Diy calculation of strip foundation reinforcement

Any construction work is standardized by GOSTs or SNiPs. Reinforcement is no exception. It is regulated by SNiP 52-01-2003 "Concrete and reinforced concrete structures". This document specifies the minimum amount of required reinforcement: it must be at least 0.1% of the cross-sectional area of the foundation.

Determination of reinforcement thickness

Since the strip foundation in the section has the shape of a rectangle, the sectional area is found by multiplying the lengths of its sides. If the tape is 80 cm deep and 30 cm wide, then the area will be 80 cm * 30 cm = 2400 cm2.

Now we need to find the total area of the reinforcement. According to SNiP, it must be at least 0.1%. For this example, this is 2.8 cm2. Now, by the selection method, we determine the diameter of the rods and their number.

Quotes from SNiP, which relate to reinforcement (to enlarge the picture, right-click on it)

For example, we are planning to use reinforcement with a diameter of 12 mm. Its cross-sectional area is 1.13 cm2 (calculated by the formula for the area of a circle). It turns out that in order to provide recommendations (2.8 cm2) we need three rods (or they also say "threads"), since two are clearly not enough: 1.13 * 3 = 3.39 cm2, which is more than 2.8 cm2, which SNiP recommends. But it will not be possible to divide three threads into two belts, and the load will be significant on both sides. Therefore, four are laid, laying a solid margin of safety.

In order not to bury extra money in the ground, you can try to reduce the diameter of the reinforcement: calculate under 10 mm. The area of this rod is 0.79 cm2. If we multiply by 4 (the minimum number of bars of working reinforcement for the strip frame), we get 3.16 cm2, which is also enough with a margin. So for this version of the strip foundation, you can use class II ribbed reinforcement with a diameter of 10 mm.

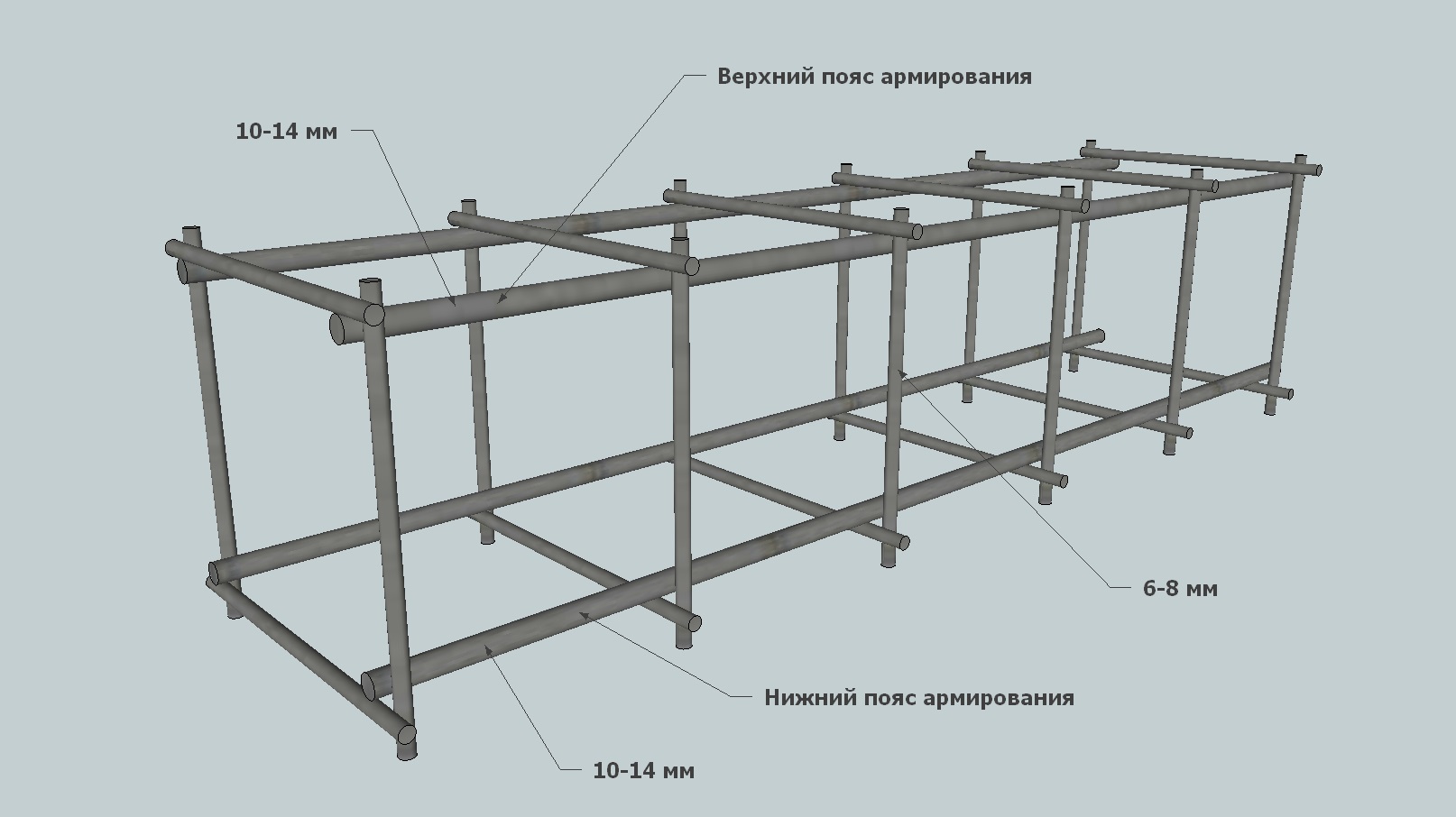

Reinforcement of the strip foundation for a cottage is carried out using rods with a different type of profile

We figured out how to calculate the thickness of the longitudinal reinforcement for the strip foundation, you need to determine with what step to install the vertical and horizontal jumpers.

