No. 2. Natural and artificial stone

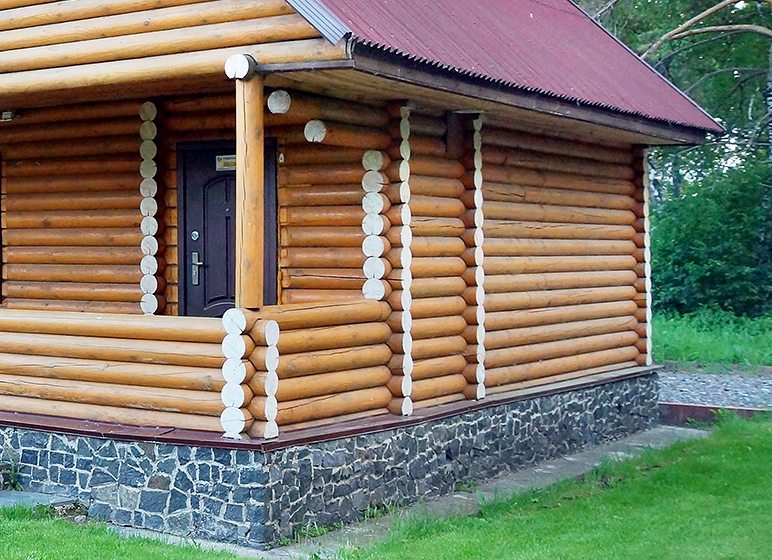

The stone has no competitors among other facade materials in terms of durability and reliability, and in terms of its decorative qualities it is considered one of the leaders. Natural stone is a very expensive pleasure, so often the owners of private houses revet only part of the facade with it, combining it with other materials, or use decorative stone

The latter has practically identical performance characteristics to natural stone, but it costs less, and even weighs less, which is important

Advantages:

- durability and practicality. It is worth spending once on finishing with a stone, and you will not remember about repairing the facade of the house for decades;

- aesthetic appearance. Using different types of stone, you can translate into reality any design idea, and the house will always look great;

- environmental friendliness;

- resistance to moisture, temperature extremes, sunlight;

- resistance to mechanical stress.

Of the shortcomings, only the large weight of natural stone and the high cost can be noted. Even decorative stone, which is much cheaper than natural stone, will cost more than most other facade materials.

Many types of natural stone are suitable for facades. More often than others, granite, gabbro, quartzite, marble, shale, sandstone, limestone, dolomite are used. Decorative stone can imitate any breed: the market is overflowing with materials of different colors and textures. A decorative stone is mounted on an adhesive base or as a ventilated facade.

Where to stop the choice?

What is the best outdoor home covering? The answer depends on many factors:

- Financial opportunities. Lining, professional sheet and siding will cost relatively cheaply.

- Plating purposes. If cladding is needed to radically change the type of facade, use a material that is significantly different from wood. Brick is ideal to prevent the building from collapsing.

- The need for wall insulation. The use of thermal panels will save the owner from additional costs for thermal insulation.

- Features of the structure. For houses with rich architecture, you cannot use a professional sheet outside. Buildings with a weak foundation will not withstand if they are overlaid with bricks.

- Desires to preserve the identity of the home. If the owner loves wooden buildings, he should revet the house with natural materials.

- Home locations. It is better to sheathe a building next to a noisy road with noise-insulating materials: a block house, thermal clinker panels, clapboard.

- Facade maintenance opportunities. Easy to clean siding, brick, thermal panels, profiled sheet.

Dear Reader! Your comments, suggestions or feedback will serve as a reward to the author of the material. The following video has been carefully selected and will definitely help the perception of the above.

Requirements for materials

The most important requirement for finishing a house from SIP panels is resistance to the negative effects of external factors. The material must be ready to last a long time, perfectly tolerate contact with moisture and withstand constant temperature changes. Such quality characteristics are possessed by clinker tiles and vinyl siding. They are also good because they just fit, which is not fully consistent with facing bricks. For its installation, certain skills will be required, as when applying facade plaster.

