Price

The price of the product is calculated from the amount of material that was spent on its manufacture. The cost of the ebb also includes whether the metal is covered with a protective paint layer or not.

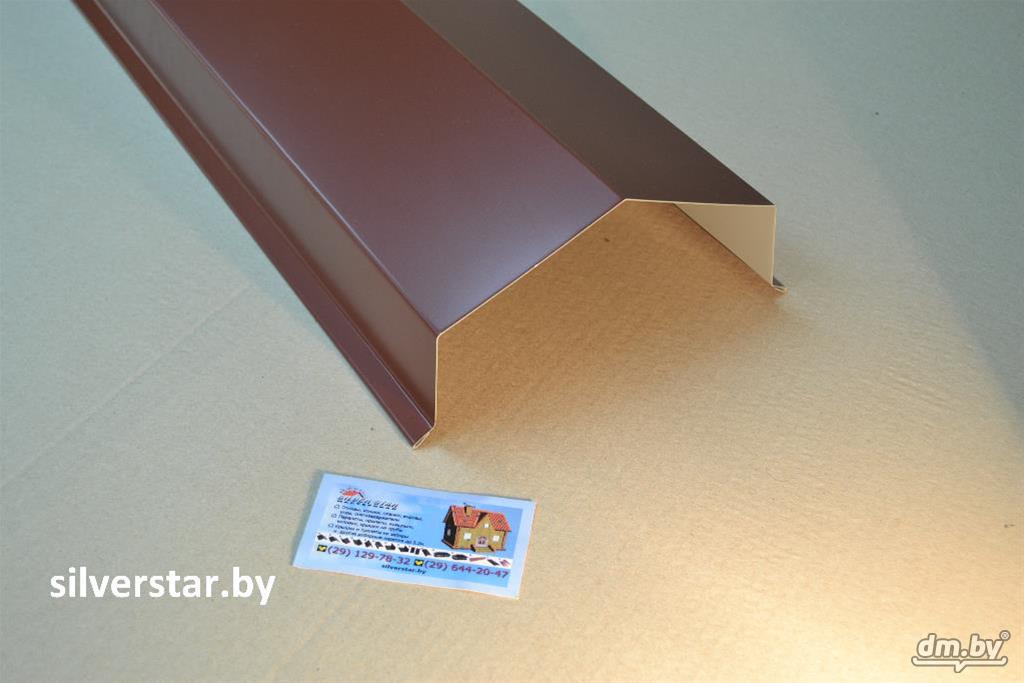

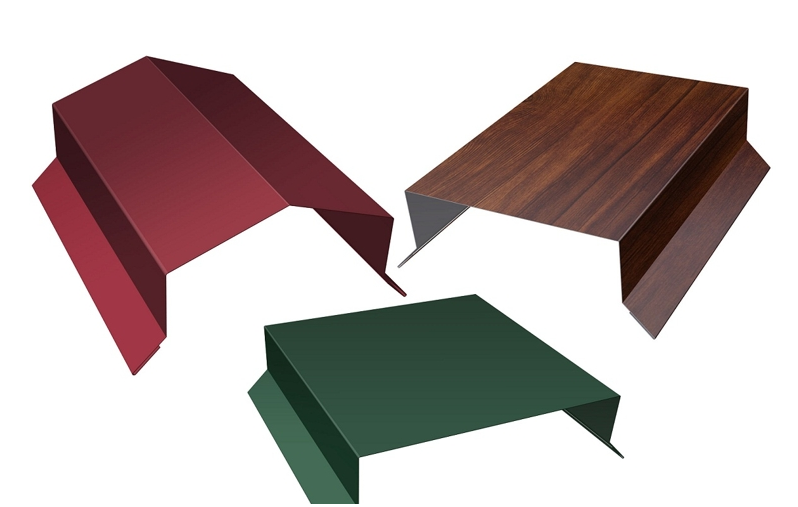

The appearance of the galvanized end of the fence

Below are the prices for the most common materials from which parapets are made.

