More about clay castles

The matured plastic dough obtained by mixing clay with water acquires unique properties after tamping. A thick layer of the laid mixture forms a waterproof screen that protects the foundation from groundwater and flooding.

Oily clay is plastic, it slowly gets wet and dries for a long time. Its color has absolutely no meaning, so you should not pay attention to it. Proper preparation of the material for use will help to make reliable waterproofing. To do this, the clay is soaked, covered and left to mature for an indefinite time, making sure that it does not dry out.

Experts recommend harvesting material in the fall and leaving it outdoors until spring. During this period, a cycle of gradual freezing and thawing of clay passes, which will contribute to the uniform penetration of moisture through the interlayer spaces into all particles. The result is a homogeneous, plastic material suitable for use in an earthen castle. To further improve the quality, lime is added to the composition of the waterproofing mixture, but not more than a fifth of the total volume.

The clay should be neither waterlogged nor overdried. You can check the required humidity in a simple folk way. It is necessary to collect a handful of the "present" breed, and then try to squeeze it in a fist. If the formed lump does not crumble and does not slip through your fingers, then the material is considered ready for use.

Clay does not deteriorate from time to time and practically does not require material costs for the purchase, since it is practically everywhere in common use. And a properly executed clay castle:

- does not need repair - cracks do not spontaneously appear in it;

- is not washed away by groundwater, but needs protection from storm runoff;

- prevents the penetration of water, but allows moisture to pass to the walls of the foundation, in connection with which it is recommended to additionally make a surface waterproofing.

When constructing a clay castle, you should pay attention to the type of soil located in the construction area. If there is a sandy or sandy loam layer around the foundation, the expansion of the clay during freezing will not play a big role

But for clay and loamy soil, an increase in the volume of the castle as a result of frost heaving can lead to unforeseen situations

In this case, it is important that the vertical surfaces of the foundation are flat - without protrusions, recesses and extensions in the upper part of the structure. Otherwise, the pushing forces created by nature itself can raise the structure, squeezing the foundation up

Procedure when carrying out work

If there is no opportunity or desire to use the services of a team of professional builders, it remains to make a clay castle for.

- Digging. A trench is dug along the perimeter of the well to a depth of 150 - 180 cm. As a result, the second seam of the rings should be visible.

- All connections must be protected from clay entering them. Any hydrophobic material that does not rot or decompose will work, such as plastic wrap.

- Material preparation. For a clay castle, it is allowed to take clay with a sand content of up to 15%, but the lower the indicator, the better. If you follow all the recommendations, then the clay is aged before use (usually left for the winter). To add strength to the lock, lime is mixed into the solution so that its content does not exceed 20% of the total mass of the mixture. The more sand there is in the clay, the more lime you need to add.

It is important that the clay is rinsed and not stirred.Previously, such an operation was performed with feet, today they use small concrete mixers or use a drill with a nozzle

The next step is to create a blind area over the castle. And without the recommendations of SanPiN, it is clear that after rains or melting snow, even a tightly rammed clay castle will turn into mud. The "soggy" top layer will get wet and dry, which will gradually lead to a leak. Therefore, the construction of a blind area is considered a logical completion of the process of creating a protective castle.

The coating material is selected based on personal preferences; both stone and paving slabs are suitable. And the technology of creation does not seem difficult:

- the castle is covered with geotextile or other material with similar properties,

- the selected material is laid on top of the screed.

You can assemble a low formwork and fill the castle from above with cement mortar. The main thing is that the bias is respected, because the task of the blind is not easy moisture protection, but also its withdrawal.

The construction of an earthen castle will not affect the bacterial and chemical composition of the water on the site, but it will help keep it clean and usable, if it was originally

... Therefore, in solving the dilemma "for" or "against" clay castles around the well, it is worth tipping the scales in the direction of a positive answer.

The main properties of a clay structure

Clay belt - several compacted layers of clay.

Raw materials have a natural ability to absorb, retain moisture, a possible increase in volume is noted by two or more times.

A simple option for protecting a structure assumes availability, low cost. The result is a clay strip, which creates a strong protective barrier against soil moisture.

The principle of operation of a properly laid protection

The principle of operation of a properly laid protection

It will be necessary to install additional insulation, otherwise the moisture from the clay will be in direct contact with the concrete.

The finished mixture may contain sand particles that reduce the initial properties of the material. There is a change in clay size due to severe frosts. As a result of strong freezing of the security lock, deformation of the building can occur.

The protective clay line allows you to protect the foundation from constant contact with soil moisture, regulates the outflow of water penetrating from precipitation, diverting it from the foundation.

However, the structure will not protect the underground premises.

How to make a clay castle: mastering technology ↑

Clay of natural moisture is used for the construction of the castle. If it is taken out of the ground for storage, it should be soaked by sprinkling with water and covered on top. Clay is ready for use when you can mold something out of it: it does not crumble or slip between your fingers when it is crumpled. It will not be superfluous to add 10-20% lime to the clay, especially with an increased content of sand in it.

