Construction

The first step is research and preparation of the soil. The easiest option would be to ask your neighbors. Perhaps they have already taken measurements and are ready to share information. But if this is not possible, you will have to do the research yourself.

To find out the characteristics of the soil, you will need to dig a hole with a depth of 2.5 meters. Then, for every 20 centimeters of the pit, it is necessary to take soil samples, determine the depth of the groundwater and the type of soil. If you are not confident in your abilities, you can always resort to the services of specialists.

After conducting the research, you should decide on the number of storeys and dimensions of the garage. The more floors a building has, the heavier it is, which means the requirements for the base will be higher. For calculations, you need to take into account the density of materials (walls, ceilings) and their volume. Multiplying the numbers, you can get the mass of the building, determine the distribution of weight.

Please note that a brick building will be significantly heavier than a foam block building, the densities differ by almost two times. To strengthen the foundation, apply reinforcement

For massive (for example, two-storey) garages, reinforcement of the foundation is often the only possible solution.

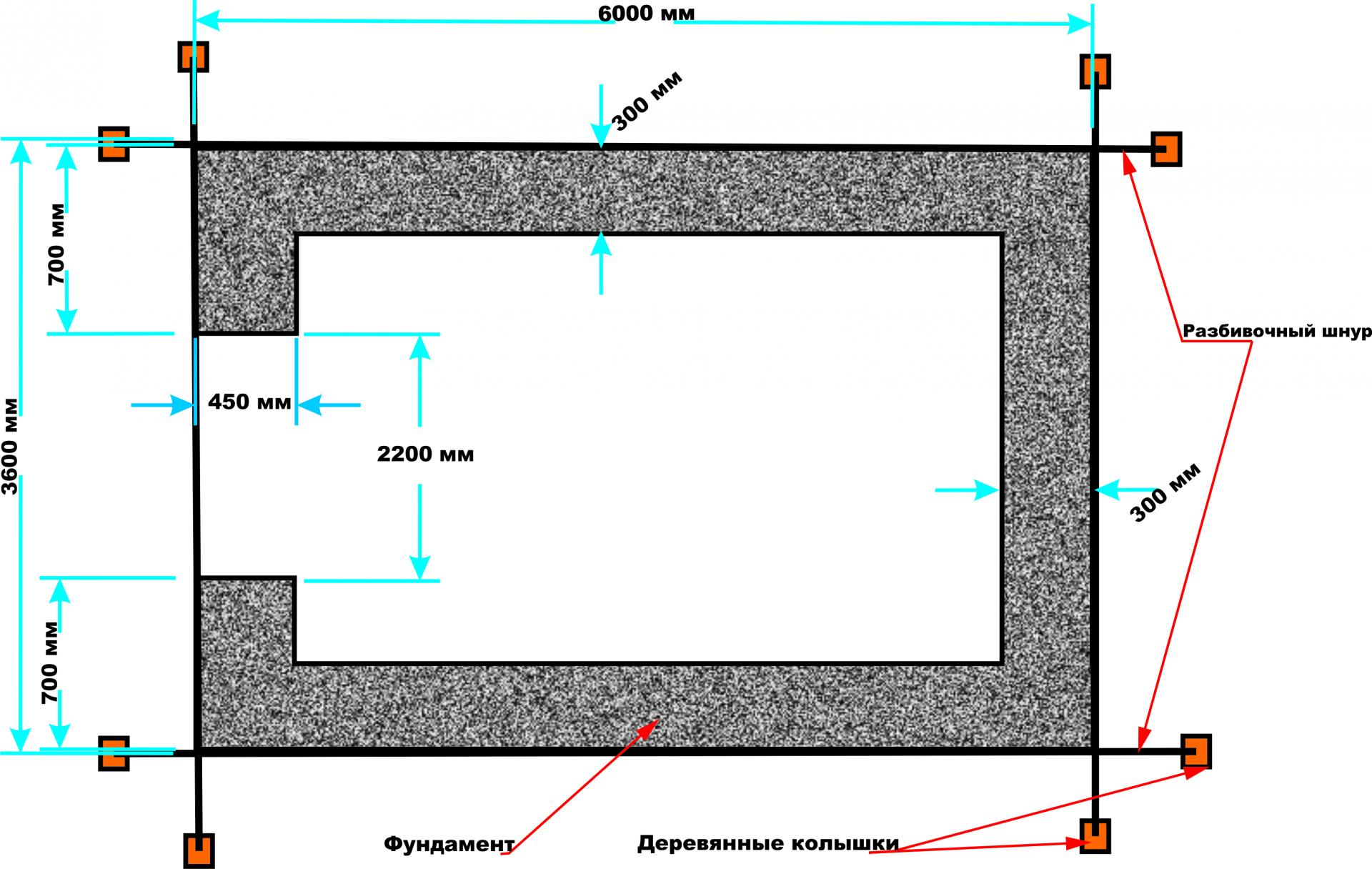

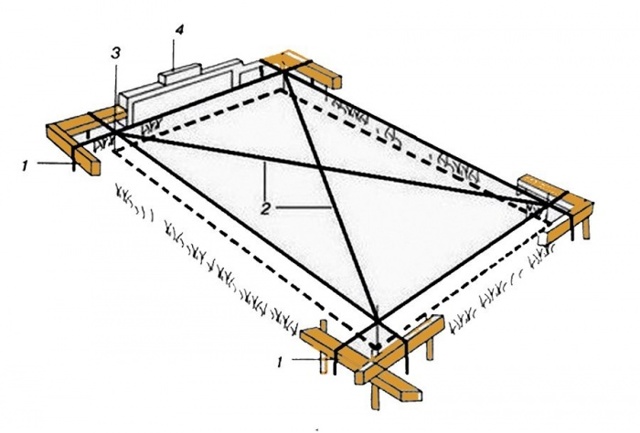

The last step is soil preparation and waterproofing. The site must be marked using wooden pegs and nylon thread. The angle must be exactly 90 degrees.

Waterproofing should be installed in both planes - vertical and horizontal. The “walls” and “floor” of the foundation are covered with insulating material.

Waterproofing should be installed in both planes - vertical and horizontal. The “walls” and “floor” of the foundation are covered with insulating material.

Waterproofing is made from roofing material or synthetic film.

Please note that the insulation process depends on the type of foundation, as different construction methods require different structural elements. Let's consider in general terms the construction of foundation types:

Let's consider in general terms the construction of foundation types:

Advice

