How to determine the type of soil

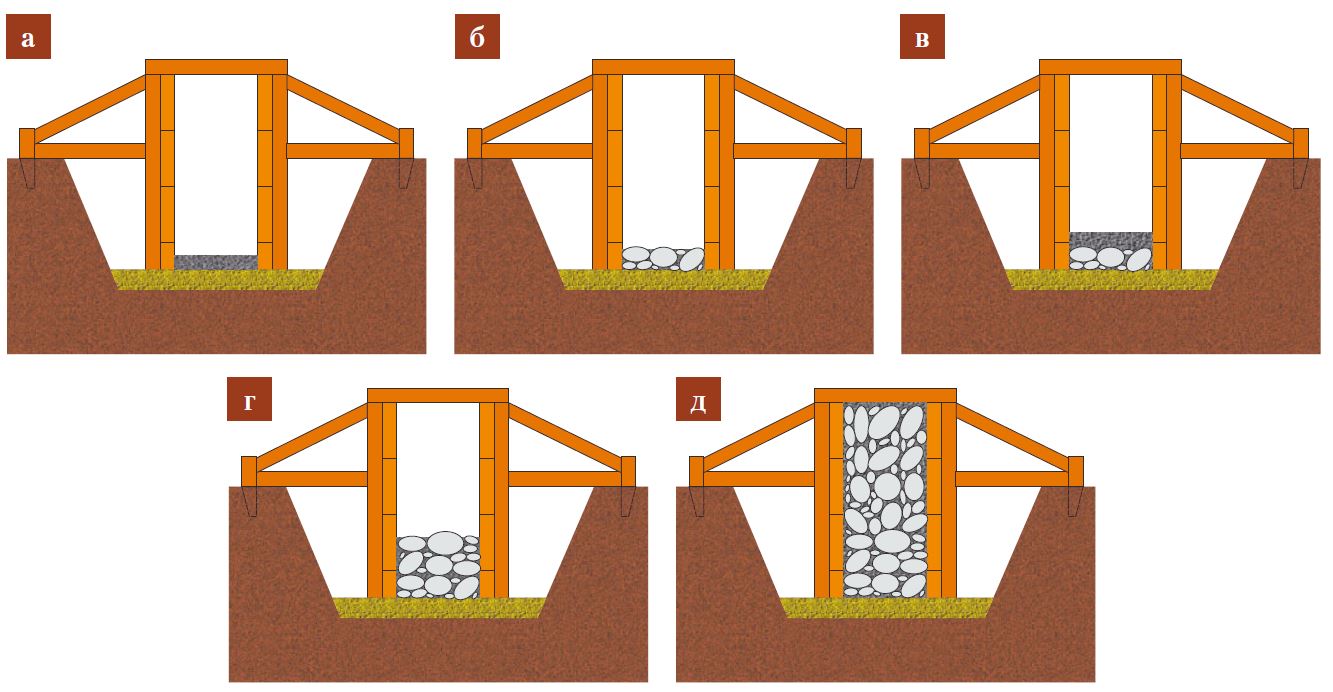

Diagram of the foundation on peat.

How can you determine the type of soil without the help of specialists? To do this, take a handful of earth from the plot of land on which you plan to build and moisten it with water. From the mixture that you get, roll up a strip and bend it into a ring. You can do this only if the mixture is made of clay. Otherwise, it will simply crumble in your hands. If the mixture consists of loam, then the product will break into several parts.

The sand mixture will crumble into many small pieces. Consider these particles. If the grains of sand in it are not less than 1.5 mm in diameter, this means that the base of the building will have to be erected on sandy soil. If the selected mixture is placed in a glass and a jar of water and shaken, then you can determine the amount of clay in the soil. Strongly turbid water, when shaken, will show that the soil contains a lot of clay.

Determine the depth of the groundwater. To do this, go to the nearest well and determine the water level in it. Consider the difference in height between the area where such a well is located and your site. This will help you calculate how close the groundwater is to the surface of the earth. After that, determine the moisture content of the soil, for which simply make a ball out of it and observe it. If the ball retains its shape, it means that it is wet soil, if not, it is slightly moist.

All these simple manipulations with the land can and must be done in order to determine what type of foundation will be used for construction. This will allow you to correctly calculate what kind of foundation, its dimensions, the amount of reinforcement and much more you need.

Types of monolithic slab foundation

Depending on the characteristics of the soil, the building being erected and the climate of the region, one of the following types of monolithic foundation is chosen:

- solid or classic. The construction technology provides for the excavation of a fertile soil layer, backfilling of the pit with sand and gravel, and the subsequent arrangement of a reinforced concrete base. The thickness of the latter in private construction, as a rule, is 20-50 cm, but depends on the type of soil and the characteristics of the building being erected. Thermal insulation is carried out if necessary. This version of the foundation is great for highly heaving soils, where movements are possible both in the vertical and in the horizontal plane;

- Russian, or a monolithic slab with stiffening ribs. In addition to the monolithic slab, stiffeners are arranged from below or from above. They are made at the locations of the load-bearing walls in order to strengthen the structure, but at the same time the complexity of the construction of the foundation increases, because it is necessary to fill not only the slab, but also the stiffeners, but the slab can be made thinner, saving on concrete and not losing strength. Stiffeners are, in fact, an analogue of a strip foundation. They can be cast from concrete or made from blocks. The first option is preferable, since in this case the structure will be completely monolithic. The use of ready-made blocks, moreover, will require the use of special equipment;

- insulated Swedish plate (USHP). The technology is recommended for areas with a harsh climate, excellent for the northern regions of our country. The peculiarity lies in the use of a floor heating system, which is hidden in a concrete slab. In addition, a permanent formwork made of expanded polystyrene is used, which serves as thermal insulation, and a polyethylene film for waterproofing.It turns out that the base heats up, but at the same time heat leakage is minimized due to the presence of thermal insulation. Naturally, the cost of construction will be higher than that of the classic version.

Please note that the slab foundation can be either monolithic or prefabricated. All the advantages and nuances of a monolithic base are mentioned above.

The prefabricated foundation is created on the basis of road slabs or FBS blocks, which, after installation, are poured with a layer of leveling screed. Prefabricated slab bases require the involvement of special equipment for the installation of heavy slabs, therefore this is a longer and more expensive solution, but at the same time, the performance is inferior to a monolithic slab foundation.

Foundation ventilation

The space under the floor of the first floor must be ventilated, otherwise the moisture accumulating there will begin to gradually destroy concrete and wooden structures. According to the current building codes, the strip foundation must necessarily have openings for through ventilation, which are popularly called "ducts" or "ducts". Very often you can see incorrectly executed air vents: there are few of them, and they are made of thin pipes, therefore they do not provide sufficient air circulation. Remember: the total area of the vents should be at least 1/400 of the area of the underground, and the area of each of them should not be less than 0.05 m2. They are located at a distance of no more than 90 cm from the corners, while the vents located on different sides of the foundation should be located opposite each other. In radon-hazardous areas, the total area of the air must be at least 1/100 of the area of the underground.

Influence of the depth of the future foundation on construction

Many inexperienced builders believe that the strength of a house will be better if the base is set deeper. Unfortunately, this is a misconception. It is worth remembering such a natural phenomenon as freezing of the lateral soil. At low temperatures, it begins to swell. Thus, it acts on the walls of the foundation.

If a deep installation of the base of the house was made, then when heaving, the entire base will be divided in half. The bottom will remain in the ground and the top will be lifted towards the top. This happens when the base is made of bricks, stones or blocks. The mass of the house can also be affected. If it is too small, it will properly affect the base.

