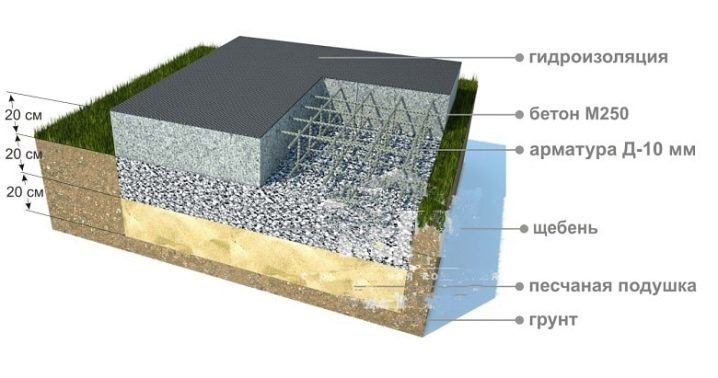

Arrangement of a concrete underlay for a foundation

The concrete pillow is characterized by the highest indicators of reliability and durability. However, it also has its own significant drawback - a high price. But on the other hand, this drawback is fully compensated by the durability of the structure.

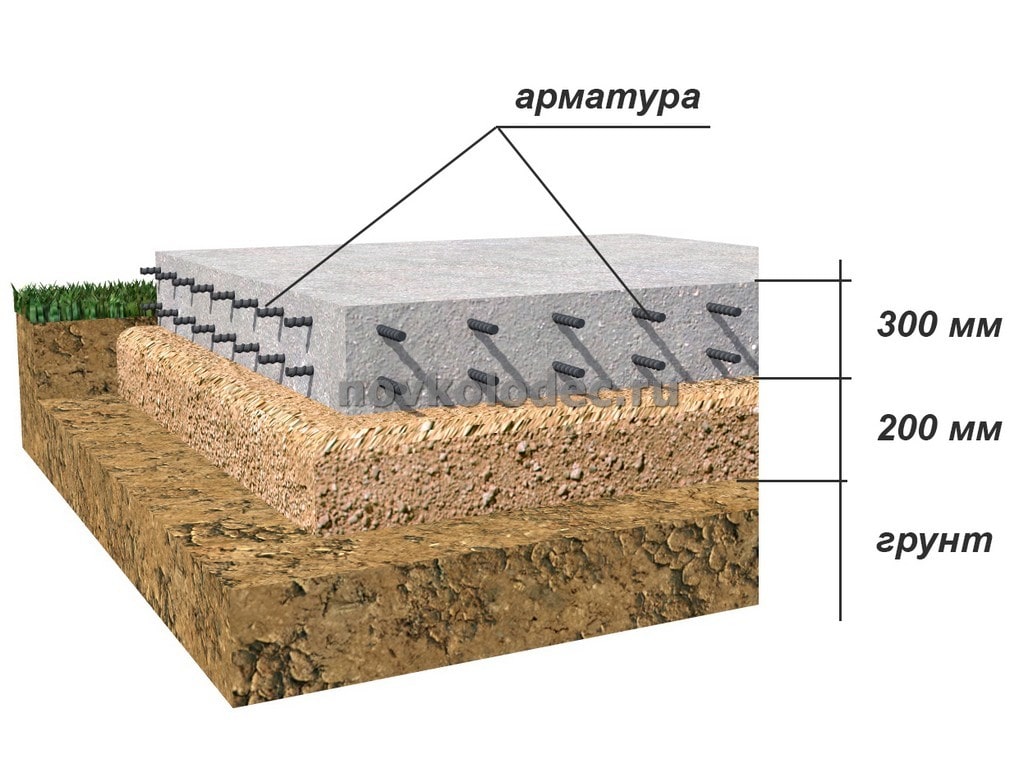

The concrete substrate is arranged in the following sequence:

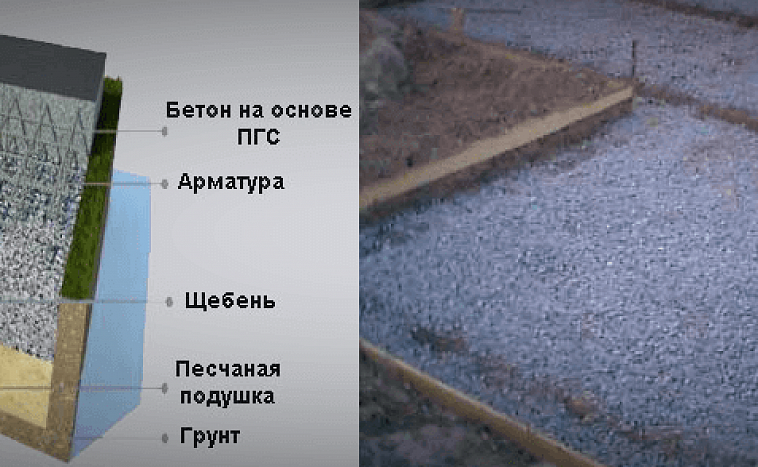

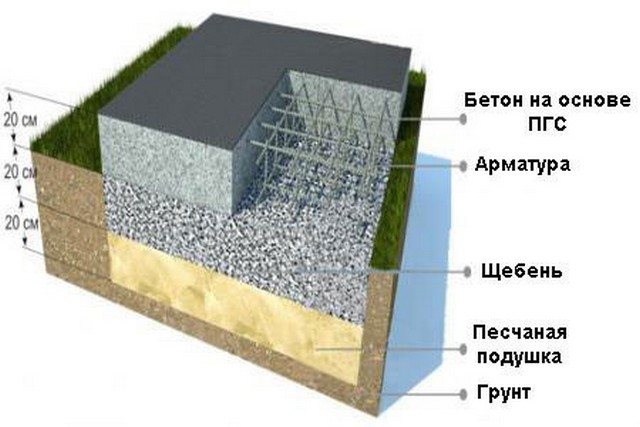

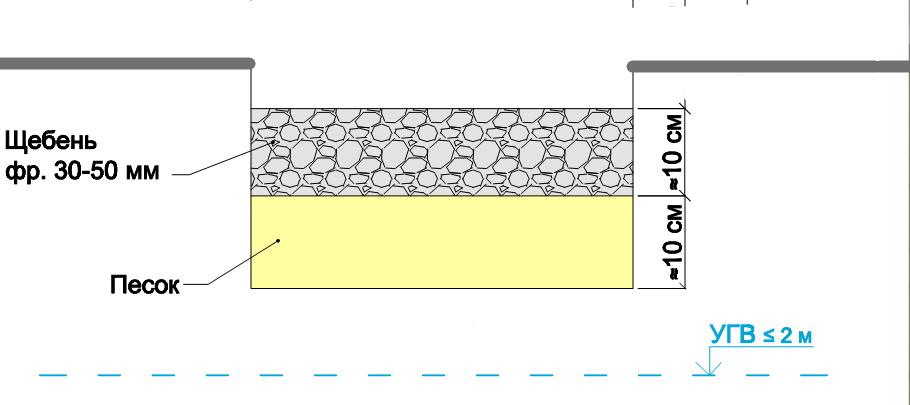

First of all, the soil is carefully leveled. After that, crushed stone is laid on the ground with a layer of about 10 cm and carefully compacted. It is best to do this with a vibrating plate.

