Installation of slabs

Let us consider the algorithm of actions for constructing a foundation made of flat foundation reinforced concrete slabs.

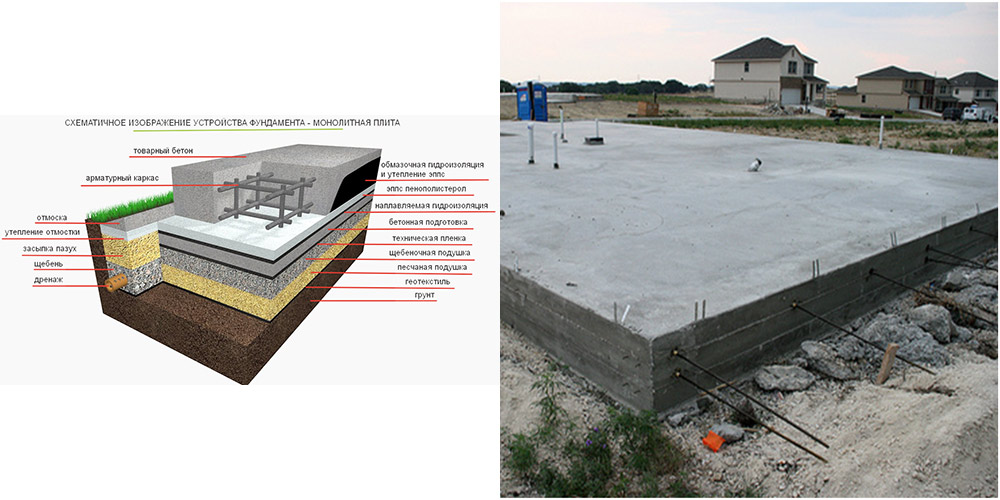

Preparation

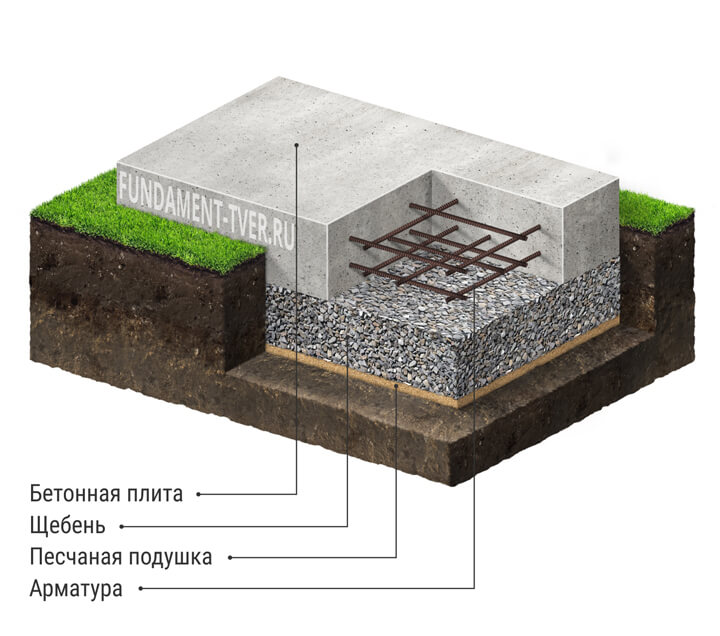

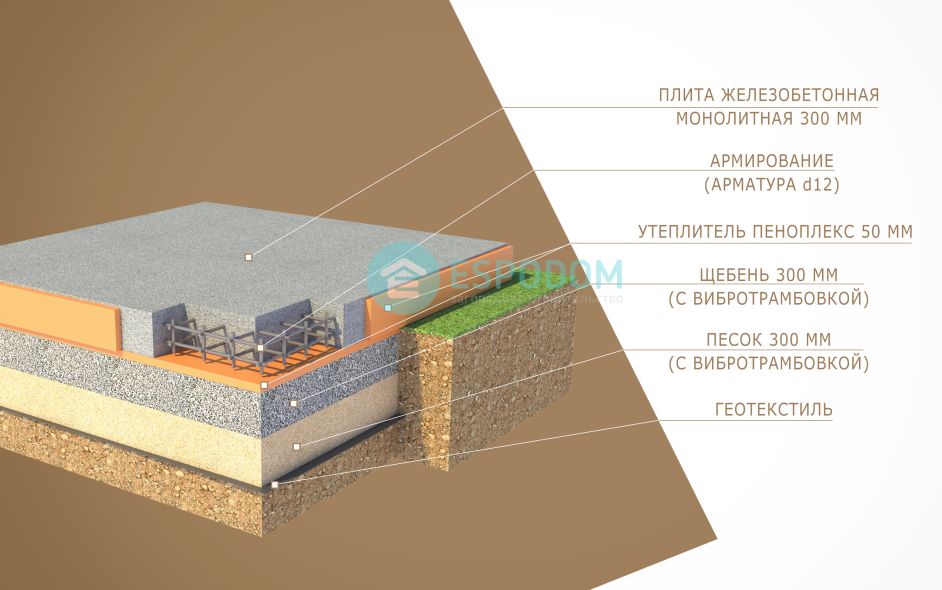

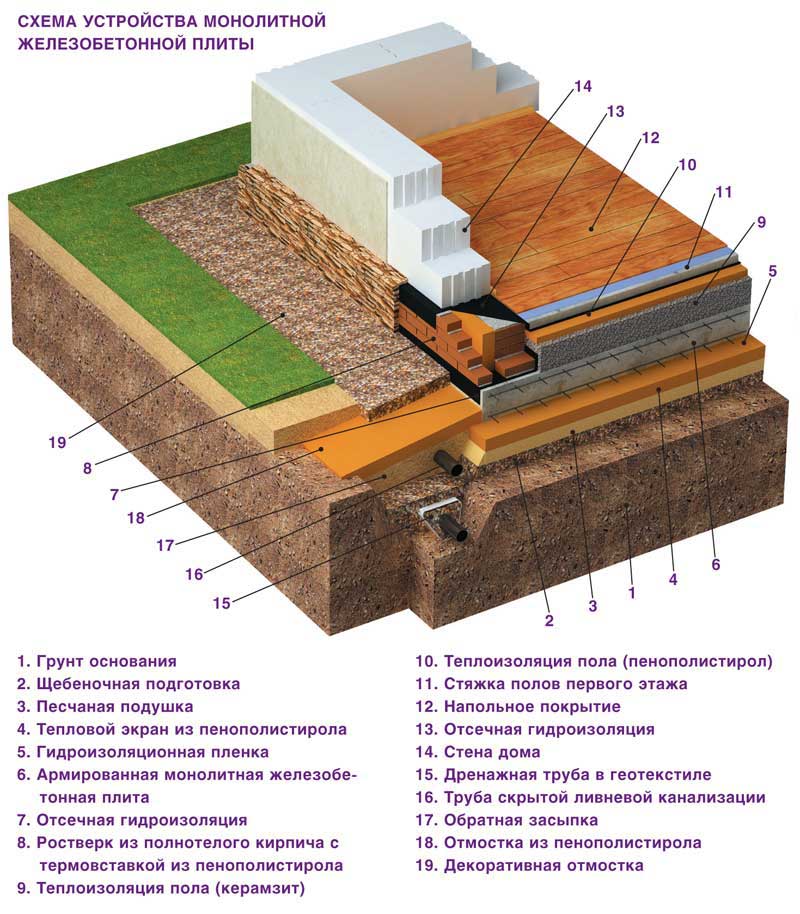

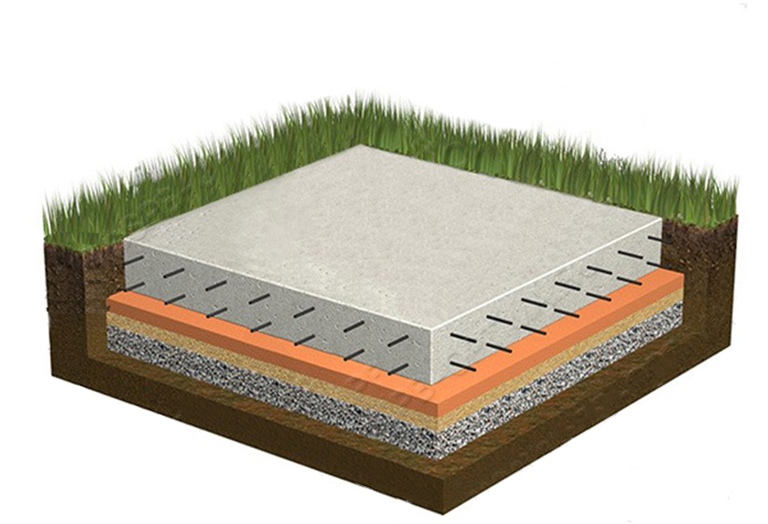

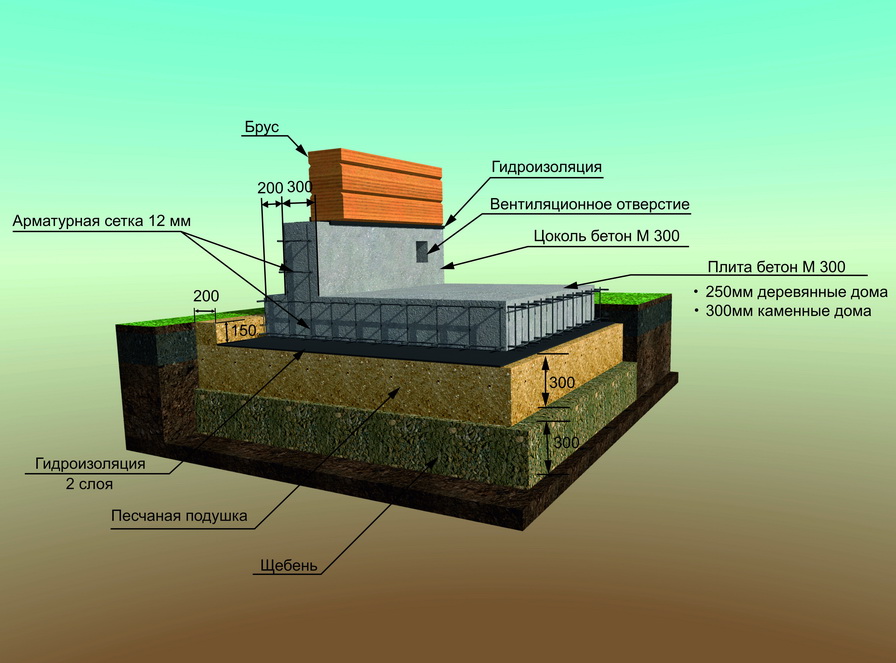

Certain preparatory work needs to be done. The slab should be laid evenly, carefully leveling the base and removing vegetation. A pit is being prepared for the entire area of the building being erected, the depth of which reaches fifty centimeters (the pillow and the thickness of the slab are taken into account)

Crushed stone and sand are poured into the bottom with a layer of fifteen to thirty centimeters, taking into account the heaving of the soil. Layers are filled with a height of eight to twelve centimeters, a thorough ramming is performed

