We prepare cabbage for the winter in pieces in brine

3. Then put the resulting vegetable mixture tightly in a three-liter jar. There is also such a nuance that it is not necessary to tamp too much. Leave room for the brine filling. Now place the jar in a tall bowl.

4. Mix thoroughly all the components of the brine until the salt and sugar are completely dissolved. Now pour the jar all the way to cover the vegetables. Cover with a napkin and leave in a dark place for three days.

Use a wooden stick, or a Chinese one, to pierce the cabbage in several places so that excess air comes out. This should be done in the morning and evening for three days of fermentation.

After three days, delicious sauerkraut in a jar is ready! You can take a little of this cabbage, season with vegetable oil, chopped herbs or finely chopped onions. This is a delicious snack. And tightly close the rest of the contents of the jar with a plastic lid and put it in the cellar or refrigerator.

My aunt loves to cook this recipe. The appetizer turns out to be appetizing, crispy and juicy - you will lick your fingers!

Ingredients:

- Cabbage

- Carrot

- Garlic - 4-5 cloves

- Water - 1 liter

- Acetic acid 70% - 1 tablespoon

- Salt - 1 tablespoon

- Sugar - 8 tablespoons

Cut the cabbage into large pieces and place them tightly in the jar.

Grate the carrots and sprinkle some of the vegetable on the cabbage layer.

Squeeze a clove of garlic onto each layer.

Pour the boiling marinade over the jar.

Let the cabbage stand for 24 hours without a lid. When it has completely cooled down, close it the next day with a nylon lid and refrigerate.

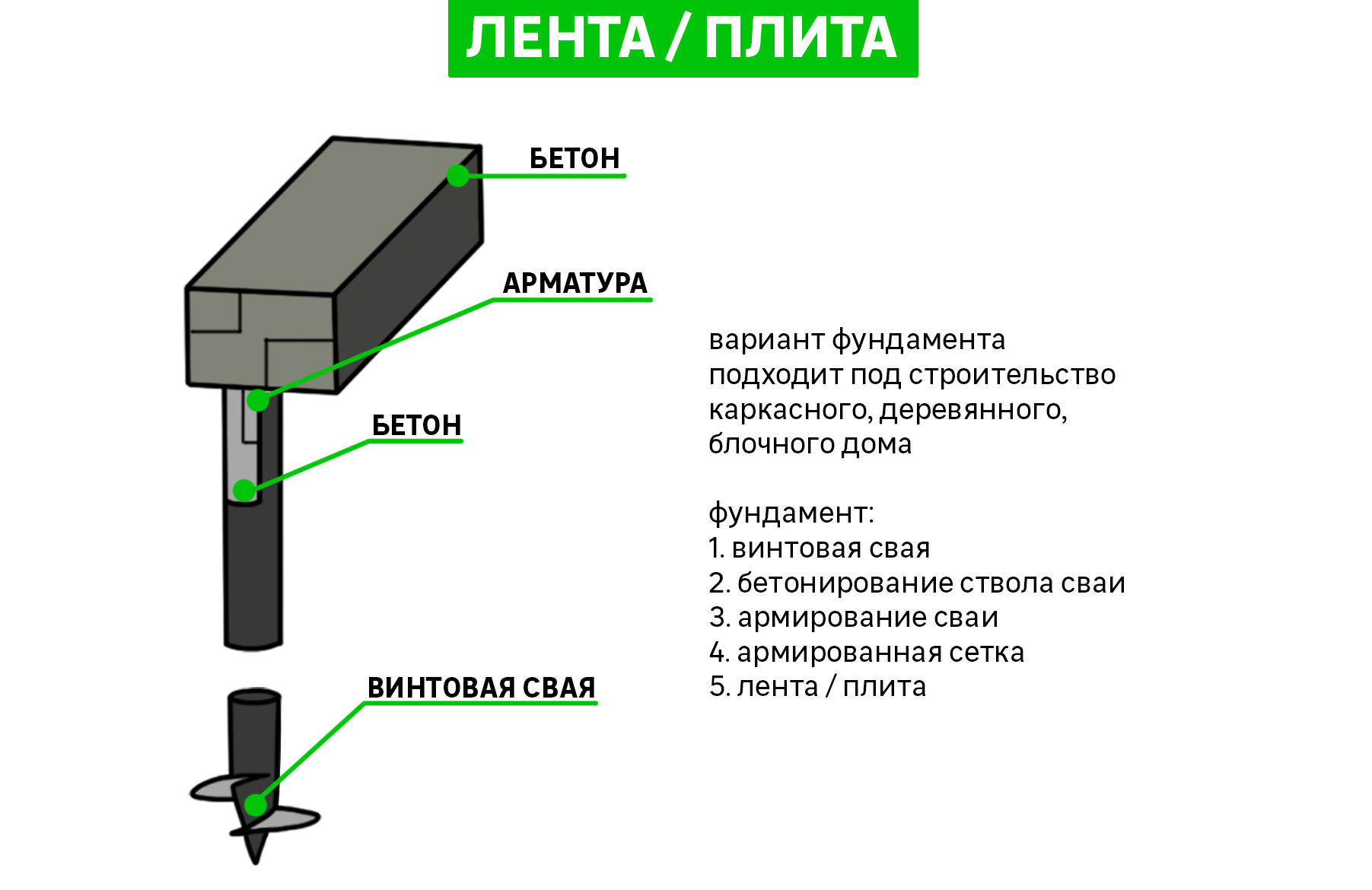

Preparation for manufacturing

At the preparatory stage, it is necessary to find out the dimensions of the future structure, the load on the foundation of the higher structures and the bearing capacity of the soil. Before erecting a frame house, you can independently carry out a soil study. To do this, you need to drill several holes in the area. The depth of the well is below 50 cm of the basement base. In this way, the type of soil and the absence of aquifers are determined.

Characteristics of soils:

- Rocky - soils with a high content of stone or gravel, are distinguished by a strong base, hold the load well, do not collect water.

- Coarse sands - represent a strong base with low heaving.

- Fine sand - poorly suited for construction, as they are highly heaving. They collect water in the upper layers and act in a pushing manner on the foundation.

Calculating the depth and number of posts

Columnar bases are buried (for water-saturated and clay soils) and shallow (for rocky and sandy soils with a low level of groundwater). The height of the buried foundation depends on the average depth of soil freezing in your area. The sole of such a foundation should be 30-50 cm below this level. Before starting work, the load of the house should be calculated, for this, the weight of the walls, floors, roofs and the mass of the foundation are summed up.

| Construction type | the weight |

| Insulated frame walls 15о mm thick | 25-50 kg / m² |

| Wooden beams with ceilings and insulation | 90-140 kg / m² |

| Roof and snow load | |

| Metal | 45-60 kg / m² |

| From flexible shingles | 45–65 kg / m² |

| Ceramic | 75-115 kg / m² |

| Snow load in different regions of Russia | |

| Middle lane | 100 kg / m² |

| Southern regions | 50 kg / m² |

| Northern part of the country | 90 kg / m² |

To determine the weight of a reinforced concrete columnar foundation, its volume must be multiplied by the specific weight of reinforced concrete (2500 kg / m³). To calculate the weight of one column, the following formula is used: V = 3.14 * G² * h.V - column volume, G - column radius, h - column height. All values are in meters. The resulting value must be multiplied by the number of pillars, and we get the total volume of the foundation.

Bearing capacity of different soils (in kg / cm²):

| Bearing capacity of soils | |

| Pebble with clay | 4,5 |

| Coarse sand | 6 |

| Medium sand | 5 |

| Fine sand | 4 |

| Gravel with clay | 4 |

| Loam | 3.5 |

| Clay | 5 |

Material selection and quantity calculation

Different materials are used for the construction of a columnar foundation:

- Wood is a very short-lived material; even when treated with protective compounds, it will last no more than 20 years.

- Stone pillars - usually built of rubble or granite stones. They are distinguished by their durability and reliability. The disadvantage is massiveness and laboriousness during construction.

- Monolithic concrete pillars.

In order to calculate the amount of concrete for a columnar foundation, you can use the following table:

| Round column radius | |

| 7.5 cm | 0.0176 m³ |

| 10 cm | 0.0314 m³ |

| 15 cm | 0.07 m³ |

| Square section | |

| 20x20 cm | 0.04 m³ |

| 30x30 cm | 0.09 m³ |

| 40x40 cm | 0.16 m³ |

The reinforcement for the columnar base is corrugated, class A, with a diameter of 10–12 mm. The metal rods are needed the same length as the supports. For a column with a diameter of 10-14 mm, you will need 4 bars of reinforcement. They are placed at a distance of 10 cm from each other and tied across half a meter with a smooth and thinner reinforcement with a diameter of 6 mm. Thus, for a two-meter post, you will need 8 m thick and 1.2 m thin reinforcement. The resulting figures are multiplied by the number of supports and we get the footage required for the columnar base of the reinforcement.