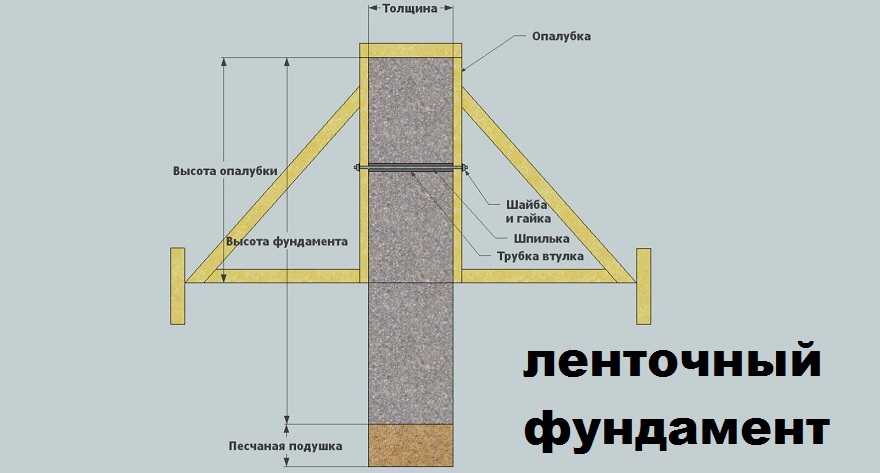

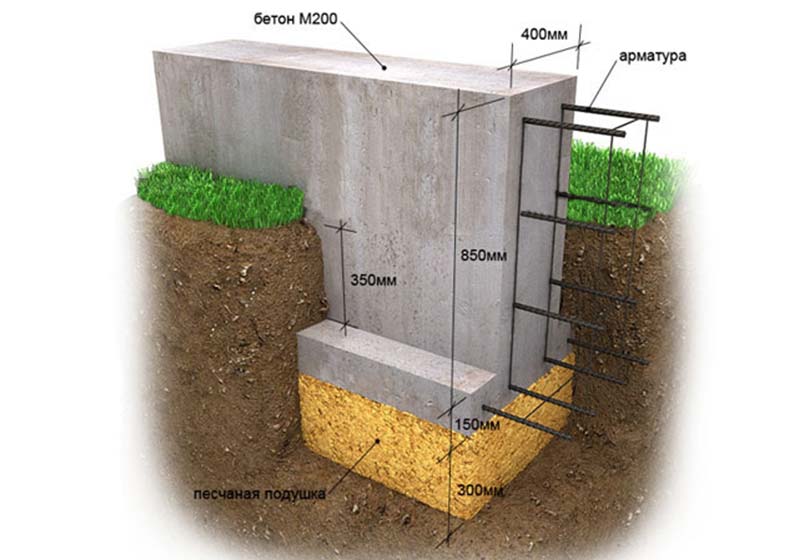

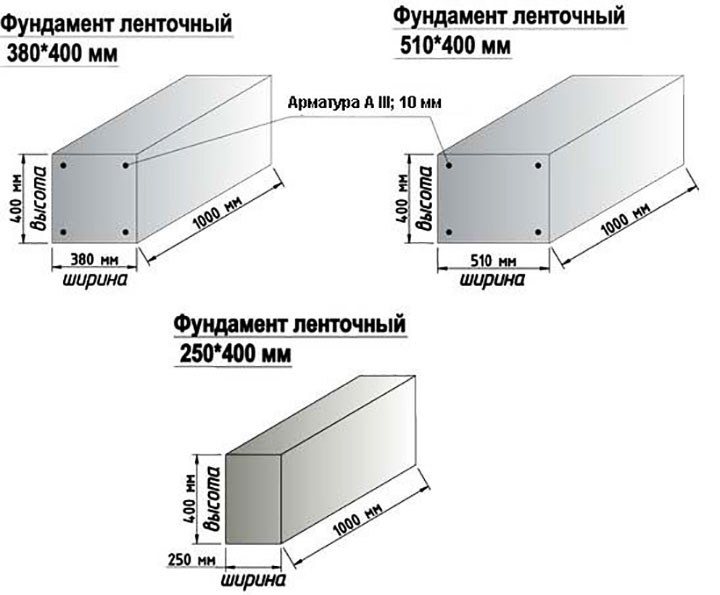

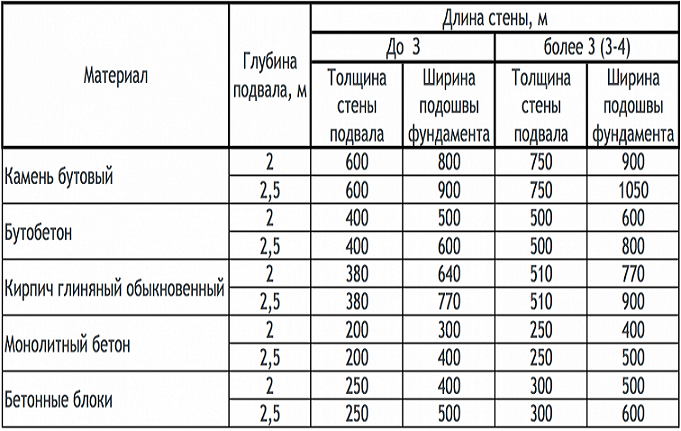

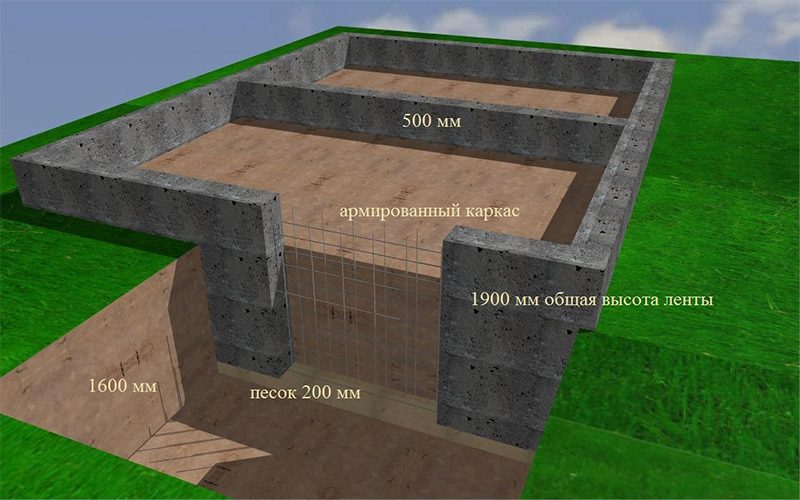

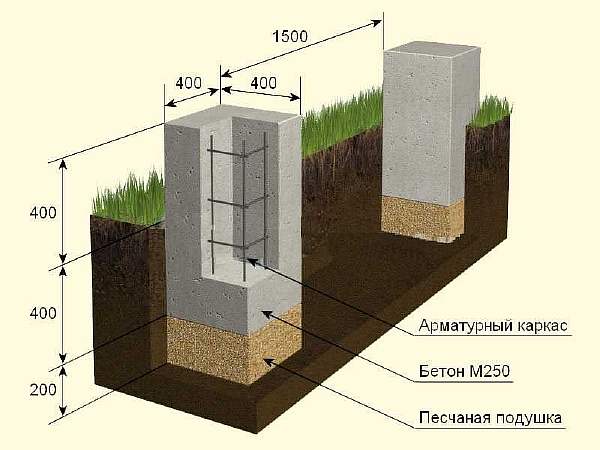

Installation of strip foundation

When choosing a basis for a two-story house, it is recommended to take into account the complexity of the installation and material costs. The most convenient, economical and durable option is the belt type. Before installation, it is necessary to calculate the width of the base, as well as the thickness, which directly depends on the material used. The smallest width is for reinforced concrete, then for concrete, and the widest base must be made for natural stone, due to the weight of the material.

