meter, and lay it on the foundation, if there is no condensation on the film in a day, you can start applying the mastic.

- Primer treatment. To achieve better adhesion, the substrate is primed with a bituminous primer. One coat of primer is applied and an additional coat at the joints.

You can make a bituminous primer yourself. It is necessary to dilute BN70 / 30 bitumen with a solvent, for example, gasoline, in a ratio of 1: 3.

- The bitumen needs to be melted. Melt the amount of bitumen that you can apply before it hardens: reheating of the bitumen leads to a partial loss of its properties. Hot bitumen is applied in 3-4 layers. For foundations buried to 3 m, the thickness of the bitumen layer should be 2 mm, buried 03 to 5 m - 2-4 mm.

- After applying all layers of bitumen, it is necessary to protect the waterproofing from mechanical damage. For such protection, roll geotextiles or EPSP insulation can be used.

- Reinforcement of bituminous insulation is mandatory for:

- Cold seams;

- Joints and abutments;

- Over cracks and damage.

Most often, fiberglass is used for reinforcing bitumen.

Fiberglass is laid on freshly applied bitumen (while it is still liquid). For better adhesion, it is recommended to roll with a hard roller. After the mastic has dried, a layer must be applied that completely covers the reinforcing fiberglass. Fiberglass is laid with an overlap of 10 cm.

At junctions close to 90, you will need to use a fillet. This is necessary so that the waterproofing layer at the joints does not peel off from the base.

Reinforcement of bitumen in places of cracks and abutments significantly extends the life of the waterproofing.

Concrete watering frequency

Periodic moistening during the day and night helps maintain a sufficient moisture level in the concrete.

The frequency of the procedure depends on the weather conditions and the characteristics of the cement:

- When the air temperature exceeds + 15 ° C, concrete is watered from the second day after pouring it. You need to moisturize for 7-15 days.

- Upon reaching an average temperature of + 10 ° C, watered for up to 1.5 weeks.

- In the first days, water it 4-5 times a day, and after 5 days - several times, if it is not hot outside.

- In hot and windy weather, the intervals between watering should be at least 1.5-2 hours, and in a cloudy period - with a frequency of 3 hours.

- Slag or pozzolanic Portland cement, you need to moisten it 5-7 times a day for 2-3 weeks.

- Alumina cement requires moisture for 7 days.

Less water evaporates from the concrete in the formwork. After its removal, the stripped surface of the foundation also needs watering.

Grasping

The period lasts several hours after the preparation of the solution. At this stage, you need to have time to complete the following processes:

- Transportation of the solution to the work site. It is especially important when ordering prefabricated concrete, since the place of production can be located at a sufficient distance from the site where the foundation needs to be poured. The issue is solved by using special equipment - concrete mixers. Constant stirring increases the life of the mortar.

- Laying the concrete mixture into the mold.

- Sealing (vibration or bayonet) and alignment.

The setting period depends on the ambient temperature, so it is so important to decide when it is best to pour the foundation for the house. To choose the right time, it is recommended to refer to the following table.

| Ambient air temperature (average daily value is indicated), ᵒС | The period during which the setting occurs (on average), the beginning and end of the process are indicated in hours |

| 30 | 1-2 |

| 20 | 2-3 |

| 6-20 |

Hardening

Hardening begins immediately after setting. This is the name of the process of crystallization of a concrete solution and its transformation into an artificial stone. Knowing the hardening time is necessary in order to understand when it is better to start removing the formwork from the foundation of the house and engage in further construction processes. An important task for builders is to reduce the duration of work without compromising quality. This can be done only by studying the regulatory documentation.

The most important characteristic of the concrete mix is the brand strength. Due to the introduction of a new designation for this value, confusion in the labeling is possible. It all depends on what GOST the plant is based on. If the marking is carried out in accordance with GOST 26633-2012, then we are talking about concrete strength classes, which are indicated by the letter B, for example B20. The figure is the brand strength in MPa. When using markings in accordance with GOST 26633-91 * (an outdated document that is still used by some specialists), strength is denoted by a brand, for example M300, where 300 is a value in kgf / m².

