Types of dressings

Several types are currently known, such as:

- wooden beam;

- metal channel;

- I-beam or beam;

- reinforced concrete.

The connection of the pillars with a tape can be performed both above the ground (from 15 to 30 cm above the soil level; used on heaving soils), lying on the ground, and submerged in the ground (this type is almost never used at present).

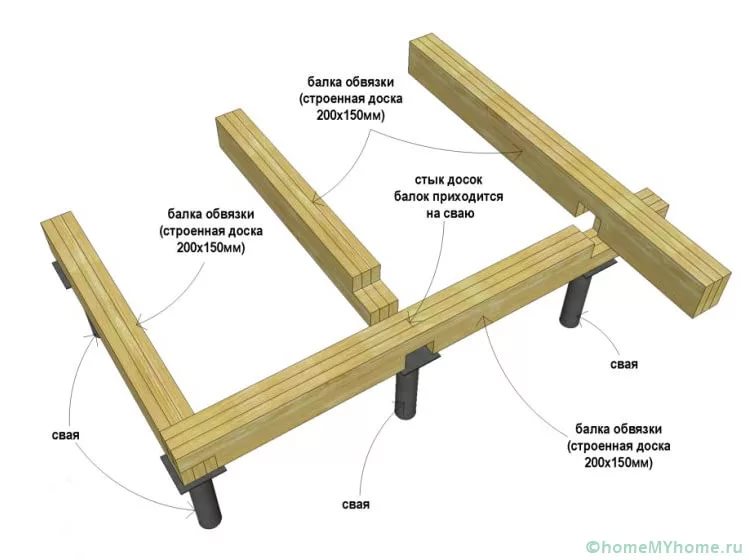

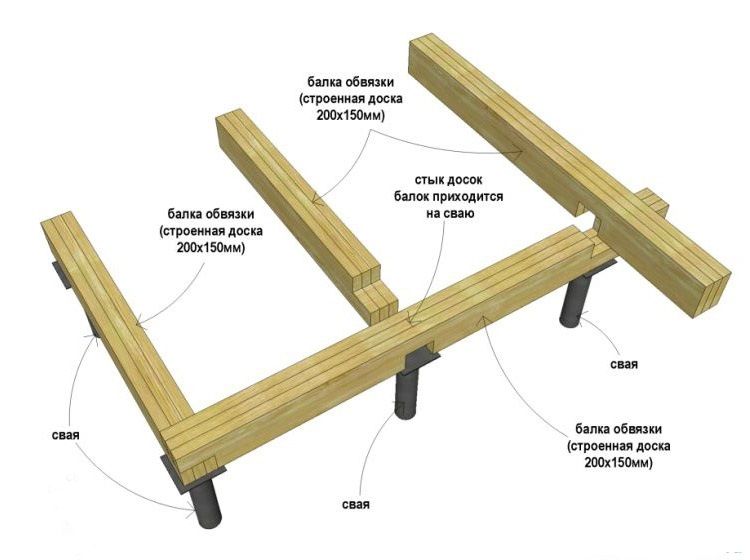

Tying the pile foundation with a bar

When building a low-rise house, an outbuilding, a bathhouse made of medium-weight building materials (frame or panel board) with your own hands, strapping with a wooden beam will be an excellent solution.

The grillage rests on pillars or piles from above, the most common size of a billet from a bar of 150x150 or 200x200 is used, since the cost of such species is several times cheaper than deciduous ones, and the strength indicators and service life of products from different species are absolutely identical.

Before installation, the surface of the wooden product should be treated with an antiseptic to prevent rotting of the workpiece, and then covered with waterproofing (bituminous mixtures are most often used). The lining of the foundation with a bar must be performed in the correct sequence:

- after twisting the piles, they must be set one level at a time;

- a head is mounted on each pillar;

- it is necessary to carry out waterproofing of units from a bar;

- the bars are connected to each other with grooves;

- the tree is installed along the perimeter of the entire foundation on the head of the pillars in such a way that the bars are fastened in the places of the head;

- check the correctness of the angles and the level of the grillage from the timber;

- the timber is fastened to the screw piles with special self-tapping screws.