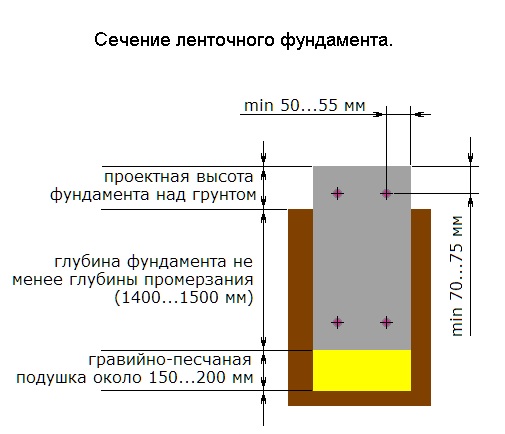

The deepening depends on the type of material of the future structure and the correlation with the freezing point of the soil. The height of the foundation varies according to the individual needs of the customer and his preferences. If there is a threat of flooding, naturally the height should be increased.

There are standard standards suggesting a height of 35–40 cm for wood, and 20 cm for brick and aerated concrete. In addition, it is recommended to add another 10 cm to the height of the snow cover, which is most typical for the construction site.

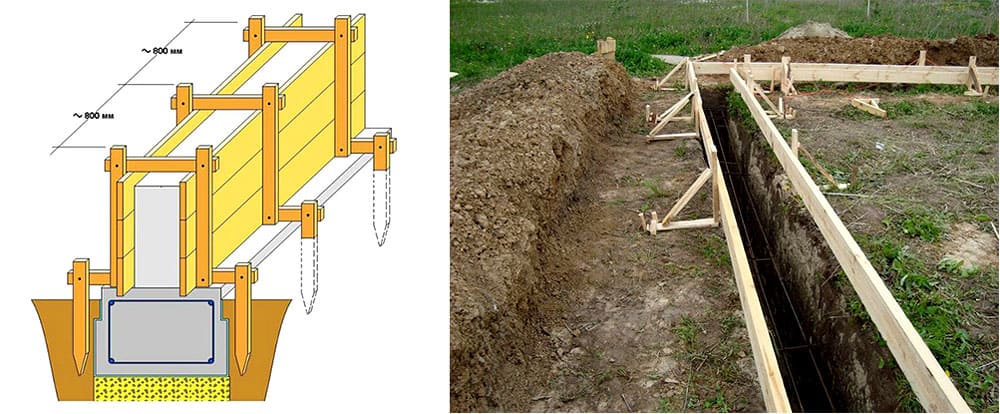

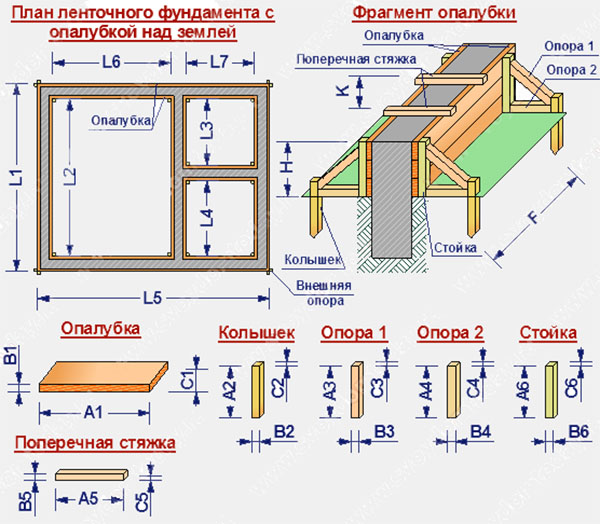

The main stages of strip foundation installation:

- a preliminary drawing is drawn up;

- marking and digging of trenches is carried out;

- laying the pillow, moisturizing it, and tamping;

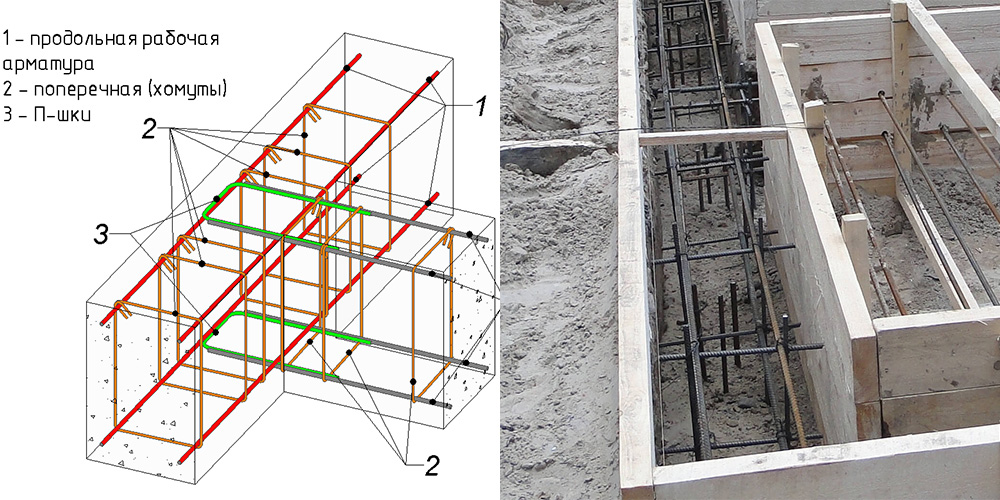

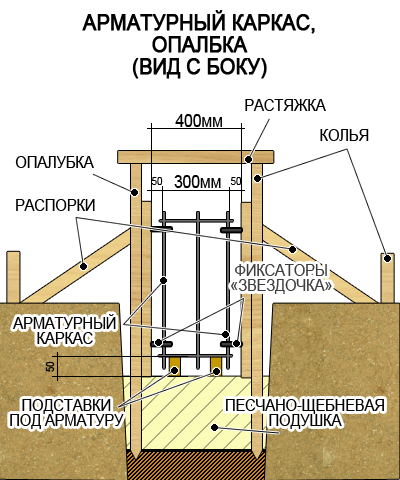

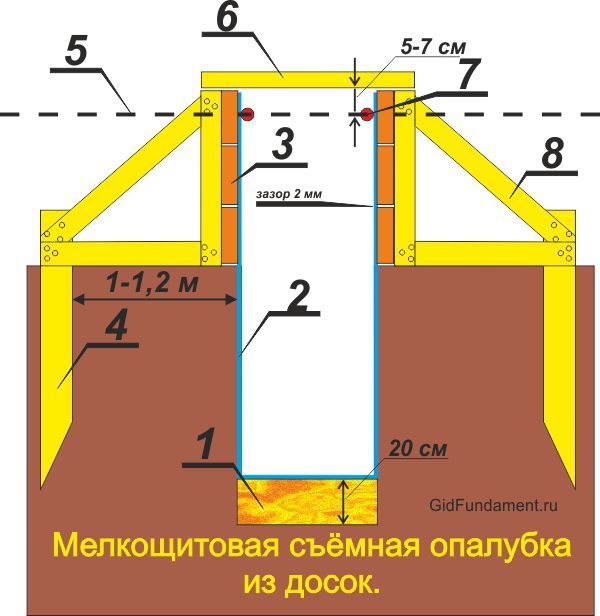

- reinforcement is done;

