Wallpapering of fiberboard walls

To solve the question - how to glue wallpaper on fiberboard, you need to decide on the type of coating. It can be paper-backed wallpaper, non-woven or vinyl rolls.

Standard glue is suitable for paper-based veneers. For non-woven and vinyl coverings, a special adhesive is required.

Covering fiberboard with wallpaper consists of several operations:

- The rolls are cut into strips of the desired length.

- The segments are stacked in one bale. For alignment, a load is placed on the strips. To do this, you can use an inverted table and other pieces of furniture.

- According to the instructions, the dry mixture is diluted with warm water (20 - 25 0 С). Water is added gradually, while the solution is constantly stirred. Stirring removes air bubbles and prevents the formation of lumps.

Straighten the canvas in all directions

Indoors, all windows must be tightly closed. Any weak air flow in the space of the room will cause the glued wallpaper to fall to the floor in one moment.

With a wide brush, glue is applied to the back of the next piece of wallpaper.

The wallpaper on the wall is smoothed with a piece of rags or a rubber roller. The strip is leveled from top to bottom and in the transverse direction - from side to side.

When bubbles form on the surface of the coating, they are pierced with a needle and the swollen area is smoothed out.

At the inner corners of the walls, one section of the coating is overlapped with another strip by 10 - 15 mm. This will hide minor deviations of the angles from the vertical. Do the same with the outer corners of the room.

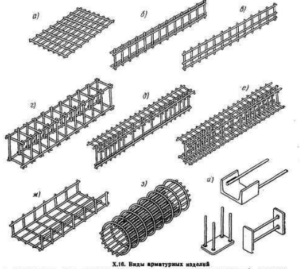

Materials and tools used for reinforcement

Since the reinforcement cage increases the stability of the structure by taking on a significant part of the load, its quality becomes of fundamental importance. The frame is formed from interconnected reinforcing rods. For knitting the frame, various are used:

Rebar types

Manufacturers offer fittings that can be classified according to:

Manufacturing material. Steel reinforcement is a classic, time-tested option; It is subdivided into 6 strength classes, it can be bent and welded. Composite rebar contains carbon, basalt, glass or aramid fibers. It is lighter, cheaper, does not corrode, does not bend or weld.

Reinforcement bars with improved performance

Profile. Smooth profile fittings are more often used as connecting straps. Rebar with a periodic profile has an embossed surface that improves adhesion to concrete.

Connection materials

Tying reinforcement under the strip foundation, the scheme of which can be changed, is made using:

-

Knitting wire. Reliable and common knot connection technology. There are different mating patterns.

-

Threaded and crimped couplings (in places of mechanical joints).

-

Metal clips. Reinforcement elements are connected without knot tying.

-

Plastic clamps and clips (clamps). Plastic products provide easy and quick installation, corrosion resistant. Their use is not approved by all professionals.

Composite reinforcement rods, fastened with a clamp

Welding. The process is fast, but the welds form a rigid connection, differ in density from the base metal and are subject to corrosion. When the load changes, they burst and reduce the strength of the foundation. The method is suitable for connecting rods of large diameters (in industrial facilities); to obtain a quality weld, a highly qualified welder is needed.

Rebar tying tool types

Tying reinforcement for a strip foundation is considered more practical than welding: the strength in the nodes does not decrease, a qualified welder is not needed, the work takes place right in the formwork (or next to it).The lattice frame made of reinforcement can be assembled either by hand (which is not easy to do with gloved hands) or with the help of a tool. For knitting use:

Knitting gun. The fastest way. The pistol is inconvenient to use in hard-to-reach places; it also uses a lot of wire. Its main drawback is the price. Models from leading manufacturers cost about 30,000 rubles, a Chinese pistol is enough for 1 foundation.