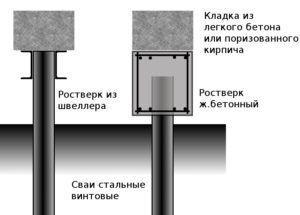

Tying of screw piles with a channel

This type of dressing has an increased bearing capacity than wooden bars; metal products are used both for the construction of residential wooden buildings, and buildings made of foam and cinder blocks, as well as of gas silicate bricks.

This type of dressing has an increased bearing capacity than wooden bars; metal products are used both for the construction of residential wooden buildings, and buildings made of foam and cinder blocks, as well as of gas silicate bricks.

More often than others, an I-beam or channel serves as a grillage. The exact selection of a certain size of the profile pipe depends on the calculated indicators of the base itself. A lintel made from an I-beam copes well with compressive loads, provides greater rigidity for fastening the posts, therefore it is more advisable to use it than other types of lintels.

When the pillars are tied with an I-beam, the bar of the same section should be laid along the entire length of the base; products of section No. 20 are used as standard. The channel is usually laid under the main walls with section No. 30, under others - No. 20.

Iron lintel installation technology:

- pillars should be aligned in height;

- the top layer of the metal workpiece must be coated with a compound with anti-corrosion properties;

- iron products are mounted on poles, the joints of the workpieces should be laid on piles; when using an I-beam as a strapping material; the joints in the corners must be cut off at an angle of 90 degrees;

- in places of corner joints, the channel must be cut in such a way that when joining, an angle of 90 degrees is obtained;

- the beams must be welded to the posts, and the joints must also be welded.

Reinforced concrete floor

A strap made of concrete will cost 30-35% less than a grillage of the same foundation made of a channel or I-beam, and in terms of strength and reliability it will surpass iron blanks.

A strap made of concrete will cost 30-35% less than a grillage of the same foundation made of a channel or I-beam, and in terms of strength and reliability it will surpass iron blanks.

Reinforced concrete overlap should be erected according to the rules:

- piles should be set one level at a time;

- it is necessary to erect a wooden box for concrete so that the mortar does not run away, the inside of the formwork needs to be laid with parchment paper;

- the frame of the grillage should be erected from corrugated reinforcing wire with a cross section of 10-12 mm; the main horizontal rods must be fastened with connecting partitions (vertical and longitudinal); elements of the skeleton must be tied with a special wire;

- the reinforcement cage is placed in the box in such a way that the indent from all the edges of the formwork is 6-7 cm;

- the iron skeleton of the grillage is attached to the reinforcement of the piles using a welded joint;

- should be used for pouring concrete mortar of class M-300;

- the formwork is disassembled only after the concrete has completely set, not earlier than 30 days from the moment of pouring. For more information on installing a reinforced concrete grillage on screw piles, see this video:

Methods for tying pile foundations with a bar, a professional pipe and a corner

Types of strapping of pile foundations

Types of strapping of pile foundations

Pile foundations are popular in industrial and private construction, when the slope at the construction site is large enough or there is a large depth of strong rocks on the ground.

In such soils, it is impractical to dig deep trenches, since the soil may shift or flood the bottom of the trenches with groundwater. In turn, pile structures are ideal, considering their features, design characteristics and low cost in general.

What is the harness used for?

Diagram of the grillage device in the columnar-pile foundation

To ensure greater structural strength and uniform transfer of the load from the building to the ground, a special foundation strapping or grillage is often used.

The grillage is connected to the piles using a swivel joint, reinforcing mesh, rigid welding and wire. In private construction, strapping is practiced with a grillage from a wooden beam, a professional pipe or a channel.

The harness is used:

- To ensure that all piles are geometrically even and correctly positioned.

- Avoid displacement of the foundation under the influence of lateral, tangential and vertical soil displacements

- Provide an even distribution of loads from the mass of the future building through the piles to the ground.

When designing pile-grillage foundations, the number of piles must be taken into account. The more piles are used, the smaller the cross-section of the strapping reinforcement will be. In addition, you can also use an ordinary wide board or a small-diameter professional pipe, you need to connect all the links with corners.

Types and types of strapping

The use of a professional pipe for tying piles of the foundations of buildings

Pile-grillage foundations are highly durable, they almost completely neutralize vertical and horizontal soil movements.

Used for the construction of houses on mobile and unstable soils, prone to heaving.

Piles are also actively taken into account not only when designing a new house, but also used during the repair of an existing one, since they are strong enough and capable of withstanding the load of buildings of several floors.

