Technological features of waterproofing of different types of bases

For different options for the foundations of the structure, separate types of insulation are required. Before pouring, you need to determine what measures to perform for high-quality waterproofing.

Strip base insulation

For prefabricated and monolithic options, the waterproofing of the strip foundation has distinctive features. The prefabricated view of the base requires the following actions:

- waterproofing the basement slab of industrial production and the concrete walls of the basement require the arrangement of a high-quality, reinforced seam joint;

- waterproofing of the walls of the foundations with roll material is laid from the first seam located at the bottom level of the basement flooring;

- at the joints of the structure of the foundation and walls, along the edge of the foundation, insulating material is mounted;

- external waterproofing of the foundation of the buried part, carried out in a vertical way;

- installation of the blind area.

The edge of the foundation is insulated to completely protect the base material from destruction by moisture. The foundation is waterproofing pasting, it is carried out with roll materials, pasting type.

Vertical waterproofing of the foundation of the new strip is carried out along the outer perimeter of the building, this helps to protect not only the structure of the support, but also the inner premises of the basement.

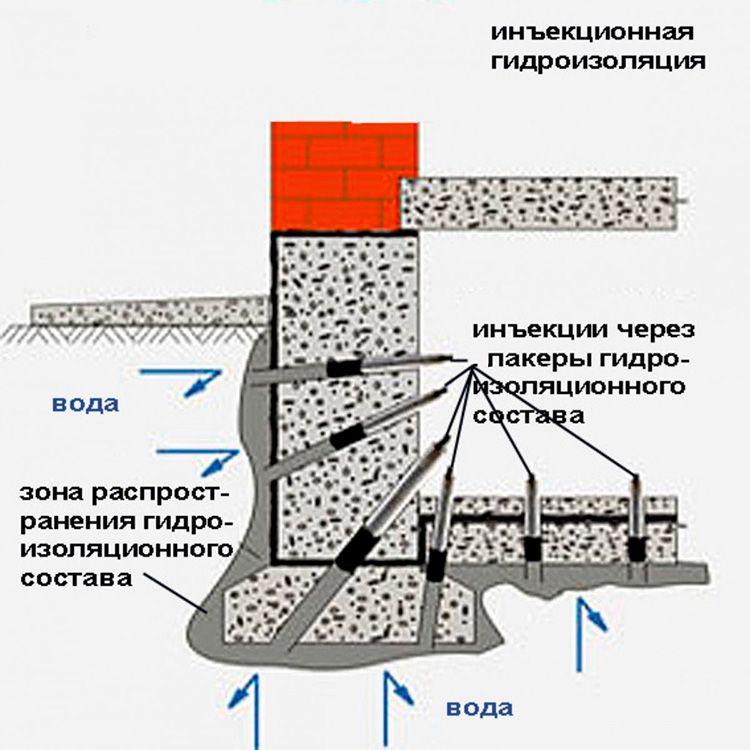

Basement waterproofing and coating waterproofing can be used. The inner side is insulated when finishing the premises, the use of injection and penetrating protection is permissible.

For waterproofing a monolithic tape, the following measures are needed:

- vertical protection;

- insulation of the edge of the base;

- arrangement of the blind area.

The sequence of work is carried out in the same order as when protecting a prefabricated type of foundation.

Pile and columnar base - waterproofing

These types of substrates do not require complex insulation from the effects of a humid environment. The main work will consist only in measures to protect the cut of the foundation, with a priming solution

The main attention should be paid to the grillage, the location of the waterproofing depends on the material of its manufacture

If the grillage and supports are monolithic, then the protection is laid at the points of contact between the walls and the base. If a basement is equipped, then it is waterproofed from the outside and from the inside from groundwater.

When using a screw base, on the pillars, which is immediately laid the first row of a wooden house, the insulation is equipped with waterproofing between the foundation and the wall.

Slab foundation protection

Is it necessary to waterproof the foundation against moisture? The answer is yes. For quality protection, you need to provide the following:

- depleted concrete foundation to isolate the slab support from bottom waters;

- waterproofing the footing, it is treated with mastic;

- external waterproofing.

When arranging the second layer of the slab, it is necessary to carry out high-quality insulation using the most modern materials. It should be understood that as the waterproofing under the foundation slab will be incorrect, the restoration of the waterproofing of the foundation when it is destroyed will be impossible.

