Pit dimensions

If everything is very clear with the shape of the pit: for the tape one you need to dig a trench, for the slab one - a pit, then the situation is much more serious with the dimensions.

If everything is very clear with the shape of the pit: for the tape one you need to dig a trench, for the slab one - a pit, then the situation is much more serious with the dimensions.

Incorrect determination of the values can lead to freezing of the foundation or filling the space under the floor with groundwater.

Depth

The pit must be at least 0.4 m

The pit must be at least 0.4 m

The development of a foundation pit must be carried out with an accurate determination of the level of groundwater flow and the depth of soil freezing in this area. According to the second requirement, it is necessary to make a hole for at least 0.4 m.

The first parameter, on the contrary, limits the depth, since for the installation of foundations on watery soil, it will be necessary to build high-quality waterproofing, which will significantly increase the cost of work.

Therefore, the level of the pit must be located between these two parameters.

| Estimated depth of freezing of non-porous soil, m | Estimated depth of freezing of slightly heaving soil of solid and semi-solid consistency, m | Foundation depth, m |

|---|---|---|

| Up to 2 | Up to 1 | 0,5 |

| Until 3 | Up to 1.5 | 0,75 |

| More than 3 | 1.5 to 2.5 | 1 |

Lenght and width

The size of the foundation should be 0.3 - 0.4 m larger than the facade of the house

The size of the foundation should be 0.3 - 0.4 m larger than the facade of the house

Here the situation is somewhat simpler: the length and width of the trench for the strip foundation is guided by the architectural plan of the house. It will run along the entire perimeter of the bearing walls of the future structure. The values should exceed the dimensions of the facade by 0.3 - 0.4 m, by about 0.15 - 0.2 m on each side.

It should be borne in mind that such values refer only to the base of the foundation, the upper part, located at the level of the soil surface, is made equal to the dimensions equal to the installation depth of the base. These parameters allow you to create a 45-degree slope of the walls, which protects against soil shedding.

For example, consider the following situation. If the foundation strip is 0.4 m, the width of the trench, for the strip base, must be at least 1 m. This value provides for the installation of formwork and a trapezoidal foundation.

How to choose a brand of cement

- M50 is suitable for the construction of light, auxiliary buildings (summer house at a summer cottage, garage, outbuildings).

- F-75 is needed if the temperature in winter is below minus 20 ° C.

- For residential buildings, a brand of at least M200 with a water resistance level of 95% is required.

If you plan to pour the base immediately, then it is recommended to use the entire prepared volume of concrete in one day. If this is not possible, work should be resumed at least 12 hours later, after the first layer has completely dried. Without this, cracks form on the surface of the base due to the uneven distribution of uncured concrete.

Cement M400 for foundation

Cement M400 for foundation

Varieties of preparation

The most common types of training:

- sandy;

- gravel or crushed stone;

- concrete;

- membrane.

Sand and crushed stone preparation

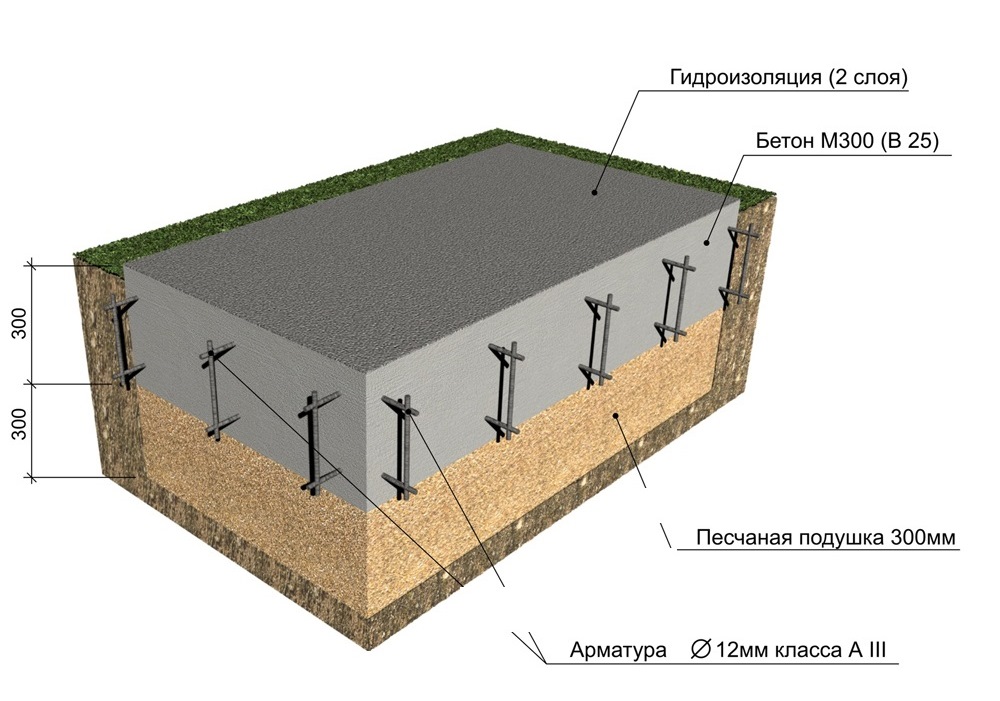

At the first stage, after excavation work, they arrange dumping from inert materials, followed by compaction with rammers. The thickness of the sandy, crushed stone or gravel cushion is 20-60 cm. With a high level of groundwater, geotextiles are spread along the bottom of the pit.

First, coarse fractions are laid, then medium ones. They provide drainage of the base. The top layer is covered with sand. This distribution of materials by size gives the cushion under the strip or slab foundation greater rigidity and strength. The use in sand preparation is necessary for the uniform transfer of the vertical load to the underlying layers.

The following requirements are imposed on fine filler:

- sand with a grain size of 2-2.5 mm is used, which is most suitable for dumping pillows - gravelly crushed with a low specific gravity and high cultivation capacity;

- the amount of clay particles, lime and salt contamination should be minimal;

- organic residues lead to a rapid loss of water permeability and siltation of the sand layer, therefore, their presence is not allowed.

The backfill for the foundation is made of gravel, granite or limestone crushed stone with an average strength of M800 and a fraction size of 20-70 mm.Layer-by-layer compaction with a vibrating plate or hand rammers is obligatory every 50 mm. The sand is pre-spilled with water.

