Tape

Shallow strip foundations are the most common type of structures designed for heaving soils. Such a base can easily withstand brick and wooden buildings, as well as buildings made of foam blocks. Two-story houses can also be built on this type of foundation.

This option is distinguished by a fair amount of durability and reliability; it is this option that most land owners choose for their new homes. In addition, the construction of such a foundation is not too expensive, and the work itself is elementary and does not take much time. But how the assembly of the prefabricated strip foundation takes place, and how to do it correctly with your own hands, is indicated in this article.

The video shows the features of the strip foundation:

In this case, the foundation is a concrete strip, reinforced with a reinforced belt-frame. A pit for such a foundation is dug to a depth of 50 to 70 cm. A small (20-30 cm) layer of sand is poured onto the bottom of the pit and compacted. Such a sand cushion is necessary for a more reliable installation of the structure. After all the preliminary work, the foundation pit is poured together with the reinforcement with liquid concrete. The very top layer of reinforcement is laid on top of the concrete mixture, when the latter has not yet hardened.

Attention: you cannot use a welding machine to connect parts of the reinforcement to each other, as it will not be able to provide sufficient structural reliability. Connect the pieces of reinforcement with a strong knitting wire

A shallow strip foundation can be made either from reinforced concrete structures, or be monolithic. The first option can be erected at any time of the year and is easy to install. The downside here is the high cost, and the insufficient degree of tightness of the base. Sometimes a reinforced concrete foundation allows groundwater to pass through if the waterproofing was done with violations.

The monolithic version is made on high-quality concrete, and is more difficult to build. A solid reinforced frame is installed inside the monolith, which gives reliability and stability to the entire structure.

But what a slab pile foundation looks like, and in which case it should be used, and how exactly, is described in great detail in this article.

Classification of soils and their properties

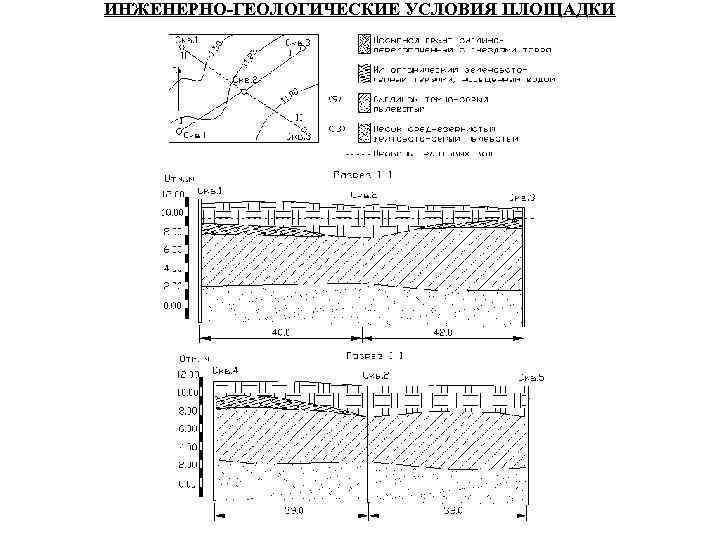

In the course of engineering and geotechnical surveys, a comprehensive study of the natural conditions of the construction site is carried out.

To lay a foundation of sufficient strength, the composition of the soil and its properties are of decisive importance. The construction industry has a clear soil classification system, which distinguishes the following types of soil:

- Rocks.

- Semi-rocky soils.

- Large debris.

- Sandy and loamy unbound soils.

- Clay or bonded soils.

Builders often have to work with all of these types. Each of the types of soils has properties inherent only in the specified category.

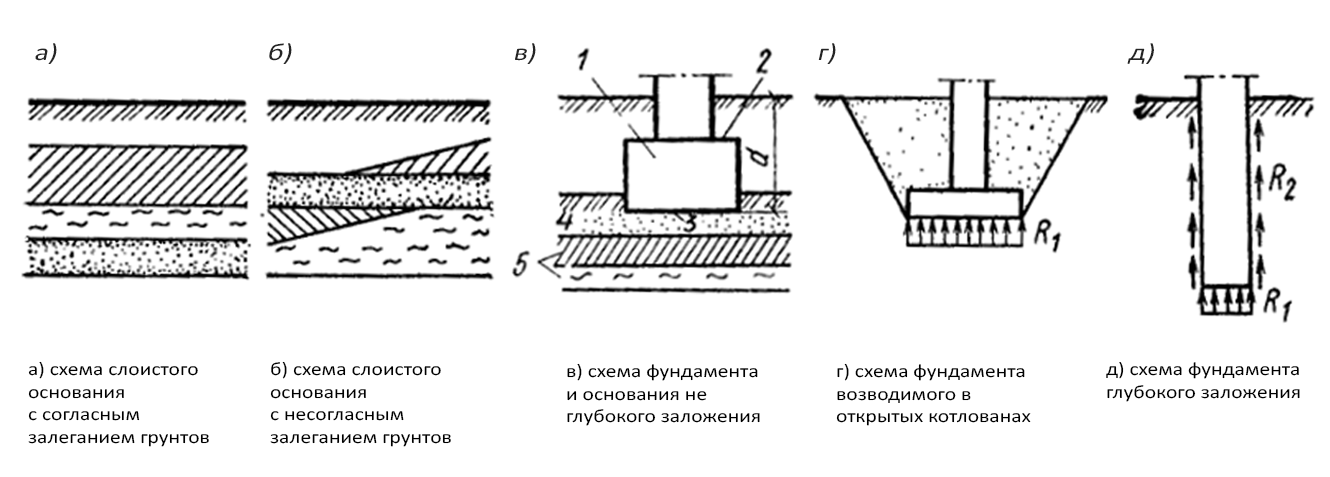

When laying the foundation, not only the type of soil is taken into account, which is not homogeneous as it deepens.

Usually land plots have an upper vegetative or fertile layer, below can be found sandy, sandy loam, clay and loam.

The thickness of the soil layers when choosing a specific foundation calculation scheme is also taken into account along with other factors.