It is important to take into account the human factor, as well as the presence of solid rock in the soil. During the installation of piles, a small slope angle is inevitably formed due to the displacement of the core, therefore, after the installation of the structures, they need to be leveled and strengthened.

Methods for strengthening piles used in private construction:

- Strapping with a professional pipe, additional connection to the top of the pile with corners, welding or flexible wire.

- Use of metal channels with different installation directions.

- The use of a wooden beam.

It is not at all necessary to do the strapping if the location of the top point of the pile is not more than 60 cm from the ground level.But if it is higher, then you cannot do without strapping, since the supporting structures will move even under the influence of wind or rain, and over time, the building itself may be skewed.

Required materials for strapping the pile foundation:

- wooden beam, thick boards can be used;

- metal channel, I-beam and connecting corner;

- flexible wire, wire rod or reinforcement with a cross section of up to 8 mm.

You will need a welding machine and building levels.

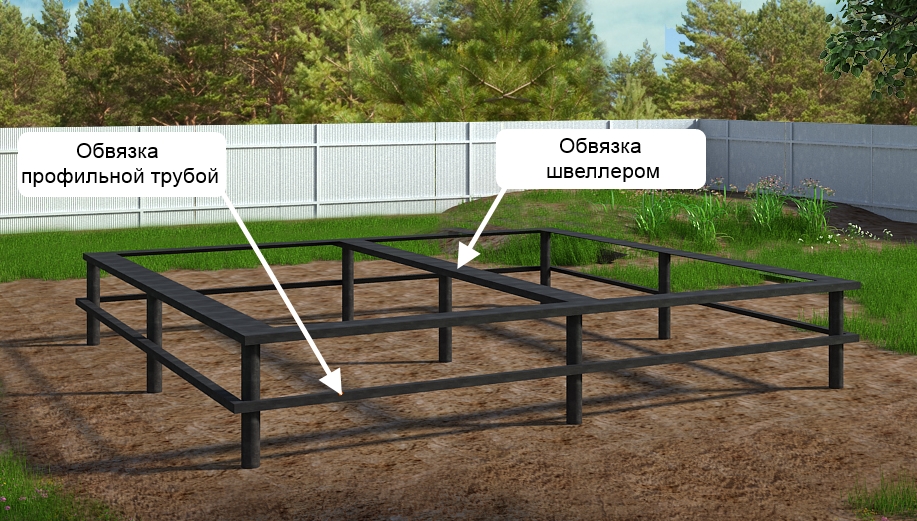

Tying with a channel or professional pipe

Channel and professional pipe for tying foundation piles

A channel is a metal rigid beam of large thickness, it has its own stiffeners, to which the reinforcement or the top of the pile is attached by welding.

A profiled pipe is cheaper, its mass is less, but it does not differ in strength either, the principle of connection is similar to a channel. The best connection method is to overlap or overlap two beams. Peculiarities:

- It is unacceptable to use separate beams on different piles, it must be a monolithic structure.

- If the foundation is large enough, then a crane will have to be used to install and fix the channel, so this method of strapping is used in the construction of warehouse and industrial buildings.

- To ensure greater strength, it is recommended to use not only welding, but also a bolted connection, cover the joints with anti-corrosion paints and check with ultrasound.

- Channels are heavy load-bearing structures, so such grillages are not used in private construction.

Recommendations of the masters

When choosing a strapping from a wooden bar, you should adhere to the following order of work:

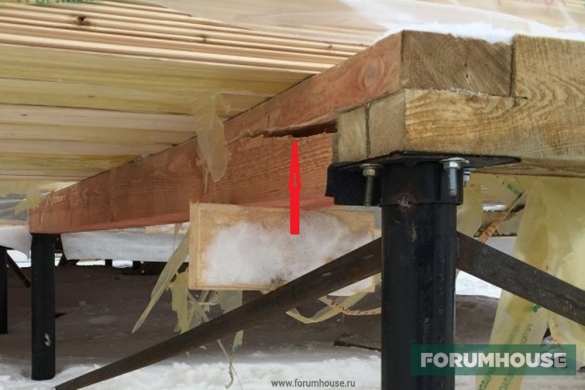

- at the end of the installation of screw piles and alignment, metal platforms made of sheet steel 20x20 cm and at least 4 mm thick should be welded onto their heads;

