Varieties of 10 mm reinforcement

According to the field of application and their design features, 10-mm reinforcement is divided into two main classes:

- working;

- assembly room.

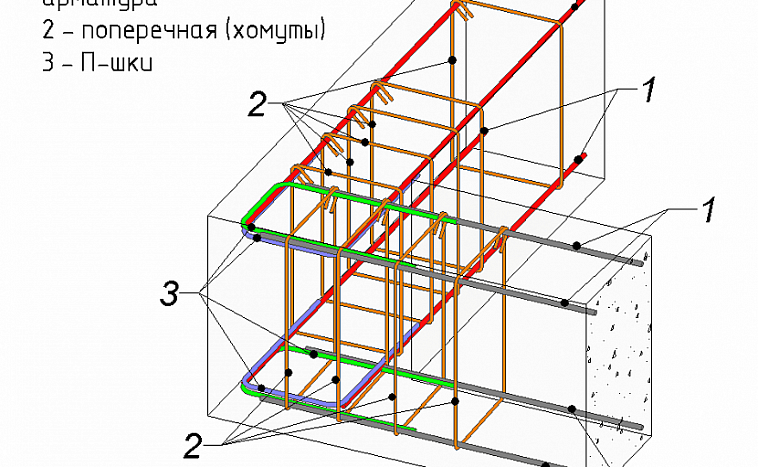

The main distinguishing feature of the working reinforcement is its corrugated surface. This is necessary for its better adhesion to concrete. Such reinforcement works perfectly for bending, significantly increasing the critical value of the load on the foundation. When creating a spatial internal frame, it is used mainly for longitudinal threads, less often for transverse bridges.

The mounting hardware has a smooth surface and is most often used as cross bridges. It gives the frame internal rigidity, preventing it from deforming under the action of loads.

By the type of material of manufacture, all modern fittings are divided into two types - steel and fiberglass. Watch the video on how to use fiberglass reinforcement.

Steel reinforcement has been proven for decades in the construction industry. Its main advantages are:

- Excellent flexibility and at the same time remarkable strength up to 19 kN.

- Functionality in use. The metal frame can be not only bonded, but also welded.

- Sufficient durability, especially for rolled alloy steel, reaching tens of years.

Fiberglass reinforcement

Fiberglass reinforcement

Fiberglass reinforcement, which has recently appeared on our construction market, also has a number of its own advantages:

- Resistant to moisture. Fiberglass, in principle, is not subject to corrosion, which makes the reinforcement made of it very durable.

- High strength. According to these characteristics, fiberglass is not much inferior to steel.

- Ease. Low weight allows to lighten the overall weight of the frame as much as possible.

As a result, we can say that the choice of one or another option of reinforcement, type of frame, and so on, should be based on the appropriate building codes

In this case, when constructing a foundation, first of all, you need to take into account the mass of the expected load (building), as well as the type of soil on which the house is being built.

Rebar connection

The easiest way to lay reinforcement in the foundation is to weld the rods into a single frame. This technology is also distinguished by its high speed. But in this case, most of the products (rods) at the place of welding lose their strength characteristics. Therefore, we do not recommend using welding, but save it for completely hopeless situations.

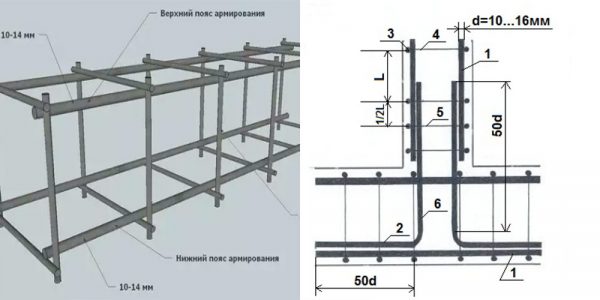

Another option for designing the frame is the so-called reinforcement knitting, which implies the creation of a wire connection at each intersection of the "skeleton" rods. This process is quite laborious, but if you get used to it, then each connection will take no more than 5 seconds. The knitting sequence is shown in the figure below. All of the above operations are best done before installing foundation formwork.

Please note that over 50% of all rod crossings must be connected. This applies primarily to the corner parts of the frame.