Professional tool - a gun for tying reinforcement

-

Crochet hook. It looks like a curved and sharpened nail with a handle instead of a head. It is often used as a nozzle, clamping in a screwdriver chuck. The industry produces screw hooks - effective in work, but slowing down the knitting process (leaving long tails).

-

Folk remedies. If the amount of work is small and the tool is not stocked up, use pliers or make a hook from a suitable nail. A quality result cannot be obtained using homemade products; this approach will invariably affect the strength of the structure.

About the reinforcement of a shallow strip foundation in the video:

Required wire

When choosing a wire, the following factors must be considered:

- Manufacturing accuracy class. The accuracy class is determined by the manufacturing method. There is a wire of a higher accuracy class, its deviation of the actual size, diameter, from the declared by the manufacturer along the entire length of the wire is less than that of the wire of a lower accuracy class. However, for knitting reinforcement, the accuracy class does not really matter.

- Wire rolling method. There are two types of rolled products: cold rolled and hot rolled. Cold-rolled steel is rolled out of billets by presses without heating. In the hot-rolled method, rolled steel is rolled out in a hot state, which gives it greater strength.

- Which tensile strength group the wire belongs to (there are the first and second groups);

- Corrosion resistance grade. On this basis, there is only one difference - whether there is a galvanized coating on the wire or not.

The criterion for choosing a wire is very simple, you need a wire, which is called "knitting". It has a full set of necessary characteristics: sufficient softness with the declared strength, abrasion resistance and reliability when fastened.

Galvanized wire is considered overkill. The optimal diameter of the tying wire is 1.2-1.4 mm. A lot of effort is spent on a wire with a diameter of 1.6-2 mm, as a result of which the construction slows down, and the unit is too weak, it will simply burst.

Care must be taken to ensure that the connection of the reinforcement remains rigid after tying the knot: during pouring, the frame must remain motionless. This will ensure the reliability of the structure after solidification.

The length of the wire recommended for one tying point is from 30 to 50 cm. The wire itself is extremely cheap - about 50 rubles. over 100 meters. To avoid its shortage at the wrong time due to loss or excessive consumption, it is recommended to buy it with a double margin. 100 rubles for 200 meters is quite inexpensive.

What should be the reinforcement

When laying the foundation, a margin of safety is taken into account. A mandatory requirement is maximum resistance to climatic and mechanical factors.

Foundation frame

Foundation frame

Reinforcement requirements:

- it is allowed to replace the bearing rods. Perhaps, if the load during the calculation does not exceed SNIP;

- with the correct structure of the base frame, it will not interfere with pouring;

- when installing reinforcement, the calculated step must be taken into account;

Anti-corrosion coating

Anti-corrosion coating

- the structure must have an anti-corrosion coating;

- no movable "floating" connections of the rods at the intersections of the frame are allowed. Refers to any connection method.

Used types of reinforcement

Before starting to analyze the topic, how to properly knit reinforcement for the foundation, you need to figure out the reinforcement itself. Indeed, today the market offers two types of it:

- This is an ordinary steel one.

- Composite.

Everyone has been accustomed to using ordinary steel for a long time. But what is the second model, how does it differ from the first, and is it better.

Steel

Metal fittings are six classes, which differ from each other in the percentage of alloying additions. And the more the latter, the higher the class, the higher the characteristics.

Rebar themselves are rods with a smooth or corrugated surface. The first class is smooth, the rest are corrugated.

The relief structure is an increase in the area of adhesion of the reinforcement to the concrete solution. In addition, the protrusions function as containment flanges when the reinforcement structure begins to work in tension.

Rods with higher performance and dimensions are too expensive, while performing the same function under moderate loads. And the lower class reinforcement for foundations is rather weak. But it must be added that even smooth reinforcement is used in reinforcing frames. It is not the main one, but it is used for jumpers, braces, ligaments and other unloaded nodes.

When choosing, you need to pay attention to the product labeling, especially the indices. Here are just two of them:

- "C" is the designation that the reinforcement can be welded.