Is it possible to change the soil on the site yourself

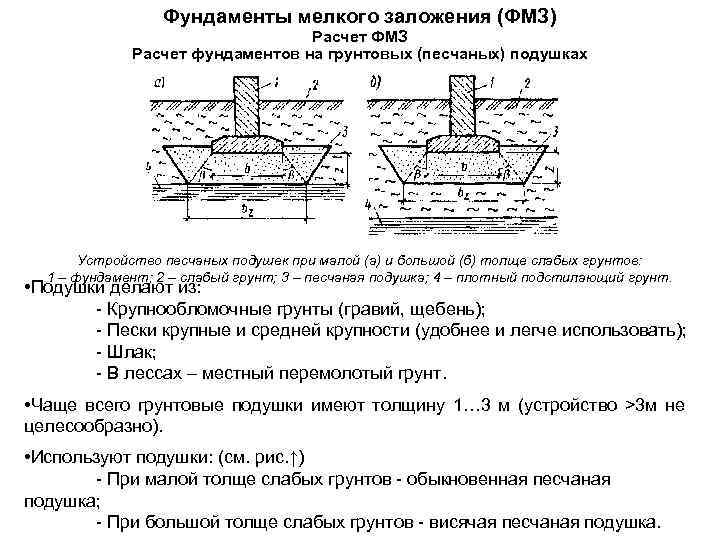

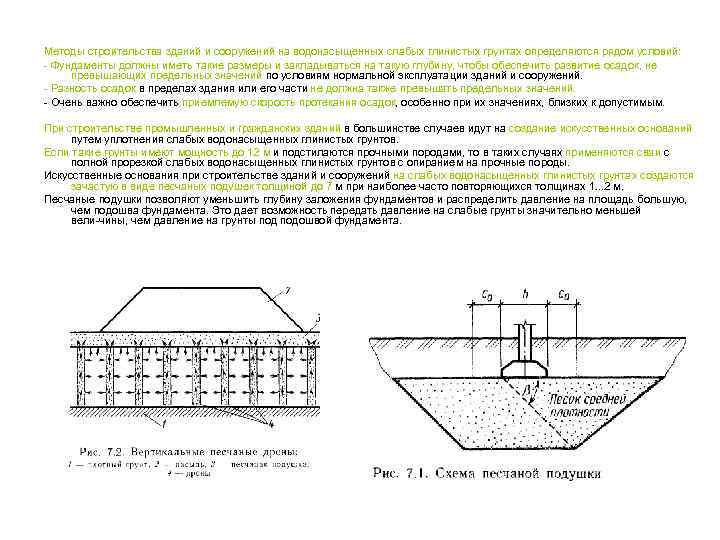

Substitution of soils for the foundation should be carried out only with the preliminary conduct of appropriate studies and calculations. Of course, you won't be able to do this kind of work yourself. Therefore, most likely, you will have to invite specialists.However, when erecting not too expensive buildings, for example, household buildings, this operation can be performed "by eye". Although we would not recommend taking risks, for general development, let's take a closer look at this procedure. So, the stages of work in this case are as follows:

- Excavation is carried out to a solid base.

- Sand of medium size is poured into the trench to the level of the sole of the future foundation. Backfilling is done in layers of small thickness with each tamping. The sand must be moistened with water before compaction. Tamping should be done as carefully as possible. The sand itself should not contain any inclusions, especially large ones. Sometimes soil-concrete mixtures and slags are used instead.

In the event that an artificial foundation is used for the foundation, it is also worth arranging a drainage system around the house. This will slightly increase the density of the soil surrounding the pillow and prevent it from being squeezed out to the sides.

Types of foundations and their use on specific types of soil

The design features of modern foundations allow you to choose the best option for use on good soils and those with the most undesirable characteristics. Let's consider each of them in more detail.