The material for finishing the outer walls must also be repairable. This requirement is well met by artificial or natural stone. If individual elements have broken off, they can be replaced if necessary.

It is also important to take into account the fact that the finish can have an impressive weight, which means it will put a load on the foundation. If the construction was carried out using lightweight technology, and the base is not too deeply buried, the external finish should have a small mass

Therefore, when deciding how to decorate a house from SIP panels from the outside, you should pay attention to an artificial stone, abandoning its natural analogue

How to sheathe the foundation of the house outside?

The material for the base is purchased taking into account the following factors:

- Installation technology. There are two methods for covering the surface: dry and wet. The first assumes that the selected products are stacked on a previously erected frame. If the specifics allow, then the products can be mounted directly, without crate. The second option is more laborious: to overlay the base, you will need to use glue or a suitable solution. It is also possible to decorate the foundation of the house with the help of plaster, which will act as an independent product.

Installation of facing material is carried out in two ways: on the frame and glue

- Frost resistance. First of all, the climate of a particular area is taken into account. The purchased products must withstand multiple defrosting and freezing cycles and not be deformed. When mounting elements on glue, the composition used must also comply with this requirement.

- Resistant to water and aggressive substances. The plating of the foundation should not strongly absorb moisture and react when chemical compounds get on it.

They also pay attention to the manufacturer of the product and the place of purchase. Better to give preference to trusted brands and specialized outlets

Suspended structures

Suspended structures involve the use of a lathing on which the finishing material is mounted. This method is gaining more and more popularity, since it allows you to create a ventilated facade, use insulation of the required thickness.

The lathing is usually made from timber or metal profiles. The latter option is preferable, since it does not require pretreatment of the elements of the sheathing with fire retardants and similar compositions for wood.

Siding is considered a type of hinged structures. It is a panel similar in size to the size of the boards. At the same time, the material has special grooves and locking systems, due to which it is assembled like a children's designer. This type of installation allows you to make it simple and efficient, it is possible to carry out installation work all year round. The material has improved performance properties, including hydro-wind protection.

The sizes and designs of the material are very diverse. It can be both colored models (bright glossy or quieter, neutral matte panels), and imitation of the texture of any natural material (brick, stone, wood). The material is easy to clean - most surfaces have a self-cleaning function. Wet cleaning of coatings is possible.

There are the following main types of siding panels.

Plastic. It is based on PVC, as well as various modifiers and pigments. Such panels are strong enough, but with increased mechanical stress (shock) they can crack. The material is moisture resistant, withstands high and low temperatures, their abrupt change, and is resistant to UV protection.

Low weight (up to 5 kg / sq. M) does not require foundation reinforcement. The disadvantage is the low rate of fire safety.

However, despite the processing of wooden panels with special compounds, their service life is short. During operation, siding requires regular maintenance.

Separately, it is necessary to highlight the basement siding, designed for cladding the lower part of the building.It has a greater thickness of profiles, better weather resistance and moisture resistance, resistance to mechanical damage. This is due to the fact that the basement of the house is more often than others exposed to shocks and other damage, freezing, moisture and other negative environmental factors.

Basement siding is rather rectangular panels. Their width is usually equal to the height of the basement and starts from 60 cm. This leads to ease of installation.

Facade panels have some similarities, in terms of fastening and possible materials used for manufacturing, with siding. They can be square or rectangular in various dimensions. Some slabs contain insulation. The multi-layer panels provide their high performance properties.

Another popular hinged type material is sandwich panels. They represent a "sandwich" in which the "middle" of the insulation is laid between 2 layers of rigid material (usually metal). The strength and durability of the structure is ensured by using the hot pressing method. The front side of the "sandwich" can be painted in any shade, be smooth or have a relief.

Sandwich panels are highly resistant to fire and moisture, exhibit excellent thermal insulation properties with low weight. The material is easy to install, and if a separate section is damaged, only it can be replaced without going through the entire facade.

