Required sand layer thickness

Many developers, without going into details, argue that the required thickness of the sand cushion under the foundation is 15 cm, it is this layer that is optimal and will not allow moisture to rise to the base of the structure.

Indeed, this is true when it comes to a slab or strip foundation in normal geological conditions.

If you use a more subtle approach to business, then the following classification should be used:

- Pillow under the strip foundation. This most common type of foundation is used in the absence of high water and involves filling a sandy layer into a prepared trench. In this case, a layer of 15 cm of sand is sufficient, subject to an easily erected structure, and 25 cm, if a brick building is planned to be built with several floors;

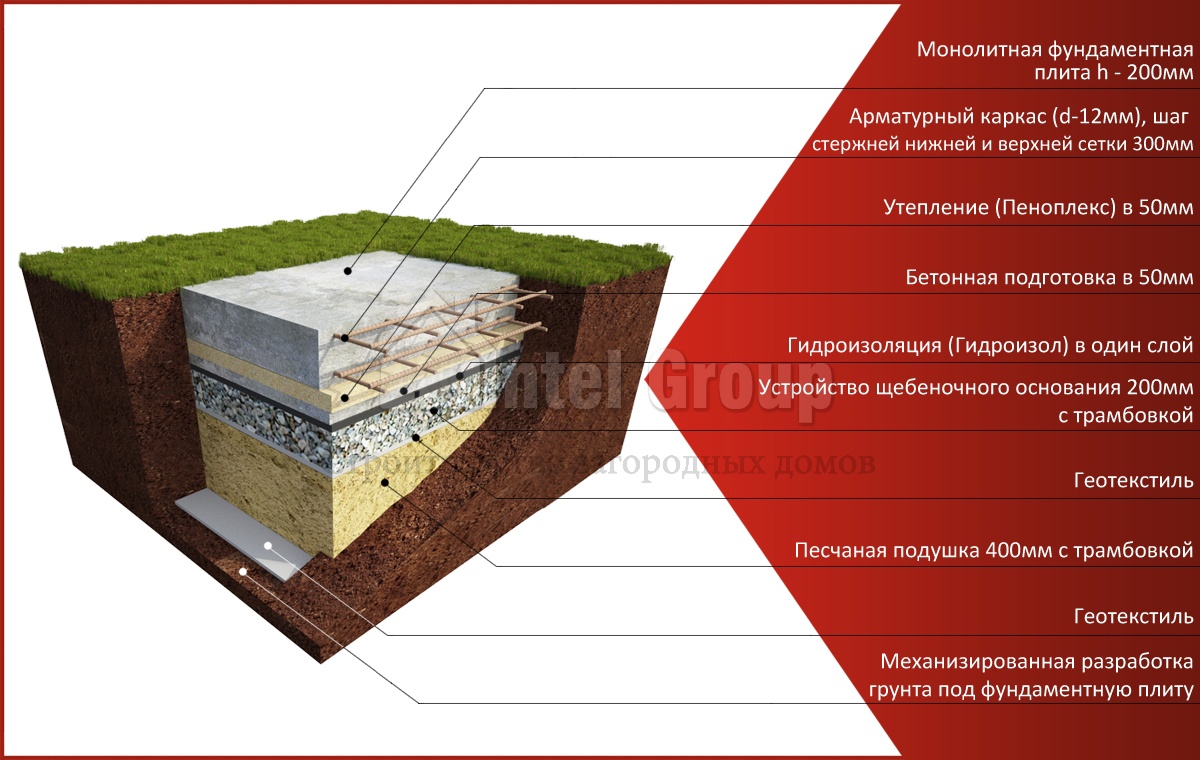

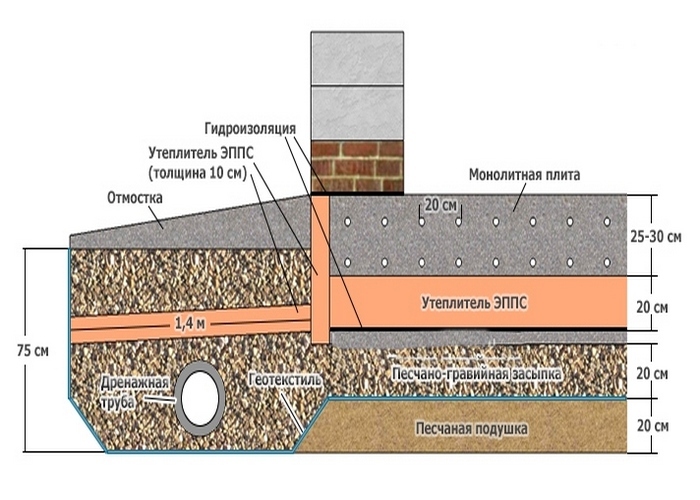

- The slab base is a widely used option on heaving soils or when the water table is high. The sand cushion is arranged along the entire base of the slab and the width of its layer is from 10 to 15 cm;

- A pile or columnar base requires backfilling with a mixture of sand and gravel, the width of which is about 25-30 cm.In addition to a sufficiently thick layer of the mixture, in the case of this type of foundation, it must be taken into account that the backfill should be 10-20 cm wider than the perimeter of the support.

In the presence of difficult geological conditions on the ground, associated with swampy or high water, the calculation of the thickness of the sand cushion should be carried out by a specialist.

In some such cases, a conventional interlayer device will not give any effect without taking additional measures to drain the drainage and drainage.

What should be the correct bedding?

Now you know that backfilling for a concrete foundation is a very important and definitely necessary element in the construction of various buildings and structures. It is necessary to figure out how to make a bedding that meets all the rules and regulations.