Concrete preparation

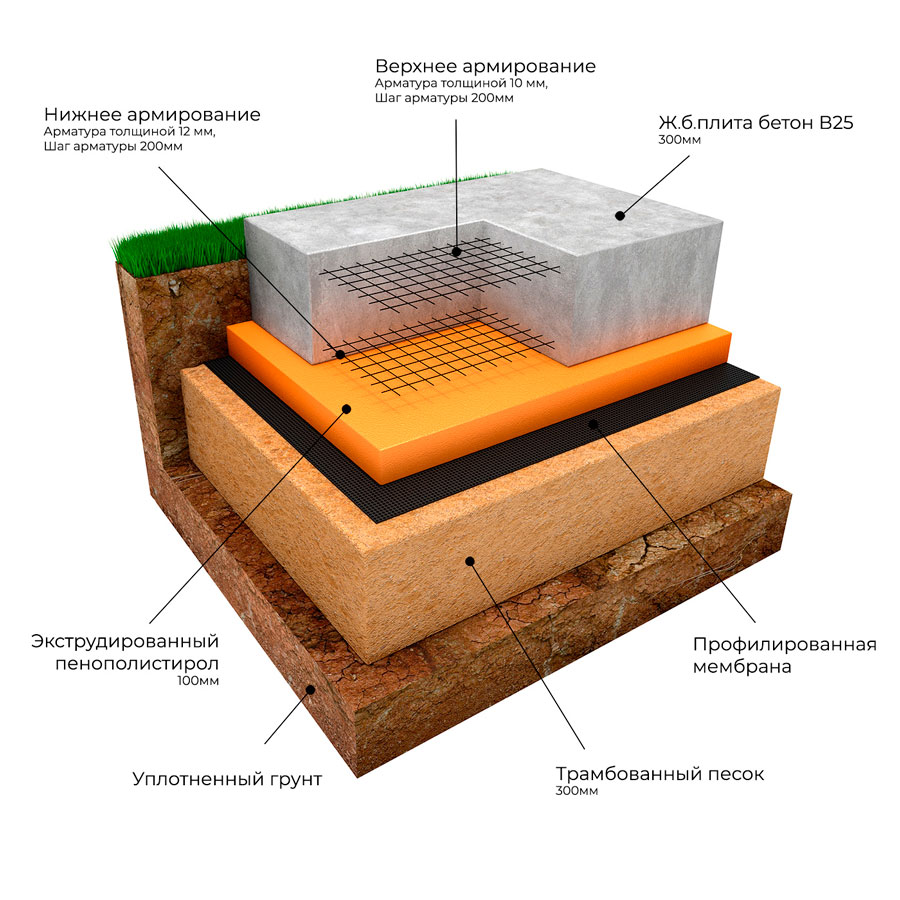

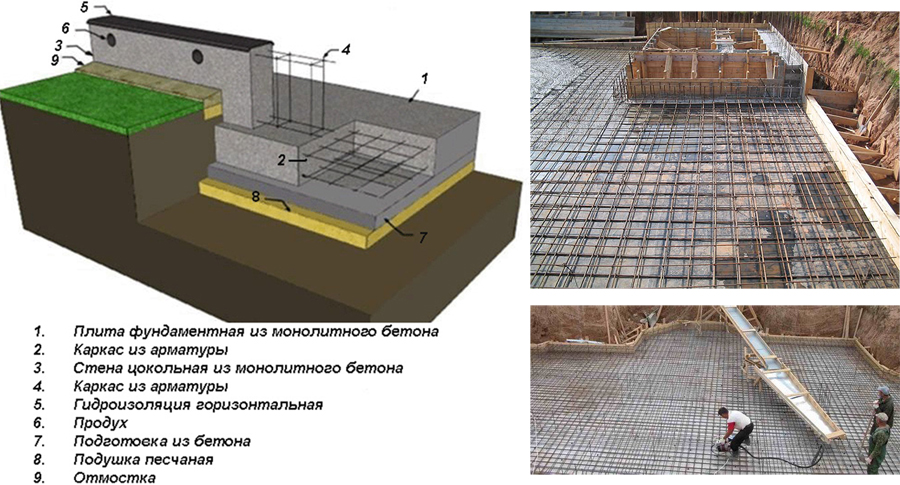

A pillow for a slab or foundation blocks is made in two ways. The first one is pouring a layer of crushed stone with liquid bitumen, the second is the installation of a foundation made of concrete of low grades M50-M100 with a layer of up to 10 cm.

A concrete cushion for the foundation is made:

- pouring into a trench or the bottom of a pit without formwork;

- installation of formwork along the perimeter of the site and subsequent spreading of the foundation;

- first place in the foundation mold, then the concrete of the design grade.

The solution is leveled according to beacons or the rule, compacted with a vibrator. From above, the foundation is waterproofed with bitumen, roll materials, waterproof films.

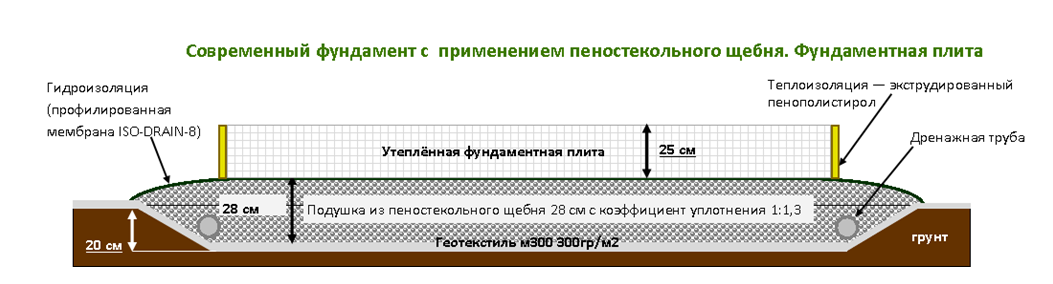

Preparation with geomembrane

Polymer membranes have recently appeared on the construction market. Fiber is used to protect the base of a building from soil moisture, i.e. as waterproofing. Fundamentally new is that the profile in the form of spikes simultaneously serves to strengthen the soil. Manufacturers claim that due to the use of geomembranes, the number of shrinkage cracks is reduced, and forces are redistributed when the load is transferred to the base. The cross-sectional shape prevents water from entering, and the voids between the insulation and the concrete are ventilated.

Fiber laying is carried out according to sand and crushed stone preparation, a layer of geotextile is preliminarily spread. Membrane seams are connected by welding. The material is strong and durable, withstands high and low temperatures.

We build ourselves: the order of work

- The territory is cleared and then marked out.

