Content of technical characteristics of crushed stone

On the meaning of purity

The purity of materials for a crushed stone foundation is one of the parameters of its high quality. Foreign inclusions get into it. When choosing a material, it is necessary to familiarize yourself with the product quality certificate, which reflects the percentage of inclusions. Crushed stone should not have impurities (more than the norm allowed by the standard) that provoke corrosion. It is inadmissible to get into the solution the inclusions damaging its strength:

- phosphorites, chlorites, apatites;

- shale, coal, acids;

- asbestos fibers.

The presence of inclusions is allowed in the normative volume. They cannot borrow more than 0.1 to 15%. Their content above this indicator destroys the concrete monolith.

What you need to know about the flakiness of rubble

This parameter gives an idea of the ratio of stones of different shapes. There are 4 main varieties:

- cuboid grains;

- acute-angled;

- wedge-shaped;

- flaky.

Flakiness indicates the presence of lamellar and needle-like fragments. The higher the percentage of flakiness, the lower the quality of the crushed stone. The most durable are cuboid stones. Concrete from them has a uniform high density. When constructing the foundation of housing, granite stone is used. In terms of flakiness, crushed stone has varieties:

- The first of them consists of cuboid grains used for the foundations of buildings.

- The second group, which has 10-15% of other types of material, is also suitable for these purposes.

Group 3 - these are limestone rocks, including 15-50% of substandard crushed stone. The stones have a weak adhesion, so they are not suitable for building the foundations of buildings. Variants of using them under a pillow and for a foundation made of crushed stone, the fraction of which with flakiness is 25-35% of defective material, are acceptable. Stones belonging to groups 1 and 2 are most suitable for making the base of buildings.

About the influence of frost resistance

The measurement of the frost resistance index is the number of cycles of complete freezing and thawing of a stone without loss of technical qualities. It is designated by the letter "F", (from English "frost" or frost). Crushed stone from various materials has the following frost resistance parameters:

- from limestone - F25 ÷ F100;

- concrete - F50 ÷ F75;

- slag - F75 ÷ F200;

- gravel - F200 ÷ F300;

- granite - F300 ÷ F400.

For the foundations of houses, crushed stone is used, the frost resistance coefficient of which is F250-300.

Crushed stone strength grades

The varieties of material have a strength grade established by finding out the coefficient of high loads, abrasion, pressure, crushing:

- М200 - crushed stone of very low strength;

- M300 and M600 - low strength;

- M600 and M800 - medium strength;

- М800 and М1200 - optimal strength;

- M1200 and M1400 - high strength.

The pillow is made on the basis of the M800 brand. It is recommended to fill the foundation with the M1200 stone grade.

On the fractional nature of rubble

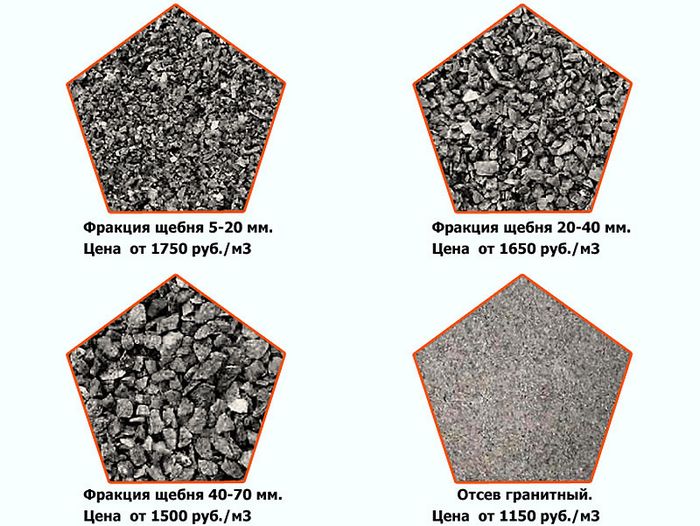

The stones are fractionated by sieving. Before deciding which fraction of crushed stone is needed for the foundation of the house, it is advisable to familiarize yourself with its types:

- The material of the European standard, calculated in millimeters, has fractions: 3 ÷ 8, 5 ÷ 10, 10 ÷ 15, 15 ÷ 20, 20 ÷ 40, 40 ÷ 80.