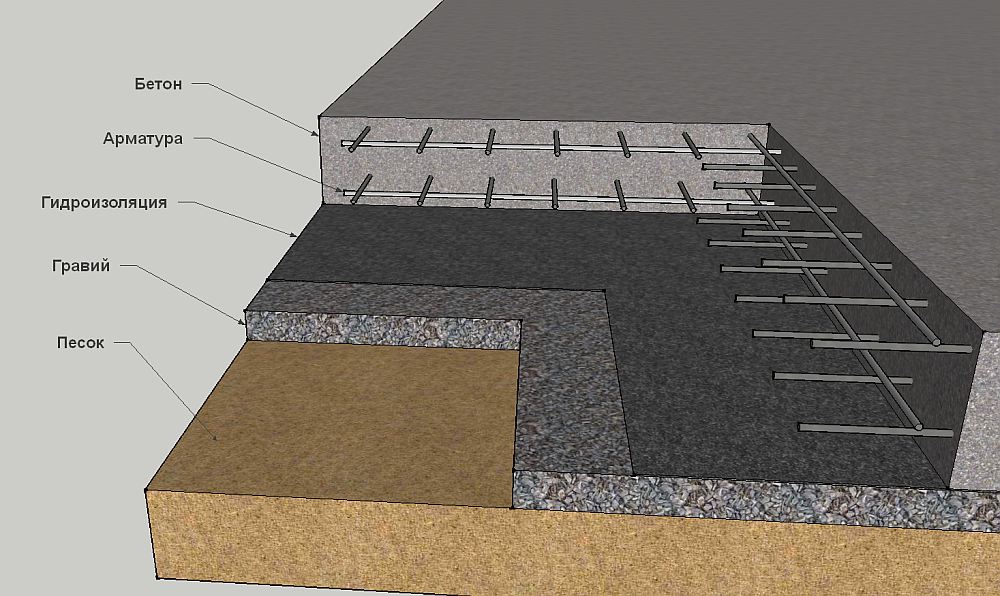

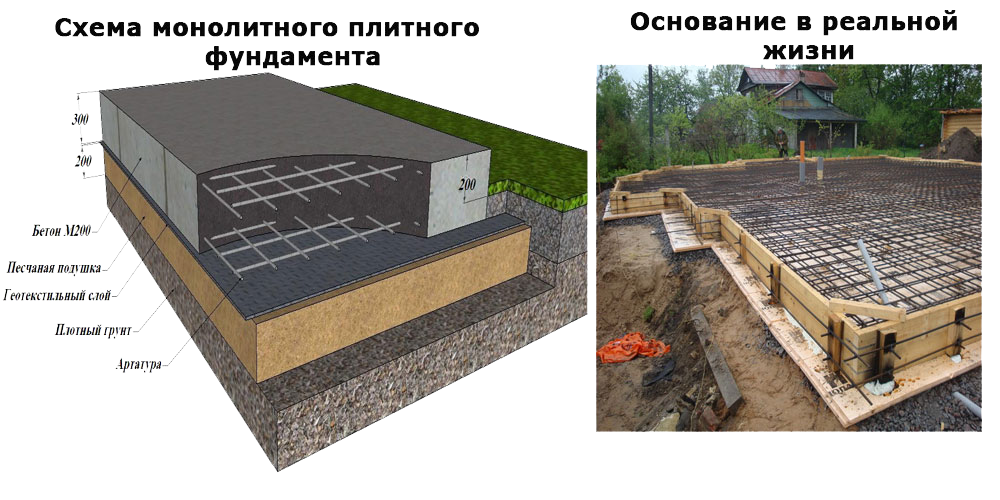

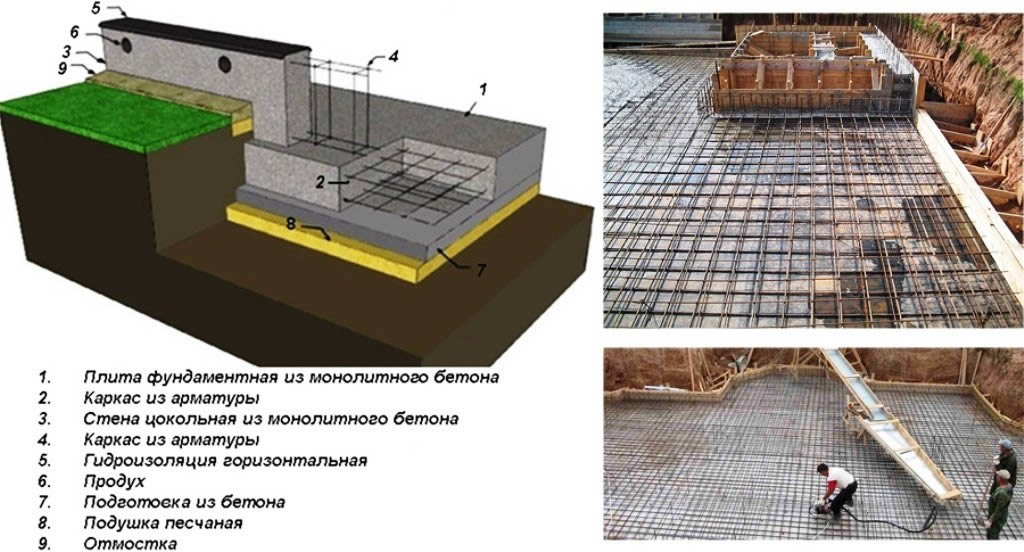

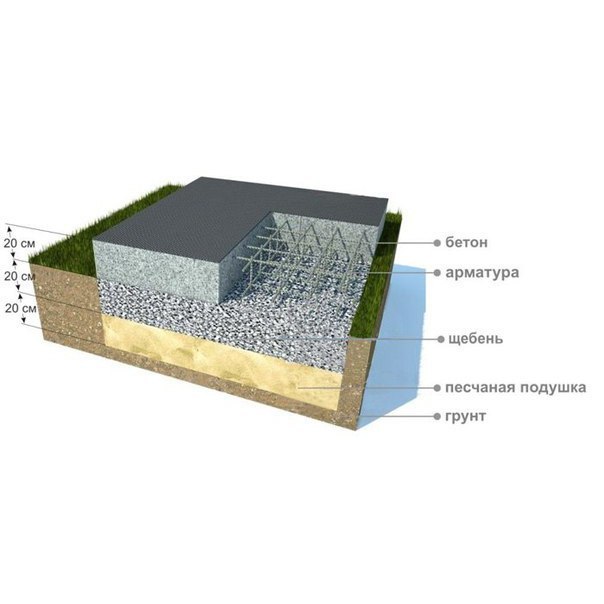

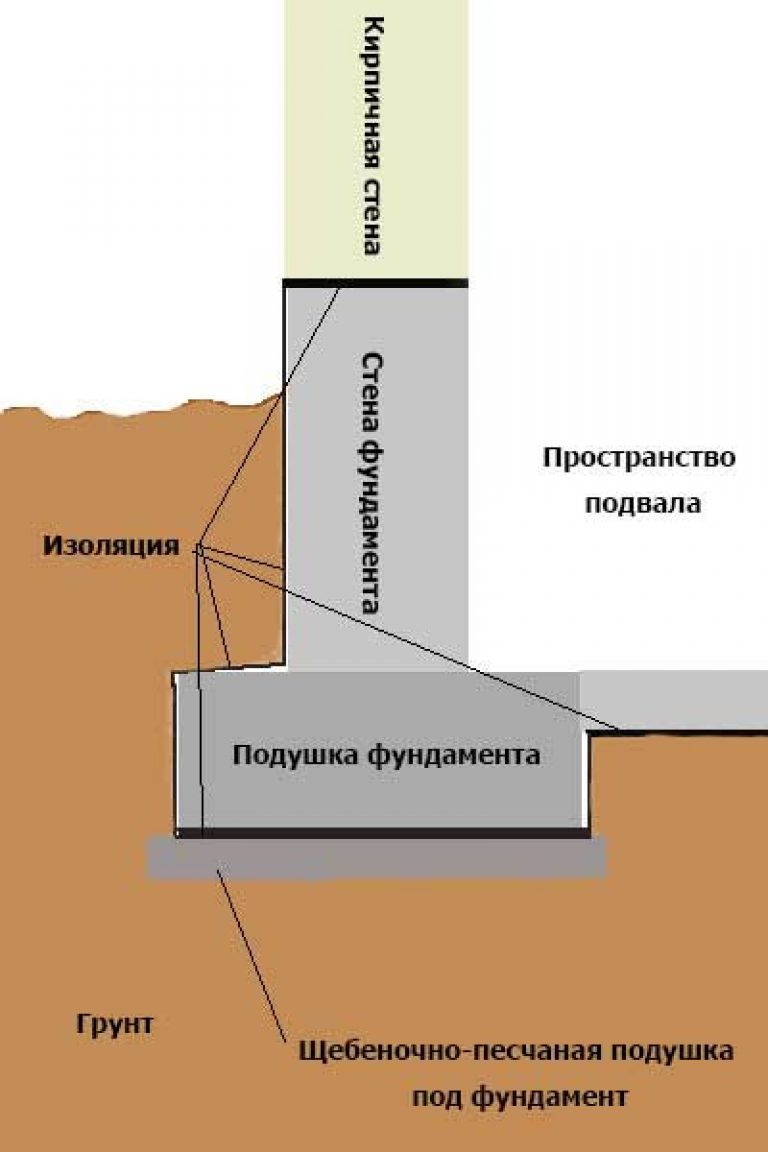

Diagram of the strip foundation device on a sand cushion.

First you need to find out that the bedding (pillow, substrate), as a rule, is arranged under the tape-type foundation. In order to create it, you must first dig a suitable trench.

If you look at foreign building requirements and norms, you can see what European experts recommend to do with a thickness of 25 cm. According to them, this value is enough for the bedding and foundation to fully perform their functions.

However, for Russian realities, European standards are not always acceptable. If you look at the experience of domestic builders, they almost unanimously declare that the thickness of the bedding under the foundation depends, first of all, on the type of soil on the site. Depending on the characteristics of the soil, the thickness of the substrate can be from 30 to 60 cm.In some cases, it is recommended to increase it up to 80 cm to provide additional safety net.

The substrate can be made of sand, crushed stone and concrete. Most often, sand is used for its device. Such a pillow needs a dense and thorough tamping. In addition, when laying such a pillow, it must be tamped gradually, layer by layer. This is done so that in the future there is no settlement and deformation of the base of the building.