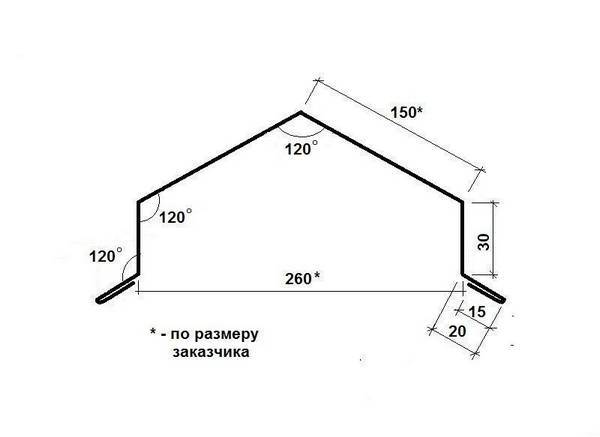

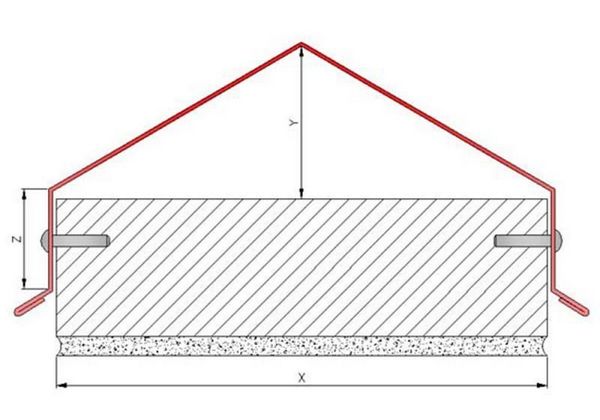

Scheme of a classic parapet from this material

Galvanized steel parapet price:

- 50 cm - 94 rubles.

- 100 cm - 120 rubles.

- 150 cm - 144 rubles.

- 200 cm - 170 rubles.

- 250 cm - 195 rubles.

- 400 cm - 269 rubles.

- 500 cm - 345 rubles.

- 750 cm - 445 rubles.

Polyester plank pattern

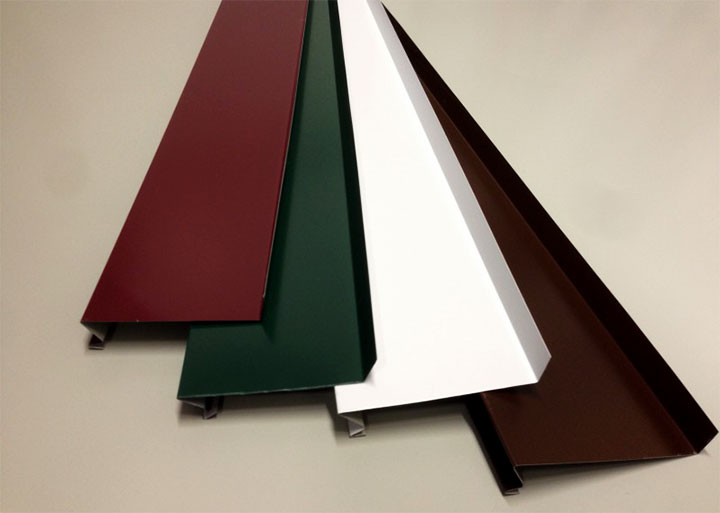

Fence parapets in polyester coated steel:

- 50 cm - 104 rubles.

- 100 cm - 136 rubles.

- 150 cm - 163 rubles.

- 200 cm - 192 rubles.

- 250 cm - 221 rubles.

- 400 cm - 305 rubles.

- 500 cm - 363 rubles.

- 750 cm - 505 rubles.

Comparison of models

Parapets in powder coated steel:

- 50 cm - 134 rubles.

- 100 cm - 161 rubles.

- 150 cm - 210 rubles.

- 200 cm - 246 rubles.

- 250 cm - 283 rubles.

- 400 cm - 394 rubles.

- 500 cm - 470 rubles.

- 750 cm - 653 rubles.

Making an ebb with your own hands from thin sheet steel

The length of the parapet must match the length of the foundation. The width is selected individually: the narrower ones protect the base, the wider ones protect the basement.

