Varieties of pile supports

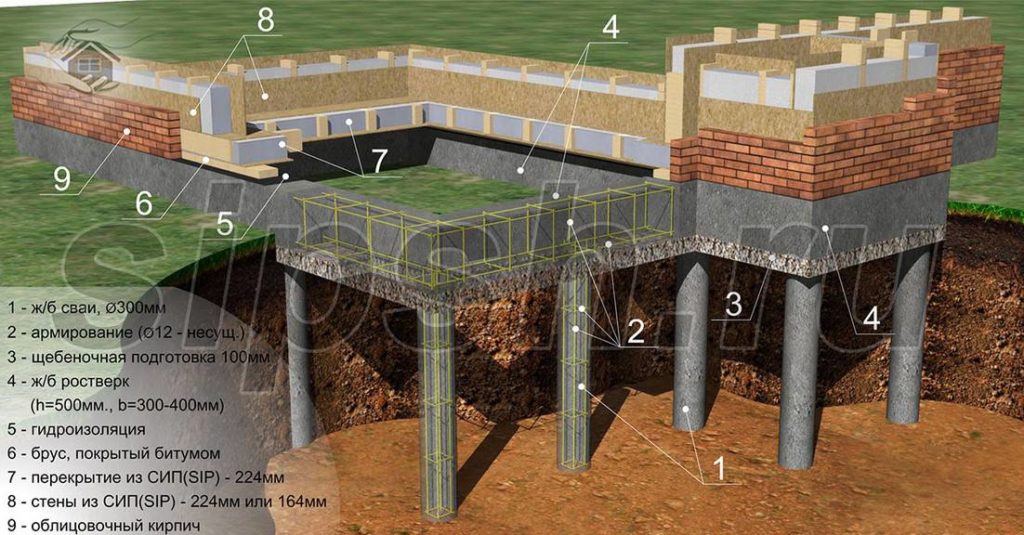

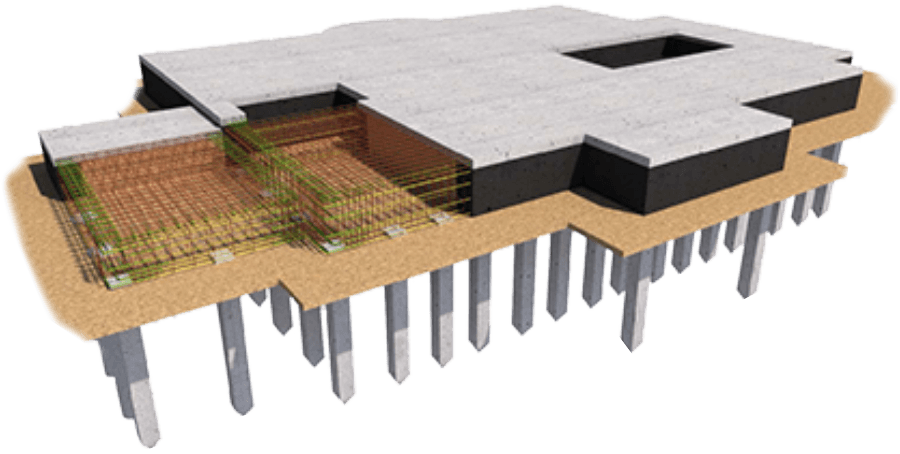

The device of a pile foundation with monolithic inclusions can be performed in various versions:

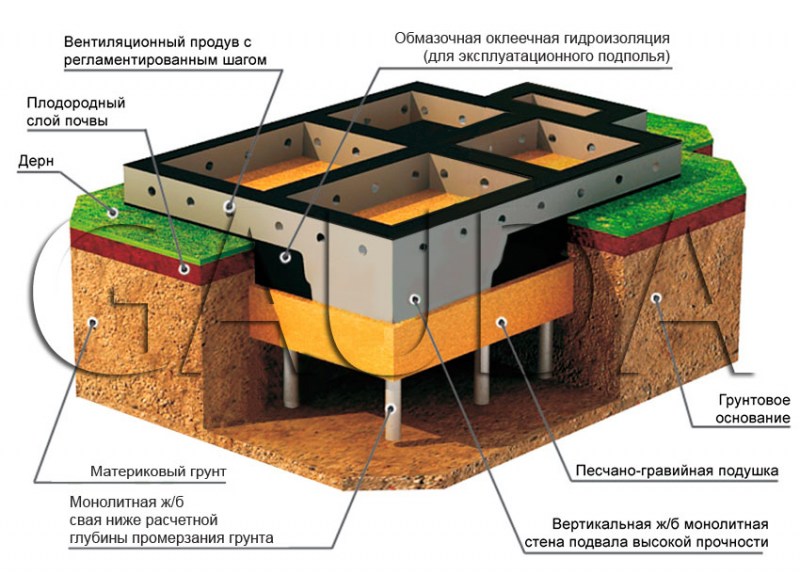

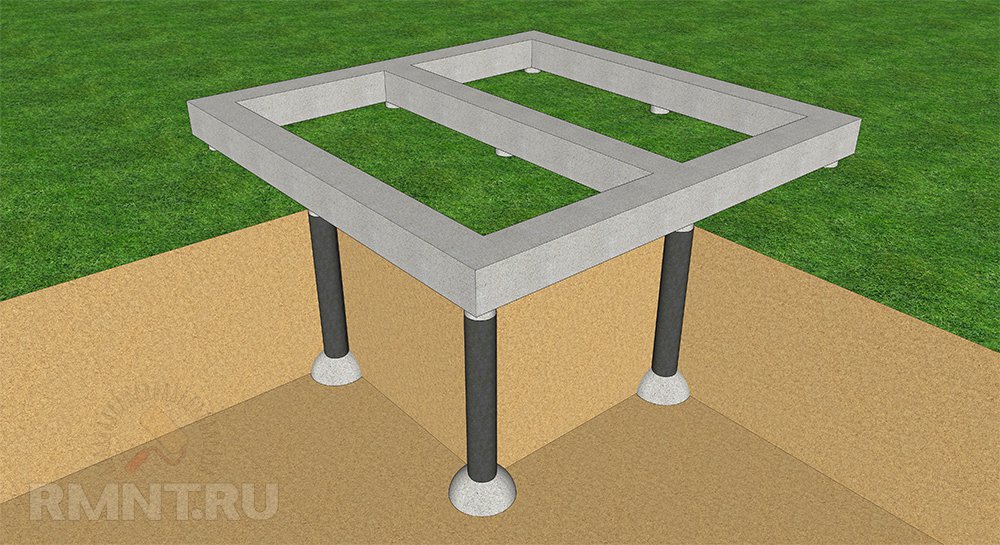

- The base with a hanging grillage, the design of which includes a small opening between the grillage and the soil up to one hundred millimeters, due to which the exterior of the house seems to hang over the soil. This technology is used to protect the monolithic surface from the bad effects of the soil. A similar type of base is used by specialists for the construction of structures from various materials.