Required tools

Before starting construction, you need to prepare the following tools:

- Concrete mixer;

- Shovel;

- Roulette;

- Level;

- Nails and screws;

- Hammer;

- Cord;

- Pegs;

- Hand drill;

- Master OK;

- Formwork pipes or boards.

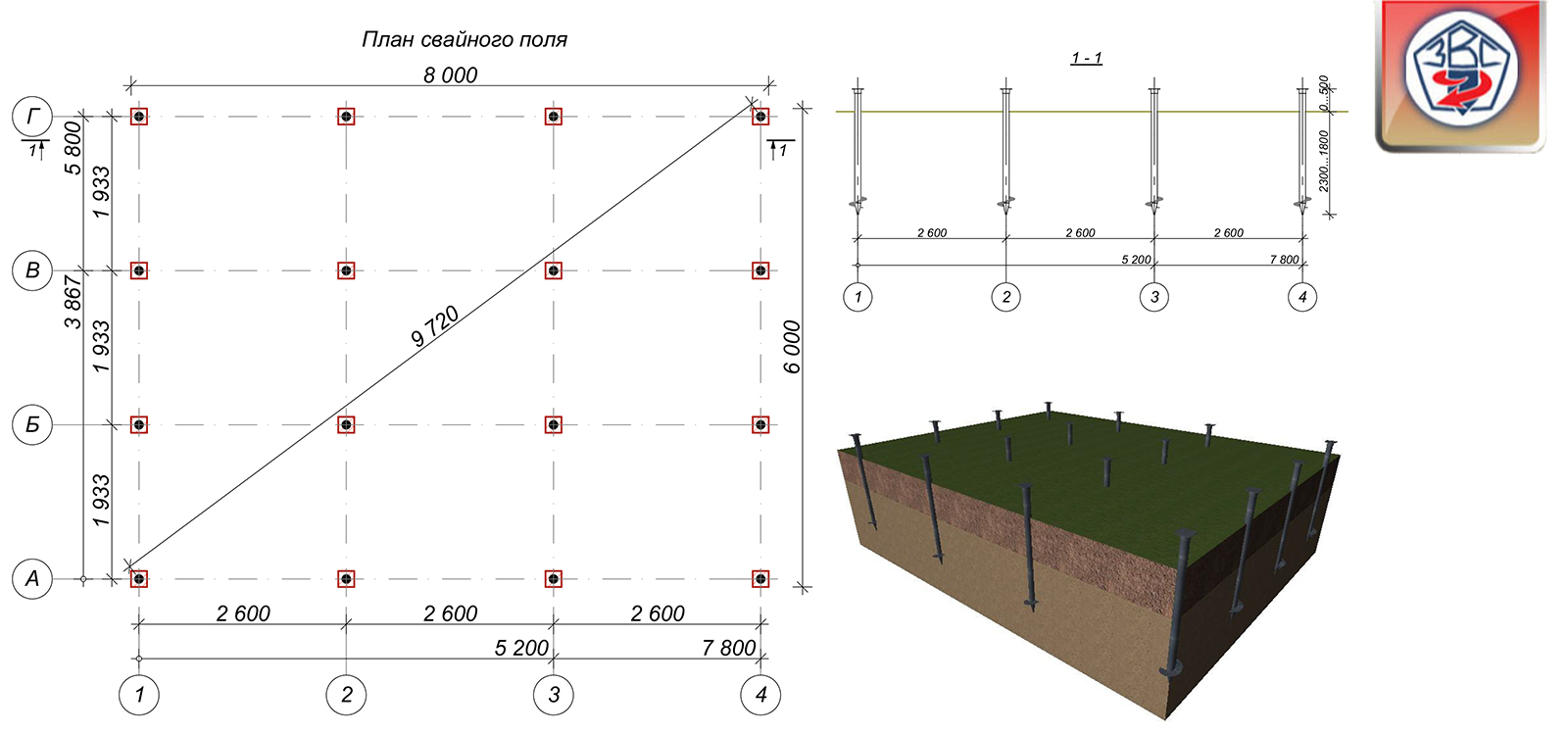

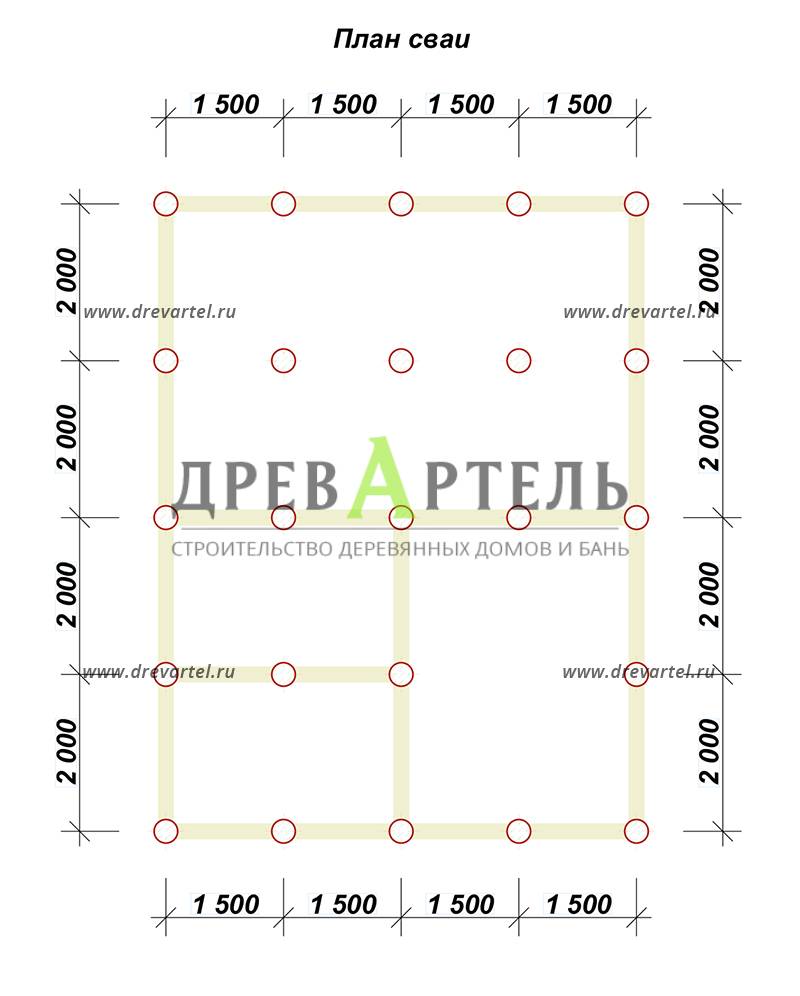

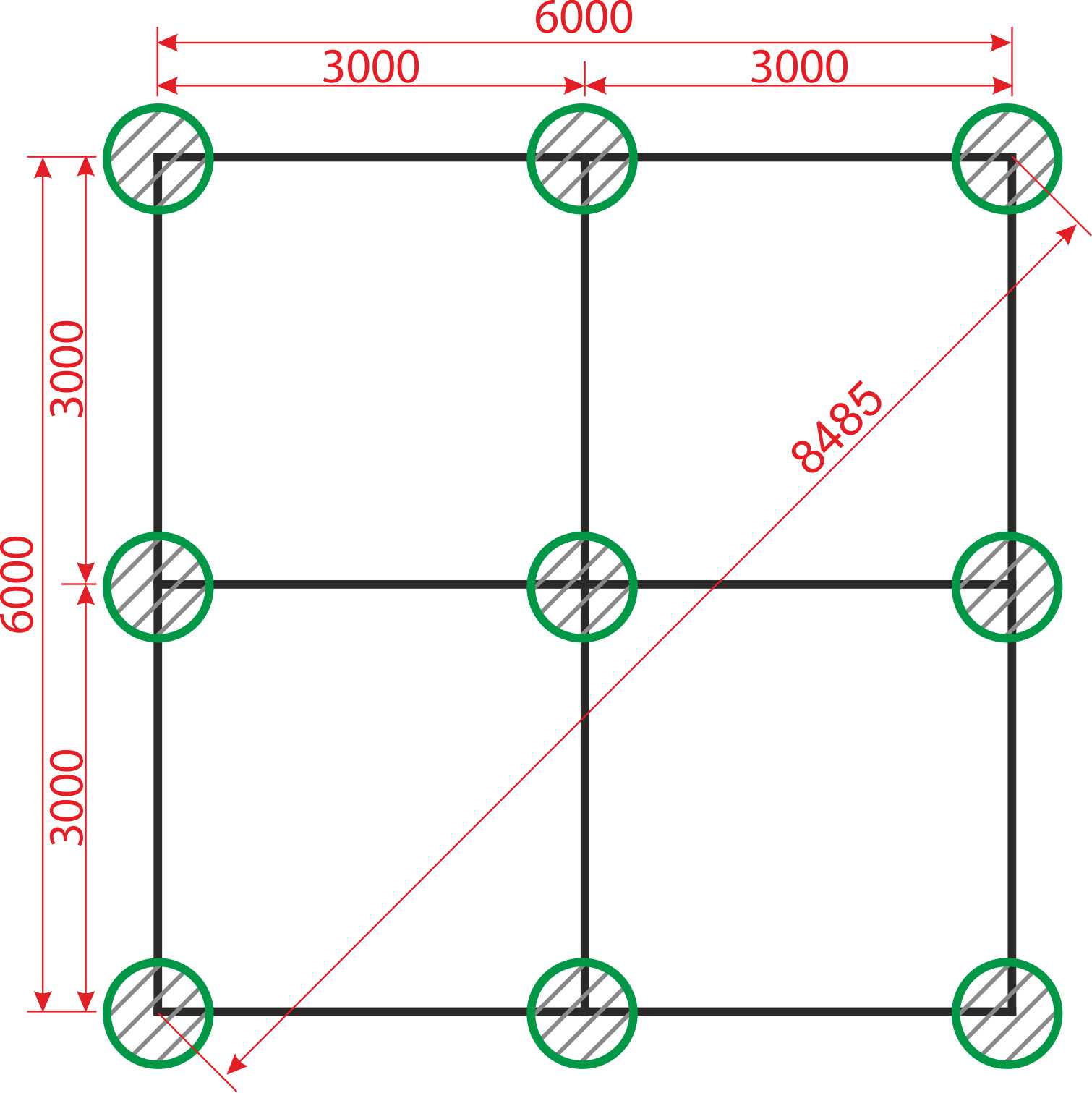

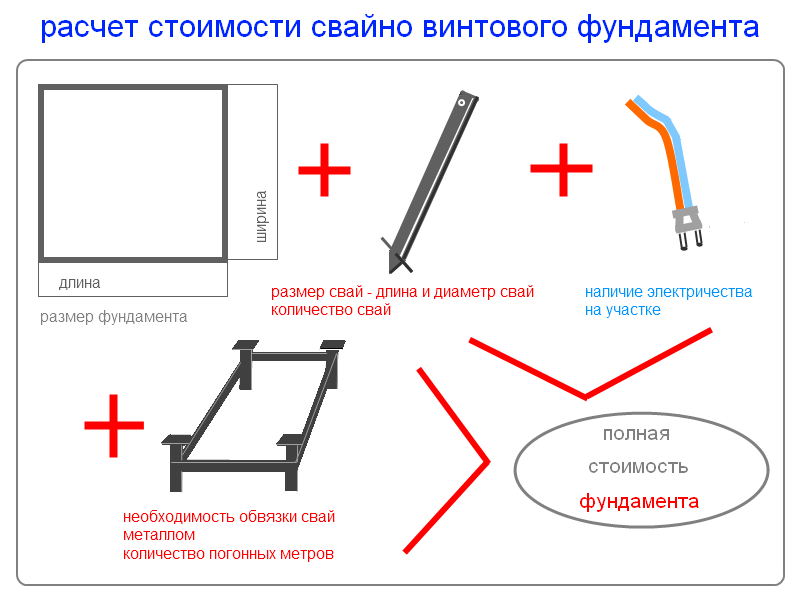

Calculation of the cost of the pile foundation

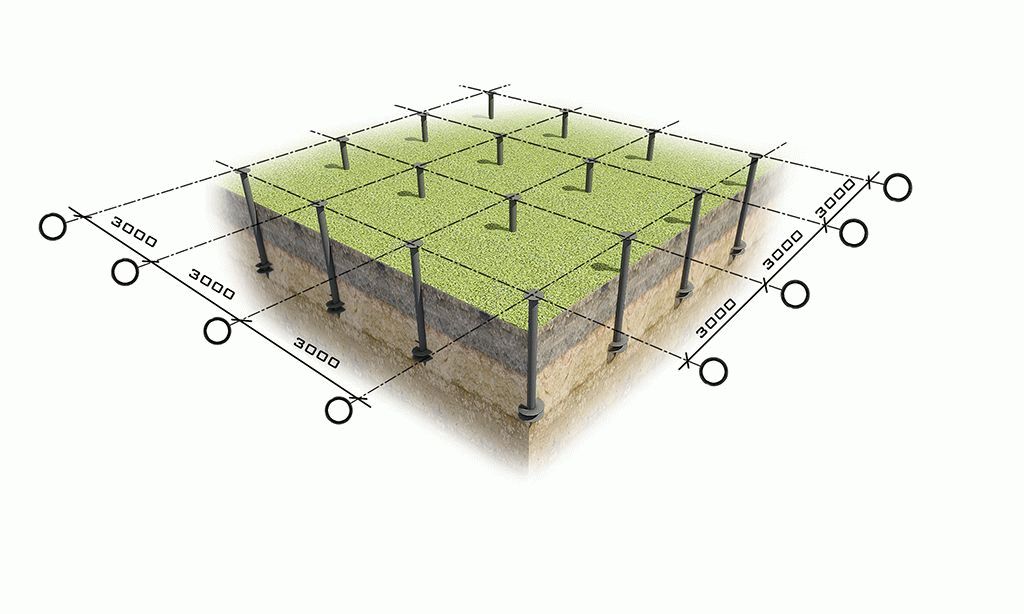

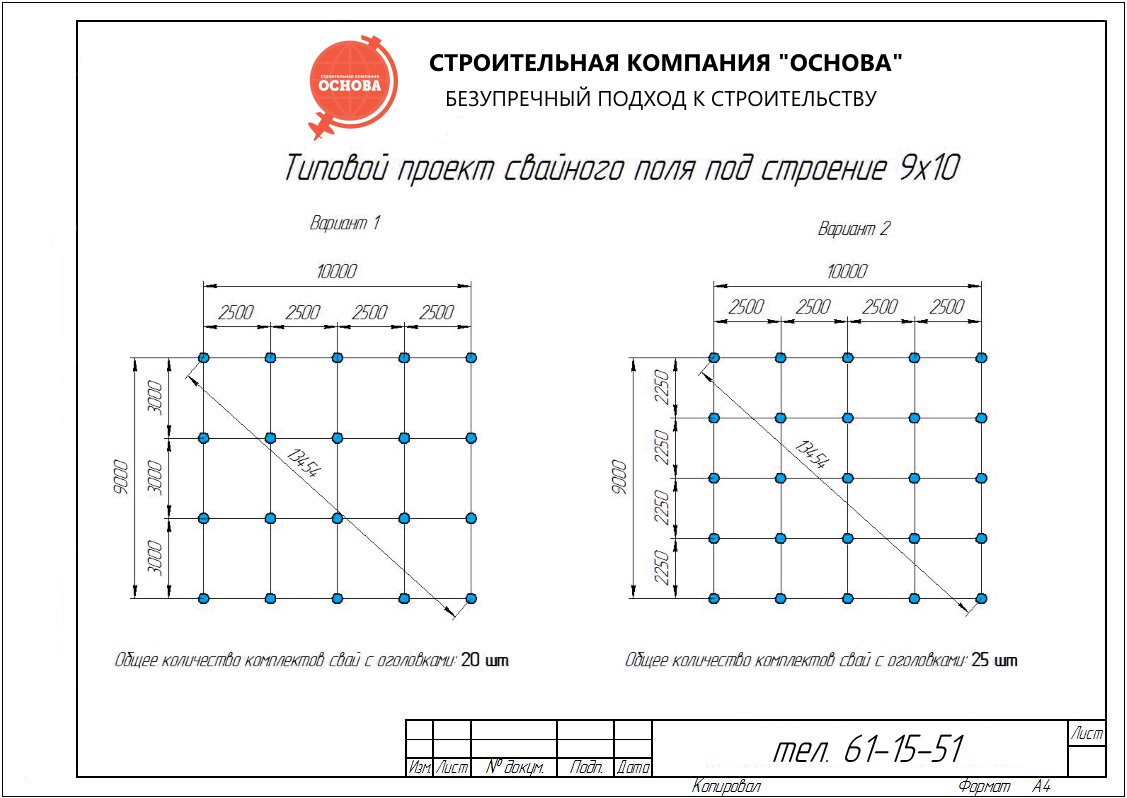

In order to calculate the cost of the foundation, let's take a project of a building with an area of 10 by 15 meters. For example, the twisting of the piles will be carried out near such a house with a step of 2.5 meters. In this case, we need 20 piles with a standard diameter of 10.8 cm.

Table for calculating the cost of a pile foundation

Now let's calculate its bearing capacity. With a square area of 150 sq. m and a specific gravity of 350 kg / m., it will weigh 52,500 kg, that is, 52.5 tons. Taking into account the number of piles, we will perform an approximate calculation of the bearing capacity, since, taking into account the reviews, the piles withstand about 5 tons of load each. Then 20x5 = 100 tons is the maximum load of the weight of our structure on the foundation.

Thus, based on market prices for piles, and today they cost about 1,700 rubles, we will need 34,000 rubles. In addition, we will purchase heads for 220 rubles. The result is 34,000+ (220x20) = 38,400 rubles. Also, the calculation must be made for additional materials, for example: roofing material, antiseptic, concrete.