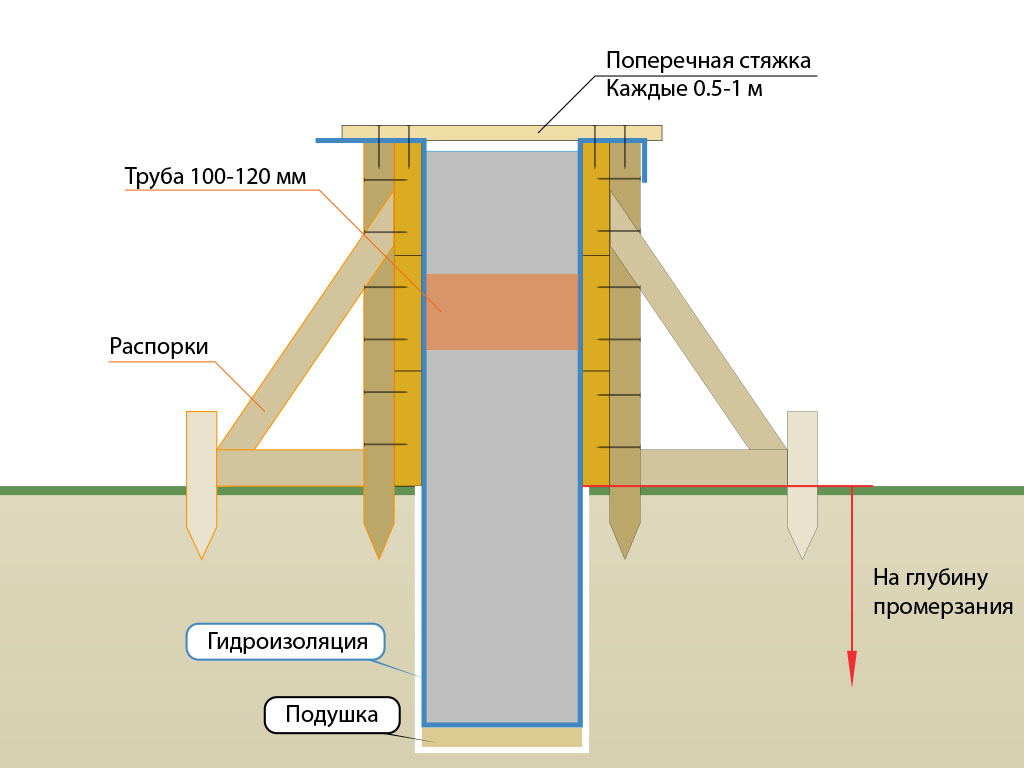

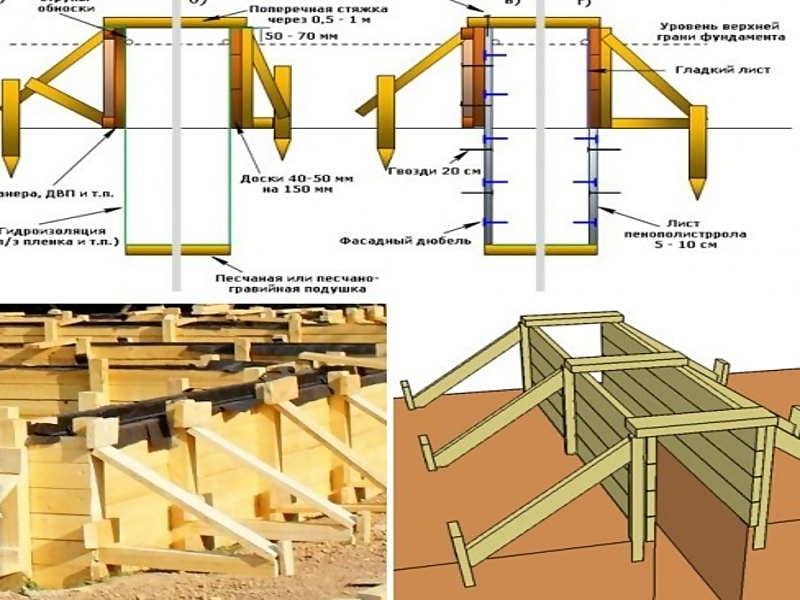

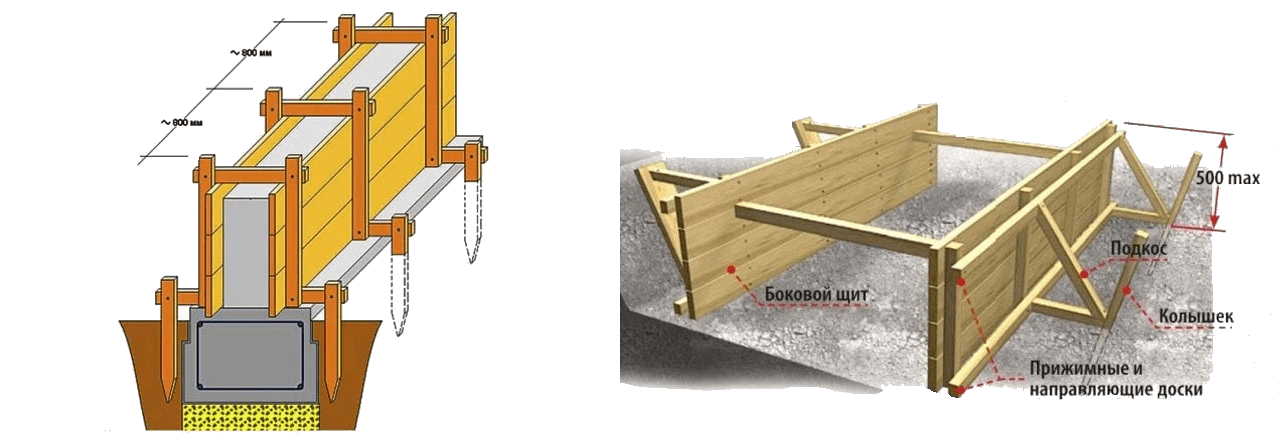

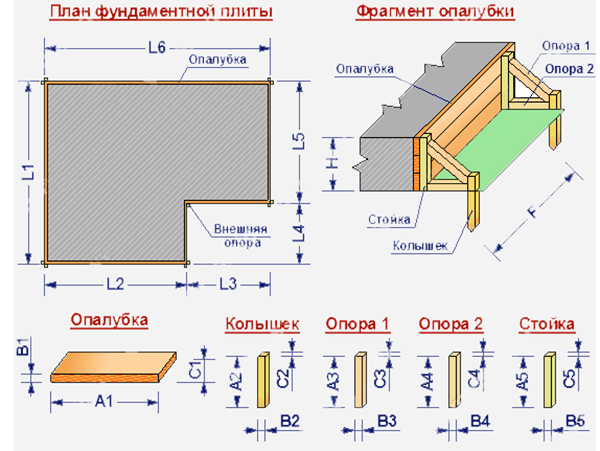

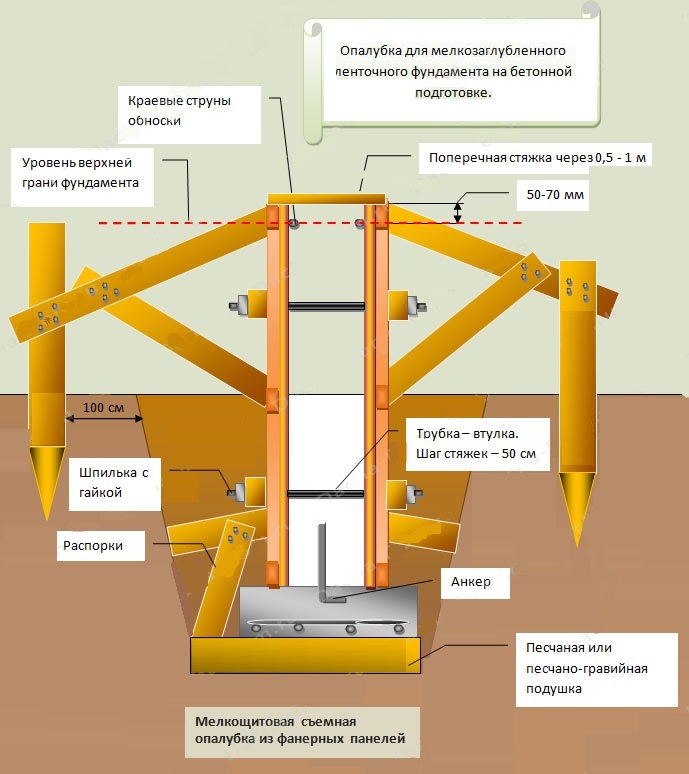