In the process of building a garage, it is important to constantly check the level of foam concrete so that each block is completely flat. For adjustment, there is a special rubber hammer that allows you to move unevenly laid masonry

It is very important to do this immediately, before the glue has set. Such activities are carried out during the entire construction. As a result, the finished garage has smooth walls.

With smooth walls, the garage can be easily plastered for painting or a layer of decorative plaster can be applied to create a unique design. If you wish, you can sheathe the building with Euro-board so that it looks spectacular and well-groomed.

When building a garage, it is very important not to forget about ventilation. It can be made forced, which is considered the best option, but there are other ways - left gaps in the masonry above and below, installing a special mechanical hood and other options

If the ground is unstable and there is a risk of a close approach of groundwater, it is best to avoid the construction of a viewing hole or basement, which will save the entire garage from moisture. If the garage was made as an extension, then additional doors can be made directly from the premises to the inside to avoid using the gate if there is no need to leave by car.

If precipitation falls too often, then it will be necessary to install a drain both on the roof of the garage and near it. This is done so that moisture does not get on the foundation and does not destroy it. With such protection, the garage will stand much longer, its protective properties will not be compromised, and the car will be reliably protected.

Depending on where exactly the garage will be built, you can make it of various dimensions.Having a private house, it is very convenient to store all work and garden tools in a separate room. In this case, the garage can be attached to the house and create the appearance of a large common building, keeping everything in one style, or vice versa, separate it and focus on a different type of design.

At the dacha, a garage is most often needed for temporary parking of a car and storage of all equipment necessary for work. If there is also a basement in the garage, then it will be very convenient to store the crops harvested from the beds in it.