- With the deepening of the foundation piles into a special monolithic base-grillage. With this technology, there is no distance between the base and the soil, but there is a base, which is provided precisely by the grillage. When using conventional pile supports, it will not work to equip the basement. The grillage can be made from a variety of options, including concrete, reinforced concrete, wood and steel. The most suitable, durable, reliable and safe option is (according to experts) reinforced concrete.

In order to equip a pile-grillage foundation using a monolithic slab, you must first perform a number of preparatory work:

- Select piles of the required size, as well as cut down the head of the supports to the required size.

- The tops of the supports are cleaned, rinsed well and then air dried.

- Formwork construction is in progress.

- For arranging a removable formwork, it is protected from mortar, as a rule, with the help of polyethylene.

- The monolithic grillage is being poured. At the same time, concrete is poured in successive layers over the surface.

Base arrangement technology

To begin with, it should be noted that houses on a combined pile foundation must be erected by professionals. It is simply impossible to independently equip such a complex foundation from a technological point of view. All work on the construction of the foundation is carried out in strict accordance with the regulatory documents for construction, as well as in a clear sequence.

The whole process of erecting a combined base can be divided into several stages:

- Site preparation. The first thing to do before starting any construction work is to plan the site. To do this, any garbage is removed from the territory allocated for construction, any green spaces are removed, and all pits and heaps of land are leveled. Pits can be filled with soil from the same area, and heaps must be leveled in accordance with the main surface. Then the site is marked for the installation of piles. Directly on the ground, special designations are installed in those places where the support will stand. The contours where the monolithic slab will pass are also marked.

- Pile deepening. At this stage, supports are brought to the site. The type of piles is chosen depending on the nature of the building and the characteristics of the soil. The types of piles differ in the quality of the material, as well as in size. Reinforced concrete supports are considered the most durable, the size is usually chosen depending on the depth of soil freezing. Then a special pile driving technique is installed on the territory. As a rule, a pile driver and other equipment is used for this purpose. Each support is first installed directly at the point where it will be buried. Then it is leveled, after which it is immersed in the ground with a hammer. There are various ways of burying supports into the ground, however, all of them are associated with the use of heavy equipment in such construction. After the installation of all the piles, they are aligned.To do this, using a special technique, the heads of the supports are cut to the zero level.

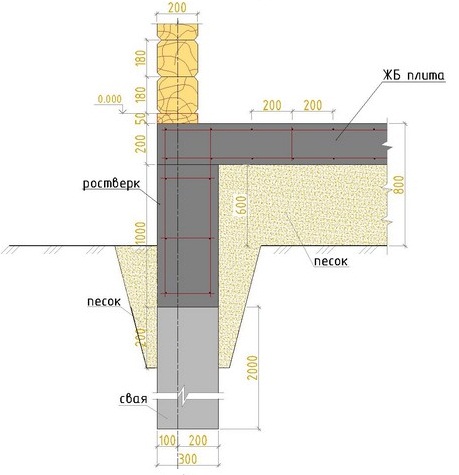

- Pouring the monolith. After all the supports are ready, you need to start pouring the monolithic slab. For this purpose, the first thing to do is to install the formwork. The resulting box is pre-supplied with waterproofing, most often in this case roofing material is used. Then a special pillow is prepared. A layer of sand about 20 centimeters thick is poured into the box, the material is well compacted and leveled. Next, the same layer of crushed stone is poured, and it is also leveled. Then the pillow is covered with a small layer of liquid concrete, which will help anchor the bulk materials. The thickness of the concrete should not exceed three centimeters. After that, a reinforcement frame is constructed in the formwork, which is subsequently poured with concrete. During the process of pouring concrete, a certain technology should be followed. For example, the solution should be poured into the box from both sides.

Expert advice:

- After the concrete slurry is completely placed in the formwork, it must be leveled and compacted. This action is carried out using vibratory rammers. Then the monolith is left to dry. Complete hardening of the concrete slab is observed 30 days after pouring. During the period while the concrete dries, you need to take care of the slab. To do this, cover the monolith with a film and slightly moisten it several times a day.

- Care for the surface of a monolithic slab allows you to prevent improper and uneven drying of the concrete solution. After the concrete is completely dry, and the slab becomes as strong as possible, you can proceed to the construction of the remaining elements of the building structure.

-

In some cases, a USHP is used as a base - this is an insulated Swedish plate. USB is not just a concrete slab, it is the most modern and efficient base that performs several functions at once. Such a stove includes a communications system, heating the entire area of the house with warm floors, already installed sewage systems, water supply systems and even marking electrical cables. USHP have a smooth surface that allows you to lay the finished floor covering directly on the monolith.

- UWB is often used in the construction of aerated concrete structures, frame houses, structures made of logs and beams. The advantage of the UWB is that it can be erected on almost any territory, regardless of the nature of the soil. The technology for the construction of such a base assumes various options for arranging a monolith, which allows you to make a basement.

Foundation construction process

It is quite easy to confuse such a basis with a combined pile-slab basis. In fact, they have one scheme and differ only in nuances, since there are several modifications of such bases, but the cost of different options practically does not differ.

Before proceeding to the procedure, you will need to carefully consider the nuances of creating each type of bases - pile and slab. Their technologies have rather strong differences that will need to be taken into account during operation. The work itself is quite laborious and complex, especially when it comes to the construction of multi-storey buildings. But if a low-rise building is being built, most of the actions can be performed without the involvement of specialists.

The construction process consists of the following stages:

- Preparatory work.

- Installation of piles.

- Installation of the stove.

Preparatory work

Preparation is an extremely important stage of work.

Preparation is an extremely important stage of work.

The initial steps are the same for any foundation. Cleaning of the area, planning, marking and calculation is carried out. The soil will need to be carefully compacted; gravel and sand are suitable for this. Also, do not forget about the creation of a drainage system, the preparation of the area and the laying of engineering communications.

The installation of the basement floor greatly influences the preparatory steps.If a decision was made to equip it, it will be necessary to excavate the soil and create a foundation pit for the base. Reinforced concrete slabs will be vertically installed in it, which will serve as walls for the constructed basement.