- in these fragments of metal sheets, it is necessary to drill four holes with a diameter of 8 mm to secure the bar;

- at the end of the work, the welding seams and heads must be treated with an anti-corrosion compound;

- it is necessary to lay waterproofing on top, usually from roofing material in two or three layers, which will prevent the accumulation of moisture at the junctions of metal and wood;

- one row of timber or a package of boards is placed on pre-prepared sites;

it is important to lay the joints of the timber from the end in a "dovetail" or "paw in paw";

when all the parameters are checked, the bars can be fixed to the supports with screws, which should have a diameter of 8 mm and a length of 150 mm, they should be screwed in with a wrench;

first you need to make a hole in the timber with a drill with a diameter of 6 mm for three quarters of the screw length. This is necessary so that the timber does not crack;

even more reliable, the structure is fastened with bolts with a diameter of 8 mm, which must pass through the beam from top to bottom

To do this, you must first make a hole using a drill with a depth of 10 mm. This is necessary for attaching the head of the bolt and washer, the diameter should be not less than 30 mm.

The strapping is also called the grillage. Today the grillage is one of the best options, characterized by very high quality and maximum reliability when strengthening the pile foundation. With your own hands, you can create a reliable support for your home. Before starting work, you need to prepare a level and roofing material, as well as self-tapping screws. Don't forget about the hammer and metal corners. The choice of other materials and tools depends on the specific technology. Best of all, according to experts, is the technology using clamps and threaded connections.

For strapping screw piles, types of strapping, purpose, need, see the next video.

Applying a package of boards

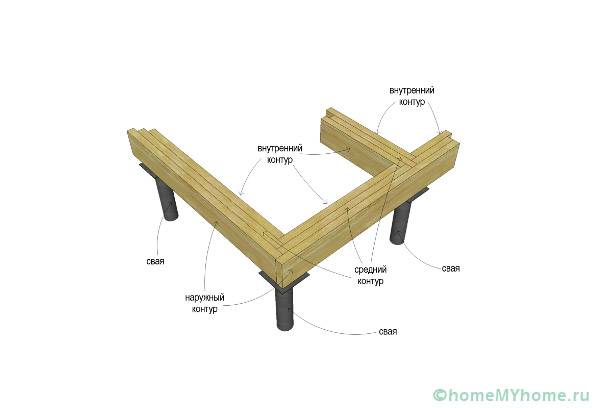

The grillage device from a package of boards has its own characteristics:

It is recommended to use boards of 50 * 200 mm, good quality, dry, soaked in an antiseptic solution

It is important that the width of the boards is exactly the same. Boards of different widths will lead to non-linearity in the height of the grillage plane when forming a package.

During installation, it is important to correctly observe the sequence in the arrangement of the elements.

A package is installed along the pile heads, as in the case of a timber, a layer of roofing material is necessarily laid on top of the pile heads.

The edge boards are mounted first along the outer axes of the foundation with 50 mm resting on the lateral side. They are attached to the heads from below with self-tapping screws through the holes in the plate. Then the middle boards of the inner axes are mounted at the end to the outer boards and fixed on nails.

After that, the middle boards are installed along the outer axes and the outer ones along the inner ones, fastened with self-tapping screws to the heads and nails at the joints. SP 31-65-2002 in paragraph 6.2.11.1 recommends using galvanized nails or plates when tying with a bar or board. The last ones to be mounted are the inner boards along the outer axes, fastened with self-tapping screws. The result is a grillage with a width of 150 mm from a package of boardsinstalled on the edge. This should result in a corner joint, subject to the technology of laying the boards into a package.

To increase the rigidity, the boards are pierced with nails from both sides of the package every 50-60 cm along the entire perimeter of the grillage. It is recommended to install brackets at the joints, inner corners, tightening screws around the perimeter of the package. Connections are made only within the base plate of the extensions. General view of the grillage from a package of boards

Pay attention to the nodes of the connections.

Tying with a channel or professional pipe

Channel and professional pipe for tying foundation piles

Channel and professional pipe for tying foundation piles

A channel is a metal rigid beam of large thickness, it has its own stiffeners, to which the reinforcement or the top of the pile is attached by welding.

A profiled pipe is cheaper, its mass is less, but it does not differ in strength either, the principle of connection is similar to a channel. The best connection method is to overlap or overlap two beams. Peculiarities:

- It is unacceptable to use separate beams on different piles, it must be a monolithic structure.