Reinforcement during the construction of a strip foundation

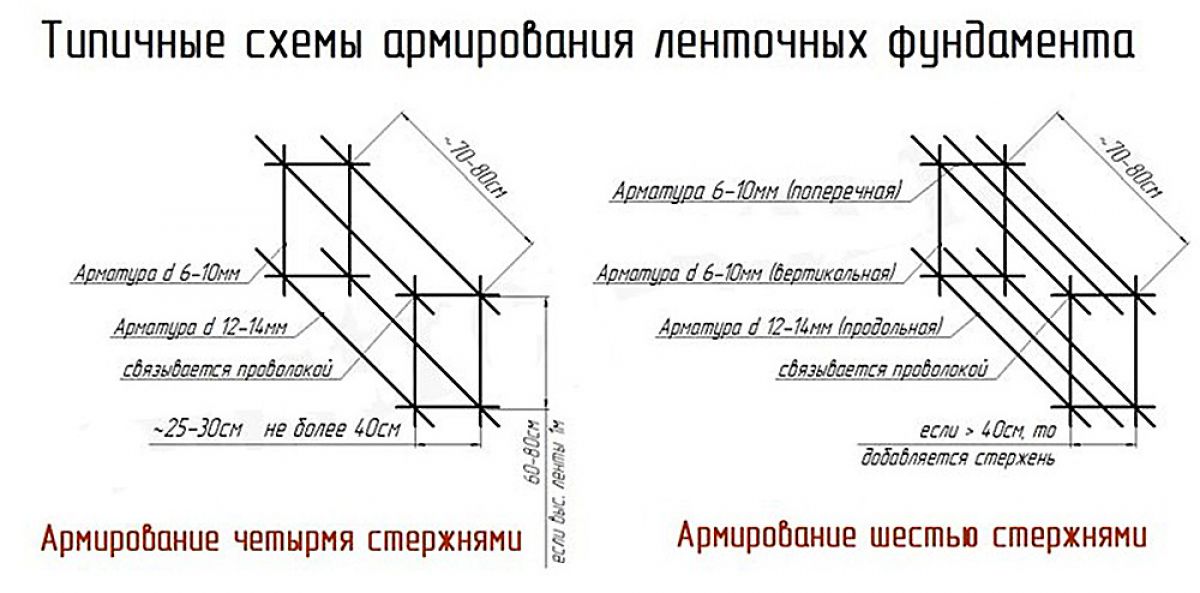

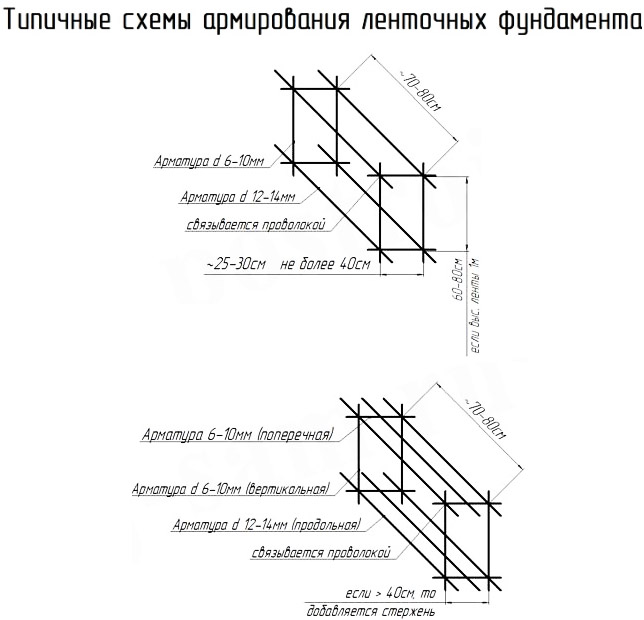

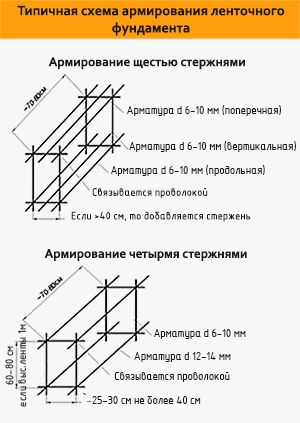

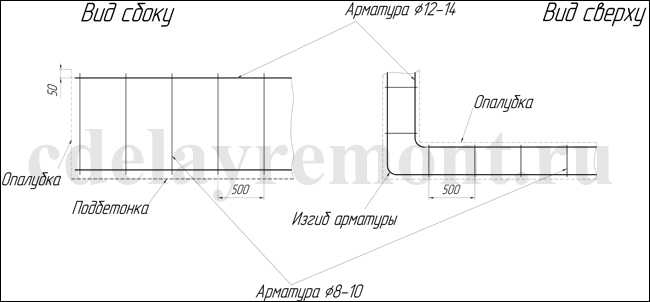

One of the features of a monolithic strip base is that, regardless of the height, when erecting it, it is enough to use only 2 reinforcement belts - above and below. Most often, rods with a diameter of 10 to 14 mm are used, depending on the load. The more substantial the building, the larger the diameter of the reinforcement used. Each reinforcing belt consists of a pair of longitudinal ribbed rods.They are connected by means of jumpers made of smooth rods with a diameter of 8 mm, located with a pitch of 500 mm in the horizontal and vertical planes.