If earlier they were used for cladding office buildings, now they are also used to decorate private buildings. This is due to the durability and reliability of the material, its weather resistance. Externally, the cassettes are squares and rectangles of aluminum, steel, less often copper, covered with a protective polymer layer. The size and design of cassettes may vary.

Do I need a foundation cladding

The purpose of the plinth is to protect the walls and make them attractive. For finishing, it is necessary to use special materials, especially since wooden walls must also be protected from moisture and harmful influences.

It is worth knowing that the facing of the foundation is not always needed. And it will not always be useful. Sometimes it is more useful to leave everything without cladding. You can also perform a simple elementary protection of the foundation structure. To solve the problem of facing the base of the house and its blind areas, it is necessary to assess the characteristics of the house and its foundation.

The main role is played by deepening the base. There is no point in protecting the foundation if it is all buried in the ground. It is invisible to anyone, and the layer of earth already protects it well. The only thing that needs to be done in this case is to insulate it. But it is also not always necessary to insulate, but only where the foundation also plays the role of basement walls.

There is a sinking version of the base. True, its use is limited. Such a finish can only decorate houses in which the walls are thick and protrude beyond the edges of the foundation.

In buildings with frame and chopped walls, or when there is a warm basement under the house, it is better to use a protruding basement.

Cladding features

The formation of external finishes can be carried out with the help of various materials. Cladding technologies differ in many nuances.

There are several common features that are characteristic of any option.

Wall decoration is carried out after complete shrinkage of the house

This avoids distortions or damage to the decorative coating.

Pay special attention to the corners. If you use curtain walls, then it is advisable to use metal corners to align the points.

They allow you to simplify the fastening procedure. It is advisable to use such elements also when finishing window slopes.

Foundation finishing is optional. It is often performed to create an original style at home.If you need to insulate the system, then materials should be used that will easily tolerate humidity and temperature changes.

When building ventilated facades, be sure to use a vapor barrier. With its help, you can easily prevent the penetration of moisture into the house, as well as create the necessary microclimatic conditions inside the system. These products are also used to protect thermal insulation.

Finishing the foundation of a log house, the first or second floor can be carried out using various materials. The main thing is to take into account the permissible loads on the frame of the house and select finishing elements based on this parameter.

Choice of materials

How to decorate the facade of a house from a bar? It is more convenient to sheathe a wooden case with materials that are easy to attach. Therefore, they choose lining, block house, imitation of timber, thermal panels, etc. The main condition for cladding is the presence of ventilation in the walls, which is created due to the gap between the wall and the finishing material. When using facing materials (bricks, tiles, plaster), they try to create ventilation holes so that the wood does not end up in thermal insulation. If the walls don't breathe, mold and mildew will form inside.

The building materials market is always ready to offer a suitable material for the exterior decoration of a wooden house. Options are chosen based on their capabilities and requests. Any building material has advantages and disadvantages:

- Imitation of a bar is an environmentally friendly material that allows you to decorate and insulate a house after standing; has unique characteristics of wood, since it is made from coniferous trees; resistant to external factors due to the resin content. The disadvantages are that there are too dense knots, increased fire hazard;

- Wooden lining is a wood material that preserves all natural properties; has high wear resistance with proper surface treatment; increases the steam exchange functions of the bar. Disadvantages: requires periodic processing and coating;

- Block house is one of the varieties of lining with imitation of a rounded surface of a log; easy to install; often ready-made structures are made from such material. Disadvantages: like other natural materials, it is susceptible to moisture;

- Vinyl siding is a lightweight, practical material that is resistant to weather conditions; available in different colors; budget option compared to natural wood. Disadvantages: does not always withstand loads, gaps may appear between the elements at high and low temperatures;

- Metal siding - imitates wood materials while remaining a fireproof material; the colors and shape are different; minimal surface care; easy to install, does not require a foundation. Disadvantages: does not allow the exit of the vapor formed in the walls;

- Thermal panels - made of high quality concrete with practically no water; the product does not crack, withstands low temperatures and retains heat; have a unique design solution, imitating brick, tile, stone, etc. Disadvantages: can be destroyed by moisture;