Photo: using a mallet to work with thin sheet metal

Photo: using a mallet to work with thin sheet metal

To work, you need the following tools:

- steel sheets;

- scissors for metal;

- drill or hammer drill;

- pliers;

- level;

- rubber mallet.

Sequence of work:

- We cut metal sheets into strips of the required length.

- We carry out the markup according to the level. The chopping line will facilitate the work.

- To fix the ebb tides it was easier, on the plinth we make a slope from a cement-sand mortar or from polyurethane foam at an angle of 15 degrees.

- We give the workpiece the desired shape. To do this, bend the side edges. The width of the shelf should be taken with a margin, at the rate of plus 2 cm for the top edge and plus 5 cm for the bottom. The upper edge is responsible for fixing with the plinth, the lower one is made at a slope for water drainage.

- The ebb installation is carried out along the upper edge every 25–30 cm using screws with dowels or self-tapping screws.

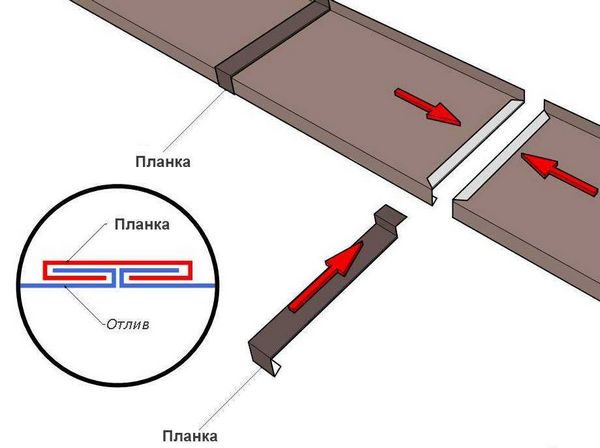

- We make an overlap between the elements at least 3 cm. We coat the joints with a sealant.

The optimal protrusion of the parapet from the base is from 5 cm or more.

It is also important to remember about color compatibility. Ebb tides should be a harmonious addition to the fence

And the result of following the installation recommendations will be reliable protection against moisture and extending the service life of the foundation, basement.

