Quality control of work

| Parameter | Parameter value, cm | Control (method, volume, type of registration) |

| Deviation of the actual dimensions and position of on-site (and prefabricated) foundations and grillages from the design ones, see: | ±5 (±2) | Acceptance (measurements with theodolite, tape and ruler) |

| dimensions in plan | +2; -0,5 | Also |

| protective layer thickness | (+1; -0,5) | Also |

| the position of the height of the top (cut) of the foundation or grillage | ±2 (±1) | Also |

| horizontal positions relative to center lines | 2,5 (1) | Also |

| NOTE The values given in brackets in the table refer to prefabricated foundations and grillages. |

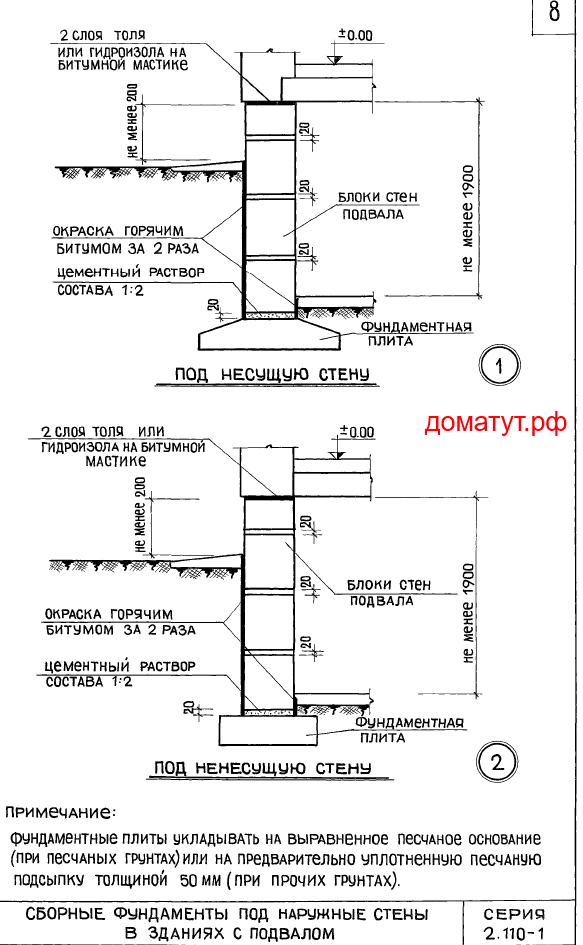

Download series 2.110-1 "Details of foundations of residential buildings" issue 1Download series 2.110-1 "Details of foundations of residential buildings" issue 4

Advantages and disadvantages of FBS blocks

The foundation blocks are brought to the construction site in a completely ready-to-work form. Of them, you just need to lay out the masonry. It is not required to wait for the concrete to set and gain strength. In terms of the speed of construction, such a foundation for a private house can only be given a head start on piles. It is generally difficult to compete with this option.

The choice for the FBS device is often due to the minimization of time costs. Plus, its construction can be done even in winter. However, this has to be paid for by the need to attract lifting equipment. It is impossible to manually lay the products into the foundation, they are too heavy. As a result, this option is 15–25% more expensive than the analogue in the form of a monolithic tape.

A crane is required for lifting

The main thing is that when compared with a monolith, the block type of foundations for buildings loses somewhat in terms of bearing capacity. And if it can easily withstand high vertical loads, then there are serious problems with horizontal ones. With strong heaving, the block can simply be squeezed out of the support structure.

How to make a foundation from FBS blocks

And also when it is planned to build a panel house.

The columnar foundation is also well suited for wooden houses.

Basically, they resort to the strip foundation when erecting light, low-rise buildings; this solution is also ideal for building a country house made of wood. You should not use FBS blocks as a material for a strip foundation if there are heavy loads on it.

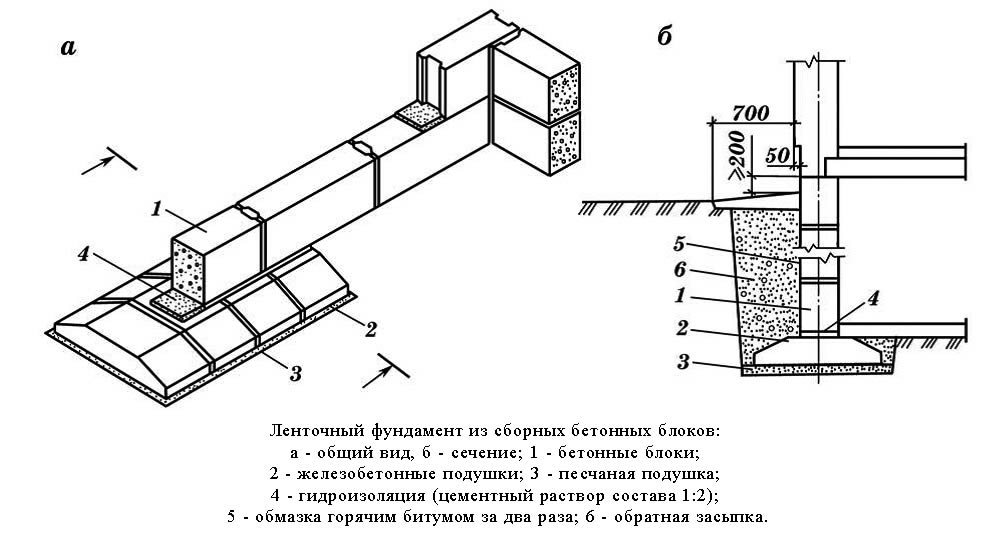

Before erecting a strip foundation, it is imperative to make a filter cushion, it is made of two layers - sand (5 centimeters thick) and crushed stone (10 centimeters). After laying these layers, they are carefully tamped, spilled with water and tamped again.

It is best to use pillow blocks on the lowest row of the foundation, if this is not possible, then for the first row the products are placed on their side. Work on the beginning of the construction of the foundation begins from the place where the walls and corners intersect. Then the correctness of the first row of the horizon is checked without fail.

When working with a columnar foundation, it is also necessary to create a pre-filter cushion. For its manufacture, crushed stone is first laid with a layer of 15 centimeters, and then white gravel with a layer of 10 centimeters.

It is also necessary to achieve the maximum density of the pillows in order to avoid distortions of the blocks installed on it. If such a bias occurs, it is rather difficult to correct it in the future.