If you plan to build a garage from scratch, then it is advisable to study the best options for planning and construction, decide on a gate opening system, the presence or absence of windows. Only by approaching the issue seriously and thoroughly, you can end up with a good and high-quality garage, where everything is foreseen in advance and each thing has its place.

For the pros and cons of foam concrete blocks, see the following video.

Insulation types

Foam sheets are often used, which are attached to the ground foundation with bitumen mastic. The gaps between the panels are filled with polyurethane foam.

Penoplex gives an even greater heat retention effect in the garage. The material is attached to the lower areas of the house using a special glue for outdoor use. Penoplex is more resistant to water than foam, the material also has a longer operational life.

Before buying, pay attention to the thickness of the insulation, its heat-insulating qualities. The local climate for the use of insulation also plays an important role.

Do-it-yourself foundation for a garage made of foam blocks

Building a foundation for a garage from foam blocks yourself can be a daunting task for a beginner in this business. But if you follow the instructions and recommendations of experienced builders, then this task will be quite simple.

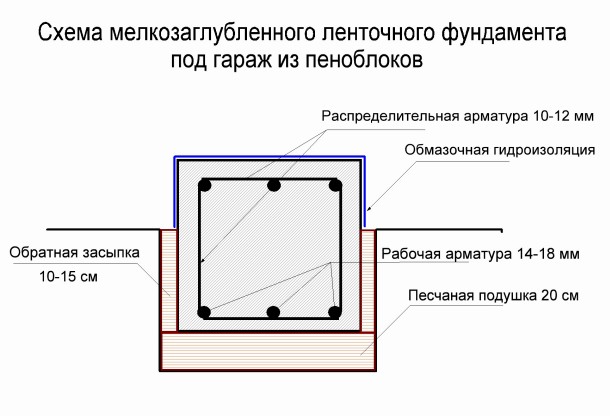

Despite the fact that there are several types of foundations, the most popular for small buildings was and remains a strip foundation. Therefore, it is about him that we will talk below.

Video:

1. Design

Any construction begins with the planning and creation of a project, the garage is no exception. Without a well-thought out systematic plan of action, there is no point in starting construction. Just at the planning stage, the type of foundation is chosen, which means that it is necessary to take into account exactly the factors that are listed above. The project should represent not only a plan of the foundation, but also the entire structure. This makes it easier to achieve accuracy and correctly calculate the amount of materials.

A garage project can be developed using a computer program. In it, you can not only create a visual model of the building, but also calculate the required materials.

2. Preparation

Don't underestimate the importance of preparatory work. Preparation for the construction of a structure includes the following activities:

- A few centimeters of soil are removed and the site is leveled on which construction will take place.

- Pegs are driven into the corners of the future building.

- A rope (construction or nylon) is pulled between the pegs. The angle between the threads must be strictly 90 °. If you are doing this for the first time, it may not come out the first time, but you need to try and achieve the perfect value.

3. Earthworks and filling

After the preparatory work, the most important and crucial part comes: the process of laying the foundation itself. In order to make it more clear, we will tell you about each action point by point.

- Along the perimeter of the future building, focusing on the stretched threads, a trench of the required width and depth is dug (what dimensions are most suitable is found out even at the construction stage). The following dimensions are most often used: depth - 50-80 cm, width - 40-50 cm (width of foam blocks plus 15 cm).

- The sand and gravel cushion is laid.To do this, the earth is compacted in a trench and 10-15 cm of sand and 7-10 cm of crushed stone are poured on top.