Installation step

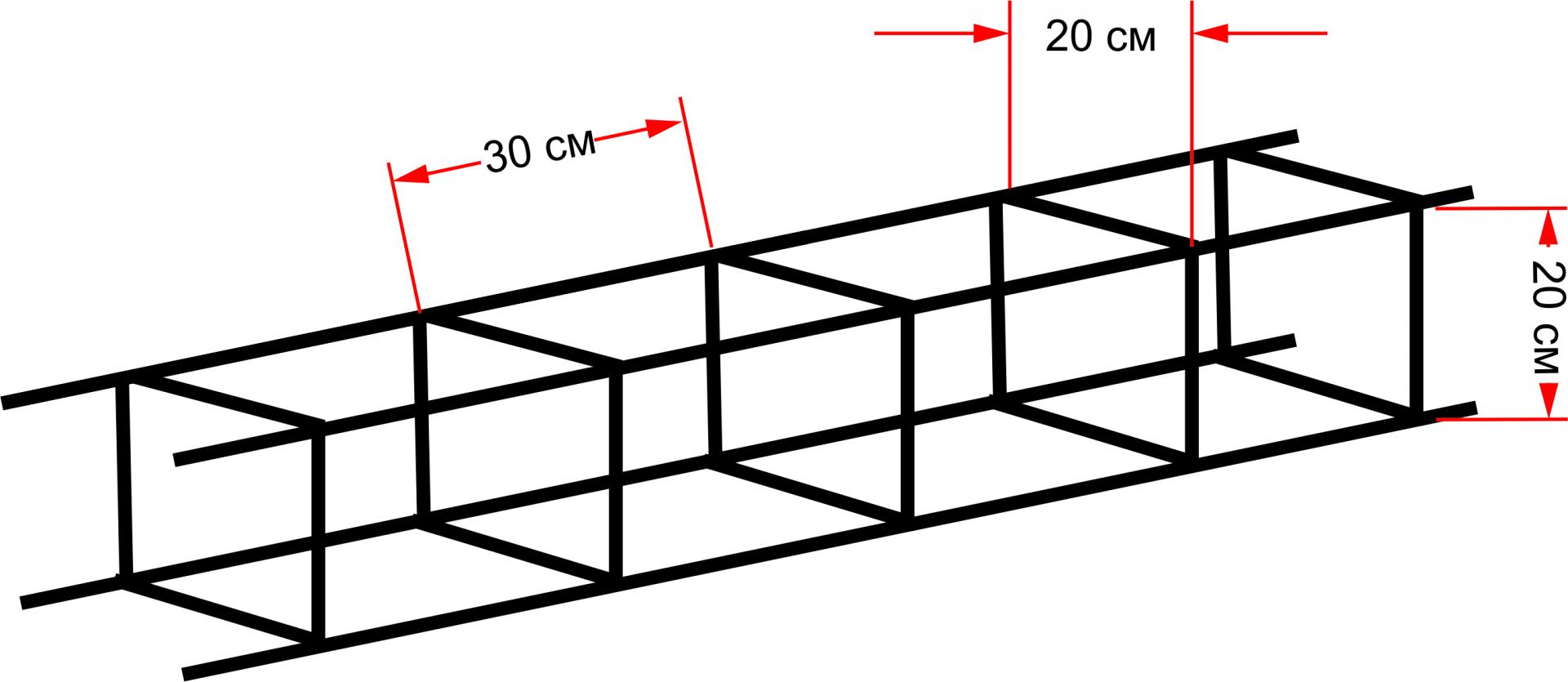

There are also methods and formulas for all these parameters. But for small buildings they do it easier. According to the recommendations of the standard, the distance between horizontal branches should not be more than 40 cm. They are guided by this parameter.

How to determine at what distance to lay the reinforcement? In order for the steel not to corrode, it must be located in the thickness of the concrete. The minimum distance from the edge is 5 cm. Based on this, the distance between the bars is calculated: both vertically and horizontally, it is 10 cm less than the dimensions of the tape. If the width of the foundation is 45 cm, it turns out that there will be a distance of 35 cm between the two threads (45 cm - 10 cm = 35 cm), which corresponds to the standard (less than 40 cm).

The step of reinforcement of the strip foundation is the distance between two longitudinal bars

If our tape is 80 * 30 cm, then the longitudinal reinforcement is at a distance of 20 cm (30 cm - 10 cm). Since for foundations of an average foundation (up to 80 cm high), two reinforcement belts are required, then one belt from the other is located at a height of 70 cm (80 cm - 10 cm).

Now about how often to put jumpers. This standard is also in SNiP: the step of installing vertical and horizontal dressings should be no more than 300 mm.

Everything. We calculated the reinforcement of the strip foundation with our own hands. But keep in mind that neither the mass of the house, nor the geological conditions were taken into account. We relied on the fact that these parameters were used to determine the size of the tape.