Installation of FBS

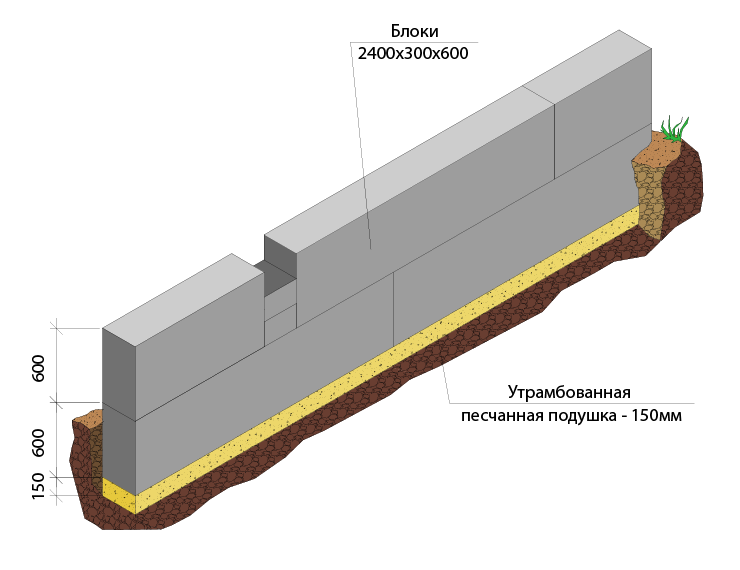

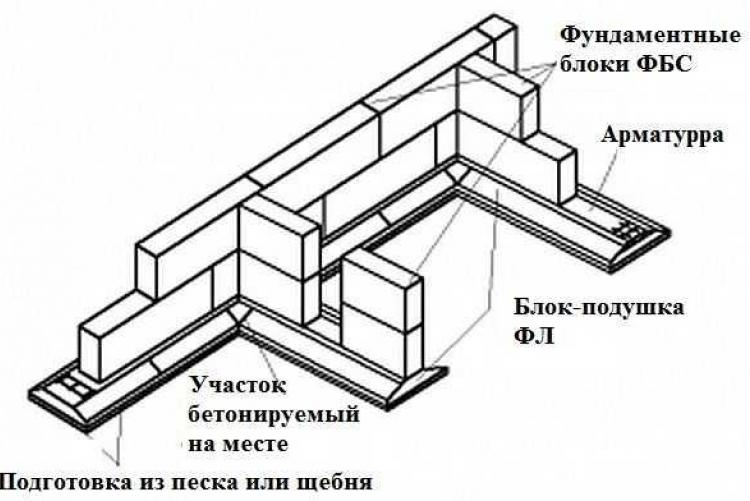

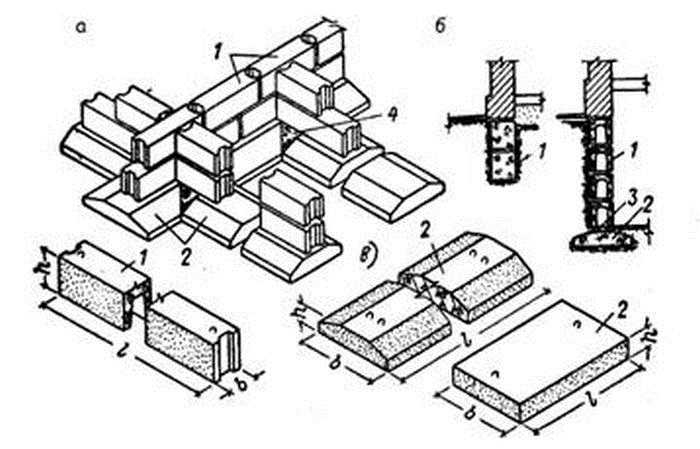

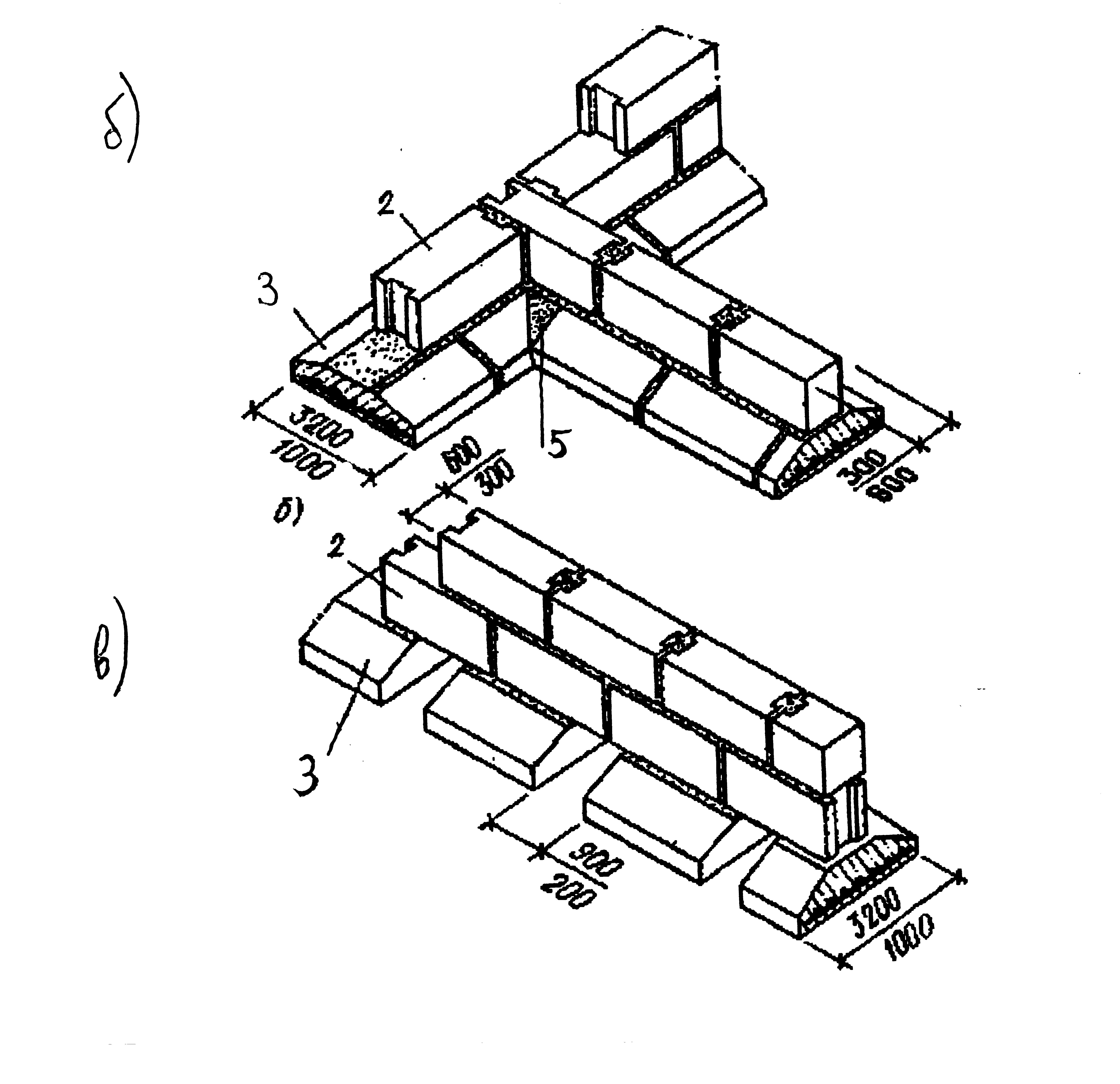

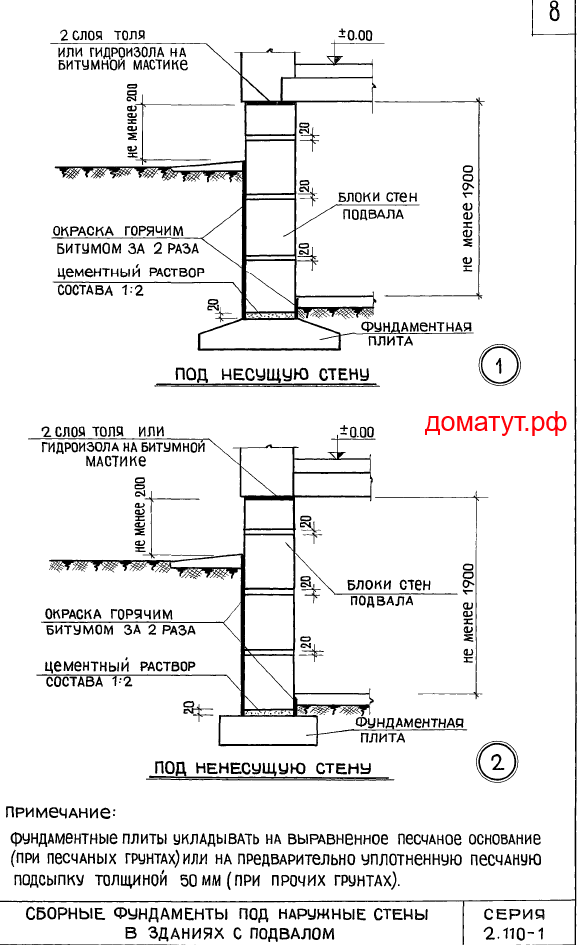

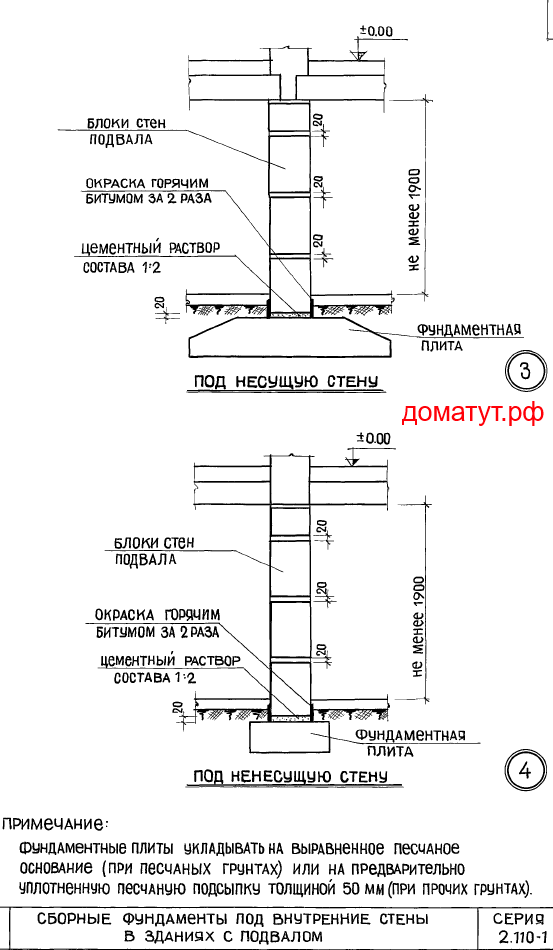

1. Laying of foundation blocks on a frozen base covered with ice, snow or water is prohibited. 2. The foundation blocks are laid on a carefully leveled sand base or sand-cement pad with a thickness of at least 5 cm (on clay base soils).The deviation of the leveling sand layer from the design level should not exceed -15 mm. 3. The installation of the blocks begins with the installation of lighthouse blocks in the corners of the building and at the intersection of the axes. The lighthouse blocks are installed, combining their axial risks with the risks of the alignment axes, in two mutually perpendicular directions. The installation of ordinary blocks should be started after verifying the position of the lighthouse blocks in plan and in height. 4. The foundation blocks are laid on cement mortar not lower than M-50. The horizontal and vertical seams between the blocks are filled with mortar to the entire thickness of the wall and the height of the seam. The thickness of the seams is no more than 20mm.