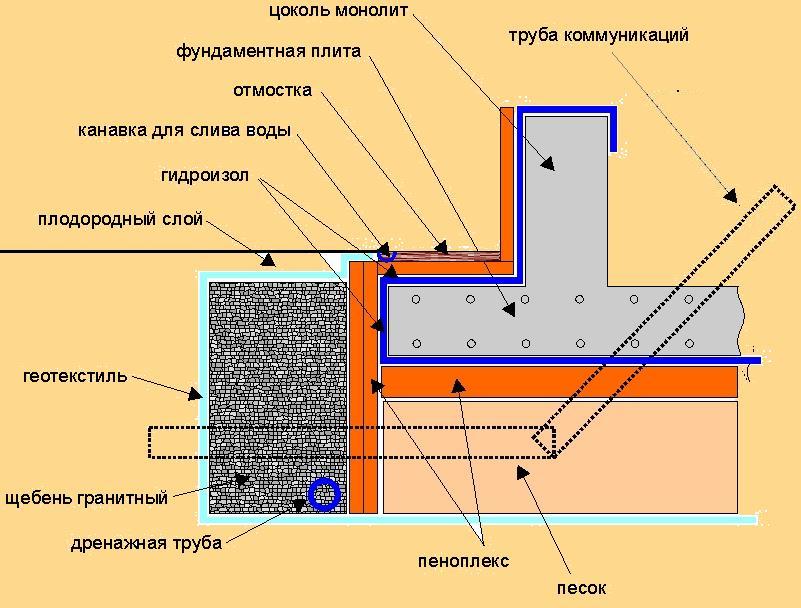

Waterproofing and insulation

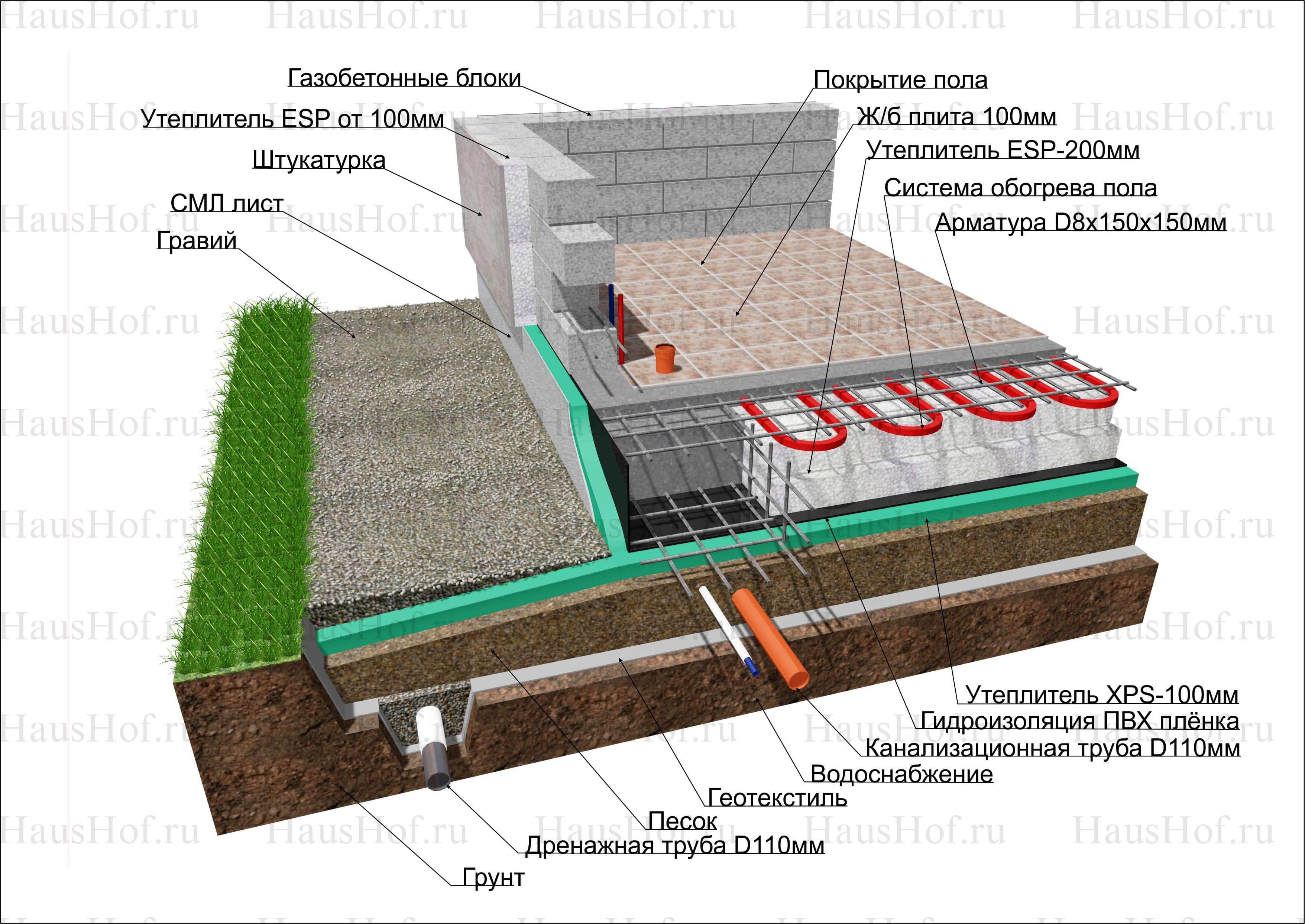

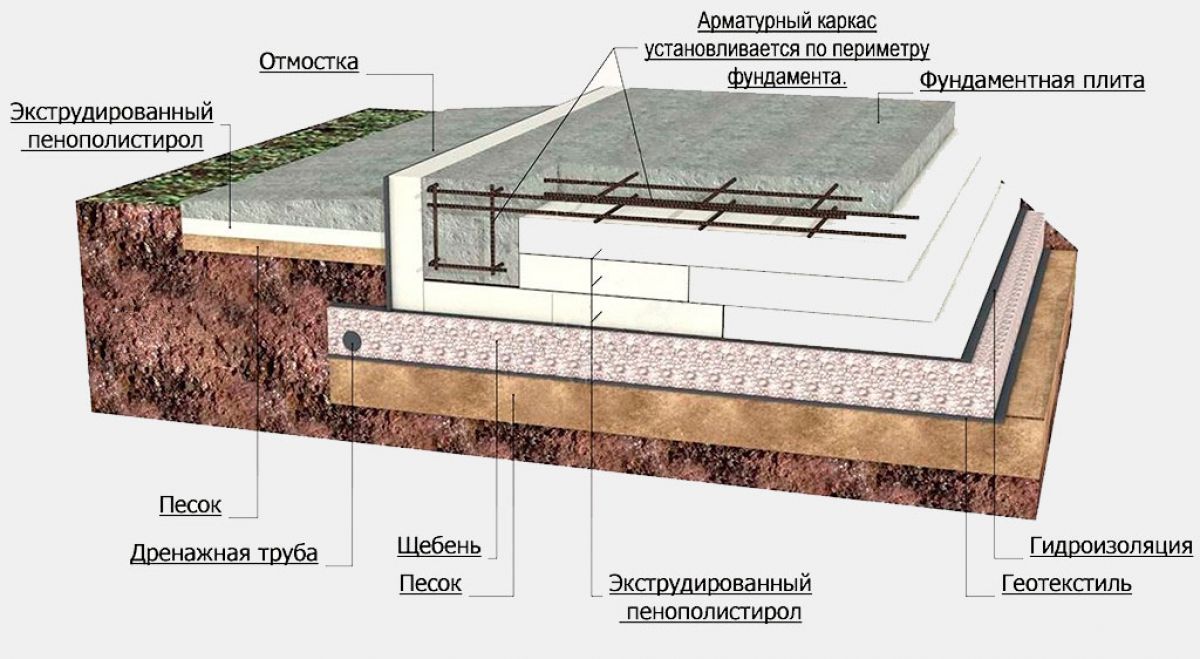

Lay a layer of waterproofing material on the prepared pillow. Most often, roofing material is used, from which two or three layers are arranged, leaving overlapping strips of fifteen to twenty centimeters.

A heat-insulating layer is arranged along the roll material. It is recommended to use foam plates or polypropylene foam as insulation. The main advantage of this material is excellent thermal insulation performance, increased resistance to the negative effects of moisture and low temperature conditions. It is allowed to make the insulation layer from expanded clay, pouring a ten-centimeter layer.

Installation of slabs

To cover the entire foundation surface, you will need a certain number of ready-made flat reinforced concrete slabs. Laying them is carried out using lifting mechanisms as close to each other as possible. The parameters of the thickness of the products are determined taking into account the expected load forces created by the future object.

Under light outbuildings, it is enough to lay slabs of standard sizes, the thickness of which varies between twelve and fifteen centimeters. For the heaviest objects, plates from twenty-five to thirty centimeters thick are used. The steel bars of the stacked products are joined together to create an overall reinforcing system. The surface of the laid slabs is carefully leveled with respect to each element.

Concreting

There are gaps in the joining areas of the laid slabs, which should be sealed with a mortar of sand and cement. For the preparation of the mixture, cement material of the m 300 and higher grade and sand, taken in a proportional ratio of "one to three", are used. As soon as the mortar dries, a leveling screed is arranged over the entire foundation surface.

For its implementation, a similar mortar mixture is used, pouring a layer from three to five centimeters thick. The main goal is to form a perfectly smooth surface, for which you will have to use a building level for control and a rule that needs to level the surface during work.

The next stage consists in proper drying of the poured screed, excluding the appearance of cracks on the surface. To prevent the material from sharply shrinking, the surface layer is periodically moistened for eight to ten days. To keep moisture longer, it is recommended to cover the screed with polyethylene material.