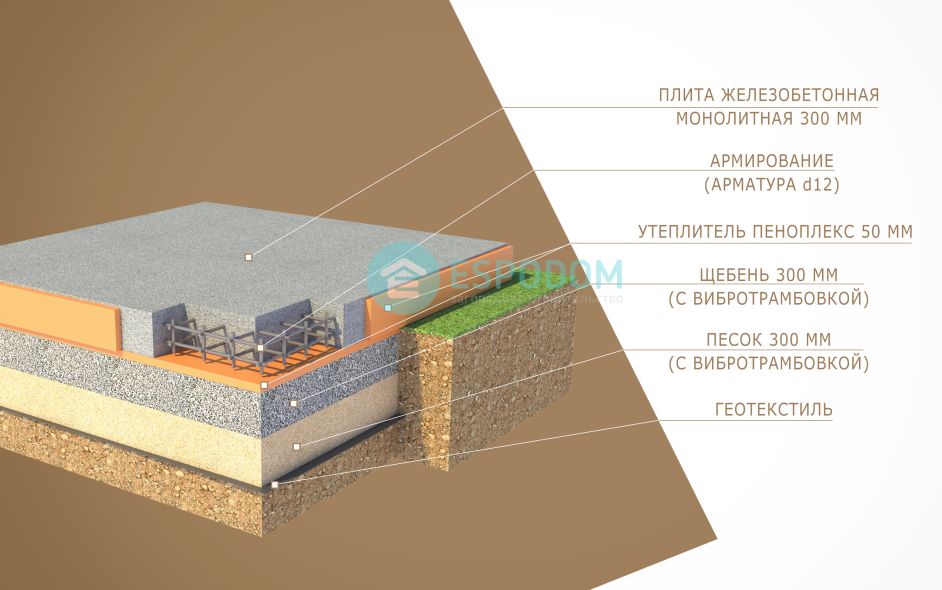

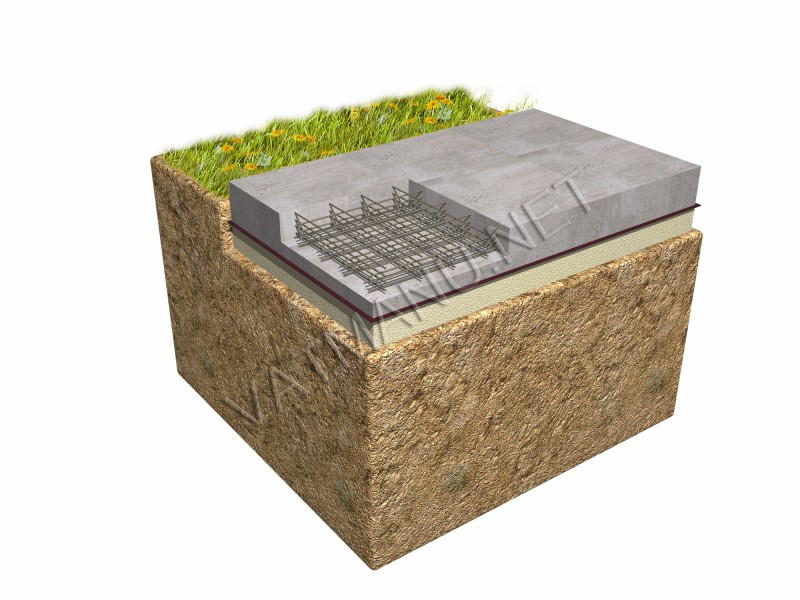

Diagram of the device of a slab monolithic foundation on a sand cushion.

It must be borne in mind that when making a pillow for a foundation, the material from which it is made is poured gradually, in layers 20 cm thick, after which it is very carefully rammed using rollers specially designed for this work or areal vibrators.The density of the finished foundation cushion must be at least 1.6 t / m³.

It is necessary to pay special attention to the fact that some builders advise using clay for the device of a sand cushion. In this case, a layer of clay is rammed into the dug hole.

According to such experts, clay is able to protect the foundation of a house if groundwater suddenly begins to rise. However, it is not. In practice, the water will really stay in the clay layer and will not rise to the foundation, but this is very harmful, since it contributes to a significant increase in the heaving of the soil.

Benefits of using

The use of crushed stone bedding has its positive aspects:

- Building material is readily available. You can find it in almost every region;

- The cost of crushed stone in comparison with other materials is much lower, which makes it possible to reduce the cost of construction;

- Installation of the pillow is simple, does not require the involvement of special construction equipment. Often, backfilling is performed manually together with the preparation of the construction site for laying the foundation;

- The substrate allows you to compensate for the compressive loads that arise under the weight of the structure being erected;

- Due to the presence of crushed stone, the heat loss of the foundation is reduced;

- Due to the use of certain fractions of sand, a high degree of compaction is achieved. The strength of the structure is significantly increased;

- The loads from the future building are evenly distributed;

- The presence of a backing prevents moisture from rising to the base by capillary means;

- If the construction is carried out on a site with uneven terrain, then the use of a pillow allows you to adjust the landscape to facilitate the construction of the foundation.

There are also disadvantages to using a substrate.

Interesting: Foundation with grillage

Why do you need a pillow under the foundation

A foundation pillow is an artificial foundation made of gravel, sand, concrete, reinforced concrete blocks, which is not included in the foundation structure, but replaces part of the soil under it. The pillow has a number of functions.

Table 1. Functions performed by the cushion under the foundation.

| Function performed | Description |

|---|---|

| Alignment | Should level the bottom of the trench. It is necessary to arrange a sub-base for prefabricated and slab foundations. When laying a shallow belt under low buildings, this function is performed by a layer of gravel or even compacted sand. |

| Protection against ground movements | Protects the foundation from seasonal ground movements. When backfilling a layer of sand or gravel on weak and heaving soils, the bearing capacity of the soil increases, which provides a reliable foundation |

| Drainage | Prevents the rise of moisture from the soil into the foundation and drains rainwater to the side |

| Frost heave protection | Preventing the ejection of the foundation from the ground by the expanding water |

| Reduction of building shrinkage processes | Creates stronger support under the object |

| Improving the stability of the structure | Especially prized in seismologically turbulent areas |

Separately, I would like to focus on the phenomenon of frost heaving, which is protected by a more dense base than the ground. This phenomenon is especially typical for clay soils.

Clay soils freeze unevenly in winter, increasing in volume up to 9%.

Moreover, throughout the winter, clay sucks moisture from the lower horizons of the soil, increasing even more in volume. Moreover, if the groundwater level is high, then the clay can swell up to tens of centimeters and raise a house, a road and even a railroad bed. As a result of this effect of frost heaving, the foundation can easily crack in the spring. Will save from the impact of destructive forces a sub-base of coarse sand, crushed stone or sand-gravel mixture, which performs a shock-absorbing and drainage function.