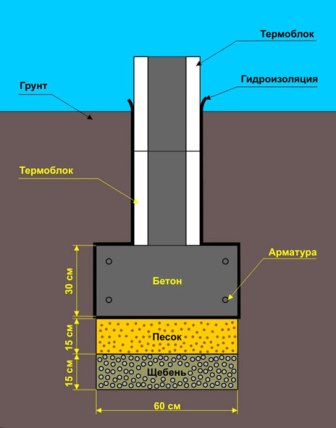

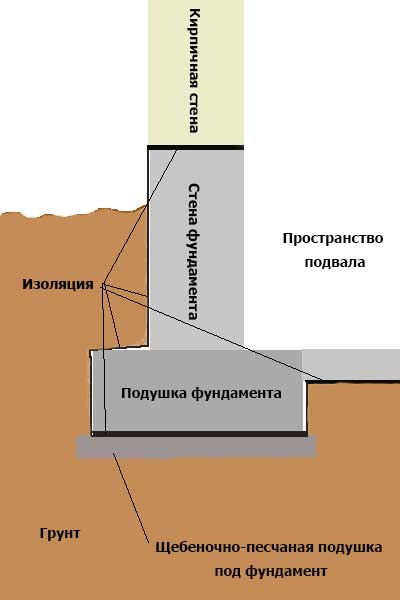

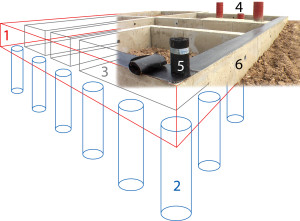

Combined bulk foundation with cast foundation and reinforced piping.

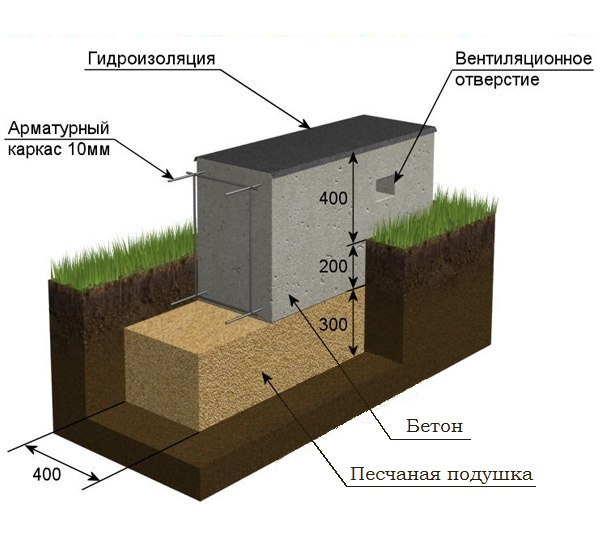

A formwork made of wooden boards is installed along the perimeter of the pillow. Care must be taken to ensure that the height of the formwork coincides with the thickness of the base, that is, it is no more than 30 cm. Of course, this is provided that the mortar is poured into the level with the upper edge of the formwork. It is necessary that the top mark of the concrete base is located where the foundation itself will begin.

In order to increase the strength and durability, it is recommended to reinforce the concrete pad. This is done using steel rods with a diameter of 8-12 mm.

Upon completion of the installation of the formwork and reinforcement, you can start pouring the concrete solution. The grade of concrete should be selected individually in each case, since it is calculated taking into account the weight of the future building.

The entire resulting structure is carefully compacted. This is done using a deep construction vibrator.

The most important thing to remember when doing this work is that the dimensions of the concrete cushion for the foundation must exceed the dimensions of the foundation itself, this is very important. Determining the dimensions is quite simple - the area of the correct substrate should protrude from under the finished foundation by about 150 mm on each side

A concrete foundation cushion is considered the most durable and reliable. It can be used in the construction of a building of any weight and number of storeys.

The device for filling under the foundation of a house is a very important, responsible and painstaking process. A properly designed pillow is the best guarantee that you can live in your home for many years without any problems.

Self-preparation of mortar for the foundation

When preparing the solution, all the tips and recommendations should be followed, otherwise the solution will turn out to be insufficiently elastic and strong, which will make all efforts and efforts in vain.

For light and small buildings, a columnar foundation is also erected. For all types of foundations, it is necessary to observe all the rules according to which self-pouring will be performed.

Upon completion of all the preparatory work, the matter comes to, here it is necessary to begin to count all the proportions.

Scheme of mixing concrete in a concrete mixer.

The components of the solution are:

- crushed stone or gravel;

- cement;

- sand;

- water;

- sometimes plasticizers are used.

All components must be dry, and the solution must be free from solid lumps and various extraneous additives (soil, clay, dry leaves and debris).

Plasticizers are used to give the finished solution elasticity or prolong its ability to harden, other types are in demand in winter, when these substances do not allow self-prepared concrete to freeze and harden as it dries.

For it is necessary to observe the proportions of concrete verified by perennial buildings.

Proportions and constituents of concrete

The grade of concrete required can be found in the construction project. Sometimes it is made with concrete prepared "by eye".What should be the concrete to meet the requirements for? The main rule when preparing a solution: the grade of cement is taken 2 times more than the required or desired grade of concrete. That is, if you need to prepare a grade of concrete M200, then you need to take cement M400, etc. Crushed stone is taken in the middle fraction - from 2 to 4 cm.

Recommended for foundations: 1 part of cement accounts for 3 parts of sand and 5 parts of crushed stone. Translated into kilograms, it will look like this: to 50 kg of cement, add 150 kg of sand and 250 kg crushed stone or gravel of medium fraction. The amount of water required for quality concrete is determined by the volume of cement taken. In this case, cement is 0.68 m³, that is, 0.68 m³ of water will also be required.

You can fill in the finished solution in several ways:

Scheme for the preparation of concrete solution.

- in the finished trench, the sides will form soil;

- into the assembled wooden formwork.

The ready-made solution can be poured without a frame, if solid soil will serve as the walls and water does not quickly leave the concrete, but if the soil is loose and soft, then it will be necessary to assemble the frame-formwork.

In the second case, the solution will not quickly lose moisture and will dry out gradually, acquiring the required hardness and strength.

The formwork is assembled from wooden boards or moisture-resistant sheet material (OSB or special ready-made formwork, which can be purchased at any construction site).

The horizontal part of the formwork is assembled strictly according to the level and serves as the basis for the construction of walls

If such an important requirement is violated, the center of gravity of the erected walls will be shifted and unnecessary and unnecessary pressure will be exerted on the foundation. In addition, the construction of walls will be difficult, the walls will turn out to be crooked.

The kneading process also has its own secrets and characteristics. First, sand and cement are combined, the mixture is stirred in a container until a homogeneous consistency is obtained. Crushed stone or gravel is added to the mixture, it is also thoroughly mixed and then water is added. When adding water, the ambient temperature should also be taken into account. If concreting takes place in a warm time - the water can be cold or taken from a well, but if the work is carried out in winter or cold time - it is better to take heated water, thus the solution will become more elastic and it will be easier to mix.

Pouring ready-made concrete should be done in small batches, while the concrete is carefully rammed. Tamping can be done using:

- Tamping machine, it can be rented during construction. This can save a lot of working time and the lease will pay off in full by quickly filling all the trenches for the foundation.

- Hammer knocking on the walls of the formwork.

Tamping can be finished after water appears on the surface of the concrete.

To save the consumption of the finished solution, use is made of quarry - large building stones of hard rocks. But when laying it down, you should carefully consider this advice: the bottle should be laid on fresh concrete and immediately poured on top with the next layer. Buying the foundation with your own hands does not exclude tamping.