- If the foundation is large enough, then a crane will have to be used to install and fix the channel, so this method of strapping is used in the construction of warehouse and industrial buildings.

- To ensure greater strength, it is recommended to use not only welding, but also a bolted connection, cover the joints with anti-corrosion paints and check with ultrasound.

- Channels are heavy load-bearing structures, so such grillages are not used in private construction.

A channel with a width of up to 160 mm is used as a supporting structure, but if the pile has an outer diameter of 108 mm, then a channel with a width of 140 mm is recommended.

First, reinforcement is made with longitudinal beams, so the piles are connected to each other and an artificial horizontal shield is created. Then a channel is installed on the top of the pile, which is connected by welding with the pile and additionally with corners with intermediate beams.

This design does not affect the strength of the foundation, because the metal of the channel, weakened by welding, has a reliable support in the form of a screw metal pile, and the beams provide an even distribution of loads.

Tying with a channel

The installation of the channel is carried out directly on the heads of screw or reinforced concrete piles prepared according to the level. The width of the channel is selected according to the size of the pile head. For example, the minimum channel width for a 108 mm diameter screw pile is 140 mm. Reinforced concrete piles are tied with a channel as soon as possible after driving in order to prevent a change in the position of the head from residual deformations of the soil during installation.

Tying with a channel on screw piles. On the sides, a frame is made of a profile pipe for facing or a false plinth.

Tying with a channel on screw piles. On the sides, a frame is made of a profile pipe for facing or a false plinth.

To screw piles, the channel is welded directly to the body. Corner joints with any piles are made by cutting the channel at 45 degrees and welding the joints. All connections are processed with a grinder.

Along the inner axes, a 45-degree stub is also performed, followed by welding. The result is a rigid grillage with an even base. Metal, joints are coated with anti-corrosion coating or marine paint.

There are solutions when a frame from a bar is mounted along the channel. Probably, the designer or customer decided to play it safe and strengthen the foundation, since the channel does not work in this position or saved on the number of piles. It is recommended in such cases, to protect the log frame house from condensation, over the profile with an insulating gasket, mount a 50 mm board (bench) with fastening on self-tapping screws or bolts.

There are options for grillages with the laying of the channel with the shelves upward and the filling of the inner cavity with concrete. At the same time, the bearing capacity of the base increases significantly, but the load on the piles from the weight of the concrete is added.

Features of the pile foundation

Pile-screw foundations are very common in low-rise construction. This is especially true for the construction of frame and log houses, which are lightweight.

This is explained by the following advantages of pile structures:

Suitable for difficult soils. This refers to weak, heaving and frozen ground. The same applies to uneven areas, when, due to the peculiarities of the relief, this type of foundation turns out to be the only possible solution.

Long service life. Compliance with the technology of arrangement, the use of high-quality materials and proper operation ensures a long service life of the pile foundation (at least 100 years).

Cheapness. Other types of foundations are much more expensive.

Simple and fast construction. A special technique is usually used to immerse the screw supports, which allows this procedure to be carried out in a few hours. There is also a manual screwing option that can be handled by 3-4 people.

Screwing in screw piles using special devices will significantly save time

When laying a foundation from screw piles, laborious earthwork is not required. The main thing is to correctly calculate the screw-in depth and the distance between the supports.

The determining factors in the calculations are the massiveness of the future building and the characteristics of the soil - its composition, the depth of groundwater occurrence and the degree of freezing.

Considering the possibility of using a pile foundation, it is important to take into account the fact that there is no solid supporting surface in the structure. This causes known difficulties when using materials for small-format walls.

The existing problem is solved by the binding of screw piles, for which several technologies can be used. The correctness of this procedure directly affects the strength qualities of the finished building.

The reliability of the entire building will depend on the strength of the pile foundation.

Types of strapping and which one is better to use

Tying the piles under the foundation of the house is necessary to ensure the rigidity of the structure and to arrange the foundation for the further installation of the building. At the design stage,

detailed calculation of the foundation for static loads from the building in several versions. The most economical, practical option in the given conditions is selected.