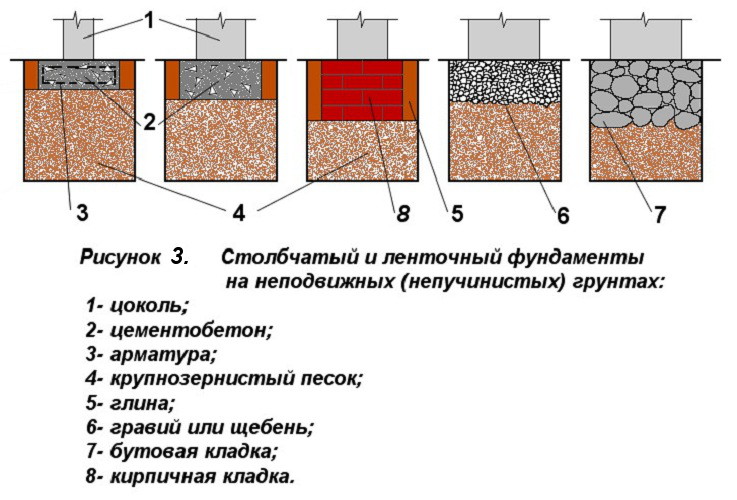

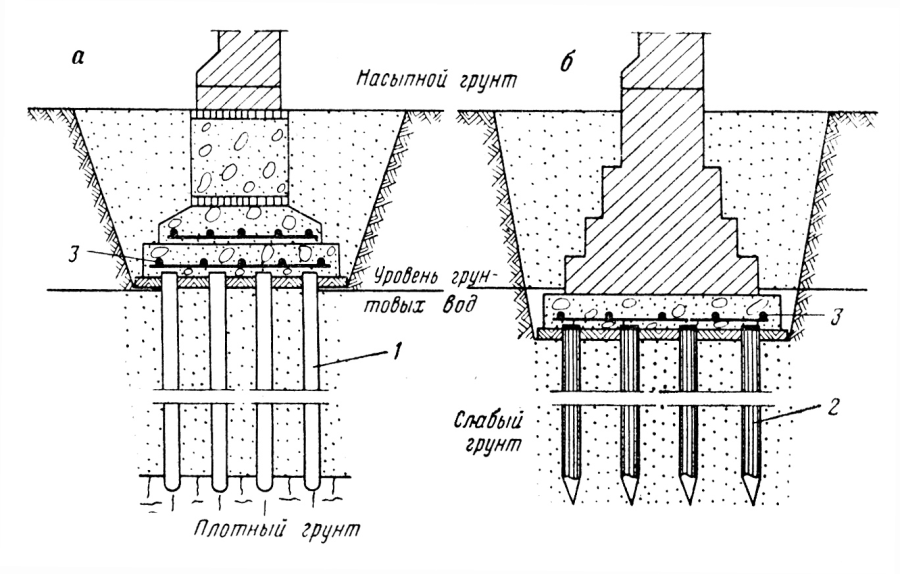

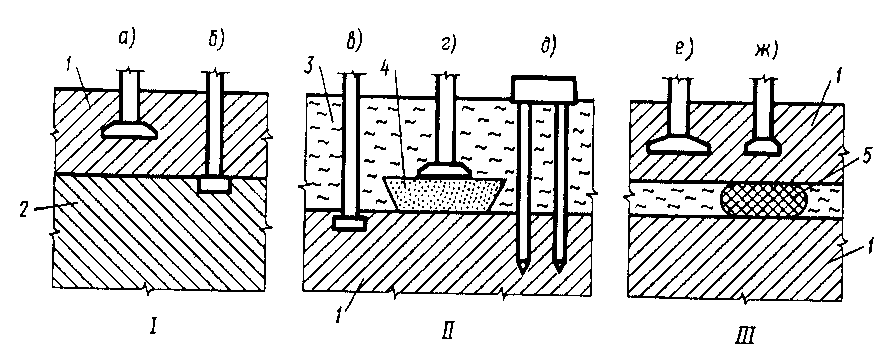

Columnar foundations

This is a structure with rectangular or round supporting pillars. Poles are made of various materials; rubble concrete with additional reinforcement is often used.

Wells are filled with concrete to the height of the soil, and then they are raised to the level of the grillage with bricks. Columnar bases are cheap in construction, you can use improvised building materials, you do not need to use waterproofing, and also erect a building on weak subsidence soils. But the grillages are not protected from airing, so it is necessary to make the underground thermal insulation. And this is additional financial costs.

Such bases are used on relatively light soils that are not subject to heaving and horizontal displacement. After all, the pillars are practically not connected to each other, therefore, during movement, deformation and rupture of the grillage are possible with further collapse of the building.

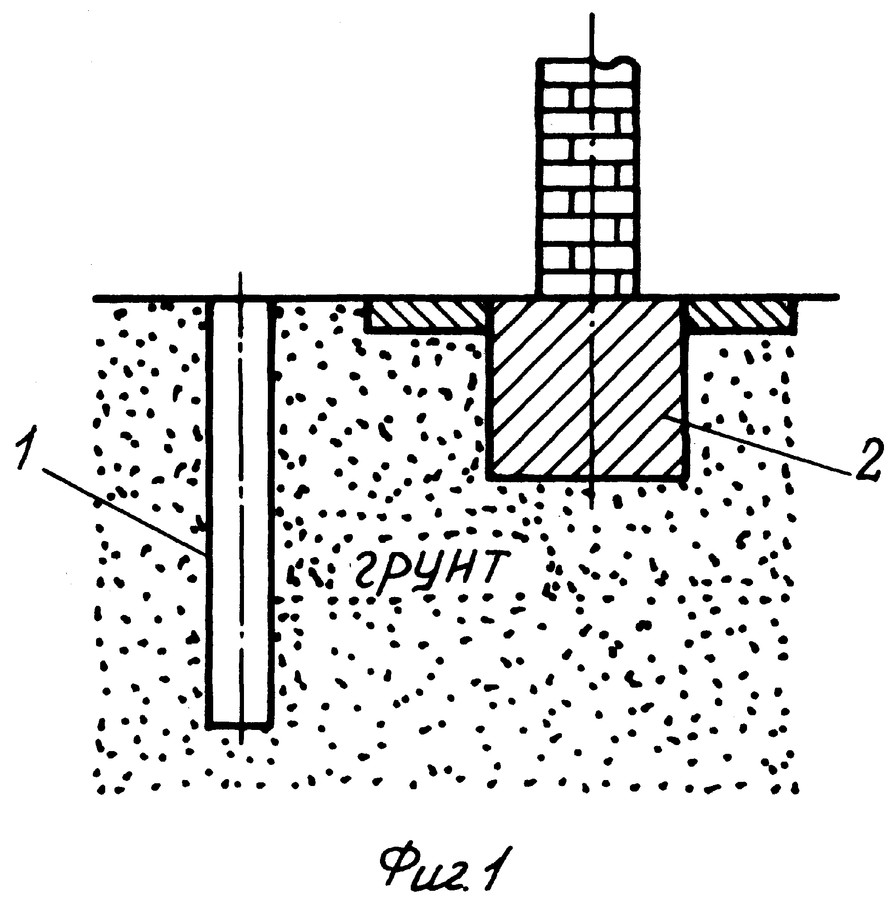

Columnar foundations with ligation

Such bases are more durable and stable than conventional structures, they use the reinforcement of horizontal and vertical belts. But the device of the market for dressing (dressing) significantly increases the cost and complicates the foundation. Since it requires a single reinforcement (bandage of reinforcement) both in the beam and in the column. Ryndbalka is placed either on the surface of the soil, or with a slight deepening, having arranged a sand cushion under it.