Their calculation is not so difficult, and the decision of which company is better to choose is up to you. If we compare the average cost of a strip, columnar and pile foundation, then their price differs markedly.

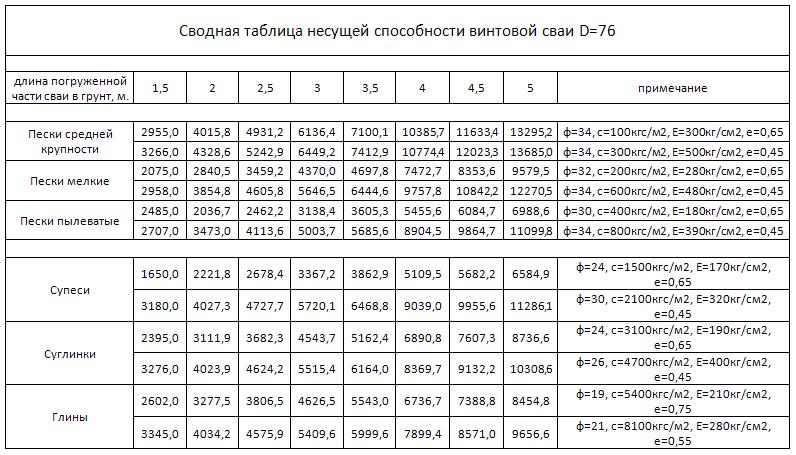

Screw pile bearing capacity table

The calculation for the strip foundation of a house 10 by 15 meters will be approximately 120 thousand rubles, based on the fact that a cubic meter of concrete costs 2,000 rubles. Draw your own conclusions. Be sure to look at reviews, tips and additional recommendations that will help you with quality work.

To date, reviews are of great importance, especially reviews of friends and relatives who have such housing or a summer residence. Probably, they have already encountered all the advantages and disadvantages of such structures, they will share their experience of construction, perhaps they will advise the most demanded specialists for construction and help them independently calculate the foundation for your future home.

How to calculate the distance correctly

There are many different methods for calculating screw piles. Most of them are incorrect and do not give any useful result. A competent calculation can be made, guided by SP 50-102-2003, which sets out all the necessary formulas and methods.

The problem is that there are no simple ways, you will have to make rather complex calculations with a high probability of error. Therefore, you need to contact specialists or, at least, use online calculators that allow you to get the desired values in just a couple of minutes and completely free of charge.

NOTE!

It is strongly discouraged to undertake the calculation of the foundation yourself without proper training and experience due to the high probability of errors and misuse of various special values.

