What brand of concrete is needed for the foundation?

In the practice of private construction, the strip foundation is considered the most preferable. Such a foundation is sufficient to ensure the retention of a relatively light structure in difficult soils, under dynamic loads. Concrete is used as a foundation solution. When choosing concrete for pouring the foundation, you can use the following recommendations:

- For houses with a light type of construction (frame or panel board) - M200-M250;

- Mixes M250 are suitable for wooden buildings, for heaving locations it is preferable to select M300;

- Residential buildings based on gas silicate blocks and similar materials will require a foundation made of M300 and M350 vintage concrete for operation;

- Brick or stone cottages will serve for a long time on the basis of the M400.

Choice of strength

When choosing a concrete grade for a strip base of a private house, it must be borne in mind that the strength properties increase with an increase in the value in the marking of the mixture. So, if you plan to use the M300 brand, the strength of such a structure will be at least 320 kg per cm².

Hardness indicators, depending on the class of concrete, are calculated. The meaning of the parameters is what kind of load the foundation can experience without destruction. You can calculate the approximate mass of the building according to the project. It is also necessary to take into account the pressure from people, furniture, things. For winter, it will be advisable to take into account the snow load.

Depending on the soil

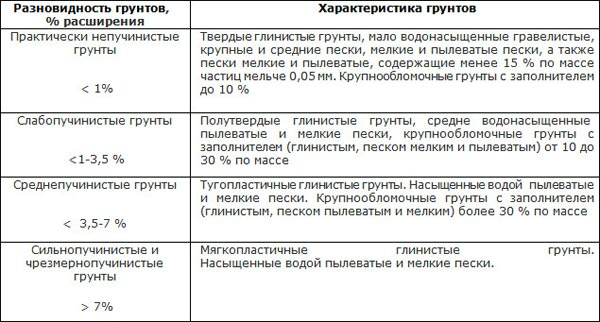

Before building the area, one cannot ignore the result of geological surveys. Of course, you can use ready-made studies in neighboring areas, but this is not recommended. Where construction has not been carried out, the soil may not show itself in the best way. The more heaving the soil, the higher the grade of concrete used, not lower than M350. The same quality of the foundation is needed for clayey soils. In rocky terrain, the base of a private house will sit firmly and securely, without increased requirements for the quality of building materials.

By type of foundation and structure

When buying concrete, a private developer usually focuses on the indicator of the "M" brand. The higher the value, the higher the strength of the finished structure will be. For example, if you plan to use the M350 for strip foundations a private house, its qualities are quite enough for a brick house.

Usually for residential private buildings, a light type of base is used made of materials M200 or M250. If a mixture is selected for the foundation of a two-story house, it is better to start with M300 materials. When mixing a solution, there is one feature, if you process concrete that has not yet hardened with vibrators, this will increase the strength of the material and increase its performance.

Additional measures to strengthen the building include the formation of an underground floor. So, you can make not only the foundation, but also make the basement of a brick house or basement concrete.

Other parameters

When choosing a brand of concrete mix for the foundation of a house, additional factors are also taken into account that will affect the operational characteristics. Today, mortar manufacturers conduct tests for properties such as frost resistance and water resistance.

For definition, the marking "W" is provided, having a range from W2 to W20. The selection of a specific brand depends on the climatic conditions of the area.

Frost resistance, as another characteristic of concrete, determines the number of cycles of the structure for freezing and thawing. The frost resistance grade is determined by the number after the letter "F". For example, F150-F300 is preferable to use in the Far North regions.If the marking contains a frost resistance value above 500, it means that such concrete is intended for military and industrial facilities.