If the building is small and has a low specific gravity, you can use a simple two-fold plastic wrap, which is laid on the footing.

After the plate is ready, it is worth taking care of its external insulation, using roll material

Particular attention should be paid to the joints of the base and walls of the house.

Now you understand how to properly waterproof the foundation.

What materials can be used for work

- Hydroizol is used as a sheet material, similar in its technical characteristics to ordinary roofing felt.

-

Fiberglass - used to protect the base, it is based on fiberglass, which is a very moisture-resistant component.

- Gidrostekloizol - has in its structure the elements of both of the above products, is used to work by gluing or scorching with a gas burner.

- Glassine is somewhat different from other insulators, since it is based on oil-impregnated cardboard.

- Roofing material - the most common or high-quality euroruberoid can be used. It is often the best choice for home owners, as it competently combines acceptable quality and affordable price.

- Materials based on bitumen, i.e. resin. It does not have pores in its structure; after heating and subsequent cooling, it forms a thin elastic waterproof film on the surface of the processed product.

- Technoelast is a roll product. It has an important quality to protect the surface from the formation of microorganisms - fungus and mold.

- Polymer based membranes. They have a long service life, reaching a half-century mark, while weakly resisting mechanical damage, but the foundation protects very well.

- Rubber of liquid consistency is convenient in that when it is used, no seams are formed on the surface, and the insulation itself has a homogeneous and evenly distributed structure.

- Uniflex is a product made on a foil basis. In addition to the protective function, it reflects heat, that is, it provides increased heat saving.

-

Elon is a material based on two layers, it is well resistant to temperature and can withstand radiation.

- Benite mats are insulators of mineral, that is, environmentally friendly origin. They are considered to be very reliable.

- Dry mixes - have a cement component, are used somewhat less often. This includes products such as penetron, hydrotex, calmatron.

Horizontal strip foundation waterproofing can be successfully performed using all of the above insulators.

Technology of penetrating waterproofing of joints and seams

It is used for the treatment of seams, joints, cracks in conjunction with a liquid penetrating waterproofing. It can also be used to restore damaged concrete surfaces.

- The concrete surface is cleaned of dirt and dust, washed with water. Cracks are embroidered, removing the remains of cement mortar, at the joints, strobes are made in size 2.5x2.5 cm using a grinder or a perforator.

- Cracks and grooves are abundantly wetted with water using a brush or spray bottle. Cracks are treated with a liquid solution of penetrating waterproofing and kept for 2 to 6 hours.

- Mix the required amount of dry mixture with water to the consistency of plasticine. Put the mixture into cracks and seams, with your hands or with a spatula. If large cracks are to be repaired, fine gravel must be added to the mortar. When waterproofing concrete structures with signs of destruction, the mixture is applied with a spatula in a layer of up to 13 mm, in several layers.

An hour after the setting of the waterproofing solution, it is necessary to treat the seams with a liquid waterproofing solution.

The process of waterproofing joints by hand or with a spatula

Blind areas to protect the foundation

Rains and melting snow form water runoff from the roof, which negatively affects the condition of the walls and foundation of the house, especially the wooden one. It is known that moisture and dampness destroys wood, log walls gradually darken and lose their original appearance, mold and rot appear.

In addition, the foundation constantly gets wet, as a result of which the performance of the structure deteriorates, subsidence occurs and the risk of flooding the basement or basement increases.Especially such problems are typical for areas with heaving soil.

To avoid the negative consequences of wetting the foundation and walls, blind areas are made around the house. This is a horizontal strip 60-120 centimeters wide with a slight slope along the perimeter of the building. Blind areas are made of concrete, clay, crushed stone and / or sand. Due to the slope of the structure, water gets under the walls and is diverted from the house and the foundation. High-quality and properly equipped blind areas will not only protect the building from moisture, but also become an excellent decorative element.

Before installing the blind areas, the perimeter of the building is thoroughly cleaned. Then a border is placed around the house, where clay is poured, and then rubble and / or sand. Layers are leveled and tamped so that the thickness of the base is at least 20 centimeters. Cover the top with a waterproof film. At the end, the site is decorated with tiles or stone and the installation of gutters is carried out.