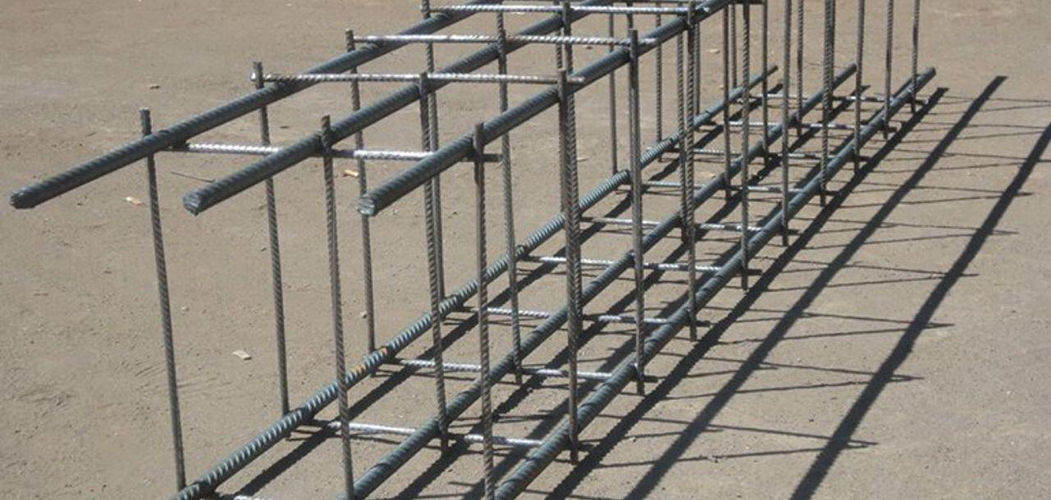

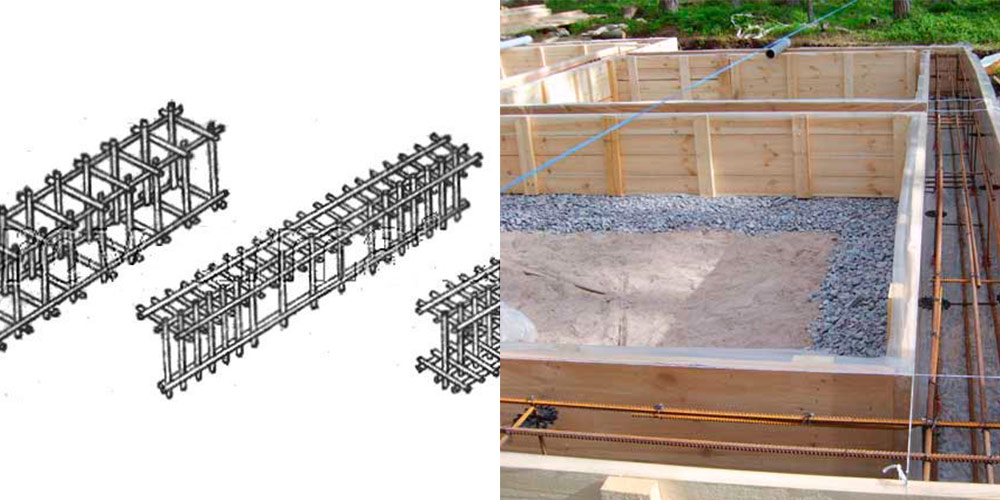

The process of tying reinforced cage on the ground

First, the straight sections of the frame are knitted on the ground, and after that they are installed in the foundation formwork and the connecting corners are installed.

Stage 1. To correctly determine the size of the frame, you need to remember that it must be filled with concrete from all sides by about five centimeters. With this information in mind, you need to prepare the wire and rods. The length of the wire for one node is about 20 cm. It is better to start making the frame from the smallest section of the foundation.

Step 2. Place the two lower rods on a flat surface and carefully align.

Step 3. About 20 cm from the ends of the rods, you need to tie the horizontal rods. To do this, a piece of wire is folded in half and with the help of it the metal elements are connected with the usual scrolling movements. In this case, the density of the knot should be moderate - not too tight, but not loose either.

Stage 4. At a distance of about 50 cm, you need to tie the rest of the longitudinal elements in the same way.

Stage 5. In the same way, you need to make the upper part of the frame.

Stage 6. The finished parts must be placed opposite each other on their side so that the parts take a stable position. The distance between them should be exactly the length of the vertical bars.

Step 7. Tie the remaining side pieces in a regular manner, while checking the dimensions of the blanks to ensure correctness. Have one side connected? Fine! Flip the frame blank and continue.

Step 8. Using the above mini guide, make all the straight pieces for the foundation.

Step 9. Place the frame on the spacers in the formwork to a height of more than 5 cm.

Step 10. Measure the corner sections and make according to the values of the workpiece.

Step 11. Attach the lower pivot parts first, then the vertical and upper ones. Remember that the overlap must be at least 50 cm.

Material selection and reinforcement rules

Reinforcement is a mandatory procedure when building the foundation of a future building. The frame is assembled from metal rods of various diameters and with different surfaces. In the course of work, rods are used:

- smooth;

- equipped with ribs;

- with a diameter of 12-16 mm;

- section 8-10 mm;

- strength class A2 and A3.

In addition, for the construction of a solid, high-quality structure, you will need knitting wire or plastic clamps, as well as a device with which you will need to bend the reinforcing bars to use them when strengthening the corners.

The main frame tape is assembled from ribbed rods with a diameter of 14 mm, which take on the maximum loads, the transverse lintels are made from rods with a smooth surface and their thickness does not exceed 9 mm. Sufficient immersion of the frame in concrete avoids the destructive effect of corrosion. The thickness of the mortar layer in the upper part of the structure should not be less than 5 cm.