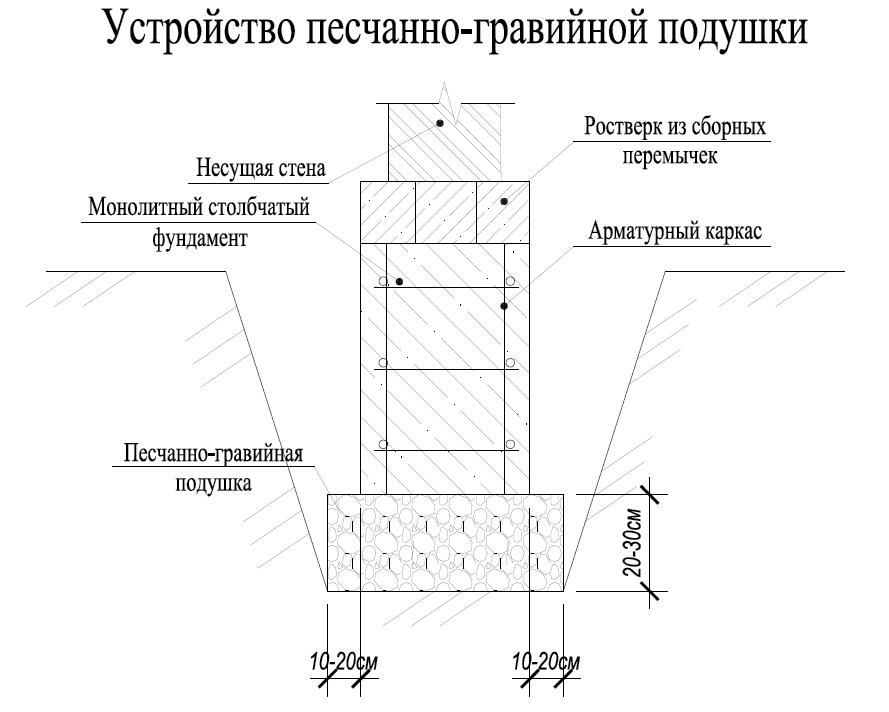

Device

Installation of some types of foundation cushions can be carried out independently without the use of expensive equipment and the involvement of specialists. The most effective, but at the same time, inexpensive way of arranging the interlayer is the installation of a sand and gravel cushion, the installation technology of which involves several stages.

Initially, you should dig a trench, the depth of which will correspond to the beginning of the dense soil layer. Then, coarse river sand should be poured into the prepared ditch. Falling asleep should be done in small portions, gradually forming uniform layers 15 cm thick, and alternately spilling them with water and tamping them.

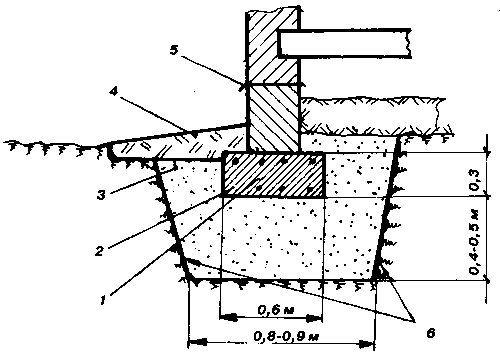

Layers of gravel are placed between the layers of sand.Their thickness can vary from 5 to 25 cm, and depends on the type of soil and the number of storeys of the house. It is recommended to equip a sand and gravel cushion under the entire structure: this will ensure uniform shrinkage of the building and prevent cracks on the walls. The width of the pillow should protrude 30 cm beyond the foundation.

An important condition for arranging this type of interlayer is a particularly careful compaction of each layer. The density of the newly poured foundation under the foundation should be 1.6 g / cm3 relative to the density of the soil.

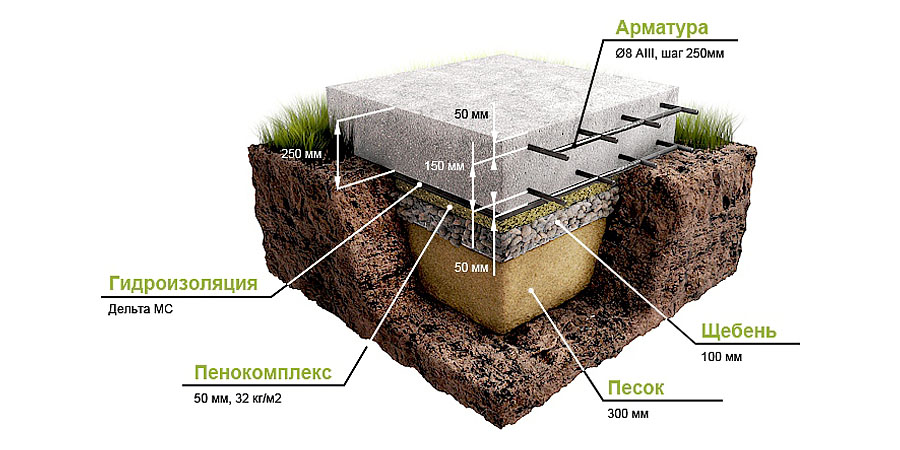

A crushed stone pillow is made in the same way. In this case, the two lower layers are sand and gravel, on which a layer of crushed stone with a thickness of 25 to 30 cm is poured from above. The horizontalness of the laid layer should be checked using a building level. The dimensions of the pillow must exceed the dimensions of the foundation by 50 cm.

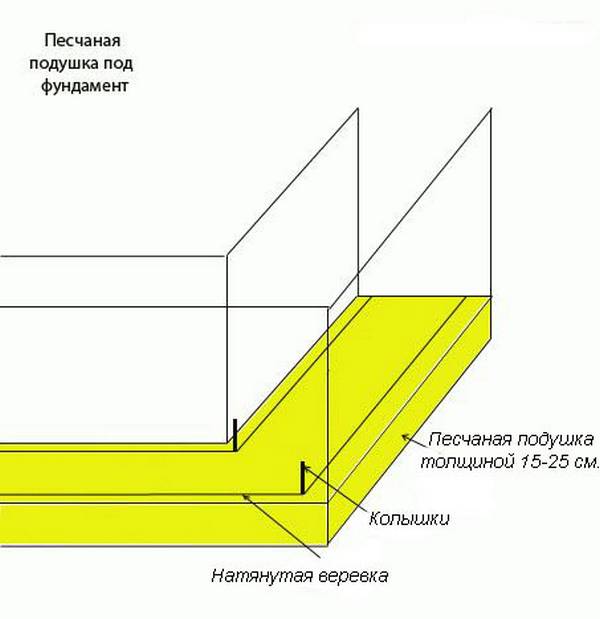

The arrangement of a sand cushion is quite simple. To install it, you first need to make a markup and extract the soil to the required depth. Then, at the bottom of the dug trench, you need to lay geotextiles, which will serve to protect the foundation from moisture. Then you can start filling the drainage layer, for the formation of which coarse sand is suitable.

The quality of the tamping can be checked as follows: you need to step on the pillow with both feet, and then get off it and check for shoe marks. Traces should not be visible on properly compacted sand. Otherwise, work should be resumed and a high density of the created pillow should be achieved.

The calculation of the thickness of the main layer is made individually and depends on the area of the house and the material for building the walls. In any case, the total thickness of the sand cushion should be at least 15 cm. Upon completion of the installation work, you need to check the horizontal position again, after which you can start building the formwork and pouring the foundation.

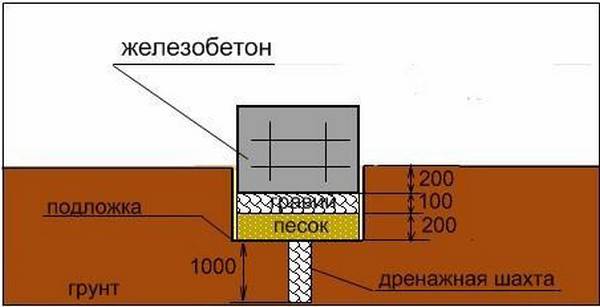

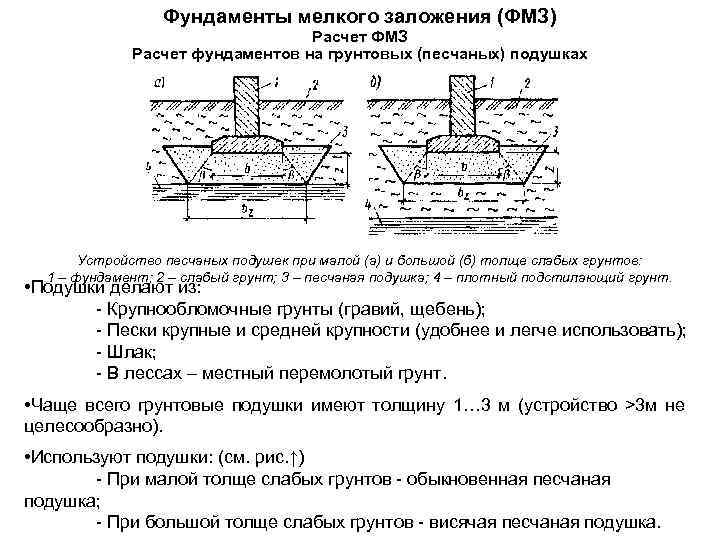

Features of the columnar-strip foundation

Such a foundation is an attempt to combine the advantages of column and strip foundations in one structure and to eliminate their disadvantages as much as possible. I must say that this is a very successful experiment because it brings a number of benefits to this type of foundation:

- Significant reduction in excavation work.