- Crushed stone with non-standard shapes, ordered by the consumer.

For the construction of the base of buildings, the optimal fractions will be: 5-10 mm, 10 -20 mm and 20-40 mm.

What is the best crushed stone for the foundation?

Crushed stone is a loose material made of stones of different sizes, which is widely used in modern construction. Due to its good adhesion to concrete, crushed stone of different fractions is used as a filler when pouring concrete and reinforced concrete structures, monolithic sections and foundations.

This makes it possible to significantly increase the strength of structural elements of buildings and structures.

Therefore, if you are going to build a bathhouse, garage or a house in a suburban area, you should know what kind of crushed stone is in its characteristics and how to choose exactly the material that is best suited for construction, providing the necessary strength and durability, but will not require from you large financial costs

Let's figure out which crushed stone is better to use for the foundation, for the foundation cushion, for concrete preparation for the slab foundation and for pouring the blind area.

General recommendations for the selection of crushed stone

After the required strength, frost resistance and flakiness level have been determined, you need to pay attention to a number of properties. High-strength material has increased radioactivity, in contrast to M600 crushed stone

Ideally, it is recommended to check the delivered batch using radiometric instruments.

High-strength material has increased radioactivity, in contrast to M600 crushed stone. Ideally, it is recommended to check the delivered batch using radiometric instruments.

Visually assess the surface quality of the crushed stone. For the foundation, the best material is a cuboid, rough material with a pronounced ribbed structure.

Builders often make the mistake of using river gravel instead of quality building material. This solution has a fairly good strength, a low percentage of crushed stone and flaky grains. However, the main disadvantage of the material is the perfectly smooth surface. As a result, it will not be possible to achieve good contact of the binder with the building material in question.

But if you can't get a cuboid material, then you can pay attention to mountain gravel, which has a sufficient grain roughness.

It is important to remember that grains of crushed stone in the composition of concrete organize a macro frame, which accounts for the main load from the building, while cement and sand are assigned the role of a void filler and a bonding agent.

It is important to remember that grains of crushed stone in the composition of concrete organize a macro-frame, which accounts for the main load from the building, while cement and sand are assigned the role of a void filler and a bonding agent. Summing up the article, we note that the choice of crushed stone must be carried out based on the scale of the project being built

The fraction of the material is also determined depending on the requirements for the project. In most cases, it is recommended to use cube-shaped crushed stone as the highest quality material.

Summing up the article, we note that the choice of crushed stone must be carried out based on the scale of the project being built. The fraction of the material is also determined depending on the requirements for the project. In most cases, it is recommended to use cube-shaped crushed stone as the highest quality material.

Crushed stone for the foundation

Therefore, the crushed stone for the foundation is also used differently. Therefore, it will not work to say unequivocally which crushed stone is better for the foundation.

Foundation

For pouring the foundation, preparation for it is often used. This is done to prevent moisture and laitance from leaking out. Sometimes its role is played by a layer of crushed stone, filled with liquid bitumen, and sometimes - a "footing", that is, a 10-centimeter concrete layer.

When calculating sand and crushed stone, the choice of stone is carried out. In the case of "footing", small crushed stone of 10 - 20 mm fraction is used. But with the option using bitumen, the fraction of crushed stone for a concrete foundation can be 40 - 70 mm. Although the aforementioned small particles are also used here. That is, the choice of crushed stone for the foundation in this case will be made easier.

Sealing pad

This is the first layer from which everything starts. When choosing material for backfilling under the foundation (sand or crushed stone), as a rule, they stop at both, since a sand cushion, although it will cost less, will not be as strong.This is especially true when the soil is weak. Thus, the device for the foundation cushion includes two materials, each of which plays an important role.