By itself, concrete is not able to withstand deformation and compression, the reinforcing cage ensures the stability of the foundation to increased loads, creating a rigid fixation for the finished base structure. Guidelines for the selection of reinforcing bars and the assembly of the frame indicates the need for calculations that determine the level of loads on the base of the building.

An important condition for creating a high-quality reliable foundation is strict adherence to the established distances from the metal parts of the structure to the surface of the foundation. The reinforcing frame of the strip foundation is a structure in which transversely fixed elements, located at a certain distance from each other, play an important role

Strict adherence to these distances (steps) guarantees the creation of a strong frame that can withstand increased loads and resist deformation

The reinforcing frame of the strip foundation is a structure in which transversely fixed elements, located at a certain distance from each other, play an important role.Strict adherence to these distances (steps) guarantees the creation of a strong frame that can withstand increased loads and resist deformation.

The steps in question are calculated in advance, and their magnitude is reflected in the project documentation. They depend on the depth of the foundation and do not exceed 25 cm. There are also restrictions on the size of the cells that make up the reinforcement cage. If the depth of each cell depends on the forthcoming loads, then the length is at least 40 cm, and the width should not be less than 30 cm.

Reinforcement scheme for strip foundation

Reinforcement scheme for the strip base of the building

Reinforcement scheme for the strip base of the building

Almost all builders practice reinforcement using ready-made geometric shapes - a square or a rectangle. Columnar foundations are reinforced in a circle. The reason for this lies in the perfectly correct shapes of the reinforcing cage, because straight lines and precise connections guarantee the strength of the structure as a whole.

To make the frame correctly, you need to observe the thickness of the cushion right in the trench, taking into account the necessary margin for waterproofing and a protective layer of concrete. Therefore, even after pouring concrete of the reinforcing cage, the difficulties in erecting the base do not end. Now you need to properly and carefully close the surface with waterproofing, and it is strictly forbidden to damage it.

It is the strip foundation that is considered the simplest and cheapest foundation in private construction. Such a base is cheap to build, since a minimum of labor is used here, there is no need to rent powerful construction equipment, and there is no need to use more expensive powerful and durable reinforcement.

The only difficulty is that you have to do complex mathematical calculations of the reinforcement, correctly install the belts and connect them with high quality.

Specificity of mating

The production of reinforcing cages with fixation of elements with a knitting wire is carried out by the following methods:

manual strapping of fittings, which is characterized by increased labor intensity, requiring significant efforts, high time consumption. The rods are fixed at the joints using annealed wire with a diameter of 0.8-1.2 mm. With the manual method, pliers or a special hook are used to perform knitting, the use of which allows you to firmly twist the ends of the wire, to ensure the fixation of the rods;

Reinforcing bars are connected together with special wire

an automated method involving the use of a special knitting gun. The device guarantees a high-quality connection of bars, fast execution of operations. The time required to fix a pair of rods does not exceed one second. The gun is used when performing significant amounts of work.

Reinforcing frames, the elements of which are fastened with knitting wire, are characterized by strength, ensure the durability of the foundation being erected.

Knitting fittings with your own hands

With all the variety of specialized construction tools, not all private developers have the opportunity to buy or rent them. An expensive tool is not required for knitting rods, and you can also do it yourself.

To do this, you need to purchase a steel knitting wire. It is flexible and strong enough, has a diameter of 2-3 mm. To bend it, you will have to use pliers or a specially made hook, which is subsequently twisted around the reinforcement and fixes it. Some craftsmen doing reinforcement with their own hands sometimes use a screwdriver as an easier and easier way to knit. If you knit with wire, then this will require:

-

One of the options for knitting the base frame using a crochet hook. Craftsmen sometimes use a screwdriver as an easier way to knit reinforcement rods with their own hands. cut a piece of wire about 30 cm long.It is possible and more, if you do not mind her, but the ends will interfere (including excess waste);

- then fold the wire in half to increase rigidity and strength;

- bend it diagonally around the reinforcement joint and make a small loop;

- install the hook into the loop and evenly, without unnecessary effort, twist clockwise until it becomes difficult to wrap, or the connection becomes strong enough. The main thing is not to use force, since the wire is easy to break and then you have to start all over again;

- Cut off the ends of the wire with pliers and discard.

In the case of reinforcement of a columnar foundation, the reinforcing cage can be bent and then fixed on the heads with special clamps. Some manufacturers already supply metal or wood piles with special clamping brackets and couplings. In this case, it is enough to bend the rod and insert it into the bracket. Clamp the staple and boil it on top, you can do all this with your own hands, using a minimum of tools. In the case of using smooth reinforcement, the knitting process is more laborious, since the hooks will constantly bend back and you cannot do without an improvised specialized tool, as well as without outside help.