Preparation of concrete mortar for the foundation

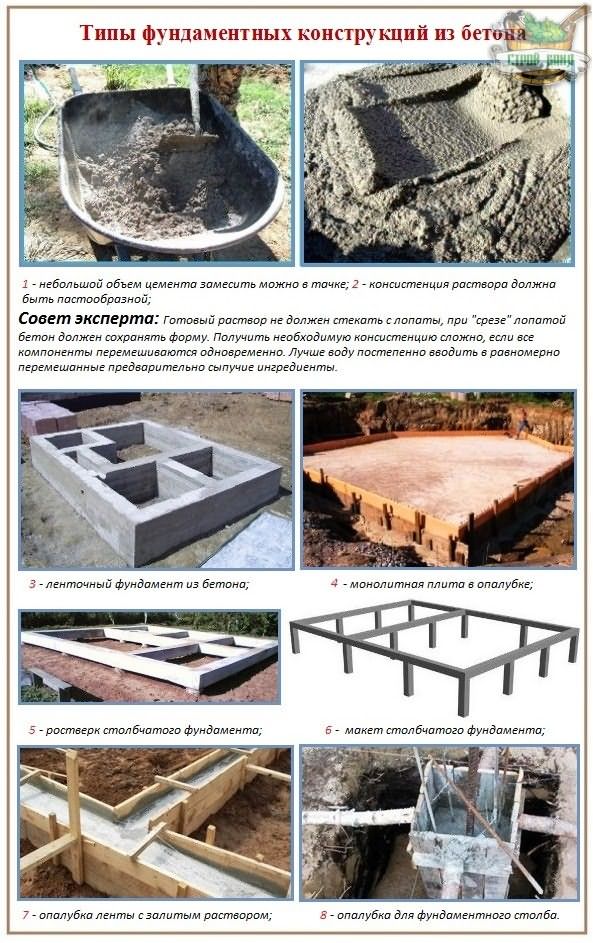

The process of making concrete mix is a crucial stage in the formation of a monolith of the foundation of a building. Any deviation from the quality and quantity of the constituents of the concrete solution will lead to a loss of the bearing capacity of the foundation. Concrete is prepared in different ways: this is a manual, mechanized and factory method of how to make a mortar for a foundation.

Manual way

For mixing concrete by hand, you can use any sealed container: an old bath, a trough or a welded structure made of auxiliary material. Before starting work, in addition to the container, you need to prepare the following materials:

- clean washed sand without clay inclusions;

- foundation pouring cement;

- crushed stone or gravel;

- filtered water, if it was collected from a natural reservoir;

- wide (grabarka) and bayonet shovel.

The process of preparing concrete is carried out as follows:

- Cement and sand are poured into the container.

- Mix the mixture thoroughly with a shovel until smooth.

- The mixture is poured with water, and everything is also mixed.

- When the cement mortar is ready, rubble is added to it.

- After final mixing, the concrete is ready to be poured.

Manual concrete preparation video:

Mechanized way

Concrete mixer in action

Concrete mixer in action

For the mechanized preparation of poured concrete into the foundation formwork, a concrete mixer is used. The mechanism is a metal rotating drum located on the wheel frame. The drum is driven by an electric motor and has a tilting pivot shaft.