- Decorative brick - provides a high level of thermal insulation; durable and reliable material in a variety of shades. Disadvantages: requires a reliable foundation and sufficient roof overhang;

- Facade stone - used more often for laying paths; made of natural stone, therefore it is expensive; fits on walls according to the principle of tiles; withstands any temperature extremes, moisture resistant, but allows the house to "breathe". Disadvantages: expensive, requires professional skill when laying;

- Facing tiles - made from baked clay; for outdoor work, choose a frost-resistant product with a moisture-repellent coating; comes in different configurations and colors.Disadvantages: for laying on a timber requires preliminary leveling of the walls;

- Fiber cement panels - made using the latest technologies from cement, reinforcing fibers, mineral fillers; resistant to stress and temperature extremes; come in different colors or are painted after installation. Disadvantages: in the absence of ventilation, they retain the escaping moisture, exposing the wood to rotting;

- Plaster is a simple and affordable material that allows you to level any walls; gives the house a modern look; you can choose any color that is added to the finished mixture; the most resistant are acrylic paints. Disadvantages: tightly closes the wooden wall, making the room unventilated.

Having decided on the appropriate type of material for cladding a house from a bar outside, they prepare everything necessary for finishing work. If you plan to do everything yourself, make sure to purchase a sufficient amount of materials, as well as have the necessary tools and devices on hand. Decorating the walls in a house from a bar will require work at a height, so you must adhere to safety rules in order to prevent industrial injuries.

Types: advantages and disadvantages

Since the block house is made from various raw materials, it is subdivided into several types. The most popular is the material made from natural wood. The main advantage of such boards is their environmental friendliness. The basis of a wooden block house can be spruce, pine or larch, therefore, choosing it for the exterior cladding of the house, you can get an unusual decor with an imitation of a log frame.

Depending on the quality of the array, wood panels are divided into three groups.

- Class "C". The boards have a well-planed surface, without knots and other large defects. However, slight discoloration, chips and scratches are allowed for this product.

- Class "B". The canvases are characterized by a low price, therefore, traces of mechanical damage, light and dark knots may be present on their surface.

- Extra class. The boards are perfectly finished and free from any flaws. They are expensive due to their high quality, which is achieved by manual selection.

Regardless of the class of production, the following advantages of a wooden block house can be distinguished:

- good heat and sound insulation;

- presentable view;

- naturalness.

As for the negative properties, such boards are expensive, easily ignite and require treatment with antiseptics.

If you are planning a budget option for finishing, then vinyl panels will be the right choice. They are sold at an affordable price, imitate natural wood. The main advantage of the products is that they do not need to be additionally impregnated with antiseptics and varnished before installation. In addition, compared to wood, they have a longer service life and do not require special maintenance. Since the vinyl block house is lightweight, it does not put pressure on the structure of the building.

The advantages of vinyl panels include:

- a huge selection of textures and colors;

- ease of installation;

- durability;

- resistance to moisture and ultraviolet light.

This material has few disadvantages: it is sensitive to temperature extremes, requires adherence to a special installation technology, and the surface of such boards looks dimmer than the solid wood.

The steel block house is considered to be no less popular type. It is a bent profile painted to look like natural wood. Thanks to this material, it is possible not only to decorate the facades, but also to carry out high-quality thermal insulation. The main advantage of the product is its super strength, but similar to vinyl panels, the material is only suitable for external decoration, as it looks unpresentable indoors.

The pluses of steel panels include:

- long service life;

- affordable price;

- ease of installation work;

- moisture resistance and fire safety.

Materials for the basement of a wooden house

First of all, it should be said that foundation of a wooden house there are two types:

- Tape;

- Columnar.

The choice of materials for finishing the basement largely depends on the type of foundation.

Strip foundation

If the basis of a wooden house is a strip foundation and the basement is made of brick or even concrete, then the choice of materials for its decoration is very extensive.