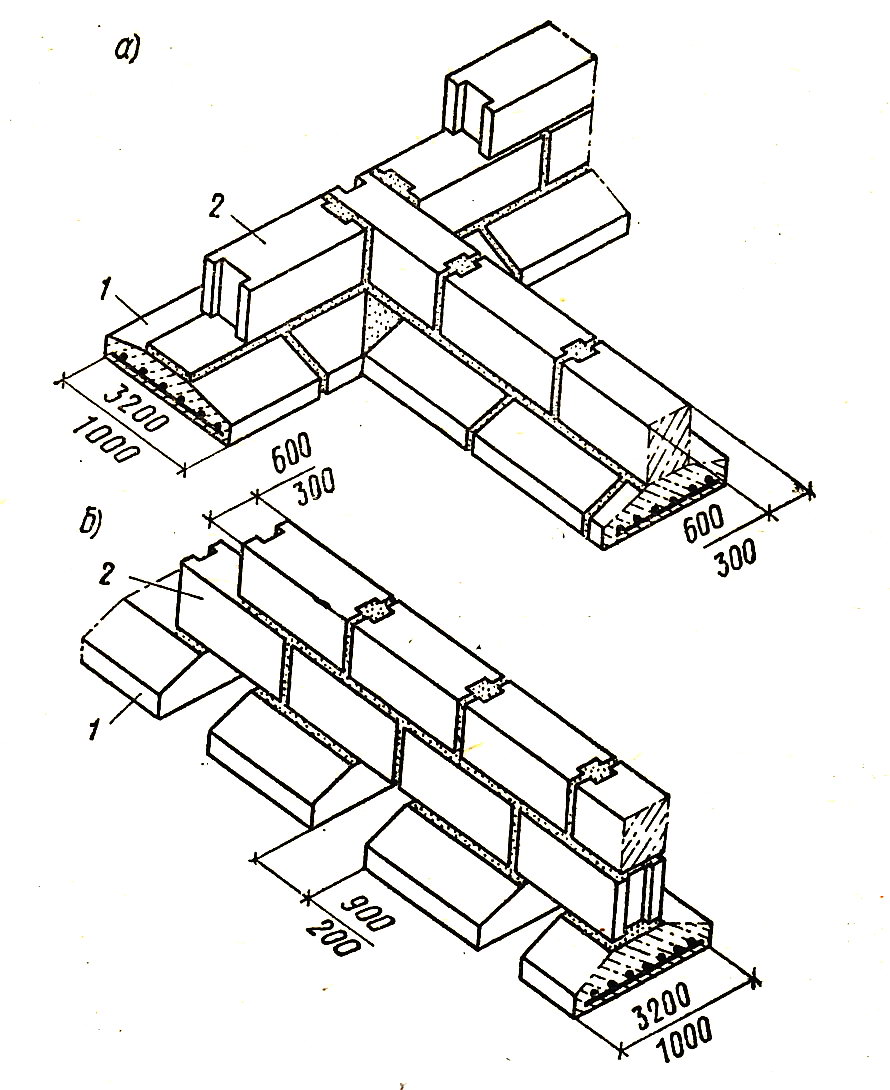

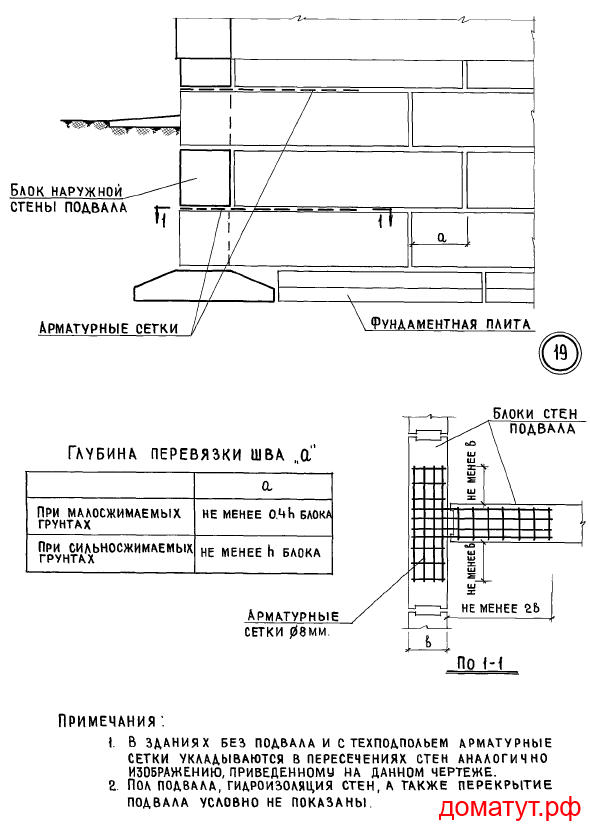

5. The installation of the basement wall blocks should be carried out in compliance with the dressing (series 2.110-1 "Details of the foundations of residential buildings" issue 1 part 19). For individual residential buildings with a height of up to three floors, the required block size is at least 240 mm. To determine the required number of FBS blocks, you need to make a scan of each wall on which to draw blocks, taking into account their size and compliance with the dressing. An example of an FBS layout drawing.

5. The installation of the basement wall blocks should be carried out in compliance with the dressing (series 2.110-1 "Details of the foundations of residential buildings" issue 1 part 19). For individual residential buildings with a height of up to three floors, the required block size is at least 240 mm. To determine the required number of FBS blocks, you need to make a scan of each wall on which to draw blocks, taking into account their size and compliance with the dressing. An example of an FBS layout drawing.  6. To increase the strength of the structure, reinforcing meshes must be laid at the intersections of the walls.

6. To increase the strength of the structure, reinforcing meshes must be laid at the intersections of the walls.  If the doorway in the basement is adjacent to one of the walls, the length of the reinforcing mesh is determined from the figure below (series 2.110-1 "Details of the foundations of residential buildings" issue 1 part 20). Reinforcement mesh layouts Reinforcement mesh sizes for manufacturing

If the doorway in the basement is adjacent to one of the walls, the length of the reinforcing mesh is determined from the figure below (series 2.110-1 "Details of the foundations of residential buildings" issue 1 part 20). Reinforcement mesh layouts Reinforcement mesh sizes for manufacturing  Metal specification for mesh

Metal specification for mesh  7. Ordinary blocks should be installed, orienting the bottom along the cut of the blocks of the lower row, the top - along the center line. Exterior wall blocks installed below ground level must be aligned to the inside of the wall, and above to the outside. Vertical and horizontal joints between blocks should be filled with mortar and sewn on both sides. 8. Monolithic sections in wall blocks in contact with the ground (below the surface of the earth) should be made of B 7.5 concrete or KORPo 1NF / 100 / 2.0 / 35 / GOST 530-2007 bricks, followed by plastering outside with cement mortar of grade 50 and hot coating bitumen for 2 times. nine.

7. Ordinary blocks should be installed, orienting the bottom along the cut of the blocks of the lower row, the top - along the center line. Exterior wall blocks installed below ground level must be aligned to the inside of the wall, and above to the outside. Vertical and horizontal joints between blocks should be filled with mortar and sewn on both sides. 8. Monolithic sections in wall blocks in contact with the ground (below the surface of the earth) should be made of B 7.5 concrete or KORPo 1NF / 100 / 2.0 / 35 / GOST 530-2007 bricks, followed by plastering outside with cement mortar of grade 50 and hot coating bitumen for 2 times. nine.

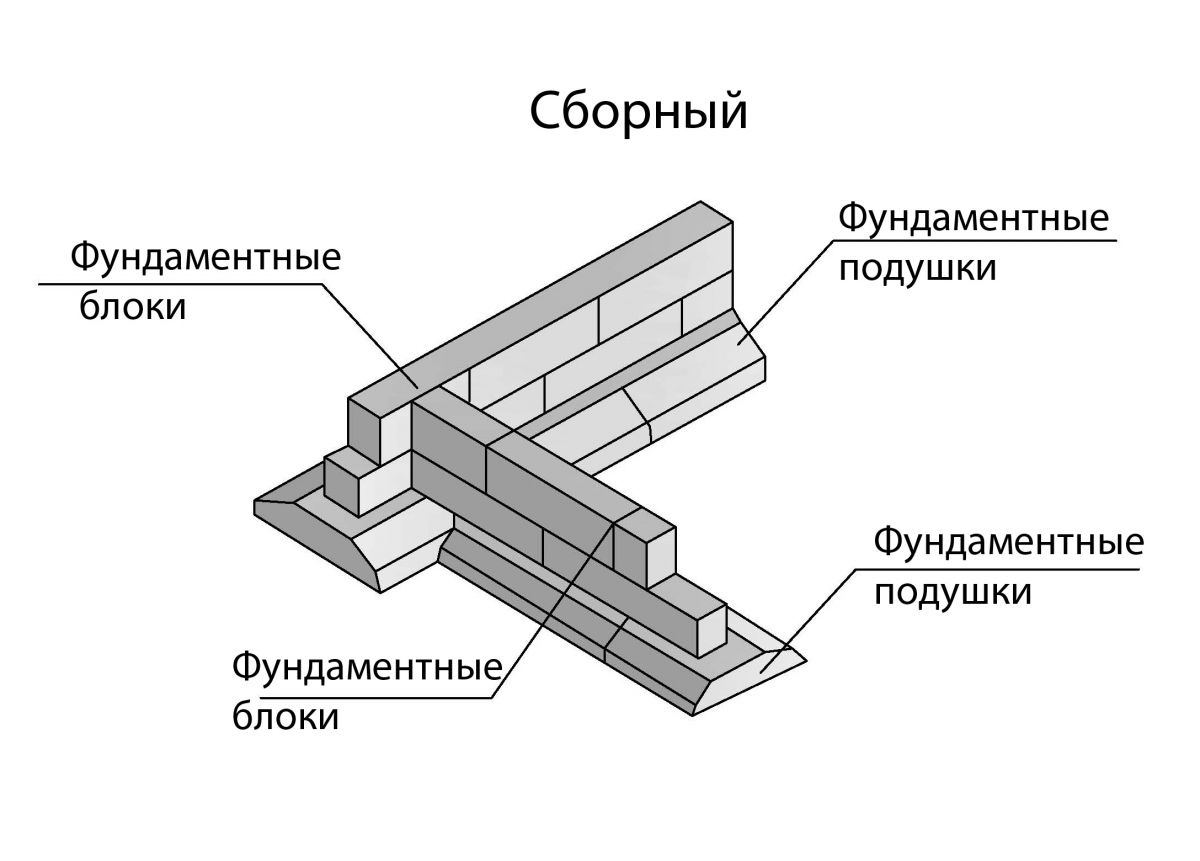

What are FBS blocks

FBS is a solid foundation block - an inexpensive and reliable material designed for the construction of walls and foundations of buildings. Such structures are manufactured in the factory from reinforced concrete, which allows them to perfectly withstand the highest loads.