- Possibility of building on medium to highly curved soils, including peat soils.

- There is no need to make sandstone or sand cushions underneath the entire foundation.

- No drainage system required.

- Reduces consumption of concrete, reinforcement and working hours.

- Heat loss is reduced and vibration isolation of the building is improved.

Pillars

The main problem in our climate is the large difference between summer and winter temperatures, when the freezing of water in the ground in winter leads to high loads on the floor of the building.

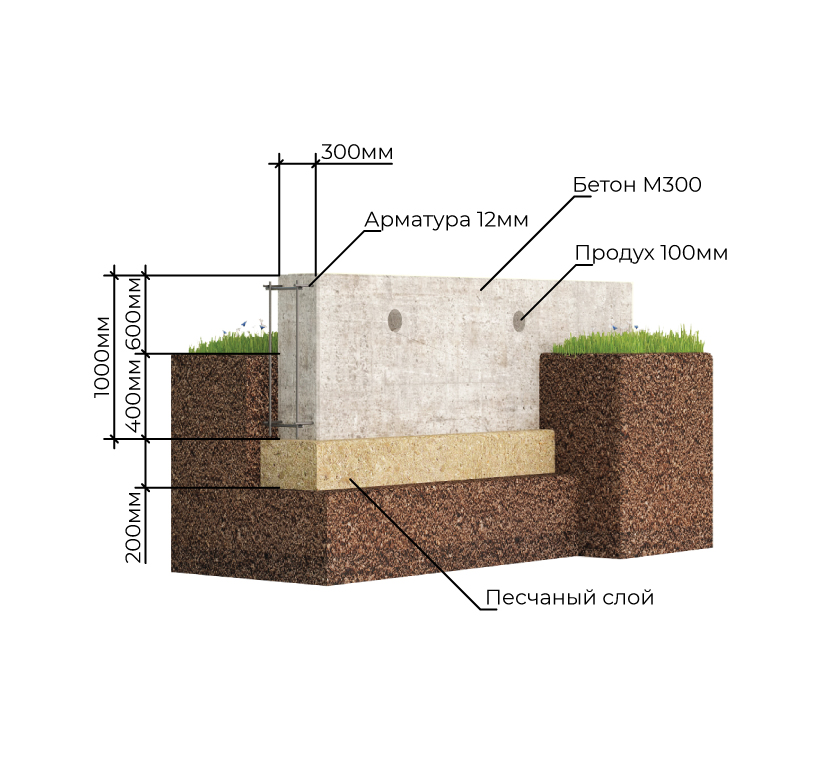

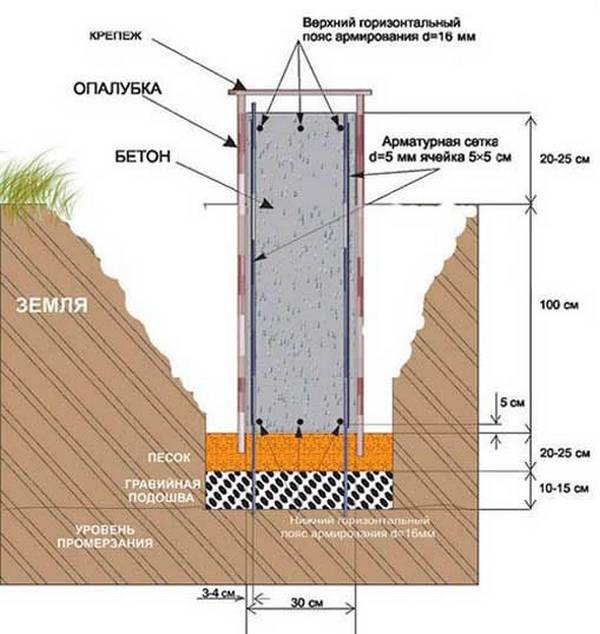

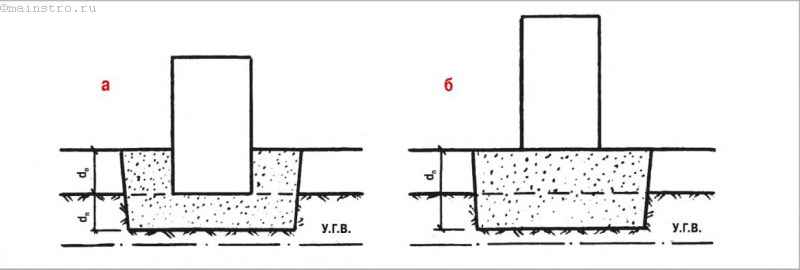

One way to protect the foundation is to submerge it deeper than the freezing level of the soil at the construction site. For example, for the Moscow region, depending on the type of soil, this value averages 1.4 meters.

If piles are used, then only they are installed at this depth. Also estimate the difference in the intensity of work and the amount of cubic meters of land that you mined yourself.

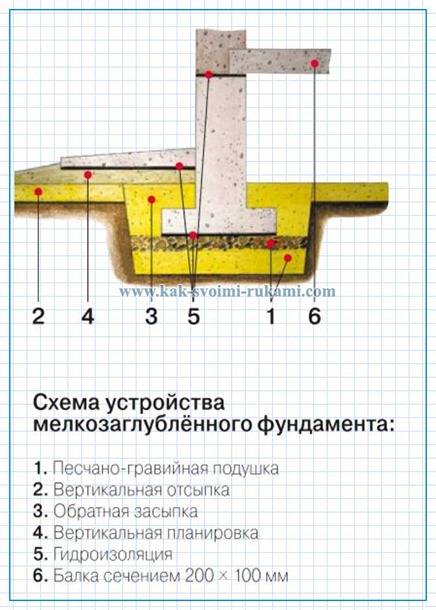

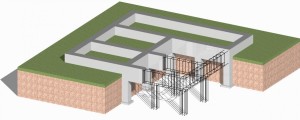

Strip foundation

The strip foundation (crane) in this structure serves as a load-bearing element that absorbs and distributes the load from the walls.

As a rule, it does not touch the ground, as it is located at a distance of 10-20 cm.If the belt is installed in the floor, for example, if a flatter device was chosen, it should be borne in mind that it is also affected by the load from the floor due to temperature fluctuations ...

In order for the belt not to be pulled away from the struts, it is necessary to provide for such a design if it can also move during vertical movements, i.e. when working as a piston.Columns must be smooth and free from expanding bases.

Materials (edit)

The poles can be made from a variety of materials, from round wood to reinforced concrete. The shape is also round, square, hollow and polygonal.

If this is an independent building with a minimum external attraction of forces and mechanisms, then a round concrete pillar is optimal.

Peculiarities

Crushed stone is one of the most common fillers for concrete mix, without which no modern building of a house or other object can do. This building material has many classifications and is endowed with different characteristics and features, which directly affect the quality of the future construction, and the strength of concrete, and the strength of the foundation. Despite the low cost as for a building material, crushed stone combines all the qualities that are irreplaceable in construction.