Most often used for these purposes:

Natural stone is a rather expensive material, but its service life is unlimited, moreover, it goes well with wooden walls. As for its other operational qualities, the stone is able to reliably protect the base from negative atmospheric influences.

Facing artificial stone

- Artificial stone - the price of this facing coating is lower than the cost of natural stone, however, it also looks attractive and at the same time can last for many years.

- Facing brick is a strong and durable material that is also able to protect the lower part of the walls from various negative influences, and to some extent even insulate them. Currently, you can find a large selection of colors of facing bricks on sale. However, this coating can also be classified as expensive materials, which is its disadvantage.

In the photo - basement siding

- Basement siding is a panel made of polymer materials, which outwardly quite reliably imitate a variety of natural coatings. Among its advantages are environmental resistance and durability. It should be noted that basement siding can be used when installing a heat-insulated ventilated facade.

- Thermal panels - the material consists of two layers - decorative coating and insulation. The decorative layer is usually clinker tiles. The use of thermal panels eliminates the need to additionally insulate the basement.

Basement thermal panel

In this case, the choice of material for the basement of a wooden house should be guided by your own financial capabilities, the exterior of the estate and the design of the house itself.

Column foundation

If the house is installed on a columnar foundation, then the basement can be done in two ways:

| Base type | Peculiarities |

| Tape based on a shallow foundation | In this case, a shallow foundation is made around the perimeter of the house, on which a wall is erected to cover the first floor. |

| Hinged | A crate is attached to the foundation pillars, which is sheathed with facing material. |

Hinged frame

In the first case, the choice of materials is the same as for a conventional strip foundation.

As for the hinged structure, the following types of materials are used for its cladding:

- Wood - finishing the plinth with wood allows you to give the structure a natural look. As a rule, a lining or blockhouse is used for these purposes.

- Vinyl siding is a PVC panel that looks like wood siding. In addition to attractiveness, the main advantage of the material is durability. Their service life can be up to 50 years.

In addition, plinth siding and other sheet materials can be used for cladding.

Plinth finish with stone

No. 7. Decorative siding

Siding is one of the most inexpensive, easy-to-use and modern materials for the facade of the house. It has excellent decorative qualities, is sold in a wide range, boasts a decent durability (up to 50 years), excellent sound and heat insulation qualities. You can revet any surface with siding and even refine a long-built house.

The main types of decorative siding:

- vinyl;

- wood;

- metal;

- cement.

Vinyl siding

Made of polyvinyl chloride, it can imitate stone, brick, wood and other natural materials. Vinyl siding is one of the most popular materials for facing facades; it is most often used in domestic private construction.

Advantages:

- long service life;

- resistance to temperature extremes, fire, sunlight, corrosion;

- low weight;

- wide range of;

- ease of installation and operation.

Often, resistance to mechanical damage is also attributed to the advantages, but a strong blow can destroy the integrity of the material. Among the disadvantages are a large coefficient of linear expansion, which must be taken into account during installation, low thermal insulation qualities and the difficulty of replacing a damaged element in case of repair.

Separately, it is worth highlighting the basement siding. It is completely identical to vinyl, but differs in increased thickness: 3.5 mm versus 0.7-1.2 for conventional PVC siding. Due to this, resistance to mechanical damage is increased, which makes the material one of the best in terms of price-quality ratio for the arrangement of the basements of private houses.

Wood siding

Wood siding panels are made from pre-treated or dried wood. Profile - a wooden beam or board.

Advantages:

- excellent appearance;

- naturalness;

- ease of installation;

- ability to withstand low temperatures;

- good thermal insulation qualities.

The material has enough disadvantages: high price, short service life, the need to constantly treat the material with protective substances and the ability to easily ignite, but beauty requires sacrifices, therefore wooden siding is used for facing facades. Today, siding is also produced from a wood-cellulose mixture, which is devoid of some of the disadvantages of a wooden counterpart, but still does not shine with high durability.

Metal siding

It is made of aluminum or steel, which are covered with a layer of primer and polymer coating. Aluminum siding in private construction is rarely used due to the high price. For cladding a house, steel sheets with a zinc protective layer and a polymer or powder coating are better suited.