The sand for the pillow will come from the quarry, its size should be about 2.2 - 2.5 mm. But the fraction of crushed stone in this layer should be medium-grained (for example, 20 x 40). Strength is also important - it should not be less than average (that is, M 600). Limestone crushed stone is not used in such pillows, since it is prone to shrinkage.

Blind area

This element is made around the entire perimeter of the foundation to prevent moisture from entering.

In this design, it is important to make a good drainage system for which gravel and sand are used.

For the blind area, you can purchase both secondary and limestone crushed stone. The building is not being erected on it, so it will not experience heavy loads. The fraction can be fine-grained: such stones are easier to ram than larger ones.

Varieties of rubble

The main division of crushed stone is as follows:

- natural material;

- artificial material (secondary).

Regulatory document, including the classification of crushed stone and gravel - GOST 8267-93 *. According to it, the following division of natural material can be cited:

- from igneous and metamorphic rocks;

- from sedimentary rocks;

- from gravel (obtained by crushing rock gravel) and gravel (of natural origin);

- from boulders.

Natural crushed stone

It is made by crushing hard rock. Depending on the raw materials for manufacturing, they are distinguished:

Granite (from metamorphic rocks). Refers to the most durable. It is made from natural granite by crushing method. Provides concrete mix with high performance parameters. The brand of crushed stone from granite is in the range of 1200-1400, and in terms of frost resistance, the material is able to withstand up to 400 cycles of alternating freezing and thawing (that is, theoretically, the service life can be up to 400 years). Such crushed stone is used in the manufacture of concrete mixtures for particularly critical structures. The disadvantage is the highest cost in comparison with other types of coarse aggregate.

Granite crushed stone is the strongest, but very expensive.

Gravel. For its production, gravel is crushed, which is mined in two ways: quarry and from the bottom of the rivers. At the bottom, gravel is part of the sand-gravel mixture, therefore, it is cleaned before use. If you answer the question, which crushed stone is better for the foundation, then the answer will be gravel, as the best option. For buildings with a normal level of responsibility, it makes no sense to spend large sums on materials with increased strength: the loads during operation are negligible compared to those that granite can withstand. In addition, the gravel material is cost effective.

Crushed gravel is the most suitable.

Limestone (from sedimentary rocks). It is used for low-rise private construction. Has low strength and cost

When used for foundations, it is important to know that limestone dissolves over time with water. If, nevertheless, a decision is made to use it, you need to take care of reliable waterproofing of the foundation.

Limestone crushed stone is highly undesirable to use for the foundation.

Advice! Sometimes it can be difficult to understand the concepts of crushed stone and gravel. It must be remembered that the crushed stone has a more uneven shape with ragged edges, since it was produced by crushing by human forces. Gravel is the result of many years of natural destruction of rocks, so its surface has a smoother shape. For concrete, crushed stone is more suitable, because its uneven edges have better adhesion to the mortar.

Artificial rubble

Manufactured by crushing:

- concrete;

- bricks;

- foam concrete;

- slag.

Artificial crushed stone from construction and production waste.

The advantages include availability and the lowest cost.The disadvantage is the dubious origin. The buyer cannot say with certainty that the material is safe. In the production of crushed stone from industrial waste, GOST "Crushed stone and sand from slags of ferrous and non-ferrous metallurgy for concrete" and GOST "Crushed stone and sand from slags of thermal power plants for concrete" are also guided.

Fractional description

Crushed stone is a free-flowing, granular building material obtained mainly in the process of crushing rocks. The crushed stone fraction is the grain size of this building material. Fractions are subdivided into small, medium, large. Small fractions include crushed stone of the following dimensions (mm):

- 3 x 8 (European standard);

- 5 x 10;

- 10 x 20;

- 5 x 20.

Crushed stone foundation diagram.