The device of the pillow under the base

A pillow is needed under the base plate, which is placed in a pre-prepared foundation pit. To properly lay the sand and gravel cushion, you can follow the step-by-step instructions, such as:

- First of all, medium or coarse sand is poured into the bottom of the pit.Without fail, the granules must be washed from clay, lime, as well as other typical impurities, due to which partial shrinkage of the structure will begin to form. This sand-based pad is required to ensure that the entire load transferred from the structure to the soil structure is uniform. Also, thanks to this installation, during the period of heaving of the soil, the foundation structure does not collapse.

- During the laying of the layers of the pillow, each of them is compacted separately. In simple words, a dense cake is formed, which contains several levels. Each of them has a height of 30 cm. Such a process of performing work is required so that after a certain period of time a residential building based on a slab foundation does not sink into the layers of the ground.

- At the stage of installing a sand cushion under the foundation, you can think about carrying out engineering communications, for example, such as: a drainage system and water supply. The rest of the types are performed much later.

- After the pillow is ready, spread a fabric consisting of geotextiles on top of it. This material will prevent sand and gravel from mixing.

- On top of the geotextile, gravel is covered with a layer of 20 cm. This pillow is necessary so that the moisture that forms on the surface does not linger near the concrete structure of the base, but gradually leaves through layers of gravel and sand into the soil.

- The gravel should be laid evenly on the sand cushion. Each layer is compacted without fail. In case of non-compliance with all requirements, the constructed building after a short period of time will begin to collapse from excessive shrinkage in the soil structure.

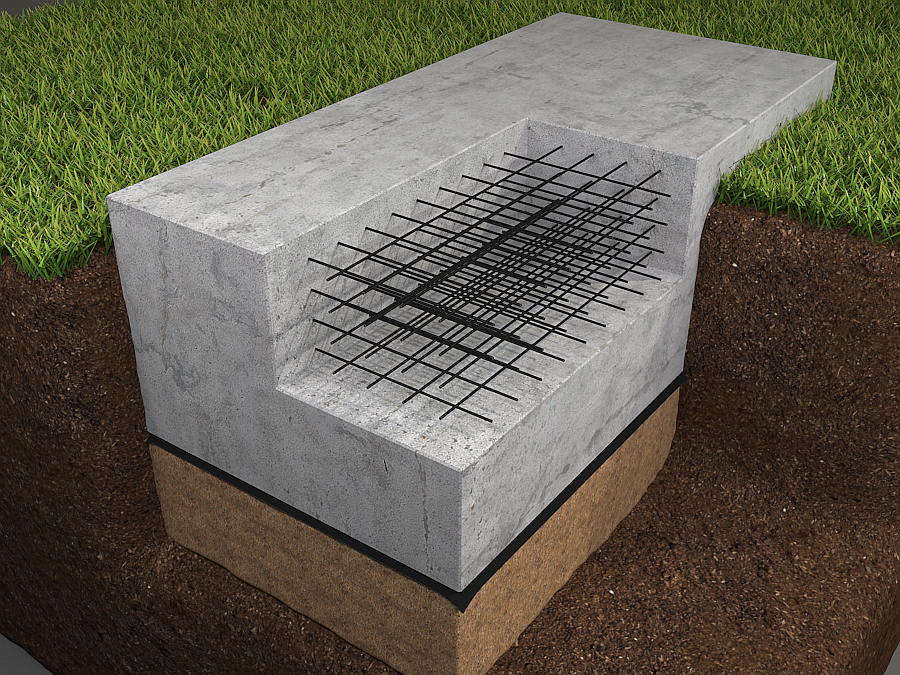

Design and calculation of the reinforcing frame

Concrete has excellent resistance to compressive loads, but poorly resists bending and stretching. If we talk about building a house on a foundation slab, then it is exposed to:

- the occurrence of a constant bending moment due to uneven loading on various parts of the structure;

- periodic impact associated with ground movements.

It is possible to actively resist the alternating soil pressure with the help of a metal frame. The so-called reinforcement belt copes well with bending and tensile forces, while the concrete actively resists compression.

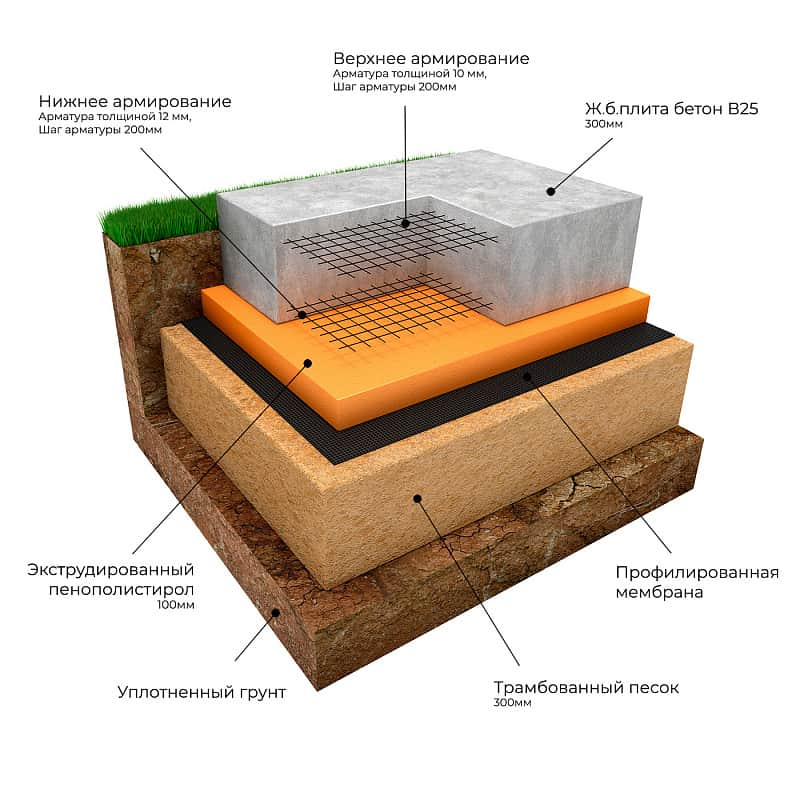

Reinforcement of the slab foundation is performed unevenly, with additional reinforcement around the perimeter, as well as in the zones of the location of walls and columns (experts call these areas punching shear zones). A slab with a minimum thickness (up to 150 mm) requires a single-layer reinforcement, while more massive structures require the construction of a reinforcing frame.

When determining the size of the cell, they are based on the design load. So, for brick walls, the reinforcement is fixed with a step of 200 mm, while when erecting lighter wooden or frame houses, the rods are knitted at a distance of 250-400 mm. At the same time, the width of the cell should not exceed the thickness of the foundation slab by more than 1.5 times. As for the pitch of the rods in the punching shear zones, there it is halved. This reinforcement of the frame prevents the appearance of cracks at the junction of the load-bearing walls and columns.