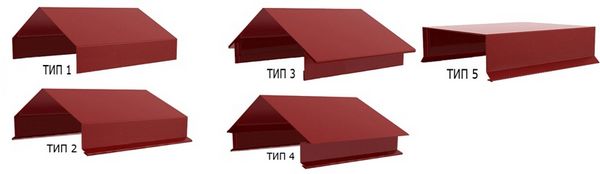

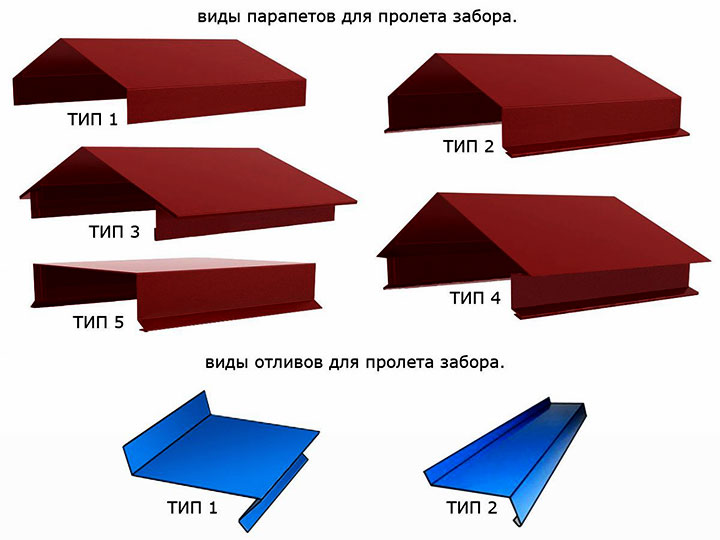

Product shape

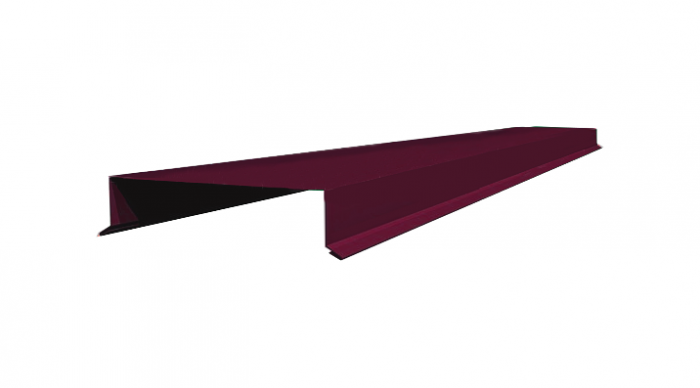

Ebb tides are divided in shape into two types. The first is installed on the base of the fence to protect the abutment of the foundation and brickwork. They have different widths of the shelves, but they are made according to the same principle, they have the shape of the letter Z. Attach the drain bar to the vertical wall using dowel-nails.

Classic low tide scheme

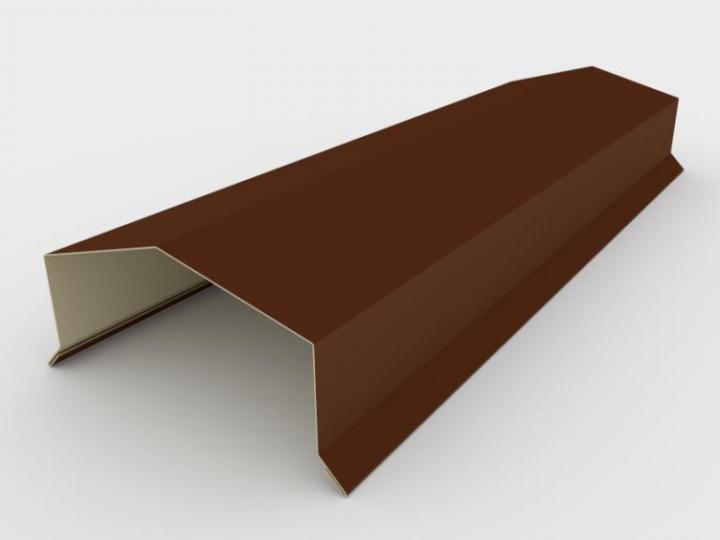

The second type is used to protect the top of the brickwork and for the foundation of the fence. They are called parapets or aprons, they are curly and flat.

The shaped metal drip has a gable shape with or without flanging at the bottom. Installed on the dowel-nails.