If the clay keeps its shape: does not crumble or spread, it is ready for use

If the clay keeps its shape: does not crumble or spread, it is ready for use

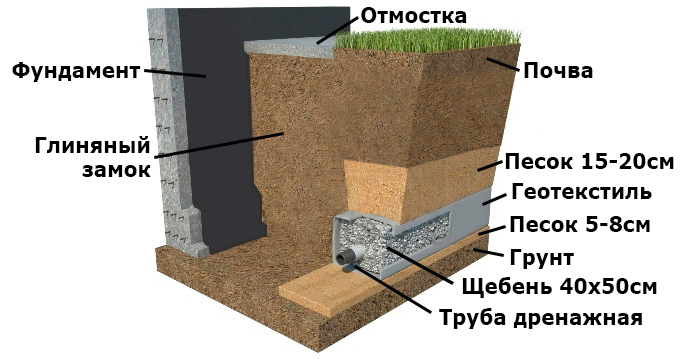

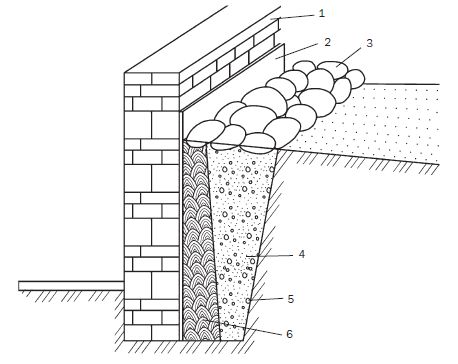

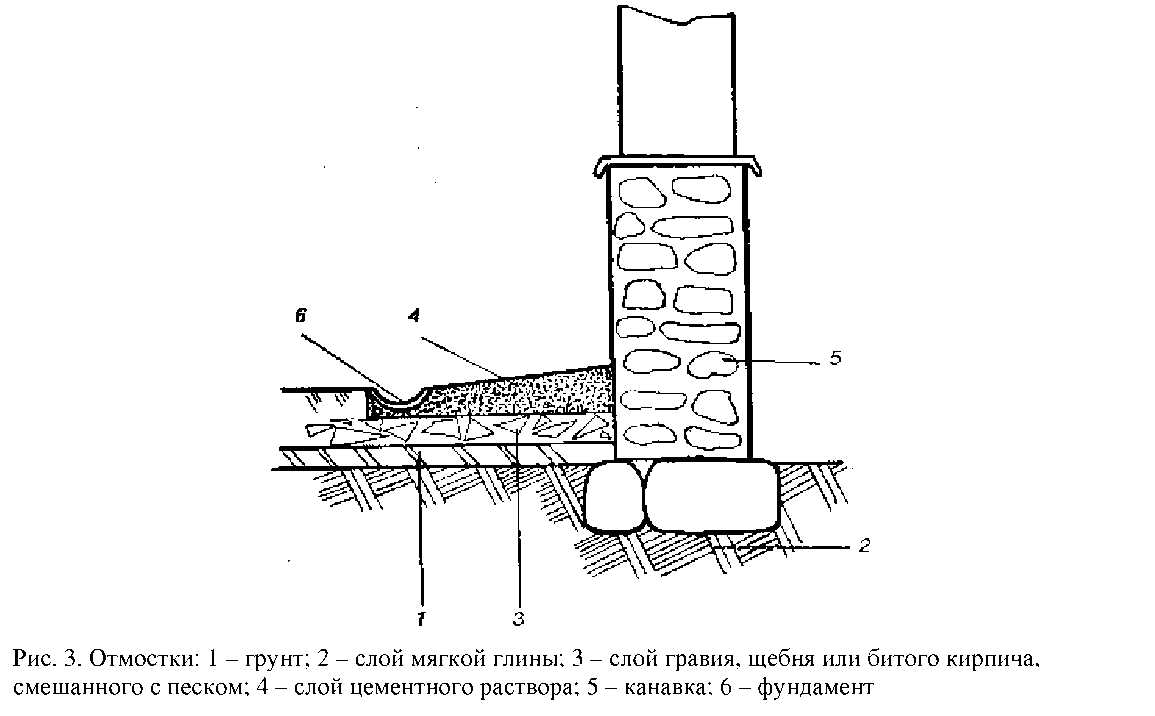

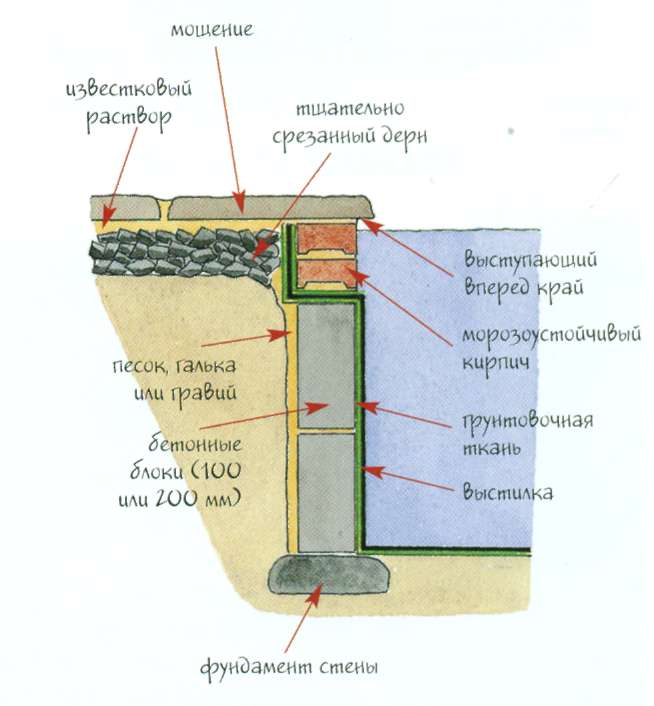

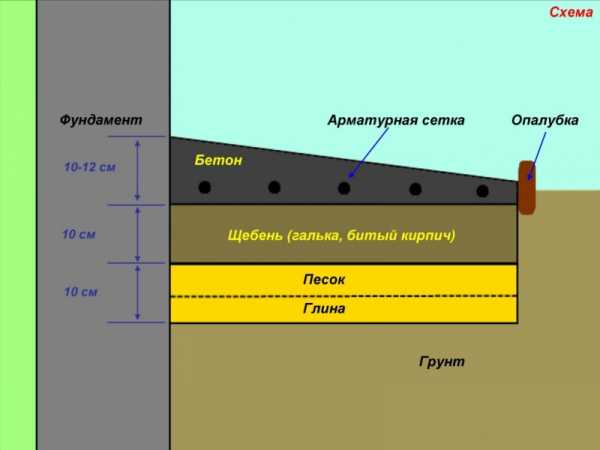

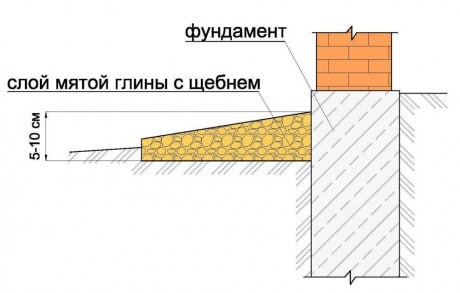

The best result is obtained by carefully tamping the clay into the formwork. You can install wooden shields, ensuring the thickness of the castle is 15-20 cm. If the pit is not wide, and there is sufficient material, the walls of the pit themselves can serve as formwork. Clay is rammed in layers 20-30 cm high. Placing a geotextile cloth outside the castle will prevent its gradual erosion by groundwater. Until there is a blind area around the perimeter of the house it is also worth laying a strip of geotextile, filling it with a slope from the building. The blind area can be made from a mixture of rubble and mint clay, paved on top.

If the pit is not wide, the formwork can be left out

If the pit is not wide, the formwork can be left out

The clay lock of the well is made similar to a blind area. It should be wide, at least one meter, and not necessarily deep, from half a meter. Better, of course, wider and deeper. If a water pipe goes from the well to the house, it must also be insulated with a lock, regardless of the depth of its laying.Clay can be covered with geotextiles on top and paving slabs or cobblestones can be laid on it.

The clay castle of the pond is made with a thickness of 8-12 cm in three layers. The clay is kneaded to a state of soft dough, applied to a horizontal or inclined surface, compacted and allowed to dry a little. The surface should become similar in hardness to plasticine, then the next layer can be applied. During drying, including at the end of work, the clay should not be allowed to dry out in order to avoid the appearance of cracks. It needs to be covered with a film, you can use hay. The reservoir will turn out to be ideal if you spread a film for ponds on top of the clay.

The clay blind area should be protected from above with geotextiles or paved

The clay blind area should be protected from above with geotextiles or paved

So, clay is not only a traditional, but also a promising material for waterproofing buildings from ground moisture. It literally lies underfoot, the work does not require the performer to have qualifications and a complex instrument, although it is quite laborious. European and American technologists continue the successful development of the latest clay-based insulating materials; their appearance in Russia should be expected in the near future.