An example of pouring a foundation using a concrete mixer

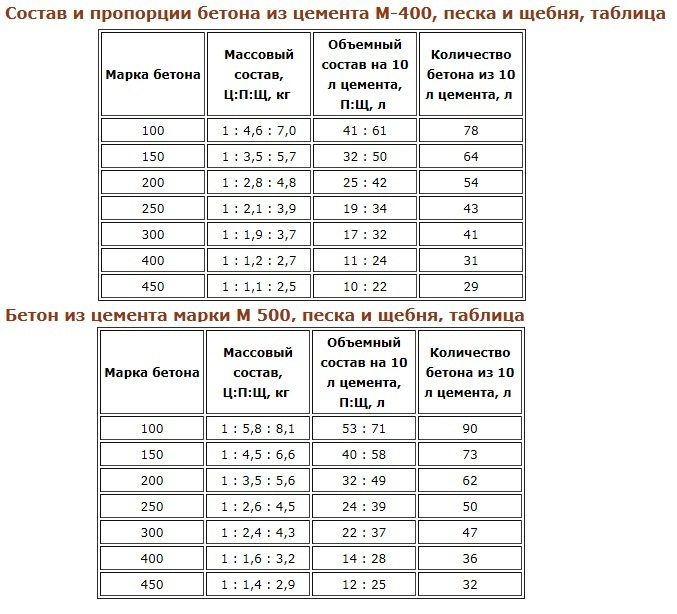

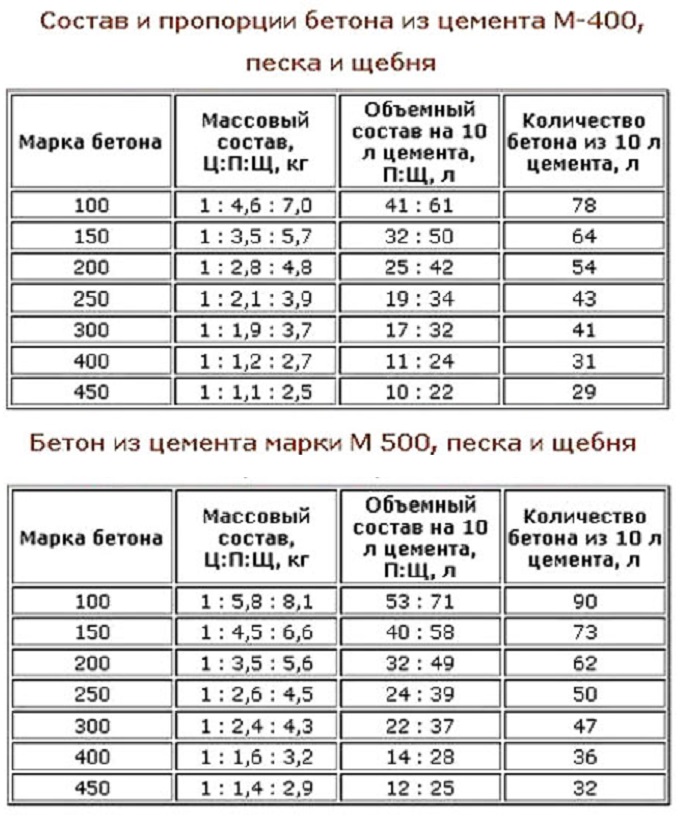

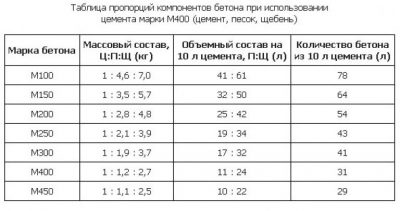

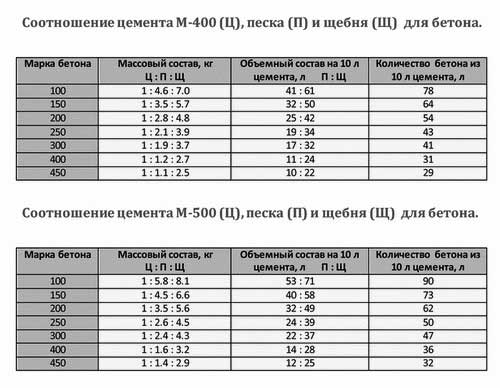

Before proceeding with the process of preparing the poured concrete, a preliminary calculation of the need for consumables is made. Determine what brand of cement is needed in order to prepare the cement mortar. In this calculation, cement grade M 400 was used for the mixture.

Initial data: strip foundation - 5 m3 of concrete, concrete mixer - 180 l, concrete grade - M 300.

Calculation of the need for materials for pouring a foundation with a volume of 5 m3

An accurate calculation of the need for materials that make up the concrete solution allows you to avoid unnecessary costs for the construction of a monolithic base of the building. In order not to regret the lack of certain materials, it is always necessary to add 5 - 7% to the estimated amount of concrete constituents for unforeseen losses.

- 1 batch of a concrete mixer will make 180 liters of the prepared concrete mixture. This volume will need cement M 400 - 31.4 kg / 24.2 l, sand - 39.7 kg / 26.5 l, crushed stone - 95.6 kg, water 17 l.

- Therefore, in order to get 1 m3 of concrete, it is necessary to make a solution for the foundation in the amount of 5.55 mixes. This will amount to 398 kg of cement M 400, sand 503 kg, crushed stone 1210 kg and water 215 liters.

- The entire foundation will need cement M 400 - 1990 kg, respectively.

- If you make similar calculations for other brands of binder, it turns out that the entire foundation will need M 300 - 2500 kg, M 500 - 1705 kg.

Factory production of concrete

Concrete mixer truck loaded with concrete

Concrete mixer truck loaded with concrete

With large volumes of construction of the foundation base of the building, concrete is ordered at the mortar unit of the concrete plant. Concrete mortar unit (BRU) - a plant for the production of concrete. BRU includes a concrete mixer with a control panel, a skip hoist, dispensers for cement, water, solids and various additives. BRU produces concrete mortar of various brands.

At the request of the customer, BRU produces liquid concrete in the required quantity at a certain time. Delivery can be carried out by trucks with a sealed body or a concrete truck.

A concrete truck is a vehicle equipped with a rotating container and an unloading device. On the BRU, concrete is loaded through a batcher into the drum of a concrete truck.

When unloading the drum, the blades begin to rotate in the other direction. The mixture enters the foundation formwork through a special unloading device. On different models of concrete trucks, the drum volume ranges from 6.5 to 8 m3.