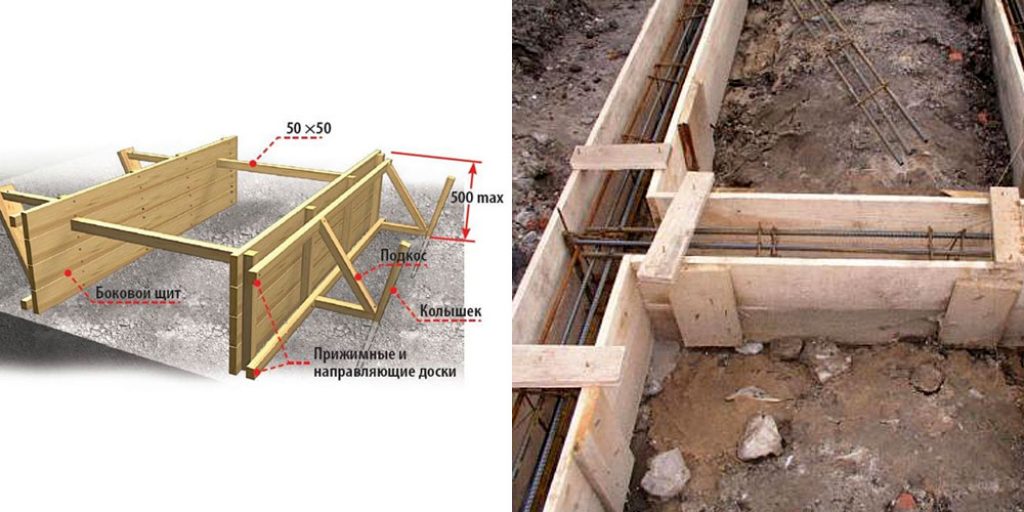

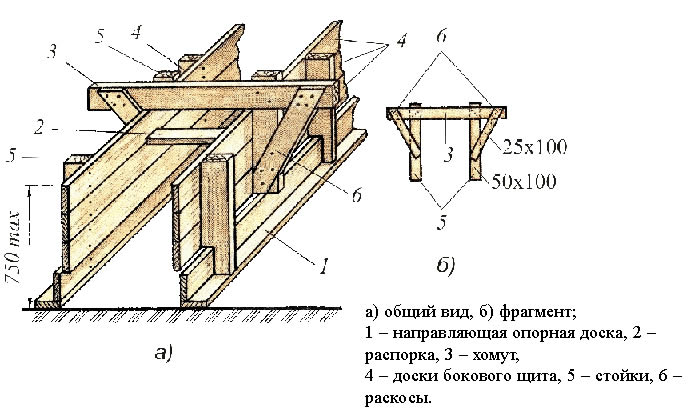

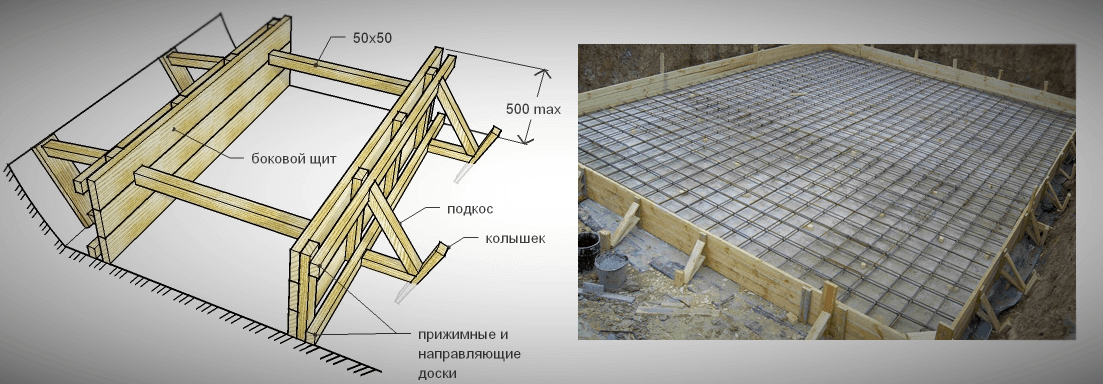

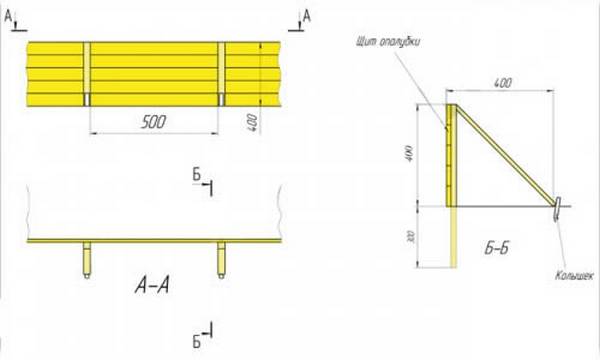

-

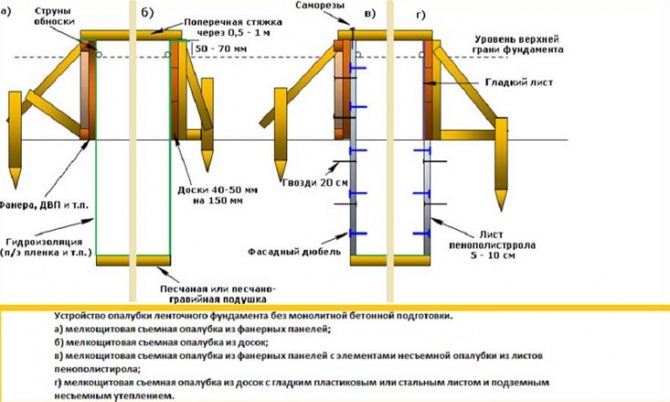

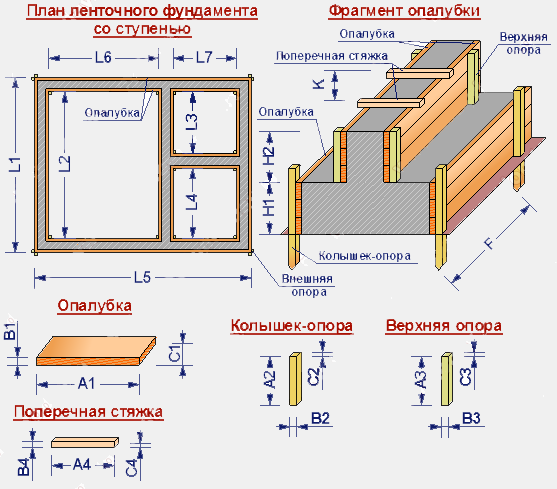

