Base for building a light type

If there is a need to level the foundation under a light building, a wooden frame is placed, which is brought to the level by placing bars of different thicknesses. However, this structure will not rest on the foundation with the entire base plane, which is a good reason not to recommend it for use in practice.

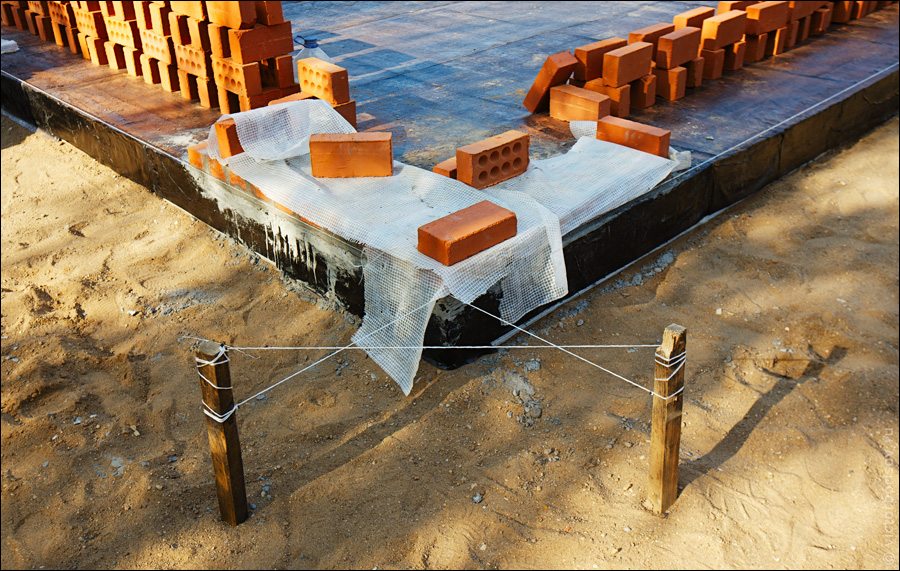

However, if the space under the board is filled with cement mortar, then the first layer of brick can be laid out on the resulting base, on which the basement will be based. You can level the height with bricks or expanded clay blocks. With a small drop, a masonry mesh is used.

Elimination of lateral irregularities

Their alignment is performed taking into account the amount of skew. If the discrepancies are small, you can fix the mesh-netting with staples or dowels and lay out a new layer of plaster mortar on it.

In the case when the difference is large enough, resort to the following actions:

- the formwork is set according to the level;

- with slight distortions, the solution is distributed over the void areas formed between the walls of the foundation and the formwork panels;

- when the gaps exceed five centimeters, it is necessary to apply a reinforcing mesh in the places where concreting is planned.

Repairing a cracked base

Repair of the brick foundations of the house.

Repair of the foundation, which began to be covered with cracks in the area of the base, should be carried out after analyzing the nature of the destruction. Such problems can arise in tandem with skewed load-bearing structures. Problem analysis will allow you to understand what technology to use for amplification.

If the foundation collapses around the perimeter due to load changes or high humidity levels, then it is necessary to equip the trench by placing it around the perimeter strip pile type foundations... The perimeter foundation should be strengthened by arranging a sand cushion, using steel mesh, anchors and boards, which will form the basis of the formwork system. After the trench has been prepared, the surface should be freed from the remains of plaster and dirt. Then, at a certain distance from the wall, you need to fix the steel mesh, using for this anchors, which must be fixed in advance in the body of the basement and foundation. This structure must be poured with concrete in several layers, each of which should be well tamped.

If you have to work with an array based on rubble masonry, concrete, buto- and soil concrete, then the foundation should be repaired by strengthening it with a reinforced concrete widened cage. It must first be well fastened to the old masonry. This must be done especially carefully, using through installation of anchors for fastening.

The foundation of a brick house can also be strengthened locally (only in those places where the foundation has especially weak areas). In order to increase the bearing capacity of these areas, a new foundation must be laid along. Subsequently, it will begin to take some of the load from the old base thanks to the fasteners that pass through it.