All FBS have the shape of a parallelepiped, and in the end parts they have small shapes, which are filled with concrete during installation for better connection with each other. The FBS base is often used in buildings with a basement, since pouring the basement walls from monolithic concrete would require the involvement of skilled workers, the construction of formwork, and spending money on the purchase of concrete. On the contrary, for the installation of a prefabricated foundation, it is required to involve a crane or a loader and a pair of workers who, according to the scheme, will lay out the blocks. Often this work only takes one day.

The cost of FBS ranges from 1,000 rubles to 10,000, depending on the grade of concrete, the size and type of blocks, the method of their manufacture and the manufacturing company itself.

The dimensions of the FBS structures for the foundation are standardized. This approach allows you to make a set of blocks for the necessary layout of the foundation without the need for trimming (which is a very time-consuming procedure).

The assortment of the most popular FBS blocks is presented in the table:

In addition, there are two additional types of FBS:

- FBV - blocks with cavities for jumpers and communications;

- FBP - blocks with cavities, empty at the bottom.

An online calculator can be used to compare the cost of a foundation made of blocks and monolithic tape.

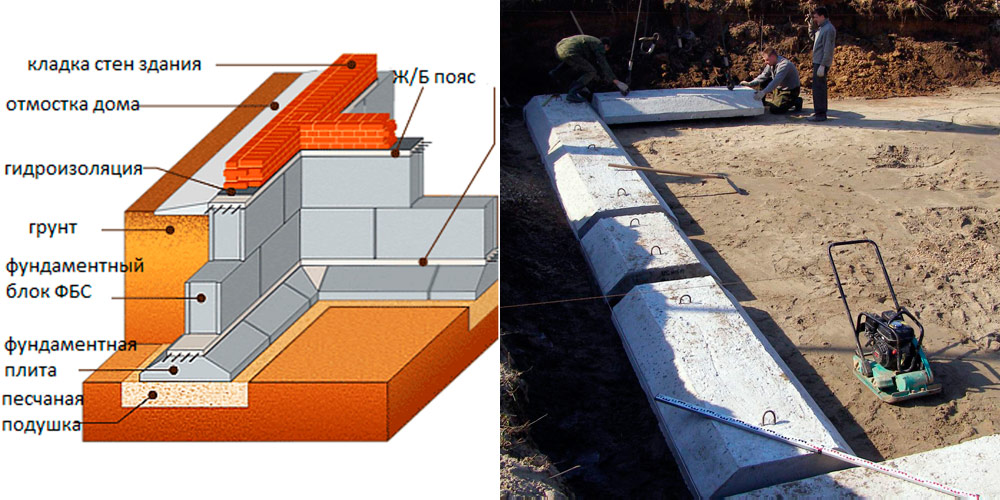

Preparatory work for the construction of the foundation

A foundation mounted from FBS is the same strip foundation as a cast-in-place monolithic foundation, only from prefabricated elements and therefore fits faster, without waiting for the solution to harden. The preparation procedure will be much the same. For the convenience of tracing the order of work, the numbering of the order of work is preserved in the next section.

The first is the transfer of the foundation contour to the terrain, that is, a breakdown. Surveyors do this, adjusting the dimensions, observing the rectangularity of the contours. If you are doing this yourself, the alignment should be very careful.

The second point will be work on excavation in a trench to the width of the foundation cushion, with a margin for maneuverability during installation or in a foundation pit when constructing a building with a basement.

The third point is the obligatory backfilling of the leveling layer (usually a sand-gravel mixture, sometimes with crushed stone), careful compaction and alignment of the coincidence of elevation marks along the entire perimeter.