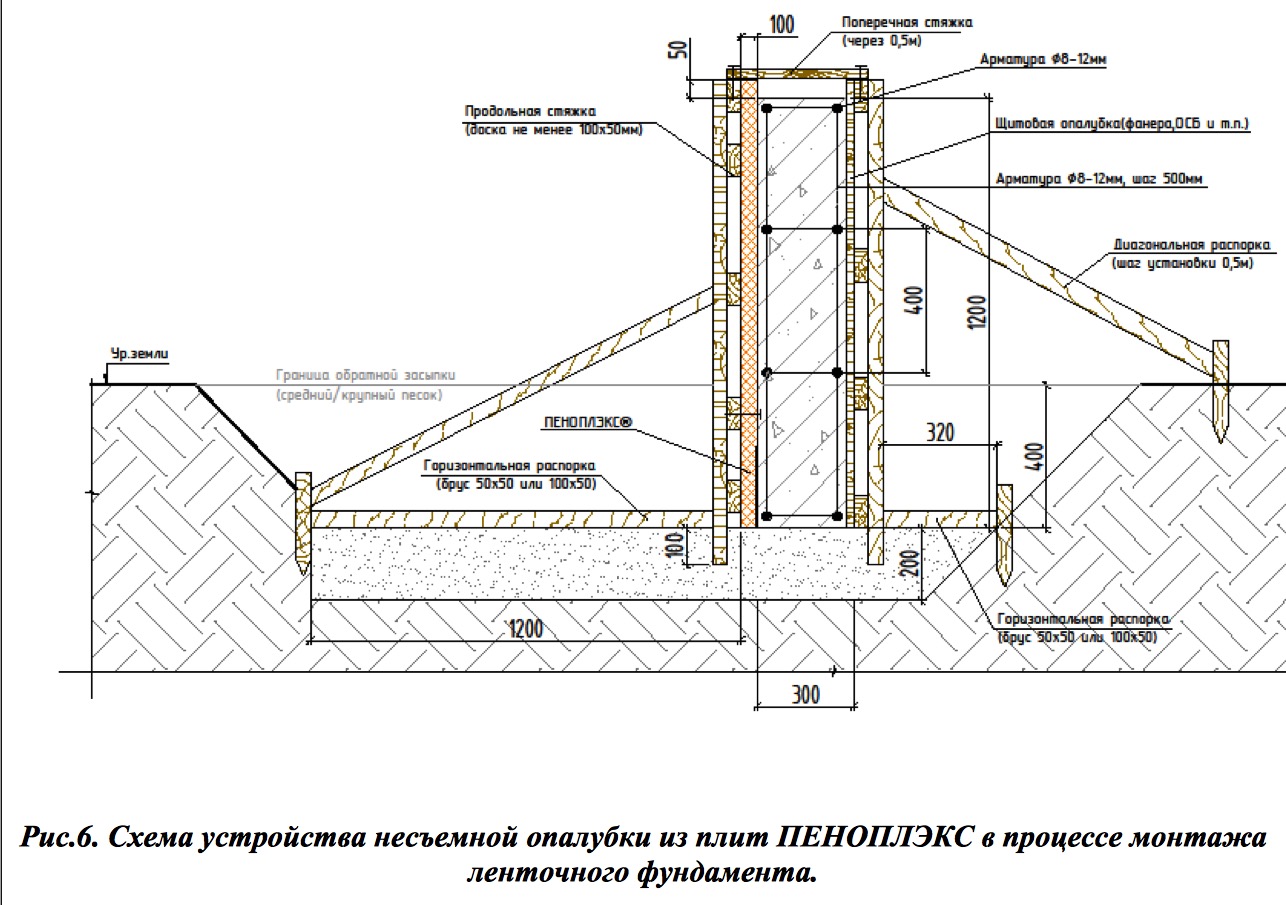

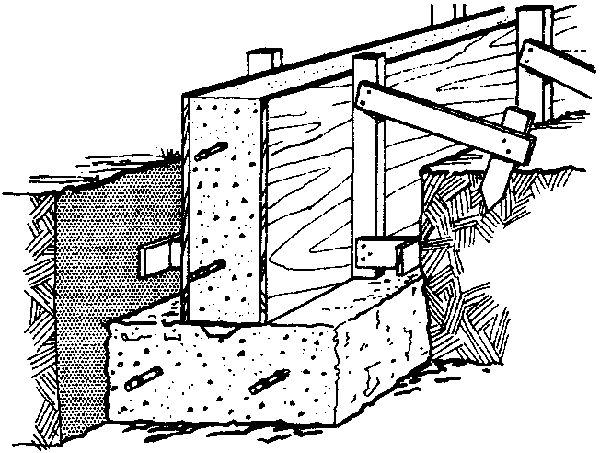

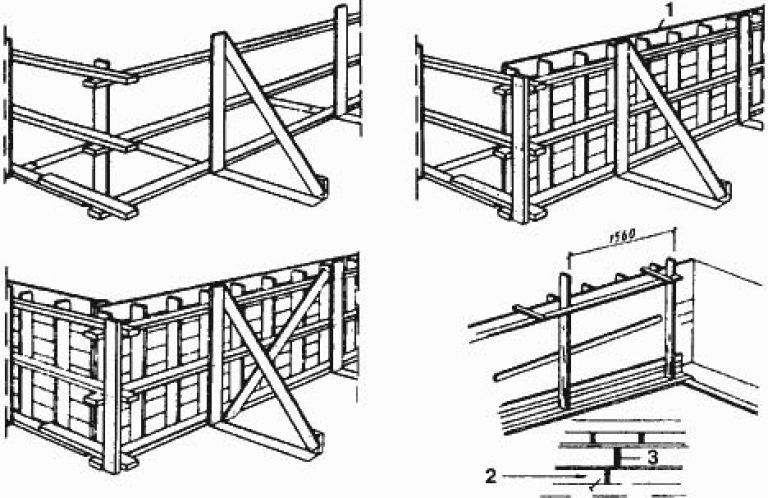

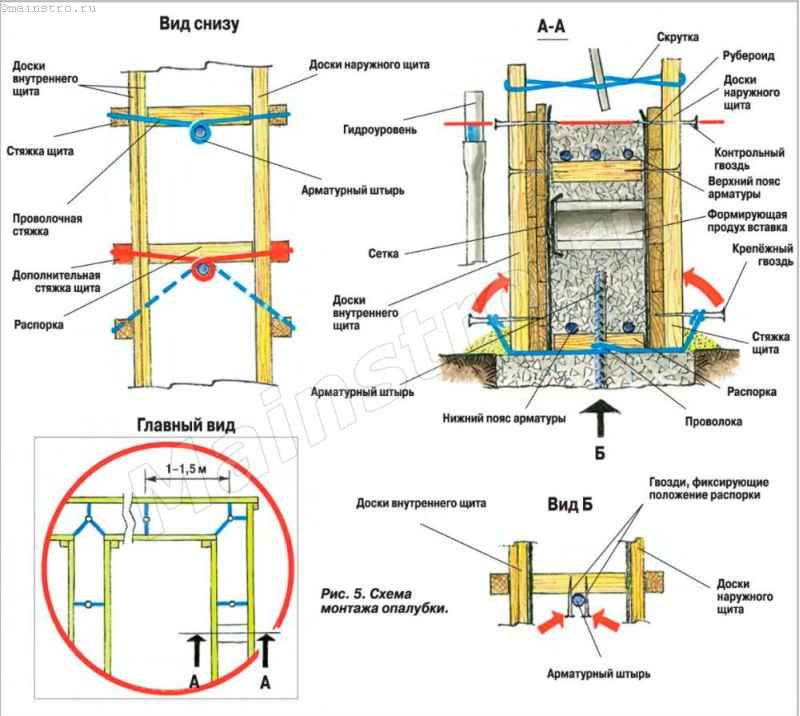

formwork device;

- pouring concrete;

- drying.