Crushed stone has the following features:

- high degree of strength - when compared with all fillers for concrete mix, the most durable of all types of crushed stone is granite material;

- moisture resistance - crushed stone does not react at all to moisture;

- excellent tolerance to temperature extremes - frost and heat, as well as resistance to environmental influences. Crushed stone is able to withstand up to three hundred changes in temperature cycles;

- high adhesion - due to the rough surface and acute-angled shape, the adhesion of the material to concrete is significantly enhanced;

- reduction of settlement and creep of concrete, which minimizes the occurrence of cracks and all sorts of deformations in the constructed building;

- ease of use;

- high performance properties.

In addition, due to the variety of types of crushed stone, you can always choose the one that is suitable not only in terms of technical characteristics, but also in terms of cost.

High-quality crushed stone must be selected based on the following technical characteristics:

- Flakiness is a characteristic of the flatness of a material. In total, crushed stone has 4 categories of flakiness: rounded, cuboid, improved and ordinary;

- degree of strength - the stronger the material, the better. The highest indicators of strength are endowed with two types of crushed stone: granite and gravel;

- radioactivity is an important characteristic that depends on the deposit of building material. High quality crushed stone is certified for radioactivity. This indicator does not affect the strength of the material, however, the level of environmental friendliness depends on it;

- frost resistance - this characteristic indicates the number of seasons that the foundation of this material will withstand. According to the level of frost resistance, crushed stone can be divided into stable, unstable and highly resistant;

- compaction coefficient - the density of crushed stone ranges from 1.2 to 3 g / cm³. This factor depends on the type of origin of the material. Crushed stone with a high degree of density is versatile and has an unlimited scope. The density and strength of this building material are directly proportional.

To do or not to add a bedding?

Compaction of the sand cushion by hand Despite all the arguments given above, there are times when it is absolutely unnecessary. Therefore, you should list the cases when sand filling and the formation of a pillow are more likely to harm than help:

- If sand is poured into dense soils, for example, clay or loam, then in comparison with the surrounding soils, the sand will be a less dense aggregate that will draw all the water into itself. As a consequence of this, the pillow will protect against the rise of moisture to the base of the foundation, but will accumulate water from atmospheric precipitation. As a result, the soil under the base will be weaker, which will reduce the performance of the foundation. To avoid such an error, a drainage system is being laid to drain rain and melt water.

- Moisture in the soil is present both in the form of water and in the form of steam.The steam easily overcomes the sandy barrier and leads to moisture condensation directly on the foundation. In order to prevent the formation of condensation, moisture-resistant concrete is used or waterproofing is performed.

- Leveling the ground and even distribution of the load over the entire surface are necessary for prefabricated structures, for example, from FBS blocks. When they are installed on an uneven surface, voids are formed under the blocks, which can be located in different places. As a result, after the end of work and uneven shrinkage, deformations are possible. Therefore, filling a sand cushion under such a base will eliminate drops and evenly distribute the weight of each element.

What is a strip foundation on piles?

The strip pile foundation combines the advantages of two types - column and flat strip foundations. The first one performs the main work on interaction with the ground, and the second one ensures the distribution of the load of the walls of the structure.

At the same time, the material requirement for materials for the construction of the foundation is significantly reduced and labor costs are reduced.

Application area

The strip pile foundation is suitable for the construction of a wide variety of buildings, from fences to brick houses, wooden beams and more modern materials such as aerated concrete, foam blocks, etc.

When using logs, they themselves can act as a pile-based grinder. If the structure consists of small elements, a rover is necessary.

There are several options for pile and strip foundations. The differences lie in the design of the lattice and the manufacture of the piles. In the simplest case, protocols can be used as such.

It's a short-lived material, but it's cheap. Usually coniferous wood is used and impregnation with mixtures is mandatory to protect against mold, fungi, etc.

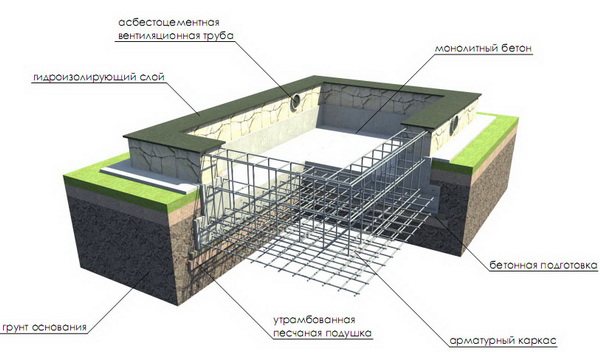

Monolithic

The monolithic foundation includes the manufacture of a monolithic reinforced concrete tap of the coupler, regardless of the type of pile.

This allows you to build almost any building from any modern material.

The load from such a foundation can be very high, although the load is slightly higher than with simpler options.

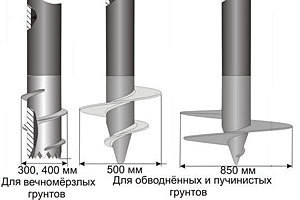

Screw

Another possibility is the use of prefabricated auger piles.

These are iron structures with threaded blades at the end. They will remind someone of a screw, a drill, but they are really screwed into the ground.

This type of pile is produced with a diameter of 57 mm and a length of 1650 mm. Given the corrosion resistance of the material from which the piles are made, it is not recommended to use them on soils with a high acid content (pH less than 5.5).

It turns out that attention to the acid-base balance is also important when building a pile foundation. For building a house, the optimal stack size is 108 or 133 mm in diameter and 2500 mm in length. After all, it is easier to cut off the surplus than to weld the missing one, especially since this length in most cases allows you to go below the soil freezing line

After all, it is easier to cut off the surplus than to weld the missing one, especially since this length in most cases allows you to go below the soil freezing line

For building a house, the optimal stack size is 108 or 133 mm in diameter and 2500 mm in length. After all, it is easier to cut off the surplus than to weld the missing one, especially since this length in most cases allows it to fall below the soil freezing line.

The benefits of this type of pile include, but are not limited to, the following benefits

- A minimum amount of excavation is required.

- This is a little time consuming.

- High speed when performing work.

- High "stability" in the ground due to the narrow entrance to the ground.

The disadvantage of piles is that the piles require a place for screwing in, which makes them difficult to install near other buildings, as well as low corrosion resistance.

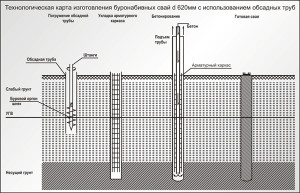

With bored piles

These piles are manufactured locally. A hole is drilled in the pile, formwork is installed, reinforcement is installed, if necessary, and concrete is poured.

This option applies to almost all soil types. The main thing is that the depth of the piles should be greater than the depth of soil freezing in the area.

The benefits of this type of fund include, but are not limited to, the following benefits

- Low cost.

- Simplicity and speed of installation.

- You can do without special construction equipment.

Among the disadvantages, it is especially difficult to maintain the required accuracy when drilling and aligning the upper pile belt.

Regardless of the pile depth, approximately 10 cm of sand should be poured into the ground as a cushion.

General information about bedding for the foundation

As you know, the foundation is the foundation of the house, and not just the foundation, but the most important and most important part in the whole process of building a private house. If the foundation is of poor quality or poorly, without observing important building rules and regulations, it will very soon become unusable and it will become impossible to live in the house. Window frames will begin to warp, walls will be covered with cracks, doors will no longer close normally, which will lead to drafts.

That is why it is very important to make a high-quality foundation in compliance with all rules and regulations. One of the pledges of a strong, durable and reliable foundation that can stand for many years without deterioration in performance is a high-quality and well-executed bedding

Thanks to the bedding for the foundation, the reliability and durability of the house as a whole is ensured.