How to put paving stones or paving slabs?

Blind area from paving stones or paving slabs especially durable and aesthetic. Various colors are available for selection, which allows you to choose the desired design. There is also a great variety of shapes: from simple geometric to intricate. The material is resistant to temperature extremes, and therefore durable. Tiles can be easily removed and installed back.

Use simple styling technology. Geotextiles are spread over the sand of the soft blind area, sprinkled with a thin layer of dry cement. Laying decorative elements. With a light tap, the mallets are leveled. A strip is applied to control the level: all tiles must be in the same plane. After completing the work, pour water on the surface so that the cement sets.

How to make clay lubricant?

Clay grease is used to insulate and seal the cellar overlap. For its preparation, you can use any kind of clay. Clay grease is prepared as follows:

- the clay is soaked for 2-3 days;

- to obtain 1 m3 of lubricant, you need to take:

- 0.7 m3 of clay dough;

- 0.28 m3 lime dough;

- 32 kg of fibrous impurities: chaff, fire, straw cutting 5-10 cm long;

- 200 kg of water, into which you can add copper sulfate at the rate of 100 g per 1 bucket;

all the ingredients are thoroughly mixed and receive clay grease for building a cellar with your own hands.

The video explains how to mine clay:

{lang: ‘ru’}

Laying technology

The whole structure resembles a layer cake, where the film is laid out first, then sand, on top - geotextiles (if it is necessary to block the germination of weeds) and decorative material.

Subsequence:

- The entire fertile layer of the earth is removed (to the depth of the second ring).

- The film is laid out so that one edge of it covers the soil near the wall (more than a meter), and the second is put on the ring itself, closing the seam between the second and first rings.

- The film must be pressed against the well so that it does not slip. To do this, cut out a metal tape and wrap it around the wall of the first ring, pressing down on the film. Fixed directly to concrete with screws.

- You can simplify the task: fix it with tape by wrapping it around the ring several times. True, in the second case, it is necessary to hide the pasting place under the decorative material.

- On top of the film, a sand pillow is poured with a slope from the well and a decorative coating is laid out.

With this method, no swelling of the soil will break the seam, because it is covered with a dense, loosely adhering film, which can adapt to the movement of the soil.

Features of waterproofing with a soft blind area

Application of temporary waterproofing in the system soft blind area around the well has a paradise of technological aspects that must be taken into account during the installation process:

- The whole structure is laid at the level of the second ring.

- Waterproofing film and sand are used as materials.

- The edges of the film strips are folded over the well rings.

- Decorative material is laid on top of the film and sand.

At the same time, all technological requirements must be met.

Laying technology

Before making a clay castle, you need to dig out the soil to the level of the 2nd ring. The selected soil is no longer used and must be removed and disposed of. A film is laid on the bottom. The size of the site to be closed is at least one meter from the outer wall of the reinforced concrete ring.

One end of the film is thrown over the well above the seam. It needs to be fixed, for which a metal belt, scotch tape or self-tapping screws are used, which are screwed directly into the concrete. In the case when scotch tape is used, it is necessary that several turns be wound. After that, the cavity is covered with sand on top of the film.

Backfilling is performed not to the very top, if FEM or rubble natural stone is used as a decorative coating. When laying, check that there is a slope away from the well of at least 1.0-1.5 degrees. But this is a temporary method, and in order to ensure the tightness of the well, an earthen lock is a must. But not every type of clay can be a material.

How to find clay for your castle

For the device of the castle, fatty varieties of red clay are used. The deposit doesn't matter. The content of impurities is a different matter. Clay is used, which contains no more than 15% sand. Absolute purity is not required, but an overabundance of solid particles that cannot serve as a binder in an aqueous solution is a factor sufficient to reject the material.

If there is no greasy clay, and there is no place to bring it, then you can use a different type. During preparation, it is soaked and kept. Usually they act as in the old days: they are soaked in the fall, and laid in the winter. At the same time, make sure that the clay does not dry out. So it becomes plastic, and all the particles are combined into a single mass.

During the soaking process, periodic freezing and thawing is allowed. This is even good, since moisture permeates the entire volume. The main thing is to make sure that the mixture does not dry out or crack. And in order to improve plasticity, lime is introduced into the composition in a ratio of 1: 5. 5 parts of clay are placed on one part of lime.

How to lay a soft blind area around a well + video

Some "experts" argue that this kind of protection against water pollution is an atavism and a relic of the past. In fact, such claims are based on two tricks:

- Few people say that you need to wait two years, and then proceed to the improvement of the well. This is in order to put the source into operation as early as possible.

- It is beneficial for them that the client turns to them every year. After all, as a rule, the same people are engaged in cleaning wells from dirt, and it is beneficial for them that garbage appears in the water as early as possible.

The technology involves laying a film that covers the soil by a meter around the walls of the well. An overlap that fits over the seam between the first and second rings should cover it. The cavity obtained after the excavation of the soil is filled with clay. It cannot be simply filled up and compacted mechanically. The styling technology is best seen.

Blind area options

- Fill up the clay castle sand and gravel

. -

Turf.

Turf layers can be used as a blind area, but a prerequisite is the organization of a drainage system. -

Tile.

Tiles are laid on top of the clay castle along the house. Having previously covered the base layer. -

Concrete blind areas.

They are more expensive than the previous one and after a few years they will begin to let moisture through even with additional reinforcement. Consequently, its replacement and additional costs will be required.

To protect the foundation from destruction by groundwater and wastewater, a weir system should be organized, an earthen castle should be built and it should be closed from above with a blind area. If additional funds are available, it is possible to use additional waterproofing materials.