Small fractions are used for the production of concrete, concrete structures, floor slabs, and bridge decks in the construction of bridges.

Average fractions (mm):

- 20 x 40;

- 25 x 60.

Scope of application of middle fractions - the production of concrete and reinforced concrete products, the construction of highways, railways, tram tracks, laying the foundation, construction of production facilities.

Coarse fractions (mm):

- 20 x 70;

- 40 x 70.

Scope of use: construction of industrial buildings, construction of large-scale reinforced concrete structures, construction of bridges.

Non-standard fractions (mm):

- 70 x 120;

- 120 x 150;

- 150 x 300.

Building materials of non-standard fractions are used extremely rarely. Scope of application - decor: decoration of reservoirs, fences, pools, plinths, etc.

Granite and gravel seeds of a smaller size than crushed stone are also used for decorative purposes (for the needs of landscape design), for sprinkling paths, platforms.

Material of origin of crushed stone

The properties of crushed stone vary depending on the material of origin

The properties of crushed stone vary depending on the material of origin

Almost all other criteria for evaluating the material depend on which mineral is the basis of the rock of origin. It is customary to split placeholder:

- Granite. It is characterized by the highest indicators of mechanical strength. Obtained by processing rocks.

- Gravel. There are 2 types: crushed and natural. It is rarely used in the construction of concrete foundations. Usually used for the manufacture of blind areas.

- Dolomite. The forming rock is limestone. Differs in weak strength and low level of frost resistance. It is not used in foundations.

- Slag. A product of blast furnace waste processing. It is used as a filler for concrete foundations.

- Secondary. It turns out in the process of processing outdated or low-quality crushing of concrete products. The most economical type of placeholder. According to building codes, the material is allowed to be used when filling foundations for one-story buildings in an area of stable soils.

Peculiarities

Crushed stone is one of the most common fillers for concrete mix, without which no modern building of a house or other object can do. This building material has many classifications and is endowed with different characteristics and features, which directly affect the quality of the future construction, and the strength of concrete, and the strength of the foundation. Despite the low cost as for a building material, crushed stone combines all the qualities that are irreplaceable in construction.

Crushed stone has the following features:

- high degree of strength - when compared with all fillers for concrete mix, the most durable of all types of crushed stone is granite material;

- moisture resistance - crushed stone does not react at all to moisture;

- excellent tolerance to temperature extremes - frost and heat, as well as resistance to environmental influences. Crushed stone is able to withstand up to three hundred changes in temperature cycles;

- high adhesion - due to the rough surface and acute-angled shape, the adhesion of the material to concrete is significantly enhanced;

- reduction of settlement and creep of concrete, which minimizes the occurrence of cracks and all sorts of deformations in the constructed building;

- ease of use;

- high performance properties.

In addition, due to the variety of types of crushed stone, you can always choose the one that is suitable not only in terms of technical characteristics, but also in terms of cost.

High-quality crushed stone must be selected based on the following technical characteristics:

- Flakiness is a characteristic of the flatness of a material. In total, crushed stone has 4 categories of flakiness: rounded, cuboid, improved and ordinary;

- degree of strength - the stronger the material, the better. The highest indicators of strength are endowed with two types of crushed stone: granite and gravel;

- radioactivity is an important characteristic that depends on the deposit of building material. High quality crushed stone is certified for radioactivity. This indicator does not affect the strength of the material, however, the level of environmental friendliness depends on it;

- frost resistance - this characteristic indicates the number of seasons that the foundation of this material will withstand. According to the level of frost resistance, crushed stone can be divided into stable, unstable and highly resistant;

- compaction coefficient - the density of crushed stone ranges from 1.2 to 3 g / cm³. This factor depends on the type of origin of the material. Crushed stone with a high degree of density is versatile and has an unlimited scope. The density and strength of this building material are directly proportional.

Crushed stone selection

All the necessary recommendations for selection are given in GOST 8267-93 * and JV "Bearing and Fencing Structures" (hereinafter GOST and SP). It is required to consider each selection criterion separately.