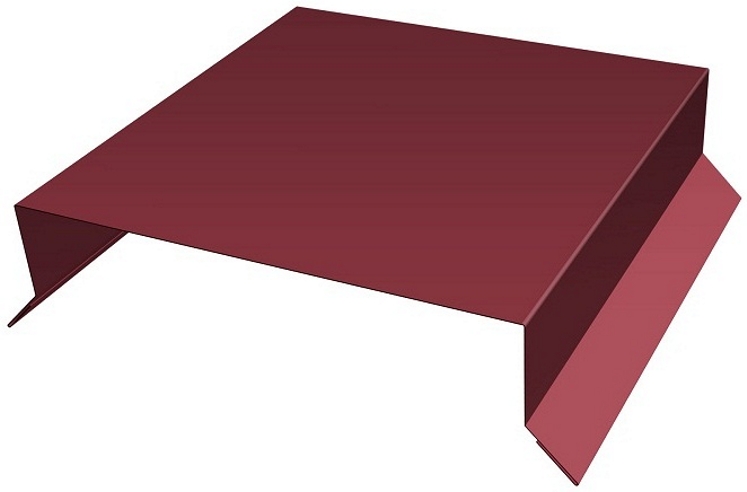

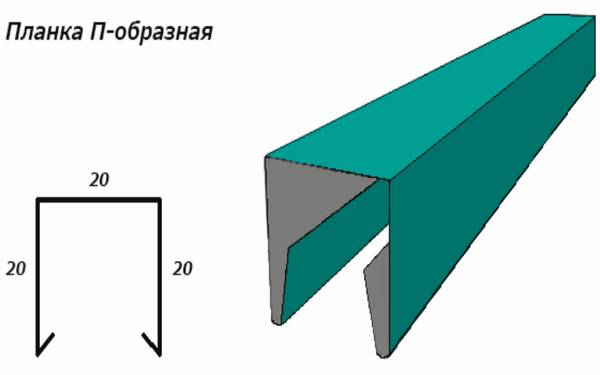

Diagram of a U-shaped model for a fence

Flat or U-shaped aprons are made with a flange or with a dropper on the overhang of the product. They are used to protect the strip foundation and the upper part of the fence. Fastened with dowel-nails.

Materials for making

Drainage elements are divided depending on the material from which they are made: concrete and metal. Iron products are copper, aluminum and galvanized with a protective coating.

Fixation scheme on the fence

For production from non-ferrous metal, it is necessary to use sheet aluminum and copper. Today, aluminum and copper protection is not often found due to the high price. But in quality they are superior to products made of galvanized material in strength and durability. Aluminum and copper do not rust, so they are not afraid of possible scratches during installation. Advantages:

- rigidity of the part;

- resistance to weather changes;

- sound absorption;

- attractive appearance;

- life time.

Docking scheme

Disadvantages:

- price;

- the weight.

Steel galvanized ebb structures, coated with polyester or powder paint, are the most common today. Various colors are available, they are easy to bend and process, unpretentious in operation.

The scheme of placing the ebb in the corners

Advantages:

- resistant to weather conditions;

- easy installation;

- attractive appearance;

- affordable price.

A sample of the finished structure with protective elements

Disadvantages:

- easily deformed;

- afraid of scratches.

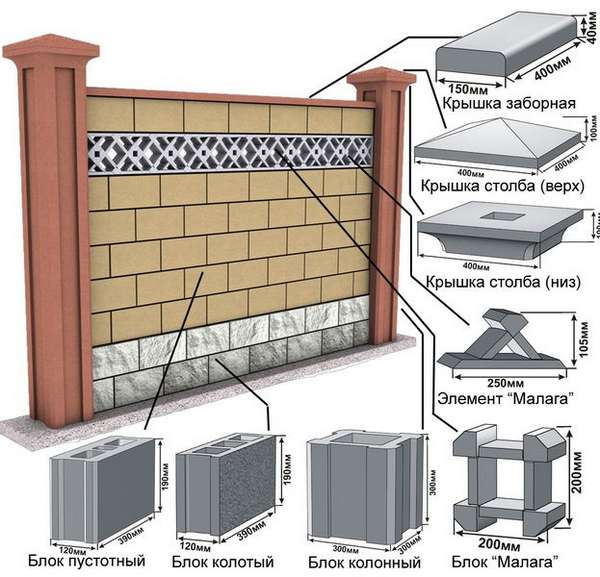

Another type is concrete slabs. Concrete blocks are made flat, gable or hipped. The material goes well with brick fences and pedestals.

Scheme of the constituent elements of a concrete fence

Advantages:

- lifetime;

- attractive appearance;

- low price;

- resistant to atmospheric precipitation;

- are not afraid of mechanical damage;

- simple installation.

The main disadvantage: weight.

Installation example of concrete sills

Tips for installing a fence drain

Caps and drips to protect the fence and foundation

Caps and drips to protect the fence and foundation

It is better to install the installation before finishing the basement, then the financial losses will be less, and less time will be spent on arranging the foundation.

If a facade finishing stone is used for an assembly-type fence, then the length of the ebb is determined by the pitch of the lathing.

It is necessary to mount metal and polymer visors using a rubber mallet so as not to damage the coating.

It is imperative to seal the space under the ebb and the ground with polyurethane foam and sealant.

If the ebb for the fence is done correctly, then it will last more than one decade, and the fence itself will not squint and will not fail. But you need to install them correctly, take into account building rules and strictly adhere to technologies. And they are almost the same, both for the installation of the ebb and for the foundation of the building.