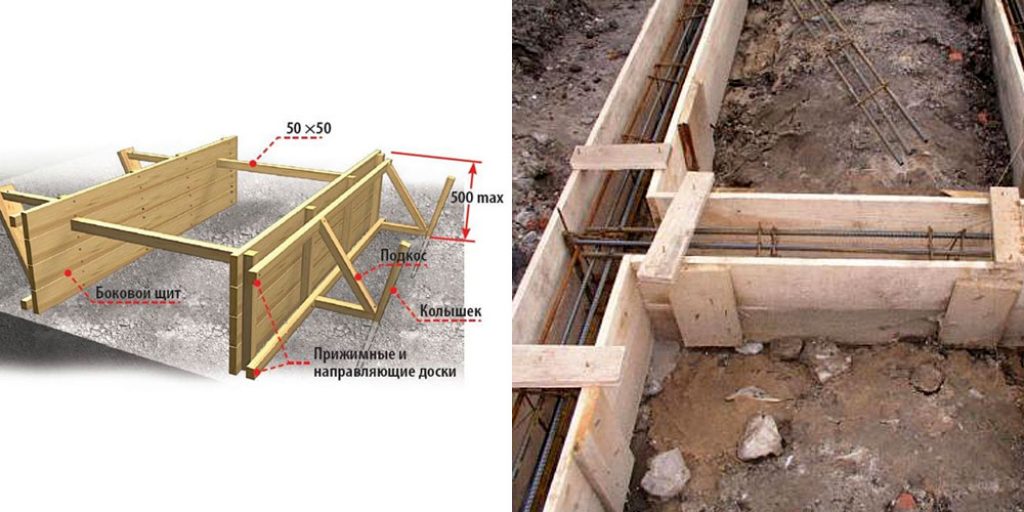

- Formwork is being installed. As a rule, the formwork is made from scrap materials: wood, metal, etc.

- Next, the foundation is reinforced - the reinforcing cage is laid. It is mounted from reinforcement rods with a diameter of 14-16 mm; rods of 8-10 mm are suitable for a bundle. Such a frame fits on a sand and gravel cushion.

- After laying the reinforcement, the concrete mixture can be prepared. For her you will need: sand, water, cement mixture. Be careful, some store mixes already contain sand and only need to be diluted. The components can be mixed both in a stationary concrete mixer and manually. But given that a fairly large amount of cement is needed for the foundation, it is better to get a small concrete mixer, as an alternative - to rent it for the duration of the work.

- The final step is pouring concrete into the trench. The mortar should be poured evenly so that there are no difficulties later when erecting the walls. After pouring, leave the foundation for a few days until it dries completely. Only then can the formwork be disassembled and proceed with further construction work.

Video:

A strip foundation is the most common type of foundation for a foam concrete garage. It is quite durable and can withstand the stress of a small technical room. In addition, it can be easily laid with your own hands. It is the possibility of self-construction that is quite often a decisive factor for many garage owners. Indeed, when building with your own hands, there is an opportunity not only to save money, but also to do everything conscientiously and in accordance with your wishes and plans.

What types of foundations are suitable for a foam block garage

You should get such a nice design at the end of construction.

The foam block is a lightweight building material, the weight of which directly depends on the density. For the construction of garage walls, structural and heat-insulating blocks with a density of 600-800 kg / m3 and a size of 200x300x600 mm are mainly used. Such a building stone weighs 19-22 kg, and 1 m3 of blocks - within 460 kg.

Thus, a low weight load will be applied to the foundation and bases with a high bearing capacity are not required. For the construction of a garage from foam blocks, the following types of foundations are suitable:

- shallow belt (MZL);

- slab (if there is heavy large-sized equipment in the garage);

- screw;

- pile.

When choosing the type of base, in addition to the weight load of the structure, several more parameters are taken into account:

- type of soil;

- soil freezing point (TPG);

- groundwater level (GWL).

Foundation on screw piles

The installation of such a foundation can be handled without special equipment.

On mobile soils with a predominance of sand or sandy loam, it is optimal to build a foundation on screw piles. These supports are immersed below the TPG by 20-30 cm, due to which the pile is firmly held in the ground and does not react to its natural or seasonal (freezing-thawing periods) movements.

For the installation of the foundation on screw piles, the help of expensive equipment is not necessary: a hole drill, a pile driver, specialized installations. Craftsmen have long developed a technology for installing metal supports with their own hands. For this purpose, a scrap or metal pipe is used, which is inserted into the technological holes under the head. The pile is screwed in by the efforts of several people. The number of supports is calculated based on the requirement: the distance between them should be no more than 3 meters.

Advantages of a foundation on screw piles for a garage from a foam block:

- Lack of labor-intensive and time-consuming earthworks.

- Installation speed.