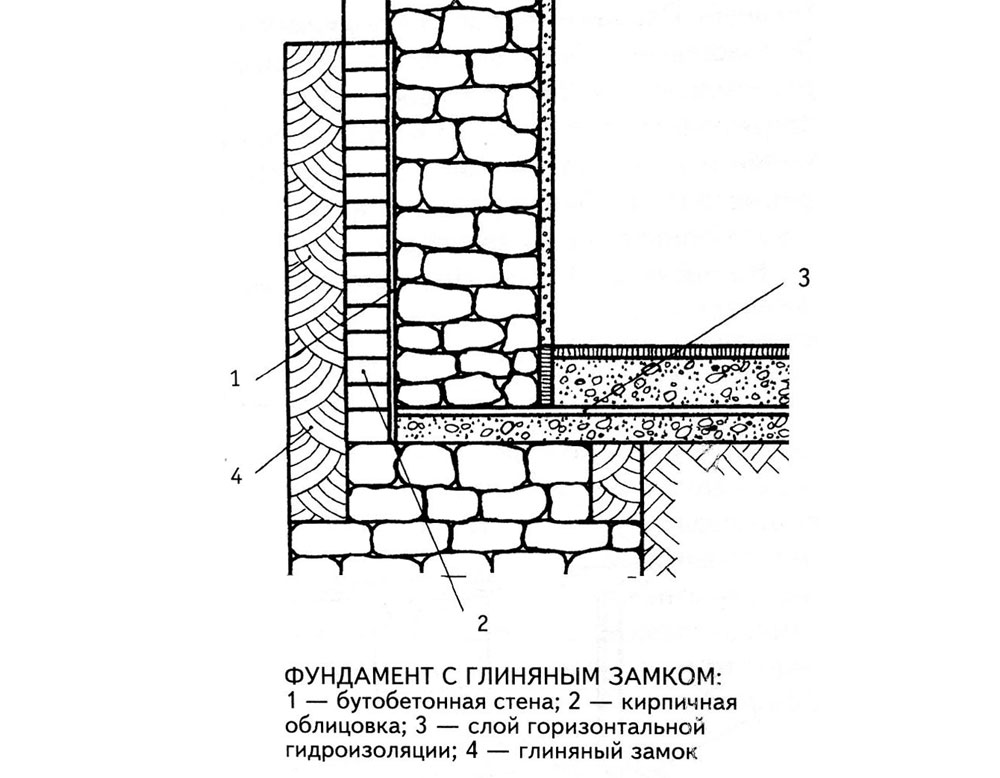

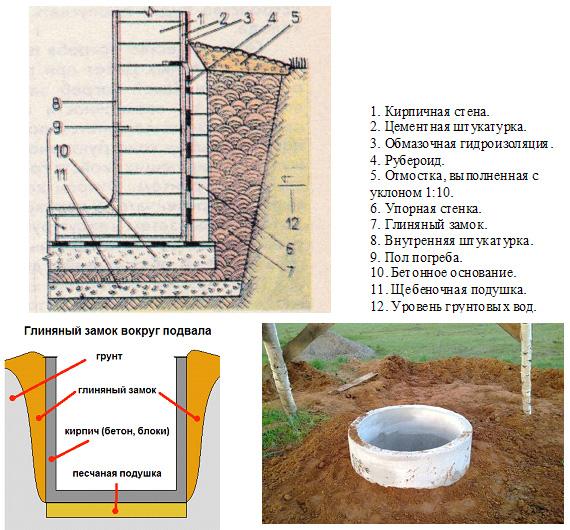

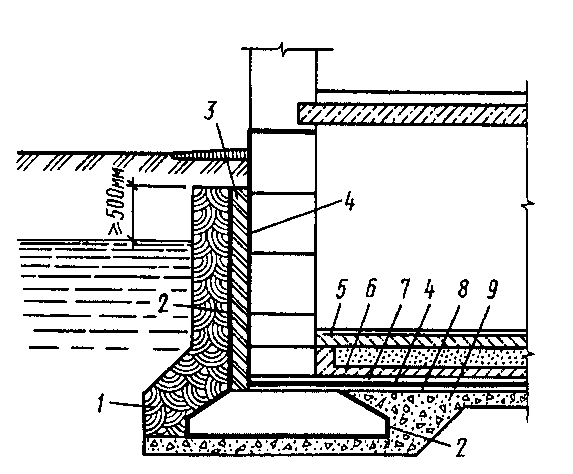

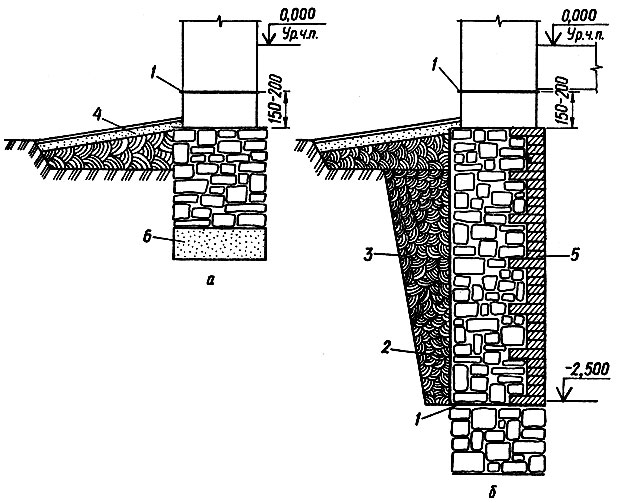

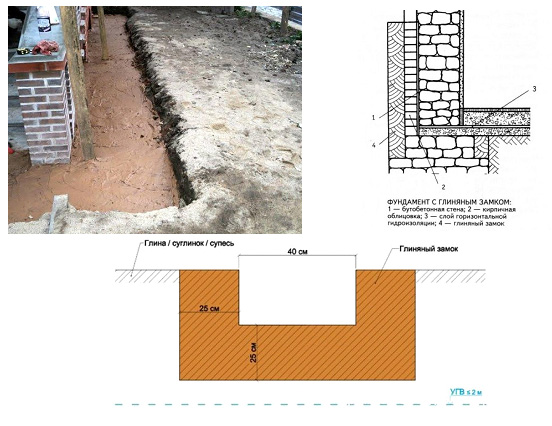

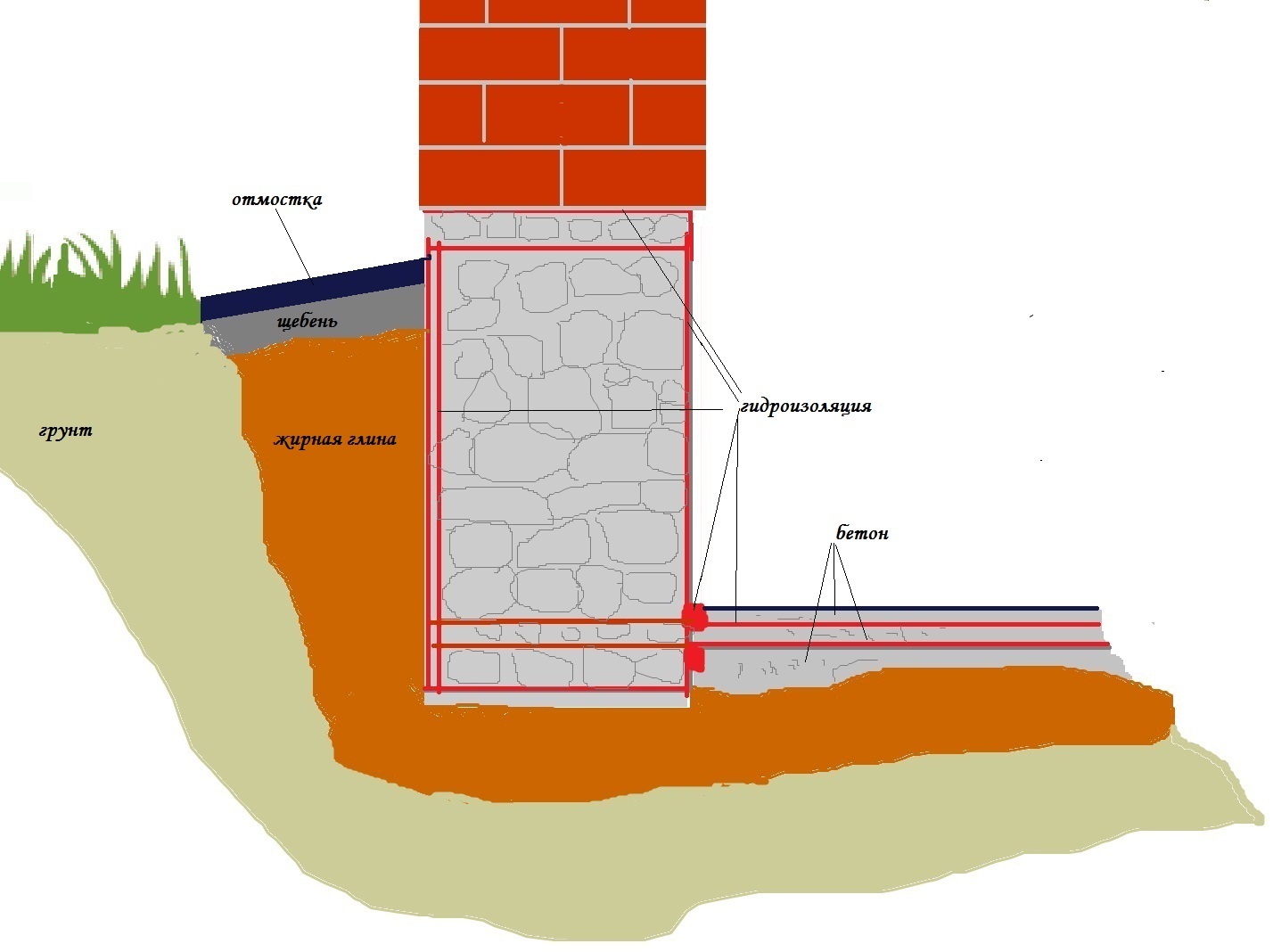

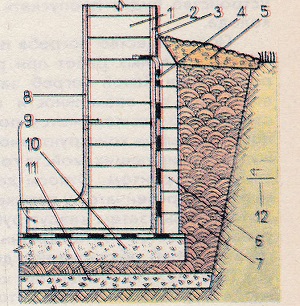

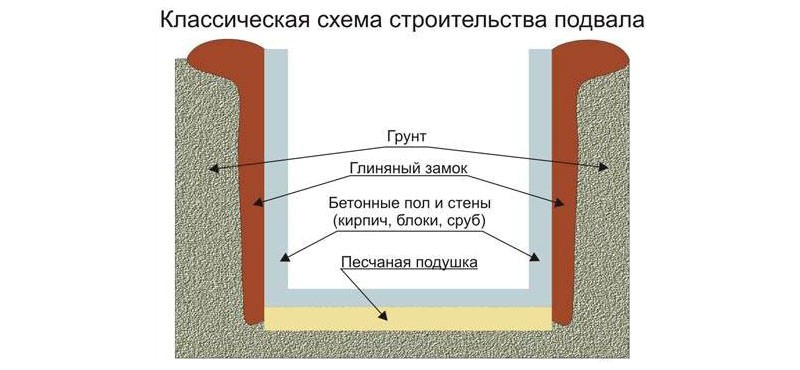

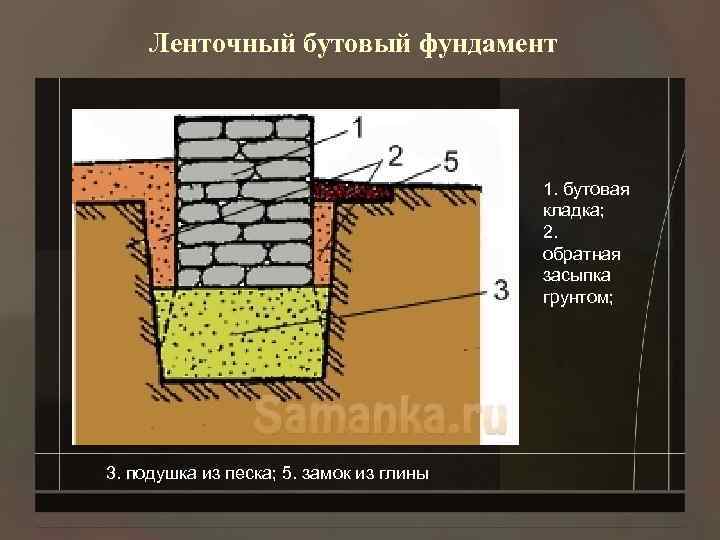

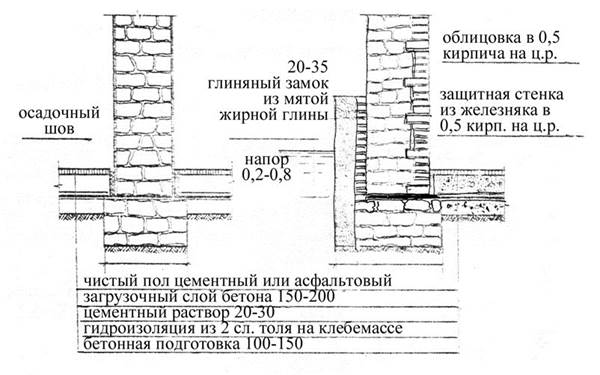

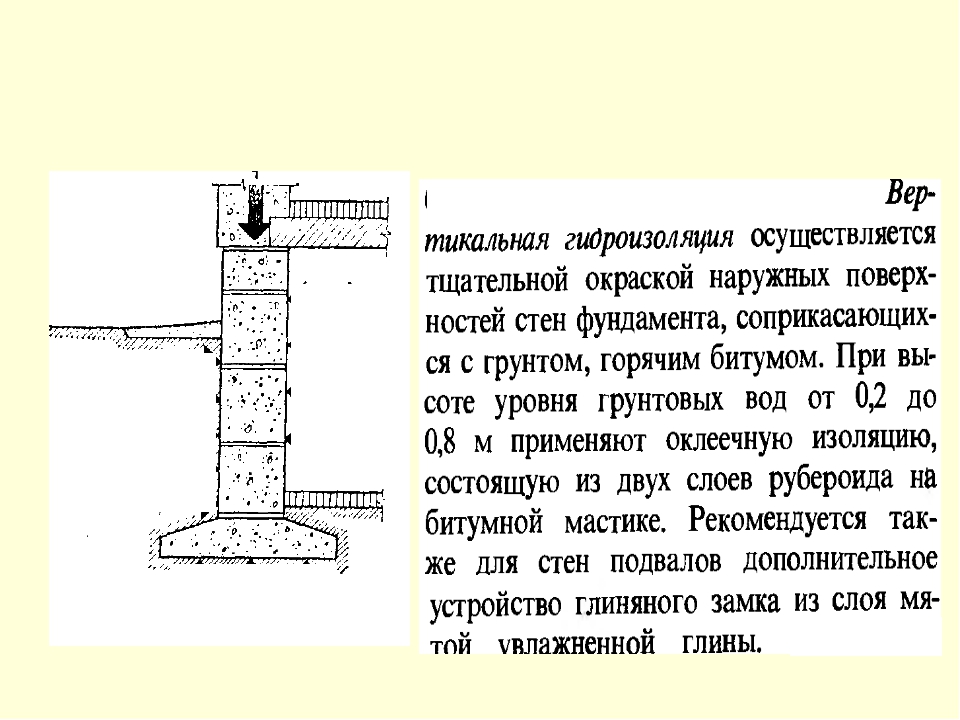

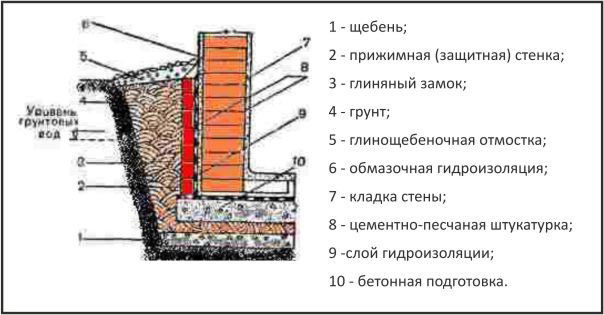

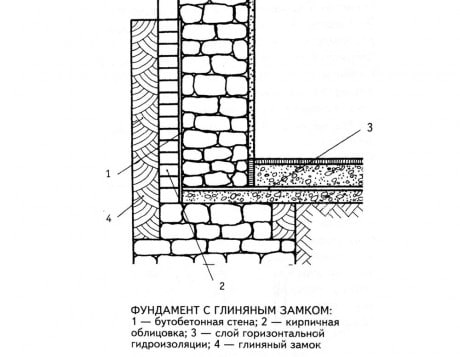

The foundations and walls of basements require a mandatory waterproofing device. Today, there is a huge range of roll and coating materials on the market, but once clay was traditionally used to protect underground parts of structures from moisture penetration. Modern builders have not forgotten about the clay castles, arranged around the foundation, so the technology is still used today. But here it is not worth talking only about the Russian hinterland, since clay waterproofing is quite popular in some European countries. The naturalness and high moisture resistance of the material provide it with a fairly high demand, especially since the quality of clay castles has long been tested by time.