Video on the topic of leveling the foundation surface

A fun way to make and adjust formwork:

The foundation and masonry of the first row of aerated concrete wall:

Preparation of the foundation for laying aerated concrete blocks

How to level the foundation

Often, when moving or renovating, we are faced with such a need as leveling the walls for subsequent wallpapering or painting in a color selected in advance. The different building materials from which the walls are made require different ways of putting the walls or partitions in order.In this case, consider how to level a brick wall.

The modern interior requires flatness and smoothness from all surfaces.

Elimination of upper irregularities

And how to level the foundation after pouring along the horizon? It is believed that such work is one of the most important measures, because it is on the basis that the waterproofing layer is arranged, and it is in direct contact with the load-bearing walls. Given this fact, the presence of the smallest irregularities on the surface is completely excluded.

So how to level the foundation to zero? The algorithm of actions is as follows:

- the formwork is reinstalled, the height is checked by the building level;

- markings are made on the shuttering boards, allowing you to keep track of whether the mortar is evenly distributed this time.

And how to level the foundation after pouring? For this, a fresh mortar is prepared, the consistency of which should be much thinner than when concreting the main structure.

Strip foundation

To fix such an uneven foundation, you will need:

- cement;

- shovel shovel;

- sand;

- level and tape measure;

- reinforcement mesh;

- formwork;

- bricks;

- Master OK.

With the help of the level, the maximum point in the discrepancies is determined, which is taken as the main reference point for alignment. Remember that this event is more serious than fixing the side surfaces.

The leveling process is carried out with brick stone, which is pre-sawn before laying. The operational period of the entire structure depends on the evenness of the surface, therefore all discrepancies must be excluded.

To fix the problems, you can set up the formwork, determine the pouring boundary, prepare the mortar and concreting to the required height.

Leveling the strip foundation after pouring with bricks is an excellent option if you plan to install the basement part.

Slab foundation

Leveling such a monolithic foundation before laying is a complex process. When pouring the slab base, it is necessary to carefully prepare the bottom of the pit, lay and compact the foundation cushion, and fill it with crushed stone. If defective areas are revealed on the plane and along the horizon, additional measures will have to be taken:

- determine the zero point;

- at the required height, set and strengthen the formwork under the foundation, level it horizontally;

- pour the liquid mortar mixture and level its surface with a long rule.

Columnar foundation

Such a support structure is considered to be economical compared to a shallow tape base and for this reason it is used frequently.

Supports are made with separate posts from concrete mortar or brick stone. They are further affected by the load forces from the entire structure, so that the installation of such a foundation requires extreme accuracy.

How to even out unevenness of the foundation and check its diagonal? To do this, use the following tips:

- columnar supports, erected from brick material, are placed at regular intervals throughout the construction site. To bring the top of the datum elements at the same height, you can use a water level and pass a zero point to each datum element. Having determined the deviations from the general design height parameter, the support is "raised" by brickwork;

- if the deviation is insignificant and exceeds the height of the brick stone, high grade concrete is laid on the pillar. Just before that, you will have to install the formwork.

Correction of finished foundations

Often it is necessary to use ready-made foundations in construction, which, for whatever reason, need to be leveled. As a rule, these are foundations that have stood for the winter (or even several), often having significant destruction.Consider the available ways to "bring to mind" such foundations of various types.

Leveling strip and slab reinforced concrete foundations

First of all, it is necessary to carefully measure the foundation, to determine its condition (the presence of collapsed areas, slopes and distortions). Mark the areas to be leveled and proceed to bringing the foundation to zero.

Before leveling the base with the horizon, measure the height of all its external and internal elements. If the height difference exceeds 10 cm, formwork is installed and cement is added to the level of the highest angle, based on their real position. New sections of the foundation are reinforced with reinforcement, which is installed before pouring the solution.

In other cases, the height of the tape is increased by adding and leveling cement mortar, without using reinforcement and formwork.