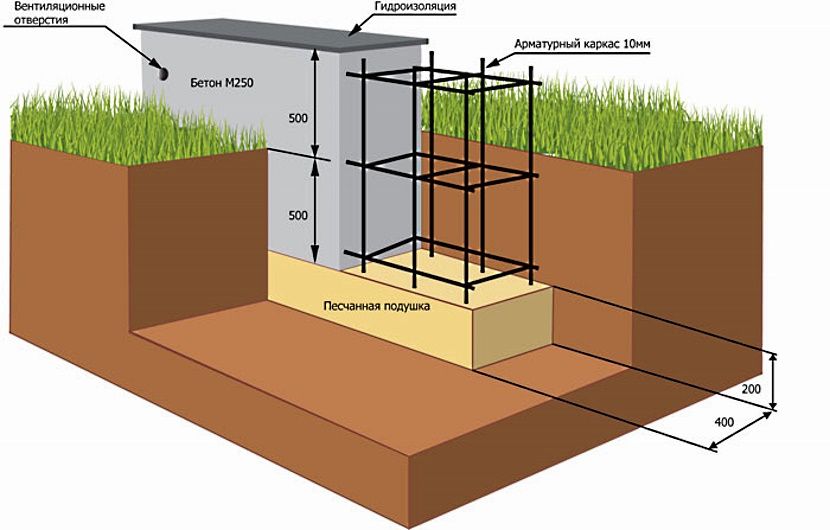

It is important that all elements of the frame are subsequently covered with a protective layer of concrete - about 50 mm (to protect against moisture). At the same time, it should be borne in mind that longitudinally oriented rods should be as close as possible to the horizontal surface, playing the role of a beam that is resistant to tension

It is for this reason that you should not get carried away and hide the belt deeper. Vertical structural elements are installed on a pre-prepared base - 30 mm foundation. This allows you to protect the metal from corrosion, which would inevitably occur in other situations due to exposure to moisture.

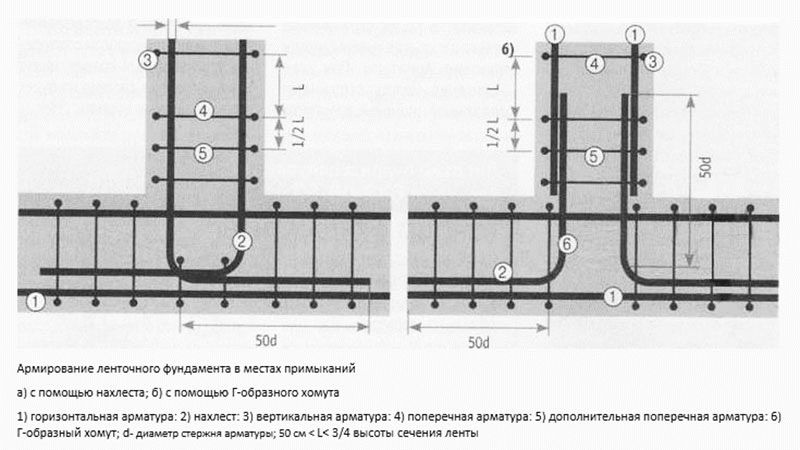

We also note the need to bend the reinforcement at the corners - you should not lay the rods at right angles to each other, because this will negate all efforts to create a monolithic structure. The rods are placed with an overlap of at least 250 mm and are firmly tied with wire.

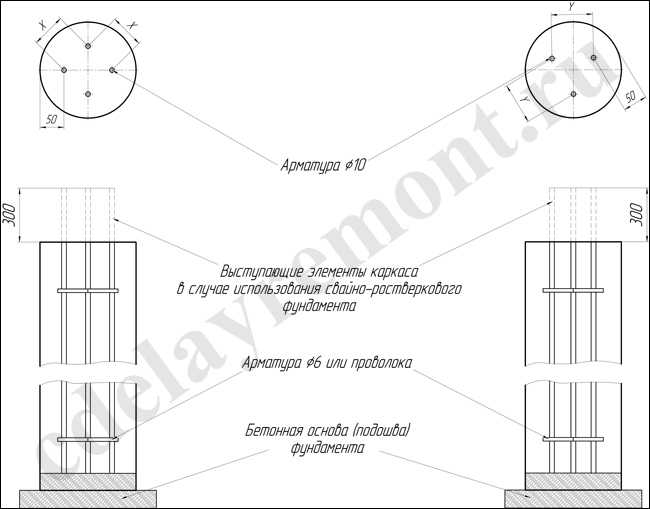

Reinforcement during the construction of a bored base

When strengthening a bored pile, ribbed rods with a diameter of 10 mm are used. There can be 2, 3, 4 or more of them - depending on the diameter of the used fill form. As a rule, an asbestos-cement pipe with a diameter of 200 mm is used as the latter. In this case, you can use 3-4 rods of reinforcement, connected together as shown in the figure below.