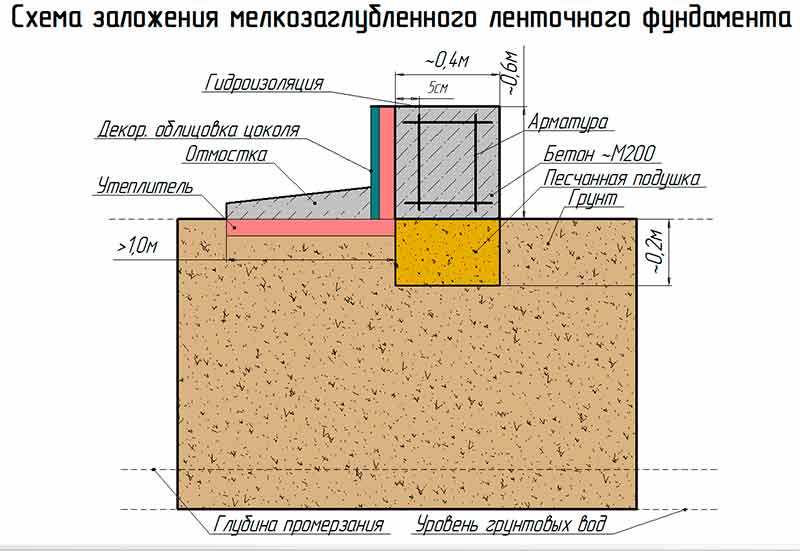

Height, thickness and waterproofing

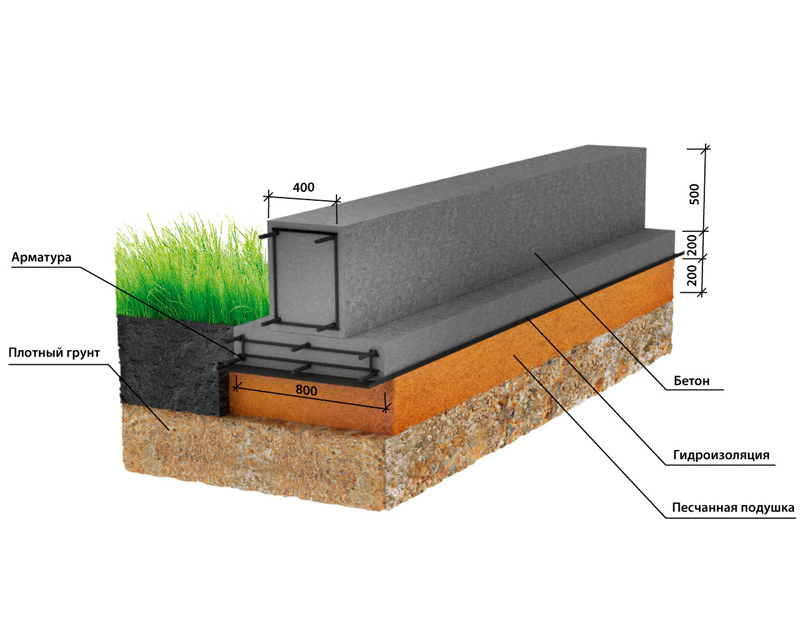

Schematic representation of a sand cushion with dimensions When laying a sole under a strip-type foundation, the total height, depending on the ground, can be up to 60 cm (foundation width 3m). For soils subject to strong frost heaving, this figure is slightly higher, and will be 80 cm. The width of the pillow itself should exceed the foundation on both sides by 10-15 cm.

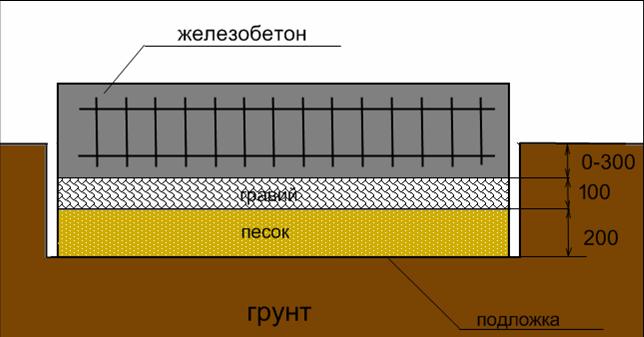

Concrete preparation for the construction of the strip foundation is also possible. The choice of this option has a relative advantage and is determined by the characteristics of the soil:

- the concreted plane makes it possible to perform reinforcement of frames or meshes with good stiffness indicators;

- on such a surface it is easier to perform formwork and reinforcement in the cold season.

After the dimensions of the perimeter of the future structure have been determined, a sand cushion is added by 10-15 cm with a width that exceeds the base of the foundation by 30 or more centimeters.

Next, concrete preparation is performed from low grade concrete or cement mortar.

Another advantage of laying a concrete base is the ability to reduce the protective layer over the reinforced frame. If adding sand requires a layer of 5-7 cm, then in the second variant, its thickness is almost halved - to 3-4 cm.

In addition, the greater the thickness of the backfill under the basement and the basement floor, the less the foundation will be subject to heaving forces. Dumping crushed stone, sand and gravel will protect the foundation and floor well.

A tape type base with an arranged cushion must necessarily be protected from the harmful effects of soil water. For these purposes, waterproofing roll materials can be used. They are glued in one or two layers. The top of the foundation is also treated with waterproofing materials to keep moisture out of the concrete.

Backfilling

Laying scheme for bedding material.

All materials used for the bedding device must meet the following requirements:

- do not change their properties when interacting with water, freezing-thawing;

- when compacted, they must provide water drainage;

- should not have heaving;

- do not contain combustible impurities and plant residues;

Gravel (including shungizite and expanded clay) can be used as a filling material; crushed stone; sands are large, gravelly and medium; grit; a mixture of crushed stone, sand, gravel; production waste and others.

The backfill material is laid in layers horizontally with a thickness of not more than 30 cm with a seal. Laying of bedding slopes should be 1: 1.5. Slopes need to be strengthened by sowing grasses, sodding, brick blind area, decorative tiles. Slopes can be limited by the device of small supporting walls. Support walls are also installed near recessed structural elements in order to exclude local subsidence of the bedding. The backfill surface should be at a slope of at least 3% from the center of the building to the outside perimeter.

Drainage trays with a section of 200x300 mm every 2-3 m across the building, filled with sand and gravel, are recommended to be installed at the base of the bedding. Their slope along the relief is 1%. The principle of "reservoir drainage" of the operation of such trays allows to eliminate the formation of the top water.

In the body of the backfill, the density of the soil is (tons / m³):

- for coarse and medium sands - 1.65;

- for waste and slag - 1.5-1.7;

- for loams and fine sands - 1.6.

Sand cushion calculation scheme.

Compaction is considered satisfactory when the density of the compacted soil skeleton is less than the actual requirement by 0.05 tons / m³. The number of samples with deviations of soil density from the design should not be more than 10% of the total number of samples taken at the tested site.

If the required soil density is not reached, the number of passes along the 1st track is increased or a heavier technique is used.

Careful attention must be paid to compaction of bedding in the corners and along the edges of the trench.

Pillows are distinguished:

- Under with dense soils: for frame buildings and for buildings with longitudinal load-bearing walls.

- Under the slab foundation over the entire area of the building pit: in a situation where floors are installed on the ground; for buildings with load-bearing transverse walls on soft soils and a relatively wide and low height as protection of such soils from disturbing their natural structure. the cost of excavation is reduced, the labor productivity of workers becomes higher in comparison with the same indicators when digging pits under different types of foundations, and the characteristics of bedding are improved.

Diagram of a sand cushion device for a strip foundation.

When arranging foundations at different elevations, backfilling is also performed at different elevations with an appropriate backfill height. They pass from one mark to another smoothly (slope - 1/10).

Additions are made in a warm period of time. An exception may be beddings, which are allowed to be performed in winter conditions according to a special PPR from thawed materials (soils)

It is important to take into account that the dumping of soil on the heaving frozen layer is not permissible

Laying soil in winter in the bedding body is carried out in the same way as in summer, with the obligatory observance of the requirements:

- The base for bedding, made in winter, must be prepared in advance at positive air temperatures.

- Backfilling is made from thawed soils (crushed stone, coarse sand, gravel, slag, shungizite gravel, etc.).

- The presence of snow and ice in the bedding, frozen lumps of sand and dissimilar additives is unacceptable.