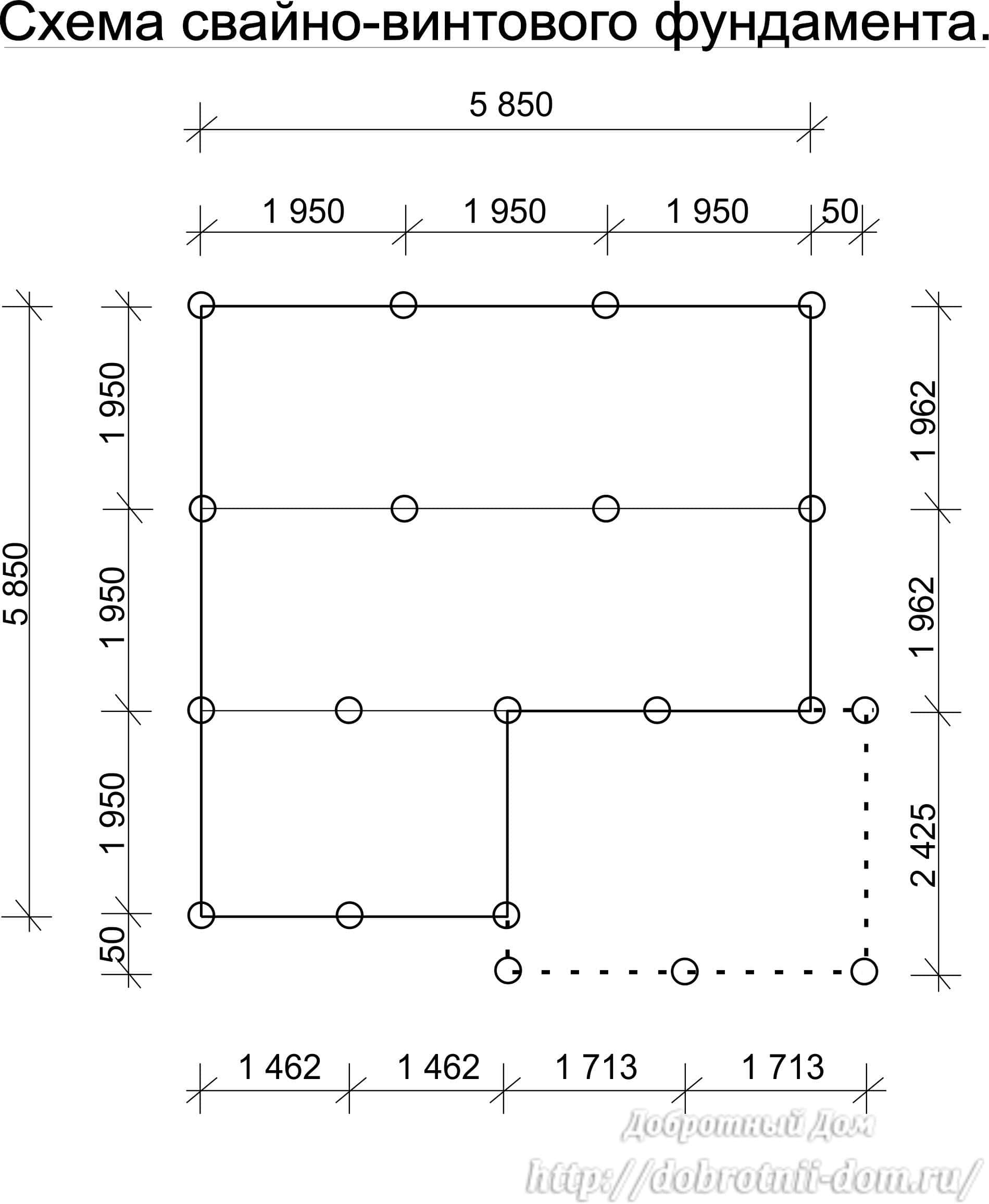

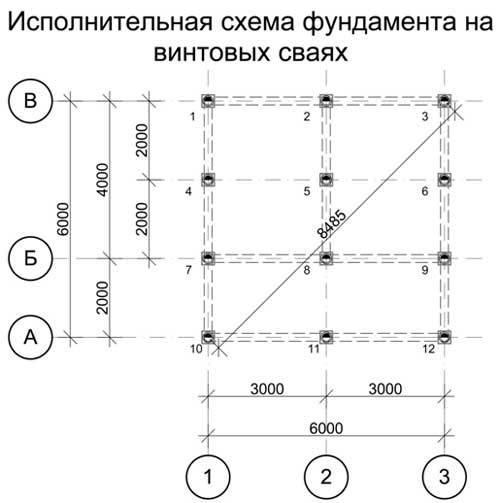

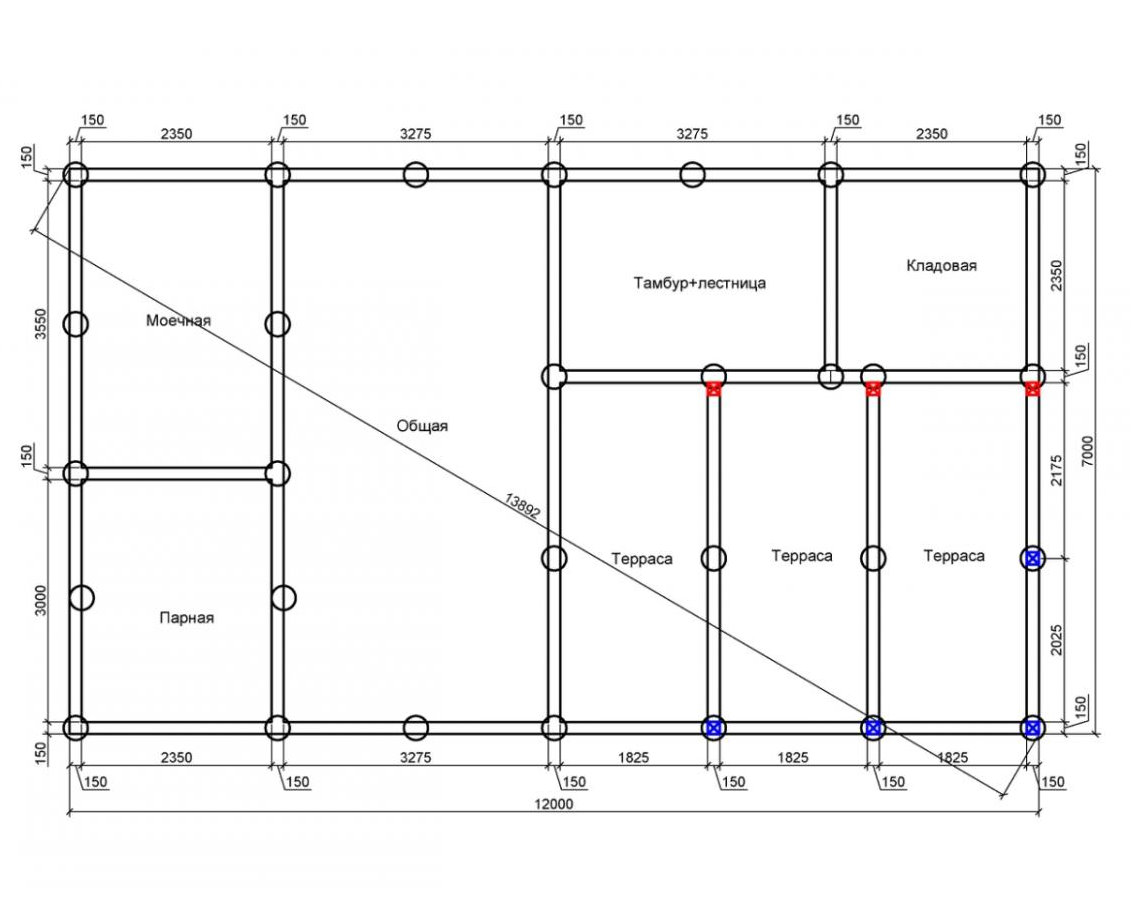

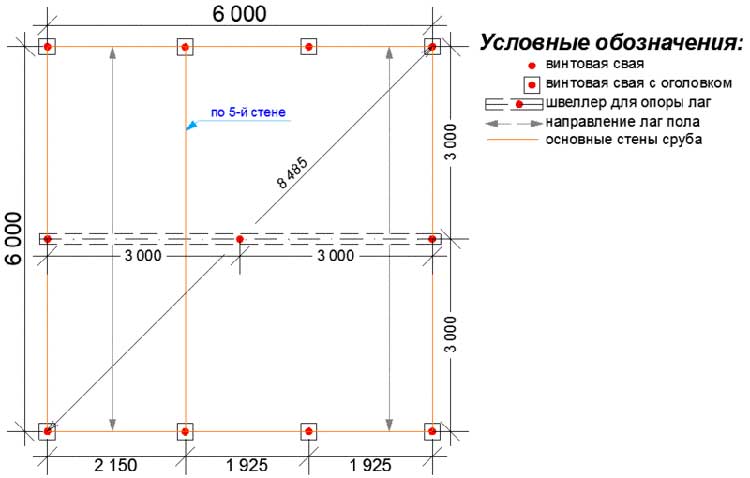

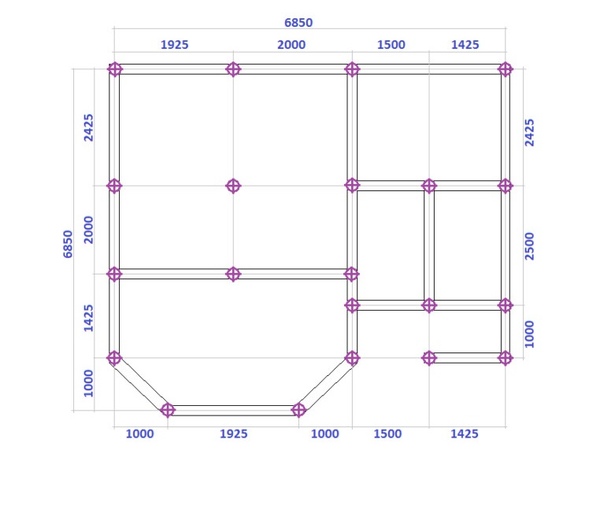

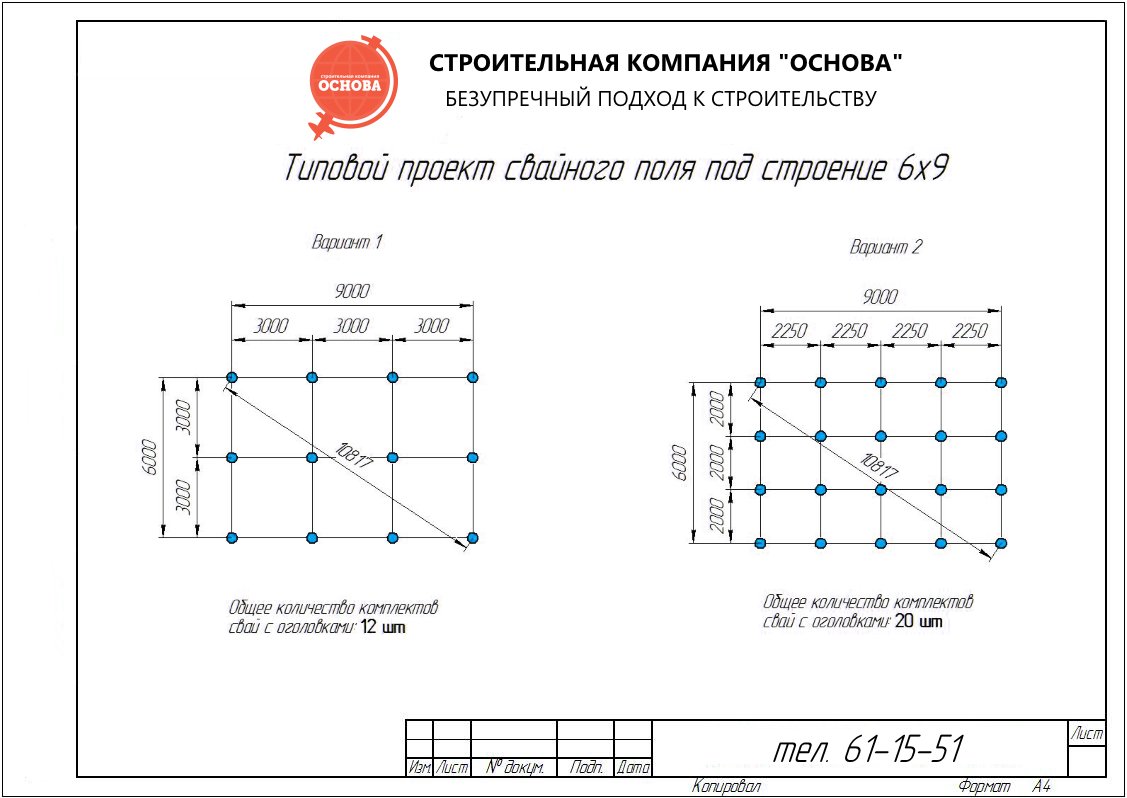

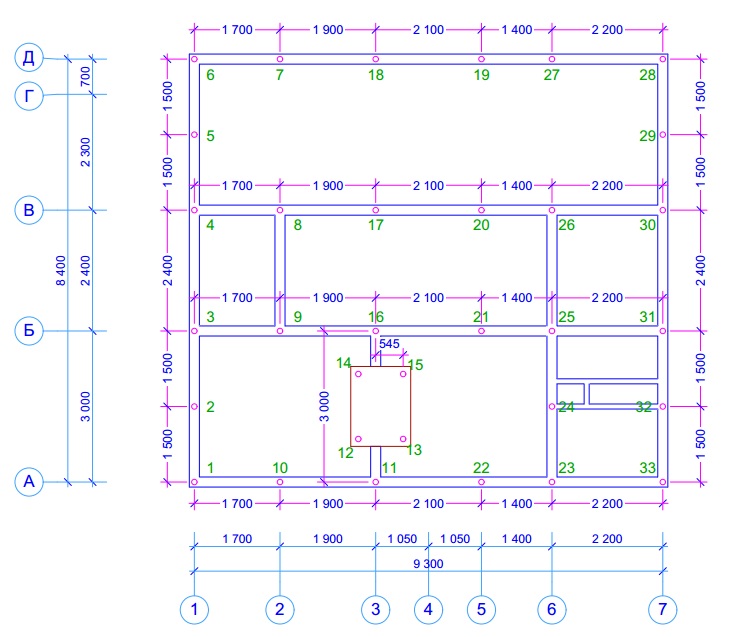

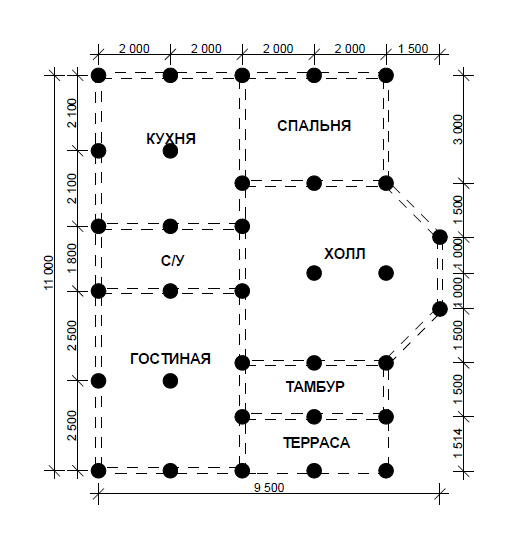

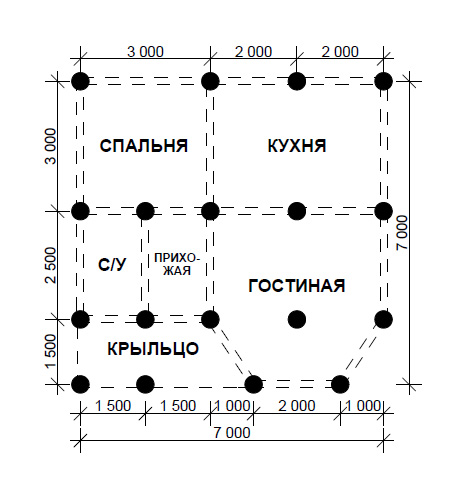

If, nevertheless, it is necessary to calculate the step of the supports, you should first draw a plan of the pile field (or use the plan of the first floor). First, piles are placed at all corners and points of abutment of the walls.

After that, piles are distributed along the lines of placing the load (load-bearing walls), based on their number.

Sometimes, when the weight is evenly distributed over all the supports, they do it simply - calculate the total length of the bearing walls and divide it by the estimated number of piles.

For example:

The weight of the house is 300 tons. The rated load on the pile is 5 tons (ВС-108).

Total number of piles:

300: 5 = 60 pcs.

The total length of the reference lines is 40 m.

Then the distance between adjacent piles will be:

60: 40 = 1.5 m.

Calculating the number of screw piles using a calculator

If you need to calculate the number of screw piles that will be required to build the foundation at your facility, you can do this without leaving your home. You only need to know the primary parameters. It is necessary to calculate the number of corners and joints of external walls with load-bearing partitions. Piles should be located in these places, they should go along the perimeter with a step of no more than three meters. If you plan to install a fireplace, then, depending on its weight, you need to install from one to four piles under it.

Use the online calculator for calculating the number of piles on our website. In addition to the required number, you can also find out their preliminary diameter and length.

The calculation of the pile field online is quite simple, you only need to enter the data in the appropriate fields:

- Indicate the length of the sides of your structure.

- Indicate the type of building - a gazebo, a bathhouse, a house, a garage, a household structure, etc.

- Indicate the number of floors, if necessary. Note: A house with an attic will be considered a 1.5-storey structure.

- Select the building material for your structure.

- Indicate the type of soil on the site.

- Indicate the number of corners of the planned house.

- Indicate the height of the basement floor from the proposed options.

- Check if you are going to install a fireplace / stove.

- Click on the "Calculate" button.