Advantages:

- strength;

- durability (up to 50 years);

- resistance to temperature extremes;

- incombustibility;

- resistance to any weather whims;

- high aesthetics;

- relative ease of installation.

In addition, metal siding is resistant to corrosion due to protective coatings, but if such a coating is damaged, it is worth waiting for the appearance of rust. Naturally, there is no need to talk about heat and sound insulation qualities.

Cement siding

The material is obtained by mixing and pressing cellulose and cement fibers. Cement siding, in terms of its decorative and operational qualities, can replace stone.

Advantages:

- high strength;

- resistance to precipitation, sunlight, high and low temperatures;

- fire resistance.

Among the disadvantages are heavy weight, complexity of installation, high cost and not a wide range of colors and textures.

How to sheathe a wooden house with corrugated board

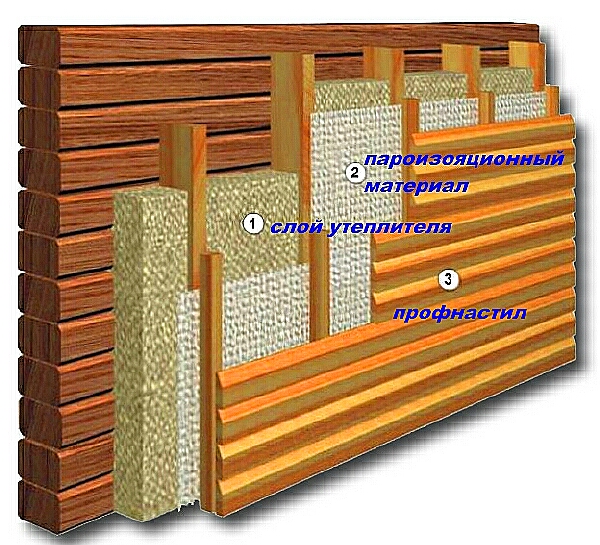

When choosing corrugated board for finishing a wooden house, you need to know that the finishing material is only one layer out of five required for facing the outer walls. The correct order of their installation will provide the building with the necessary protection and an attractive appearance.

The correct procedure for using materials when finishing with corrugated board guarantees high-quality heat retention in the house

- The first stage of the work will be the installation of the frame. For this purpose, you can use both a metal profile and wooden blocks. When choosing bars, they are pre-impregnated with an antiseptic. The use of wooden blocks when cladding a wooden house greatly facilitates the process of work.

- Initially, markings are made on the surface of the wall to fix the brackets, and then the bars are attached to them. It should be noted that the distance between the bars must be at least 1 meter, and the bars are installed as evenly as possible. To check when installing the bars, a plumb line and a level are necessarily used.

- The next step will be the installation of a thermal insulation layer. The best choice for this layer is rock wool. The insulation is cut into pieces of the required size, inserted between the bars, and then fixed with plastic dowels.

- A vapor barrier layer is laid on top of the insulation and fixed with fasteners with wide caps. Laying starts from the top, the next layer is overlapped, and the seams are fixed with special tape. This ensures maximum protection against moisture penetration.

- The installation of the profiled sheet is finished. It is attached to the bars with galvanized self-tapping screws using rubber gaskets every 40 cm. The holes for the fasteners are drilled with metal drills. The installation of additional elements for windows and doors is being completed. The process of finishing with a profiled sheet will become more understandable after watching the video.

What material to choose

If you decide to use SIP panels for building a house, then you must first decide on the choice of material for decoration. Today, no problems should arise with this, since there is a wide range of these products. But what a ventilated facade looks like, and how you can install it yourself, this article will help you understand.

Stone

Using this building material, it is possible to make the exterior cladding of the house. They use stone for partial finishing of SIP panels or for facade work. Natural stone differs in its structure and color, but this does not in any way affect the characteristics of the structure.

Decorating a house from vulture panels with stone

The advantages of the stone include: a low level of heat conductivity and excellent performance of sound and heat insulation. And here is how the stone facing tile is used, you can see here.