It is important that the frame elements are at least 50 mm away from the pipe. It is also necessary to take into account that the lower parts of the rods rest on a pre-prepared concrete platform (see

(See the article on bored piles).

Reinforcement for slab foundation

The slab base is one of the most reliable and at the same time the most expensive solutions. The price of reinforcement for the foundation, which will have to be paid for a zero cycle in such a construction, can be up to 20% of the total cost of construction.

When erecting this type of foundation, ribbed reinforcement with a diameter of 10-16 mm is used, depending on the heaving of the soil and the magnitude of the load from the future building. The more difficult the construction conditions, the larger the diameter of the steel rods. Two belts are laid, and in such a way that cells with sides of 200 mm are formed.

Features of the loads acting on the strip foundation

The foundation is considered to be the part of the building structure located below the zero mark and serving as a support for the entire structure. There are several types of base device.

The choice depends on such features as the presence of a basement, the characteristics of the soil under the base, the material from which the building is built, its number of storeys and others.

loads from the following elements

- from the plantar base;

- from the ground located above the base;

- from the floor, basement, ceiling, stairs and other internal structures in the house;

- from the roof, walls of the building, including the weight of finishing materials.

Most often, the strip foundation is made from a concrete mixture using a reinforcing rod. It is a product of high-quality rolled metal and has different sizes and external design. Composite reinforcement is sometimes used.

The use of reinforcement makes the concrete foundation resistant to bending loads arising from uneven loads during house operation and soil swelling. The reinforcement serves as the base frame.

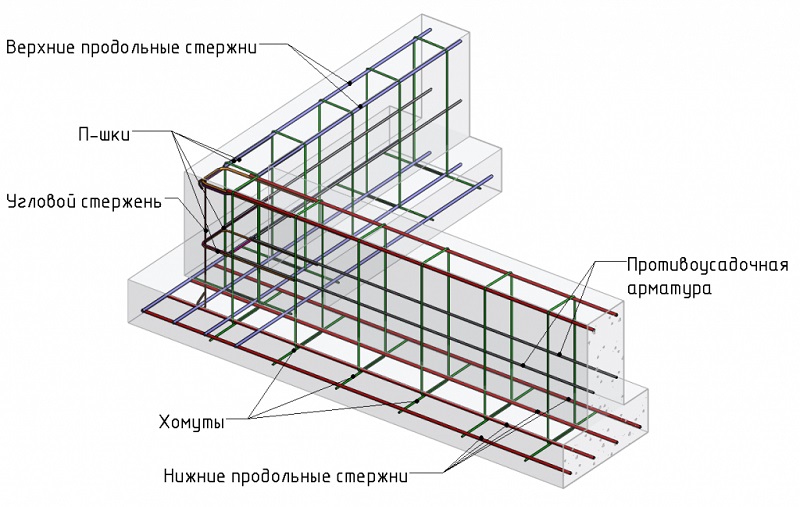

What kind of reinforcement is used for the strip foundation depends on the type of strapping, which is divided into:

- longitudinal;

- vertical;

- transverse.

For longitudinal strapping

With longitudinal strapping, the rods are laid along the base. The purpose of such a strapping is to take on the main tensile loads. Therefore, the reinforcement for the strip foundation, from which the longitudinal strapping is made, must be the most durable and have parameters sufficient for such a load: the diameter and shape of manufacture.The ribbed side surface provides good adhesion to concrete, which increases the strength of the base.

For vertical and transverse reinforcement

The rods used for reinforcement in the vertical and transverse directions serve as the connecting links of the base and ensure the integrity of the entire reinforcing structure. They accept the load acting during the shrinkage of the concrete base or during its temperature deformations, which is less than the load acting on the longitudinal strapping.

Calculation of strip foundation reinforcement

Calculation of reinforcement for the foundation.

The standard width of the tape is 0.3-0.4 m, with a height of 0.7 m, that is, its cross-section is quite small. Therefore, the diameter of the used reinforcement usually does not exceed 12-14 mm. performed in the form of two belts. The armature is located in the upper and lower parts of it in 4 rods. The diameter of the reinforcement is calculated based on the data on the parameters of the foundation and the materials used for its construction.