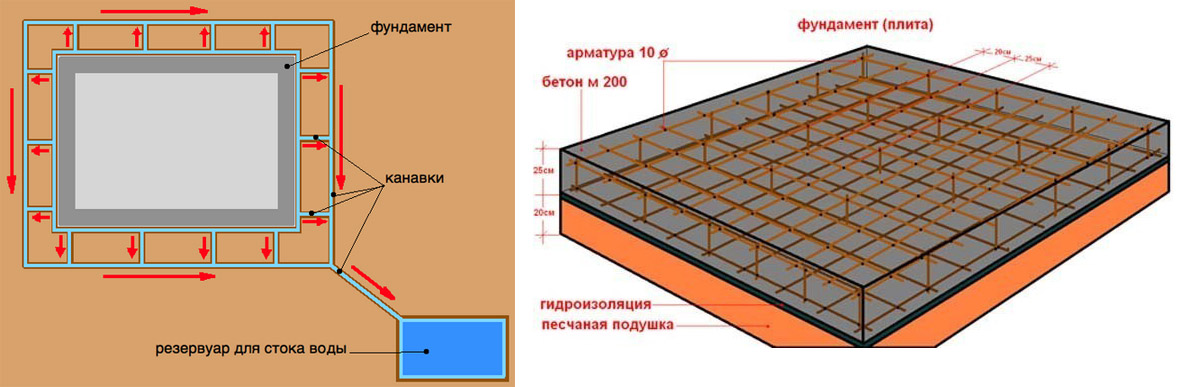

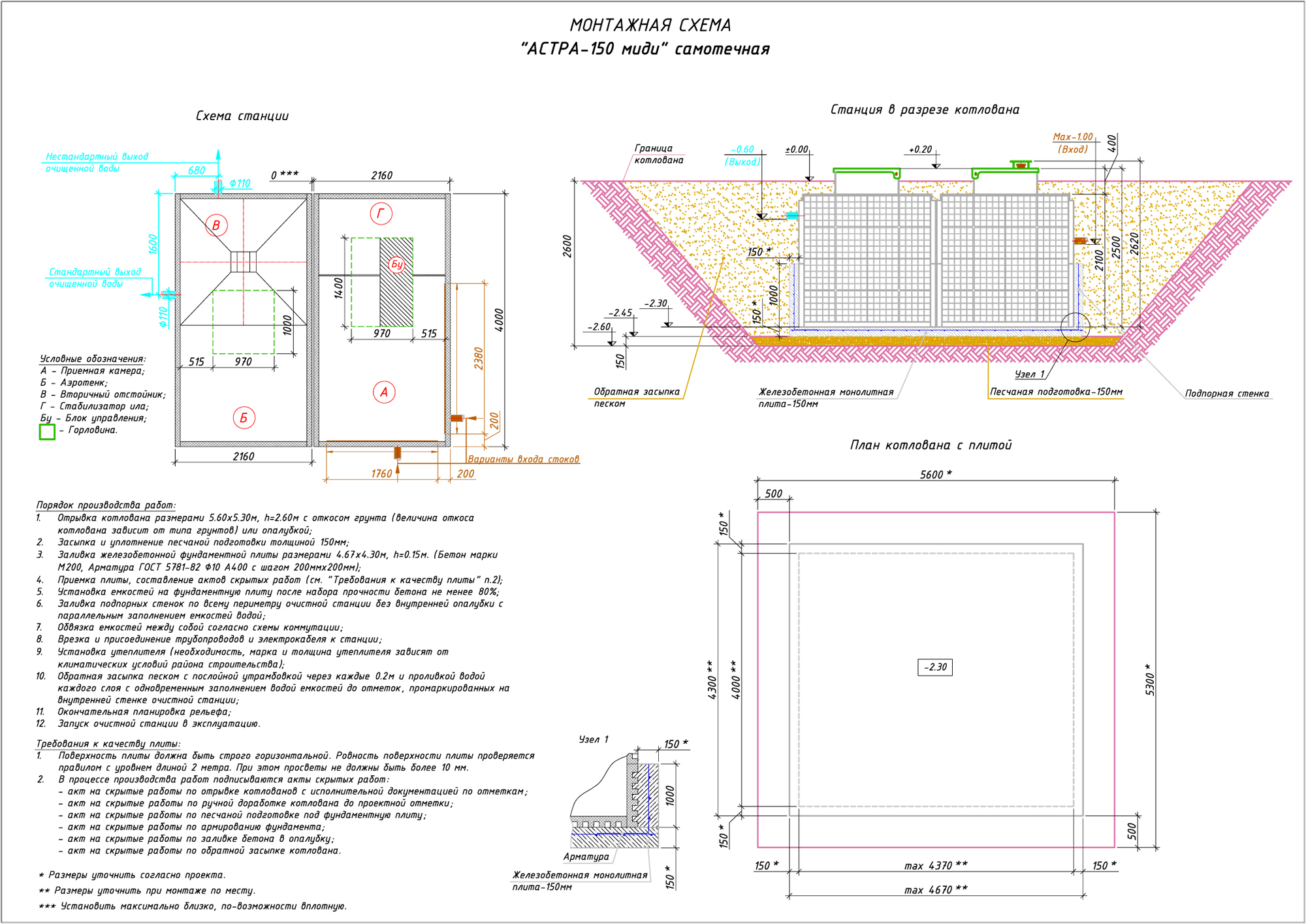

- For the device of the slab, a pit is dug into the depth of 0.5 m. The length of its sides must be greater than the length of the walls of the building being erected (per meter). This will allow the construction of drainage lines to drain water from wall structures. Installation of all components is carried out even before the concrete is poured.

- Geotextiles are laid on the finished pit, creating a barrier to the penetration of a layer of sand into the ground.

- Formwork is prepared and installed from a board or plywood sheet. In the latter case, the material must be strong enough to withstand the dynamic load of raw concrete and not deform (keep the desired shape).

- Sand is scattered all over the bottom to form an air cushion. It ramps well to near-perfect smoothness. The sandy mixture, due to its soft structure, will allow it to accept and compensate for the loads, redistribute them, leveling them over the entire base and transfer them to the soil surface when it freezes. The sand smooths out the arising tensions, "dampens" them.

- Another layer is poured onto the sand layer - crushed stone, which protects the sand from washing out. It will serve as a drain. Spreads evenly and compresses carefully.