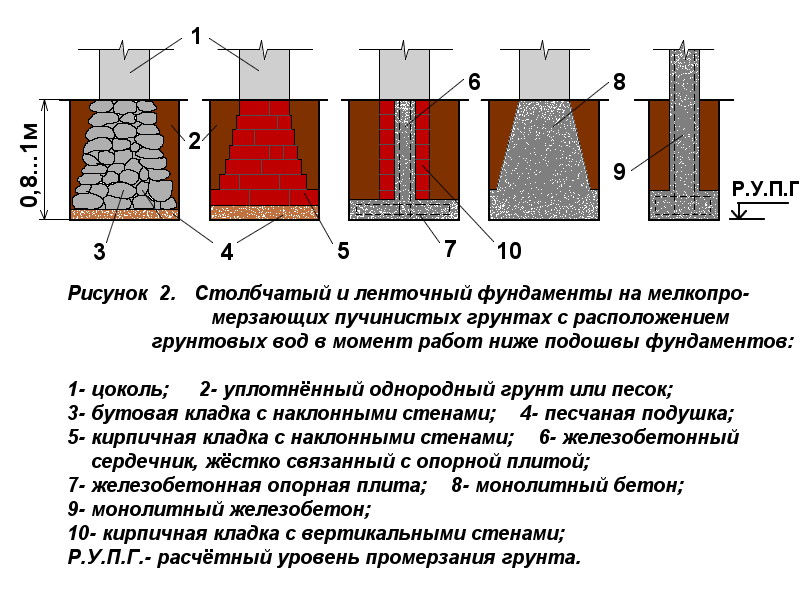

Shallow strip foundation

This is a monolithic structure, erected at a shallow depth and protruding above the surface, forming a plinth. The tape lies at a depth of up to a meter, sometimes even up to 50 cm, a sand cushion is provided under the concrete belt.

This type of foundation is practiced when erecting small high-rise buildings; you can make an underground or a small cellar. When constructing such bases, the construction of pits is practiced, which are used to further strengthen the structure.

The interval of the pits is up to one and a half meters, they are reinforced and filled with concrete, and the wells are often arranged below the freezing depth. It is practiced on sandy soils and loams, its advantage is its versatility and low cost. You just need to remember that this is a monolithic structure and all blocks must be connected to each other with reinforcement and high-quality concrete mortar.

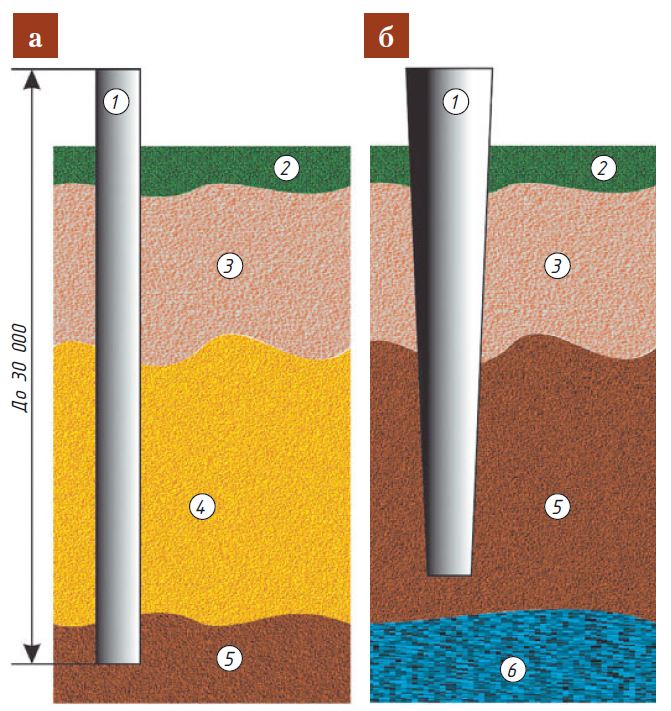

Deeply buried strip foundation

This is the most reliable type of foundation, which is used on weak heaving soils, or with a large content of subsidence rocks. The properties of such a base make it possible to use it also on rocks with a deep sedimentary layer.

The sole of the tape is always installed below the freezing depth of the ground, so it can withstand even strong vertical ground movements. Such a base also contributes to the arrangement of a full-fledged basement of various heights.

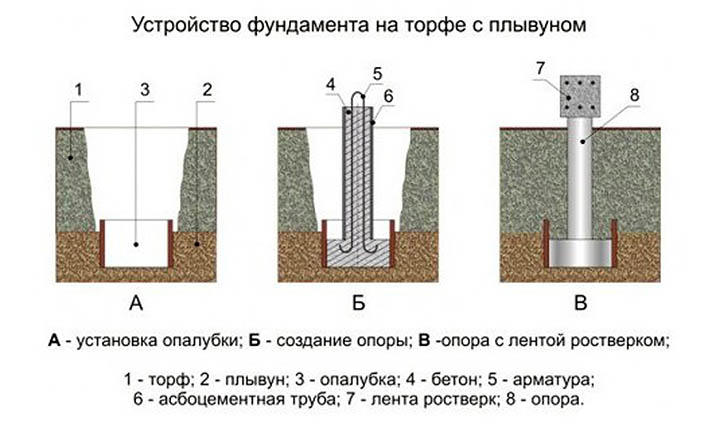

Monolithic base

This is the only type of foundation that can be used on peaty or clayey soils with a high groundwater table. It can be shallow or deeply buried, it allows you to make a basement, because here a monolithic reinforced concrete slab of calculated thickness is created on a sand and gravel cushion.

The only drawback is the need for a perfectly flat construction site, otherwise, over time, the monolith will slowly begin to slide. The properties of the structure are such that it is possible not to make complex calculations of the bearing capacity or even do additional strengthening of the soil.

Rocky soils

Rocky soils are monolithic rocks or in the form of a fractured layer with rigid structural bonds, lying in the form of a solid mass or separated by cracks. These include magmatic (granites, diorites, etc.), metamorphic (gneisses, quartzites, shales, etc.), sedimentary cemented (sandstones, conglomerates, etc.) and artificial.

They hold the compressive load well even in a water-saturated state and at negative temperatures, and are also insoluble and do not soften in water.

They are a good foundation for foundations. The only difficulty is rock excavation. The foundation can be erected directly on the surface of such soil, without any opening or deepening.

Coarse soils

Large-detrital - incoherent fragments of rock with a predominance of fragments larger than 2 mm (over 50%).

According to the granulometric composition, coarse-grained soils are subdivided into:

- boulder d> 200 mm (with a predominance of unrolled particles - blocky),

- pebble d> 10 mm (with non-rounded edges - crushed)

- gravel d> 2 mm (with non-rolled edges - grit). These include gravel, crushed stone, pebbles, gruss.