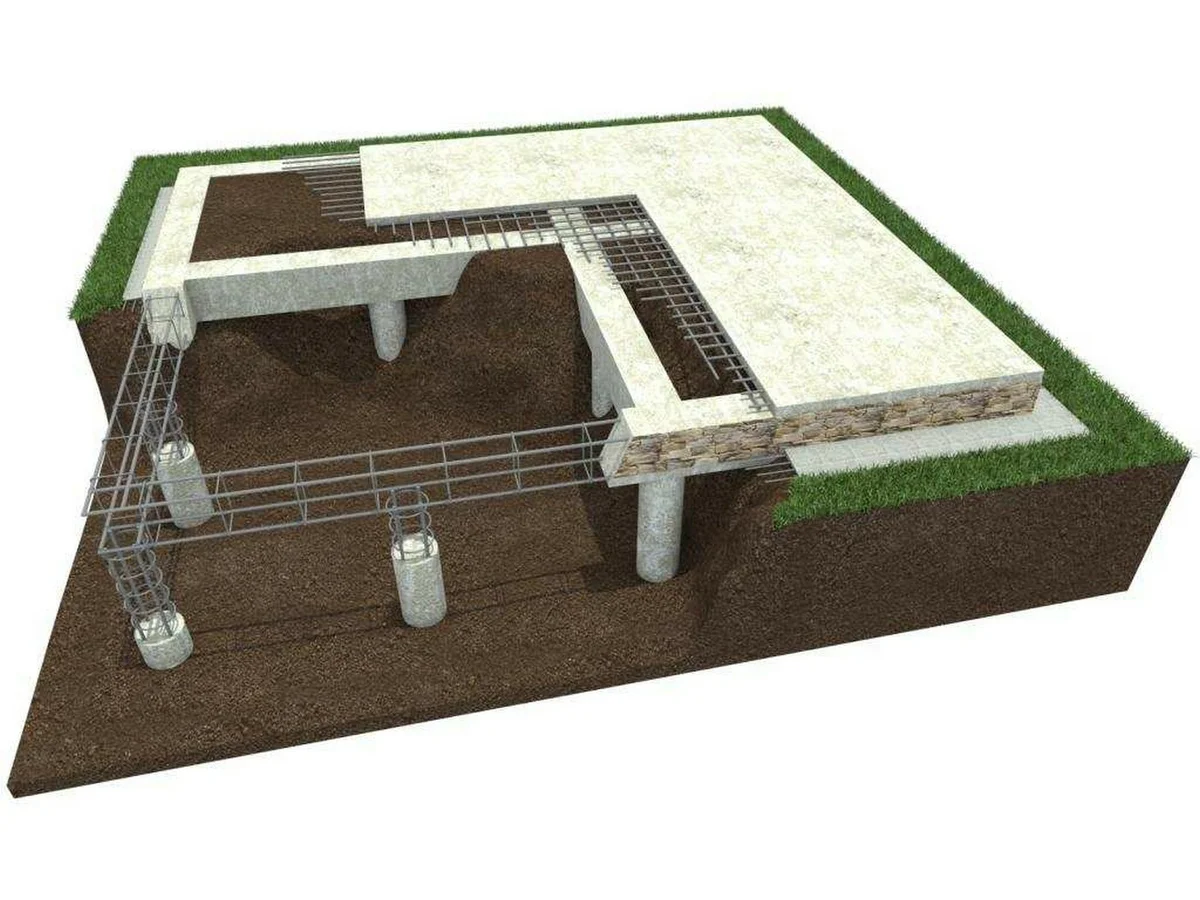

Installation of piles

For the installation of piles, additional calculations will be required.

For the installation of piles, additional calculations will be required.

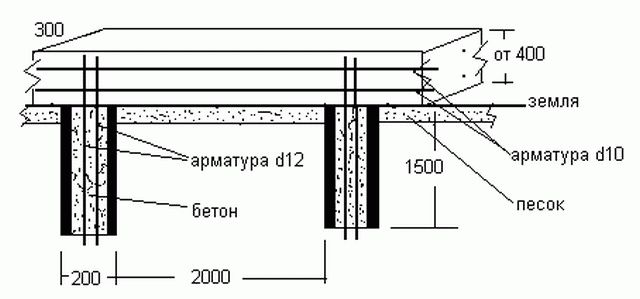

The methods for installing piles may differ depending on their type. For private buildings, asbestos-cement pipes are often used, which can save a lot. After installation, they are reinforced and filled with a cement mixture.

When installing piles, you need to consider the following:

Due to the fact that the slab will be installed on top, the pile cuts must be located at the same level.

The reinforcement in the piles is being laid with surplus. This will allow the two parts of the base to be rigidly connected.

The more the number of supports, the more financial costs will be. It is best to install supports under load-bearing walls, at the junction of adjacent surfaces and in corners. The place for installation also depends on the size and type of the building being erected.

The interval between the supports of the pile-slab foundation. To determine the optimal distance, you will need to perform a calculation. The optimal spacing is calculated from the pile diameter

It is quite difficult to perform the calculation, but it is extremely important, so it is better to seek help from a specialist. It will be much easier to calculate the required number of piles, knowing their approximate location.

Installing the stove

To transport the slabs, you will need to use special equipment.

To transport the slabs, you will need to use special equipment.

Plates can be mounted with different depths, but the installation process itself is no different. During operation, the following factors must be considered:

- The slab acts not only as a foundation, but also is the floor of the lower floor of the building. To provide a higher level of waterproofing, it is better to pour a layer of clay on the ground, then level and compact it. Then a cushion of sand and gravel is created, and already on it, the foam panels are installed. Such procedures will reduce the amount of heat loss, and, consequently, save on heating the house.

- During the reinforcement of the slab, you will need to tie the frame to the rods coming out of the piles.

- In the manufacture of the mixture, it is necessary to use only small and medium-sized fillers. Otherwise, significant complications may arise when compaction of the frame.

- Pouring of concrete must be carried out completely over the entire area of the base. It is not recommended to postpone the installation of the plate for the next day, as seams and holes may form.

This completes the process of creating the pile-slab base. The following video will help you find out all the features and nuances of such work.

The pile-slab base has a number of features. Its use is necessary for the construction of multi-storey buildings or on poor-quality soil. The creation process itself is quite complicated, but if you follow the instructions, you can do the work on your own.

Features of the fundamental basis

Each of the component parts takes on a portion load, namely: slabs 15%, piles 85%. The difficulty lies in the correctness of the calculations. Incorrect data will lead to an increase in pressure. If the height of the building is up to three floors, then the construction of a slab without a grillage is allowed. This is an additional part of the horizontal pile-type foundation, which transfers the load of the supporting structures to the piles. As an additional function, the grillage is used to evenly distribute the load over the surface.

Feasibility of building a SPF:

- in geographic conditions where there is a high level of seismic activity;

- where there are problem soils with an excess of heaving indicators, freezing depth. As a rule, a pile foundation is used. But, if the designers plan the construction of a multi-storey building, then they reinforce the base with a slab type;

- the construction of an SPF is important when the structure is sensitive to vibrations or is made of foam concrete;

- if you plan to build an extension to an already finished structure;

- there is no reliable data on the building site, type of soil base, characteristics, composition.

There is no need to experiment when building. Failures or errors lead to the destruction of the structure.