The distance between the frame bars can be different and depends on the area covered by the slab

If, when mounting an armored belt, the length of the rod is not enough to cover the longitudinal or transverse dimensions, then it is increased with rolled products of the same diameter. The connection is made with an overlap of 40 bar diameters, that is, for Ø14 mm reinforcement, the joint will be 40x14 = 560 mm.

With frame reinforcement, the rods are mounted in two tiers, with attachment to vertical rods. The step between these structural elements may differ from the cell width by 1.5–2 times.

The ratio of the cross-sectional area of the foundation and steel reinforcement laid in the longitudinal or transverse direction is 0.3%. The minimum diameter of the rods is 10 mm - such rods are used for slabs with a side of up to 3 m. For larger structures, rolled products with a cross section of 12, 14 and 16 mm are used. For vertical rods, rods with a minimum diameter of 6 mm are used, taking into account the method of fastening - welding or wire.

Reinforcement errors: 1 - it is forbidden to use stones as frame supports (spacers); 2 - vertical rods stuck into the ground will contribute to the spread of corrosion inside the slab; 3 - there is no waterproofing that prevents the absorption of cement laitance into the ground

DIY foundation construction technology

Here's a step-by-step guide to help you lay the foundation.

Pit preparation

The depth of the pit depends on the density of the soil:

- If the ground is very dense, then a depth of 50 cm will be optimal.

- If peat prevails on the site, then it is better to deepen the base by 1 m.

The bottom of the pit is leveled horizontally. If, in the process of its preparation, holes were formed in some places, then it is impossible to fill them with earth, only sand. Otherwise, the slab foundation for the house may shrink.

Substrate

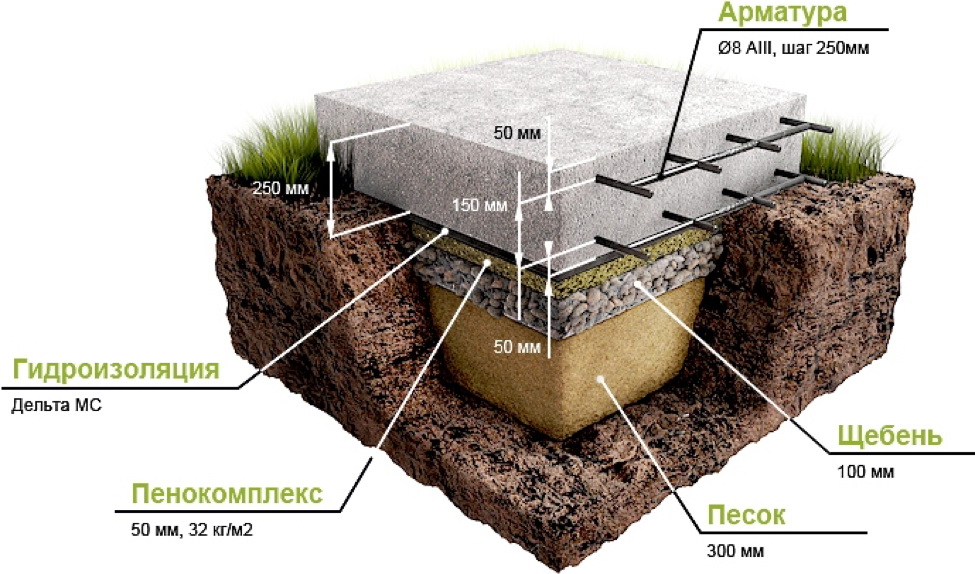

At this stage, it is necessary to prepare a pillow for the slab foundation. For this:

- Pour washed sand without impurities at the bottom of the pit.

- Tamp down the sand layer. If the pit is very deep, then tamping must be done in layers.

- If you plan to carry out communications, then you need to lay sewerage and water supply at this stage (gas and electricity can be carried out later).

- Place a gravel pad and compact it. Make sure that the crushed stone is distributed evenly and strictly horizontally; it is better to use a hydro level for this.

- Spread geotextiles over the pillow.

Formwork and insulation

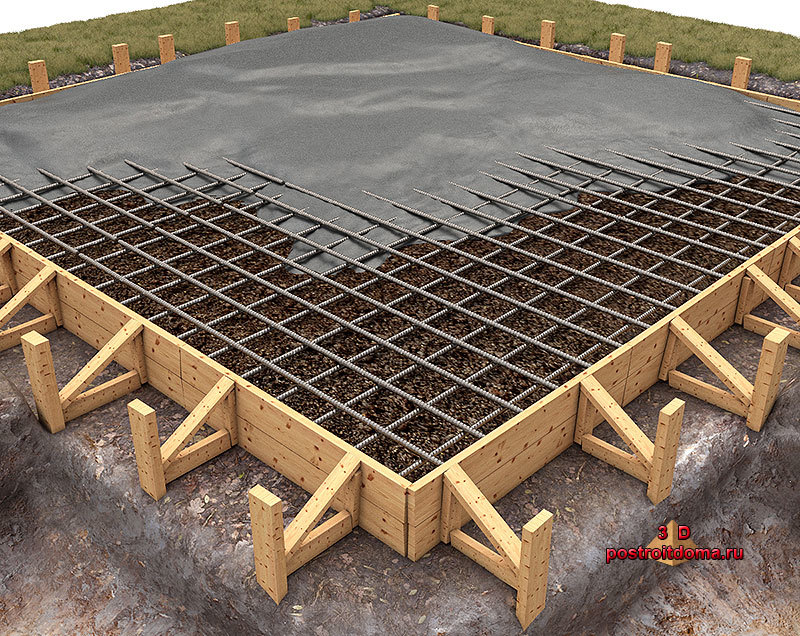

To prepare the formwork for the slab foundation, consider the following nuances:

- The formwork is exposed along the perimeter of the house, and not along the markings "with a margin" of 1 m.

- For construction, use boards of 50 mm.

- The formwork is exposed in height, which will be equal to the thickness of the monolithic slab. Use cords and a level to level it horizontally. If you do not do this, then before making the screed, you will have to set marks on the formwork itself (with such a marking, you can easily make a mistake).

- After that, waterproof the slab foundation. To do this, lay the material with an overlap on the formwork boards.

- Also at this stage, an additional layer of insulation can be laid under the waterproofing. For this, it is best to use high strength EPS.

The next stage is the insulation of the slab foundation is carried out using sheet material (for example, XPS expanded polystyrene), which must be laid in two layers. The height of both layers of insulation should be about 20 cm. The material should be laid close to each other.

Reinforcement and pouring

To perform reinforcement, the following step-by-step instructions will help you:

- It is necessary to knit a reinforced frame in two rows with a step of 20-25 cm.Place the lower lattice on special clamps, so that there is a distance of 5-7 cm between the waterproofing layer and the metal rods.

- The second row of reinforcement (top) is laid in such a way that after you pour the concrete, the lattice "disappears" in the cement by 5 cm, but not less.

- Connect both layers of reinforcement with vertical drains, which must be made from the same rods.

After that, the concrete is poured. It is best to use the M 300 composition grade for this.