Useful additives for concrete mix

| Additives | Characteristic | Featured Products |

| Antifreeze | They give strength and reliability, allow construction in winter and freezing temperatures, cannot be used in high humidity and during rain | Calcium Formate, Sodium Formate, Calcium Chloride, Potash, "FrostStop", "Plus" |

| Waterproofing | Concrete with the use of such a substance is marked W, increases the resistance of the composition to moisture, is perfect for areas with a high content of groundwater, located next to a pond, river or lake |

"Crystal", "Penetron", "Xypex" |

| Plasticizers | They increase the plasticity and elasticity of the mixture, reduce the consumption of water during the preparation of concrete, prevent the stratification of the mixture, increase the mobility of the mass and the strength of the concrete |

Plasticizers and superplasticizers, "Plus", "Technonikol" |

| Hardening accelerators | Provides fast hardening, eliminates reinforcement corrosion, unlike chlorides, and reduces cement consumption | "Sika", "Relamix",

"Ferrokrite" |

How to calculate the amount of concrete for a strip foundation

To independently determine how much concrete you need to create a base for a house or bath, you need to determine the total values of the future tape, namely:

- Length. The length of the tape that runs under the inner walls of the building.

- Height. The depth of the bookmark (including the length that will rise above ground level).

- Width.

In the construction industry, there is a standard formula by which you can easily calculate the volume of concrete in cubic meters:

V (concrete volume required) = S (cross-sectional area) x L (belt length) x H (belt height)

Let's say we are planning to build a bathhouse, for this we estimate approximate parameters:

- The uniform cross-section of the tape will be 0.20 "squares".

- The total length of the tape will be about 30 meters.

- The height will be somewhere around 0.6 meters.

Multiplying 0.20 by 30 and 0.6, we get 3.6 cubic meters (0.6 m = 3.6 m3). This will be the concrete cubic capacity we need for the basement for the bath.

If the cross-section of the tape is non-uniform and in the same area:

- the length will be 10 meters (0.16 m2);

- section length - 20 meters, section will be 0.24 m2;

Then, then the calculation will look like: V = (10 x 0.16) + (20 x 0.24) x 0.6. As a result, we get 3.84 cubic meters of the composition.

Healthy! If you plan to order a mixer for mixing, then it is better to take a small stock of solution (about 10-15% more).

In addition, there are a number of tips that can be useful when building a fundamental strip-type base.

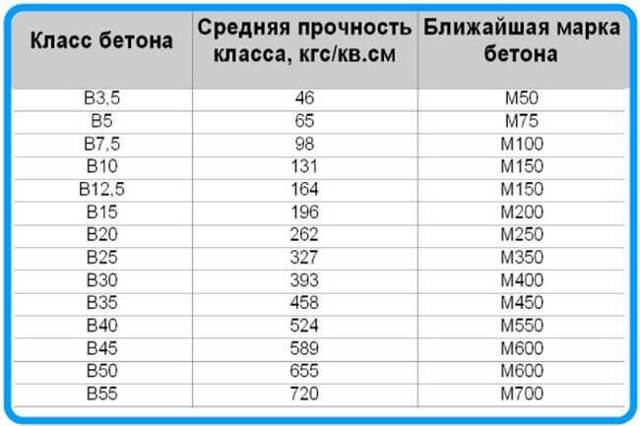

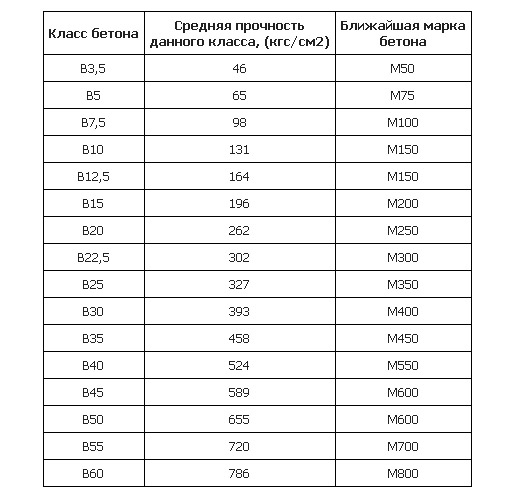

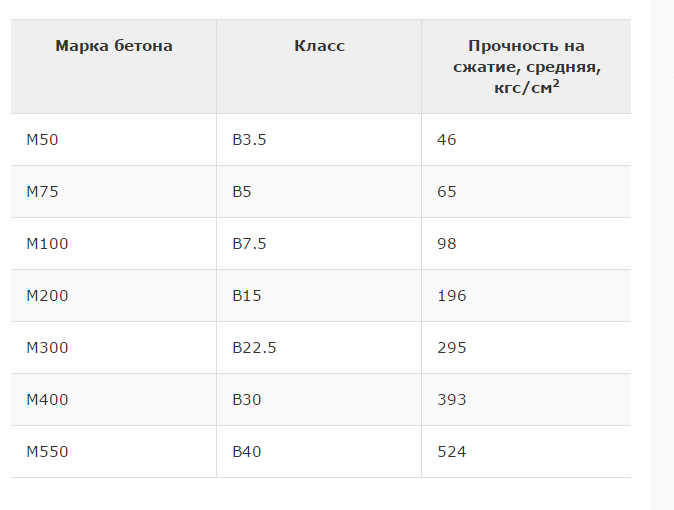

Concrete grades

Some information about the brands of concrete. Concrete as a building material has such characteristics as:

- strength,

- Class,

- frost resistance,

- plastic,

- water resistance.

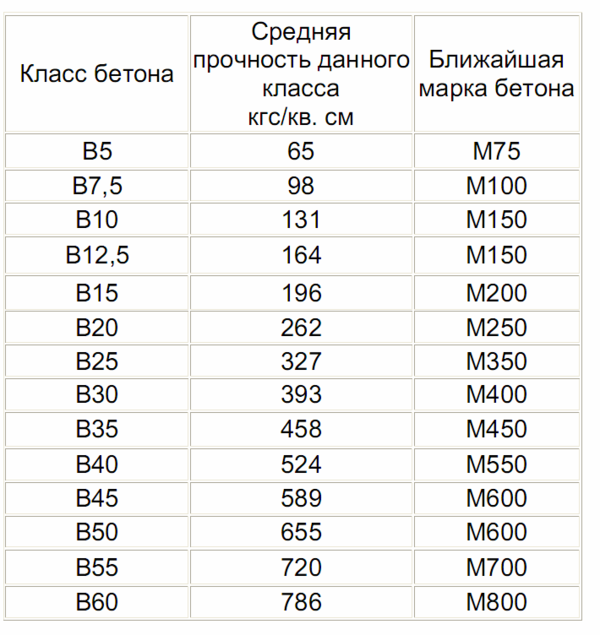

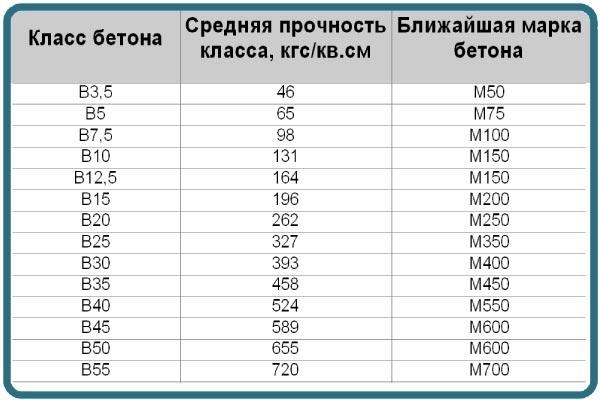

All of the above indicators are indicated in the marking. Let us examine, for example, concrete with the design grade B25 P3 F300 W20. The first character in the mark indicates the class of concrete; shows how high the claimed strength of this building material is. A specific grade of material is suitable for a certain class, showing the ultimate compressive strength of concrete.

- Known to builders brands M100, M200, etc. Private developers are usually guided by the above combinations, choosing the appropriate class of concrete for the construction of a two-story house on their site. In the example we are analyzing, the class of concrete B25 coincides with the grade of the material M350.

- The second alphabetic character is P; it indicates the mobility of the finished concrete. It is this indicator that determines the resulting quality of the fill. Concrete mixture marked P3 is usually used in the construction of simple monolithic structures.In cases where the monolith has places with difficult access or there is a lot of reinforcement in it, it is preferable to use concrete marked P4 or P5.

- The third alphabetic character is F; it indicates frost resistance. The numbers next to it indicate the magnitude of the freeze-thaw cycles. The higher the number following the F, the more porous the finished concrete. Practice shows that the best concrete for work on a foundation is F200. A further increase in this indicator of strength does not at all impart, on the contrary, it somewhat decreases.

- Finally, the last alphabetic character in the marking of the building material is W; it shows the water resistance of concrete. This indicator can be increased if hydrophobic cement or certain additives are used.

Cement grade

Various ingredients are added to the powder, forming a mixture of a certain brand. The brand is designated by the letter "M" and a number. In the factory laboratory, samples of each batch of material are tested. Samples from a solidified solution of PC and sand (1: 3) in the form of prisms 40x40x160 mm are tested for compression until complete destruction. The load threshold determines the number of the cement grade.