When calculating, take into account the natural characteristics of soils at the base of the site and their heaving, the depth of freezing, the level of occurrence of groundwater, and the seismicity of the area. The category of the designed building is taken into account by classes of responsibility and service life

To stiffen the entire structure, preserve it in the design position, and establish the foundation for mounting the walls of the building, 2 types of strapping are used:

The bottom strapping for reinforced concrete piles is not required due to the stiffness of the reinforced structure. The connection on the heads is made of various materials according to certain technologies, which ensure the stability of the structure and the possibility of the further process of installing the walls.

Screw piles are used in the construction of structures of 2-3 categories, light frame houses, wooden, with walls made of blocks with a density of D400 - D700. The bearing capacity of screw piles allows the construction of lightweight structures with a service life

For screw piles with a head protruding above the surface of> 400 mm, it is necessary to use a lower strapping in addition to the upper one. This makes it possible to increase the rigidity of the screw piles and the stability of the entire structure.

An example of a properly executed lower strapping of screw piles with high heads.

An example of a properly executed lower strapping of screw piles with high heads.

Standard pile strapping is made of materials such as:

- wooden beam with a section of 150 * 200 mm, 200 * 200 mm, 200 * 250 mm;

- package of 3 boards 50 * 200 mm;

- channel 140-300 mm;

- corner> 50 mm;

- thick-walled profile pipes;

- two channels in a pair or I-beam;

- suspended reinforced concrete grillage supported by piles.

The strapping is carried out after the complete installation of the pile field, trimming of the heads in one project level, pouring with concrete, if provided by the project. Concreting screw piles increases their rigidity by an order of magnitude.

Preparing timber for installation on piles

Preparing the harness for installation on piles consists in processing wood with antiseptic compounds, as well as cutting off workpieces of the required length. For antiseptic treatment, bioprotective compounds are best suited, at the same time capable of performing the functions of a primer. You can get acquainted with the recommendations of developers regarding the use of certain protective compounds here.

Some developers strive to dry the timber to the optimum moisture content before installing the strapping. What should be the moisture content of the timber used for the construction of the strapping? Experienced FORUMHOUSE users believe that if the wood has a marketable appearance, if its moisture content does not differ beyond extreme values, then it is better to use it for the construction of the strapping in the form in which it was purchased. And drying a board or timber at home will do more harm than good.

It is necessary to dry the timber in a special chamber, and not behind a shed or under a film. The harness is built immediately after the purchase of wood, and it dries already inside the building structure. All that had time to lie down before the construction, then only for firewood is good, alas.

This advice is for those who do not want to get a timber twisted in all possible directions after inept drying.

Stages of work

Consider how to correctly make a strapping from a bar for a columnar foundation. For this, certain types of work have to be performed.

The quality of the strapping timber

Experts recommend choosing products made from wood harvested in the winter. They should be free of cracks, chips and places damaged by pests.

Strapping timber with a moisture content above 18% cannot be used without preliminary drying, as it deforms after drying. Drying is carried out indoors, as the tree cracks in the sun. Larch is considered the best material for the first crown laid on the foundation, since it does not rot and is not afraid of moisture.

The prepared material must be treated with a fire retardant to increase fire resistance. Especially if it is made of pine, which contains flammable resins. Antiseptic impregnation will protect against fungal attack and decay.

Preparing pile heads

To make it more convenient to strap the columnar foundation with a bar, it is necessary to equip the pile tops with square-shaped plates, the dimensions of which are 25 by 25 cm.

Prepare them as follows:

- three to four holes are drilled, with the help of which the process of fastening a wooden bar with self-tapping screws is simplified;

- a waterproofing layer is arranged on the tops with the help of roofing material or bitumen composition. When cutting out pieces of roll material, it is recommended to leave a two-centimeter margin on each side to facilitate the fixing process.

Due to the waterproofing layer, the wood is protected from the negative effects of water, the source of which is the condensate that appears on the cool metal surface after changes in the temperature regime. Therefore, every effort should be made to keep the wood dry.

Installation of heads

But in the case of strapping with a bar, given its strict dimensions, it is advisable to install flanges (the letter "P" upside down). The distance between the “legs of the letter” depends on the parameters of the blanks, since they will fit between them (the minimum section of the timber for strapping is 150 mm). Naturally, the holes for the fasteners are prepared in advance.