Frost heaving action

To do or not to add a bedding?

Compaction of the sand cushion by hand

Compaction of the sand cushion by hand

Despite all the arguments given above, there are times when it is absolutely unnecessary. Therefore, you should list the cases when sand filling and the formation of a pillow are more likely to harm than help:

- If sand is poured into dense soils, for example, clay or loam, then in comparison with the surrounding soils, the sand will be a less dense aggregate that will draw all the water into itself. As a consequence of this, the pillow will protect against the rise of moisture to the base of the foundation, but will accumulate water from atmospheric precipitation. As a result, the soil under the base will be weaker, which will reduce the performance of the foundation. To avoid such an error, a drainage system is being laid to drain rain and melt water.

- Moisture in the soil is present both in the form of water and in the form of steam. The steam easily overcomes the sandy barrier and leads to moisture condensation directly on the foundation. In order to prevent the formation of condensation, moisture-resistant concrete is used or waterproofing is performed.

- Leveling the ground and even distribution of the load over the entire surface are necessary for prefabricated structures, for example, from FBS blocks. When they are installed on an uneven surface, voids are formed under the blocks, which can be located in different places. As a result, after the end of work and uneven shrinkage, deformations are possible. Therefore, filling a sand cushion under such a base will eliminate drops and evenly distribute the weight of each element.

Adding sand is not necessary in the case of pouring a monolithic tape. Plastic concrete will fill possible drops and prevent voids from forming. The monolithic structure will transfer the load and distribute it over the entire surface.

How to make your own sand pillow

Consider how to make your own sand bedding, which allows you to reduce the estimated cost of construction. To complete the work, complete the preparatory measures:

- Use the cord and pegs to mark the construction site.

- Remove vegetation and debris.

- Remove the soil by forming a pit to the required depth.

- Smooth the soil surface.

- Lay geotextiles on the base of the soil to protect the array from moisture.

- Prepare and deliver coarse river or quarry sand to the work site.

Having carried out a complex of preparatory work, it is possible to backfill the sandy base and compact it.

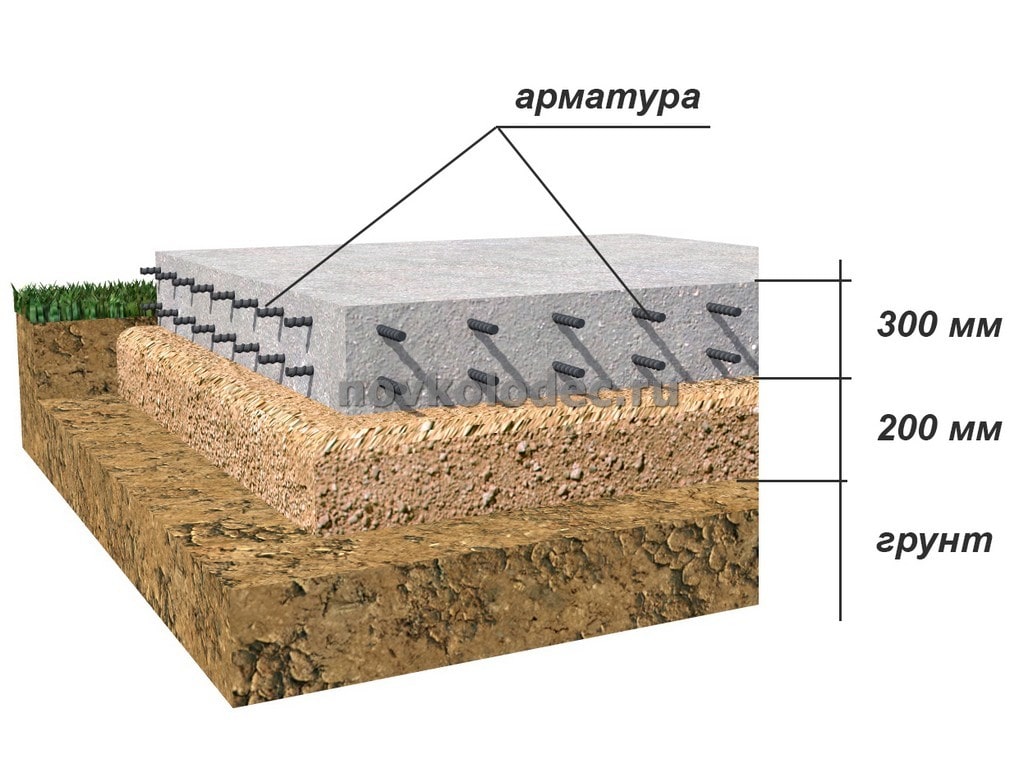

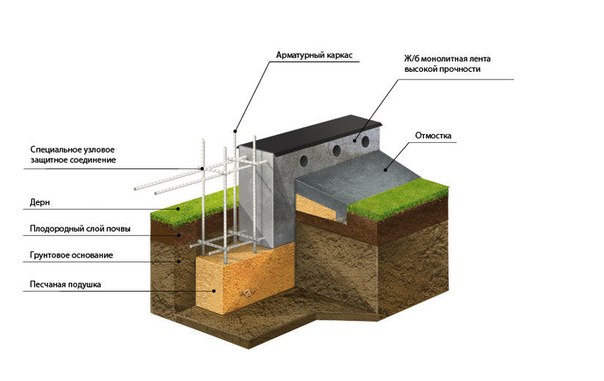

Reinforcement

Laying reinforcement under the future base adds strength to the concrete being laid, turning it into reinforced concrete. Ordinary concrete tolerates compression well, but does not withstand stretching and bending well.