Important: It should be borne in mind that the thickness of the newly poured fragment of the foundation must exceed 30-40 mm, otherwise the concrete layer will be fragile. If it is necessary to fix a foundation that has an uneven width (the tape "walks" in width), they resort to increasing the thickness of narrower sections. To do this, a reinforcing mesh is attached to the side surface of the foundation, on top of which a mortar is applied

The ground part of the restored foundation is plastered

To do this, a reinforcing mesh is attached to the lateral surface of the foundation, on top of which a mortar is applied. The ground part of the restored foundation is plastered

If it is necessary to fix a foundation that has an uneven width (the tape "walks" in width), they resort to increasing the thickness of narrower sections. To do this, a reinforcing mesh is attached to the lateral surface of the foundation, on top of which a mortar is applied. The ground part of the restored foundation is plastered.

Aligning columnar foundations

Restoration of the old foundation

The restoration of the columnar foundation is reduced to leveling the height of the supports and controlling their verticality.

Just as in the case of a floating or strip foundation, before leveling the columnar foundation, it is necessary to determine how far the heads (upper parts) of the posts deviated from the horizontal plane defined by the project. The next step is to bring the base to zero.

For this, a horizontal plane is determined, and beacons are applied at its level on each pillar. Surplus is cut off at too long supports, the missing height is built up in traditional ways.

- If the foundation is laid out of stone or brick, then the missing centimeters are laid out from the appropriate materials, fastened with cement mortar;

- If reinforced concrete supports are fixed, then, before leveling the foundation blocks, formwork is installed in their upper part. Reinforcement is mounted inside it and concrete is poured to the required level.

It is important to know: Before you start building a columnar foundation, you should check the integrity of the existing bases. Destroyed or unreliable fragments must be removed and replaced with new solid masonry. A grillage can be erected on top of the aligned pillars, which will evenly redistribute the loads to all parts of the foundation

A grillage can be erected on top of the aligned pillars, which will evenly redistribute the loads to all parts of the foundation.

It should be borne in mind that the restoration of old foundations should be done with caution, trying to ensure their maximum solidity. A good foundation should "work" as a whole, the presence of weak links will lead to uneven transfer of loads from the structure to the ground and will entail the need for expensive repairs.

.

Leveling the foundation with a brick plinth

Hello.I have a dead end in my thoughts and, accordingly, in the construction site, namely: They poured a foundation for me 1.2 m into the ground at ground level, the difference along the site from the upper corner to the lower one is 55 cm.

Tell me how to make a basement on such a foundation? Immediately drive out of bricks or, worse, align first. House 14.3 * 14.3.

Oleg, Belgorod.

Hello Oleg from Belgorod!

Most often, in such cases, they still prefer to make the formwork on the existing plinth.

Naturally, the top of the formwork must be exactly level. After that, concrete is poured with its reinforcement.

Sometimes they make stepped brickwork. That is, the formwork is somewhat raised above the soil surface in a certain area (a couple - three meters of the length of the foundation). Starting from the high point of the old poured foundation. Then another section of the basement basement is made about the same size, etc. Concrete is poured with the same reinforcement.

It turns out the semblance of several steps made of reinforced concrete. And then they report everything with a brick to the desired height of the basement at a single level. It doesn't look quite ordinary, so the plinth has to be plastered so that the distinctive brickwork and concrete monolith are not visible.

It is preferable to proceed according to the first scenario.

In addition, in any case, do not forget about laying waterproofing between concrete and brick, since they have different moisture permeability. Otherwise, the bearing capacity will differ in different parts of the foundation.

Everything. Good luck! See a similar topic here >>.

Construction in Moscow and Moscow region

A wide range of construction services. Foundation, walls, floors, roof, turnkey!

Other questions on the topic of repairing the foundations of houses:

Construction in Moscow and Moscow region

A wide range of construction services. Foundation, walls, floors, roof, turnkey!

Construction in Moscow and Moscow region

A wide range of construction services. Foundation, walls, floors, roof, turnkey!

Construction in Moscow and Moscow region

A wide range of construction services. Foundation, walls, floors, roof, turnkey!

Construction in Moscow and Moscow region

A wide range of construction services. Foundation, walls, floors, roof, turnkey!