- On the sand-crushed stone carpet, concrete preparation begins (a layer of 10 cm thick) to protect the future base from leaks of concrete milk into the ground. Creates all conditions for distribution over the reinforcing cage slab.

- Sticky mastic is applied. Waterproofing is being laid. Rolled cloths are fastened to each other along the edge using a torch or lamp. In size, the resulting canvas should be slightly larger than the dimensions of the foundation. When the slab is completely made, the remaining at the edges of the canvas will turn up and the same lamp will be fixed at the end of the slab.

- Tiled thermal insulation with a layer of 10 or 15 cm is laid over the entire area of the blind area structure on the waterproofing layer. It is tightly fixed with a ridge-groove connection so that there are no cracks and no “cold bridges” are created. Extruded polystyrene plates are considered one of the most inexpensive and effective materials. They will protect the foundation from freezing.

- It is possible to protect the insulation from the liquid aggressive environment of the concrete solution with the help of a polyethylene film laid on them in one layer.

- Further, a metal mesh is made from reinforcement with a cross section of 12 mm ribbed type. Vertically arranged rods and share reinforcement are connected with knitting wire.

Reinforcement of the slab foundation is carried out with reinforcement

- The parameters of the cells are determined by the calculation. The indicator of the loads that are planned to be exerted on the foundation affects. The accepted standard is 30x30 cm. But the smaller the section, the more rods will be spent on the formation of the frame, the stronger the entire reinforced system as a whole. Two frames are formed in the thickness of the slab: one mesh will be located 50 mm from the insulation slabs, the other - from above, 50 mm below the top of the slab.

- A solution of high-quality concrete is poured onto the finished structure into the formwork. This is done manually, with shovels followed by ramming or vibrators, which distribute the concrete to the most problematic areas.

- It is best to perform concreting immediately, without interruption.

- If it is impossible to form the base immediately, the layers of the mortar are laid in a horizontal position, immediately filling the entire area at one mark. But you cannot lay the composition in separate zones, and then connect them together. In this case, cracking may occur at the joints under the action of loads and soil movements.

- The formed "mirror" of concrete is leveled, smoothed, assuming the required roughness.

- The finished base is covered with a moisture-proof material and left to achieve the desired strength. The surface should not dry out and be waterlogged. Therefore, in hot weather, it must be periodically sprayed with water under the film, preventing cracks from forming.

- It is necessary to wait until the concrete has fully set. Usually, this happens a month after the end of the work.

- You can continue to build walls further.

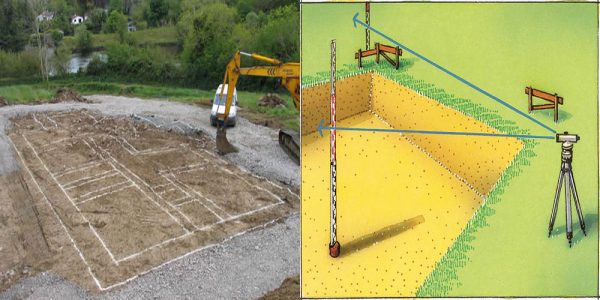

Execution of works on construction of foundation pits

This process is conventionally divided into certain stages:

- on the site allocated for the construction of the building, a check is carried out for the passage of communication lines, the schemes of which can be clarified with the local administrative authorities. If such systems are available, you will have to obtain written approval for the procedure for performing earthworks with the organizations serving this site;

- a site is being prepared for the construction of a private house or other structure, the fertile composition of the soil is removed to a depth of forty centimeters;

- water is pumped out, a drainage ditch is arranged;

- earthworks are being carried out. If the depth of the pit for a monolithic or other foundation exceeds 1.25 m, support beams are installed to prevent soil shedding, steps are arranged.