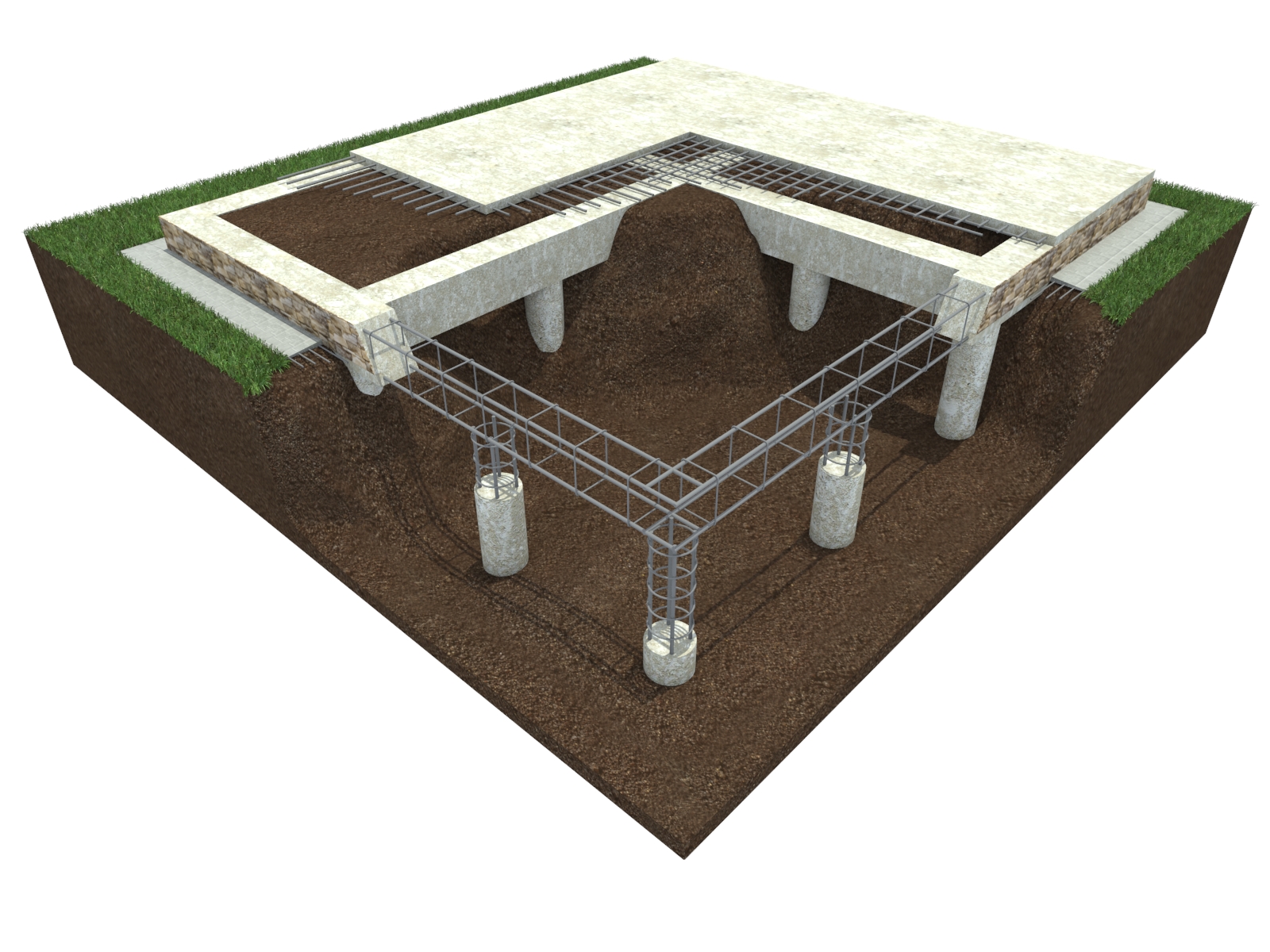

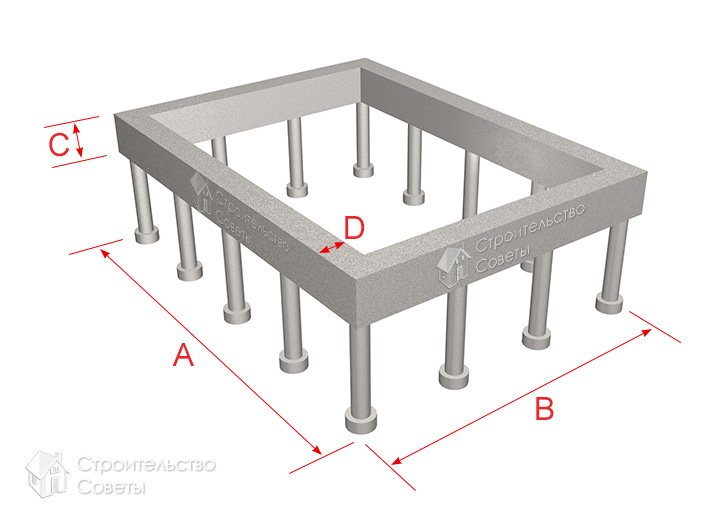

Types of SPF by grillage location:

- low level;

- high level;

- frameless base of the foundation.

General information

The slab foundation can be made in two ways: using ready-made reinforced concrete slabs or pouring a monolithic foundation.

In the first case, road slabs are suitable for use, laid close one to one on a prepared base with a cushion and waterproofing.

Sectional layout of the slab foundation

This project provides for quick installation, but requires additional costs for the use of special equipment for transportation and handling.

The features of the slab foundation lead to the need to carry out rather complex calculations to take into account the effects of loads in different sections of the slab. For the qualified design of this type of foundations, you should use the "Guidelines for the design of slab foundations of frame buildings and tower-type structures".

This tutorial provides recommendations for choosing the parameters of the foundation, design schemes. It allows you to determine the preliminary dimensions of the slab foundation according to the criterion of the minimum concrete consumption. The features of design and construction of slab foundations are described. Requirements for the measurement of heels, settlements and shifts are given.