- "K" - anti-corrosion additives were added to the steel. This type is the most expensive, so it is not used in private housing construction.

As for welded fittings, they are also not the cheapest option. Therefore, for private traders, the best option is knitting with steel wire. As for the question of what kind of wire the reinforcing frame is knitted with, then we will talk about it below.

Composite

This variety is relatively new material. It is based on plastic, where the components filling it are added: glass, carbon, basalt.

The most popular is the fiberglass variety, because it is simply cheaper than the other two with practically the same strength characteristics.

If we talk about the technical characteristics of this material, then:

- The tensile strength of plastic reinforcement is 1000 MPa, of steel 390.

- It is 3.5 times lighter than metal.

- Steel corrodes, plastic does not.

- It does not conduct electricity.

- It has low thermal conductivity.

As for the negative aspects, then:

- Metal reinforcement is better in terms of elasticity.

- Plastic belongs to the category of slightly flammable materials.

- It softens when heated.

- Fiberglass reinforcement can only be connected with clamps or wire, steel can be welded.

Today, clear recommendations on the technology of using composite reinforcement have not yet been developed, therefore experts recommend using it in foundations for lightweight buildings. It is better to lay steel under heavy ones.

Reasons for reinforcement

Reinforcement is carried out in order to compensate for the loads acting on the foundation.

Reinforcement is the most important stage of construction

Reinforcement is the most important stage of construction

For the construction of the foundation, a high grade of concrete is used to avoid the destruction of structural integrity.

Steel reinforcement

Steel reinforcement

A steel bar turns ordinary concrete into reinforced concrete. The base acquires the highest resistance to loads and snow.

The tape base is a monolithic reinforced concrete frame.

Ground water

Ground water

The soil on which the foundation is being erected is rather heterogeneous. Influenced by:

- jumping atmospheric pressure;

- grass;

- snow;

- water (ground);

- moisture.