Construction in Moscow and Moscow region

A wide range of construction services. Foundation, walls, floors, roof, turnkey!

Other questions about walls in various rooms:

Zavalinka

Plinth

Brick the house

Construction in Moscow and Moscow region

A wide range of construction services. Foundation, walls, floors, roof, turnkey!

Questions about the walls

Construction in Moscow and Moscow region

A wide range of construction services. Foundation, walls, floors, roof, turnkey!

How to align the bottom of the foundation and its vertical surfaces

You need to start the process with the preparation of a tool that can be useful when performing work: a hammer, a construction tape, a plumb line, a shovel and a box for mixing the solution.

The absolute flatness of the base of the foundation can be made with a sand cushion. You should strive to make this surface absolutely even, despite the fact that it will not be noticeable after pouring the base of the house. This is done so that the thickness of the foundation is the same along its entire length. In the event that the base of the foundation is not made according to the level, this deficiency will no longer be eliminated later.

The outer and inner sides of the foundation can be made even by high-quality formwork installation. It should be level and plumb. However, irregularities at the base will appear even if all these recommendations are followed. To make the upper plane of the foundation even, correcting the detected deviations in several ways:

- Large defects in the side planes are corrected with concrete by installing a new formwork.

- If the deviations are insignificant, then the outer side can be laid out with a layer of brickwork. You can replace the bricks with plaster, which is used to level the surface, after fixing a metal mesh on it.

- Small errors from the inside can be left intact. In addition, if the building is located in a region with a harsh climate, then the foundation will need additional insulation, under the layer of which all defects will be hidden. Expanded polystyrene or rock wool is an excellent choice for thermal insulation.

Leveling brick walls

Application of drywall or PVC sheets

Aligning walls with drywall is not difficult

When leveling the walls, special attention should be paid to sealing the joints between the plasterboard slabs

As a rule, professional masters do not use a specific solution to apply the mixture.

Experience shows that ordinary water is an excellent substitute for all kinds of bonding mixtures and solutions. Water should be sprayed over brick walls. This must be done in order to create moisture on the wall surface. Then the moisture from the plaster solution will not transfer to the brick, which can lead to deformation of the brickwork.

If the irregularities are quite large and there is a doubt that the primer will "grab" enough for further construction work, it is necessary to use a special reinforcing mesh. It is mounted on self-tapping screws using a hammer drill or an ordinary drill. That is, the primer is applied before the reinforcing mesh, and also on it to cover the supporting structure.

- After drying, metal guides are attached to the primed brick wall in order to subsequently lay PVC or drywall panels on the wall.

- The guides should be attached so that they fall on certain edges of the plasterboard or PVC sheets. In this case, the layer of insulation, with the help of which the walls are also leveled, will be even and suitable for subsequent processing.

- Sheets of drywall or polyvinyl chloride are stacked tightly to each other, and then a separate putty is applied on top, which hides the joints of these plates. After a layer of primer, a two-layer finish must be applied.

Leveling with plaster and primer

Leveling the surface with plaster is a laborious procedure. Without proper training, it is very difficult to get all the work done right.

If the alignment is carried out without the use of special PVC sheets or drywall, three layers of plaster are required. Each of them has its own name. Each subsequent layer differs in the thickness and composition of the solution, as well as its purpose.

These three layers are:

- splashing;

- priming;

- cover.

What is spatter.

Spray is a liquid plaster that must be applied to the brickwork using a special construction tool. Spray should be applied abruptly, with effort, so that, hitting the wall, the plaster can close all the cracks and small holes in the brick wall.

What is soil.

It is necessary to carry out work on the lighthouses. There is an inventory metal and mortar beacon.

The second layer, the soil, is the thickest. Often a layer 10 to 15 cm thick is required to level the wall. It is impossible to immediately lay such a layer, especially so that it holds. That is why the plaster is applied in several passes. For this, the solution must be quite "steep". After applying each layer, you need to wait a certain time to apply the next layer.

What is cover.

The last layer is the thinnest.

It becomes grinding. This solution is applied using a construction tool such as a trowel. It should be rubbed into an already plastered wall in a semicircle until a flat surface is obtained.