It is necessary to pour the solution in one day - the shorter the intervals between the portions of concrete, the stronger and more reliable the base will be.

The poured foundation can only be leveled with the rule and wait until the base is dry (28 days for complete solidification).It is best if the weather is warm outside and the humidity is about 80%. It is also recommended to cover the base with polyethylene and moisten the concrete mass with water from a sprayer every day.

How to calculate the thickness of a foundation slab

Having decided on the type of slab foundation, they begin to calculate the parameters of a reinforced concrete slab. Its thickness is determined in such a way as to ensure the optimal specific ground pressure

It is extremely important to achieve balance in this matter, otherwise, with an excessive load on the ground, the house will sit down, and if insufficient, it will skew

When calculating, several factors are taken into account:

- type and characteristics of soil;

- the mass of the slab foundation itself;

- the weight of the building materials required for the construction of the building;

- payload in the form of equipment, furniture, utilities and infrastructure elements;

- snow and wind load.

Determining the thickness of the foundation slab for large-scale construction is a topic for a separate article. If it is necessary to calculate the base for a small residential building, then use a simplified technique.

- The total weight of the building with finishing and communications is calculated, after which the climatic (snow, rain, wind) and operational (environment, equipment, people) load is added to the obtained value.

- Based on the total weight and area of the structure in the plan, the pressure on the ground is calculated (the weight of the foundation is not taken into account).

- According to the data from the table below (numbers in brackets), the weight is determined, which is not enough to achieve the optimal load on the ground.

- Considering that the density of reinforced concrete is 2.7 g / cm3, and based on the area data, the thickness of the slab is calculated.

- The resulting number is rounded to the nearest 5 cm. In this case, the permissible deviation from the optimal pressure should be no more than 25%.

Table: calculation of the thickness of the slab foundation

| Priming | kgf / cm2 |

| Crushed stone, gravel | 5 |

| Sands are large, gravelly | 4 |

| Medium sands | 3 |

| Sands are fine and silty dense | 2 (0,35) |

| Fine sands of medium density | 1,5 (0,25) |

| Sandy loam hard and plastic | 2,5 (0,5) |

| Loams, hard and plastic | 1,5 (0,35) |

| Hard clays | 4 (0,5) |

| Plastic clays | 1,5 (0,25) |

An option is possible when the calculated value exceeds 35 cm.This suggests that when choosing the type of foundation, a mistake was made and the house can freely stand on a strip or columnar foundation. If it turned out that the thickness of the slab should be 15 cm, then this indicates the excessive weight of the building - in this case, it is better to entrust its construction to specialists.

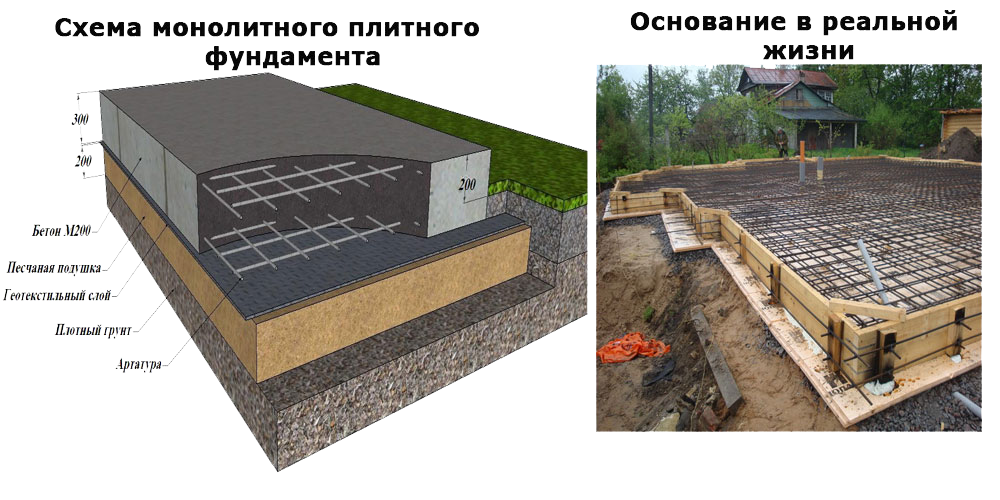

Varieties and characteristics of a monolithic base

The choice of a type of slab-type monolithic base depends on a number of factors:

A number of factors determine the choice of a type of monolithic base of a slab type

A number of factors determine the choice of a type of monolithic base of a slab type

- location of the slab surface relative to the zero mark;

- method of construction of the foundation structure;

- constructive version.

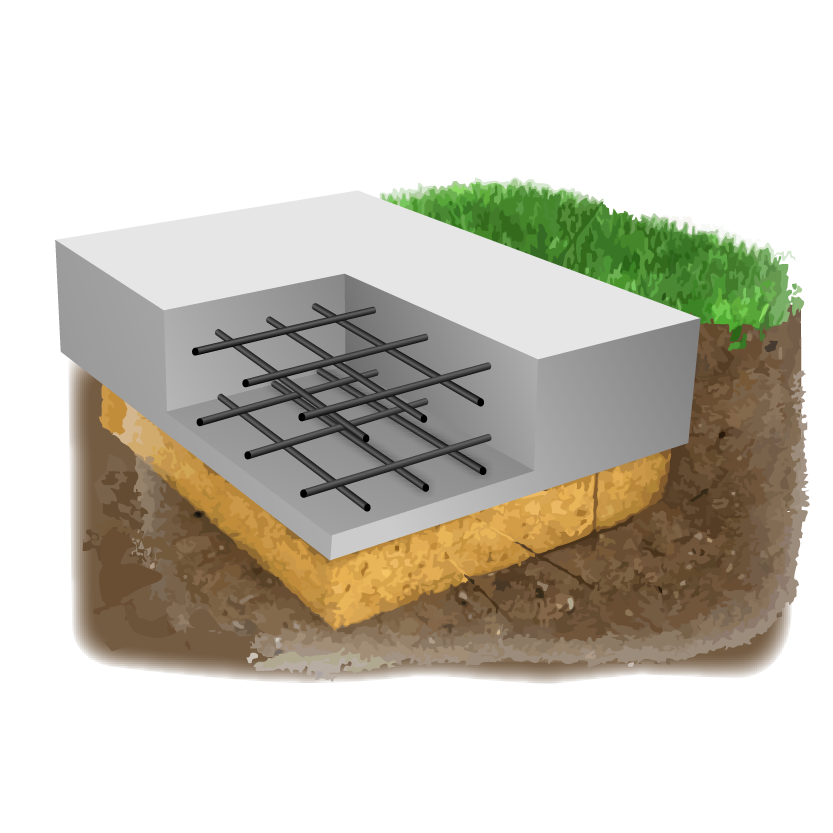

According to the depth of penetration into the soil, slab bases are classified as follows:

- unburied foundations. They are erected on a graded soil surface from which debris and vegetation have been removed;

- shallow foundations. The technology for the construction of the foundation slab provides for its immersion in the ground 40-50 cm below the zero mark;

- recessed foundations. The lower plane of the reinforced concrete foundation slab is located at or below the freezing depth of the soil.