Waterproofing a foundation is a complex and time-consuming process. Improper technology and poor quality materials will lead to the formation of mold and mildew on the walls of the house, cracking of the foundation and leakage in basements. To avoid mistakes, entrust the work to professionals!

Experienced masters of the company "MariSrub" will select high-quality materials, equip blind areas, reliably perform installation, waterproofing and insulation of any kind of foundation!

Types of waterproofing

The device of waterproofing on a strip foundation is possible with your own hands, without the involvement of appropriate specialists. But before starting work, it is necessary to determine the appropriate version of the protective layer device, to clarify the technological features of the work.

The materials with which the strip foundation can be waterproofed in the ground are four groups:

- coating;

- sprayed;

- roll;

- lining.

The entire technology for performing waterproofing work will depend on the final choice.

Bitumen

The mastic is used for the coating option. The main advantages of this method are:

- acceptable price;

- high level of elasticity;

- excellent indicator of the hydrophobicity of the coating;

- ease of work;

- good adhesion level.

There are also certain disadvantages:

relatively short service life. After about six years, the mastic loses its elasticity, becomes brittle, cracks appear on the surface of the layer, and the degree of protection decreases.

But today the construction market offers a lot of options for coating compositions based on polymers, rubber, latex. With their help, increased protective characteristics are created:

- improves elasticity and adhesion;

- the spread of the temperature regime increases during the work.

The workflow is straightforward. To begin with, the surface is cleaned from construction debris and dirt. After that, the base is treated with primers with a deep level of penetration. Once the primer is dry, it is allowed to apply a waterproofing layer. The coating should be solid.

Roll

In such cases, roofing material, isoelast, aquaizol and other roll materials are used, which are divided into two types:

- pasting - attached to bituminous mastic or other compounds with adhesive properties. There are self-adhesive materials;

- floating - to perform it, you have to use additional equipment - a gas torch, blowtorch.

The method is distinguished by its simplicity of execution, a long operating period, excellent moisture resistance, reliability and good indicators of strength against mechanical influences.

Deformation capabilities and resistance to chemical compounds of a material are determined by its basis.Roll material on fiberglass or fiberglass does not differ in high deformability and resistance to chemistry, but polyester has such qualities.

The sequence of work is as follows:

- preparing a surface that must be dry and clean;

- bitumen is applied;

- roofing material is glued in a flowing way;

- webs of material at the joints are superimposed on each other fifteen centimeters, processed with a burner.

Sprayed

This waterproofing option is considered innovative. It is allowed to use it for the construction of any foundation foundation, during the repair work of old coatings. There is only one drawback - the price, which is not acceptable for everyone.

The advantages are as follows:

- long service life;

- high degree of adhesion;

- ease of work;

- lack of seams;

- fast hardening;

- ecological cleanliness and absence of toxins;

- UV resistance;

- good degree of elasticity.

The work is carried out in the following sequence:

- the surface is cleaned, covered with an antiseptic composition;

- seamless waterproofing coatings are applied with a special spray device;

- as an additional measure, the surface must be reinforced with geotextile material.

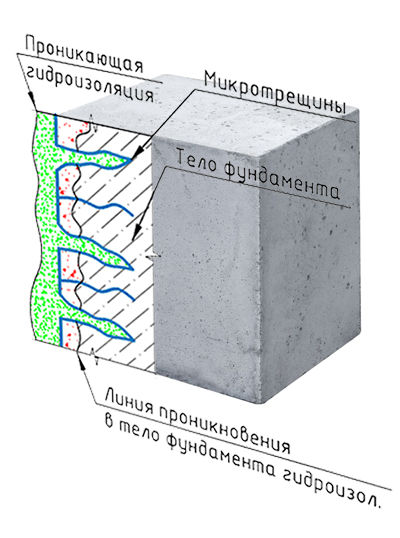

Penetrating

An efficient and costly method for applying waterproofing coatings. Materials for this, as a rule, are prepared from cement, quartz sand and certain additives. The application method is similar to plastering work. But today on the construction market you can buy compositions that are applied by spraying or coating.

With this method, special elements in the form of crystals are created in concrete voids, which repel liquid.

Clay

A simple and effective way that perfectly protects against water. A trench is dug around the foundation base to a depth of 50-60 cm, and a cushion of gravel or crushed stone up to five centimeters high is placed at the bottom. Then clay is poured in layers, carefully compacted. It will act as a moisture buffer.