These soils are a good base if there is a dense layer underneath them. They shrink slightly and are reliable bases.

If there is more than 40% of sand aggregate in coarse soils or more than 30% of clay aggregate of the total mass of air-dry soil in the coarse soil, add the name of the type of aggregate in the name of the coarse soil, and indicate the characteristics of its state. The type of filler is set after removing particles larger than 2 mm from the coarse soil. If the clastic material is represented by a shell in an amount of ≥ 50%, the soil is called shell, if from 30 to 50% is added to the name of the soil with a shell.

Coarse soil can be heaving if the fine component is dusty sand or clay.

Conglomerates

Conglomerates are coarse-grained rocks, a group of rocky destroyed, consisting of separate stones of different fractions, containing more than 50% fragments of crystalline or sedimentary rocks that are not connected with each other or cemented by foreign impurities.

As a rule, the bearing capacity of such soils is quite high and capable of supporting the weight of a house of several floors.

Cartilaginous soils

Cartilaginous soils are a mixture of clay, sand, stone fragments, rubble and gravel. They are poorly washed out by water, are not subject to swelling and are quite reliable.

They do not shrink or blur. In this case, it is recommended to lay the foundation with a depth of at least 0.5 meters.

Soil types

The type of soil is of decisive importance when designing the foundation of a house

There is no ideal site for construction, therefore it is so important to have complete and reliable information about the property of the land under the future house.Only a non-professional will undertake the design and construction without the necessary data or having laid in the project a greater strength of the foundation than specific conditions require

So, what types of soils are there? As mentioned above, by origin, soils are subdivided into natural and artificial, that is, the former were formed in natural conditions, the latter - as a result of human activity.

Natural soils

This type of soil includes rocky and non-rocky, the latter are subdivided into coarse, sandy and clayey.

Rocky - deposits of solid rocks (limestone, quartzite, granite, etc.), monolithic or in the form of cracked strata. They are characterized by high strength, resistance to deformation, water, low temperatures. In other words, they do not change their properties and condition under the influence of natural conditions and are the most solid foundation for any construction. In practice, they are quite rare.

Non-rocky soils combine the most common types of soils for construction. These include coarse, baked and clayey.

Coarse soils are soils with more than half of their composition in the form of destroyed rocks (crushed stone, gravel, pebbles, etc.) with a size of 2 mm or more. Depending on the size of the particles, crushed stone (or pebble, particle size from 10 mm) and gravel (or gravel, particle size from 2 mm) are classified as coarse. Soils belonging to this group have sufficient strength and allow the construction of houses with foundations, a depth of half a meter. An exception is the situation when such soils are affected by groundwater. In this case, a shallow foundation will not be reliable.

Sandy soils are soils with the main content of particles up to 2 mm and up to half of the composition - particles larger than 2 mm. The reliability and strength of such soils is determined by the particle size, composition density and moisture content. In this regard, it is customary to classify sandy soils:

- by particle size (gravel, large, medium, fine, silty);

- by density (dense, medium density, loose);

- by humidity (low moisture, very wet, saturated).

It should be understood: the larger the fraction of the sandy soil, the less the ability to deform (sag) and the higher the strength of such a foundation. Fine and silty sandy soils, when saturated with water, lose their strength and are often mobile (float). Sandy soils, relatively homogeneous in structure, do not swell, give a quick and final settlement. The depth of the foundation on such soils is determined by the depth of freezing.

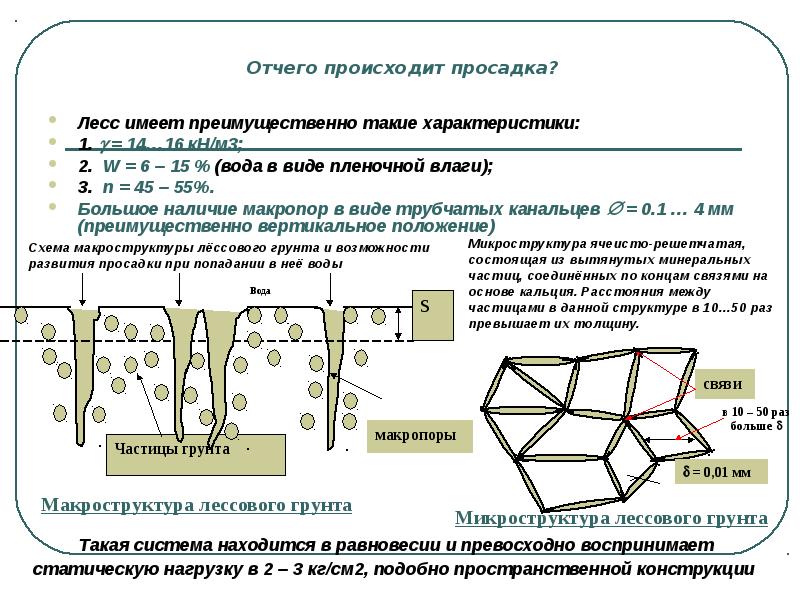

Clay soils are soils with particles in the form of the smallest scales. The properties of such soils change depending on humidity: dry - withstand significant loads, wet - become plastic. In addition, moist clayey soils are highly susceptible to deformation under the influence of temperature: when they freeze, they swell, when they dry, they shrink.

clay, sandy loam, loamy and loesslike

- clays - more than 30%;

- loams - 10-30%;

- sandy loam - 3-10%;

- loess - 5-30% of silty clay particles.

In a dry state, clayey soils are stable and durable, which allows you to safely engage in construction. However, under the influence of humidity and temperature differences, the arrangement of the foundation on such soils requires accurate calculations, which are based on the data of engineering and geological surveys.

Artificial soils

Artificial soils include soils that are not able to independently withstand the load from the house (peat, silt, vegetable soil, etc.). This also includes soils formed by human hands, they are also called bulk soils.In terms of structure and properties, artificial soils are loose and heterogeneous, which imposes significant restrictions on the arrangement of foundations in such territories. Before construction work, soils of this type must be prepared and strengthened in one way or another (compaction, cementation, etc.). In addition, artificial soils often contain elements that negatively affect foundation materials. Therefore, it is better not to choose such land plots for building your own house.