Purity and radioactivity

These requirements will affect not only the reliability of the foundation structure, but also its safety. It is especially necessary to check compliance with the use of recycled crushed stone from construction and production waste. The content of dusty and clay particles, as well as clay in lumps, is given in tables 9 and 10 of GOST.

According to clause 4.8 of GOST, material mined and manufactured in any way must be resistant to decomposition of any kind, negative environmental influences and the effects of alkalis. Resistance to disintegration must comply with table 11 of GOST, which gives the maximum percentage of weight loss during disintegration for materials of various grades of crushing.

In addition, a radiation-hygienic assessment is mandatory. Based on its results, the possibility of using it for the construction of residential buildings is determined. The total specific effective activity of natural radionuclides should not exceed 370 Bq / kg.

Fraction and brand

Crushed stone of various fractions.

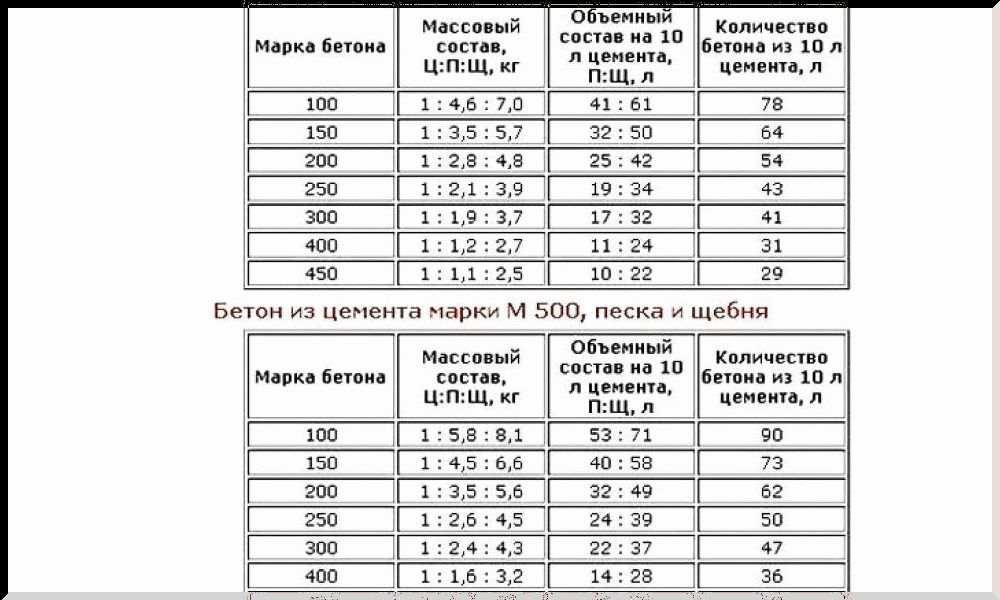

Particle size of the coarse aggregate will be an important factor in the construction of foundations. The requirements of the joint venture can be summarized in one table:

| Used crushed stone fractions |

1) 5-10 mm; 2) 10-20 mm; 3) 20-40 mm; 4) 40-70 mm. The best option would be to use 40-70 mm as the main fraction (but depends on the distance between the reinforcement rods), and two more additional requirements (see below). |

| Largest particle size of coarse aggregate for concrete | The largest fraction in the composition has dimensions of no more than 2/3 of the smallest distance between adjacent reinforcement rods in the clear. This will ensure that large particles are evenly positioned in the structure. |

| Number of factions | It is not allowed to make concrete mix using coarse aggregate of the same size. If the largest grain size is less than 40 mm, then two or more fractions are required. If - more than 40 mm, then - three or more. |

You also need to correctly select the grade of material in terms of strength, depending on the required grade of concrete.For foundations, concrete classes above B25 are rarely used, since this is economically unprofitable.

| Brand (class) of concrete | Crushed stone mark | Gravel grade |

| M200 (B15) | 300 | 600 |

| M250 (B20) | 400 | |

| M300 (B22.5) | 600 | |

| M350 (B25) | 800 | 800 |

A competent choice of aggregate for concrete will ensure its high strength and reliability of the foundations.