The main advantage of this method is simplicity of execution. But for a residential building, it can only be used as an additional degree of protection.

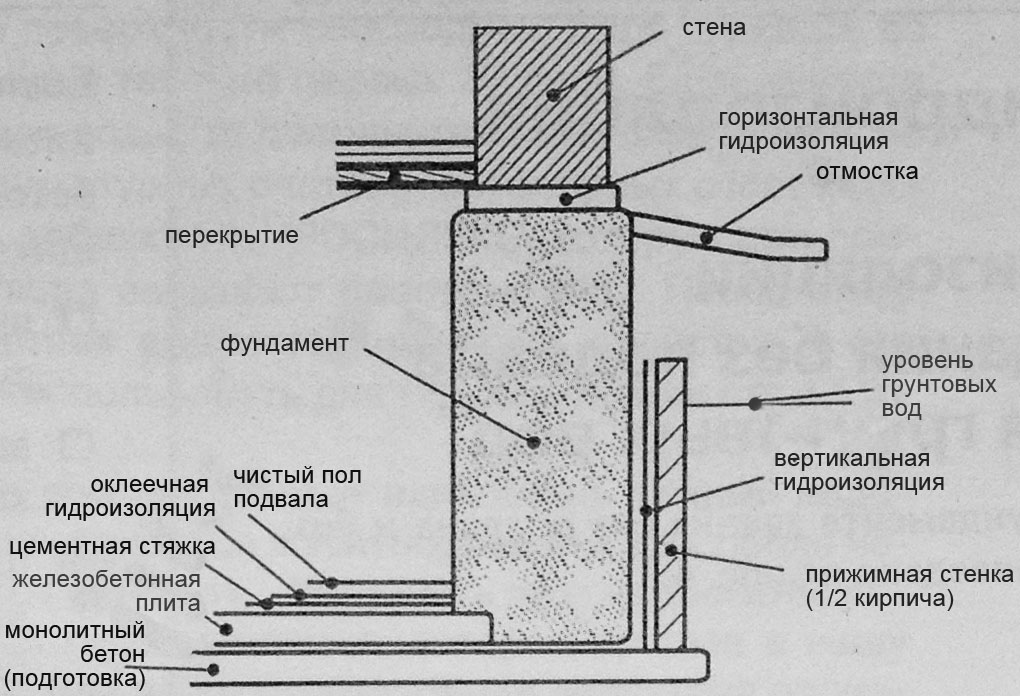

Horizontal waterproofing

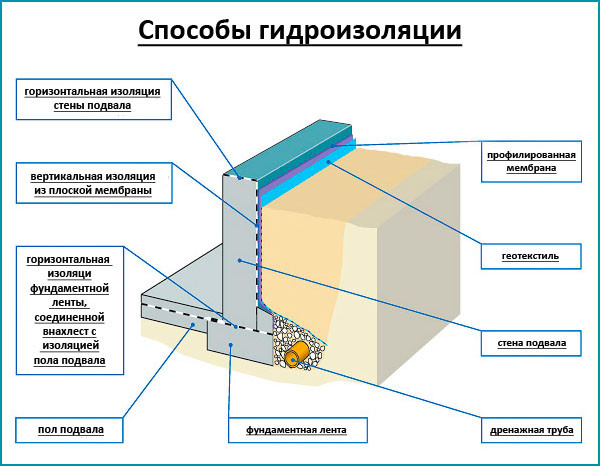

Horizontal waterproofing of strip (prefabricated) or monolithic (solid) foundations should be carried out in two places:

- Insulation is carried out at the level of the basement floor.

- Insulation is done at the joint between the foundation and the wall.

Horizontal waterproofing is carried out exclusively during the construction period, therefore it must be carried out in a timely manner. Before the foundation is erected, sand or clay wakes up to the bottom of the pit. The thickness of the sand layer should be between 5 and 20 cm. This is the so-called leveling layer. The backfilled layer must be rammed. After tamping, a concrete mass up to 7 cm thick is poured. This is a preparatory layer for creating a waterproofing cake.