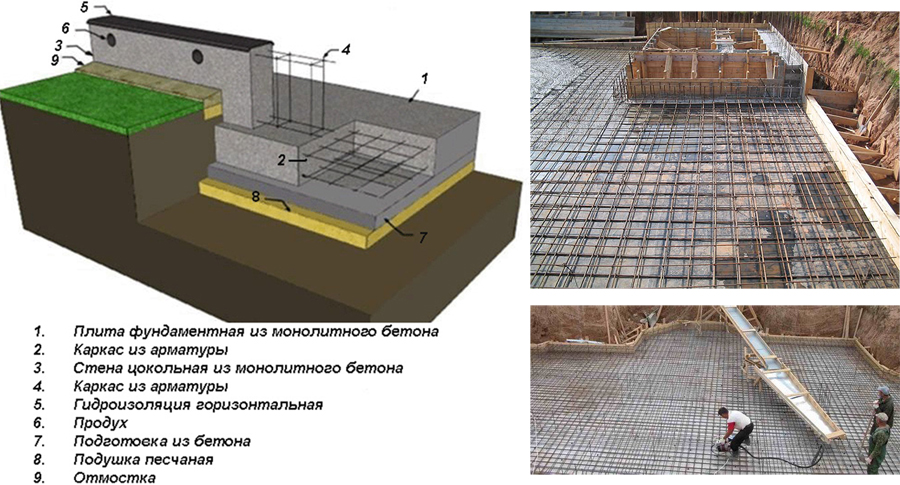

The way of arranging a solid slab is also different:

- a monolithic structure is being erected on a planned and cleaned site. The technology provides for the construction of a cushion, installation of formwork, waterproofing, reinforcement and concreting. No lifting equipment is required to build a solid slab. Engineering networks and necessary communications are placed inside the concrete base. The dimensions of the foundation platform are not limited;

- the prefabricated version is constructed from standard slabs manufactured in an industrial environment. The panels are laid on a crushed stone-sand bed using a crane. After the completion of the installation operations, the butt sections are filled with mortar. Reinforcement of the prefabricated platform with the subsequent pouring of the screed layer is allowed. The thickness and dimensions of the prefabricated structure are regulated by the dimensions of the finished panels.

This option of the foundation is considered one of the available ones.

This option of the foundation is considered one of the available ones.

The following slabs are constructed, differing in design features:

- bowl-shaped platform. It is a complex structure that allows you to build a spacious basement under the house;

- flat foundation. It is made in the form of an ordinary plate, which is additionally insulated with a sheet heat insulator.

Let us dwell on the characteristics of a solid foundation slab, which is distinguished by the following properties:

- increased load capacity. The solid structure of the reinforced concrete slab does not collapse, taking on the weight of the structure and the reaction of the soil;

- increased moisture resistance. A properly constructed monolithic foundation does not allow moisture to penetrate through the foundation to the walls;

- long term of use. The reinforced concrete platform guarantees the stability of the buildings over a long period.

The dimensions of the slab are made in accordance with the dimensions of the structure being erected, and the thickness depends on certain conditions:

- the stability of buildings on normal soils is ensured with a platform thickness of 40-50 cm;

- for the reliability of buildings erected on problem soil, the thickness should be increased to 100 cm.

The operational characteristics of a monolithic platform are also determined by the brand of concrete solution, the diameter of the reinforcing bars and the structural version of the slab.

In accordance with the dimensions of the structure being erected, the dimensions of the slab are performed

In accordance with the dimensions of the structure being erected, the dimensions of the slab are performed

Professional builders and private developers have become convinced of the many advantages of a monolithic structure:

- constructive simplicity. The base configuration follows the outline of the building. The construction of a monolithic platform is carried out in a limited period of time;

- the economy of the design. As a result of the construction of a solid slab, there is no need for a floor arrangement. This saves money;

- increased strength. Thanks to the use of high-quality concrete and the correct diameter of the reinforcement, the slab foundation prevents wall deformation;

- versatility. The monolithic foundation is used for various types of buildings, provides durability on moving, wet and freezing soils;

- frost resistance. The strong construction of the reinforced concrete slab does not crack as a result of seasonal temperature fluctuations that cause ground movement.

Along with the advantages, the design also has weaknesses:

- the complexity of the construction of a solid slab in a sloping terrain;

- increased costs and increased labor intensity of work;

- the need to perform additional volumes of earthworks for the buried base.

Slab foundation erection technology

Like any type of foundation, a monolithic slab is erected in several stages. Let's consider each of them in more detail.

Preparatory work

At this stage, it is necessary to prepare a site for construction. To do this, you need to clear the area from various contaminants and debris, and also remove the upper part of the soil (about 10 cm). After that, the markup of the future foundation is performed. As a rule, this will require pegs and fishing line, the first are hammered in the corners of the future base, and between them the fishing line is pulled along the perimeter

When marking, it is important to check the correct angles, for this you can use a square