Of course, this calculation is preliminary, it will serve as a guideline when planning a budget and further ordering.

Foundation arrangement: basic requirements and parameters

After carrying out geological work and confirming the selected option for the pile foundation, it is necessary to take into account the type of support

After carrying out geological work and confirming the selected option for the pile foundation, it is necessary to take into account the type of support

After carrying out geological work and confirming the selected option for the pile foundation, it is necessary to take into account the type of support, it is better to take the values given in the table below as the standard (length values are given in cm):

| priming | Pile length 76 mm | Pile length 89 mm | Pile length 108 mm | Pile length 133 mm |

| sand | 350 | 250 | 250 | 250 |

| peat | determined by trial drilling to the depth of the dense layer | |||

| loam, clay | 300 | 250 | 250 | 250 |

In addition to the bearing capacity of the soil, it is necessary to calculate the weight load (total mass) of the structure, for which the following values are taken into account:

- Number of storeys of the building;

- The material from which the load-bearing and intermediate walls are made;

- The presence of local structures of a massive nature (pools, fireplaces, stoves, etc.);

- Floor slab material.

The weight load is calculated up to the expected furniture, if you plan to put impressive headsets or other household items. After that, you should look at the table given for an example (the calculation is given for a one-story residential building with dimensions of 10 * 10 m without additional weighting factors):

| House type | Pile diameter | Number of piles |

| Frame-panel board | 108 | 25 |

| Beam 100 * 100 | 108 | 25 |

| Beam 100 * 150 | 108 | 25 |

| Beam 150 * 150 | 108 | 25 |

| Bar 200 * 200 | 133 | 25 |

| Log house | 133 | 25 |

The total area of the foundation is also taken into account. The dependence of the number of piles on the size of the foundation is great, for example, for a suburban structure 3 * 3, only 4 pile elements with a diameter of 89 mm are required, for a structure 8 * 8 already 16 piles with a diameter of 89 mm, and for a house of 10 * 10 m 25 screw piles with a diameter of 108 mm ...

Note that the size range of pile elements is much wider, so it is easy to select them for each individual type of development. Regardless of the choice of diameter, it is necessary to monitor the strength and practicality of the piles. Developers most often use galvanized welded piles or cast piles with tips. Otsinkov prevents the development of corrosion and with high-quality coating, additional waterproofing procedures can be avoided.