The primer is applied to the brickwork after all three layers of plaster.The primer should dry in the area of several hours, at least 5-6. Only after that the finishing is carried out in two layers. Each of them should dry well. As a rule, the first finishing layer is thicker, it is intended to level out. And the second is thin, finishing.

So, whatever you choose, in any case, it is unrealistic to level a brick wall as much as possible in one day. In addition, it is worth evaluating the proposed methods and at their cost. Of course, there are various leveling mixes available, and their price fluctuates over a fairly wide range.

However, the cost of drywall sheets is usually constant. This means that it is really possible to reduce the cost of only the second method by replacing expensive mixtures to equalize foreign production with a mixture of cheaper, similar quality and Russian production.

Construction of residential buildings from expanded clay concrete blocks, aerated concrete blocks, bricks, etc. mainly accompanied by the construction of a strip foundation (or strip with bored piles). For the longest possible service at home, the owners must take the process of making the foundation as seriously as possible.

An uneven foundation can significantly reduce the technical characteristics of the future structure. In addition to the obvious problems with the subsequent erection of the walls, such a foundation can create the preconditions for the rapid destruction and unwanted deformations of the supporting walls of the building.

Leveling foundations with bricks

Leveling the foundation-plinth with bricks

When erecting foundations, especially without initial careful calculations, the occurrence of subsidence or slope of the structure in different directions is inevitable. This is especially noticeable in tape structures, where prefabricated elements are used.

It is strictly forbidden to build load-bearing walls on such an uneven foundation. First you need to level the surface, eliminate all irregularities and achieve the most even horizontal plane. How can the plinth of a building be leveled?

- Using concrete mortar. Small irregularities, bumps or depressions are eliminated there. Also, with its help, a plinth is prepared for the installation of finishing materials, as well as primary plaster. Too large slopes cannot be eliminated this way.

- With the help of brickwork. This eliminates distortions and too large altitude differences.

As a rule, small irregularities can already be noticed at the stage of gaining strength with concrete.

But distortions always arise already during the construction of load-bearing walls, they arise through the uneven distribution of soil layers, design errors and calculation of the foundation depth, as well as errors in the calculation of the boundary of soil freezing.

Depending on the type of foundation, there can be many methods for leveling the basement, but the cheapest, practical and most popular is with the help of bricks.

How to level the top plane of the foundation with a brick

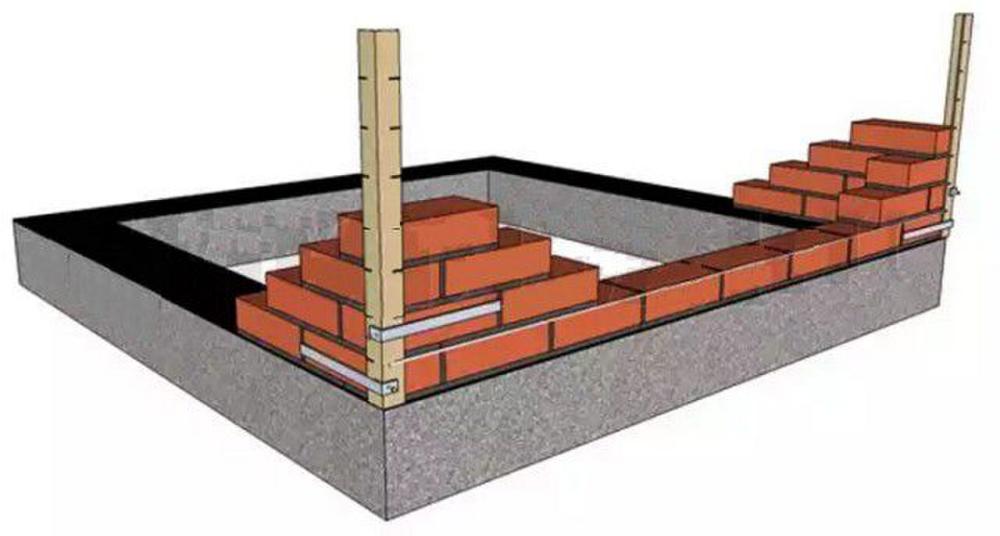

Leveling the foundation with a laser level

Considering that leveling the upper plane of the base requires a considerable investment of time and resources, this must be done competently, with knowledge of the matter. First you need to figure out why the foundation was skewed.