You can read about self-determination of the type of soil here.

Foundation materials

The selection of materials for the construction of the foundation is carried out at the design stage, based on calculations of the reliability and strength of the structure. In this case, the material must be resistant to environmental influences, frost resistance and sufficient strength.

The most common are concrete, bricks, aggregates of various densities and sizes, cement-soil, as well as artificial and natural stone materials. In rare non-critical cases, wood can be used, for example, for a columnar foundation.

Rubble stone (quarry) - large pieces of rocks of various irregular shapes. Work with this material should be approached carefully, since in the process, voids may form between the stones, which must be filled. Mostly for foundations, rubble stone of the same size is used - this greatly facilitates laying.

Crushed stone is a mixture of small fragments of rocks obtained by crushing. It is mined from hard rocks and has an irregular shape. It is commonly used as aggregate for concrete mixes along with gravel.

Gravel is a natural stone material formed as a result of the weathering of rocks. The origin can be mountain, river and sea with a certain proportion of impurities (clay, sand, etc.).

Brick is used both for the construction of the foundation itself and as a filler (broken and burnt) for a binder solution. However, this is a rather expensive material for arranging the foundation, therefore, it is rarely used for complex and large foundations. In addition, the brick has a low durability and a high degree of moisture absorption.

Concrete is the main and most common material for building foundations. There are several types of concrete, depending on its density and strength (heavy, light, etc.). Reinforced concrete is a type of concrete reinforced with metal and belongs to the class of composite materials. Usually in the form of concrete blocks and slabs.

Steel - used as the main material for piles, as well as a reinforcing component for concrete products.

Wood, with some restrictions, can also be used as a foundation material. The most reliable, strong and durable species for these purposes is larch.

In terms of popularity of use, concrete is, of course, in first place. Further - its varieties with one or another filler, for example, rubble concrete, and dense, high-quality brick.

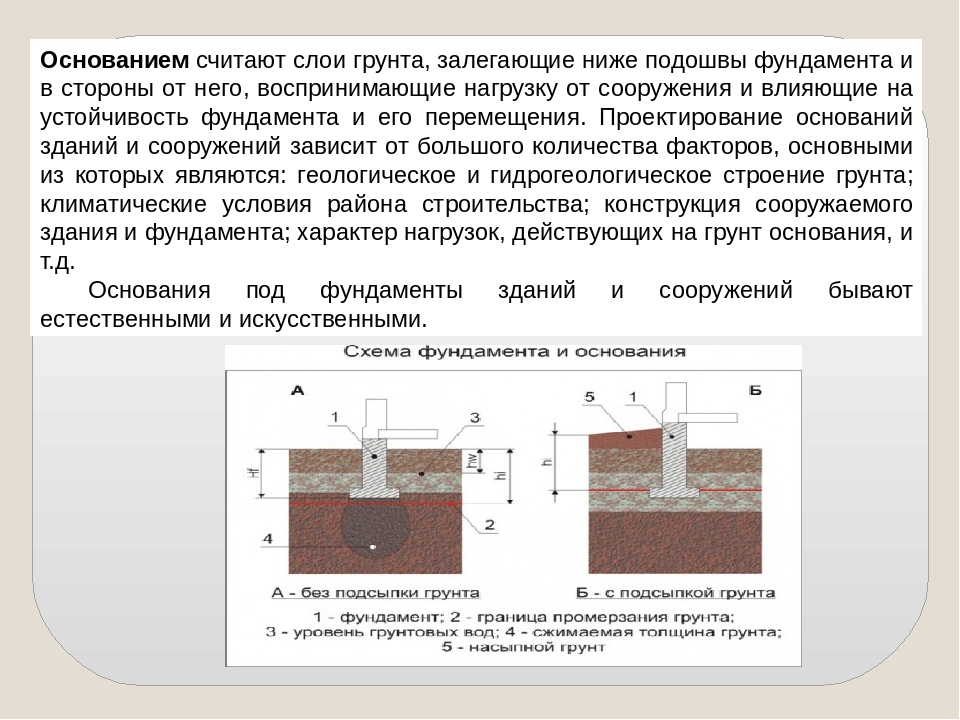

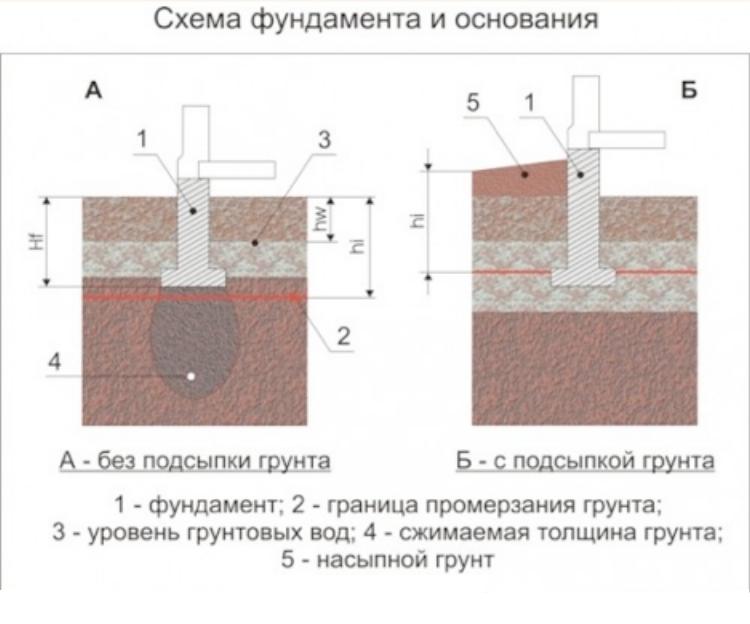

Foundation depth

In order for the foundation to qualitatively fulfill its purpose - to evenly distribute (transfer) the loads from the above-ground parts of the house to the base (ground), it is necessary to correctly calculate the depth of its foundation - the distance from the sole to the surface of the earth.