It should be remembered that when building a massive house or performing construction on moving, soft soils, longitudinal reinforcement is laid in 3-4 bars in each belt.

The bottom of the base in cross-section is subjected to a bending load, which is taken by the transverse reinforcement. Vertical reinforcement ensures the rigidity of the entire frame, while avoiding oblique cracks in the foundation body in the future.

An example of calculating reinforcement for a strip foundation

Foundation installation diagram.

We will carry out for the foundation of a strip-type building with a size of 6 x 6 m, the width of the strip is 40 cm, the height is 70 cm.The length of the bearing wall is 6 m.

For longitudinal reinforcement, rods of class A-III with a ribbed surface are used, the diameter of which is 12 mm. The rods are laid longitudinally in 4 rods along the tape along the entire perimeter and under the load-bearing wall (2 rods in the lower and upper chords). The total length of the tape is 30 m, where 24 m is the length of the perimeter and 6 m under the load-bearing wall. The total amount of reinforcement, the diameter of which is 12 mm, is 120 m. The weight of 1 m of reinforcement of this section is 0.888 kg, therefore, 106.56 kg will be needed to reinforce the entire monolithic base.

Since the transverse and vertical rods do not experience significant loads, it will be enough for reinforcement to use smooth reinforcement of class A-I, the diameter of which is 6 mm. Transverse and vertical rods are installed with a step of 0.5 m, the indent from the foundation surface should be 5 cm.Taking into account this, the number of rods with a diameter of 6 mm per connection is 1.8 m.There are 61 such connections, therefore, the total length of the rods will be 109 , 8 m. The weight of 1 m of reinforcement, the diameter of which corresponds to 6 mm, is 0.222 kg. Consequently, its total amount required for reinforcement will be 24.38 kg.

Choosing the diameter of the knitting wire and the way of knitting the frame

The amount of knitting wire per bundle is 0.3 meters, there are 4 such bundles in one connection. Multiplying by the total number of connections - 61, we get 73.2 m of knitting wire. The diameter of the wire, which is used to tie the rods in the corners of the frame, is 0.8-1.2 mm. In the manufacture of the reinforcing cage, it is the steel wire knitting that is used, which guarantees the durability of the entire structure. Welding should not be used in order to avoid corrosion of the metal at the joints of the reinforcement.

The knitting technology is as follows: at the intersection of the bars, the wire is first tightened, and then the remaining ends are twisted with pliers. In addition, a special pistol is also used, which significantly reduces labor costs. The disadvantage is the rather high cost of this tool.

The diameter and quantity of the used reinforcement directly depends on the massiveness of the structure, on the type of soil at the construction site, as well as on the type of strip foundation (shallow or buried). The process of calculating the reinforcement cage should be carried out at the design stage of the entire building. Only strict adherence to the requirements of design documentation, construction technology and professional performance of construction work can guarantee the service life of the strip foundation of at least 150 years.

What kind of fittings to choose for the strip foundation of the house

Today on the market you can find two types of reinforcement used in strip foundations:

- Composite (fiberglass, carbon composite, etc., the requirements for such reinforcement are set out in GOST 31938-2012),

- Metal (the range of steel reinforcement is described in detail in GOST 5781-82).

Depending on the design loads, the type of soil, the grade of concrete and other factors, various grades and diameters of reinforcement are used.

But as is customary in our country, in everyday life, most often the foundation is made in the "reserve", according to the principle, the more, the better.

Composite reinforcement compares favorably with a lower price, absence of corrosion, and has no shielding properties for radio signals. It is very light and flexible, which allows it to be transported even in the body of a car (it is rolled up into a special roll), most often it is not limited by the transport length of the rod. It lasts much longer in comparison with its metal counterpart, and is more tensile strength. The disadvantages include only the impossibility of welding and bending sharp corners.

Steel reinforcement is more affordable (you can buy it in any region of Russia), more familiar to builders (it has been used for a long time) and can be welded using arc welding into a single frame. In all other respects it is clearly inferior to composite analogs.

Of course, the choice of fittings is always a choice of preference. If you want to weld the frame into a single structure, then the choice is obvious - steel. Residents of Yekaterinburg can purchase fittings from the Steel Industrial Company -

Steel reinforcement can be cold or hot rolled of a class not lower than A2 (with a ribbed surface). Smooth reinforcement class A1 can be used for cross connections.

However, we recommend fiberglass or other composite rebar:

- You will significantly save on transportation (if you have your own car).

- Trimming will be minimal (rods can be cut directly to the length required for your foundation).

- Even with long belts, you will not have welded joints, which will have a positive effect on the bearing capacity of the frame.