In two weeks, when the concrete is completely dry and becomes as strong as possible, anti-pressure gluing waterproofing is applied to it. This insulation consists of four layers. First, the concrete base is plentifully coated with mastic, and the roofing material should creep onto it tightly. Then another layer of mastic and another layer of roofing material. Instead of two layers of mastic and two layers of roofing material, only one layer of Stenofon 290 waterproofing can be used.

After laying the waterproofing, the last concrete layer, or concrete floor, goes.

Foundation waterproofing and its types

The construction of the foundation is the first step towards the construction of any structure, but if the developers think about which option is suitable for a particular area and a particular structure in advance, then they remember about the reliable protection of the foundation of the structure last.In fact, it is even exposed to moisture that permeates the soil throughout the year. If you do not take care of reliable, soon moisture, combined with the destructive force of soil movement, will simply destroy the concrete, and then lead to corrosion of the reinforcement, which will significantly reduce the foundation's ability to withstand the loads imposed on it.

The scheme of waterproofing the foundation of the house.

Without reliable waterproofing protection, the foundation of the house is doomed to slow destruction, which can ultimately lead to the collapse of the structure standing on it. Especially thorough waterproofing is required if the basement is planned. There are a number of different parameters, thanks to which the main ones can be distinguished.

According to the direction of protection, waterproofing can be distinguished:

- horizontal;

- vertical.

Horizontal waterproofing is the protection of the lowest part of the foundation, that is, the horizontal part of its base. Vertical waterproofing includes all types designed to provide protection for vertical walls.

Depending on the materials used, the following waterproofing options can be distinguished:

Layout of horizontal waterproofing of the foundation.

- bituminous mastic;

- liquid rubber;

- plaster;

- penetrating waterproofing;

- screen;

- roll.

The above methods of waterproofing based on certain materials have both their advantages and disadvantages.

When choosing a waterproofing material, special attention should be paid not to the cost of the material, but to its characteristics, especially when it comes to additional in areas with an elevated level of groundwater, since if the equipped basement is not properly protected, the room will be constantly flooded. You can choose the appropriate option for a particular case only after understanding the characteristics of all the most common types of waterproofing, so it is worth considering in more detail the main ways to protect the foundation

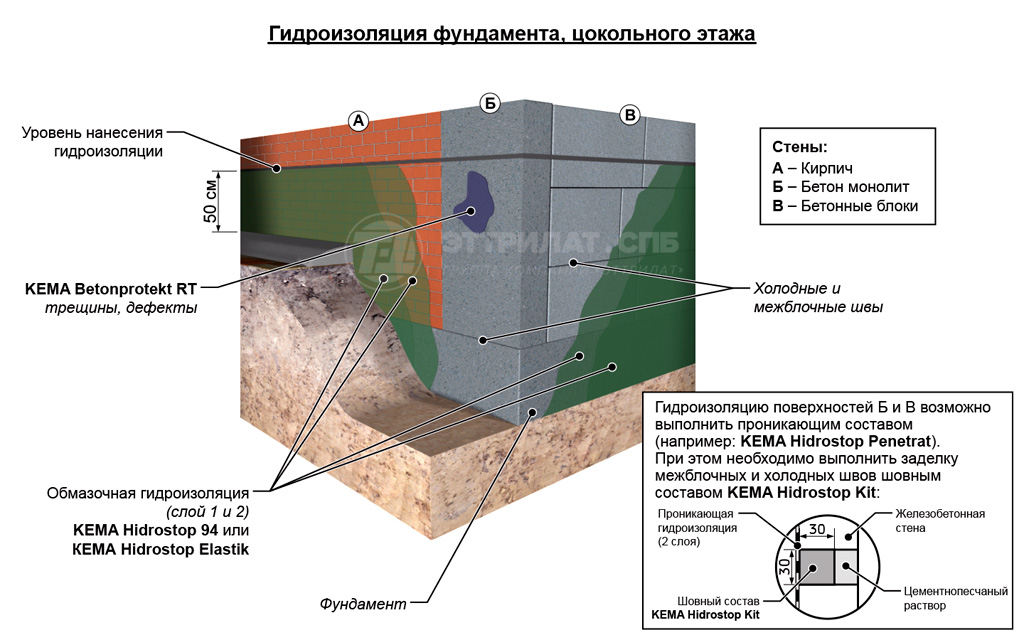

Other types of insulation

In addition to expensive injection insulation, it is possible to use lining or horizontal cut-off insulation to protect the foundation blocks.