- Possibility of installation at high ground level.

- Ventilation of the lower floor.

- The possibility of installing hollow concrete slabs on piles, which is optimal for a garage with a car). In this case, the distance between the supports is reduced to 2 m.

Disadvantages:

- The need for a ramp to enter the garage, since the building will be raised above the ground level.

- In the absence of the possibility of installing reinforced concrete slabs, the lower floor is made of wood, which is fraught with other disadvantages and operational difficulties.

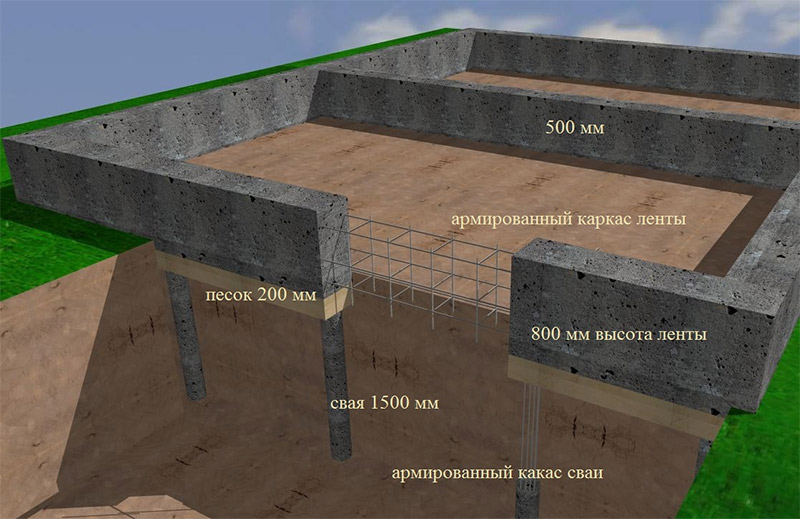

Pile

Pile is in many ways similar to the foundation on screw piles

A pile foundation has the same pros and cons as a screw foundation. The difference lies only in the material from which the supports are made, and the method of their installation.

For the construction of a pile foundation, the following can be used:

- narrow and long concrete blocks;

- metal or asbestos-cement pipes with concrete poured into them;

- pillars, hand-made with formwork and concrete.

The supports are immersed in the ground below the TPG by 20-30 cm. They are fixed in a vertical position using backfilling and concreting.

Platen

If you plan to keep trucks in the garage, we recommend opting for a slab foundation.

A slab foundation for a garage made of foam blocks can be arranged in two cases:

- if there will be trucks in the building;

- if there is heaving soil on the construction site and in the region there are harsh climatic conditions.

In the first case, the slab is deepened by analogy with the MZL: by 30-40 cm. In the second, a USHP (insulated Swedish slab) is arranged, which is at the same time a "floating" foundation that compensates for all ground movements.

Insulation is necessary to create favorable conditions for the operation of the garage and its durability in cold climates. Often, such a decision is made when building a garage next to a house, since the presence of a UWB reduces heat loss.

This is interesting: How to remove the smell from the refrigerator

Projects

Once the decision has been made to build a garage, the first thing to think about is creating a project. This type of work can be done independently or you can use the services of a specialist. Depending on the availability of the territory, you can plan the size of the future building and the buildings adjacent to it, if necessary.

If the family has two drivers and two cars, then a garage is built accordingly. The building for 2 cars should be spacious so that cars can easily fit under one roof and there is a place to store inventory, tires and other trifles. When space is sorely lacking for one car, you can make a two-story garage, where a car will stand on the first floor, and a full-fledged workshop will be located on the second. With the second floor, it becomes possible to equip not only a work area, but also a place for a hobby, for some it is music, for some collecting and so on.

The most successful are the dimensions of the garage 6 by 4, where it turns out to put the car, and supplement the building with various household items and equip it with a working area. If there is a desire to make not only a comfortable garage, but also a beautiful one, it can be equipped with an attic, where you can do some of the work or have the opportunity to take a break after repair work. Those who like to take a steam bath can organize an appropriate extension.