How to make a pillow

First, a trench or foundation pit is lined with river sand, preferably large, 10-15 cm thick. There are no organic inclusions in it, which excludes the processes of decay.

The sand should completely cover the bottom of the pit. The surface is leveled and compacted. To exclude mixing of soil with a sandy layer and washout by groundwater, a substrate is made of geotextile or roofing material.

A crushed stone layer up to 20-25 cm high is laid on top of the sand. The greater the load of the structure on the base, the thicker the substrate is made. Crushed stone is leveled and compacted with a special roller or vibrating plate. Sealing is required to eliminate voids, tighter fit of components to each other. The ideal density of the finished pillow is from 1.6 t / m³.

The backfill is poured and tamped until its surface is at the level of the edge of the pit.

A coating is made with mortar with cement 15-20 cm thick from the ground level. If there is a site with closely located groundwater, it is better to increase the height of the crushed stone layer. During installation, constantly monitor the evenness of the surface, and correct flaws in a timely manner. The reinforcement cage helps to strengthen the foundation.

Frost resistance of material

Under existing conditions, it must be borne in mind that low temperatures can have an extremely negative effect on the condition of the foundation. In this case, we need to apply frost-resistant crushed stone. With regard to the essence of this characteristic, we are talking about the cycles of freezing / thawing of the material. If the crushed stone is really frost-resistant, then even dozens of such cycles will not affect its condition in any way.

In this situation, there are also grades of crushed stone, the minimum is f15, and the maximum is f400. Again, granite crushed stone has a high level of frost resistance, so it is more advisable to purchase it for owners working on the creation of a structure in eastern Europe, as well as in central and eastern parts of Russia. In these areas, extremely low temperatures can turn into heat in record time. Accordingly, excellent frost resistance is required from crushed stone. You can choose some average value (by grade of material), and this will be the best solution.

If in your region the temperature practically does not change throughout the year, then the issue of frost resistance fades into the background. In this situation, you can safely take any crushed stone, which in terms of strength meets all the requirements in construction.

Fraction and amount of crushed stone

Crushed stone production scheme.

For laying the base of a residential building, it is most preferable to use granite crushed stone of an average fraction of 20 x 40 mm of a cuboid shape. The use of just such a building material will provide a high compaction density of the filler, the absence of air inclusions. Consequently, concrete will have high strength, reliability and durability. In seismically inactive areas, areas characterized by deep groundwater, the use of fines is common for laying the foundations of small houses.

Gravel has high strength characteristics. It can also be used in the construction of small buildings. The preferred particle size is 20 x 40 mm.

To lay a monolithic foundation, it is necessary to prepare a mixture of gravel, cement, river sand, water. Cement is a binder, crushed stone and sand are fillers. The amount of crushed stone and other building materials required for laying a solid foundation must be calculated based on this ratio: for 1 part of cement, 3 parts of sand, 1.5 parts of water, 5 parts of crushed stone are needed.

The information collected here in the future will be useful not only for laying the foundation of the structure, because we are talking about a very popular building material with a wide range of applications.

BEST CHOICE - GRAVEL GRAVEL

Usually, in the manufacture of the foundation, the use of crushed gravel is relevant. It is quite durable and expensive in relation to crushed granite.But if the plans are to build a heavy and large object, for example, a residential building, then the best option would be to use expensive granite crushed stone. And if light buildings are planned, such as garages, gazebos, sheds, then the use of inexpensive crushed limestone would be an excellent, suitable option.

The most important advantage inherent in crushed gravel is its significantly low level of radioactive background. Other materials are inferior to him in this.