This minus is corrected by reinforcement with rods and welded steel frames. Such a base does not react to soil shrinkage, and firmly holds the structure.

Reinforcing steel 12 mm - lightweight reinforcement supplied in batches. Thicker (heavy) fittings are supplied in rods. Before pouring, a lathing is performed: two types of reinforcement are connected by welding or wire twisting.

The rods are laid in parallel with a step of 10 cm. Similarly, but perpendicularly, the next level of rods is laid. Each joint of the reinforcement is tied with galvanized wire. To do this, you need an automatic pistol and a hook for manual dressing. A 20cm piece of wire is aligned with the rod, bent in half and tied. Then the ends are threaded through the loop and pulled tight with a crochet hook.

Why does a foundation need a pillow

The building will last as long as possible if its underground part is done correctly. The pillow allows you to:

- Get a high-quality, flat bottom of the pit.

- Observe the conditions for the uniform distribution of the weight of the structure and the loads on the soil due to the resistance to soil compression.

- Minimize the likelihood of freezing the foundation.

- Ensure the stability of the position of the entire structure.

- Minimize shrinkage of various origins.

- Avoid getting moisture from the soil into the base of the building.

Substrate stability is ensured by correct dimensions, adequate compaction and leveling of the pad surface. It should have a width greater than the width of the slab, and the height is chosen taking into account:

- The depth to which the soil freezes;

- The height of the rise of groundwater at the construction site;

- The approximate amount of loads on the future foundation;

- Geological and seismic data of the area.

If a pillow is not placed under a monolithic slab, it can undergo significant deformations in conditions of freezing of the soil. Freezing water expands and increases the volume of soil, which is why cracks appear in the base of the house, leading to violations in the waterproofing of the building.

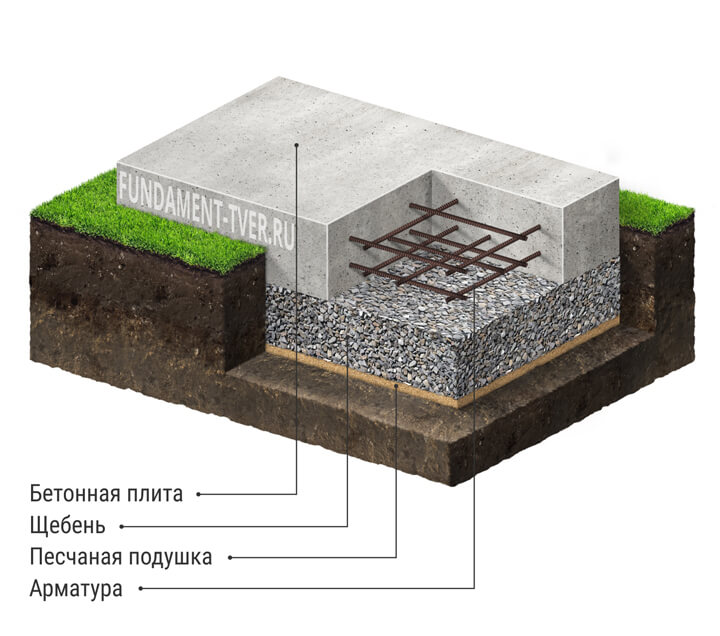

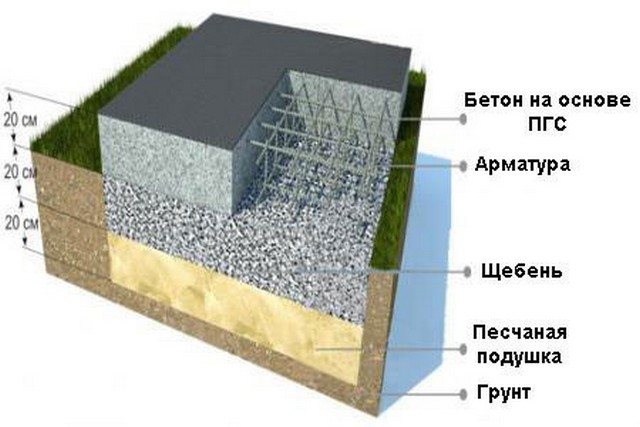

The slab foundation implies the use of the entire area under the house as the base. Therefore, under it, for greater stability of the building, two pillows are usually covered - the lower one made of sand and the upper crushed stone. Sand reduces the flow of moisture to the base, and crushed stone makes it more stable; both materials reduce the likelihood of foundation shrinkage during operation.

Types of foundation cushions

The foundation cushion is a kind of pad between the ground and the base itself. In order to choose the right material for its manufacture, it is necessary to carefully study the characteristics of the soil at the construction site and know the estimated weight of the future structure.