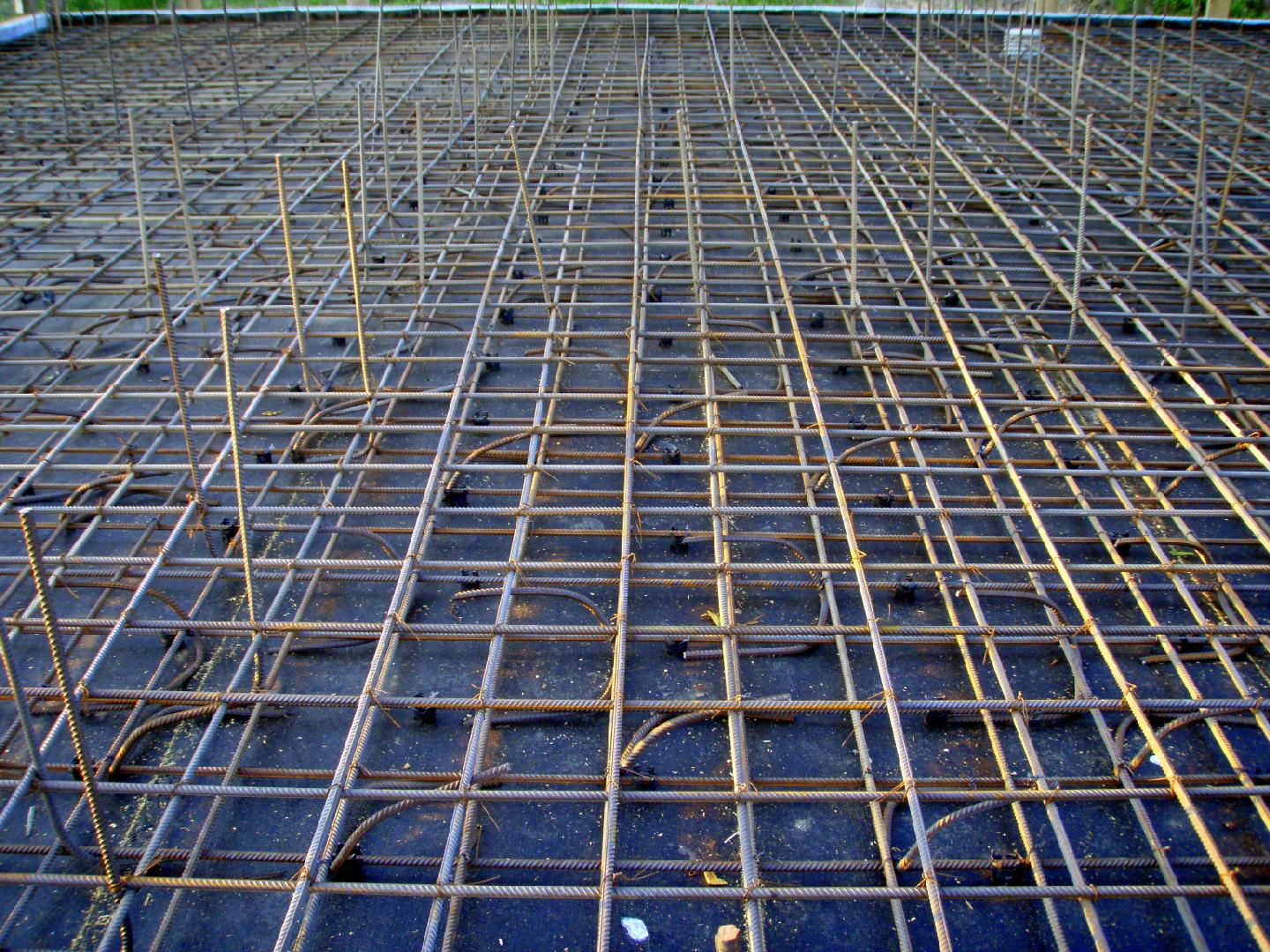

It is better to tie a reinforcing cage for a slab monolithic foundation from several belts. For the horizontal tier, spiral rods with a cross section of up to 16 mm are used, and for vertical links - smooth rods up to 10 mm. When installing the lower mesh, it is recommended to use plastic expansion joints, which will create an even spacing

Then, when knitting vertical rods, it is important not to forget to bring them outside the foundation, in view of the fact that the bearing walls will be connected to them

Using plastic cable ties for knitting is a more expensive option for replacing the wire, but cable ties (ties) can be found in any household. The strapping principle is the same, but the plastic for the screeds is less durable. Therefore, it is better not to use force during installation. The most popular clamps with a special core at the end of the tie, with their help, fasten cables and pipes to vertical surfaces. Plastic showed itself perfectly when knitting with your own hands in warm weather, in cold weather it quickly loses its elasticity and bursts.

Mating video:

Important rules for knitting reinforcement and basic SNiP

Before you start to embroider your future foundation with reinforcement or wire, you need to roughly calculate the load on it in order to determine which section of the bar you need. You do not need to know for sure, since they always take with a margin. For example, when building a temporary metal structure with a wall weight of up to 400 kg / 1 m2, you can use reinforcement with a diameter of 8 millimeters. When building a garage from a cinder block with walls up to 3 meters in height, a rod with a cross section of 12 millimeters is used. If you are building a two-story cottage, then you will have to embroider with more serious metal - a diameter of 14-18 millimeters.

Of course, you can give this project for calculations to experienced specialists who will save money and select the minimum permissible value, but if a few thousand rubles do not play a big role, take it with a margin. Often there is a desire to complete a floor with an attic or to make a multi-level heavy roof - the base must be ready for such a "turn of events". There are several SNiPs that regulate the manufacture of this design. Let's consider them in more detail.

- SNiP 7.3.4 states that the minimum distance between two vertical rods should be no less than the section of the reinforcement itself, and preferably 2-3 times more. The maximum value is not indicated, since it is already chosen personally for each project, depending on the method of masonry, the presence of a sealant, the grade of cement, the quality of the aggregate and other factors.

- SNiP 7.3.6. The distance between two parallel longitudinal rods should be no more than 40 centimeters. The greater the load on the base, the smaller this distance will be.The minimum distance for a strip foundation is 10 centimeters with a reinforcement diameter of 14 mm.

- SNiP 7.3.7 regulates the pitch of the transverse reinforcement. A value of not more than half of the working height of the section should be taken, but, in no case, it should not exceed 30 centimeters.