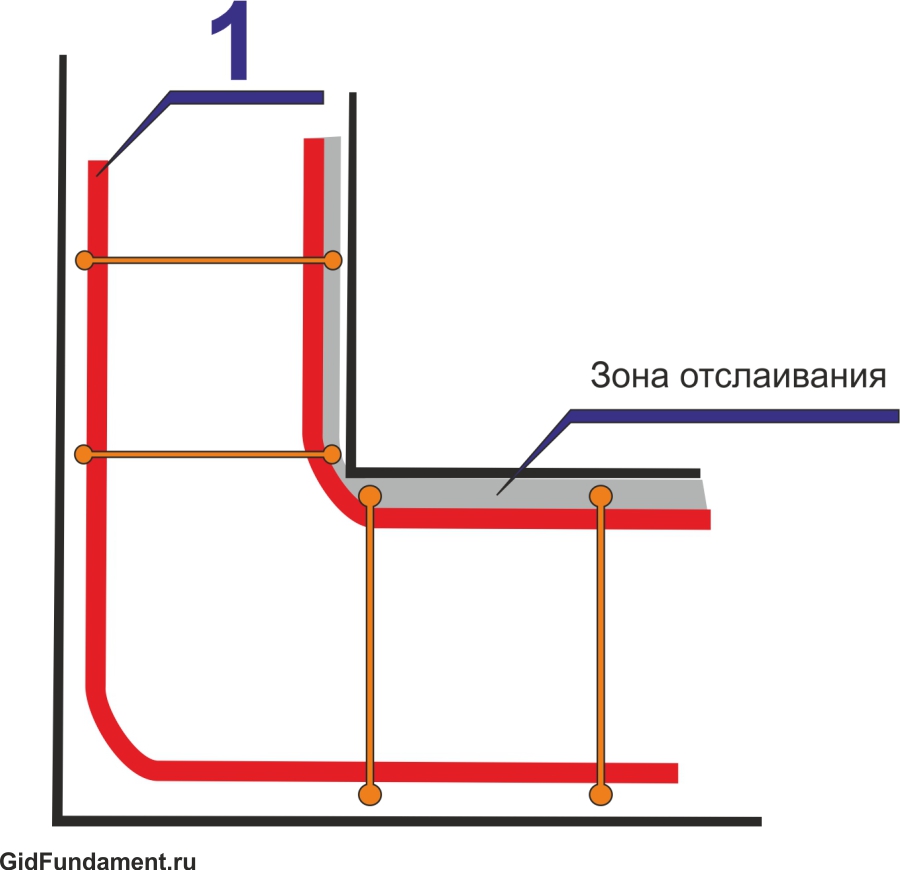

When the soil moves, it acts on the foundation. The lower part is affected by stretching, the upper part by compression.

Steel is a fairly flexible material prone to elongation. By joining together, steel and concrete cope with the existing loads.

Sometimes, only the lower part of the foundation is reinforced, poured with concrete into a trench dug for pouring.It is caused by the load of the structure, which does not allow the beam to bend.

According to the builders, the approach is incorrect, the lifting force of the wet, expanding soil, the force of frost heaving, when the water in the soil freezes, is not taken into account.

The resulting load is much greater than the load provided by the building. Stretching occurs in the upper parts of the base. Leads to the destruction of the foundation structure.

How to crochet

Nobody does the job manually. It's almost impossible. For this purpose, there are special tools that speed up and simplify the process. Each tool has its own characteristics for use. The following devices are available for bundling reinforcement:

- Hand hook.

- Knitting gun.

- Screwdriver.

- Ticks.

Each of the tools has its pros and cons, we will consider them, as well as the technology of their use, and based on this data and the opinion of an expert (a fitter with 10 years of experience), we will summarize and choose the best option for knitting reinforcement.

There are even automatic hooks on sale, but the reviews about them are twofold. Some note a small resource, others say that it is difficult to twist a wire with a thickness of 2 mm or more.

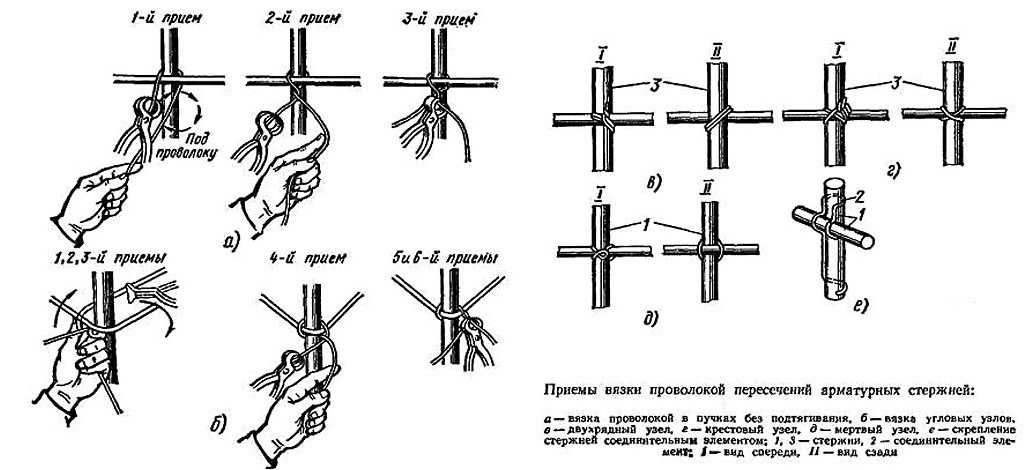

There are several options for connecting knots when crocheting reinforcement. Let's consider the most popular ones.