In most cases, these are errors in the design and calculation of the load-bearing elements of the building frame. Brick leveling technology:

- Installation of vertical guides along all bearing edges of the foundation. You can use an indicator tape, rope or other device here. Alignment must be performed using a hydro level, laser level or other devices.

- Then a layer of brick is laid on the concrete, and installation at an angle is allowed. The brick is connected with liquid concrete mortar.

- In case of slight differences in height, you can use broken brick, which is used as a filler for concrete mortar.

- After laying the bricks and checking the horizontal, the top layer is covered with concrete and left to dry for several days.

When a single brick is used to level the surface of the foundation, it must be remembered that it does not have as good load-bearing characteristics as concrete.

Therefore, in order to achieve optimal structural strength, it is necessary to use the masonry to the maximum, breaks must not be allowed, as well as voids.

How to properly level the base with concrete mortar

The process consists of several stages of varying importance, and here materials are used that are optimal for leveling vertical and horizontal surfaces. Thus, depending on the characteristics of the substrate and the type of unevenness, sometimes it is enough to just plaster and level the surface. But this is possible only if the difference is insignificant and is more characterized by irregularities.

And if the height difference is significant, then a whole technology is used:

But this is possible only if the difference is insignificant and is more characterized by unevenness. And if the height difference is significant, then a whole technology is used:

- First, the surface is cleaned from adhering dirt and stones.

- Then formwork is erected from wood or roofing material. Here it is recommended to make horizontal and vertical strapping so that the formwork itself is as even as possible. This determines the highest and lowest point of the base, where the alignment is carried out. Considering that the entire structure will be filled with concrete, it is better to mark key points on the formwork.

- On the inside of the formwork, where the concrete strip of the supporting structure passes, horizontal lines are drawn using a level and poured with concrete. If the distortions are minor, then it is better to use a more liquid solution. And, if the distortions are significant, then it is better to fill it with a thick solution.

After pouring the concrete, the base is left to dry for several days and the formwork is dismantled. In some cases, it can be left, because the outer surface is perfectly flat. A waterproofing layer can be installed on the formwork and foam plastic can be glued for thermal insulation.

How to level the foundation with bricks?

For work you will need:

A box is erected from the board along the perimeter of the foundation, limiting the basement from the outside and from the inside of the brickwork. Broken brick is laid in the resulting trench - this is necessary to increase the density of the solution. On a soft base with a brick, you can partially align the edge of the foundation in height. Next, the cement slurry is mixed with the addition of sand. Filling takes place in 2 stages:

- First, a small layer of mortar is applied to level the chipped brick horizontally. You should get a flat foundation, raised by 5-8 cm;

- Brick is laid on fresh mortar over the entire width of the formwork so that the long edge is completely immersed in the mortar, and the brick itself is at an acute angle to the base of the building. Such masonry is called "herringbone". After making sure that all the bricks are laid at the correct angle and to the maximum depth, the structure is poured with a slurry with a high sand content.

The solution should be compacted as much as possible before drying (in the first 30-40 minutes after mixing). If the trench is too high or wide, the load when compacting the mortar can break the formwork. To strengthen the structure, the boards are installed in several rows or formwork panels are used.

The most crucial moment when leveling the foundation with brickwork is the removal of the formwork. This should be done in 48-72 hours from the moment the second layer is filled. When fully solidified, uneven evaporation of moisture from wooden panels can deform the foundation.If the formwork is removed early, the base / plinth can "go", which will not only change the slope around the perimeter, but also deform the lateral edge of the foundation, which will lead to cracks in the future.

In commercial buildings, the formwork is removed with construction equipment. Manual removal of wooden boards and boards should be carried out strictly perpendicular to the foundation: loosening the solution when swinging will reduce the strength of the composition and affect the slope of the base.