Eco-friendly block house

The facade of a house made of SIP panels is often decorated with wooden lining. The finish is very similar to a log cabin, because natural wood is used for its manufacture. The block house is based on a rounded log, and its sides are cut from 4 sides. Houses built from SIP panels and finished with a block house gain strength and reliability.

But what is the design of the facade of a country house, and how to choose what you need, you can see here.

On the video, finishing the facade of a house made of vulture panels with imitation of a bar:

Natural wood is an environmentally friendly and fireproof material, because in the process of processing, non-toxic and environmentally friendly compounds are applied to the surface. The blocks are practically not subjected to processing, due to which the installation process is carried out quickly. At the same time, the house will look beautiful and resemble old solid structures. In this case, there is no need to think about additional insulation. You may also be interested in learning more about what block house siding looks like.

Plaster

This option for finishing the facade is considered the most popular. And this is not surprising, because this material has an attractive appearance and at the same time its cost is low. There are several types of plasters used for the facade: silicate, cement, acrylic and silicone.

The greatest demand is for cement-based plaster. It has a low cost, easy to apply, and also has high strength and resistance to mechanical damage. In addition, cement plaster has a long service life, and the facade, sheathed with plaster, is able to "breathe". It is also worth learning more about what the scope of application of facade plaster should be.

On the video, decorating a house from vulture panels with plaster:

As for the disadvantages, cement plaster does not have such a wide range of colors. Silicate plaster remains the next most popular. It is perfect for facade decoration. It is based on only natural ingredients that are linked to each other using liquid potassium stele. The disadvantages of such material include the high cost. But how to put the beacons under the plaster, and how to do all the work, this article will help you understand.

Facade from DSP

The front part of the house, made of CBPB, is a cement slab containing shavings and chemical additives. The advantages of this material include size. The cladding of the house does not carry anything complicated. This business will take you several hours. In addition, this material is environmentally friendly. There are no harmful additives in its composition, it is easy to cut, and it also does not lend itself to the influence of weather and fire.

You may also be interested in information on the best way to sheathe a wooden house from the outside.

On the video finishing of a house made of vulture DSP panels:

OSB panels

This option for decorating houses is considered modern today. This is OSB based siding. It is less brittle compared to fiber cement siding. In addition, it does not lend itself to the influence of temperature extremes, which cannot be said about vinyl siding. In the photo - OSB-based siding:

House facade decoration from OSB vulture panels

You can use this version of the material instead of the wall, since the design of the panel assumes the presence of an external wall and siding at the same time. To give the finish an original look, you can paint the material in any color you like. To create a rich and luxurious finish, the type of material in question is imitated under a tree. And here is what houses from metal sandwich panels look like here.

Siding: Vinyl cladding panels - the cheapest outdoor decoration of the walls of the facade of the house, photo

This option is considered one of the most aesthetic, beautiful types of cladding. This decoration material for the facade of the house is a decorative panel that can be made of wood, PVC, metal, cement, etc. Depending on the material, this is a fairly inexpensive way of finishing, but surprisingly beautiful.

Vinyl records are used for covering all types of wall surfaces of a house: bricks, blocks, concrete, putty, etc. A wide range of colors, a wide range of styles (imitation wood, stone) are the advantages of vinyl panels. The material is highly resistant to weather conditions, it is considered shockproof, insulating.

Perhaps today, together with decorative plaster, siding is the most popular cladding method. Especially when you are wondering: how to sheathe a house with insulation? This is the exterior decoration of the house with special panels made of metal, wood, concrete, PVC, which provide good thermal insulation. Matching the color of the roof and walls of the house will not be a problem - dozens of color solutions are offered to the buyer.

Vinyl panels are used for finishing any type of exterior surface of the house: wood, brick, blocks, concrete, putty, etc. A wide range of colors, a wide variety of styles (imitation of wood, facade decoration with stone) are the advantages of vinyl panels. The material is highly resistant to weather conditions, it is considered shockproof, insulating.