Clay castle properties

The main properties and technical characteristics of a clay castle include the following:

- Arrangement of a clay castle does not require repair work and lasts a long time;

- Clay as a building material has a good ability to keep out water, but it absorbs moisture, so the way out of this situation is to use an additional layer of waterproofing;

- Clay is a mineral material, does not deteriorate and has no shelf life, and due to plasticity, cracks do not form in the clay layer;

- This building material is inexpensive, so the cost of equipping a clay castle for the foundation is minimal;

- Due to the ability of clay to expand in volume during freezing, it is necessary that the walls of the base of the house have a smooth surface.

For arranging a waterproofing layer of clay, any of its varieties with a minimum sand content are suitable. It is recommended to use a greasy clay with a sand content of no more than 15%.

Sometimes, in order to increase the operational parameters of the clay, lime is added to it in proportion to the total volume.

How to do it yourself

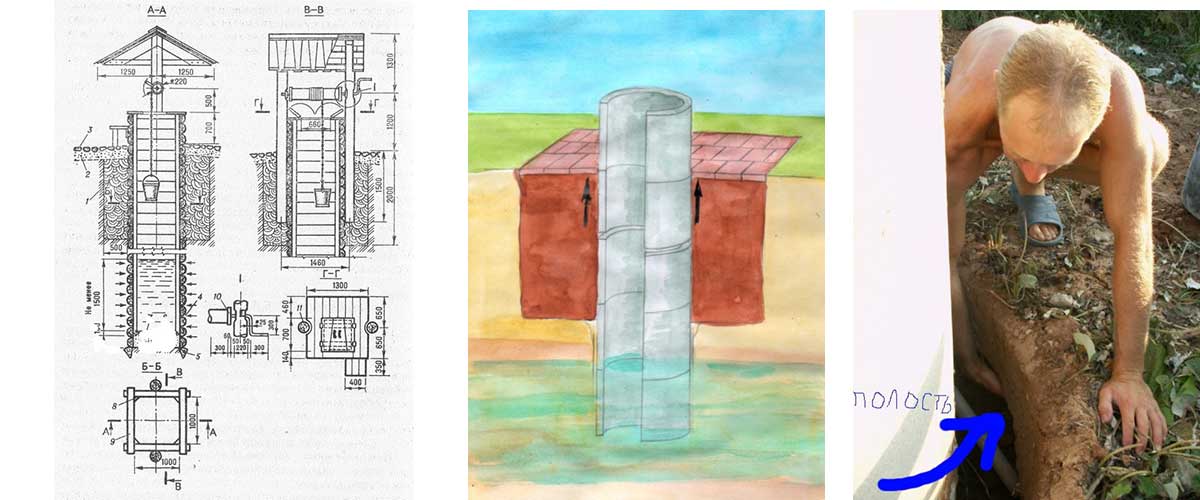

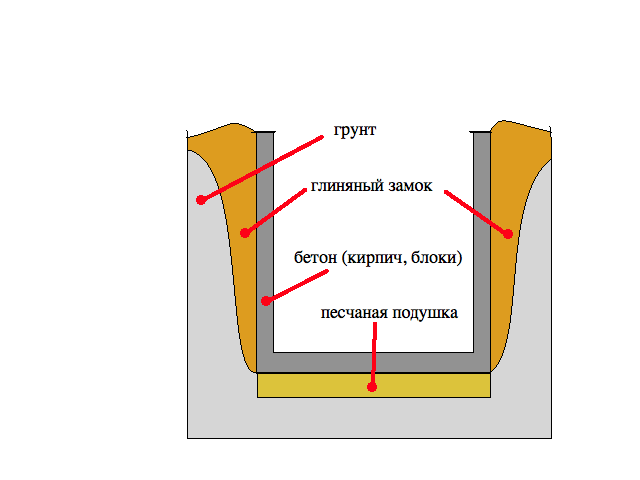

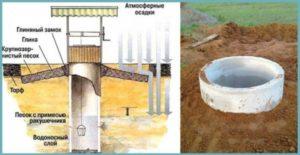

Diagram of a clay castle for a well made of concrete blocks.

A clay castle for a well of concrete rings should be built after the soil around the hydraulic structure has settled and stabilized. The soil around the reinforced concrete rings is removed to a depth of about 2 m, the width of the pit is 1 m.

The bottom of the trench should slope away from the well walls and be narrower than its diameter at ground level. Before laying clay, the bottom of the trench must be covered with a small layer of sand or pebbles. It is permissible to lay sand on top of the geotextile - it will strengthen the bottom of the trench.

The clay mixture should be moistened and thoroughly washed to a plastic state before placing it in the pit. The optimum moisture content of the material for making the lock is 15-30%.