For coating insulation, hot bitumen or mastics based on it are used. Bitumen, creating a film on the surface, clogs pores, cracks, holes in FSB blocks, creating an impenetrable barrier for water.

Insulation of foundation wall blocks is carried out as follows:

- the surface is thoroughly cleaned of dirt, soil, concrete humps;

- a solution of cement with sand carefully insulate the cracks;

- primed the surface of the walls;

- the first ball of heated bitumen is applied to the dried layer;

- after the first ball of bitumen has completely dried, a second layer is applied with strokes perpendicular to the strokes of the first layer to create a durable coating;

- for proper operation, such a coating should not be less than three millimeters thick in a single ball.

Cold bituminous mastics are much more effective in this case. The composition of such a mastic includes polymers, which makes it plastic.

The most modern material for coating waterproofing of foundation blocks is penetrating waterproofing with penetrating compounds based on cement, quartz dust, polymer additives. When the mixture is applied to concrete, due to capillary suction, it gets inside and crystallizes in the pores of the concrete. As a result, after the mixture dries, we get a monolith, which is one third stronger than a concrete base. When water tries to penetrate deep into the concrete, it becomes even stronger.

Dry penetrating mixtures are sold dry in bags and diluted with water to the consistency of thick sour cream. The composition should be easy to apply with a brush or brush. When working, you need to observe a time lag of 30 minutes, since the solution quickly sets. It is strictly forbidden to dilute the solution.

The stages of waterproofing a foundation about penetrating insulation look like this

- the foundation is cleared of dirt:

- wall blocks are cleaned of paint residues, plaster, old coatings;

- with a glossy surface of the old foundation coating, it is treated with acid for several minutes;

- the surface must be damp when applying the waterproofing solution.

The solution is applied by hand with a brush or roller in several layers. The full effect of waterproofing with a penetrating mixture is visible after a few days.

Horizontal insulation strip foundations

It all depends on the chosen method of manufacturing the structure, of which there are two:

- Made;

- Monolithic.

In both cases, it is necessary to provide for the laying of waterproofing material between the outer wall of the house and the basement. Such insulation is necessary so that the contact of materials with different characteristics does not lead to damage to one of them. The main cause of damage is moisture. The liquid content of some structures is normal, but other materials can rot, mold or rust from this. This is especially true when in contact:

- concrete with masonry;

- concrete with wood;

- metal with wood;

- metal with brickwork.

Waterproofing between brick wall and foundation

If you forget about the isolation between these structures, the consequences can be dire. For installation along the edge of the base, you can use:

- roofing material;

- linocrome;

- waterproofing.

All of the above materials are stacked in two layers. If we consider old textbooks, such options as roofing paper and glassine are often used there. The use of the first is prohibited, the second can be considered only as a last resort, when it is not possible to purchase more modern materials for waterproofing.

Providing insulation between the plinth and the masonry of the walls is important not only for tape bases, but also for everyone else. The way to protect the foundation from moisture depends on the pressure of groundwater

The way to protect the foundation from moisture depends on the pressure of groundwater

The way to protect the foundation from moisture depends on the pressure of groundwater

When arranging a strip prefabricated foundation, it will be necessary to provide an additional layer of horizontal waterproofing. It is located at the level of the floor, basement, or 15-20 cm lower (in the nearest horizontal seam between the blocks). The materials used are the same as in the previous case. The styling technology is no different: in two layers.

An additional layer of insulation for the strip foundation can be the laying of material on a sandy floor in a foundation pit or trench. This prevents damage to the sole. As raw materials, you can use:

- roll materials;

- diffusion membranes;

- clay (making a castle);

- plastic wrap;

- pouring from concrete of low grades.

Multi-layer foundation protection

Multi-layer foundation protection

Such insulation is especially relevant during construction on heaving soils.

Horizontal insulation of slab foundations

In monolithic slabs, horizontal waterproofing of the foundation plays a major role. Here it will be necessary to carry out protection measures not only between the masonry and the base, but also in other places. In general, the following stages of moisture barriers can be listed from bottom to top:

Roofing material prevents moisture from entering the structure

Roofing material prevents moisture from entering the structure

- Lean concrete preparation. Performs several functions at once. Levels the base for pouring the slab, strengthens it. At the same time, it does not damage the base of the foundation by groundwater and reliably protects it.