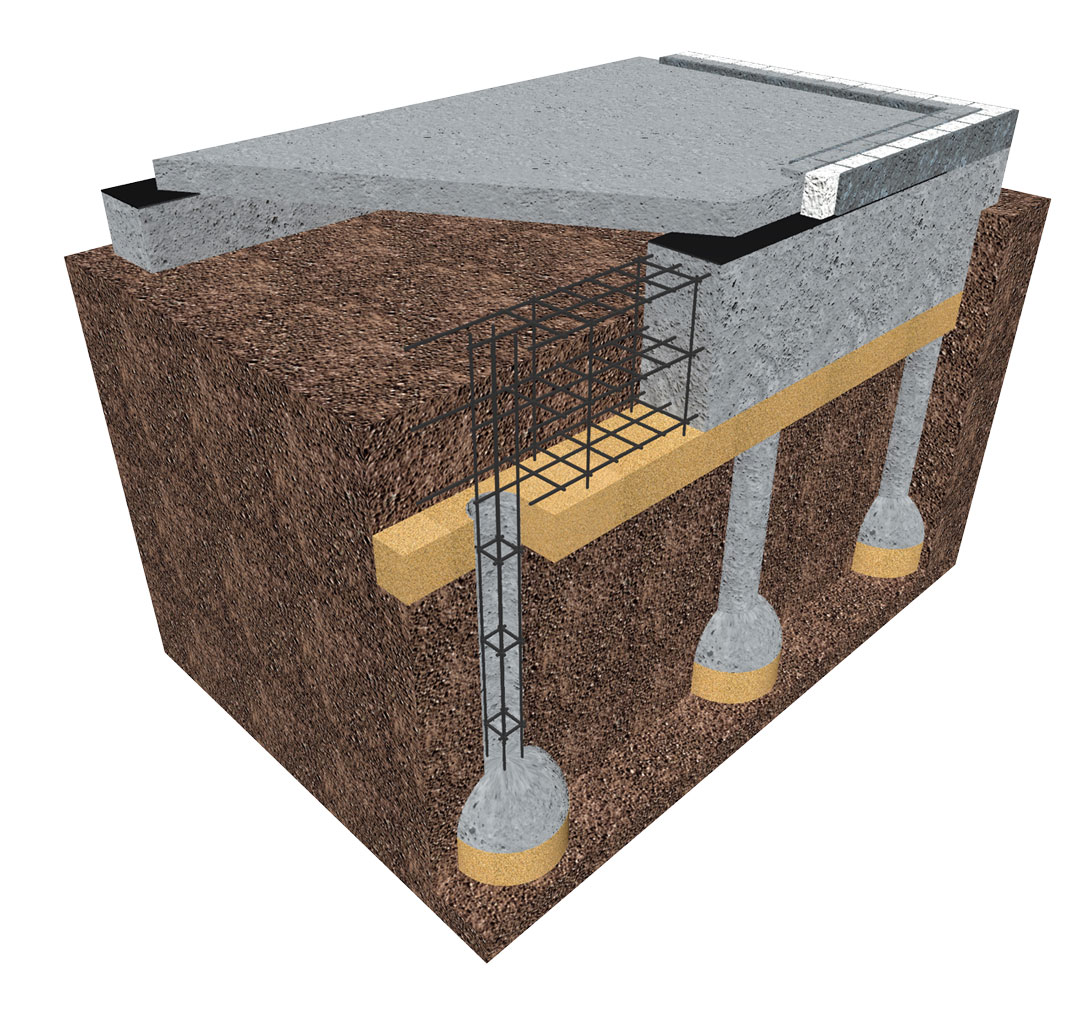

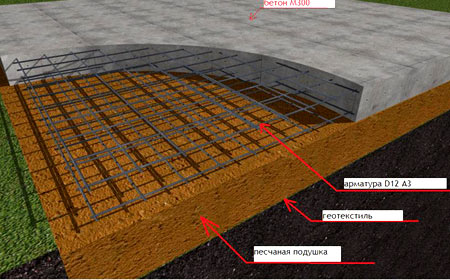

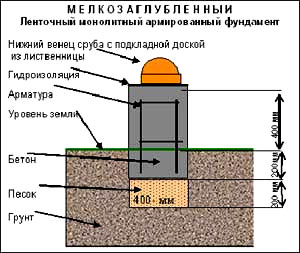

Like the strip, the slab base is laid on a pre-rammed cushion of a mixture of sand and gravel.

Then waterproofing and a reinforcing cage are installed on it. When reinforcing, you need to use two reinforcing meshes - an upper and a lower one, which are rigidly fastened with wire to one another. Slab foundation fittings are used from 12 mm to 16 mm in diameter. It should have a variable cross-section, that is, be ribbed. If a strip foundation is being erected, then ribbed reinforcement must be used only with longitudinal reinforcement.

Such a base of the house is under load in the longitudinal direction, because its width is less than the height. And the slab foundation is affected by loads in all directions.

The distance between the reinforcement rods is 20 - 40 cm. If the reinforcement is laid with a step of 30 cm, then about 14 m of reinforcement will go per square meter of the slab. A monolithic slab foundation, when poured, requires a higher consumption of reinforcement and concrete than other similar types of foundation. Accordingly, the cost of its construction is higher.

Scheme of reinforcement and concrete pouring of a slab foundation

Slab foundations are divided into ribbed, box-shaped and solid.

If the structure is planned to be performed without a basement, then a continuous floating foundation is erected, and the slab will in this case be a floor.

A slab foundation with stiffening ribs is used in the construction of residential buildings, while the height of the rib will be equal to the height of the basement and located on the lower side of the slab, that is, directed downward. At the same time, the top of the slab serves as a floor in an unfinished room. Such ribs are made from a concrete monolith or reinforced concrete blocks are used.

The advantages of such a stove:

- the plate becomes more resistant to deformation;

- stiffening ribs prevent horizontal movement of the slab.

A box-shaped foundation that can withstand heavy loads is erected during the construction of a multi-storey building.

Drawing of several options for a box foundation

It looks like a ribbed base and the height of its ribs is equal to the height of the wall underground, the ribs are connected to each other by a floor slab, thereby forming a concrete box.

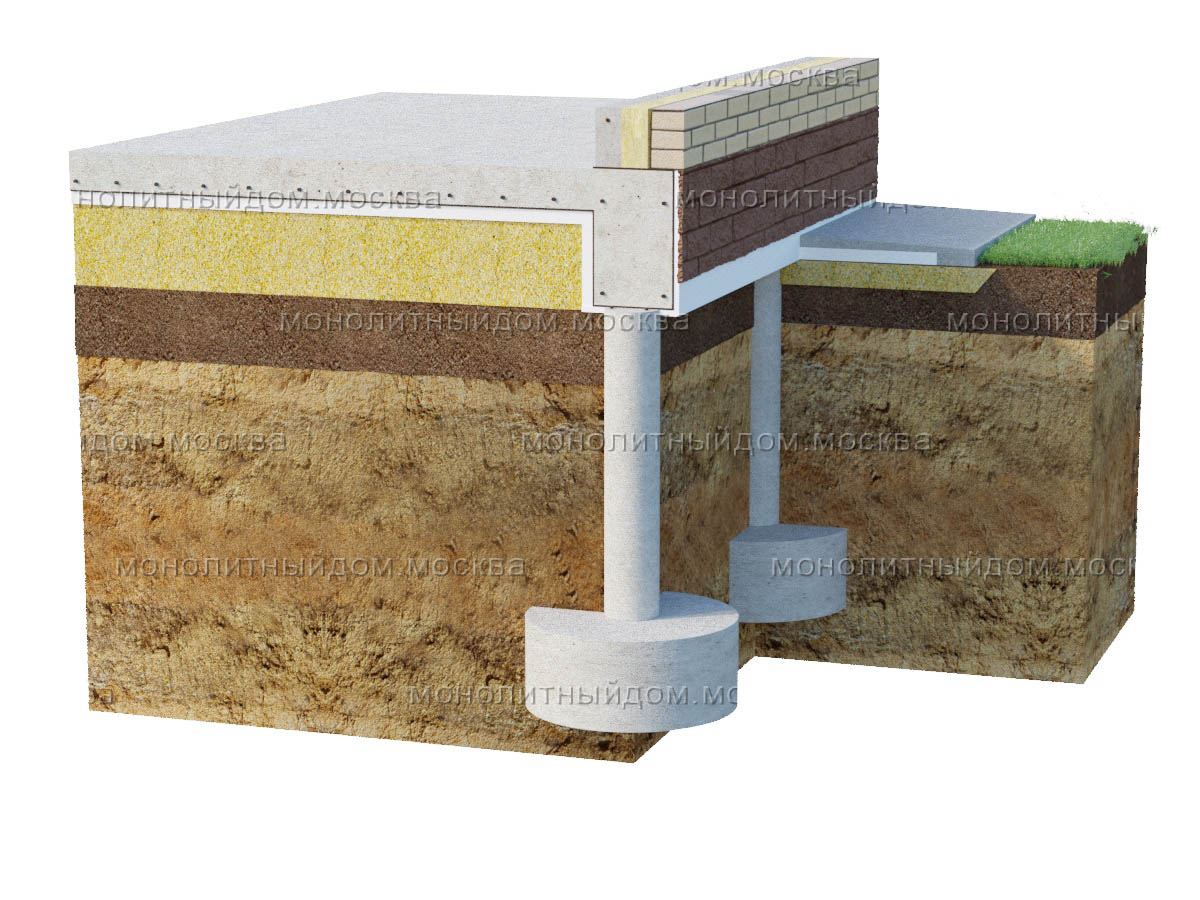

Monolithic-slab foundation can be deep or shallow. The deeply buried foundation is poured into a pre-dug foundation pit. This provides an increased load-bearing capacity of the structure. But the presence of such characteristics for private construction does not make sense, therefore this type of foundation is rarely used in it.