We fix the timber

To facilitate the installation work on strapping the screw foundation with a bar, wooden elements are pre-laid out along the perimeter of the base under construction. This will allow you to comply with the dimensions determined by the design solution. The unfolded beams must be docked with each other at right angles, the check of perpendicularity is carried out by measuring the diagonals of the angles, the dimensions of which must be the same.

Installation work:

- the installation begins at the intersections of the beams;

- the timber is joined "in a half-body". Sometimes the “paw” connection is used, which is more reliable. To make the fit of the timber tight, its end sections are cut evenly. In the joints, it is recommended to coat the wood with an adhesive composition;

- the bar is attached to the soles with a head with self-tapping screws. It is better to use hardware with hex heads - it is more convenient to screw them in from the bottom. To facilitate this work, small-diameter holes are pre-drilled, the screws are tightened with a socket wrench;

- inside the grillage perimeter, the beam cuts “into the half-frame”. The bar is previously grooved at the connection points. Then part of the end is trimmed so that the timber plunges into the main harness.

How to attach the harness

Before proceeding with the strapping of the pile base, you should choose the method of assembling and fastening the grillage, as well as select the appropriate building materials.

The standard strapping of the foundation with a bar is interconnected in two ways: a straight joint or an oblique cut. The joints are protected with a board lining or a Gerber hinge. The outer strapping of the pile base is made double.

A wooden, metal and reinforced concrete grillage is attached to the piles as follows:

- For threaded hardware - bolts, screws, studs;

- For welding;

- On clamps or staples.

Grillage material

Often the following materials are used for the grillage of screw piles during the construction of low-rise buildings (list in ascending order of strength):

- Wooden beam (cross-section 20x20, 15x20 cm)

- A package of edged boards arranged perpendicular to the head (section 5x20 cm, the package can be made of 3, 4 boards)

- Steel U-shaped channel (sheet thickness 15, 20 mm)

- Steel I-beam (thickness similar to channel)

The choice depends on the structure - the more massive it is, the more durable material you need to use.

Installation on self-tapping screws

The method of fastening a bar, a package of boards to the head of a pile has become widespread. The reason is manufacturability, availability of consumables. The fastening is based on a plumbing bolt, a self-tapping screw with a hex head.

The general view of the hardware is presented in one of the illustrations given here. Average length - about 8-10 cm. Hexagonal head for a wrench. You can screw it with a screwdriver, wrench. Hand keys are impractical. For attachment to one head you need 4 plumbing bolts.

Using brackets, clamps

The grillage method is combined with the classic one for self-tapping screws. The difference is that pieces of timber 50-60 cm long are attached to the heads of the piles, a timber is mounted on them, a package of boards located on the edge. In corner, cross connections, the fasteners are supplemented with metal brackets driven in the shape of a diamond (at the crosshair of the harness), inclined to the right ("/"), left ("") side of the line.

Welded connection

For I-beams and U-beams, the best connection method is welding. For the latter, anchors can be used, but this option requires special metalworking skills.

For this installation method, waterproofing is not provided due to the similar composition of materials. The I-beam shelf is laid on the pile heads and welded. At the corners, the beams are brought close to each other or cut at an angle, after which a seam is applied.

Threaded fit

It is more rational to use the presented method in the case of placing U-shaped screw piles. To install the foundation strapping with your own hands, you must perform the following steps:

- Install the grillage beam in the opening between the pile posts. Before laying the beam element in the U-shaped flange, we lay an insulating layer of roofing material treated with linseed oil.

- We fix the connecting elements. From the sides, we fasten the beam to the head by means of self-tapping screws, and directly to the pile - with anchors or through pins.

We recommend watching a video of how the timber is fastened with fasteners.

Additional fasteners

In order to increase the level of reliability at the joints, such areas are additionally fixed with metal brackets, the diameter of which is 8 mm. This measure is used when the length of the self-tapping screws is insufficient for a strong connection of the beams.

The brackets are installed in the upper parts of the timber, opposite the connection points. The pointed ends are driven into the solid surface of the timber, which has no grooves.

It is sometimes difficult to drive in an eight-millimeter bracket entirely, and it is recommended to perform this procedure in this way:

- marking is performed, for which the fastener is applied to the surface of the beam and outlined with a marker;

- along the applied line, a groove is arranged at 1 and 0.8 cm in depth and width, respectively;

- the places in which the legs of the bracket are to be immersed are drilled. Pre-prepared holes 5 - 6 mm in diameter will prevent cracking;

- each groove and hole is treated with antiseptic compounds;

- hammering of steel brackets begins, which should be immersed flush with the wood surface;

- at the intersection points of the beams, the "half-tree" docking option is used. Self-tapping screws are screwed in from the bottom, four staples are hammered so that they form a square.