Adhering to these SNiP, you will get reinforcement according to the "book standards". But there are several rules that were specially developed by builders to facilitate the process of establishing the foundation. These recommendations have been tested by time and will significantly improve the physical and mechanical properties of your structure, as well as save a little on the purchase of materials.

- Do not weld fittings together. Heating the metal significantly impairs its properties, but strong joints are useless there at all - they are held by concrete, and not by the metal that you will be fused for hours.

- The reinforcement corrodes, so you need to deepen it from all sides into concrete in order for it to serve for decades. On the sides, the metal should "go" into the concrete by 8 centimeters at least, from the bottom by 10, from the top by 10.

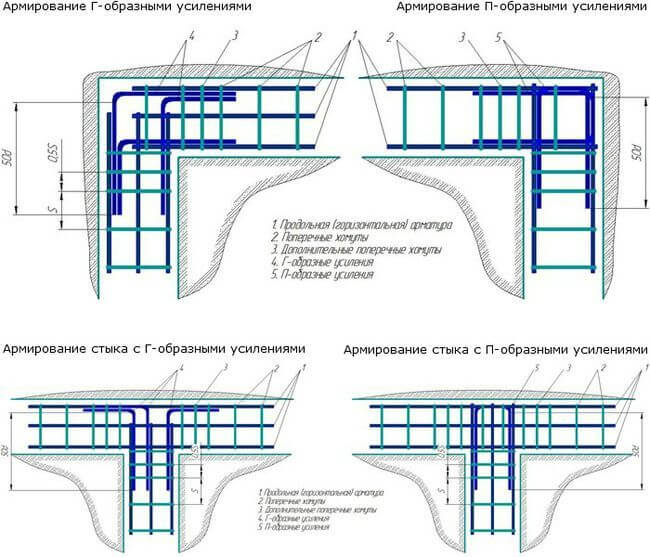

- It is impossible to make cross joints at the corners, the rods should not intersect perpendicularly, it is better to take and bend the metal of the required shape so that the next joint is no closer than 100 centimeters from the corner. The greatest load always falls on them, and the connection on a short section of the section will not give the required strength.

- The corners should be additionally reinforced with crossbars and verticals. Very often people simply do cross-stitching, believing that the mass will rely, for some reason, on the rod itself. But such a knitting of reinforcement for the base is simply unacceptable, because you will get 2 separate blocks that will not have any connection with each other. The sense of this action is exactly 0.0%. We need U-shaped and L-shaped reinforcements at the corners and on the crossbars first from them.

We have analyzed the basic rules of how to make high-quality reinforcement of the foundation, the diagram for which is located below. Now you can proceed to the phased construction of this structure and disassemble all the nuances in more detail.

How much reinforcement is needed for a strip foundation

Reinforcement cage diagram with calculation of the strip base length

Reinforcement cage diagram with calculation of the strip base length

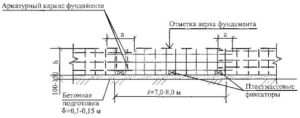

For calculations, you need to know several parameters of the future foundation. For example, the parameters of the base are as follows: width 3.5 m, length 10 m; height 0.2 m, width 0.18 m.

Calculation stages:

Calculation of the total volume of the casting. For this, the volume of a typical parallelepiped is taken into account, namely, we use all the parameters:

P = AB + BC + CD + AD = 3.5 + 10 + 3.5 + 10 = 27 V; 27 x 0.2 x 0.18 = 0.972.

Calculation of the internal volume of the foundation: 10 x 3.5 x 0.2 = 7 m³.

Subtract the volume of the casting: 7 - 0.97 = 6.03 m³.

Result: the volume of the casting is 0.97 m³, the volume of the filler is 6.03 m³.

Calculation of the number of reinforcement. To facilitate calculations, an average metal diameter of 12 mm is taken.

The casting will have two horizontal belts, and the vertical rows will be spaced at 500 mm intervals. The perimeter of the strip foundation is 27 meters. Thus, you need to use 54 meters of horizontal rods and 114 rods of 0.5 meters for vertical strapping. Taking into account the factory configuration of the rods, for the vertical, you will need 114 x 0.7 = 79.8 m of reinforcement.

So, for the construction of a strip foundation with such parameters, you need to use 1 cubic meter of concrete, 6 cubes of filler (sand and crushed stone), 134 meters of reinforcement, which will then need to be cut into specified pieces with a grinder. The volume of timber for formwork is not carried out in this calculation.

The principle of operation of the reinforcing cage

The quality of the frame affects the properties of the foundation

The quality of the frame affects the properties of the foundation

When building on an industrial scale, the correctness of the laying of the reinforcement cage is monitored quite strictly. The conscientiousness of performing reinforcement in foundations with a reinforced concrete frame in this case is checked by special commissions, which are armed with collections of building codes and regulations specially developed for this case.

However, when building a private house with his own hands, the developer does not always approach the reinforcement of a reinforced concrete foundation with full responsibility.As a result, deformation and premature destruction of the base of the building, which often entails also the destruction of the entire building.

Properties of concrete structures

To better understand the whole need to reinforce the base, you need to go a little deeper into such a difficult subject as resistance material. Several multidirectional forces act on any foundation of a building, and these forces are not constant, but change their magnitude, direction and place of application over time.

To better understand the whole need to reinforce the base, you need to go a little deeper into such a difficult subject as resistance material. Several multidirectional forces act on any foundation of a building, and these forces are not constant, but change their magnitude, direction and place of application over time.