How to install an ebb with your own hands

Installation of drips to protect the foundation of the fence

Installation of drips to protect the foundation of the fence

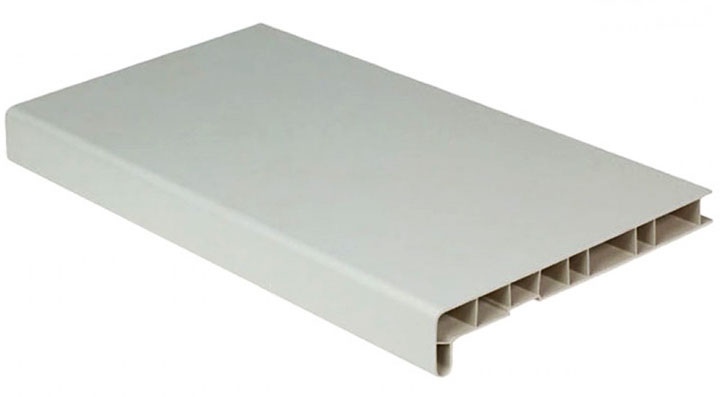

As a rule, all foundations for fences are small in size and design, therefore, ebb tides are often installed on their own. Plastic is now especially popular and reliable, because it is inexpensive and can be transported in a car.

Most often, plastic ebbs on the foundation of the fence are installed on the basement tier of a columnar or strip structure of the base, and the process takes several hours. What do I need to do:

- If the structure of the foundation is columnar, then you must first clean the top layer of the base from adhering dirt and stones, and then carefully level it with concrete mortar.

- Cover the surface with a small layer of roofing material or liquid rubber and let it dry.

- For waterproofing using a building level, mark the horizontal level of the ebb and fix the finished plastic structures. It is advisable to perform all work with a screwdriver, drill holes for fasteners at intervals of 10-15 cm. Seal the joints between the plates with sealant.

If a strip foundation is used, then it is recommended to install fasteners at intervals of 30 cm and use long sheets. Here all the work must be done in two hands, because it is quite difficult to install flexible and lightweight plastic on your own.

Production

Parapets are made of two types: metal and concrete.

Metal ones are made from aluminum, copper and galvanized metal. Today, polyester is more often used - a galvanized sheet with a special coating. It is produced in rolls and sheets. Polyester sheets come in two sizes: 3000x1250 or 2500x1250 mm.

The use of drips to protect the base of the fence

Products are produced as follows:

- The material is cut and bent using a listogib machine.

- The required size of the workpiece width is set on the machine.

- They put the workpiece on the machine, placing the sheet in the stops.

- A sheet is cut with a roller knife, a workpiece of the required width is obtained.

- Using a grinder or a special cutter, the workpiece is cut to the desired length.

- Mark the place of the fold on the outer (white) side of the sheet.

- Mark the inside of the workpiece.

- The sheet is fed to the machine, back side up, and the workpiece is bent according to the marks made.

- The operation is repeated from the back side: mark, bend.

- The metal is fed into the listogib with the outside (white) and bend.

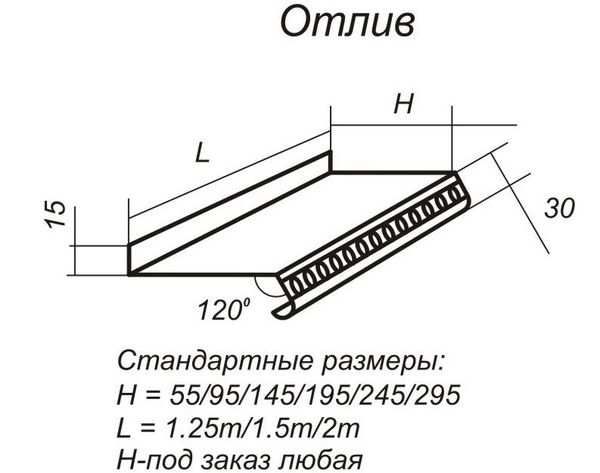

Basic parameters diagram

This is how all parts are made of polyester sheet.