- The tensile tensile strength (and for the strip foundation it is this indicator that is important) is much higher than that of steel.

- The expansion coefficients during temperature fluctuations of concrete and composite are very close to each other.

- Steloplastic fittings are very easy and simple to cut in a domestic environment.

- The list goes on with other pluses.

To make it easier for you to correlate the dimensions of steel and composite reinforcement, use the table below.

Rebar size

The fittings are produced in a wide range of sizes:

- rods of classes А240, А300, А400, А600, А800, А1000 are produced with a diameter of 6-80 mm, and reinforcement of classes А500С and В500С - with a diameter of 4-40 mm;

- the length of the reinforcement in coils or rods (depending on the diameter) is 6-12 m;

- Among the additional parameters of reinforcement, it is worth noting the step of corrugation, which is 0.51-0.86 parts of the reinforcement diameter, and the height of the corrugation protrusions is 0.065-0.07 parts of the diameter.

What kind of reinforcement is better for the foundation? It all depends on the type of foundation and the load on it - in each specific case, a complex and accurate calculation of the diameter of the rods will be required. To give you a rough idea of which rods you will have to buy, we give the following information:

- the diameter of the working reinforcement depends on the cross-sectional area of the foundation (S), the data are given in the table;

- for transverse clamps, reinforcement with a diameter of at least 6 mm is used;

- vertical clamps must have a diameter of at least 6 mm for a foundation height of less than 80 cm and at least 8 mm for a height of more than 80 cm.

Reinforcement class and steel grade

By the class of reinforcement, one can judge the strength of the material. Along with the new marking, the old one is still used, therefore we will mention both:

- A240 (according to the old GOST - AI) is a hot-rolled steel with a smooth surface, diameter - 6-40 mm. Reinforcement with a diameter of up to 12 mm can be supplied in coils and rods, more than 12 mm - only in rods.It is not suitable for the construction of a foundation as a working armature, but it can be used for clamps;

- A300 (AII) - reinforcement with a ring-shaped profile, it is not recommended to use it when erecting a foundation, but in private construction for small buildings and irresponsible objects it is still used. Naturally, it can be used as structural reinforcement;

- A400 (AIII) and A500 are ideal for foundations. The rods have a relief, the diameter ranges from 6 to 40 mm, the length is from 5 to 11.7 m;

- А600 (АIV) - reinforcement of increased strength, used in the construction of critical facilities, suitable for structures with prestressing;

- reinforcement A800 (AV) and A1000 (AVI) are used in the construction of multi-storey buildings, bridges and other structures, where special strength is extremely important.

In addition, during the construction of the foundation, other types of steel reinforcement are used, the properties of which can be judged by the marking:

- the letter C indicates the ability to fasten the rods into the frame by welding (examples - А400С, А500С, А600С). The A500C class fittings have recently become especially popular;

- the letter K speaks of resistance to corrosion (A400K, for example);

- AT in the marking means that the steel has been thermomechanically hardened. Intermittent cooling, which is used with this technology, increases the strength and resistance to corrosion. A popular class of such fittings is AT800.

GOSTs and TUs require the use of steel of a specific grade for the production of a certain type of reinforcement. The manufacturer must indicate what steel he used - this is very important information for the developer, allowing him to correctly perform all the necessary calculations.

Some of the steel grades used are shown in the table below. The characteristics of each brand are the topic of a separate article. Here we only note that, for example, steel 35GS is low-alloyed, and steel 25G2S is made using silicon and manganese as alloying additives. Both of these alloys are characterized by high strength.

Reinforcement connection methods

In industrial construction, metal rods are usually connected by spot welding. This method of fixing, in addition to the main advantage - speed, has certain inconveniences. Firstly, only fittings can be connected by welding, in the marking of which there is the letter "C" ("welding").

Secondly, such a connection always turns out to be tough. Although the technology of reinforcing a concrete base admits such a situation, it does not welcome. Ideally, the laid power belts at the points of attachment of the rods should have a small play in order to better resist the resulting loads. Thirdly, in the places of welding, steel rods lose some of their strength.

Preparation of clamps using flexors.

Therefore, in private construction, the use of knitting wire for fixing is more popular. At each intersection with this method, you need to fix a loop of wire. This method is very economical and easy to implement, but rather laborious.

The third method has appeared relatively recently. The joints of the rods are fixed with special plastic clamps. The cost of this method of fastening is higher than when using a knitting wire, but in terms of the speed of work, it is only slightly inferior to electric welding.

Regardless of the chosen method of fastening, they have a general rule. Installation in the corner parts of the base of the rods should be overlapped, with their edges bent, and not simply stacked on top of each other.