Difficulties arise when, during shrinkage, the distance between blocks in a composite foundation changes. Pillars and block reinforcements are placed strictly at the corners of the future building and along the masonry in order to reduce the load on the cement base. Block misalignment cannot be corrected by sanding, and resurfacing the foundation is expensive. To solve the problem, the reinforced screed method is used.

The set of building materials and tools is similar to brick leveling. Additionally, you will need steel reinforcement bars and a cutting tool for them. At a height of 10-15 cm at the level of the cement base, a reinforcement screed is installed, resting on the blocks. When tensioned, incorrectly positioned blocks are shifted and fixed with reinforcement. Formwork is mounted along the perimeter of the future building and bricks are laid out. After pouring the solution, both the level of the basement and the base in which the blocks are walled rise.

Leveling the foundation is expensive. So, the cost of building materials when reworking a block foundation can exceed its initial cost, i.e. it turns out to be more profitable to erect the foundation for the building in another place. A strip foundation is initially more expensive, but several methods are available to level it out at once. The most difficult and effective is the perimeter brickwork. The mass of the formwork is sufficient to cause serious injury, therefore, when assembling and removing the supporting structures on your own, it is imperative to observe safety precautions.

Alignment options

The flatness of the walls of the future monolithic tape directly depends on the quality of the formwork device. You can get rid of flaws on vertical surfaces after removing the box in one of the following ways:

- clean off or gently knock down the protrusions;

- cover the grooves with cement mortar.

When correcting significant irregularities, a reinforcing mesh is used. It is securely fixed to the foundation wall, after which the plaster mixture is applied layer by layer. This procedure is very important for the base. Often it is lined with bricks or sheathed with decorative materials.

The problem of how to align the foundation with the upper level is solved in a slightly different way. Formwork can help with this. It is clear that it is pointless to navigate along the cut of the box, since initially it is quite difficult to set the boards or timber clearly along the horizon. For convenience, markings are applied on the inside of the formwork using a level or laser level. It is allowed to use old-fashioned methods that have positive reviews. For example, some people recommend using a transparent hose filled with water. It works on the principle of a communicating vessel.

To begin with, the design mark is fixed at the corners of the foundation, and a cord is pulled between the marked points. Beacons from a bar are installed along it, or a line is simply drawn with an indelible marker, which will serve as a guide when pouring a monolithic tape. But do not think that at the first stage it will be possible to bring out a perfectly flat surface. Quite often, it turns out to be crooked and, at least slightly, but chipped.

Leveling the horizontal surface of the foundation is called differently:

- removing the base to zero;

- comparing horizontally;

- setting by level, etc.

But the goal in any case remains the same and is to maximize the leveling of the upper surface of the foundation.Most often, it is proposed to re-erect the formwork and again set the horizon level using a level. The bottom line is to determine the highest and lowest point of the concrete tape. By the way, this method can also be used if there are prefabricated blocks instead of a monolith.

It is recommended to take the highest point as the initial mark. This greatly simplifies the work, since it is not required to knock down the artificial stone. In addition, as a result of chips, reinforcing bars can be exposed, which is highly undesirable.

The zero level is planned in the same way as during the initial pouring of concrete into the formwork. The only difference is the corrected base / plinth height. Experienced craftsmen recommend marking "zero" in the corners, making cuts in the formwork at the required level. A strong cord is driven into the prepared slots, after which it is pulled tightly between the control points. This will become a kind of lengthy beacon and will allow you to abandon other tags. The disadvantage of this method is a certain mobility of the cord relative to the horizon. Beacons from a bar do not have such a minus.

After the preparatory work, the top of the main foundation is poured with cement mortar. It should have a more fluid consistency compared to the concrete mix previously used. After the initial setting of the cement, the surface is smoothed.

There is another way to level the foundation horizon. For its implementation, it is required to set the upper level of the formwork as clearly as possible, and then fill the box "to the eyeballs". In this case, they talk about the initial removal of the base to zero. The method gives good results, but its implementation requires certain skills and ideal formwork geometry in height.