The prepared mixture is placed in a trench in a layer no more than 15-20 cm thick and intensively compacted. The layers are tamped with a heavy tool with a small foot area. They are laid out one by one until the surface of the castle is equal to the surface of the ground. A roller is arranged around the well above the level of the castle so that rainwater flows from the walls of the shaft.

Thoroughly compacted clay does not allow moisture to pass through, but its surface becomes viscous after rains. A nearby blind area or a pebble layer around the well will help to ensure the convenience of using the source.

To prevent clay swelling from affecting the integrity of the well shaft, the concrete rings are wrapped with a layer of non-woven material. In this case, the soil near the walls will be able to move freely up or down without affecting the structure of the well.

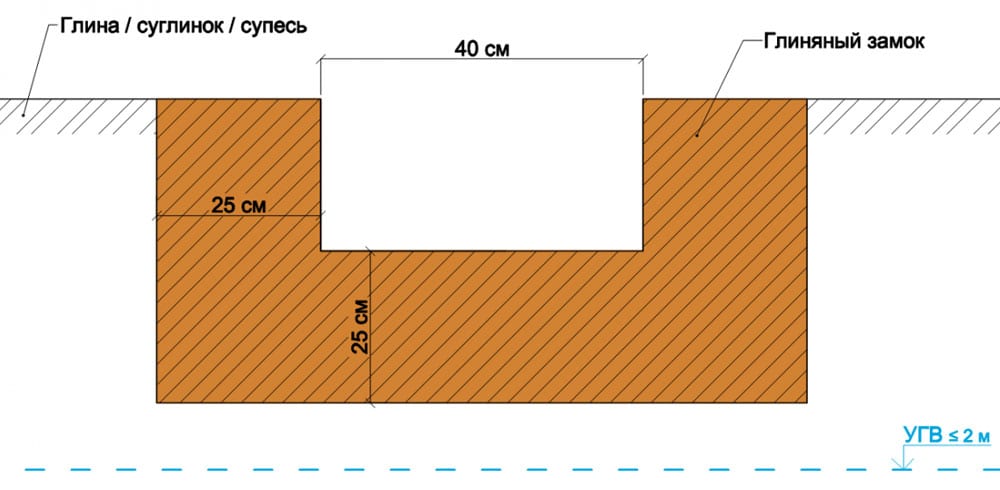

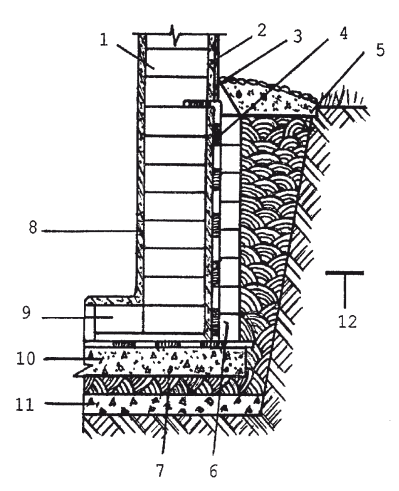

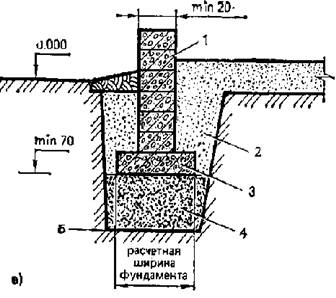

How to make a clay castle

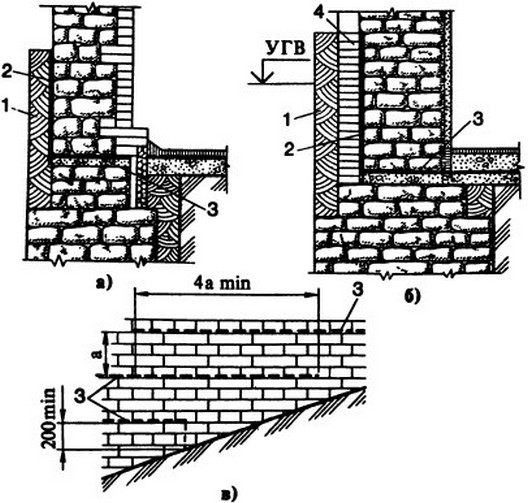

The width of the crumpled clay waterproofing depends on the depth of the foundation, and for the upper and lower parts, the size may be different. With a standard deepening of an underground structure up to two meters, the width of the castle at the lower mark should be at least 40 cm, and at the upper mark at least 25 cm. Clay should be laid in the pre-installed formwork in even layers of 5-10 cm with the obligatory compaction of each layer. If the sinuses of the pit correspond to the size of the waterproofing lock, then the formwork can be abandoned.

The film will also be required upon completion of the installation of the clay waterproofing to the required mark. In the covered state, the lock should be left for at least two weeks, after which it will be possible to start the device blind areas around the house.

The well was made for me by local craftsmen. Half of the wells in our SNT were dug by their hands. So I had a rough idea of what they were capable of, and there was neither desire nor time to look for someone on the side - autumn was coming, and I really didn’t want to leave the solution of this issue for the next year.

It was clear in advance that there would be imperfections, but I was ready to put up with this. One such imperfection was the absence of a clay castle. More precisely, it was difficult to call what the workers did when they covered the gap between the rings and the soil with clay.

The main argument in favor of their technology sounded something like this: They always did this, and everything was fine !. They were not ready to create something more in line with the norms. Resigned to the situation, I decided not to argue, but to try to take care of the castle myself.

Clay castle. The construction of a clay castle is prescribed by the Sanitary Rules and Norms (SanPiN 21.4544-96, "Drinking water and water supply to populated areas").

In clause 4.3.4. says the following:

Around the perimeter of the head of the well, a lock should be made of well-washed and thoroughly compacted clay or oily loam 2 meters deep and 1 meter wide, as well as a blind area of stone, brick, concrete or asphalt with a radius of at least 2 meters with a slope of 0.1 meters from the well towards the cuvette (tray).