Pit preparation

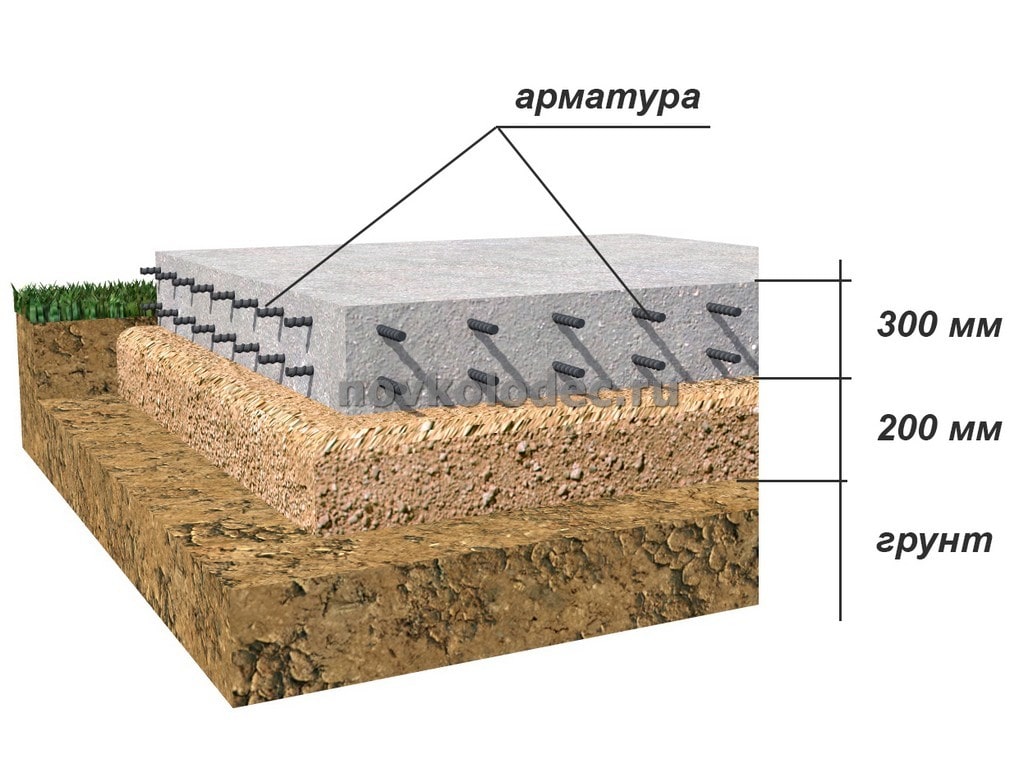

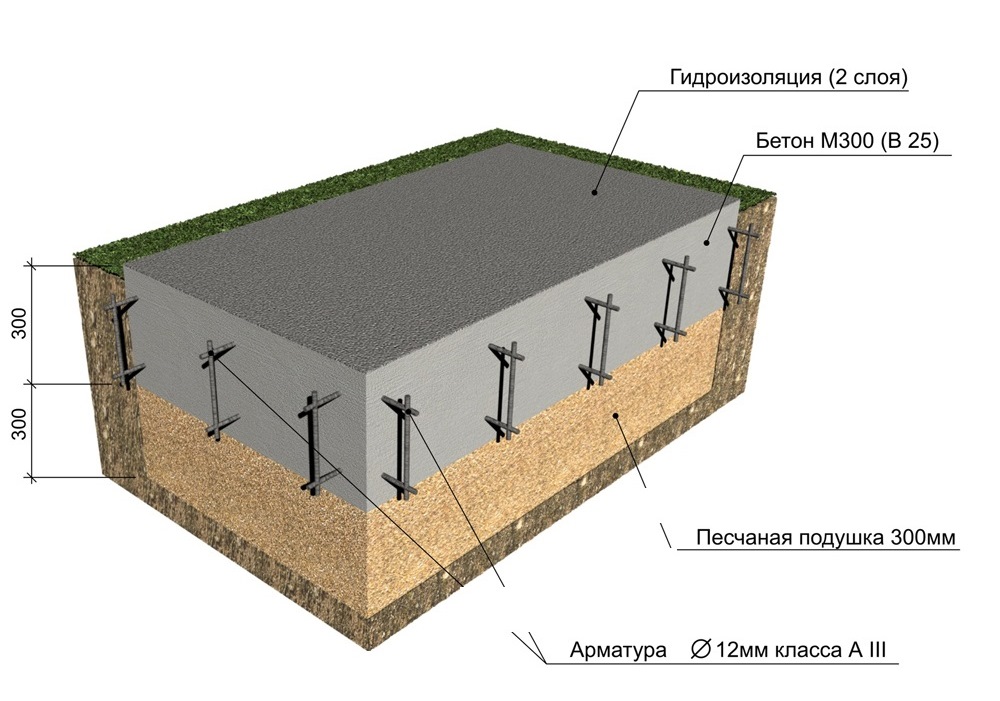

When the marking of the territory has been carried out, you can start digging a pit. To do this, you can use a special technique or do it manually.The depth of the pit is usually about 30-40 cm.

Next, you need to make a sand cushion that will distribute the load along the entire perimeter of the foundation. The sand must be poured into several layers, while each of them must be well watered and tamped until traces cease to remain on the surface of the pillow. The thickness of the cushion is usually 15-20 cm. Also, to prevent damage to the cushion during work, it can be covered with 100 mm of cement screed.

Formwork execution

For the manufacture of formwork, boards or plywood are most often used. The thickness of the boards is usually around 25 mm or more. Boards must be knocked down into shields and installed around the entire perimeter of the future foundation. To prevent the formwork from bursting during the pouring of the foundation, spacers are installed on the outside. You can find more details on our website in the formwork section.

Reinforcement of the foundation

For the reinforcement of the foundation, steel reinforcement of a periodic profile is used, the diameter of which is from 12 mm. The diameter depends on the thickness of the foundation itself and on the type of building. For example, for a foundation about 30-40 cm thick for a one-story or two-story house, it will be enough fittings with a diameter of 14 mm, which is laid in two levels along and across with cells of about 20x20 cm. The armature is tied with a knitting wire with a special hook, or welded.

Pouring concrete

It is best to pour the concrete solution at a time using a concrete mixer, since it is very laborious to make the concrete mixture yourself and requires a large number of people. During the pouring process, the concrete solution must be treated with a deep vibrator in order to expel all air from the solution that can affect the strength of the structure. After complete pouring of concrete, the surface of the foundation must be leveled and smoothed.

Final work

7 days after pouring the concrete, when its strength reaches about 70%, the formwork can be removed, and the waterproofing material can be wrapped on the surface of the foundation and fixed. It will not be possible to erect walls earlier in 3-4 weeks, since it is during this time that the foundation will reach its maximum strength.

In conclusion, it must be said that you can make a slab foundation yourself, it is only important to observe the technology of its manufacture.

How to fill the solution correctly

In order for the house to stand on a solid monolithic foundation, it is necessary to unload the solution in an even layer over the entire area. The number of mixers or concrete mixer preparations is counted to meet this requirement. Sectional application is unacceptable due to the appearance of transverse seams, which reduce deformation resistance to loads. Watch a video on how to properly fill a monolithic slab.

Quality improvement techniques

Practice shows that solidity is achieved when performing the following operations:

- Pour evenly at several points. If the entire mass spreads from one place, then solidification will be uneven;

- Moisten the surface of the settling foundation for the first 12-14 days;

With a casting thickness over 0.4 m, it is advisable:

- Plow the first layer of concrete with your own hands so that the air trapped in the mortar jet can escape;

- Approximately on the 10th day (no footprints on the concrete should already appear), holes are drilled with a hammer drill every 6 m². They will protect the solidified mass from cracking. After complete hardening, they must be covered with mastic.

In what cases is a slab base used

If you do not plan to build a basement, then a slab foundation will suit you.

If you do not plan to build a basement, then a slab foundation will suit you.

If you carefully consider the various supporting structures of a residential building, then the slab part of the foundation is poured in such cases as:

- if there are soils on the construction site that have a weak density and unstable characteristics;

- in residential buildings that do not provide for a basement;

- buildings in which the slab foundation acts as a floor, but in this case it is necessary to protect the upper layers of the concrete structure from moisture and insulate it.

The technology that requires a slab foundation for a brick house is often used in regions with large drops in air temperature. As a result, strong heaving of the soil structure occurs.

Slab foundation device

Slab foundation device

For the construction of the foundation slab in regions where the soil freezes to a great depth, special thermal insulation is used. In the process of construction, this material is first laid, after which the construction of the base is carried out.

Extruded polystyrene foam is used as a heater. It has many positive characteristics, due to which it is considered not only reliable, but also practical. The whole process of insulation and waterproofing is carried out at the initial stage of installation of a concrete foundation slab. After completing the preparatory work, you can safely mount the monolithic base. In practice, the foundation built using this technology serves for a long period of time.

Use

Use