First of all, the mass of the building being erected presses on the concrete base, and this pressure force is not the same everywhere. No matter how hard you try to evenly distribute the mass of the house over the entire area of the foundation, you will not be able to do this - in some places the pressure will be stronger.

If the house stands on moisture-saturated soil, the deforming forces of "heaving" press on the concrete base from below from below. Expanding when freezing, the soil begins to bulge to the surface in the form of mounds, lifting and squeezing up the foundation elements. When the soil thaws in these places, on the contrary, swampy pits can form, and entire sections of the foundation can simply hang in the air.

If the house stands on moisture-saturated soil, the deforming forces of "heaving" press on the concrete base from below from below. Expanding when freezing, the soil begins to bulge to the surface in the form of mounds, lifting and squeezing up the foundation elements. When the soil thaws in these places, on the contrary, swampy pits can form, and entire sections of the foundation can simply hang in the air.

Concrete, being a fairly strong material, is completely inelastic - coping well with compression, it cannot work in tension and bending. So, the resistance of concrete to compression is 50 times greater than to rupture. This is manifested to a greater extent in the design of the strip base: due to its large length, it can have several zones of bending or stretching. As a result, concrete inevitably bursts and cracks, and the base of the building collapses.

Technical features of reinforced concrete

Reinforced concrete foundation combines the best qualities of metal and concrete

Reinforced concrete foundation combines the best qualities of metal and concrete

In order to avoid these significant disadvantages of concrete structures, a reinforced concrete foundation was invented. The improvement in technical characteristics was achieved by combining the best qualities of two building materials - concrete and metal. A supporting frame made of steel or fiberglass reinforcement is mounted inside the formwork, which is then poured with concrete.

As a result, the reinforcement makes it possible to transfer the tensile and bending loads to the frame reinforcement, which copes with them much better than concrete.

Design features

The reinforcing frame for the strip foundation ensures the strength and reliability of the base of the building, preventing it from cracking and collapsing under the influence of loads and many negative factors. The choice of fittings is carried out at the stage of project development. The service life of the building and its reliability depend on the quality of the selected variety. The preparatory stage includes several types of work, including:

- soil analysis;

- determination of the depth of groundwater;

- calculation of the mass of the future building;

- choice of the type of future foundation.

The manufacture of the reinforcing cage of the foundation is carried out both before the start of construction-related work, and during their implementation.

This feature of the used reinforcement rods for the strip foundation provides reliable adhesion to the mortar used for pouring the foundation. How strong the structure will be depends on several factors:

- brand of metal rods used for installation;

- section of the rods;

- assortment of reinforcement;

- compliance with the rules and regulations while working on the scheme of the future frame;

- the selected method of fastening the rods.

A high-quality reinforcement frame will provide full resistance to compression of the structure.

Reinforcement of the foundation requires the use of metal rods during the installation of the frame, with a cross section of at least 12 and no more than 16 mm. The necessary reinforcement of the structure is ensured by using rods of class A 2 or A 3, the strength characteristics of which are a guarantee of the reliability and durability of the foundation and, accordingly, the entire structure.

Reinforcement of the strip foundation with your own hands cannot be called a very complex operation, but it should be carried out in a strictly established manner and in compliance with all the intricacies of the technological process. This concerns the selection of the right rods for the framing and the way they are fastened.

The main criteria for the selection of reinforcement for the construction of the foundation

Reinforcement of the foundation is needed primarily to prevent its rapid destruction and ensure its durability. The “right” material for reinforcement, thanks to which the base of the house will stand for more than a dozen years, must meet clear requirements and standards. It must be absolutely corrosion-resistant, have high strength, fatigue life and ductility, and adhere well to concrete. In addition, this material of a certain diameter and class is used to strengthen the foundations.

The fittings existing on the modern market of building materials are of two varieties - metallic and non-metallic. The first is made of special hot (rod) or cold (wire) rolled steel. Non-metallic is also called composite, since it is made from glass, basalt, carbon or aramid fibers using thermoplastic or thermosetting polymer impregnation. In domestic construction, the first type of reinforcement is used more often than the second, due to the relatively recent introduction of the latter. Therefore, it is better to choose the “proven” option.

Corrugated fittings

According to the method of formation, wire, rod and rope fittings are distinguished. Its surface can be either smooth or corrugated (with a periodic profile). For the construction of foundations, it is rods with a ribbed surface that are used, since they allow them to adhere more firmly to concrete. Round smooth reinforcement serves mainly as a structural element; its diameter should be less than that of profiled ones.

The next parameter that must be clearly known when choosing a reinforcement is its thickness, or diameter. It can largely determine the strength of the reinforcement cage and, therefore, the foundation as a whole. The thickness of the reinforcing bars usually depends on the type of soil and the expected load on the foundation. Most often, products with a diameter of 8-16 mm are used, but it is better to choose at least 10 mm.

The type of reinforcement will also depend on where exactly it will be used. So, to prevent the occurrence of vertical cracks, a longitudinal one is used, for inclined ones - a transverse one. According to their purpose and areas of application, the following types of construction fittings are also distinguished:

- working - used to reduce external loads and reduce the voltage that the block mass has;

- distribution - as the name implies, it is used to distribute the load and maintain the stability of the working rods;

- clamps - protect the concrete structure from cracks at the supports, and are also used to tie the rods in the reinforcing cage;

- assembly - necessary for the assembly of the reinforcement "skeleton", supports steel rods during concreting in the desired position; produced in the form of a frame, structure or mesh;

- piece - also used when assembling the frame, but on the condition that the amount of work is small.