- During the dumping procedure and after its completion, the soil must be protected from freezing.

Types of pillows

The pillow for the basement floor is considered to be a kind of layer separating the soil composition and the base of the structure. To choose the right material and arrange a pillow with your own hands, it is necessary not only to study the step-by-step instructions for performing the work, but also to clarify the features of the soil composition on the site, to determine the expected load.

From sand

This building material is considered the most affordable and is used in cases where a small budget is allocated for construction. Sand has certain properties that allow it to be used for such work:

- a sand pillow is arranged under a columnar foundation, erected under a one-story structure;

- if the object is being built from light materials, or the water table is deep enough.

When performing work, pay attention to certain points:

- the sandy surface should be as flat as possible;

- bulk material is carefully rammed;

- the optimal pillow height is twenty to forty centimeters.

From gravel

Due to the weak soil composition, sand alone turns out to be ineffective, and the site is reinforced with gravel. This preparation option does not allow the foundation to shrink.

A pillow made of pgs compares favorably with the previous version, as a more durable and durable base, because the main component is gravel.

How is such a foundation made? Before filling crushed stone under a monolithic foundation slab, the bottom of the trench is lined with river coarse sand, which is leveled and compacted. After that, crushed stone is poured up to twenty - twenty-five centimeters high. Everything is compacted to prevent the formation of voids.

Sand and gravel

If you have chosen this option for a pillow for a foundation structure for a house, the following work will have to be done:

- a pit or trench along the bottom is laid with a quarry, the diameter of which should not exceed fifteen centimeters. If the depth of the pit allows, and you assume that the load from the object will be significant, it is allowed to lay the pit in two layers;

- a layer of gravel up to ten to twenty centimeters high is poured;

- after that, a layer of sand is arranged to cover the gravel;

- everything is abundantly moisturized;

- if necessary, sand is allowed to be added and again spilled with water until the surface is a sandy crust;

- the site is rammed and watered again.

This type of pillow is recommended for the device on clay soil. It does not allow moisture to pass through, protects against groundwater, but does not negate the need for waterproofing.

A pillow of this type is arranged under outbuildings, for a bath or a garage room.

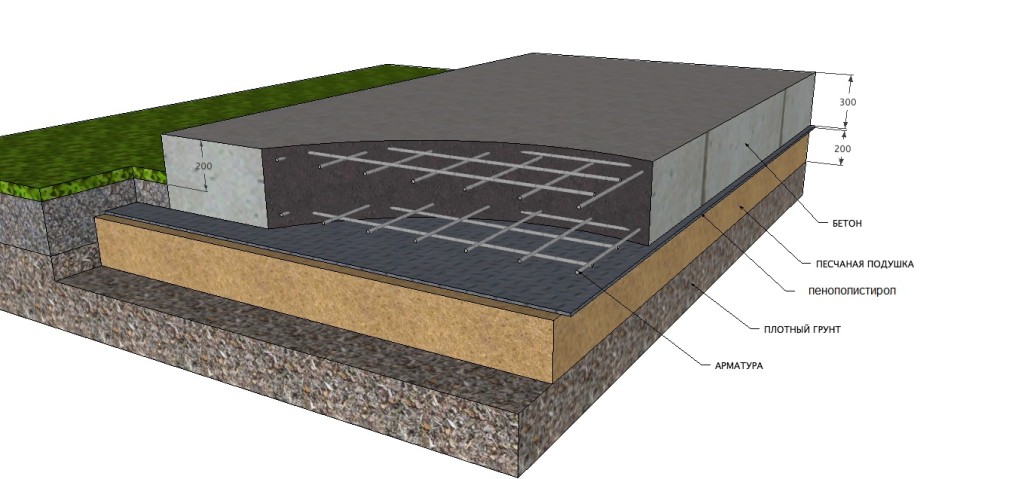

Concrete

This version of the monolithic base is the most durable. Unfortunately, due to the high cost of materials and work, pouring a concrete foundation pad is rarely used.

How to fill such a pillow correctly? The device technology has certain complexities:

- excess soil is removed on the site;

- backfilling is carried out, a waterproofing layer is arranged;

- a concrete solution up to one centimeter high is laid;

- reinforcement is arranged according to the design scheme;

- concrete mix is poured, rammed.

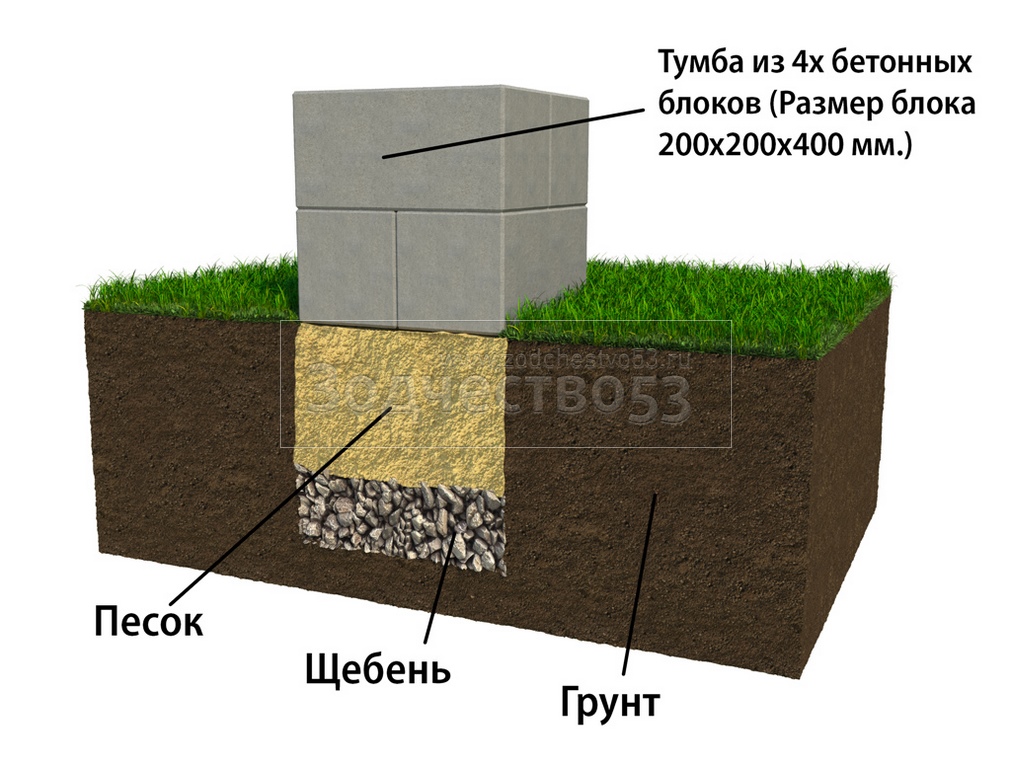

The second method for constructing a concrete pad is to install pre-fabricated reinforced concrete blocks of standard sizes.

How to make such a pillow under the foundation? It is necessary to level the ground, lay a half-meter layer of sand, install blocks.