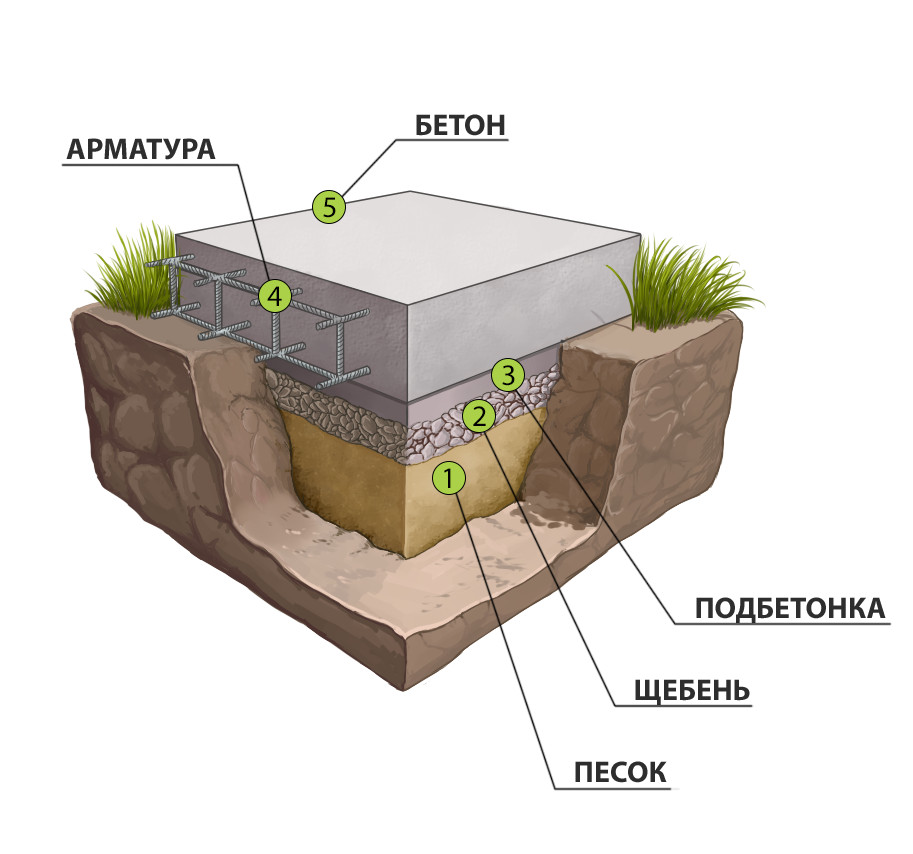

Sand, crushed stone and concrete are most often used as materials for making pillows.

Sand pillow

Sand is one of the available building materials, so it is used with a minimal building budget. It has properties that make it possible to use it in events of this kind.

The sand cushion is used in the following cases:

- The main building has a low height; a one-story structure is considered the best option.

- A house or other structure is made of lightweight materials.

- The groundwater is deep enough. If the groundwater is close, then you can equip the drainage system.

Sand base pillow

It is possible to build a foundation cushion only from coarse sand, material with small particles is prohibited for use for such purposes.

In the process of backfilling the sand cushion, you should pay attention to the following points:

- The surface of the pillow should be as flat as possible.

- The sand layer should be tamped down thoroughly.

- The height of the pillow can be from 20 to 40 cm.

Rubble pillow

The need to use a crushed stone pillow arises when a surface is required that can withstand high loads.

Crushed stone for a pillow under the foundation can be of different fractions from different stone breeds. The most durable material is considered to be crushed stone of the middle fraction from granite.

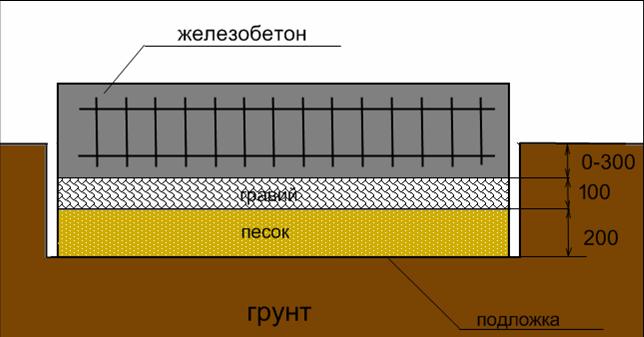

When arranging crushed stone soles, the following scheme is followed:

- The surface is covered with a small layer of sand so that the crushed stone adheres more tightly to the soil.

- The sand is leveled and compacted.

- Crushed stone is poured, choosing the optimal fraction. The layer thickness should be approximately 0.2 meters.

- Using special equipment, it is necessary to carefully tamp the backfill.

When creating a cushion for a foundation made of sand or crushed stone, it is important to remember that it should be about 0.3 meters wider than the base itself. This is necessary for the construction of a stable structure that can support the weight of the structure.

Concrete pad

The pillows are made of reinforced concrete at specialized enterprises and have the shape of a trapezoid. They are considered the most reliable foundation for heavy stone houses, but the cost of such products is quite high.

Laying of foundation cushions is carried out as follows:

Concrete pillow

- The soil is carefully leveled.

- Sand is laid in a layer of up to half a meter, depending on the characteristics of the soil at the construction site.

- Reinforced concrete foundation cushions are installed.

What else can you make a pillow from?

For the foundation cushion, you can use almost any material that will have good compressive strength.

Sometimes, for the construction of large and heavy buildings, interlayers made of concrete are used. They are reliable enough and have great strength, and they can be used for buildings of any number of storeys and weights.

To arrange a concrete cushion you need:

- Pour gravel into the trench, with a layer of no more than 10 cm, and tamp it.

- Install the formwork, the height of which should not exceed 30 cm.

- To increase the strength of the concrete pad, reinforce it. As a reinforcing material, you can use rubble or reinforcing rods.

- Pour the concrete mixture into the prepared trench.

- Carefully distribute the concrete around the entire perimeter and compact with a construction vibrator.

- After the concrete pad has dried, put a layer of waterproofing on it.

The construction of a sand cushion is an important step in the construction of the foundation. Observing the above simple rules, the foundation will be strong, reliable and will last for many years.

Pillow laying technology

In addition to sand, crushed stone or gravel, geotextiles must be purchased to create a cushion for the foundation. This material will serve as a barrier to groundwater penetration into the embankment, which can turn the pillow into ordinary soil.

The creation of a pillow under the base of the house is a step-by-step work:

-

A pit is dug in the ground, the bottom is carefully tamped.

The bottom of the dug hole must be perfectly flat

-

The bottom and walls of the resulting pit are covered with geotextiles.

It is desirable that the geotextile fabric be large and cover the pit walls

-

The pit is filled with one layer (if only sand is used) or several layers of construction raw materials (in the case of organizing a crushed stone or sand-gravel cushion). On the embankment of each material, a vibrating plate is carried out several times, compacting the construction raw materials.