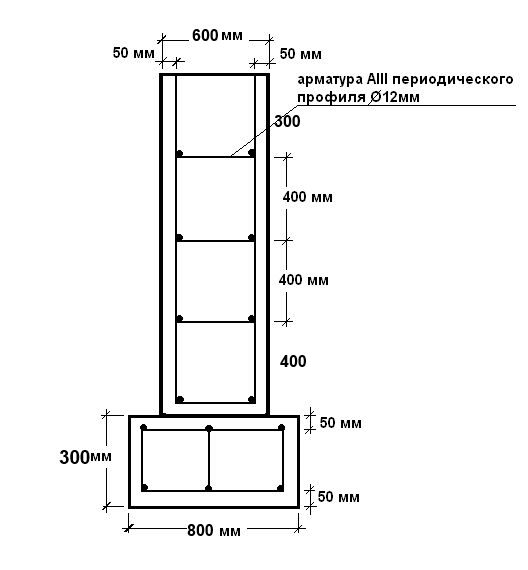

Reinforcement is the main stage in the strip base, since it is the reinforcement frame that creates a strong structure. Usually rods with a diameter of 12-16 mm are used.The interval between the rods is about 30 cm and may vary depending on the individual parameters of the building.

Filling must be carried out in one or a maximum of two stages in order to maintain the solidity of the structure. With manual mixing or using a private concrete mixer, this is difficult to achieve, so it is better to resort to factory concrete. After the final casting, a high level of insulation must be ensured. The pillow can be made of sand, gravel, mixtures thereof or concrete, which justifies the density of the soil.

What is a strip foundation on piles?

The strip pile foundation combines the advantages of two types - column and flat strip foundations. The first one performs the main work on interaction with the ground, and the second one ensures the distribution of the load of the walls of the structure.

At the same time, the material requirement for materials for the construction of the foundation is significantly reduced and labor costs are reduced.

Application area

The strip pile foundation is suitable for the construction of a wide variety of buildings, from fences to brick houses, wooden beams and more modern materials such as aerated concrete, foam blocks, etc.

When using logs, they themselves can act as a pile-based grinder. If the structure consists of small elements, a rover is necessary.

There are several options for pile and strip foundations. The differences lie in the design of the lattice and the manufacture of the piles. In the simplest case, protocols can be used as such.

It's a short-lived material, but it's cheap. Usually coniferous wood is used and impregnation with mixtures is mandatory to protect against mold, fungi, etc.

Monolithic

The monolithic foundation includes the manufacture of a monolithic reinforced concrete tap of the coupler, regardless of the type of pile.

This allows you to build almost any building from any modern material.

The load from such a foundation can be very high, although the load is slightly higher than with simpler options.

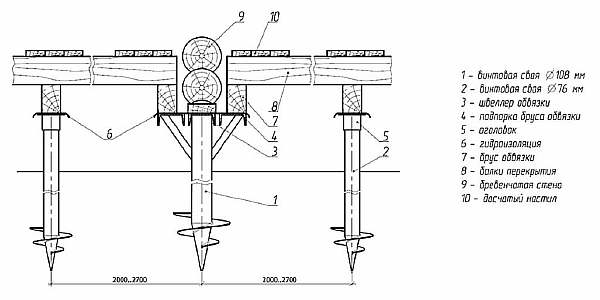

Screw

Another possibility is the use of prefabricated auger piles.

These are iron structures with threaded blades at the end. They will remind someone of a screw, a drill, but they are really screwed into the ground.

This type of pile is produced with a diameter of 57 mm and a length of 1650 mm. Given the corrosion resistance of the material from which the piles are made, it is not recommended to use them on soils with a high acid content (pH less than 5.5).

It turns out that attention to the acid-base balance is also important when building a pile foundation. For building a house, the optimal stack size is 108 or 133 mm in diameter and 2500 mm in length. After all, it is easier to cut off the surplus than to weld the missing one, especially since this length in most cases allows you to go below the soil freezing line

After all, it is easier to cut off the surplus than to weld the missing one, especially since this length in most cases allows you to go below the soil freezing line

For building a house, the optimal stack size is 108 or 133 mm in diameter and 2500 mm in length. After all, it is easier to cut off the surplus than to weld the missing one, especially since this length in most cases allows it to fall below the soil freezing line.

The benefits of this type of pile include, but are not limited to, the following benefits

- A minimum amount of excavation is required.

- This is a little time consuming.

- High speed when performing work.

- High "stability" in the ground due to the narrow entrance to the ground.

The disadvantage of piles is that the piles require a place for screwing in, which makes them difficult to install near other buildings, as well as low corrosion resistance.

With bored piles

These piles are manufactured locally.A hole is drilled in the pile, formwork is installed, reinforcement is installed, if necessary, and concrete is poured.

This option applies to almost all soil types. The main thing is that the depth of the piles should be greater than the depth of soil freezing in the area.

The benefits of this type of fund include, but are not limited to, the following benefits

- Low cost.

- Simplicity and speed of installation.

- You can do without special construction equipment.

Among the disadvantages, it is especially difficult to maintain the required accuracy when drilling and aligning the upper pile belt.

Regardless of the pile depth, approximately 10 cm of sand should be poured into the ground as a cushion.

Foundation calculation

This procedure, as a rule, does not cause serious complications if approached with the proper level of responsibility. It involves the collection of load data and the study of the bearing layers of the soil. The thickness of the foundation for a two-story house will be determined depending on the ratio of these two components.

The video explains in detail how to calculate the base yourself.

The first step is to conduct a thorough study of the working area. The depth of the foundation for a two-story house made of foam blocks should be 35–55 cm higher than the average freezing depth.

Formwork and reinforcement

Such data are acceptable only if the living space is heated in the winter season. Otherwise, it is necessary to adhere to the set freezing temperature for a particular region.

The relative value of the width of the tape will be 25 cm. This value is approximate and will change during the calculation.

The next step is to calculate the pressure on the strip foundation for a two-story house. It is advisable to use the table below to determine the appropriate value.

| Construction type | Density (kg / m2) |

|---|---|

| Walls | |

| Brickwork (half brick) | 210–240 |

| Foam concrete houses | 170–180 |

| Log houses (d = 240 mm) | 130–145 |

| Houses from a bar (150 mm) | 11–125 |

| Overlap elements | |

| Attic (wooden beams) | 10–120 |

| Hollow concrete slabs | 30–380 |

| Reinforced concrete floors | 450–520 |

| Roof | |

| Metal tile, profiled sheet | 25–35 |

| Two-layer roofing material | 35–45 |

| Slate (comb height - 4 cm) | 50 |

| Snow load for the central regions of Russia | 100–120 |

The next step is to calculate the total weight of the strip slab. To do this, you must first calculate its volume, which is calculated using the product of length - L, width - A and height - B.

The resulting value is multiplied by the specific gravity of reinforced concrete, which is 2500 kg / m3. The end result is total weight. To calculate the total load - M - on the supporting soil layer, it is enough to add this value with the weight of the building.

Now it becomes necessary to set the optimal value of the base sole width - O. It is derived by the following formula: O = 1.3 * M / (L * R). A value of 1.3 serves as an indicator of the bearing capacity, and R is the density of the soil layer, which is indicated in the table below.

| Soil type | R |

|---|---|

| Clay with pebbles | 4,2–4,5 |

| Pise | 4 |

| Coarse sand | 6 |

| Medium-grained sand | 5 |

| Fine-grained sand | 4 |

| Sandy loam | 3,2–3,5 |

| Loam | 3,2–3,5 |

| Clay | 6 |

If the width of the tape is less than the approximate value, the final width will be the declared 20 cm. If, according to the results of the calculations, this value has exceeded the initial figure by more than 4–6 cm, it is necessary to re-calculate the base mass with a new value of the width of the tape.

Errors in the construction of foundations

Mistakes made during construction can lead to the complete destruction of the building. For those who want to strengthen the foundation on their own, seek to save money or want to hire a team of specialists, while not understanding anything about construction, the most common mistakes when pouring the base will be listed below.

Choosing construction according to a standard design, the customer usually saves time and money on the development of unique drawings.But at the same time, keep in mind that there is no data on the type of soil, its freezing, the horizon of the groundwater. All indicators are directly related to the installation depth of the main structure, which must be calculated immediately. This is the first technically possible mistake, and the following unsuccessful building ideas are also possible:

- Saving on material. Usually leads to the rapid appearance of cracks, after which the entire foundation will begin to crumble. A cheap brand of concrete for the foundation of a two-story house is not suitable, since the base made of it, having collapsed, entails the destruction of the walls and the entire structure.