So, M 200 means that the hardened cement mortar can withstand a load of up to 200 kg per 1 cm2 of its surface. The modern building materials industry produces binder grades: 50, 100, 200, 300, 400, 500 and 600.

What factors influence the choice of the brand of composition

Unfortunately, there are no universal recipes, the price is not always a fundamental factor. After all, even expensive formulations have their own recommendations and restrictions on use.

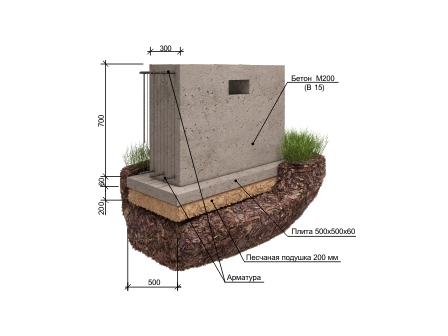

Scheme of the formwork option for the strip foundation.

Dependence on the weight of the building

If you want to build a house with your own hands, and you do not have a ready-made project with prescribed recommendations, then, first of all, you should pay attention to the total weight of the building. This is the first indicator from which they start when choosing a brand of composition.

Here are some general guidelines:

- A prefabricated panel house with a height of 2 floors, in most of our country, will comfortably stand on a reinforced concrete foundation filled with the M200 brand.

- For 2 - 3 storey log buildings, as well as for houses built of foam concrete, gas silicate blocks or other cellular concrete, M200 - M300 grades are recommended.

- For heavy, permanent buildings made of bricks, solid concrete structures or other heavy materials, it is recommended to use the M300 grade and above.

Reinforced blank for filling the structure.

Soil characteristics

Much depends on the geology of the soils in a given area, their composition and how deep the groundwater is.

Sandstones and rocks are considered the most favorable. They can be poured with concrete M200 - M250.

Clay soils and loams are quite a problem. The fact is that these soils, when frozen, are prone to heaving. That is, they do not freeze evenly and are able to squeeze out a shallow-buried strip foundation in some places, which leads to a general deformation. In this case, you can do it in two ways.

-

- First, to deepen the structure to a level higher than the average total soil freezing in the region.

- Secondly, you can equip a strip-columnar, well-reinforced foundation. This is when at key points support concrete pillars are poured to a considerable depth, which stabilize the entire structure.

- If we talk about what grade of concrete is needed for a strip foundation laid on clay, then experts recommend taking a grade an order of magnitude higher, approximately M250 - M300.

Scheme of a tape-and-column structure.

Waterproofing on the foundation.

Common grades of concrete

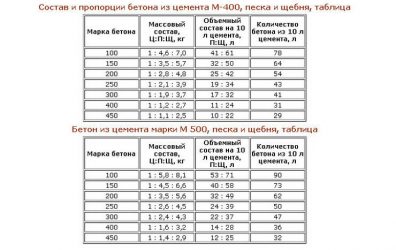

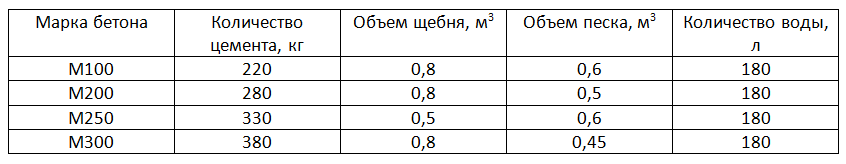

In the production of concrete of different grades for foundations, cement M 400 is most often used, but in different proportions.

- M100 - used as a bedding cushion in road construction, laying deep foundations or pouring screed for floors.

- M200 - suitable for shallow foundations based on stable soils. Cellars and all kinds of open areas are poured into it.

- М250 - used for casting fences, all kinds of stairs and tape-and-columnar structures.

- M300 - is considered the most popular brand for pouring the foundation. It is successfully poured into the vast majority of known foundation structures, and can be used in a humid environment.

- М400 - used for filling underwater structures, bridges and other capital structures. It is used for the construction of houses in extreme conditions.

- М500 - used for pouring sheer structures, repairing roads and structures, or as an additive.

Detailed table of proportions.

What else is worth paying attention to

There is also a marking characterizing the strength class of the hardened composition. It is designated by the letter "B", characterizes the compressive strength and is measured in megapascals.

Classification of concretes for cement M500.

The level of strength and the grade of concrete are related indicators. According to GOST, each grade of concrete corresponds to its own level of concrete strength, here are some basic indicators:

-

- B7.5 corresponds to M100

- B15 corresponds to M200

- B20 corresponds to M250

- B22.5 corresponds to M300

- B25, B27.5 correspond to M350

- B30 corresponds to M400

- B35 corresponds to M450

For our country, the frost resistance indicator is also relevant, it is marked with the letter "F" and a certain number after it. The number indicates how many times the structure can freeze

For a larger territory of the country, F200 is enough, the more thaws in winter, the higher this figure.