The bathhouse can be part of the garage, but in this case it is important to isolate both rooms as much as possible so that water and moisture from one does not get into the second.

Having planned the inspection pit, it is important that its depth is maintained within the established norms for it and is no more than two meters. When planning the construction of a garage, it is necessary to calculate the amount of materials that will be needed in the work

If the length of the building is six meters, then 10 foam blocks will be required for one row. The number of them in height is also calculated.

As soon as the issue with the walls is resolved, you can move on to the roof.It can be lean-to, built with a slope to one side, or have a standard view of the roof of a residential building, but not raised high from the ceiling of the garage

It is worth paying attention to the material with which it will be covered. To do this, you can use slate, shingles, metal tiles or corrugated board

Each of the above options has its own advantages and disadvantages, but the first thing you should pay attention to is the availability of any materials with which you can perform a number of works.

Project preparation is an important stage in the construction of a garage

Getting started with any construction object, you should decide on a future project, which will allow you to plan the consumption of materials and the entire budget as a whole. An important aspect is the characteristics of the soil, the passage of groundwater. This information will help you determine the structure of your foundation.

The garage layout can be very arbitrary.

At the same stage, it is necessary to decide on the purpose of the garage - whether it will only store the car or the room will be able to function for other purposes. The main selection criteria:

- the presence of a viewing hole;

- the need for a basement for canned products and vegetables for the winter;

- installation of racks for inventory and tools;

- the possibility of equipping the working area in the form of a table, workbench.

The garage project can be as detailed as possible

Taking these requirements into account, you can start designing, where the first question will be to determine the type and parameters of the foundation, the height of the walls. The following guideline values apply for standard designs:

- the garage can be up to 3–3.5 m wide;

- in height it will be no more than 3 m;

- the length of the room is about 4.5–6 m.

The schematic image can be presented in several angles

How much material is needed to build a garage

Traditionally, the blocks have dimensions of 600x300x200 mm, while the walls can be both 200 mm thick and, if turned over, then 300 mm. The determining factor when choosing a thickness is the presence of heating - 200 mm is enough for a cold garage, and a warm one requires at least 300 mm. When the project is fully prepared, you can proceed to detailed calculations of the number of blocks according to the scheme below (for example, a 4x5x3 m garage is taken):

- Calculation of the length of the walls around the entire perimeter of the room and the number of foam blocks per row: (4 + 5) x2 / 0.6, where 0.6 is the length of the block. The result is 30 pieces.

- Determination of the number of rows with a garage height of 3 m and a product height of 0.3 m. Everything is simple here: the height of the room is divided by the height of the block and it turns out 3 / 0.3 = 10 rows.

- In total, according to preliminary data, 30 × 10 = 300 blocks will be needed for the entire garage, but it must be taken into account that due to door and window openings, material consumption will be reduced.

- Deduction of the amount of materials at the locations of gates, doors, windows. When building a garage without heating with a wall thickness of 200 mm per 1 sq.m. the consumption will be about 6 foam blocks. It remains to measure the area of all openings. With standard designs, the savings will be about 50 blocks, and for the construction of a 4x5x3 garage you will need 300-50 = 250 blocks.

This calculation scheme applies to any garage boxes.

Foam blocks have standard sizes

What tools will you need to work

The construction of the garage will be completed much faster if all the necessary materials and tools are at hand:

- The material for the construction of the premises is foam blocks, a binder mortar of cement, concrete, sand and crushed stone.

- Consumable additional material - boards for the roof and formwork, several rolls of roofing material.

- Metal parts - corners, fittings.

- A container for mixing a solution, a bucket.

-

Masonry tools - trowel, spatula; shovel for digging a trench under the foundation.

- Welding machine.

- Other inventory - hammers, screwdriver, hacksaw.

Strip base under the garage

Very often, for garages from foam blocks, they erect a strip foundation of two types with their own hands: monolithic or prefabricated. It is worth noting that the construction of a support strip structure with your own hands is possible only when choosing a monolithic foundation. Prefabricated belt supports must be mounted using lifting equipment, which significantly increases the cost of construction, since the rental of cranes is not cheap.