Usually, when designing houses, the minimum required depth is indicated. Moreover, it is mainly based on the data of engineering and geological surveys. Due to the fact that the cost of the foundation and work on its construction is a significant part of the total cost of building a house, it is clear that mistakes at this stage will be very expensive.

The depth of the foundation depends on:

- geological conditions of the land plot (type of soil and foundation, groundwater level);

- type of building under construction (house, garage, bathhouse, etc.);

- structural features of the building (presence of a basement, basement, etc.);

- loads (size and nature);

- climatic conditions of a given area (temperature drops).

In each specific case of designing a foundation, the depth of its foundation must be calculated individually, based on the conditions on the selected plot of land. A competent solution to this problem allows you to find that "golden mean" in which the foundation will have the necessary stability, strength characteristics and at the same time optimal consumption of materials. The latter is more than relevant today - houses are becoming larger and heavier, respectively, and the cost of the foundation also increases. When building a large house, it is already financially tangible to lay the foundation strength "with a margin", that is, the depth of laying the foundation should be rational and based on calculations.

The cost of a foundation is directly proportional to the depth of its foundation: the deeper the foundation, the higher the costs for its construction, associated earthworks and materials, and vice versa.

Features of the technology of building a foundation, depending on the type of soil

With the help of the correct type of foundation and adherence to the technology for building the base, you can create a solid support for construction on any kind of sandy soils.

Dusty and fine-grained

To build a house on dusty and fine sand, due to the extreme instability of the layers, it is necessary to create the most solid foundation. In such cases, the construction of a slab foundation is permissible. To do this, remove the fertile soil layer and cast a concrete slab, the scale of which is slightly larger than the area of the planned building. The structure does not collapse under the influence of seasonal changes in the soil, since this type of foundation is able to move with the ground, therefore it is called a floating foundation.

Another more common way to create a solid foundation for a building on silty and fine sandy soil is to use a monolithic strip foundation of a shallow type. It is recommended to make it trapezoidal with lines expanding downward. This contributes to a significant reduction in the influence of frost heaving on the base of the house.

Before pouring the foundation tape, the trench is equipped with a waterproofing layer. When laying the sole structure under a structure on fine sand and silty soils, drainage is especially important. Closed systems, which are equipped on the basis of drainage pipes, are recommended as effective methods.

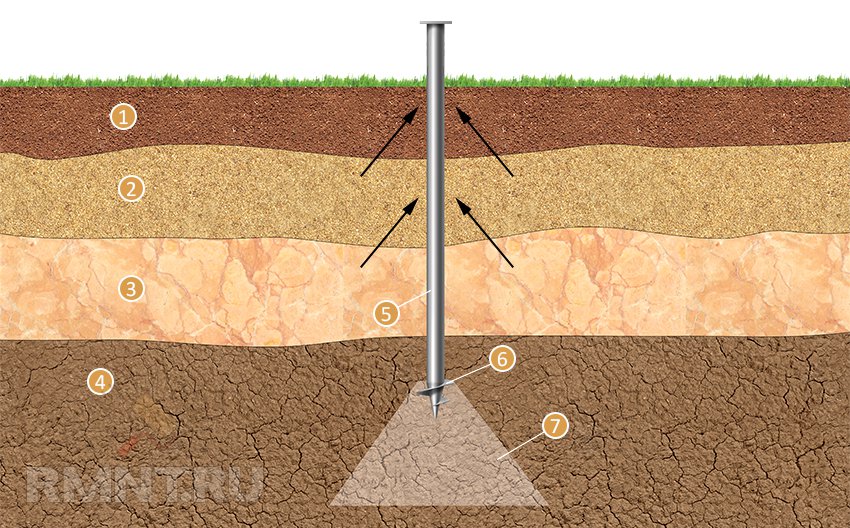

When working on the construction of the base of the base for heavy buildings on fine and dusty sand, it is worth using the pile-tape option for arranging the foundation:

- carry out the markup, dig a pit, install the formwork;

- at the intersections of the tape, wells are drilled to a depth of stable soil layers;

- pipes based on asbestos cement are installed in the wells, the structures are leveled qualitatively, and reinforced with spacers;

- the pipes are poured with concrete solution by 1/3, slightly raised to form a thickening at the bottom. Next, the pipes are filled with a solution, having previously lowered the fittings into them.

Formwork and reinforcement for pile-strip foundations

Piles can be poured without installing pipes, if the environment is not very wet and the wells are not filled with water:

- the lower part of the well is expanded with a special plow;

- reinforcing material is lowered into the well and poured with a solution;

- after the pile structures have solidified, they begin to pour the tape into the formwork.

Experts note that after pouring the foundation on fine-grained and dusty sand, the structure must stand for six months before continuing construction work.

Large and gravelly

Since coarse sandy soils have a reliable level of bearing capacity, any types of foundation structures are relevant here:

- if it is planned to build a house without a basement, the tape version of the shallow type is most often used;

- a columnar base is suitable for a structure made of light materials in the form of frame structures, wooden houses or panel structures;

- for massive buildings with a basement, a strip foundation of a strongly recessed type is performed.

Column foundation for a frame house

When laying a columnar or strip version of the base of the base, foundation blocks or ceramic bricks are also used.

On a shallow strip base on coarse sand, you can put a building made of foam blocks or wood, a frame / panel view of a structure, or a small brick house. At the same time, the depth of laying the sole varies in the range of 40-70 cm.

Do-it-yourself technology for pouring a monolithic shallow tape:

- Site preparation. Having removed the fertile layer of earth, the surface will be leveled.

- Markup. The work is carried out on the basis of the house project.

- Trench preparation. Dig a trench 60-80 cm deep. The width of the recess is equal to the thickness of the planned walls plus 20 cm, that is, 5 cm on both sides of the wall for the stability of the structure and 5 cm for the formwork.

- Filling the formwork with concrete mortar.

Foundation trenches

For formwork, plywood sheets, edged boards, profiled sheets are used, the inner surface is lined with polyethylene, reinforcing materials are used to strengthen the composition.