It is also worth paying attention to the indicator of resistance to high humidity. It is indicated by the letter "W" and the number after it.

Technical characteristics according to GOST.

Class

Concrete marking includes not only the brand, but also the material class. The concrete class is designated with the letter B, and shows information about the compression ratio, water resistance and other characteristics. Foundation concreting should be carried out only with the material of the required class. When choosing it, you should take into account the following characteristics:

Mobility. It is designated by the letter P. This characteristic of the material indicates its homogeneity and the coefficient of fluidity. In this case, even a slight increase in water in the composition of the mixture can reduce its strength, which will lead to significant problems with the foundation in the future.

Waterproof. It is designated by the letter W. The indicator is in the range from 2 to 12. The value of this indicator should be taken into account if there is groundwater on the site.

Frost resistance. It is designated by the letter F. This indicator characterizes the number of frosts and defrosts that the material can withstand.

Particular attention should be paid to this indicator in the northern regions.

Therefore, in addition to the brand of the mixture for the base, its class must also be taken into account. Before choosing a material, one should take into account the load on the foundation, the climate of the region, as well as the geodetic features and the degree of soil heaving.

Concrete composition

Concrete is a mixture of cement (plays the role of a binder), filler (sand, fine gravel particles or other components), additives (additives that increase frost resistance and other parameters of the finished structure) and water. The composition of such a mixture is periodically improved, more "recipes" for the preparation of better quality mixtures appear.

For example, for strip foundations, some people prefer to make rubble concrete. In this case, large rubble stones are used as a filler, of which at least 15% at the base.This saves on cement and creates a stylish base that does not actually need finishing. Such a foundation is not only more durable, but also much more resistant to low temperatures and the influence of groundwater. Thanks to these characteristics, such a foundation will last up to 150 years.

But, such a composition is more expensive, therefore, usually in private construction, more classic mixtures are preferred.

Standard composition

Before building a country house, fence, shed and any outbuildings, you should pay attention to the features of the components:

- Sand. Not everyone is suitable for durable concrete. It is necessary to choose exclusively cleaned sand (can be river or quarry). If there are impurities in it, then such a foundation will not last long.

- Crushed stone. This component gives strength to the mixture. As a rule, gravel is used with a fraction of 5-20 mm.

- Plasticizers. You can do without them. But, today there are many additives on the market that increase the life of the base, simplify the mixing process.

Healthy! It is recommended to use additives that increase the plasticity of the mixture if you are using a reinforcing frame.

Water. The main requirement is that it must be clean. If it is collected from a reservoir, then it is imperative to pass the liquid through a filter.

Of course, cement is also required for any foundation.

Required cement grade

The brand of cement and of the future concrete itself are designated by the symbol "M". The numbers after it define the mass load threshold. That is, if we mix cement M 200, then after the mass has solidified, such a base will be able to withstand up to 200 kg per 1 cm2 of surface. However, when it comes to concrete, Portland cement (PC) is usually used for it. It is a binder consisting of cement clinker, additives, gypsum. There are many of its brands (from M 50 to M 600).

If you plan to build a foundation, then PC 200 or 400 is usually used for such bases. Portland cement 600 is much more expensive and is usually used in the construction of industrial or other specialized facilities. Therefore, PC 200-400 is sufficient to obtain concrete of the desired grade.

The influence of slags and impurities.

Despite the fact that for the foundation of a house it is better to use Portland cement without mineral additives (they lead to a decrease in the strength of structures), in some cases mixed varieties are also needed. Their main advantage is efficiency (with the exception of formulations with modifying and specialized additives, they, on the contrary, are more expensive), the PPTs M400 d20 brand is considered an example of a good price / quality ratio.

The advantages of using slag and pozzolanic cements include sulfate resistance, they should be chosen with a high proportion of salts in the soil or other aggressive influences. But they are slower to reach the required strength, so the laying of foundations on their basis is carried out in the spring. A significant disadvantage of cement mixed with slags is a decrease in the frost resistance of concrete; it cannot be used on moving soils.

Which cement is better for the foundation.