It is possible to remove the formwork from the foundation of the house and start erecting the walls only when the concrete has gained at least 70% of the brand strength. This requirement is given in the joint venture "Bearing and Fencing Structures". It is better to observe precisely these conditions, but if there are justifications, it is possible to do stripping with a strength gain of more than 50%.

Most often, when it is necessary to fill the foundation for a private house, concrete of classes B15-B22.5 is used (which corresponds to the M200-M300 brands) mixed with normally hardening Portland cement of the CEM32.5 or CEM 42.5 brands (according to the old marking PC400 or PC500). It is for such a solution that the table below is shown, which shows the dependence of the speed of hardening on the temperature conditions of the environment.

| Time interval from the beginning of hardening, days | Percentage of brand strength at average daily air temperature | ||

| 5ᵒC | 10ᵒC | 20ᵒC | |

| 1 | 12% | 21% | 34% |

| 3 | 23% | 38% | 60% |

| 7 | 31% | 51% | 78% |

| 14 | 37% | 60% | 90% |

| 28 | 43% | 70% | 100% |

For a fast-hardening and slow-hardening mixture, the values will differ greatly during the first week, and after that they will become approximately equal to the percentage for a normally hardening binder.

Features of care for a dry floor screed

A dry floor screed is equipped without the use of liquid, therefore, the care of such a coating is fundamentally different from the options described above. The material used for dry leveling the floor surface is as follows:

- expanded clay or fine fraction slag;

- vapor barrier coating;

- damper tape;

- solid, board material - OSB, GVL or plywood.

Deep penetration impregnation

In order for the top layer of the coating to serve for a long time, the seams between the plates are putty with a gypsum composition, and the surface itself is covered with two layers of primer.

Eliminate moisture

The first thing the owner of the room where the dry floor screed is made to know is to prevent a large amount of water from getting on the floor covering. Otherwise, the material will swell and warp the finish layer.

Do not place heavy structures

The peculiarity of a dry screed is that if you install heavy objects or partitions with a large specific weight on the floor surface, then it can bend. In order for the coating, equipped with a "dry" method, to serve for a long time and preserve the horizon, it is better to exclude the installation of bulky and heavy objects.

How to water concrete products

To moisturize the structure, it is recommended:

use a hose with a spray;

pay more attention to nodes and edges (in such places, water evaporates faster, for this reason cracks or chips may occur);

to prevent evaporation from the surface of a large area, cover it with a film;

distribute water evenly;

irrigate, in addition to the top layer, the base.

In the first 2 weeks, the surface should be constantly wet, water should be regularly watered, not allowing moisture to evaporate completely. If the surface is not moistened, premature dehydration occurs and the brittleness of the material increases.

Factors affecting the rate of drying of the poured foundation

In order for the foundation to turn out to be of high quality and reliable, it is necessary not only to follow all the rules for concreting, but also to give it enough drying time... How long it will freeze is impossible to say for sure. Indeed, this process is simultaneously influenced by several factors:

- air humidity level;

- the presence of precipitation;

- the type of soil on which the foundation was built;

- air temperature;

- features of the terrain;

- proximity to the base of the water table;

- the quality of the material used during the pouring of the foundation;

- technologies used in construction;

- type of formwork;

- type of waterproofing used.

Builders have to work hard to get the perfect foundation for their future home. But, as practice shows, even compliance with the recommended conditions is not a guarantee of obtaining the desired result. Therefore, unfavorable conditions should be taken into account in advance, which can extend the time during which the foundation must be defended.

Builders have to work hard to get the perfect foundation for their future home. But, as practice shows, even compliance with the recommended conditions is not a guarantee of obtaining the desired result. Therefore, unfavorable conditions should be taken into account in advance, which can extend the time during which the foundation must be defended.

It is advisable to carry out work related to pouring the foundation and laying the walls at an air temperature of at least 5 degrees Celsius. Otherwise, you will have to take additional care of the insulation of the structure, which will also increase the period of solidification of the base of the house after the foundation is poured.