- Waterproofing for concrete preparation. Fits under the insulation (if any). It can be made from various materials. Prevents the penetration of soil moisture into the supporting structure.

- Insulation of the slab from above across the entire width. The method is not always applied. Allows to protect the foundation from moisture penetration from the air or room.Such protection is especially relevant in wet rooms (bathrooms, toilets, kitchens), where there is a risk of flooding.

- A layer between the foundation and external wall railing of different materials.

In the second case, the following materials can be applied:

Application of a diffusion membrane to protect the base

Application of a diffusion membrane to protect the base

- roofing material;

- linocrome;

- hydroisol;

- diffusion membranes;

- polyethylene film.

The most modern and expensive option would be to use a membrane. For horizontal insulation, materials with a smooth surface are intended (they are easy to visually distinguish from perforated membranes for vertical protection).

Horizontal insulation along the cast surface of the slab can be done in several ways. The simplest and most affordable of them is iron. It can be carried out using two technologies:

- Wet way. Performed at least 2 weeks after pouring. The simplest mortar is prepared in compliance with the proportions of sand, cement and lime dough 1: 1: 10, respectively. Lime is needed to prevent cracking. Advantage of the method: greater strength compared to dry.

- Dry method. It is carried out immediately after setting. The surface of the concrete is sprinkled with a dry mixture of sand and cement one to one. Layer thickness - from 3 mm. Next, you need to wait until the mixture is saturated with moisture from the concrete and rub it into the surface. The work is performed with a trowel. The method is simple and cheap.

A simple way to protect against moisture penetration

A simple way to protect against moisture penetration

In addition to ironing, the upper edge of the slab can be coated with bitumen. This option is also available, inexpensive and quite simple to implement.

The most famous in this group was "Penetron". It penetrates deep into the concrete and crystallizes in the capillaries, preventing moisture penetration.

Between the external enclosing structures and the foundation, for the manufacture of which different materials were used, a layer is laid, as is the case with strip foundations.

Where are penetrating compounds used?

At the moment, penetrating waterproofing for concrete (reviews indicate this) is quite popular and is used both in the construction of buildings and structures, but it is also often used in the construction of wells, reservoirs, pools, cellars and other things (for all structures that somehow come into contact with water). Its peculiarity is that it can be applied not only outside the building, but also inside, at the beginning or at the end of construction work. It is especially important to use such insulation for already erected buildings, where it is difficult to provide external moisture-resistant insulation.

Many simply do not know about this type of material, and in the old fashioned use bitumen-based solutions or roll materials. Although, bitumen cannot withstand the pressure of water, and after a while it loses its properties. Then, when the building collapses, the bituminous coating may be damaged, cracks will appear, the integrity of the structure will be violated, and as a result, the waterproofing itself will no longer be effective.

Key Benefits of Penetrant Insulation

To summarize, it is worth considering in more detail what advantages penetrating waterproofing for concrete has, how it differs significantly from other materials. So, the pros are as follows:

- it is allowed to apply to a damp surface, even at the stage of the foundation;

- can be applied on finished buildings;

- safe in the ecological plan, often used in the construction of pools and reservoirs;

- after application, the characteristics of the concrete itself are improved, such as strength, thermal conductivity, frost resistance;

- the mixture can be applied both to the inner surfaces and to the outer ones;

- application of the composition does not require special skills or knowledge;

- the design retains its vapor permeability properties.

The market is replete with a variety of such material, the most common of which are: Antihydron, Penetron, Drizoro, Lakhta, Crystallisol, Hydrochit and others. Such compositions can vary in price category, composition, processing method. Quality plays an important role. As you know, there are many handicrafts that differ significantly in properties from the originals. This means that such a material not only does not protect the foundation from moisture, but, on the contrary, can affect it negatively. Before you buy a certain mixture, it is better to consult with a master.

As you can see, penetrating waterproofing has undeniable advantages. An increasing number of builders are in favor of using such a composition to protect the foundation from moisture. After all, as you know, reliability, strength and durability are the main qualities of any structure. And they, in turn, depend on the quality of the base itself.