Foundation reinforcement

Drafting the frame

Choose a metal profile of class A-400

Choose a metal profile of class A-400

Before proceeding with the installation of the frame, a number of mathematical calculations should be performed. First of all, you should decide on the diameter of the steel bars and their number.

When creating a reinforcement cage for a strip foundation of a building, steel reinforcement from a periodic profile of the A-400 class is most often used. This rolled product has a special design, equipped on the sides with protrusions that spirally encircle the metal bar along its entire length.This design has been specially designed for better adhesion of the reinforcing frame to concrete.

Fiberglass reinforcement

Fiberglass reinforcement

Recently, fiberglass reinforcement is increasingly used as a material for the frame. Among the main advantages of fiberglass in comparison with steel are:

- low weight;

- corrosion resistance;

- lower cost.

Among the minuses, it should be noted the worst indicators of tensile strength than that of standard steel reinforcement.

When creating a three-dimensional frame of a strip base, the reinforcement scheme looks as follows: horizontally, along the future walls, there are threads from corrugated rolled metal. They are arranged in several rows: both horizontally, and vertically.

When creating a three-dimensional frame of a strip base, the reinforcement scheme looks as follows: horizontally, along the future walls, there are threads from corrugated rolled metal. They are arranged in several rows: both horizontally, and vertically.

Between them are transverse round bars connecting longitudinal horizontal threads to each other.

The procedure for calculating the required number of reinforcement

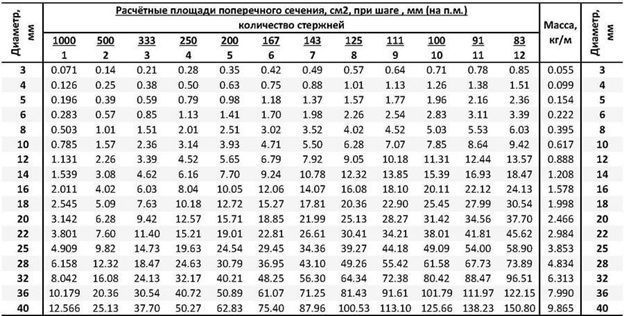

To accurately calculate the required amount of reinforcement, you will again need to refer to the collection of building codes. According to GOST, the total cross-sectional area of the longitudinal threads of the frame to the cross-sectional area of the concrete base should be related as 1: 1000. For example, consider a strip foundation of a 10 by 10 m building with one internal main wall.

To accurately calculate the required amount of reinforcement, you will again need to refer to the collection of building codes. According to GOST, the total cross-sectional area of the longitudinal threads of the frame to the cross-sectional area of the concrete base should be related as 1: 1000. For example, consider a strip foundation of a 10 by 10 m building with one internal main wall.

The section of a standard concrete base is taken as 0.5 sq. m (1 m height from base to top and 0.5 m width). Suppose, according to the project, we plan to use a periodic ("ribbed") steel bar with a diameter of 10 mm to create a frame.

Diagram of the dependence of the cross-sectional area of a metal bar on its diameter.

Knowing the minimum allowable cross-sectional ratio, we find that the total cross-sectional area of the frame in our case should be about 5 sq. see. Next, we take a diagram from SNiP, which regulates the number of reinforcement threads to create a metal frame, and with its help we calculate the number of threads in our frame. For an overview of composite and metal reinforcement, see this video:

The frame of the 10th reinforcement must have at least 8 longitudinal threads

The frame of the 10th reinforcement must have at least 8 longitudinal threads

As you can see, the cross-sectional area of one rod with a diameter of 10 mm is 0.78 sq. see Dividing the total cross-sectional area of the reinforced cage 5 sq. cm by 0.78, we get approximately 8. That is, a three-dimensional frame from the 10th reinforcement for a strip foundation 1 m high and 0.5 m wide must have at least eight longitudinal threads.

The next step is to calculate the total amount of periodic rental required to reinforce our building. Take the perimeter (10m x 4 walls) and add the fifth inner wall to it. As a result, we get that the total length of our strip foundation is 50 m. We multiply the resulting total length of the base by the number of threads: 50 x 8 = 400 m.

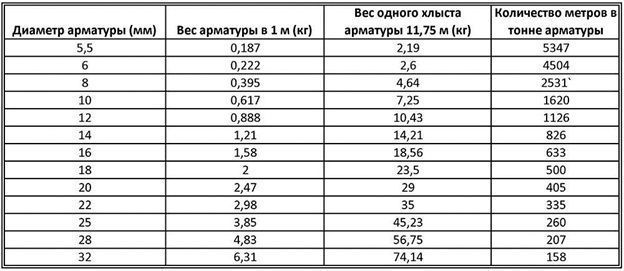

This is exactly how much corrugated reinforcement is needed to make a reinforcing cage for a five-wall 10 by 10 meters in size. Since the price of almost all rolled metal is calculated based on its mass, we will need to convert running meters into tons. For this, we will use another diagram showing the ratio of the length of the rolled stock to its weight.

As you can see, 1 m of reinforcement with a diameter of 10 mm weighs 0.61 kg. Thus, the total mass of the corrugated bar in our frame will be about 350 kg. And knowing the price of a ton of rolled metal, you can easily calculate the estimated cost of our frame.

As you can see, 1 m of reinforcement with a diameter of 10 mm weighs 0.61 kg. Thus, the total mass of the corrugated bar in our frame will be about 350 kg. And knowing the price of a ton of rolled metal, you can easily calculate the estimated cost of our frame.

True, for this, the number of transverse rods connecting the main threads into a three-dimensional frame should be calculated according to the same scheme.