Thermal insulation

The protection of the interior space under the house, where the pile-screw foundation is installed, is of paramount importance. The presence of cold air moving freely under the floor increases heat loss, and accordingly, the cost of heating the home increases.

It is enough to make a false base and insulate the pick-up. The result is the prevention of cold air penetration under the house.

The basement is insulated with polystyrene plates, and foam or extruded polystyrene foam is also used. These materials have a low thermal conductivity, which makes them ideal for home insulation. The second advantage is their durability, resistance to atmospheric precipitation and low weight.This means that there is no additional load on the foundation due to the insulation.

The procedure for warming the foundation:

- Waterproofing works are carried out for the pile heads and grillage. For this, roofing material is used;

- Then a false base is made of bricks or special decorative panels are used;

- Under the grillage, a brick wall is displayed. The brick itself lays down with an edge so that the thickness is half a brick.

Types of strapping

The strapping belt of the pile foundation can be implemented in different design options. They have their own capabilities and are designed to work with different loads and conditions.

There are the following types:

Wooden

A beam with a section of 200: 200 mm is used, or a pack of edged boards 50: 200. The beams are installed along the perimeter of the house (under the external load-bearing walls), along the lines of the internal load-bearing walls, and also tie the rest of the supports to equalize the loads and tie all the trunks to the common system ...

Corner joints are made into the floor of the tree, fastening to the tops is made through a double layer of roofing material for waterproofing.

The advantages of this solution are:

- Ease of processing, availability of material.

- The wood has sufficient strength and relatively low weight, which does not load the foundation.

- Installation is possible in the field, without the use of construction equipment or even without power tools.

The disadvantages of wooden types of strapping can be considered:

- Features of wood, tendency to warping or cracking, the need for high-quality waterproofing, etc.

- Fire hazard of wood.

- Possibility of damage to the material by insects or rodents.

Despite the obvious shortcomings of wood, a grillage from a bar is a common and popular option.

Metal grillage

Metal strapping requires the use of welded work.

From the point of view of installation, it has noticeable advantages:

- High connection speed.

- Strength, resistance to all possible loads.

- A wide selection of types of rolled metal, allowing you to get various options for strapping.

Along with the advantages, the metal strapping has disadvantages:

- The tendency of metal to corrode.

- The need for periodic maintenance of the structure (painting with moisture-proof polymer materials).

- Welded joints require the participation of a professional welder who is able to correctly select the operating mode and current strength. Otherwise, the seams will be brittle and brittle, which will create a significant danger to the building.

The main argument in favor of creating a metal strapping is high maintainability and quick assembly of the grillage.

The cost of rolled metal and welding is significantly higher than that of wooden beams.

Nevertheless, there are about the same number of supporters of this type of strapping as there are fans of wooden parts.

The strength and stability of the metal is highly valued by users and increases the competitiveness of the material.

Concrete strapping is almost a full-fledged analogue of the pile-strip foundation.

The fundamental difference is the distribution of loads - on pile-strip foundations, both elements share the loads equally, and the concrete grillage of the pile foundation only transfers the load to the supports, not performing the bearing functions as such.

At the same time, being only an intermediate element, the concrete piping allows you to get the maximum effect.

It has high strength, durability, and resistance to stress.

In addition, the concrete grillage is able to compensate for changes in the loads or bearing capacities of individual supports, redistributing or partially taking over new working conditions.

The advantages of this design are:

- Ensuring the maximum load-bearing capacity of the system.

- Independent of climatic or weather conditions.

- Relatively low need for periodic maintenance.

- Durability, material reliability.

The disadvantages of concrete elements are:

- The complexity of creation, the need to perform various sequential stages of work.

- Large volumes of materials (concrete, reinforcement, timber for formwork, waterproofing materials, etc.).

- The hardening of the piping requires a long period of time (28 days from the moment of pouring), during which no further construction is possible.

The construction of concrete strapping is usually chosen when erecting large and massive structures, where it is especially important to ensure the strength and reliability of the belt despite the high consumption of materials and labor costs