To fill the foundation, concrete with a grade of at least M200 should be made. The quality of work is directly dependent on the use of the correct ingredients, their preparation and mixing with proven proportions. Ideally, these are: fresh Portland cement without lumps, dry and sifted river sand, gravel or crushed stone from hard rocks, clean (drinking) water. A coarse-grained filler is selected with a grain size of no more than 30 mm, preferably with a square flakiness, it must be cleaned of debris and, if possible, washed. The kneading is carried out in a concrete mixer, this is required not only to reduce the labor intensity of the process, but also to obtain the desired structure.

The ratio of cement, sand and gravel depends on the type of substrate.So, for columnar foundations, it is better to choose a ratio of 1: 3: 4 with a W / C of no more than 0.65, the same mixture is suitable as a masonry mortar when building it from blocks. In this case, a cement grade of at least M400 is used. For a strip type of foundation, these proportions are 1: 4: 6, with the same with a W / C ratio of 0.65. Excess water is unacceptable, it leads to disruption of the hardening processes and the formation of cracks.

The method of preparing concrete for pouring the foundation has shown itself well, taking into account the recommended brand standards. A proven proportion is chosen: 1 part of cement, 3 - sand and 5 - gravel. The W / C ratio in this case depends on the required parameters of the concrete:

Expected grade of concrete.

Cement strength grade.

Which cement is best for the foundation. What else do you need to consider?

The quality of the cement is inversely proportional to its shelf life, and given the fact that high-quality (that is, rapidly losing its properties) is acquired for filling the bases, it is necessary to use the freshest powder of a light gray or greenish color that wakes up through your fingers. The attached certificate is checked, if the volume of work allows, then the material is purchased in plastic big bags, the packaging is opened immediately before preparing the solution.

Strengthening the strength of concrete is very simple: it is enough to add fiber or plasticizers, but this method increases the costs. Strip foundations must be reinforced, for them it is recommended to purchase gravel or hard crushed stone with a maximum size of fractions up to 20 mm. Regardless of the type of construction, waterproofing works are provided.

How cement is marked

Not only the operational life of the structure, but also its tensile and bending strengths - those types of loads that the concrete tape experiences most of all - depends on the cement used for pouring the foundation base. To know what brand of cement is needed for the foundation of a house, it is recommended to understand its differences.

Not so long ago, a concrete mixture was prepared on the basis of one of the binders - PC (Portland cement) or SHPC (slag Portland cement). The main differences were in powder composition and strength characteristics. Cement grades for the foundation corresponded to the current GOST.

In addition to the name, the brand of cement material for the construction of foundations and other work contains a designation with numbers that indicate the maximum strength under load until complete destruction.

Now let's see what brands of cement are, how the marking is applied and what its decoding means.

According to the old designation system, several brands were distinguished:

- M 300 - withstands loads of up to three hundred kilograms per square centimeter of surface;

- M 400 - corresponds to a pressure of 400 kg;

- M 500 - withstands impacts of at least five hundred kilograms per site unit;

- M 600 - carries a load of six hundred kilograms.

The characteristics given here are not able to give unequivocal advice on which brand of cement to use for the foundation of a house, and what to use in the construction of lighter structures. Naturally, for large structures it is necessary to take material with a greater load. But you can prepare a concrete solution with the required indicators by changing the amount of a lower grade cement composition, increasing its amount.

This criterion is present in the marking of the material, and its presence is indicated by the corresponding letters and numbers D0 or D20. Before making the final choice in cement, it is recommended to clarify how the mineral components affect the quality of the binder. For example, D0 does not contain any components, and the solution is of the highest quality. But the brand with the designation D20 carries up to twenty percent of impurities that lower not only strength, but also cost.When choosing a cement material, for example, for the foundation of a fence, you can use a powder with a lower strength indicator, thereby reducing the cost of the total cost of construction work.

When deciding which material is best to use for pouring a strip foundation, you should study the remaining characteristics of the component indicated in the marking. The following designations are most often found:

- PL - there are plasticizers in the cement. Such material for the foundation is used when temperatures are low in the region in winter;

- VRC - this abbreviation denotes the moisture resistance of the mixture and the increase in volume during solidification. If you are in doubt about which cement is best for a foundation in a swampy area, then you will not find another option;

- B - such material requires less time before final solidification. If you have a choice of what to use on the foundation of a house, when the terms of work are limited, choose this particular cement material;

- SS - sulfate resistant cement. It is rarely used by private developers, because its main purpose is considered to be the concreting of hydraulic structures. When plugging oil and gas wells, plugging cement is used - a mixture of clinker powder, gypsum and other components;

- H - cement with this marking has undergone additional rationing using clinker. This additive ensures high strength of the material;

- BC - "white cement". A distinctive feature is that it brightens after hardening. It is rarely used, mainly for finishing work.