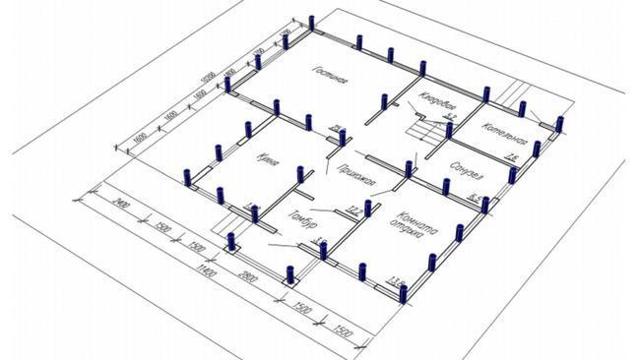

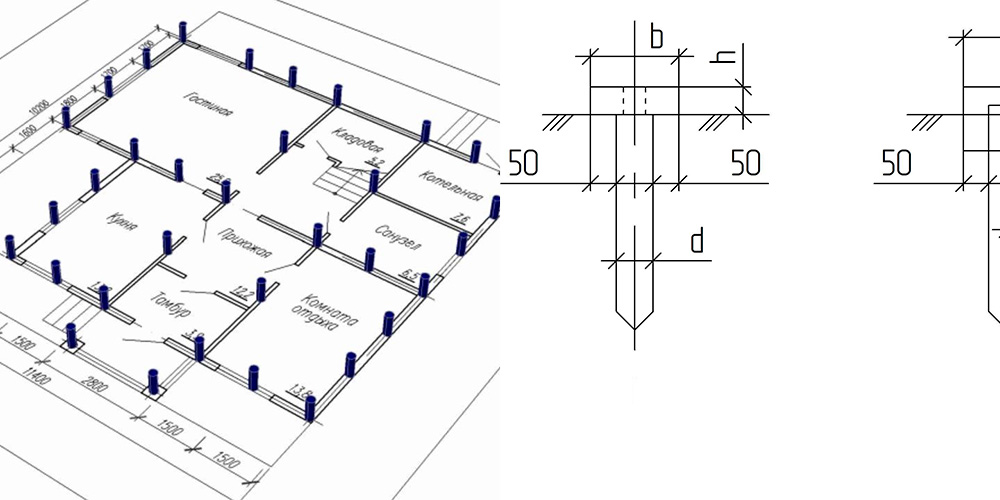

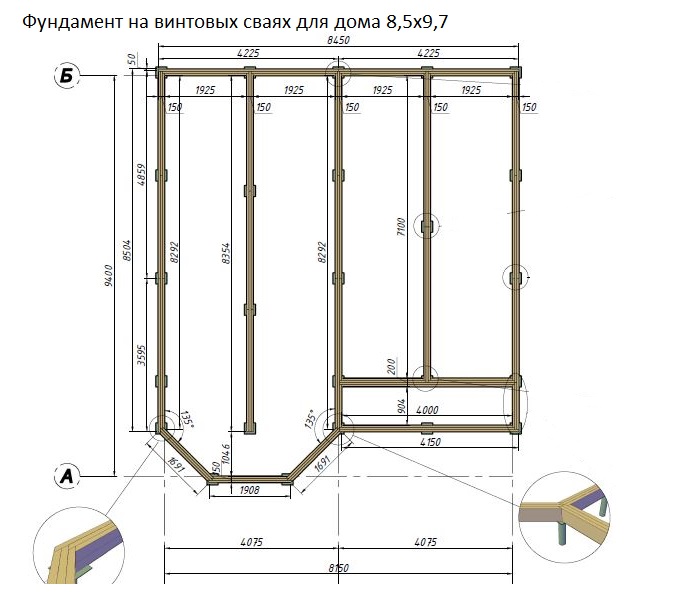

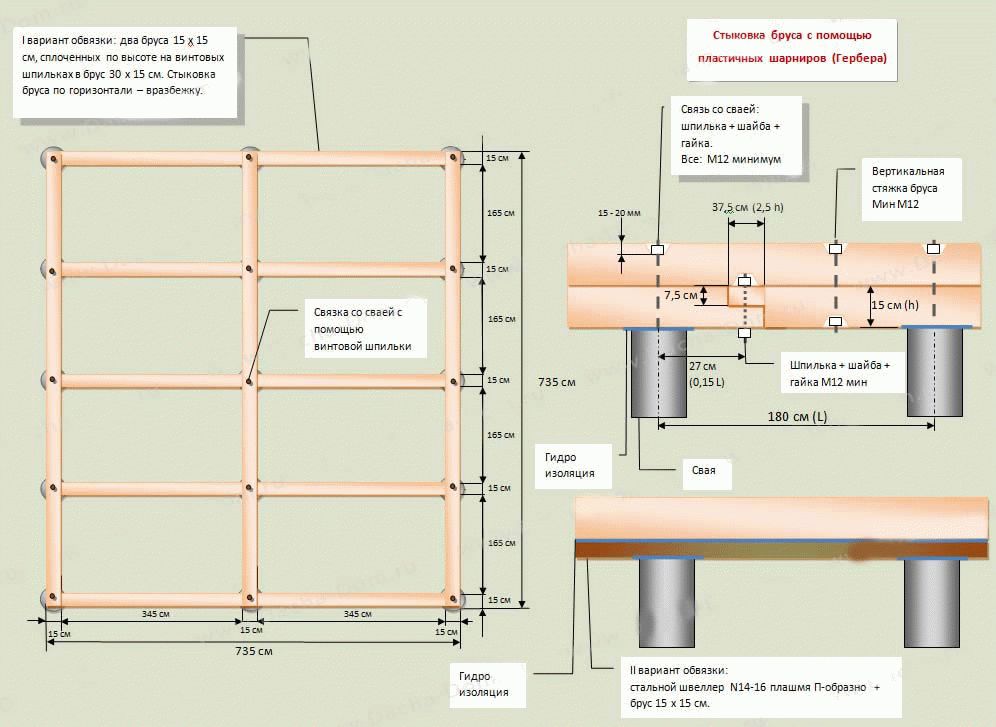

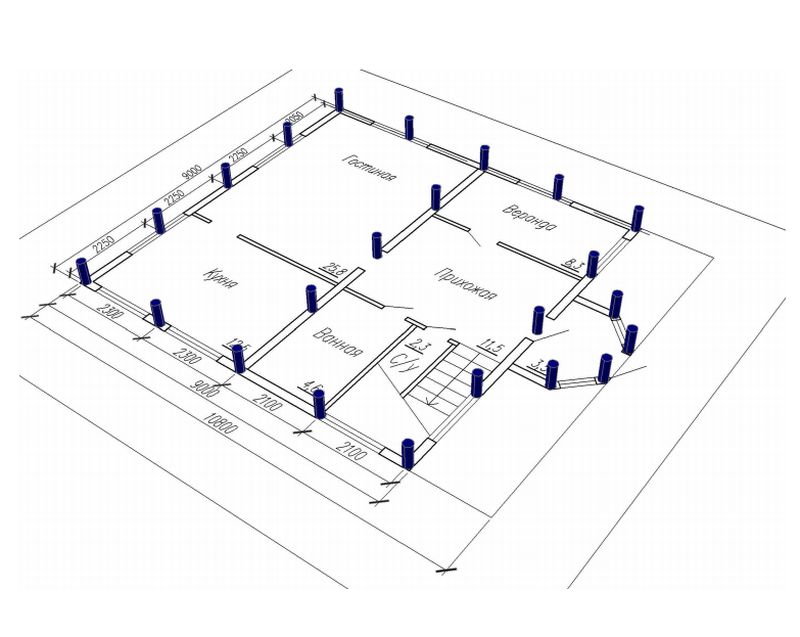

As for the stage of work, before arranging a house from a bar on screw piles, the following procedure for erecting a foundation is assumed:

- Prepare a place for installation, mark the site;

- Drill small holes for the installation of piles, determining the points, according to the design documentation (do not forget that the foundation is made both under the load-bearing walls and under the interior partitions);

- It is imperative to make pivot points under local massive objects, elements.

And now the question: the distance between the screw piles, what should it be? Developers with experience recommend placing screw supports for a frame house in increments of no more than 3 meters. But if necessary, under a log house with a large mass or in the presence of a sufficient number of supporting internal bases, the gap between the piles can be reduced to 1-1.2 meters (not less). The main thing is that the pile-screw foundation does not represent a palisade of supports: such a structure will not have greater strength and stability, but it can break the integrity of the soil and lose all its positive qualities.

Calculation of the distance between piles

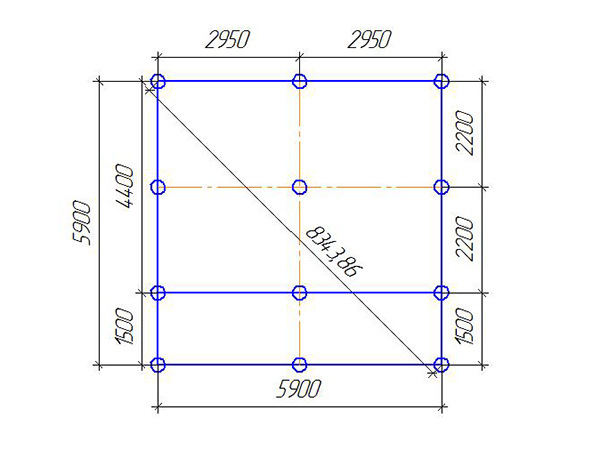

To determine the distance between the piles of a pile foundation, you need to know two values: the required number of piles and the size of the building in plan.

The algorithm for calculating the number of supports is approximately the same for all of their types, therefore it is enough to consider one option - for example, bored piles.

The initial data for the calculation are:

- soil analysis in the construction area;

- the maximum load of the future house on the ground;

- area of the house.

Soil analysis

You can determine the composition of the soil on the site yourself (if you plan to erect a light building). To do this, at the site of the future foundation, it is necessary to dig several holes with a depth of about 2 meters.

In the process of digging "holes" you will see what type of soil you will come across, and at what depth is a dense layer (for example, hard clay).

You will need this parameter to calculate the length of the pile.

We collect loads

The total ground load is defined as the sum of the weights of all building materials that are supposed to be used in construction, snow and wind loads.

The last two values are normative.

They depend on the region of construction and are determined according to the tables of SNiPs in force in Russia.

Determine the required number of piles

To determine the required number of supports, you must perform the following steps:

- calculate the foot area of one pile;

- the result obtained is multiplied by the resistance (4);

- divide the total load by the product of the sole area and the resistance.

Having received the number of supports, it is necessary to adjust the load: after all, the piles themselves press on the ground. The weight of a bored pile is calculated without taking into account its expansion.

Multiplying the weight of one element by their total number, we get an additional load on the ground.

Pile installation step

How to determine the distance between the foundation piles, knowing their number and overall dimensions of the building?

It seems that there is nothing simpler: the calculation of the distance between the piles for the foundation consists in dividing the perimeter of the building by the number of supports.

But there are some nuances here too - there are minimum and maximum allowable distances between the supports:

- the minimum distance between the bored piles of the foundation along the axes should not be less than three diameters of the support;

- the maximum distance between the foundation piles is from 5 to 6 pile diameters.

There are a few exceptions to the above rule:

- when building on sandy soils, the minimum permissible distance between the concrete foundation piles is 4 diameters. With a decrease in the step, soil overconsolidation occurs, which leads to the complication of installation work;

- wooden piles are installed with a minimum step of 70 cm, regardless of their diameter;

- the minimum allowable step for reinforced concrete supports is 90 cm.

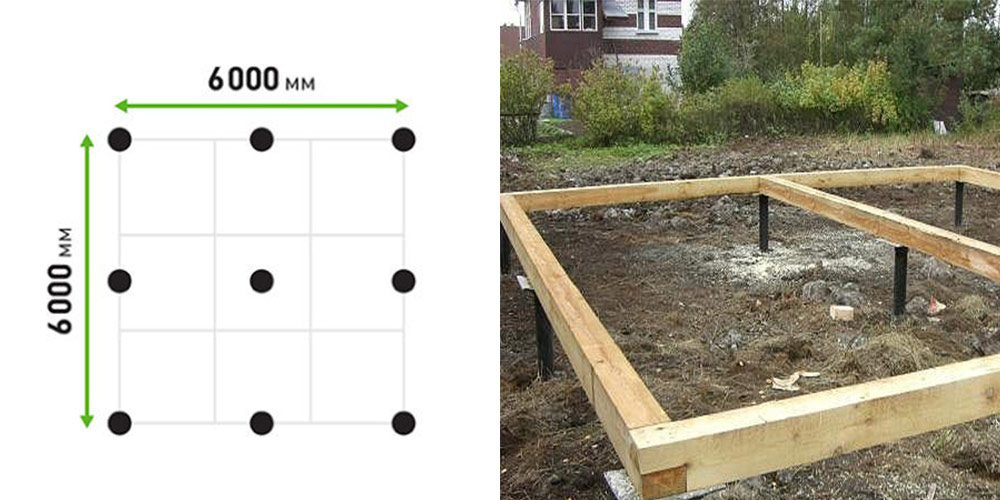

Depending on the type of foundation, piles can be placed in a row or staggered manner. The first method is used in the pile-strip foundation, the second - in the pile-grillage foundation.