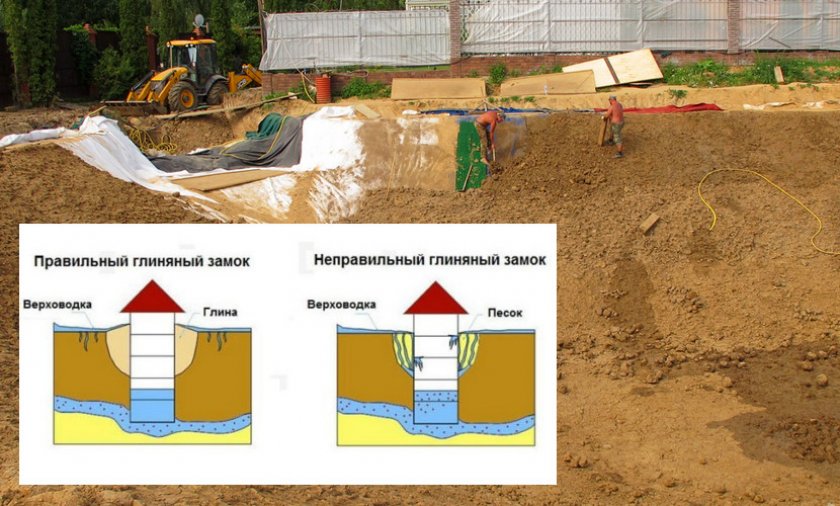

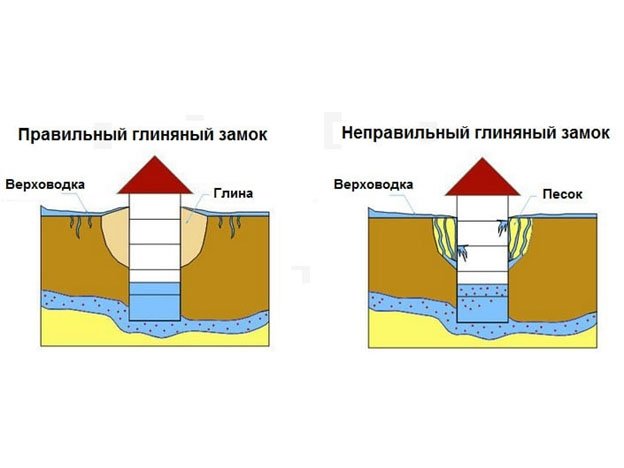

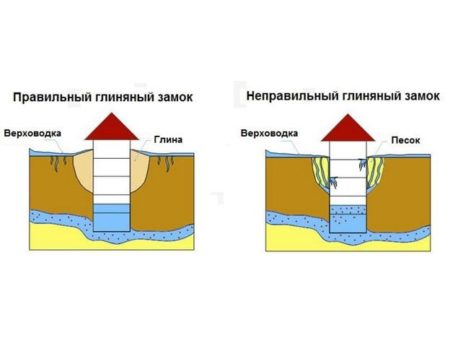

The main function of such a castle is to protect the well from the penetration of surface water (the so-called overhead water) into it during rains and melting snow. Top water is not purified by filtration through the soil and should not be used as drinking water. So I never had any doubts about the need for a castle. The question remained: how to do it?

Information on the topic, obtained from available sources, primarily from the Internet, puzzled me a little. As it turned out, recently there have been many opponents of the construction of the castle.

They put forward as the main argument that in our climate, clayey soils that find themselves in the freezing zone swell strongly - the soil frozen from the shaft of the well increases in volume.

This leads to borehole rupture, opening of the joints between the rings, and often to horizontal displacement of the rings. This happens almost every year, and in the end it becomes impossible to use the well - dirty water penetrates into it from the surface. That is, the castle not only fails to cope with the task at hand, but also worsens the situation.

In Russia, a clay castle was used, for example, to protect cellars, basements, and undergrounds from water.

They also made a castle around the wells, and it did not seem to destroy the well itself. Why? This question remained not entirely clear for me, but one answer option more or less satisfied me. The fact is that in the old days, wells were built in the form of wooden log cabins. In the heaving zone, there were about a dozen mezhventsovy seams, and with uniform opening, they each had only a few millimeters, which did not lead to depressurization of the well shaft. Today, most of the wells are made of concrete rings.The rings are most often connected to each other by a weak mortar seam, and there is usually only one joint in the heaving zone, which is not capable of compensating for heaving deformations without damage.

To somehow reduce the risk of depressurization of the structure, there are various recommendations. For example, it is more firmly to connect the rings (with steel plates, for example). But tightening the top rings with metal overlays usually does not help. The fact is that the forces acting during heaving are very significant and are capable of deforming even powerful fastening structures.

Other recommendations relate to measures to reduce heaving forces. In this case, the well is considered as an unloaded foundation, and the same measures are applied to it as to the foundations. Namely: replacing heaving soil around the well with a non-heaving one (in fact, backfilling), warming the soil and arranging drainage around the well

The scope of application of clay insulation in our time ↑

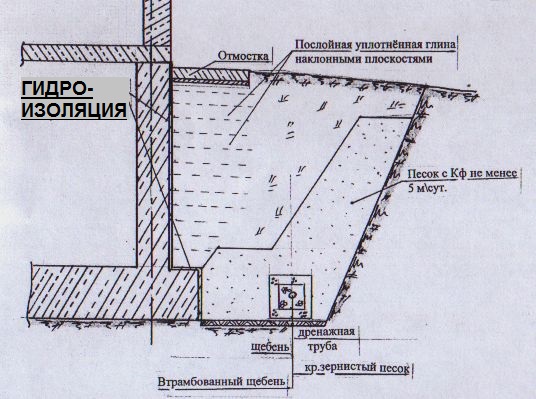

As in the old days, the clay used to protect from moisture in basements and building foundations. The ideal option is a combination of modern and traditional methods. Surface insulation can be made with bituminous materials (roll or coating) or polymer-cement composition. Build a clay castle outside. Such a solution will increase the reliability of waterproofing many times over.

Very often builders make mistakes when constructing buildings in clay soils. They dig a pit, build a basement floor, and backfill, as is customary, with a sand and gravel mixture in order to neutralize the heaving effect of clay on the foundation. Builders want the best, but it turns out "as always". Clay soil retains water, and sandy, like a sponge, absorbs well. After the rain, all the water goes into the sand, and remains there. The backfill around the building is saturated with water for a significant part of the year, and regardless of the level of groundwater.

One of the options for building a dry basement. If the walls of the basement are concrete, the brick cladding can be replaced with coating or pasting insulation.

One of the options for building a dry basement. If the walls of the basement are concrete, the brick cladding can be replaced with coating or pasting insulation.

If there is even the slightest hole in the surface insulation of the basement, water will surely find its way inside the house. This problem is eliminated by the construction of a clay castle or by expensive underground drainage. When building on clay soils, it is better not to use sand bedding at all. Under the cushion of the foundation it is better to place a layer of rubble, back up the clay removed from the pit and compact it. This recommendation does not apply to shallow foundations erected in heaving soils.

Clay is the most popular waterproofing material in the construction of ponds and reservoirs. Perfectly retains water without any additional measures. However, the use of a film will only improve the properties of the pond, preventing the erosion of the clay layer.

The property of clay to retain water is used in the construction of ponds.

The property of clay to retain water is used in the construction of ponds.

The industry produces high-tech waterproofing materials containing clay components. The products of the American company "Akzo Nobel Geosynthetics" are quite well-known in the West - three-layer waterproofing mats "NaBento", based on bentonite clay in a geotextile shell. Mats expand after filling the pit sinuses, tightly "packing" possible cracks, they are used to isolate critical underground structures in difficult conditions. Clay mats are produced by a number of enterprises in the USA, Canada, European countries and China.

The construction of a clay castle when constructing a village well for drinking water is a must. Otherwise, dirty surface water will seep in along the walls.

The clay castle and the blind area of the well should have an outward slope

The clay castle and the blind area of the well should have an outward slope