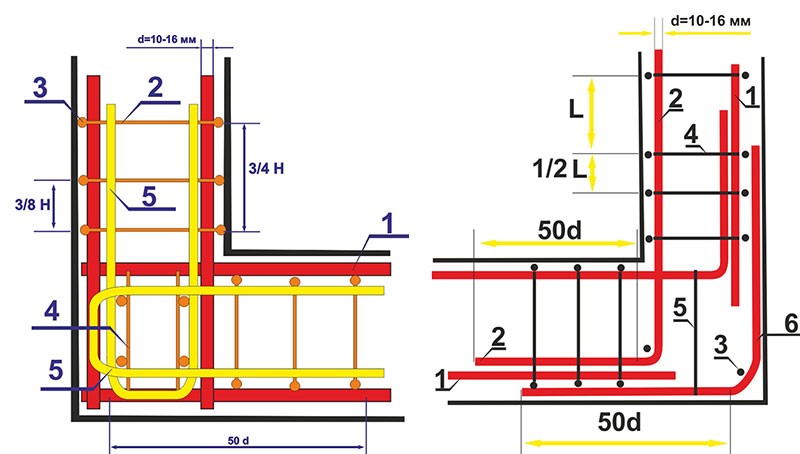

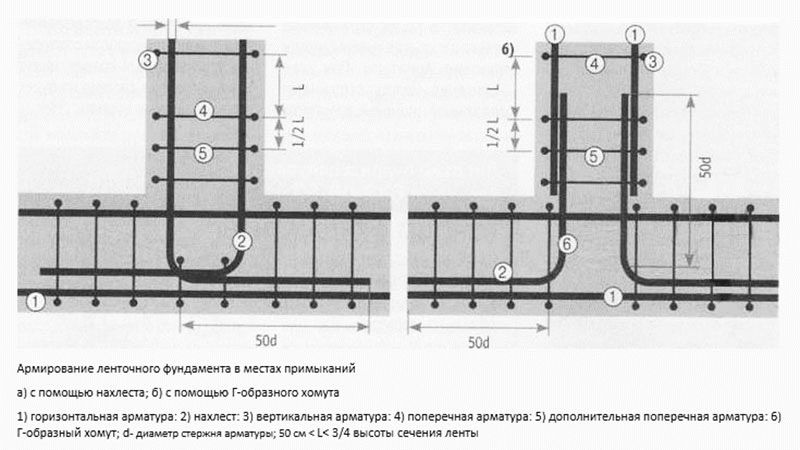