For the manufacture of concrete parapets, special concrete is needed: 1/2 part of cement and sand, 1/4 of fine gravel from the total mass, additive, water, dye.

Popular types of fence products

Making concrete parapets step by step:

- The concrete is kneaded. Dye is added if necessary.

- The prepared form is placed on a vibrating table.

- Concrete is poured into it.

- Vibrate and leave to harden.

- Get the workpiece out of the mold.

It is recommended to install concrete ebbs not earlier than three days after concreting.

Variety of elements for a concrete fence

Types of ebb

According to raw materials, they are divided into several types. Technical characteristics, properties of each of them have significant differences.

Concrete

Concrete casting is created using molding technology. The solution of the correct consistency is poured into molds and dried in special chambers. Many craftsmen have learned how to make such parapets at home.

Suitable for massive fences with brick, metal, stone, forged sections and decorative low fences.

Photo: concrete block intended for the construction of ebb tides

Photo: concrete block intended for the construction of ebb tides

Benefits:

- strength, durability of the product;

- compatibility with many materials;

- affordable price;

- choice of colors.

Polymer sandy

The main raw materials are sand and low pressure polyethylene. Looks beautiful. Textured products that imitate tiles and more are popular.

In terms of service life, they are many times superior to metal ones. But the cost of polymer sand products is high.

From corrugated board

The base is profiled iron, covered with a protective layer of polymers.

Among the pluses:

- Strength. The professional sheet is not afraid of mechanical stress.

- Durability. Provided the integrity of the coating.

- Needs no maintenance. To clean the surface from dirt, it is enough to rinse it with water from a hose.

- A light weight. It is convenient to transport the ebb from the corrugated board.

- Choice of colors and shapes. Allows you to choose a parapet that is combined with other elements of the fence.

- Ease of installation. You will be able to do the work yourself.

- Resistance to ultraviolet light, moisture, frost, precipitation, sudden temperature changes.

Photo: ebb and parapet configurations for fences

Photo: ebb and parapet configurations for fences

Prices for parapets made of profiled sheet are different. It all depends on the selected metal thickness, manufacturer.

Wood

Previously, this material was used due to the lack of alternative materials.

Even a painted tree, over time, under the influence of moisture, begins to rot, become covered with fungus, and be damaged by insects.

Galvanized

The product is based on hot-dip galvanized sheet steel.

Photo: the use of galvanized metal as a material for the parapet

Photo: the use of galvanized metal as a material for the parapet

Of the advantages of such ebb tides:

- Long service life.

- A light weight.

- High material strength. Resistance to increased loads.

- Excellent flexibility, due to which products can be given any shape.

- Ease of installation that does not require skills.

- Resistance to environmental influences (precipitation, temperature extremes).

- Possibility of painting with any type of product, even powder.

- Low price.

Disadvantages:

- The slightest damage to the protective galvanized layer will provoke the formation of rust and reduce the life of the product.

- During installation, it is recommended to waterproof the foundation so that it is not exposed to moisture from the inside.

If you have non-standard sizes of ebb tides or want a product of an unusual shape, then you can place an individual order.

Stone, from paving slabs

Suitable for stone, forged or welded fence sections.

The first option is expensive. The most durable and durable stone is granite.

Installed on top of the foundation on concrete mortar or special glue. Weighs a lot.

Ebb tides from paving slabs will cost an order of magnitude cheaper, but the strength will not be so high.

Plastic

Benefits:

- long service life;

- resistance to any environmental influences;

- choice of shapes and colors;

- a light weight;

- ease of installation;

- affordable price.

Copper, aluminum

Previously, they were used to protect and decorate the strip foundation under the fence, but due to high prices, the popularity has declined.

Among the advantages of the material:

- high strength, wear resistance;

- resistance to environmental influences;

- light weight;

- convenience of fasteners;

- exquisite look;

- corrosion resistance.

The disadvantages include the risk of theft, since non-ferrous metals are of interest to intruders.

Choosing high-quality ebb tides

When buying, you should adhere to the following recommendations:

The thicker the metal, the heavier the product. However, this increases strength and deteriorates flexibility.