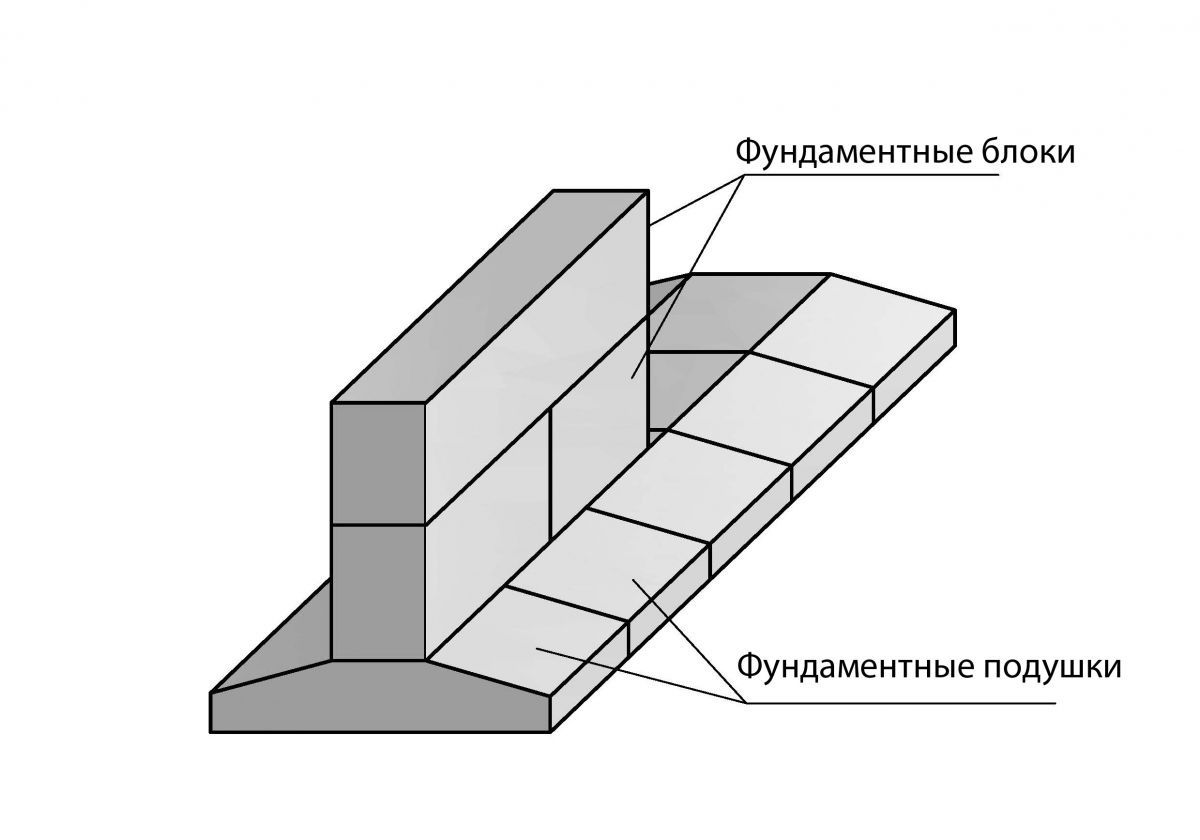

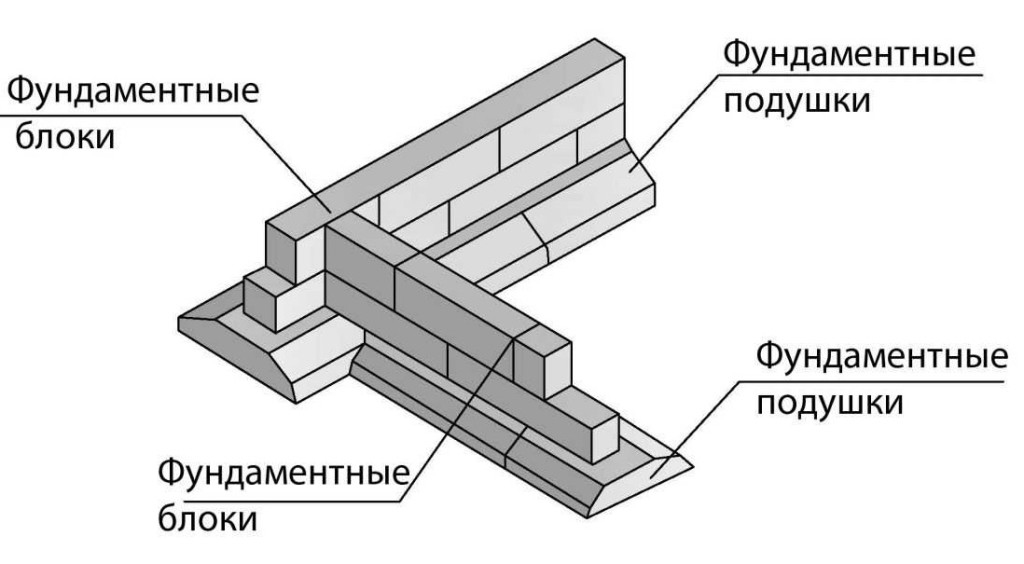

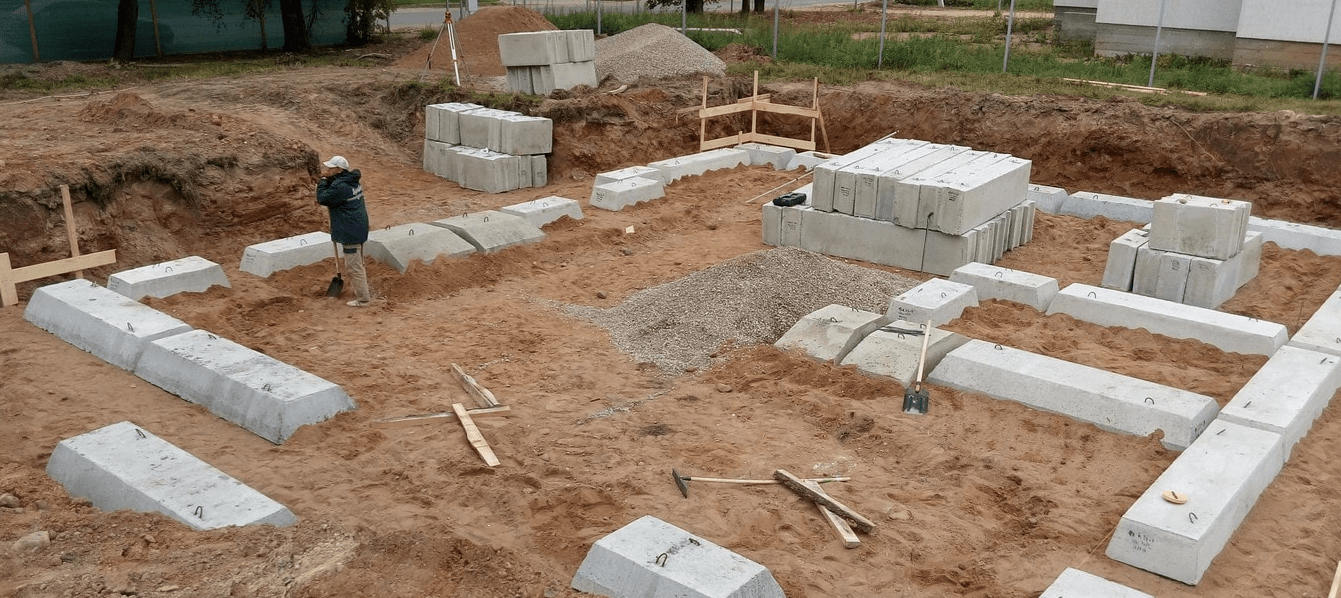

Installation of foundations from FBS

The fourth point is the laying of ready-made elements of foundation cushions or, in the construction of low-rise private houses, monolithic reinforced concrete pouring. What is it for? For the foundation of FBS blocks for small buildings, you can use narrow blocks equal in width to the wall. The soil load under the narrow block will be large and, if adverse factors coincide, can cause sedimentation. In order to increase the support area and distribute the load over a large area of the soil, foundation pillows are laid, marked with FL. For multi-storey buildings, an extended lower part of the foundation is mandatory. After laying, it is again necessary to check that the upper surface is horizontal.

Further, the foundation blocks are stacked like masonry, with a horizontal offset of 0.4 of their height starting from the corner blocks. Adjustment in the middle of the foundation strip is carried out using short length expansion blocks. At small distances between the blocks, inserts from brickwork on cement mortar are allowed, but only if their location does not coincide with the vertical joints of the mates of the lower or upper row of blocks. Recesses in the side faces of the blocks are poured with concrete mortar.