Determine the required amount of materials

Above, we found out what types of reinforcement for the foundation are and considered the features of using each of them. Before proceeding to the description of the calculation of the amount of materials required for the reinforcing frame, let us dwell in more detail on its device.

We have clarified what the foundation reinforcement is for.It forms internal stiffeners that prevent the destruction of the base of buildings. In order for it to perform its task with maximum efficiency, it is necessary to correctly make a reinforcing frame.

Reinforcement calculation

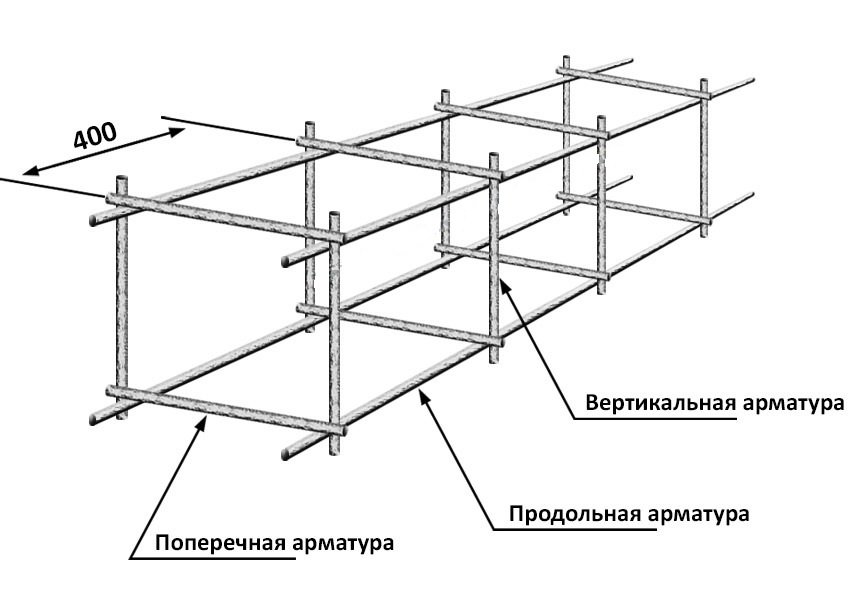

It represents rods laid in two rows. In this case, the frame of the strip foundation consists of two parallel rows of rods, connected by transverse and vertical scraps of reinforcement. At the base of the slab base, the rods form two grids located one above the other. A prerequisite is the deepening of the rods inside the concrete pour.

Calculation of the strip base

For example, we will determine the required amount of strip foundation reinforcement for a 6x6 meter house with one partition. Based on the parameters of the building, the total perimeter of the walls will be 6x4 + 6 = 30 meters. We put the rods in four strips, therefore, we multiply the length of the walls by 4, getting 120 meters.

To maintain the high strength of the reinforcing frame, individual rods in the corners of the house must overlap each other by at least 1 meter. Based on this, the total length of the rods should be increased by 16 meters and, with subsequent rounding, as a result, we get the number of reinforcement of 140 meters.

Reinforcement calculation scheme for strip base

Transverse horizontal and vertical inserts with a tape cross-sectional size of 1.5x0.5 meters are equal to 1.4 and 0.4 meters, respectively. We install them in pairs in 1 meter increments. Therefore, the length of such rods will be 60x1.4 + 60x0.4 = 80.4 + 24 = 105 meters. Due to the lack of load on them, the diameter can be reduced to 6-8 mm by taking a smooth wire.

A soft knitting wire is used to connect the frame elements. For each connection, it requires 0.3 - 0.5 meters, depending on the diameter of the reinforcement. Connection points for our variant will require 30x4 = 120. After calculating the amount of knitting wire, we get the required length 120x0.3 = 36 meters. By adding a few meters to join at the corners, round off the footage to 50.

Calculation of the slab base

Above, we gave recommendations on which reinforcement to make the foundation from. The calculation of its quantity depends on the specific type. So, a slab foundation of the same size 6x6 will require much more reinforcement. The standard mesh size is 25 cm. Therefore, the number of rods is determined by the formula: 6 / 0.25x4 = 96, and the total length is 96x6 = 576 meters.

Vertical racks with a slab thickness of 25 cm will be equal to 0.15 meters. And their total length will be determined as 24x24x0.15 = 86.4 meters. Rounding off, we get an additional 90 meters of reinforcement for the posts, which will give a total of 666 meters.

The number of connections of the rods of the upper and lower mesh to the posts will be determined as the product of the tying points by 4, since each reinforcement is attached to the vertical spacers: 24x24x4 = 2304, and the total required length is 2304x0.15 = 345.6 meters.