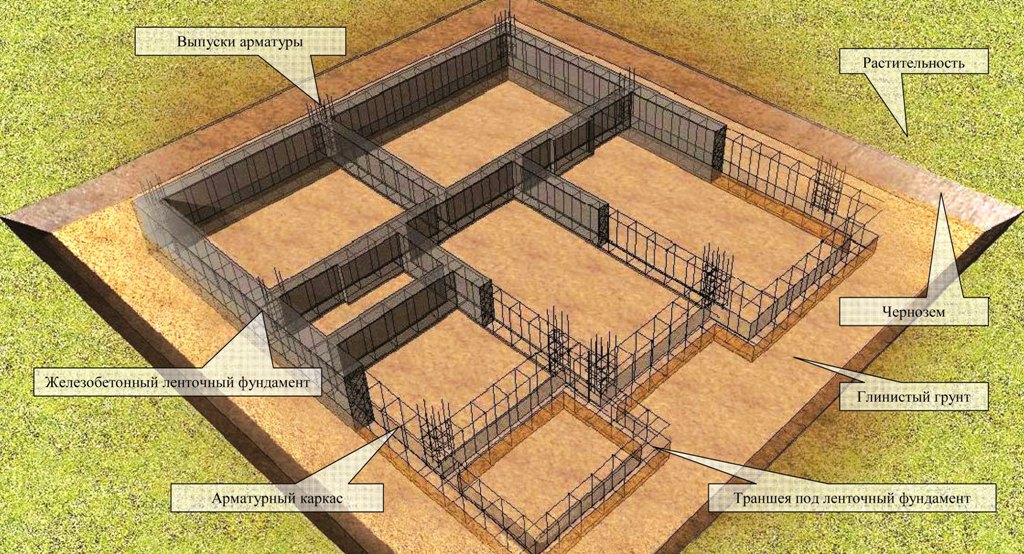

Under the strip foundation

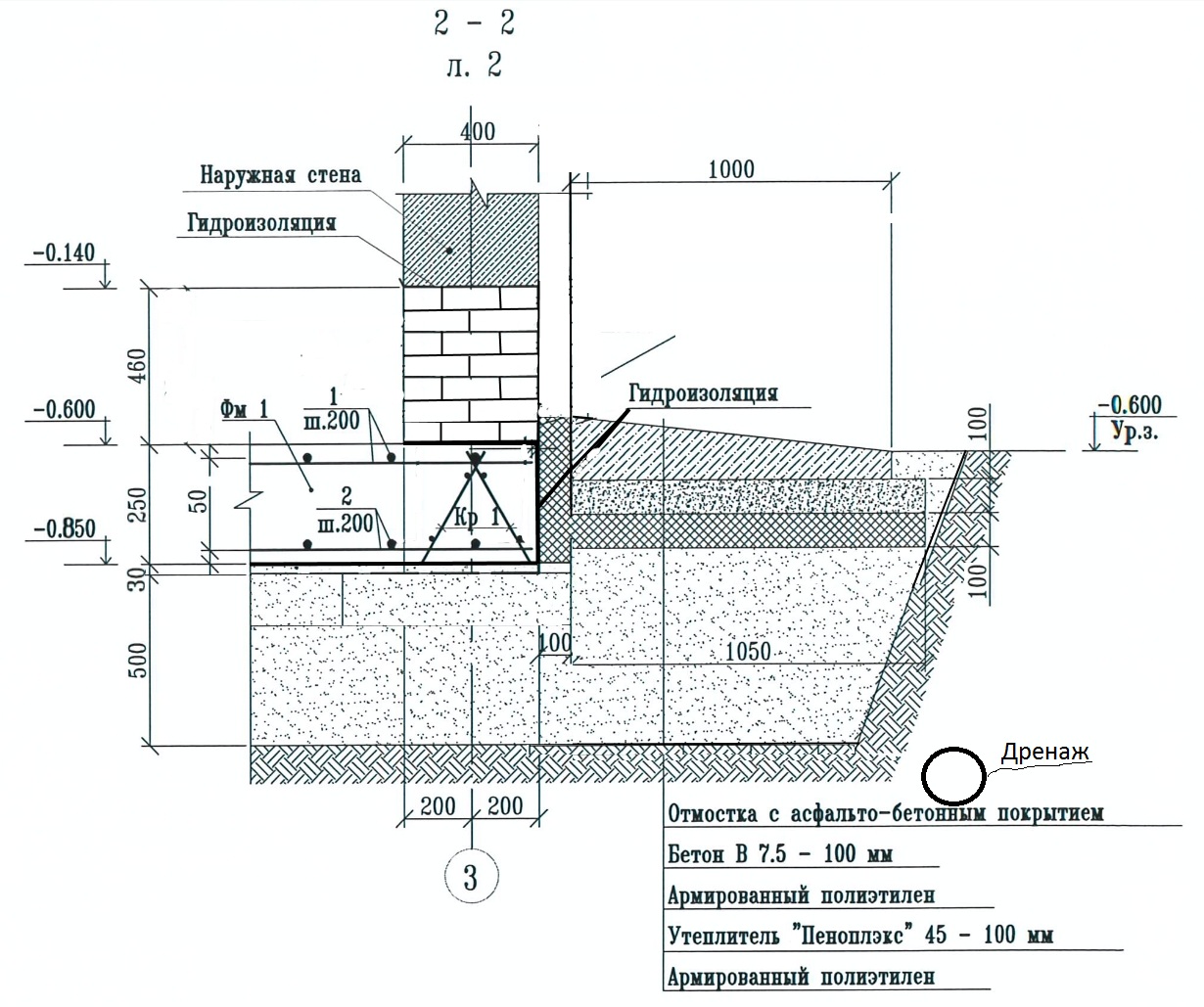

If you have to arrange a foundation pit for a strip-type foundation for a garage or other building, it looks like a buried trench, with its dimensions providing for the exposure of formwork panels.

The dimensions are determined as follows - the parameters of the length and width increase by thirty to forty centimeters, the width of the trench is equal to the sum of the similar value of the walls and the gap area of fifty centimeters for the installation of shields.

First, the boundaries of the future foundation on the soil surface are determined, the highest angle is determined. After that, it is allowed to dig using a shovel or a tractor and periodically control the depth with the pillars.

The soil is poured nearby so that there is something to fill the backfill and drainage system.

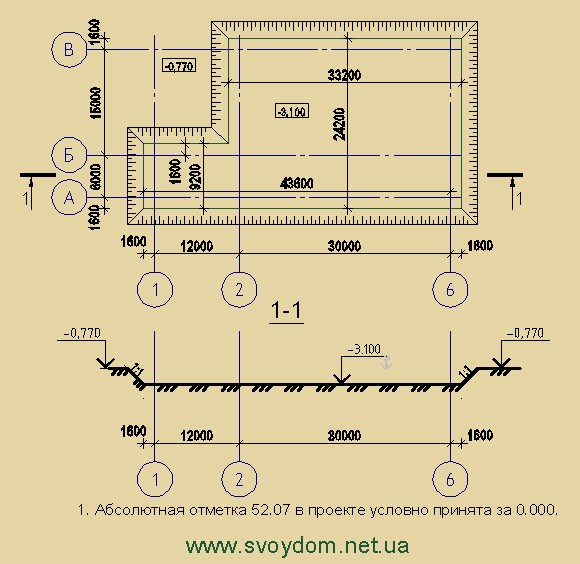

Platen

A step-by-step instruction for arranging such a foundation in a rammed pit is as follows:

with a small deepening, the dimensions correspond to the facade parameters of the object. If the slab foundation with insulation to a great depth is to be poured, the dimensions of the bearing walls of the building and the height of the base are summed up;

the soil is developed gradually, in the first layers of fifty centimeters with a gradual decrease in their thickness.As a result, steps are formed on the walls. By the way, if someone does not know how to dig a foundation on a slope, use this technology.

It is convenient to fill this type of foundation under standard buildings - a house 8 by 8 or a house 10 by 10 m. It is an ideal solution for the construction of three-storey buildings, it is an integral reinforced concrete structure that almost does not shrink and does not fear heaving of the soil composition.

Columnar

Consider how to dig holes for a columnar foundation. In this case, a half-meter trench is prepared for the foundation around the perimeter of the object (as for laying a water supply system), at the bottom of which pits for support pillars are arranged. Note that such a supporting structure is made without formwork.

Stepped foundation construction technology

Stepped foundation design

In areas with a slope and difficult terrain, buildings are located taking into account the direction of the slope, not taking into account the location of the cardinal points and ensuring the best natural lighting.

In this situation, the stability and stability of the support base is a priority.

Digging a pit on a slope site is not easy, it is very important to choose the correct angle of inclination of the slopes. When performing excavation work to prepare the pit, it is necessary to prevent the occurrence of shedding and slipping of the soil

When carrying out excavation work to prepare the pit, it is necessary to prevent the occurrence of shedding and slipping of the soil.

The following standards are usually accepted:

- Sandy soils - from 30 to 45 °.

- Clays, loams - from 50 to 60 °.

- Freezing soils - 70 °.

Earthworks and formwork

Foundation on a slope

Foundation on a slope

Excavation work begins to dig a foundation pit by removing the upper part of the soil in an area with a bevel. When performing work, the angle of inclination must be observed, the soil is removed above the level of the support base.