A shallow foundation involves the removal of part of the soil, and the presence of a cushion of a mixture of sand and gravel, the depth of which is laid up to half a meter. As a result, the upper surface of the slab should be slightly higher than the ground level - about 10 cm.

Construction work on pouring the foundation must be included in the project of the house. To calculate the need for a support plane for a house, you need to correlate the load on the base and the bearing capacity of the soil. A floating foundation is best suited for construction on weak or unstable ground, or in areas with elevated water levels. The slab-pile foundation also serves the same purposes.

Design of a pile-slab foundation from combined piles.

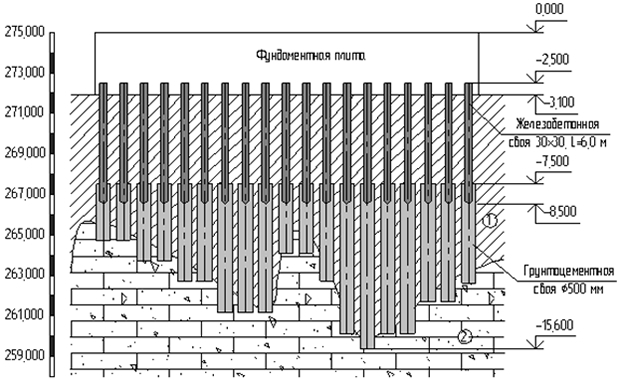

Currently, a cement plant is being built at the Akkermanovsky mine. Initially, for the raw meal silo, the project envisaged a pile-slab foundation made of reinforced concrete driven piles 30x30 cm, 6.0 m long.

Number of piles - 300 pcs. The size of the slab is 18.8x18.8 m, the thickness is 3.0 m. The total load from the silo and the slab is 25,139 tf (71 tf / m2).

According to preliminary surveys, the geology is clay, which is underlain by limestone. According to the project, the piles were to be based on limestone. But after the start of drilling the leader wells for driving the piles, it turned out that the top of the limestone has a crater-like character with peaks and troughs, as a result of which most of the piles do not reach the top of the limestone, which is the bearing layer. This can lead to abnormal rainfall and tilting of the silo.

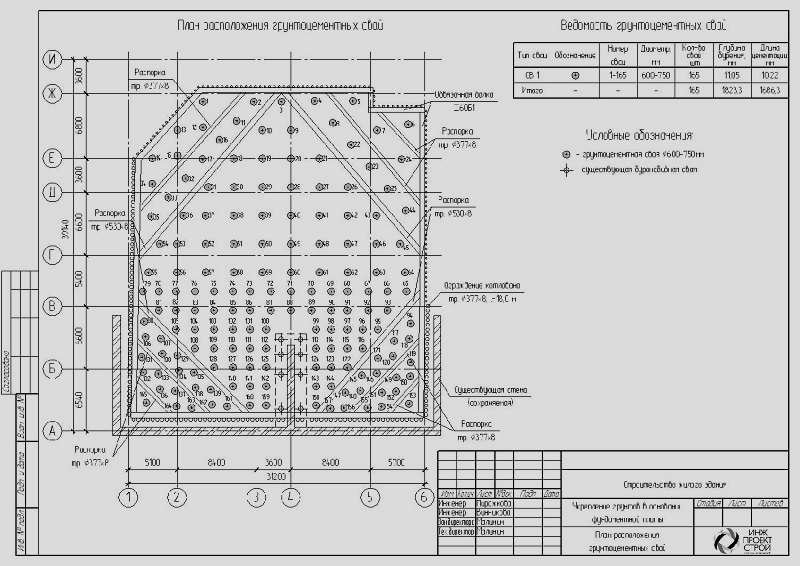

In order to reduce the settlement to a safe level, it was proposed to make soil-cement piles at the base of reinforced concrete piles using the technology of jet grouting of soils (Fig. 3).

Rice. 3. Section of the pile-slab foundation. 1 - clay, 2 - limestone.

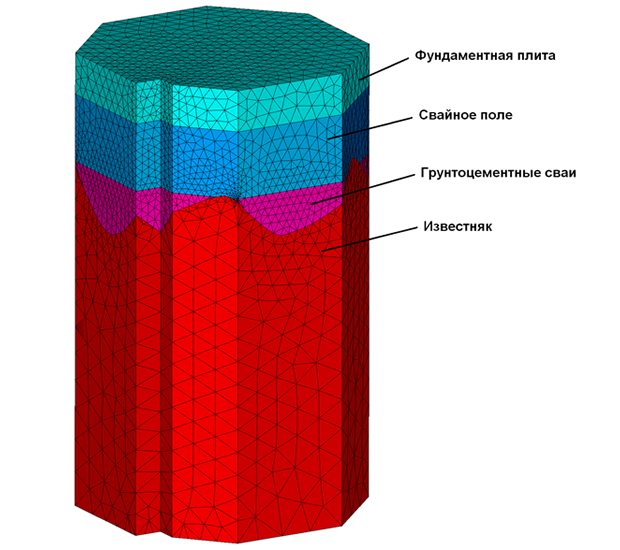

Modeling of the stress-strain state of the pile-slab foundation and soil mass is carried out using the finite element method in a three-dimensional setting.

Discretization of the computational domain was performed by triangular elements with linear approximation of displacements in the element area. The finite element model of the computational domain is shown in Figure 4.

According to geological surveys, the deformation modulus of clay is 15 MPa, limestone - 1000 MPa.

The diameter of soil-cement piles using the Jet1 technology in clay soils is taken equal to 500 mm, the modulus of deformation of soil-cement piles is 500 MPa.

The piles were taken into account by specifying the design layer with the averaged deformation modulus according to the mechanical mixture rule.

In the computational model, 4 layers were specified. The averaged deformation moduli of the layers are shown in Table 1.

Table 1

| № | Layer name | E, MPa |

|---|---|---|

| 1 | Foundation slab | 32 500 |

| 2 | Clay with reinforced concrete piles | 2 972 |

| 3 | Clay with soil-cement piles | 132 |

| 4 | Limestone | 1 000 |

The main difficulty was in modeling the crater-like limestone relief. In accordance with the additional engineering and geological data carried out, points corresponding to the elevations of the limestone roof were plotted on the calculated area, then these points were connected by surfaces.