If you need ebbs, caps on posts of non-standard sizes, shapes, then it is better to contact the representatives of the manufacturers.

They will help you prepare a drawing, complete an order in a short time.

To avoid a large number of joints, it is important to take measurements correctly, since water can get into leaking joints.

The width of the ebb should be greater than the width of the tape. This will allow water to drain freely from the foundation.

Make a metal ebb and install it on the base of the fence

Manufacturing of a metal ebb for the foundation

Manufacturing of a metal ebb for the foundation

It is necessary to cut metal sheets into strips of a given length and width. Carefully bend the side edges to create full-fledged gutters. It is recommended to use the shelf width plus 2 cm for the top fold and 5 cm for the bottom. You can give large supplies, but they are simply not needed for fences.

Mark the stripes and fold the side edges. The top fastening edge is always folded upwards in order to then create an airtight connection with the foundation surface. The lower edge is bent down, and the strip itself should be attached at a slight slope.

The marking of the places of installation of the future ebb tide is being made. First, a horizontal marking is applied along the entire perimeter of the fence with a level along the upper edge of the ebb. For this, it is better to use a marking cord if the foundation of the fence is tape monolithic.

Fix the strips. The low tide is fixed along the upper edge of the marking with dowels and screws with an interval of no more than 25-30 cm.

Installing a purchased ebb tide

The process will not cause difficulties if you follow the step-by-step instructions.

Plastic

Used frequently. It costs a little.

Installation takes several hours. Ebb tides are attached to the basement of the columnar, strip foundation.

Installation recommendations are as follows:

- In the case of a columnar base, the top of the base / plinth is cleaned of dirt and leveled with a concrete mortar. The tape does not need alignment.

- The dried surface is covered with a waterproofing layer made of roofing felt or liquid bitumen.

- With the help of the level, markings are made for the installation of ebb tides.

- Fastening of plastic products is carried out using a screwdriver and special self-tapping screws with an interval of no more than 15 cm for a columnar base and up to 30 cm for a tape.

- It is better to treat the joints between the ebb with a sealant.

To ensure evenness of fixation, it is recommended to carry out the work together.

Users often search for:

- Fence foundation

- How to make a strip foundation for a fence

Stone, from paving slabs

Photo: the process of installing stone ebb tides on the lower part of a brick fence

Photo: the process of installing stone ebb tides on the lower part of a brick fence

Not mounted on top of the foundation. Here the fastening principle is slightly different:

The base of the fence must be excavated to a depth of 20 cm from the surface.

Level the bottom of the trench obtained, tamp it.

Fill up with a layer of sand.

After that, you need to create a slight slope towards the base.

Lay stones or paving slabs on top of the sand cushion

Check the evenness of the masonry with a level.

It is important not to forget about the gutters for the natural flow of water.

It is allowed to fill the joints between the tiles with liquid concrete mortar.

Required sizes, shapes

The form is standard and curly.

Popular:

-

House. It needs to be fixed to the top of the fence. Precipitation flows down unhindered. Suitable for structures made of brick, stone. Ebb material - galvanized or polymer coated metal.

- U-shaped. It is fixed to the lower part of the fence - the foundation. Provides excellent water flow. Fastened with self-tapping screws or assembly glue. Installation directly into the basement masonry is allowed in the case of brick, stone sections. Then the ebb tides will last longer, but it will be almost impossible to replace them.

The dimensions of the parapets are selected individually, depending on the material used and the thickness of the walls of the fence.

Where do they install

Another name for low tides is parapets. In the standard form, they consist of a shelf, drip edges on the sides. Fasteners are made using bends that are perpendicular to the shelf.

Depending on the design, they are fixed on top of the intake sections or the base.

On the foundation

The product resembles a plinth visor, which fits closely with one of the cuts to the wall, and covers the base with the other curved edge.

And the cladding should be carried out upon completion of finishing work.

On top of a brick fence

They are mounted together with caps, giving the structure a neat look. In color, both types of elements should be the same or contrastingly complement each other.

But the main function is to protect the masonry from moisture ingress.