In this case, the pillow is created from sand and gravel.

- Layered cake is covered with geotextiles.

When is it necessary to lay a foundation under the foundation?

The decision to create a substrate for a strip foundation should be based on a correctly performed assessment of the external conditions in relation to the structure of the foundation itself.

Structurally, the strip foundation is presented in two types of execution:

- Prefabricated foundation assembled from standard factory-made concrete blocks;

- Monolithic foundation, poured directly on the construction site into the prepared formwork.

According to the depth of the foundation, the strip foundation is divided into two types:

- Buried below the depth of soil freezing;

- Shallow strip foundation (MZLF).

The main external factors to be analyzed include:

- Soil composition;

- Soil characteristics;

- Climatic conditions.

Departmental building codes VSN 29-85 "Designing shallow foundations of low-rise rural buildings on heaving soils" determined that the use of a pillow made of non-heaving materials can achieve a double effect:

- There is a partial replacement of heaving soil with non-heaving soil (clauses 3.2 and 3.3 VSN 29-85), which makes it possible to reduce the movement of the foundation during freezing and / or thawing of the soil. Thus, the pillow is considered as a means of preventing frost heaving of the soil under the base of the foundation.

- The unevenness of the deformations of the building support is reduced.

Hence, it follows that for non-heaving soils, a sand cushion under the strip foundation is not needed if we consider the issue solely from the standpoint of counteracting frost heaving processes.Such a one-sided approach may contradict the requirements of the set of rules SP 50-101-2004 "Design and construction of bases and foundations and structures", which in cl. 8.7 and 8.8 when determining on which soils prefabricated block or monolithic types of shallow and unburied strip foundations, unambiguously establish the need for arranging cushions made of non-porous materials under concrete blocks. We can unequivocally say that for strip foundations deepened below the freezing depth, the device of a sand cushion is required only for a construction of foundation blocks; for a monolithic foundation, such a cushion does not play any role.

In the case of a monolithic MZLF on non-porous soils, backfilling can also be omitted, since sand in this situation does not perform any work - the concrete pouring of the tape will even out all surface defects.

Summing up, we can say that:

- For foundations laid below the calculated freezing depth, a sand cushion is needed only for a prefabricated block structure; for a monolithic base, such a cushion is not required.

- For a shallow foundation, a pillow is required only for heaving soils, regardless of technology, or for a foundation made of prefabricated blocks, regardless of the type of soil.

- For a non-buried foundation, a pillow made of non-porous materials is definitely required, if only because it is necessary to replace the fertile layer under the base.

Views

Foundation cushions can be made of various materials, the choice of which depends on the number of storeys, the state of the soil, seismicity and the purpose of the structure.

Sand

The most inexpensive building material used when arranging pillows for light frame or wooden one-story buildings. With a layer thickness of 25-30 cm, sand reliably protects the base of the house and acts as a compensator in the event of soil shrinkage. When making a pillow, both river and quarry type of sand can be used. The main advantages of using this inexpensive material are its availability, ease of installation, low thermal conductivity, which significantly reduces the heat loss of the building and high rates of compaction.

The disadvantages of sand include the impossibility of its use in the construction of multi-storey buildings and industrial enterprises, as well as the irrationality of its use on soils with a high occurrence of groundwater. In cases where the aquifer level is unstable and experiencing seasonal fluctuations, a drainage system should be installed before building a pad.

Sand and gravel

This option is the most common for the formation of pillows, it is widely used in the construction of private houses and summer cottages. Such a pillow is formed on weak soils and needs careful compaction. The mixture must have a medium-grained structure, the use of sand dust or fine-grained sand is unacceptable.

Crushed stone

Quite durable material that evenly distributes the weight load over the entire area of the base. It is used to form foundation cushions in houses not exceeding two floors. To form a crushed stone layer, sand and gravel are used as auxiliary components, the proportion of which must be at least 30% of the total thickness.

Concrete

It is the most expensive and reliable material used in the construction of multi-storey residential buildings and industrial buildings. The concrete pad acts as a compensator for the reaction of problem heaving soils and takes on the entire weight of the structure. A concrete pad is a block of reinforced concrete marked FL, which means a tape foundation

Gravel

The use of this material as a pillow in the construction of multi-storey buildings presupposes the presence of large-fraction elements in the composition, the size of which varies from 2 to 4 cm.

Each of the materials used to create a foundation cushion has unique technical characteristics or combines several properties inherent in its constituent components. So, when forming a crushed stone layer, sand and gravel are mandatory components, without which the functioning of the pillow will not be complete. Therefore, when choosing the right material, it is necessary to take into account the totality of all factors that affect the strength and durability of the foundation.

Concrete pillow for a monolithic slab

Finally, we will consider how to make a do-it-yourself installation of a concrete platform. This design has only one drawback - its high cost, otherwise such a project consists of solid advantages.

Installation of a monolithic base plate

Installation of a monolithic base plate

First of all, I would like to note the endurance of the pillow, provided that the work on its installation is carried out correctly, and they look like this:

- The site is cleared of plants and debris.

- The soil is carefully leveled.

- Crushed stone is laid in a layer up to 10 cm thick.

- Crushed stone is being tamped.

- A wooden formwork is mounted around the entire perimeter of the pillow.

- The foundation site is being reinforced.

- Concrete is poured. Its brand depends on the weight of the future building.

- The solution is rammed with a deep vibrator.

- The structure is left to dry completely (1 month).

Such a base is ideal for the future construction of a house, although it is the most difficult to make with your own hands.

Following the recommendations of the article, as well as weighing all the pros and cons, there is every reason to assert that a pillow for a strip foundation is definitely needed, and it is categorically not recommended to save on it.