Monolithic slab on a concrete pad

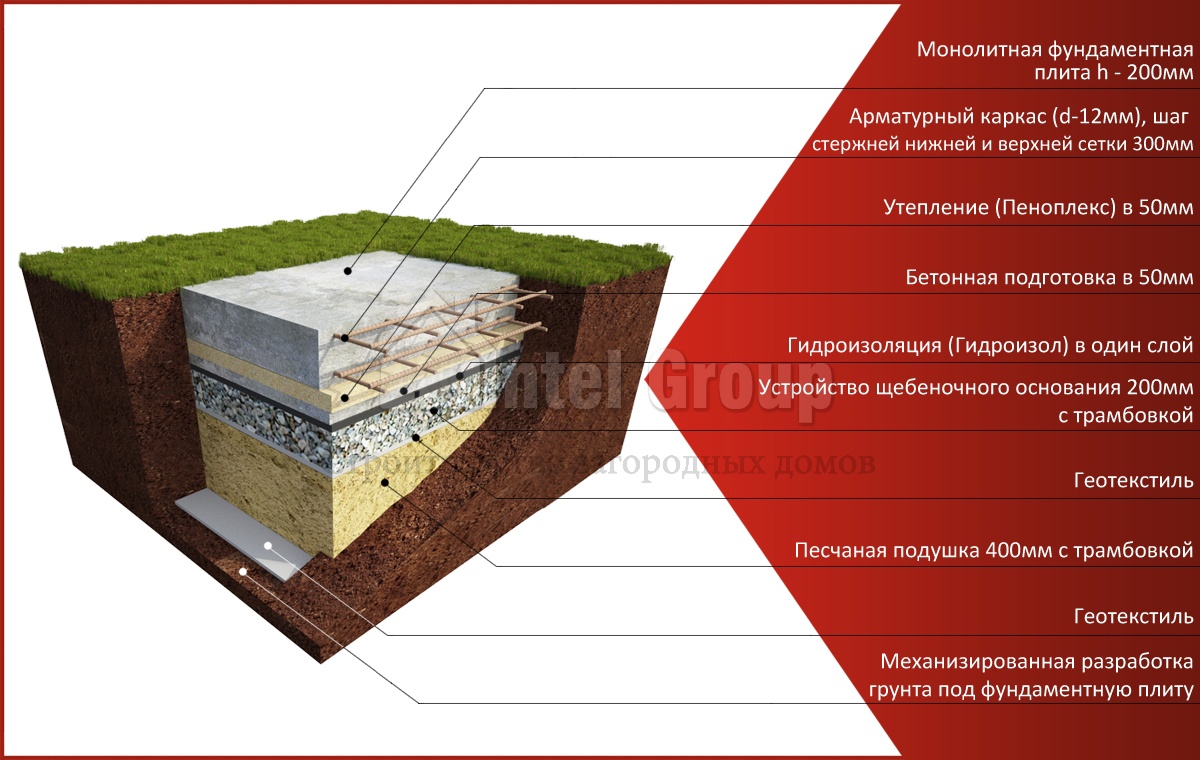

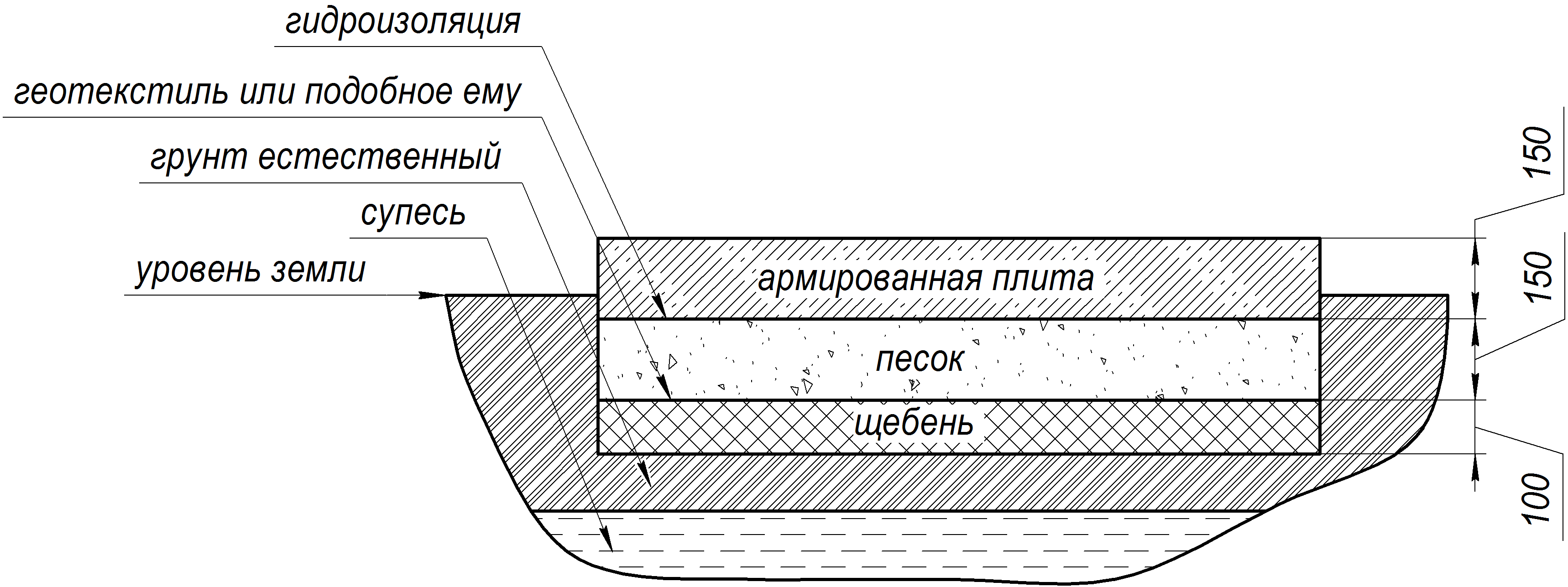

The foundation based on a concrete layer has an increased bearing capacity and can be equipped on various soils for the construction of multi-storey buildings. The technology for forming the lower concrete layer provides for the following operations:

- Arrangement of a crushed stone base with a layer thickness of up to 15 cm.

- Vibration compaction of the formed array.

- Installation of wooden formwork around the perimeter of the created concrete layer.

- Controls the height of a conventional frame corresponding to the ground elevation.

- Reinforcement of the concrete layer using steel rods with a diameter of 0.8–1.2 mm.

- The connection of the reinforcement with a knitting wire with an interval between the rods of 15-20 cm.

- Formwork concreting and further vibration compaction in order to remove air bubbles from the concrete mass.

- Planning the concrete surface at the frame level.

- Periodic moistening with water and protection from cracks with plastic wrap.

Compliance with the technology of creating a concrete layer ensures the reliability of the foundation being erected.

This design has only one drawback - its high cost, otherwise such a project consists of solid advantages

Step-by-step instructions for installing sand bedding under the foundation

Sand bedding has a low cost, so this option is perfect for those who want to save a little on construction work. In addition, it is distinguished by its comparative simplicity in the device. However, despite the low price, such a substrate for the foundation perfectly copes with its tasks.

Its main advantages are that it provides a moderate load that does not exceed the norm on the foundation, or rather, on its lower part, and also protects the foundation from the negative effects of groundwater.

Correct foundation laying, taking into account the level of soil freezing.

There are situations when there is a layer of soil unsuitable for construction work in the pit dug for the foundation. Such cases are by no means uncommon. If this happens in your case, you need to remove unnecessary soil and put sand in its place.

The finished lining is neatly leveled. Do this carefully so that the substrate does not have dips and excess. After leveling, the sand layer is carefully tamped. Thanks to this, the fluctuation of the material is removed. The ramming is performed using a special tool - a vibrating plate. If possible, it is recommended that you abandon the old compaction methods. It must be remembered that with the help of improvised means it is impossible to achieve the same accurate and high-quality result as with the help of special equipment.

In the process of tamping, the sand cushion must be moistened with water. Due to moisture, the sand layer will gain maximum density.

Using rubble to make a pillow

There are different types of crushed stone:

- Gravel - has high strength, low radiation background. It is obtained by sifting rocks, crushing stones using specialized equipment. It has a low cost.

- Granite is a high-strength type, used mainly in civil engineering, is easy to process and can withstand serious loads. It is obtained by processing natural granite, which is mined by blasting rocks. It is ideal for the production of reinforced concrete blocks, foundation pouring. But he has a minor drawback, he accumulates radiation in himself. Of course, the savings are not significant and are not at all dangerous for human health.

- Limestone is the cheapest type of crushed stone. Possesses lower quality characteristics in comparison with the two previous types. It is obtained from limestone rocks, resistant to low temperatures.