When building a house with a basement, you will have to dig a pit for the foundation. For a house without a basement, it is sufficient to prepare individual narrow trenches corresponding in size to individual steps.

It is most convenient to start excavation work from the lowest mark, moving up the slope.

The height and length of the individual steps are measured in accordance with the design drawings. The formwork is installed immediately during the preparation of the steps, thus it is possible to avoid soil shattering on the ledges. Installed shields are rarely removed after the foundation is poured; usually, the formwork is not removable.

Prepared trenches are leveled at the bottom, tamping the soil at the bottom. The installed formwork is lined with a layer of protective waterproofing. Formwork for a stepped foundation, its manufacture and installation is a rather laborious and complex process, because often the foundation is located at a great depth, which requires additional work to arrange a reliable drainage.

For the foundation on a slope, the formwork is made of wooden materials, while it is important to ensure that the shields do not have significant gaps

Reinforcement of the foundation for a house on a slope

Rebar 10 mm for reinforcing the base on a slope

Rebar 10 mm for reinforcing the base on a slope

Reinforcing the foundation foundation for a house on a slope is a very demanding work that requires attention

When considering a concrete ledge, it is very important to remember that its height should not exceed 0.3 m.

Reinforcement of the strip foundation is carried out using a spatial reinforcement cage, connected (or welded) from reinforcement with a diameter of 10-20 mm. The formwork must be higher than the reinforcement frame installed in it, so that when concreting, reinforcing rods do not remain on the surface of the poured foundation.

In this case, reinforced concrete products with additional reinforcement with longitudinal and transverse reinforcing bars are used.If necessary, the ledge is reinforced with anchors, this is done if there is a significant slope of the surface on the site (more than 18 degrees).

Concreting and foundation maintenance

The concrete mixture for pouring the foundation base will have to be prepared at the construction site, because it is rather difficult for heavy concrete trucks to drive to a site with difficult terrain. It is advisable to pour the foundation structure in one day in order to prevent the formation of dried layers of concrete mixture.

When placing concrete in the formwork, the mixture should be compacted in order to avoid the formation of voids inside the structure. Typically, such "pockets" are formed at the intersection of the reinforcement cage. The formwork must be filled with concrete to the proper marks, the surface of the mixture is carefully leveled.

A monolithic concrete structure will gain strength up to 28 days, at which time the formwork should not be disturbed. It is allowed to remove the shields from the foundation base after 2 weeks, when the structure gains up to 70% of the strength of the design indicators. The permanent formwork must remain in the body of the foundation supports.

After gaining strength of the stepped support structures, you can proceed to the construction of the walls.

What is a concrete base for a foundation for?

A pillow is required specifically for a monolithic foundation; it is not made for a prefabricated one. What's the point:

1. Firstly, the concrete layer forms an impermeable base through which the working concrete will not flow into the ground, milk will not escape from it. Accordingly, after the mixture has hardened, the stone will gain the design strength and will not lose quality.

2. Secondly, it is convenient to install the reinforcement frame assembly on a flat base, which is a concrete substrate. This is the only way to get a perfectly flat foundation with the correct distribution of internal loads.

3. Thirdly, the pillow is always combined with sand and / or gravel, which distribute the pressure of the soil, stabilizing it for each square centimeter of the foundation. The layer is also a drainage for groundwater that passes the concrete structure through sand and rubble.

4. Purely theoretically, you can do without a pillow, but in this case you will have to think over the foundation more carefully, which will inevitably lead to an increase in the cost of installation work and the volume of materials. In practice, only those who build a garage, shed or other light structure save money on the device of concrete preparation.

A backing pad is necessary for strip and slab foundation structures that rest on the ground below or above the level of its freezing.

DIY foundation construction technology

Here's a step-by-step guide to help you lay the foundation.

Pit preparation

The depth of the pit depends on the density of the soil:

- If the ground is very dense, then a depth of 50 cm will be optimal.

- If peat prevails on the site, then it is better to deepen the base by 1 m.

The bottom of the pit is leveled horizontally. If, in the process of its preparation, holes were formed in some places, then it is impossible to fill them with earth, only sand. Otherwise, the slab foundation for the house may shrink.

Substrate

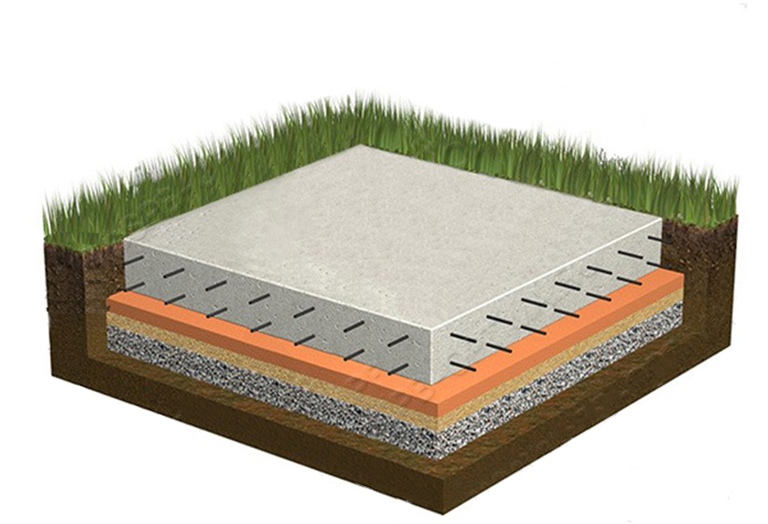

At this stage, it is necessary to prepare a pillow for the slab foundation. For this:

- Pour washed sand without impurities at the bottom of the pit.

- Tamp down the sand layer. If the pit is very deep, then tamping must be done in layers.

- If you plan to carry out communications, then you need to lay sewerage and water supply at this stage (gas and electricity can be carried out later).

- Place a gravel pad and compact it. Make sure that the crushed stone is distributed evenly and strictly horizontally; it is better to use a hydro level for this.

- Spread geotextiles over the pillow.

Formwork and insulation

To prepare the formwork for the slab foundation, consider the following nuances:

- The formwork is exposed along the perimeter of the house, and not along the markings "with a margin" of 1 m.

- For construction, use boards of 50 mm.

- The formwork is exposed in height, which will be equal to the thickness of the monolithic slab. Use cords and a level to level it horizontally. If you do not do this, then before making the screed, you will have to set marks on the formwork itself (with such a markup, you can easily make a mistake).