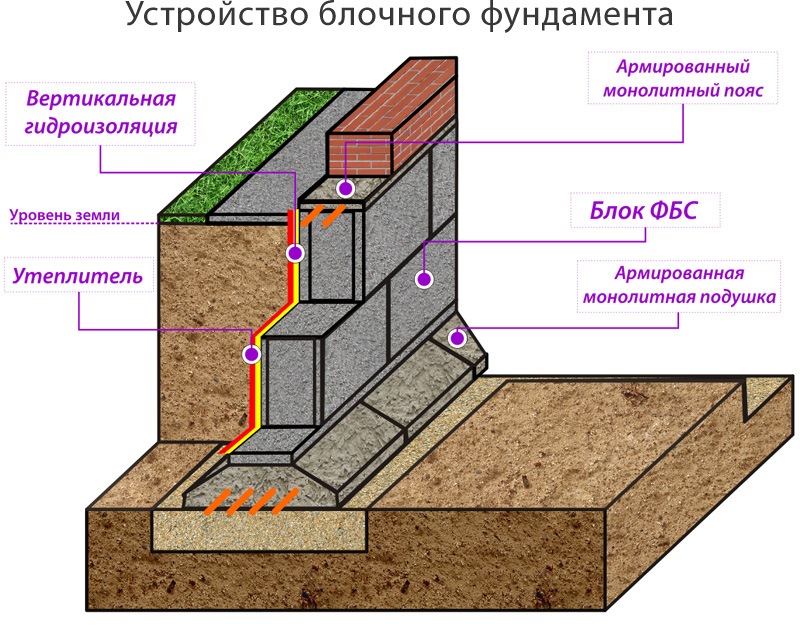

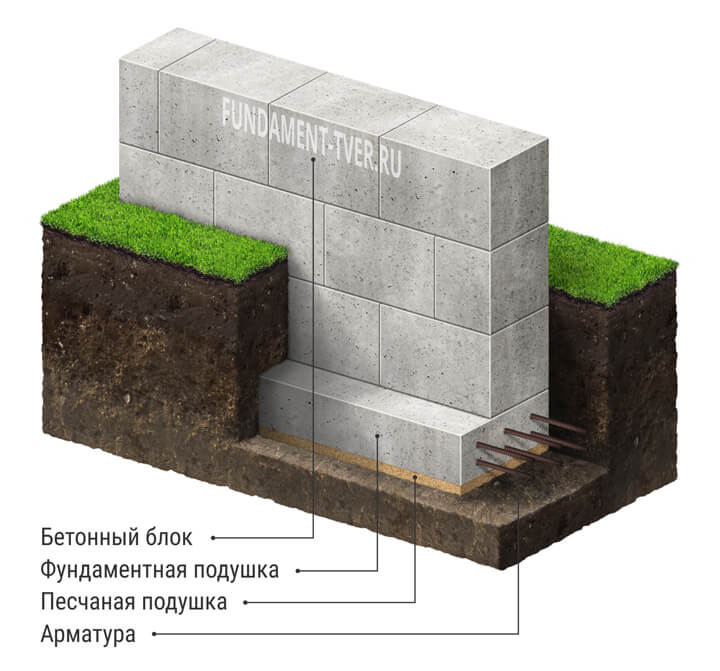

At any depth of the foundation and the depth of groundwater, waterproofing of the walls is required, which is carried out immediately after the installation of the FBS. Otherwise, when high water approaches after rain or melting snow, they can seep through the seams between the blocks. Work is being completed on the construction of a strip foundation made of FBS by backfilling a trench with mandatory layer-by-layer compaction. Usually a sand and gravel mixture is used for this.

Step-by-step instructions for creating a strip block foundation

- At the first stage, a pit is dug to the depth of soil freezing. The size of the trench for the foundation of the FBS should be larger than itself in width for the convenience of laying blocks, and the depth of the pit should not hide the supporting structure. Even before starting work, it is necessary to determine the parking place of the crane - it is necessary that the boom has enough reach to any point of the support structure.

- In the second step, the sole is created. A prerequisite for building a foundation for a FBS house from blocks is a tape - a pillow filled with concrete. In rare cases, a masonry mesh is used to create a pillow so that there are no gaps between the blocks. To make a sole, you need materials such as sand, crushed stone and reinforcement. The marking in the trench is made exactly according to the level, the bottom is covered with sand and rammed. Then it is backfilled with gravel and this layer is also rammed. Then you need to impose reinforcement and install the formwork.

- At the third stage, the formwork is assembled. When assembling the formwork, a 25 mm board is used.This structure must be assembled as evenly as possible, for which it is necessary to mark the depth using a water level, and then, according to the marks, you need to pull the cord inside the formwork and trim it along the cord. At the end of the casting of the frame from the reinforcement, it is left for two weeks to shrink. To assemble the formwork, you need rods of 60 cm and 4 meters each, plus you will need a knitting wire of about 10 kg. The reinforced belt has standard dimensions (width 30 cm, thickness 20 cm).

- At the fourth stage, the pillow is poured. A faster and more reliable way would be to use a mixer. The pillow is filled with a mixture of concrete 10-15 cm. Then the structure is covered with burlap or plastic wrap and dries for a week under the condition of a 20-degree air mode and 90% humidity. After drying, the pillow is waterproofed, this is done with roofing material or other similar material. In this case, an overlap is made on the walls on the outside and is joined with the waterproofing material of the walls. A concrete screed is made on a layer of roofing material, which in the future will be the basement floor. The remaining space of the trench is filled with soil and rammed. Sometimes pillows are made prefabricated, but they are not suitable for all types of soil, but monolithic structures are considered to be universal.

- At the fifth stage, the blocks are assembled. For faster assembly of blocks, you need to use a crane, because the material is heavy. In the event that the size of the blocks is small, then the installation can be done using the old method. The installation of the FBS foundation blocks is carried out simultaneously with the bandaging of the vertical seams. The blocks are laid on the grout and the vertical joints are filled. Communication sleeves are installed between the blocks at the locations indicated in the drawing.

- At the sixth stage, one more waterproofing is done and the remaining trench space is filled up. This time the waterproofing is done with bitumen grease. More thoroughly it is necessary to cover with grease those places that are in contact with the ground; this must be done to the entire depth of the pit from the outside of the foundation. In cases where the house is made of beams, an additional reinforced belt is made. The device of a block foundation for a house is not an easy process, but it is very reliable, therefore it is worth the effort and money spent.

Installation of foundation blocks.

Installation of foundation blocks.

What are (sizes)

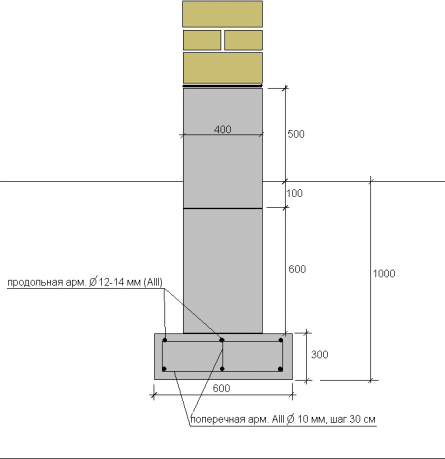

As the name suggests, the main purpose of the FBS is to make the base and walls of the house. Regulates the size of FBS blocks GOST 13579-78. According to this regulatory document, the dimensions of the foundation blocks can be:

- height h - 0.3, 0.6 mm;

- width B - 0.3, 0.4, 0.5 and 0.6 m;

- length L - 0.6, 0.8, 0.9, 1.2 and 2.4 meters.