A strip foundation can be erected on sites under the following conditions:

- The depth of soil freezing is up to 40 cm.

- Groundwater does not lie close to the surface (the depth of the aquifer is from 1.2 m).

- At the site there are soils with good bearing capacity: sandy, hard clays and loams, soils with the inclusion of detrital rocks.

Monolithic tape construction technology

It is important to carefully mark the area before laying the foundation.

If the site intended for the construction of a garage meets all the conditions, you can start preparatory work.

To begin with, the surface of the site is cleaned of household and construction waste, plant residues, pits are filled in and embankments are cut off. If necessary, make a vertical layout of the site - it's easy to do it yourself.

After completing the planning and cleaning of the site, you can start marking the boundaries of the future garage. To do this, on the site, measurements are made of the sides of the garage around the perimeter, pegs are hammered in the corners, along which the string is stretched, which will help to maintain a straight line when digging trenches with your own hands for the foundation.

Earthworks and formwork

You can dig trenches for the construction of a foundation tape for a garage with your own hands or with the help of mechanized earthmoving equipment, but in both cases it is worth carefully cleaning the bottom and side walls of the trenches.

The formwork of the strip base is made of board panels

The formwork of the strip base is made of board panels

Sand of coarse fractions is poured onto the compacted bottom of the trench, which is carefully compacted, constantly spilling the sand cushion with water. The compacted layer of sand should be 10-12 cm high. A layer of fine gravel or pebbles is laid over the sand, which is also compacted with your own hands using manual or vibratory rammers.

The formwork is placed in the trenches manually, trying to maintain the vertical position of the boards. Shields should be made from wooden boards, thick plywood and chipboard

It is also possible to use disposable or reusable formwork for the device of the formwork for the foundation strip, in the latter case it is very important to clean the reused shields from dirt, dust, frozen mortar

Reinforcement and concrete pouring

High-quality fittings are the key to the reliability of the foundation of the house

High-quality fittings are the key to the reliability of the foundation of the house

To increase the strength of the supporting base, the strip foundation for the garage needs to be strengthened, for which a spatial frame made of reinforcing steel with a diameter of 10 mm is placed in the formwork, which is connected by welding or tied with a knitting wire.

The frame is positioned in the formwork in such a way that unprotected metal reinforcement does not come out onto the surface of the foundation. Bars or pieces of rolled metal are laid at the bottom of the trench in order to raise the welded frame above the sand and crushed stone pillow.

The concrete solution is poured into the formwork simultaneously from both sides; the concrete mix must be compacted with vibratory rammers. This operation is performed with particular care at the joints of the reinforcing cage.

It is very important that voids do not form in the body of the strip foundation.

The upper surface of the concrete solution is leveled and poured with water. It is required to moisten the foundation for about 2 weeks. To protect the concrete surface from cracking, the strip foundation is covered with several layers of film.

Watch the video on how to properly fill the slab base with your own hands.

The structure gains strength within 28 days, after which it is necessary to perform waterproofing from roll materials and start laying walls from foam blocks.

Performance properties of the material

In the manufacture of foam concrete, cement and foam created in a special way are used. By stirring the solution, the bubbles are gradually distributed throughout the mass, creating cells. The liquid mass is poured into molds, after which it naturally cools and hardens.

Depending on the strength required for the material, the level of its density varies in the range of 200-1200 kg / m3, which is reflected in the grade of the finished product.

Foam block is lightweight but durable material

Foam concrete is produced in the following grades:

- D900–1200 - has the maximum strength characteristics, is used in high-rise construction; called structural concrete;

- D500–900 - it is distinguished by an impeccable balance, suitable for the erection of load-bearing foundations of a building; called structural and thermal insulation;

- D200-500 - due to its low thermal conductivity, it is used as a heat-insulating material, while the level of strength also reaches minimum values.

The composition of aerated concrete, also called a foam block, currently includes cement, sand, a foaming agent and water. Thanks to this modern material, low buildings are being quickly erected and insulated today.

Unlike aerated concrete, the foam block is highly popular among builders, which is explained by the simplified process of manufacturing a unit of the product.

It is very easy to build a garage from a foam block