The distance between the piles of the pile-grillage foundation should not exceed six column diameters. Otherwise, the support will be subjected to an increased load and work as a single support. This will ultimately lead to the destruction of the grillage and even the collapse of the building.

The optimal distance between the piles of the pile-strip foundation is considered to be 1.5-2 meters.

The maximum allowable spacing depends on the placement of the supports:

- in one row - 1.33 m;

- in two rows - 2.67 m.

Basic settlement rules

Performing calculations is one of the important stages on which the strength and reliability of the future structure depends. However, despite this responsibility, everyone can calculate the step between the supports of the pile-screw foundation, taking as a basis the advice and recommendations of experienced craftsmen.

When calculating the distance between piles, there are several factors to consider.

Base shape

In order to evenly distribute the load of the structure on the supports, it is necessary to correctly position them on the site. Piles must be in the following places:

- At every angle.

- At the intersection of load-bearing walls and partitions inside the building.

- At the entrance.

- Under a stove or fireplace.

Estimated load on the foundation

To determine the load on a pile-screw base, you need to know the following indicators:

- The type and weight of building materials to be used for the walls.

- Floor weight including floor and ceiling.

- Characteristics of the materials from which the construction of the roof frame is planned, as well as the roofing material.

- The number of people who will live in the house, and the furnishings of the premises.

- The approximate load from the snow cover on the roof, determined by the climatic conditions of the region.

Determination of the load on the foundation

In addition, the length of the grillage beams must be taken into account; it is very important that the beam with both ends rests on the head of the pile. This question is especially relevant in the construction of frame or timber-frame houses on a pile-screw foundation.

Earlier we wrote how to build a frame house on screw piles.

To obtain the final result, the obtained value is multiplied by a safety factor equal to 1.2-1.3.

Features of the soil on the site

Ground characteristics are one of the important factors when calculating the distance between screw supports.The distance between the piles and their number depends on the bearing capacity of the soil. On weak, unstable ground, it is recommended to install more supports, therefore, the placement step is reduced. The process of studying the soil involves drilling wells in several places and further examining the excavated soil

It is very important to find out the presence of water-saturated layers, since water significantly reduces the bearing characteristics of the soil. In addition, the type of soil should be determined, high-quality fixation of the pile is possible only in hard rocks, for example, in hard clay, sandy soil does not give a good result

Determine the bearing capacity of the soil

Even if it is not there, there are no hopeless situations. Information will be shared by the Internet and neighbors. But even having received the necessary data, undertake to drill a test hole at the lowest point of the site. An ice screw for winter fishing with unusable sharpened knives will help out. Get a complete picture of moisture content, depth and composition.

It is desirable to perform the drilling depth below the planned point of the foundation of the house being built. The quality indicators of the soil lying at the depth of the planned fixation of the tip are the desired ones, which we will use for all calculations. The upper horizons do not matter.

According to the bearing capacity, according to the degree of increase in the bearing capacity, the soils in the table are arranged in the following order:

- Bulk soil;

- Sandy loam;

- Loam;

- Fine sand;

- Medium fraction sand;

- Coarse sand;

- Clay.

The strength and reliability of the contact of the trunk and blades of each pile with the adjacent layers largely depends on the parameters of the soil. According to the SNiP requirements, for soil analysis it is necessary to carry out test drilling, laboratory studies of the composition and properties of soil layers.

In addition, it is recommended to install reference piles capable of demonstrating in practice the bearing capacity of the pile and the value of resistance to loads. In practice, most studies are limited to test drilling and visual determination of soil quality.

NOTE!

An experienced driller is able to assess the condition of the soil no worse than a specialist geologist, however, if it is possible to perform a high-quality analysis of the soil, it should not be neglected.

For the installation of a pile-screw foundation, you need to know about the bearing capacity of the soil. The project of the house, including the foundation, is created on the basis of this data. It is not difficult to find out the structure, for this you can look on the Internet or ask your neighbors.

We suggest that you familiarize yourself with How to attach a bathhouse to a brick house: construction stages

Even after finding out this information, it is better to check the soil on the site yourself. To do this, you need to take an old fishing drill and drill a hole in the far corner of the site. This will help to visually see the state of the soil: its moisture, the depth of the horizons, etc.

For verification, it is recommended to drill a hole below the estimated pile penetration level. This will help you become familiar with the qualities of the lower horizons of the soil, which play a major role in fixing the supports.

Pros and cons of the pile-screw foundation

Pile foundations are fundamentally different from strip and slab foundations in that each pile transfers a concentrated load to the ground at a separate point. And the pile-screw foundation, in turn, differs from the pile-driven foundation made of reinforced concrete piles in that:

- Piles are metal pipes that resist bending much worse than reinforced concrete.

- Metal piles in the ground corrode.

- Driving in screw piles, in contrast to driving in driven piles, does not compact, but loosens the soil.

Due to these factors, the quality of the pile-screw foundation depends very much on the properties of the underlying soil. An ideal "cushion" for a spiral foundation is a thick dry loam or slightly moistened alluvium, sand with small pebble inclusions.In the latter case, the screw of the pile, when screwing in, pushes in front of it an increasingly expanding and compacting cone of soil. At the same time, water is squeezed out of it, and small particles of clay, always present in the alluvium, cement it. In the end, the soil cone acquires the strength of concrete, and the cones of individual piles close in depth. The pile is wedged tightly, so that it is easier to turn it into a corkscrew than to turn it or turn it out further; the strongest foundation is now complete with virtually no zero cycle.

Gazebo with a swimming pool on screw piles

In the fertile multilayer soils of most of the Russian Federation, the foundation pile works differently. How - we will analyze below, but for now we will indicate the pros and cons of screw piles in Russia, with the exception of mountainous regions and the permafrost zone:

- Site planning and equipment of access roads to it are not required - a plus.

- Construction is not tied to the season, weather / natural conditions and the geographical location of the object; piles can be wrapped both in a swamp and in permafrost - a plus.

- Labor costs for the installation of a pile-screw foundation are an order of magnitude or more less than any other; it can be assembled in 1-3 work shifts - a plus.

- There is no need to wait for the foundation to shrink, construction can begin immediately after its installation - a plus.

- Extensions to the main building can be made without fear of shrinkage of their foundations relatively old - a plus.

- Construction is possible in the area of developed underground communications - a plus.

- With the use of industrial assembly methods and in combination with a reinforced concrete strip pile-screw foundation, it is possible to carry out construction on the weakest soils, up to quicksand - a plus.

- The same industrial construction technologies make it possible to extract piles from the soil for reuse - a plus.

- Limited service life: in moist soils with a chemical reaction other than neutral, metal piles serve 50-60 years; boring (see below) up to 100-120 years - minus.

- Bearing capacity limited by soil properties: capital multi-storey construction on pile-screw foundations is impossible - minus.

- Pile-screw foundations for long-term residential buildings per unit of bearing load from the building are 10-30% more expensive than pile-driven or belt foundations - minus.

- Basement construction is impossible, because the interaction of the piles with the soil is disturbed - minus.

- The ingress of flowing water into the subfloor of the building is unacceptable, therefore, a rather complex finish of the basement and blind area is required - minus.

- Erection of the foundation requires preliminary geological studies at the construction site and rather complex and laborious calculations. If standard projects can be developed for strip foundations, then each pile-screw is designed individually - minus.

In individual construction, the advantages of the pile-screw foundation undoubtedly push back its disadvantages in the following cases:

- Temporary light residential buildings. For example, we take an inexpensive feasible mortgage on a prefabricated panel house, and gradually build a major mansion nearby.

- Wooden baths: reliable insulation of the floor from the ground also gives a fairly light and soft steam from the metal stove.

- Outbuildings, sheds, trellises.

- Fences.

- Swing gates.

The pillars of sliding gates should not be made of screw piles: the mechanism still needs thorough concreting, and its shrinkage in the future will lead to distortion of the sash; also, the piles do not hold the regular alternating loads during its extension / retraction. Pile-screw foundations are not very suitable for garages; for entry-exit, you will have to make a ramp with a height of about 0.5 m, which is inconvenient, takes up space on the site, complicates and increases the cost of work

The exception is welded metal garages, but everyone knows their aesthetics.