Fbs block, photo

| Brand | Dimensions, mm | Weight, t | Concrete class | Consumption of materials | |||

|---|---|---|---|---|---|---|---|

| L | B | H | Concrete, m3 | Steel, kg | |||

| FBS24.3.6 | 2380 | 300 | 580 | 0.97 | B7.5 | 0.406 | 1.46 |

| FBS24.4.6 | 2380 | 400 | 480 | 1.3 | B7.5 | 0.543 | 1.46 |

| FBS24.5.6 | 2380 | 500 | 580 | 1.63 | B7.5 | 0.679 | 2.36 |

| FBS24.6.6 | 2380 | 600 | 580 | 1.96 | B7.5 | 0.815 | 2.36 |

| FBS12.2.6 | 1180 | 200 | 580 | 0.32 | B7.5 | 0.133 | 0.76 |

| FBS12.3.6 | 1180 | 300 | 580 | 0.485 | B7.5 | 0.203 | 0.76 |

| FBS12.4.6 | 1180 | 400 | 580 | 0.64 | B7.5 | 0.265 | 1.46 |

| FBS12.5.6 | 1180 | 500 | 580 | 0.79 | B7.5 | 0.331 | 1.46 |

| FBS12.6.6 | 1180 | 600 | 580 | 0.96 | B7.5 | 0.398 | 1.46 |

| FBS12.2.3 | 1180 | 200 | 280 | 0.16 | B7.5 | 0.066 | 0.38 |

| FBS12.3.3 | 1180 | 300 | 280 | 0.24 | B7.5 | 0.1 | 0.38 |

| FBS12.4.3 | 1180 | 400 | 280 | 0.31 | B7.5 | 0.127 | 0.74 |

| FBS12.5.3 | 1180 | 500 | 280 | 0.38 | B7.5 | 0.159 | 0.74 |

| FBS12.6.3 | 1180 | 600 | 280 | 0.46 | B7.5 | 0.191 | 0.74 |

| FBS9.2.6 | 880 | 200 | 580 | 0.235 | 0.36 | ||

| FBS9.3.6 | 880 | 300 | 580 | 0.35 | B7.5 | 0.146 | 0.76 |

| FBS9.4.6 | 880 | 400 | 580 | 0.47 | B7.5 | 0.195 | 0.76 |

| FBS9.5.6 | 880 | 500 | 580 | 0.59 | B7.5 | 0.244 | 0.76 |

| FBS9.6.6 | 880 | 600 | 580 | 0.7 | B7.5 | 0.293 | 1.46 |

Tip: if during the purchase it was found that the dimensions of the fbs block differ from those presented above, then you should think about it before buying such material. It is probably handcrafted and suspicious of its quality.

Slab foundation for aerated concrete building

This solution for difficult ground conditions is becoming more and more popular among developers. Its effectiveness has been proven by the experience of foreign construction, for example, on extremely weak and extremely wet soils in Holland. Similar conditions are found in the North-West of Russia and in some other regions.

Filling the slab foundation.

The base for the walls looks like a reinforced concrete slab with a height of 20 to 40 millimeters reinforced in two layers. It can be poured at the surface level or be buried to the depth of freezing or below, which makes it possible to arrange a basement in the building. The resulting bending loads are redistributed in the slab mass due to the joint work on tension of reinforcement and concrete in compression. This provides the necessary rigidity and invariability of the geometric characteristics of the slab surface, on which all building structures are erected.

Slab foundation with not disassembled formwork.

When installing a slab foundation at the level of the design elevation of the relief, natural soil is replaced under it with carefully compacted bulk material with high bearing capacity. The bottom of the sample may be higher than the standard freezing depth in the region.

Advantages of FBS-block foundations

The popularity of FBS blocks among builders is understandable, since this building material has a number of advantages. In particular, they include the following criteria:

- frost resistance

- large selection of sizes and models

- acceptable cost

- resistance of blocks to the effects of various aggressive media

In the manufacture of blocks, manufacturers take into account the possible requirements that will be imposed on them during the construction of the foundation. It is for this reason that various additives are added to concrete in the course of work, which make the products more resistant to various kinds of external influences (low temperatures, humidity, etc.).

Thanks to this, with the help of blocks, it is possible to erect a foundation even in those areas where there are severe climatic conditions, up to large daily temperature drops.

Very often, FBS blocks are made for specific technical conditions, so they come in various configurations, sizes, and production composition. As a result, everyone has the opportunity to choose the material for the foundation, taking into account their own needs.

When using FBS blocks in construction, the work does not take much time, and it is also easier to perform it.

It is also worth paying attention to the low susceptibility of blocks to the effects of aggressive media, therefore they are often used during construction work on soils with high acidity. Soil with similar characteristics is found in many regions.

Disadvantages of the FBS foundation

A prefabricated foundation made of large-format products cannot be reinforced using traditional methods. Meshes, reinforcing bars bend even under the weight of the FBS themselves. Therefore, a lower belt of reinforced slabs (FL or shallow strip foundation), an upper reinforced concrete belt are used, which serve to stabilize the geometry of the spatial structure of blocks.

The main disadvantages of the precast foundation technology are given below.

Construction budget

The foundation is expensive due to the costs of the owner of the site, who chose this technology, of the following type:

- rental of special equipment - products must be delivered to a building spot by truck; if you can unload them with a manipulator from your own side, then for installation you will need a full-fledged truck crane with a normal lifting capacity with a maximum boom outreach;

- services of specialists - before installation, it is necessary to level the pit, compact several layers of sand, crushed stone of the pillow with a vibrating plate, fill in the foundation, then lay out the foundation slabs, fill the voids with concrete, install blocks, at the last stage it will be necessary to glue the walls of the tape with waterproofing.

In addition, it may be required to manufacture an armored belt on the top of the FBS blocks. The work will take a few more days.

If FBS are included in the project initially, the designers bind the dimensions of the walls and the layout of the building to the standard block sizes. In this case, they will not have to be pricked in a building spot using folk methods. In practice, such projects for individual developers are rare; nevertheless, it is necessary to form several pieces from the whole FBS.

Complex technology

In 90% of cases, an individual developer chooses blocks due to the manufacturability of construction. He has no experience, specialized education and does not suspect that additional costs will begin during the construction:

- it will not be possible to avoid concreting, it is necessary to make a foundation;

- you will have to buy roll waterproofing for the basement sole;

- knead the solution in solid volumes (about one and a half buckets for laying each block + a mixture for filling vertical seams);

- it is necessary to lay part of the voids between the FBS with bricks, and without them it is impossible to enter communications into the building and provide ventilation ducts;

- for the maximum resource, an armored belt is required (formwork boards + concrete + reinforcement).

The lack of reinforcement inside the FBS is regarded by specialists in two ways. On the one hand, it is convenient to break them when filling individual sections of the tape. On the other hand, they do not always break off along the line, they have uneven edges. Until now, there is no normal technology for cutting massive products from heavy concrete.

Thus, for individual developers, FBS blocks are not the best option. The estimate is increasing, the prefabricated belt is less stable by default than the monolithic structure. Therefore, blocks are more often used in industrial and civil construction. However, in the construction of baths, cottages from log cabins, SIP panels, using frame, half-timbered technology on a shallow strip foundation (MZLF), one layer of blocks without pillows is much more profitable than a monolithic structure.

We recommend: How to make a foundation from FBS blocks.

Good publicity