- After that, waterproof the slab foundation. To do this, lay the material with an overlap on the formwork boards.

- Also at this stage, an additional layer of insulation can be laid under the waterproofing. For this, it is best to use high strength EPS.

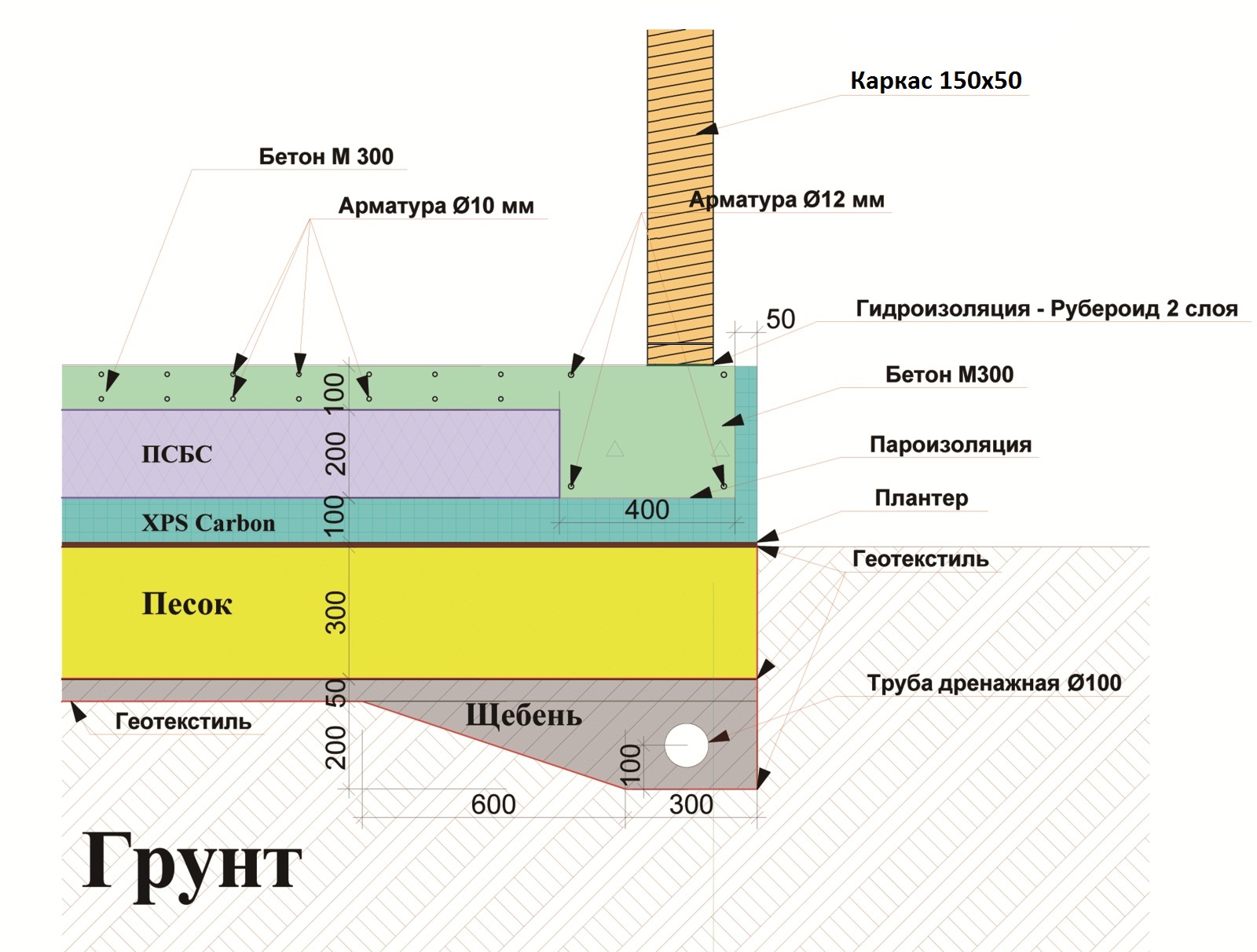

The next stage - the insulation of the slab foundation is carried out using sheet material (for example, XPS expanded polystyrene), which must be laid in two layers. The height of both layers of insulation should be about 20 cm. The material should be laid close to each other.

Reinforcement and pouring

To perform reinforcement, the following step-by-step instructions will help you:

- It is necessary to knit a reinforced frame in two rows with a step of 20-25 cm.Place the lower lattice on special clamps, so that there is a distance of 5-7 cm between the waterproofing layer and the metal rods.

- The second row of reinforcement (top) is laid in such a way that after you pour the concrete, the lattice "disappears" in the cement by 5 cm, but not less.

- Connect both layers of reinforcement with vertical drains, which must be made from the same rods.

After that, the concrete is poured. It is best to use the M 300 composition grade for this.

It is necessary to pour the solution in one day - the shorter the intervals between the portions of concrete, the stronger and more reliable the base will be.

The poured foundation can only be leveled with the rule and wait until the base is dry (28 days for complete solidification). It is best if the weather is warm outside and the humidity is about 80%. It is also recommended to cover the base with polyethylene and moisten the concrete mass with water from a sprayer every day.

Pouring with lean concrete

The price of concrete preparation for the foundation takes an average position between the previous ones. At the same time, the strength of the foundation is much higher than a crushed stone pillow.

After pouring with lean concrete, the soil does not sag, and the structure is fixed as securely as possible. The thickness of the concrete preparation for the foundation, according to SNiP, ranges from 15 to 30 cm.

This indicator is determined based on the following parameters:

- soil type,

- groundwater level,

- the mass of the building being erected.

The components of the concrete solution are standard, but their proportions in the solution differ from the ready-mixed concrete

The components of the concrete solution are standard, but their proportions in the solution differ from the ready-mixed concrete

Lean concrete is called a mortar consisting of 6% cement of the M100 brand with strength B15 with aggregates of crushed stone and sand. The specificity of the composition and the minimum of components contributes to the rapid hydration of the mixture.

The recipe for the composition for the concrete for 1 m3:

- cement - 275 kg,

- sand - 590 kg,

- crushed stone - 1377 kg,

- water - 165 liters.

If necessary, to increase the frost resistance or moisture resistance of the interlayer, additives and plasticizers are added to the composition. The preparation time for the solution should be no more than 5 minutes.