If we talk about flakiness, then this criterion measures the flatness of the elements. Crushed stone will be better compacted if the largest number of stones have a shape that is approximate cuboid. But if the material contains the largest number of needle-shaped and plate-shaped pebbles, then in the process of mixing concrete for the construction of the foundation, the costs of cement will significantly increase.

Specifications

What kind of crushed stone is needed for the foundation is determined based on the main characteristics of individual parties.

Strength

According to the result of laboratory tests, which are carried out for each large batch, crushed stone is assigned a strength grade:

- М1200 ... М1400 - high strength;

- М800… М1200 - durable;

- М600 ... М800 - medium strength;

- М300… М600 - weak strength;

- M200 or less - very weak strength.

Frost resistance

The ability to maintain properties in conditions of temperature extremes, in particular, destructive frosts. Frost resistance of different types of crushed stone:

- Gravel - F15… F200;

- Granite - F300 and more;

- Limestone - F25 ... F

For a cushion of rubble and pouring foundation walls, especially those that are above the freezing level of the soil (in shallow strip foundations, in columnar structures), stones with a frost resistance index of at least F200 are required.

Fraction

Crushed stone, while still in production, is sorted by grain size into groups:

| Fraction, mm | Appointment |

|---|---|

| Up to 5 | Screening, used for the preparation of "washed" concrete and plasters. |

| 5-10 | It is used as an aggregate in combination with large crushed stone to fill voids: creating floor slabs, lintels, etc. |

| 10-20

(5-20) |

The best fraction of crushed stone for the foundation of the house, construction of the roadway. Due to its size, it is evenly distributed in the concrete volume. |

| 20-40 | Concrete production for prefabricated structures and monolithic construction, road construction. |

| 40-60 and 60-70 | Crushed stone for massive structures. |

Flakiness

The shape of the stones is no less important than the strength indicator and the fraction - the ability of crushed stone to adhere to concrete mortar depends on the flakiness.

Screening can be conditionally divided into 3 groups according to the shape of the constituent components:

- cuboid is the best solution for filling concrete mix. It is evenly distributed in volume and provides uniform adhesion to concrete. The name "cuboid" does not mean that all stones in the screenings are cubed. The definition hides the convex shape of the stones;

- improved - this is crushed stone, in the batch of which a cuboid type of aggregate is artificially added to improve the general properties of the material;

- ordinary is a mixture of stones of different shapes and qualities. The flatter the individual elements, the poorer the adhesion and load distribution. In addition, when mixing flaky crushed stone, voids can form in concrete, which is extremely undesirable for critical load-bearing structures.

| Content of needle-shaped and lamellar grains,% | Crushed stone type | Group |

|---|---|---|

| Less than 10 | Cubiform | I |

| 10…15 | Improved | II |

| 15…25 | Normal | III |

| 25…35 | IV | |

| 35…50 | V |

Radioactive background

The mined rocks can have a radioactive background, especially granite. The background is measured in Bq / kg (becquerel per kilogram); stones of no more than 370 Bq / kg can be used for residential buildings.

When concrete preparation is required

A footing is a skinny cement interlayer between a layer of gravel or rubble and the body of the foundation. As a rule, the thickness of the pillow does not exceed 1 dm.

Thanks to her, the building reliably rests on a stable base. This is most lacking in situations like this:

- loose soils;

- the existence of seismic hazard;

- close proximity to slopes, slopes and embankments;

- high compressive load from the building.

In addition to the basic purpose - a solid support of the structure - foundation preparation facilitates many stages of the process:

- The assembly of prefabricated structures on a leveled surface is more convenient and the results are accurate.

- High grade concrete is consumed more economically when it is laid out on a flat compacted base made of cheap material.

- On concrete, it is easier to install a reinforcement frame with maximum accuracy for the manufacture of a monolithic foundation. A crushed stone pad will not give as accurate a result.

- A special coating is created to prevent moisture penetration.

- Preservation of concrete from loss of brand due to leakage of cement laitance, complete hydration of binding grains.