When constructing massive buildings or houses with a residential basement or basement, a deep foundation tape is laid. Moreover, the sole under the brick house is installed 20 cm below the level of soil freezing. The deeply buried strip foundation is provided with a waterproofing layer on all sides, including the lower surface. Quality drainage is also required.

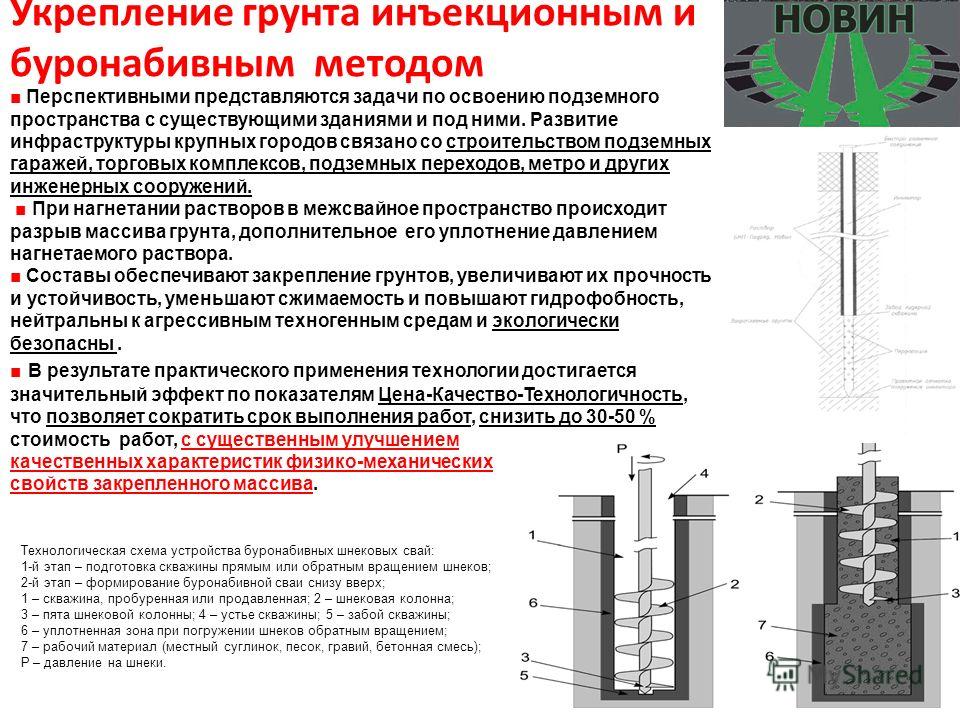

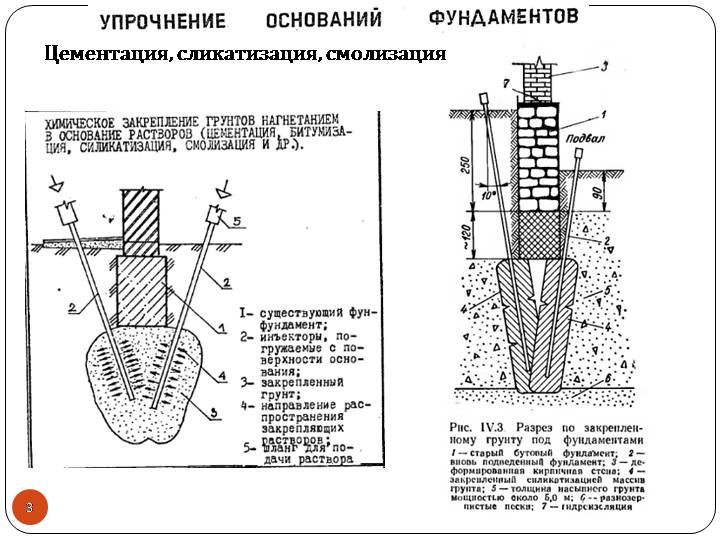

Thermal method

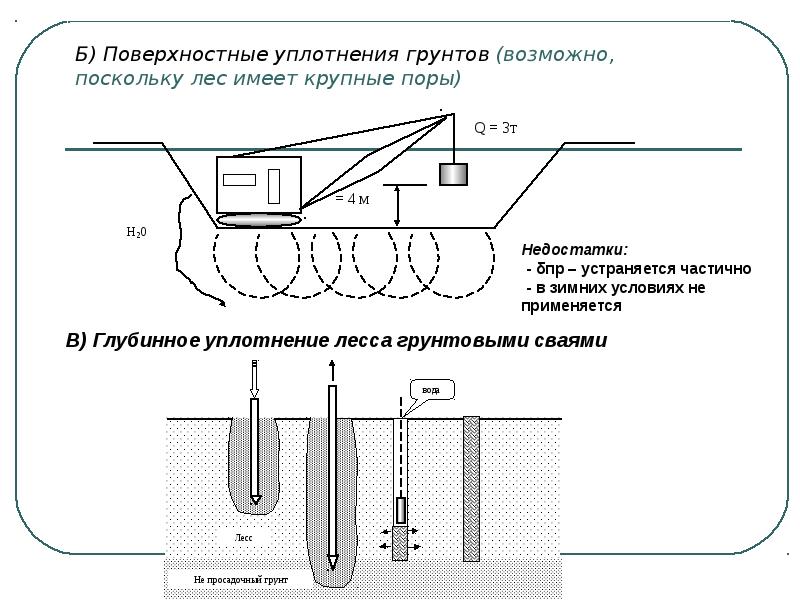

The choice of the soil reinforcement option depends, first of all, on its composition, the procedure for determining which is regulated by GOST. Soils, the classification of which was presented above, usually require strengthening only if they belong to a non-rocky group.

Thermal is one of the most common amplification methods. It is used for loess soils and allows for strengthening to a depth of about 15 m. In this case, very hot air (600-800 degrees Celsius) is injected into the ground through pipes. Sometimes the heat treatment of the soil is done in a different way. Wells are dug into the ground. Then, flammable products are burned in them under pressure. The wells are previously hermetically closed. After such treatment, the fired soil acquires the properties of a ceramic body and loses its ability to absorb water and swell.