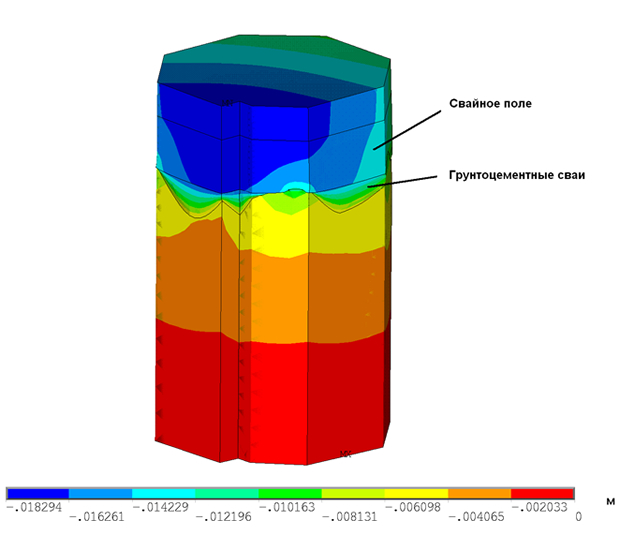

The performed calculations showed that the maximum settlement of the foundation slab was 1.8 cm, which is lower than the accepted permissible value of 5.0 cm (Fig. 5). The roll value of 0.0005 also does not exceed the permissible value of 0.0020.

Rice. 4. Fragment of the finite element model.

Rice. 5. Diagram of the distribution of precipitation in the soil massif, m.

At the first stage, the installation of soil-cement piles was carried out using the technology of jet cementation of soils (photo 3).

The wells were drilled to the top of the limestone to establish its actual elevation and buried 1.0 m into the limestone layer. Then the monitor was raised to a mark 1.0 m above the bottom of the reinforced concrete piles.

During the installation of soil-cement piles, numerous layers of limestone in the clay layer were also identified, which made it difficult to drill wells.

At the second stage, reinforced concrete piles were driven into the body of soil-cement piles by 500 mm. Pile driving was carried out with the device of leader holes with a diameter of 250 mm.

For quality control, a core was taken from the experimental soil-cement piles and the deformation and strength characteristics of the soil-cement were determined. The average compressive strength was 2.5 MPa, the deformation modulus was 543 MPa, and the elastic modulus was 1082 MPa. The test results confirmed the values set in the project.

Photo 3. Installation of soil-cement piles.

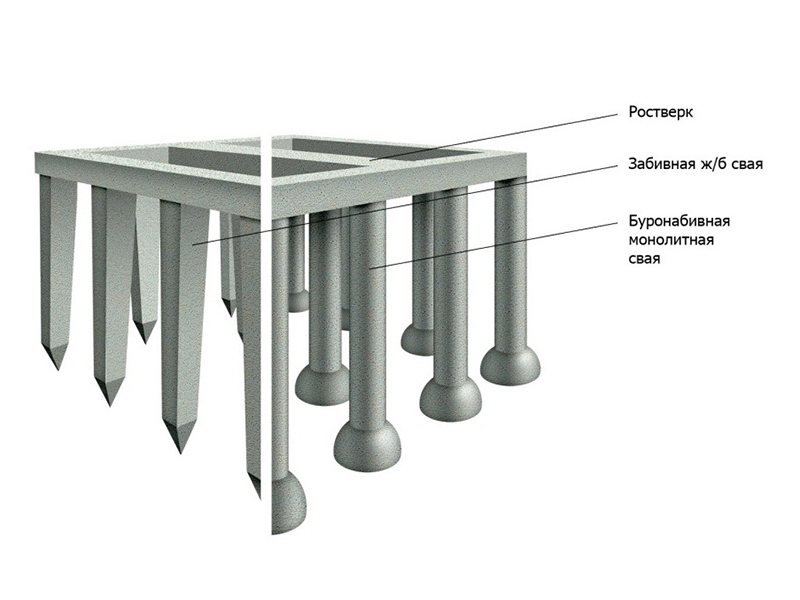

Installation of a pile foundation with a monolithic slab

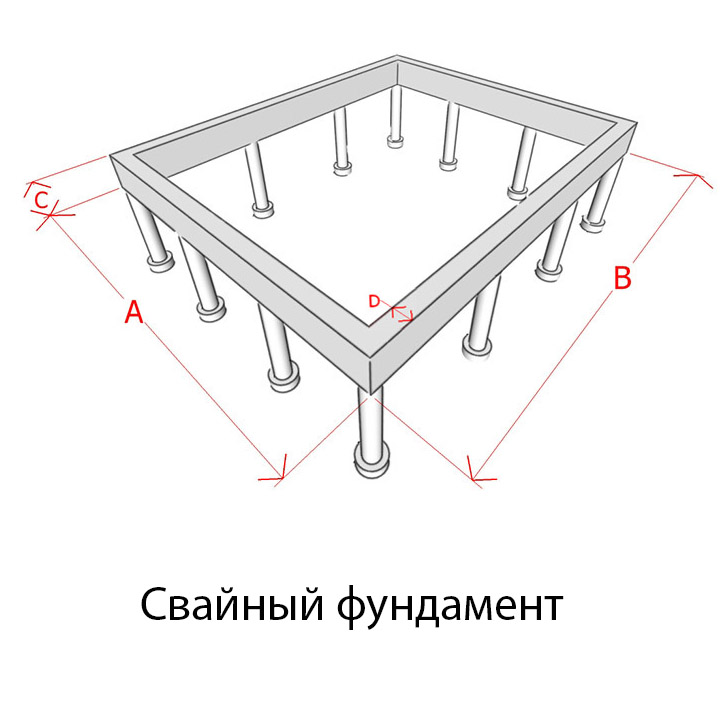

The two-component base of the cottage is made of structurally different parts, united by a common internal reinforcement. Visually, the device of a pile foundation with a monolithic slab looks like a stool - a horizontal plane is laid on the vertical supports, connecting all the individual components. From the point of view of construction, everything is a little more complicated, since it requires a careful calculation of all installation processes, taking into account the characteristics of the soil, as well as the need to pour high-quality concrete into the formwork. InnovaStroy specialists carry out turnkey pile foundations in accordance with technological standards and requirements of SNiPs, GOSTs. At the same time, the design includes requirements for the construction of monolithic structures - thus, already at the development stage, the foundation receives up to 20% of the safety and stability margin.

The two parts of the foundation are created in a clear sequence to ensure the structural integrity of the future foundation, and, as a result, to give the cottage stability and durability:

- Earthworks are being carried out in clearly marked places where the piles will be installed. As a rule, the deepening is brought to the level of the lower soil layers, which are not subject to external influences and shifts;

- Ready-made structures with wide supports are inserted into the holes obtained, or concrete is poured on site. An obligatory part is reinforcement with steel structures in order to exclude damage to the elements when compressed by soil. In the process of self-creation of piles, the reinforcement rods are left outward so that they become the rudiments of a horizontal monolithic slab;

- Formwork is installed at the bottom of the subfloor and on the sides, if the plane is not laid on the ground or deepened;

- Installation of reinforcing parts that create a mesh inside the structure is being carried out. In this case, it is not necessary to use welding - just twisting the components together is enough. Naturally, the amount of reinforcement is calculated by the designer and directly depends on the expected loads on the structure;

- Pouring with high quality concrete in several stages to harden the layers. During summer periods, concrete can be laid continuously, as the temperature will allow it to dry faster;

- The thickness of a monolithic slab or grillage depends on the structure of the house and the weight of the entire structure, which will be transferred to the base. As a rule, the height of the panel is not less than 30 centimeters in order to give the structure increased characteristics in terms of strength and wear resistance.