In the photo, a diagram of the maximum possible set of a cake of the foundation of a monolithic slab with a foundation device

In the photo, a diagram of the maximum possible set of a cake of the foundation of a monolithic slab with a foundation device

Slab foundation: pros and cons

The slab foundation must stand

Like any base, it has a slab foundation, pros and cons.

The disadvantages include:

- The duration of work requiring the preparation of the pit, the time of concrete maturation, as well as their seasonality.

- There is also a dependence on climatic conditions (the formation of a concrete surface is carried out only under specific conditions).

- The concrete monolith makes it impossible to build a basement.Although it is believed to be a versatile "sole" for any soil, rocks with a high viscosity are not desirable for this type of foundation.

There are much more positive moments. Among them are:

- High bearing capacity (yet unparalleled among other types of bases).

- The slab is not afraid of soil shrinkage and deformation.

- The ability to withstand the loads from heavy wall structures and the interior of the room.

- There is no need to carry out a large excavation: the slab is laid shallowly (for deeply buried foundations it is up to 1.5 m, for shallow ones - 40-60 cm). The second option is just chosen for a private house.

- The foundation, as a whole, with the structures erected on it, moves in the event of ground movements, does not "tear" the building, and does not allow cracking. This property is especially important in earthquake-prone areas.

- In practice, there are no restrictions on the type of soil (except for viscous).

- The frame is considered equivalent to support all the walls in the room on it, which allows any redevelopment of the internal space.

- The “old-timer” foundation can serve more than one generation (the period is more than one and a half hundred years)!

- Uncomplicated technology allows even unskilled builders to build a slab foundation with their own hands without involving special bulky equipment.

Slab foundation cake

Serves as additional insulation from ground water, waste water, floods.

Why do you need a pillow under the foundation

A foundation pillow is an artificial foundation made of gravel, sand, concrete, reinforced concrete blocks, which is not included in the foundation structure, but replaces part of the soil under it. The pillow has a number of functions.

Table 1. Functions performed by the cushion under the foundation.

| Function performed | Description |

|---|---|

| Alignment | Should level the bottom of the trench. It is necessary to arrange a sub-base for prefabricated and slab foundations. When laying a shallow belt under low buildings, this function is performed by a layer of gravel or even compacted sand. |

| Protection against ground movements | Protects the foundation from seasonal ground movements. When backfilling a layer of sand or gravel on weak and heaving soils, the bearing capacity of the soil increases, which provides a reliable foundation |

| Drainage | Prevents the rise of moisture from the soil into the foundation and drains rainwater to the side |

| Frost heave protection | Preventing the ejection of the foundation from the ground by the expanding water |

| Reduction of building shrinkage processes | Creates stronger support under the object |

| Improving the stability of the structure | Especially prized in seismologically unsettled areas |

Separately, I would like to focus on the phenomenon of frost heaving, which is protected by a more dense base than the ground. This phenomenon is especially typical for clay soils.

Clay soils freeze unevenly in winter, increasing in volume up to 9%.

Moreover, throughout the winter, clay sucks moisture from the lower horizons of the soil, increasing even more in volume. Moreover, if the groundwater level is high, then the clay can swell up to tens of centimeters and raise a house, a road and even a railroad bed. As a result of this effect of frost heaving, the foundation can easily crack in the spring. Will save from the impact of destructive forces a sub-base made of coarse sand, crushed stone or sand-gravel mixture, which performs a shock-absorbing and drainage function.

Frost heaving action

Types of foundation pits

Having decided to start building a trench for a foundation, you should clearly understand what type of foundation pit is needed. This condition depends on the type of foundation structure defined for filling with the project plan and drawings.

There are certain parameters according to which the foundation pits are divided into several categories associated with the presence or absence of the following conditions:

- slopes and their number;

- corner mounts;

- vertically inclined walls.

There is one more condition that determines what the pit under the foundation is called - a foundation pit or a trench.

Under the arrangement of the strip foundation, it is dug around the entire perimeter and the places where the internal load-bearing walls of the trench are installed. For pouring the foundation slab, the minimum dimensions of the pit must correspond to the area of the building under construction.

If someone does not know how to dig the foundation for a house with their own hands, their attention is offered a list of priority earthworks:

- the type of soil composition is determined, its expertise is carried out;

- the technical parameters of the structure are being clarified in order to determine the maximum load on the base;

- the depth of the pit or trench is calculated;

- the climatic conditions of the region are specified in order to identify seasonal soil movements.

Calculation of cement mortar

The process of completing the footing

After the marking of the area planned for the construction of a concrete protective layer for the foundation has been completed, the work is carried out in the following order:

- A pit or trench is dug, depending on what type of foundation is planned for the device.

- Crushed stone is poured into the bottom of the prepared pit, after which the layer is compacted. The thickness of the crushed stone layer is on average about 10 cm.

- Formwork panels are being mounted. The height of the panels should be at the level of the planned fill layer, this will simplify the leveling process and allow the reinforcement frame to be placed correctly.

View of the prepared site for pouring lean concrete

View of the prepared site for pouring lean concrete

- Horizontal reinforcement is laid. Usually, bars of steel periodic profile with a diameter of 8 mm are used. To simplify the process, you can use special maps of the construction reinforcing mesh.

- Vertical reinforcement rods are installed, protruding beyond the edge of the formwork by 20 - 30 cm. These rods will allow connecting the foundation to the base of the building. Sometimes vertical rods are installed in poured and rammed concrete.

- The composition for pouring is mixed. The cement binder used for mixing the mortar is cement grade M50 and more.

- The ready-made mortar is poured into the formwork and tamped using mechanical vibrators.

After that, the footing is left alone until it fully sets. This process takes place within 4 weeks. You can learn more about the technology of making a footing with your own hands by watching the video in this article.

Building regulations

If you are not a professional builder, and at the same time want to carry out work on the installation of the foundation on your own, then we recommend that you first familiarize yourself with the following regulatory documents:

- SNiP 52-01-2003 “Concrete and reinforced concrete structures. Basic Provisions ";

- SP 50-101-2004 "Design and construction of foundations and foundations of buildings and structures."

These documents prescribe the basic requirements for materials, solutions and process technology. In them, you can clarify for yourself everything related to technological elements and requirements for the quality of materials.

Summarizing the standards, the following can be noted:

- Skinny concrete is made using cement M50 and above.

- Filling crushed stone cushions before pouring is required.

- The time to full strength is 4 weeks (28 days).

- The diameter of the reinforcement is prescribed under various conditions.