- Wall masonry and installation of any supporting structures earlier than 4 weeks after the foundation is poured. Without waiting for the concrete to fully set, the construction of the entire box of the house takes place on a movable base, which ultimately leads to its destruction literally immediately after the end of construction.

-

Lay a concrete tape around the entire perimeter of the same width and thickness without taking into account the internal features of the house. This creates an uneven load, and, accordingly, different shrinkage at different points in the building. The thickness at each specific point should be calculated depending on the thickness of the walls, their location and purpose in the supporting structure.

- The use of shields from unsuitable boards for formwork leads to the fact that liquid flows from the concrete through the cracks. Subsequently, this leads to stratification of concrete, a decrease in its strength and further destruction of the house.

- Replacing the factory fill with a manual batch is time-consuming and the canvas itself becomes heterogeneous. A solid foundation requires a one-step pouring, which ensures its homogeneity and increases its strength. The appearance of air voids, which leads to the destruction of the foundation, occurs due to poor tamping of the concrete mixture.

- The reinforcement and piles are the supporting frame for the foundation, therefore, its thickness, grade and metal must be selected in accordance with the requirements of the architectural project, without saving.

A common mistake in construction is a careless attitude to the season and climatic conditions. In winter, it is imperative to use specialized plasticizers (anti-freeze), and in summer, cover the concrete with polyethylene and moisten it with water twice a day in order to maintain the strength of the material.

Work in construction can be done independently, for complex tasks, professional mixing of the solution and calculations, you should contact the professionals. The base must be made of the highest quality materials, in the required quantities

Savings are possible in decoration or design, and in order for the house not to collapse, maximum attention must be paid to the installation of the foundation.

Types of foundation

According to the method of execution, it is divided into several types. The most common ones are:

- columnar;

- pile;

- tape;

- monolithic slab.

Private residential building

Private residential building

Columnar

The use of the presented type is more justified in the construction of panel-type townhouses, and, for example, houses made of aerated concrete or a Finnish mansion made of timber planks, resting on poles, gained popularity not only in our country, but also abroad.

The technology for the construction of such a foundation is reduced to the fact that supports are installed along the planned perimeter of the future building. They are installed at a certain interval in pre-drilled holes. The diameter of the latter is variable.

Taking into account what depth is the most acceptable in a particular case, builders give preference to different types of pillars. Pipes, reinforced concrete stepsons, logs, natural stone can act as supports.

Stoby

Stoby

Pile

Another type of support element that has become widespread in various areas of construction is a pile.The modern technology of using piles as a key component of the supporting surface is a single complex of complementary structural elements.

This engineering solution eliminates the deformation of individual peripheral parts and ensures an even distribution of the force on the ground.

According to the principle of pile installation, the pile foundation is divided into hanging and retaining.

Scheme of the pile-tape design option

Scheme of the pile-tape design option

The first category of bearing supports is installed in dense soil layers, the height of which reaches several meters. Piles are driven into the ground at a calculated interval. A significant part of the load of such a support falls on its lateral surface, while the base plays a secondary role.

In this position, the soil under the pressure of the support walls can, as they say, "crawl". This disadvantage is compensated for in the following ways:

- an increase in the section of workpieces;

- increasing the length of the pile;

- shaping the pile into bulges at the base and in places of lateral contact with the ground;

- increasing the density of piles.

Screw pile installation diagram

Screw pile installation diagram

Retaining piles in their functionality are strikingly different from previous samples. Unlike pile and hanging supports, this type of basic structure sinks to a shallow depth with a small gap between two adjacent elements. The average height of such supports is 40–70 cm. This technology is typical for 1-storey frame-type buildings.

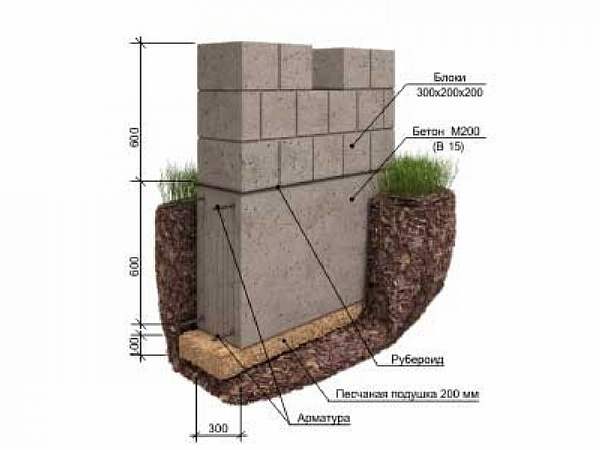

Tape

Special attention should be paid to the so-called strip type of laying the foundation of the building. Its fundamental difference lies in the fact that in the presented case, a block type of bookmark or a solid concrete tape is used.

In accordance with the requirements for strength and degree of load, blocks can have a solid or hollow structure. Aerated concrete houses based on this technology are distinguished by high seismic resistance and durability.

Depth drawing

Depth drawing

Monolithic slab

Slab foundation - it is characterized by a large load-bearing area and an exceptionally high level of resistance to seismic ground vibrations.

In the event of natural disasters that cause displacement or subsidence of the soil, such a structure will remain intact due to the large area of the base of the monolithic foundation, made in the form of a single slab.

The height of such a platform varies in accordance with the conditions of a particular area. Nevertheless, the implementation of such a project will require significant material investments. On average, only a slab takes about 20-25 m3 of concrete to make, but it all depends on the size and load of the building.

Reinforcement of a monolithic slab

Reinforcement of a monolithic slab

The procedure for calculating the foundation

In order to correctly calculate the thickness of all elements of the foundation for building a house, it is necessary to act in stages. The first thing you need to decide on is a sand pillow.

The function of the sand cushion is to protect the base from being exposed to excess moisture and groundwater. In addition, the sand, when pressed, creates a strong soil layer. According to general building codes, a sand cushion is always made under a monolithic foundation slab. To calculate its height, you need to consider:

- The height can vary in size from 15 to 60 centimeters and will depend on the depth of freezing of the soil on the land plot where the house is being built, the types and depths of the located soils that prevail in the region, the presence of groundwater;

- The sand must be well tamped, for which, after filling it, it is necessary to water it with water for several days. This can compensate for a couple of centimeters when shrinking;

- Some experts recommend pouring a layer of fine crushed stone on top of the sand, the thickness of which should not exceed 5-10 centimeters from the total height of the sand cushion.

Based on this, one can come to the following conclusion. In places where the depth of soil freezing is high (more than 1 meter), there is groundwater, and the soils are unstable and subject to constant heaving, the thickness of the sand cushion should be up to 60 centimeters. In places with a shallow depth of soil freezing, in the absence of groundwater and the presence of dense soil layers, you can make a pillow from 20 to 30 centimeters. Having received these dimensions, you can calculate the amount of material required.

The next step is to calculate the amount of reinforcement that will be needed to reinforce concrete. The general rules for determining the number of reinforcement per quadrature are described in this article. It should be noted that such a mesh should be done in two layers. The distance between them is no more than 50 millimeters. That is, the base will consist of two sections of the reinforcement mesh.

Next, we calculate the slab. The minimum thickness of the slab should be at least 150 millimeters, but the size can be increased if the depth of soil freezing is more than 1 meter. According to general rules, concrete should not only fill the layers of the reinforcing mesh, but also protrude 50 millimeters behind them both above and below. Plus, a sand cushion will be added to the general parameters of the foundation.

Sectional construction of a monolithic slab.

Sectional construction of a monolithic slab.