The above calculations clearly show a significant excess of the slab base of the house over the tape base in terms of material consumption. Before choosing a reinforcement for the foundation, it is necessary to carry out calculations of the financial costs for the entire structure.

Reinforcement calculation example

For example, it is worth calculating the reinforcement that will be required to install the foundation, with dimensions of 6 by 5 m, in which there will be one load-bearing wall, 5 m long. In the scheme, a reinforcement rod with a ribbed section was selected, in the amount of 4 pcs. and a diameter of 12 mm. The perimeter of the house is 22 running meters (6 + 5 + 6 + 5). The length of the base along the inner part of the wall will be 27 m; for the calculation, the length of the bearing wall is added to the perimeter of the house. So, it turns out that 108 m of reinforcement (27m * 4) will be required. If you could not buy a rod of the required length, do not worry. You can connect metal rods to each other, while they should overlap each other in the connection by one meter. The length of the overlap must also be calculated in advance.

Strip foundation under the fence

When independently carrying out work on installing a fence on a site, most often when choosing a base, they give preference to a strip foundation device. It perfectly withstands massive types of fences installed on soils that are prone to seasonal swelling. The solid reinforced concrete structure of the strip foundation ensures its reliability and durability, as well as high bearing capacity - the strip foundation can easily withstand a monolithic or prefabricated fence made of concrete or natural stone up to 2.5 meters high.

A strip foundation for a fence is a structure in the form of a monolithic tape of concrete up to 30 cm wide, in general, the width of the foundation directly depends on the size of the supports and the type of fence. The foundation is being erected along the entire perimeter of the fence, its depth is 0.5 - 0.7 m.

For pouring the foundation, concrete of the M200-300 brand is used. When erecting especially massive fences or when carrying out work on the foundation in the cold season, it is permissible to use concrete of the M-400 brand. From the inside, it is recommended to arrange a reinforcing frame made of reinforcement with a diameter of 8-12 mm, which will ensure the redistribution of the load and protect the foundation from destruction.

Device

Due to the fact that the depth of the strip foundation for the fence does not exceed the level of soil freezing, it is classified as a shallow foundation. When building a fence, it should be borne in mind that such a base may undergo deformation, the origin of which is associated with seasonal swelling of the soil, which rises during freezing and descends during thawing and increasing temperature.

With a homogeneous soil located within the entire perimeter of the abyss fence, you can not be afraid. If the foundation has to be arranged on heaving soil, then gravel or sandy filling of the base should be arranged, ideally if this is done to the full depth of freezing. Alternatively, with very heaving soils, you can consider the possibility of installing a more expensive pile-strip foundation.

The procedure for performing work when installing a strip foundation for a fence is as follows:

- Digging a trench around the entire perimeter of the future fence with a width of 20 cm more than the width of the tape obtained by calculation. The depth of the trench, as a rule, is in the range of 0.5-0.7 m and is determined by the type of soil and the mass of the structure.

- Preparing the bottom of the trench - backfilling a layer of sand 10-15 cm thick, followed by tamping. For better compaction, the sand should be moistened with water.

- If the sections of the fence will rest on the pillars, then holes with a diameter of 20 cm should be drilled at a distance of 2.5-3 m from each other. In this case, the depth of the hole should exceed the depth of the trench by at least 0.4 m.When installing the pillars on the bottom of the holes, you should also fill in a layer of sand 10 cm thick and compact it

- Installation of formwork for pouring the foundation. For the manufacture of formwork, plywood or planed and well-fitted boards can be used. The formwork should be leveled and secured with spacers. In order not to spoil the boards with concrete, the inner side can be closed with plastic wrap.

- The next step is to knit the reinforcement. For reinforcement, four horizontal rods arranged in pairs are used, fastened into a rigid frame using horizontal and vertical rods located with a step of 0.5 m. Vertical rods cannot be driven into the ground - they should be installed in special plastic cup holders. Knitting is done with a hook and special wire. In the corners of the future foundation, the edges of the rods are best taken into a clamp. The metal rods of the frame must be hidden under a layer of concrete with a thickness of at least 5 cm.

- For the installation of load-bearing pillars, it is necessary to provide for the device of reinforcing belts associated with the reinforcing frame of the foundation.The main task of such belts is to evenly distribute the lateral load.

- The final step is to pour the concrete.

Diagram of a strip foundation for a fence

When erecting a fence on a slope, a stepped structure should be arranged - the construction of an inclined foundation is not allowed. Before pouring, the vertical position of the supports should be checked again, which will prevent problems with the installation of the fence sections. After pouring every 20-25 cm of concrete, it should be compacted. After the concrete has hardened, which takes 24-36 hours, you can start installing the sections.