The device of a monolithic foundation is based on the relevant GOSTs and requires a certain level of reinforcement, a higher grade of concrete and increased reliability indicators. Slab foundations are sometimes called floating foundations because they are placed on the surface of the ground and can move with it.In the case of using a monolithic plane as a grillage, all norms of the standards are carried out especially carefully, because several multidirectional forces act on the base at the same time - and the foundation must withstand all of them, maintain integrity, and ensure the stability of the cottage structure.

This is interesting: Do-it-yourself tire foundation - we pose the question

What is a strip foundation on piles?

The strip pile foundation combines the advantages of two types - column and flat strip foundations. The first one performs the main work on interaction with the ground, and the second one ensures the distribution of the load of the walls of the structure.

At the same time, the material requirement for materials for the construction of the foundation is significantly reduced and labor costs are reduced.

Application area

Piles and strip foundations are suitable for the construction of a wide variety of buildings, from fences to brick houses, wooden beams and more modern materials such as aerated concrete, foam blocks, etc.

When using logs, they themselves can act as a pile-based grinder. If the structure consists of small elements, a rover is necessary.

There are several options for pile and strip foundations. The differences lie in the design of the lattice and the manufacture of the piles. In the simplest case, protocols can be used as such.

It's a short-lived material, but it's cheap. Usually coniferous wood is used and impregnation with mixtures is mandatory to protect against mold, fungi, etc.

Piles are not installed without the use of special equipment, so there is no need to talk about their use in independent work. And delivering them is not easy. ...

Monolithic

The monolithic foundation includes the manufacture of a monolithic reinforced concrete tap of the coupler, regardless of the type of pile.

This allows you to build almost any building from any modern material.

The load from such a foundation can be very high, although the load is slightly higher than with simpler options.

Screw

Another possibility is the use of prefabricated auger piles.

These are iron structures with threaded blades at the end. They will remind someone of a screw, a drill, but they are really screwed into the ground.

This type of pile is produced with a diameter of 57 mm and a length of 1650 mm. Given the corrosion resistance of the material from which the piles are made, it is not recommended to use them on soils with a high acid content (pH less than 5.5).

It turns out that attention to the acid-base balance is also important when building a pile foundation. For building a house, the optimal stack size is 108 or 133 mm in diameter and 2500 mm in length. After all, it is easier to cut off the surplus than to weld the missing one, especially since this length in most cases allows you to go below the soil freezing line

After all, it is easier to cut off the surplus than to weld the missing one, especially since this length in most cases allows you to go below the soil freezing line

For building a house, the optimal stack size is 108 or 133 mm in diameter and 2500 mm in length. After all, it is easier to cut off the surplus than to weld the missing one, especially since this length in most cases allows it to fall below the soil freezing line.

The benefits of this type of pile include, but are not limited to, the following benefits

- A minimum amount of excavation is required.

- This is a little time consuming.

- High speed when performing work.

- High "stability" in the ground due to the narrow entrance to the ground.

The disadvantage of piles is that the piles require a place for screwing in, which makes them difficult to install near other buildings, as well as low corrosion resistance.

With bored piles

These piles are manufactured locally.A hole is drilled in the pile, formwork is installed, reinforcement is installed, if necessary, and concrete is poured.

This option applies to almost all soil types. The main thing is that the depth of the piles should be greater than the depth of soil freezing in the area.

The benefits of this type of fund include, but are not limited to, the following benefits

- Low cost.

- Simplicity and speed of installation.

- You can do without special construction equipment.

Among the disadvantages, it is especially difficult to maintain the required accuracy when drilling and aligning the upper pile belt.

Regardless of the pile depth, approximately 10 cm of sand should be poured into the ground as a cushion.

Features of operation

A feature of the combined foundation is that first of all, a pile foundation is erected, and then a monolith is installed on top. The slab better holds the supports together, and also gives additional rigidity, strength and stability to the entire base as a whole. Thanks to this design, the need for arranging a grillage, which is usually provided for when erecting a foundation base, disappears.

It is best to install a combined base option in the following situations:

- When the construction is located in an area located in areas of increased seismic hazard.

- During construction in particularly problematic areas. For example, these can be territories with heaving soils, underground watery strata and lakes, as well as a large depth of soil freezing.

In addition, in some cases, the combined base is used to strengthen the supporting belt of the structure. This is necessary for a number of reasons:

- The use of a slab foundation coupled with a pile foundation is mandatory when erecting extensions to the main buildings that were erected in problem areas.

- The lack of geological research on the construction site requires the construction of a foundation of higher strength.

- Combined bases are used during the construction of vibration-sensitive buildings.

Foundation calculation

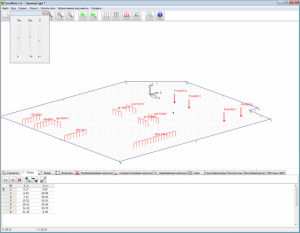

Screenshot of calculation in GeoPlate

Screenshot of calculation in GeoPlate

The calculation of the foundation of the house should provide for the connection between the pile trunks and the soil. The piles are placed under the monolith, so the mass of the house under construction will be distributed equally to all pile shafts.

With this method, you can eliminate the subsidence of the base of the house. It becomes possible to significantly shorten the construction time of the foundation if ready-made reinforced concrete slabs are used in this case. The joints are poured with concrete, as a result of which the resulting slab is, as it were, a ready-made building base.

The state-of-the-art building foundation calculation utility can even simulate soil behavior. It is well known that the construction of such a foundation requires extensive earthwork.

After preparing the excavation, its bottom is rammed and compacted with a layer of gravel mixed with sand. The sand is moistened so that it gives the maximum subsidence.

A waterproofing pad is placed on the compacted layer, after which a thin layer of concrete is poured. Then the frame reinforcement is laid, which is necessary for the greater strength of the concrete. After that, another layer of concrete is placed. Such large layers of building materials that go to form the slab, as well as the work associated with the preparation of the pit, make such a foundation very expensive.

Concrete mix under the foundation

To determine the amount of concrete that will be needed to fill the foundation slab, you need to calculate its volume. Take, for example, a house of 6 x 6 m and a minimum foundation thickness of 10 cm, then the volume of the slab will be 6 x 6x 0.1 = 3.6 m3. So much concrete is needed for the foundation slab, excluding the stiffeners. Since the stiffeners are made every three meters, in this case they will need three along the rib and three across.

The height of each such rib should be equal to the thickness of the slab, the length is 6 m, and the width is 0.8-1 times the height. If we take the shape of an edge in the form of a rectangle, then its volume will be 0.1 x 0.08 x 36 = 0.288 m3. So, for a solid slab of 6 mx 6 m s and six stiffeners, 3.89 m3 of concrete will be needed.