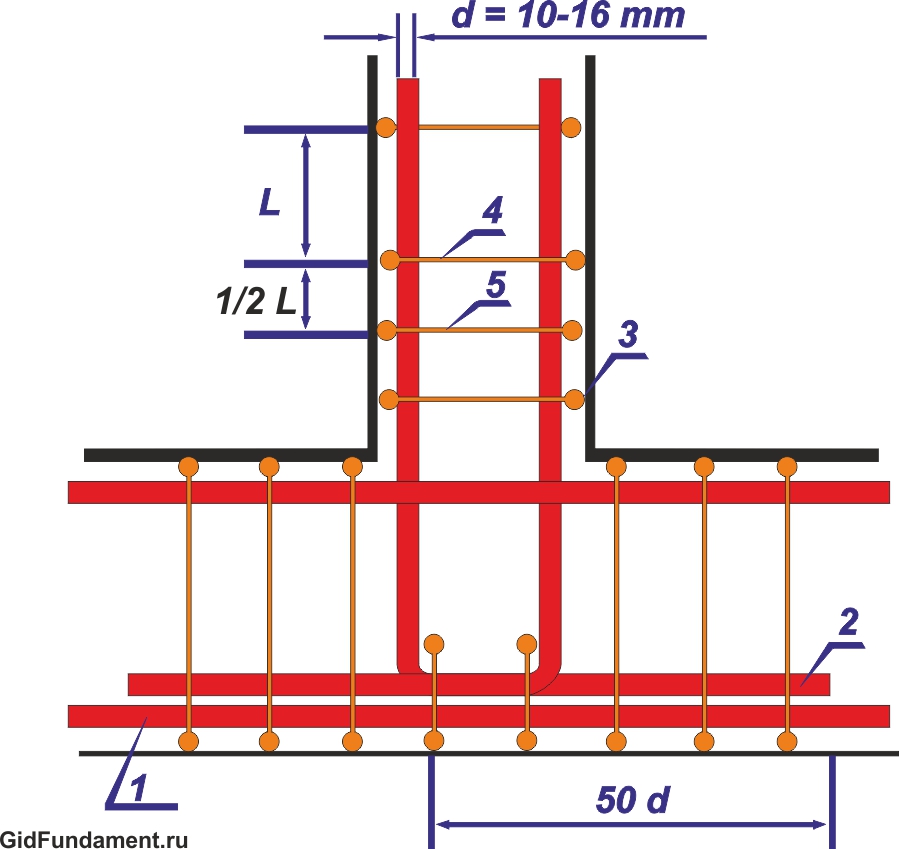

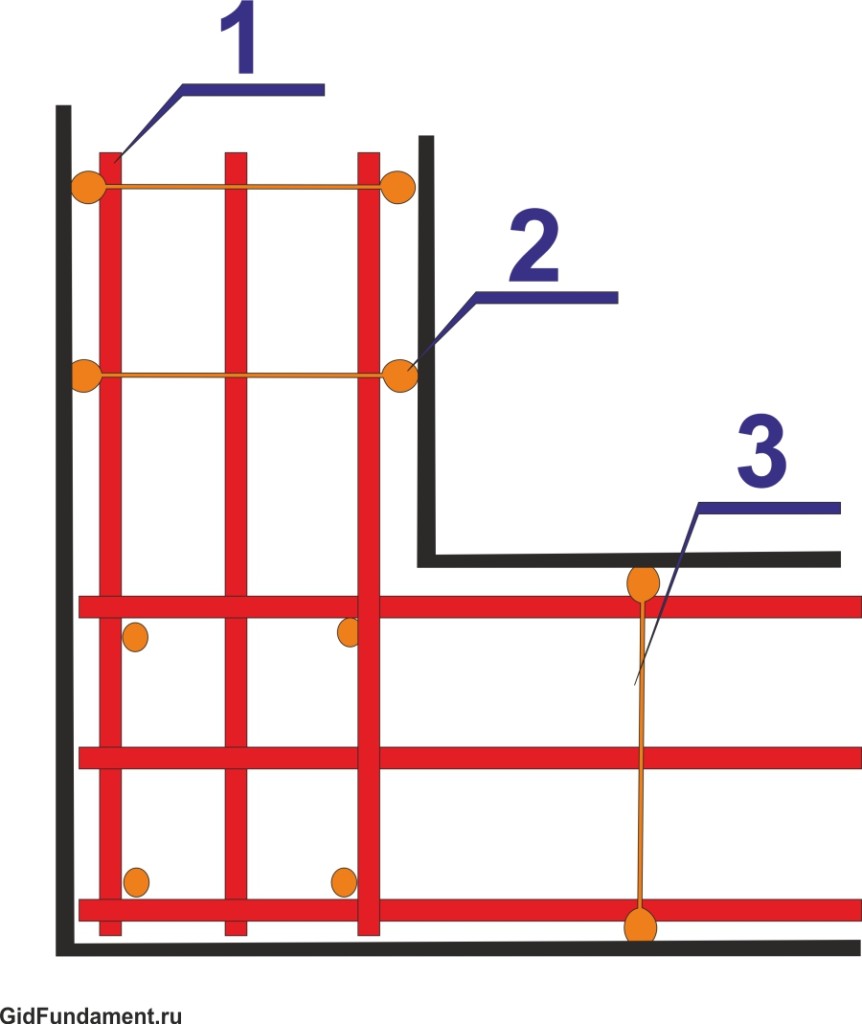

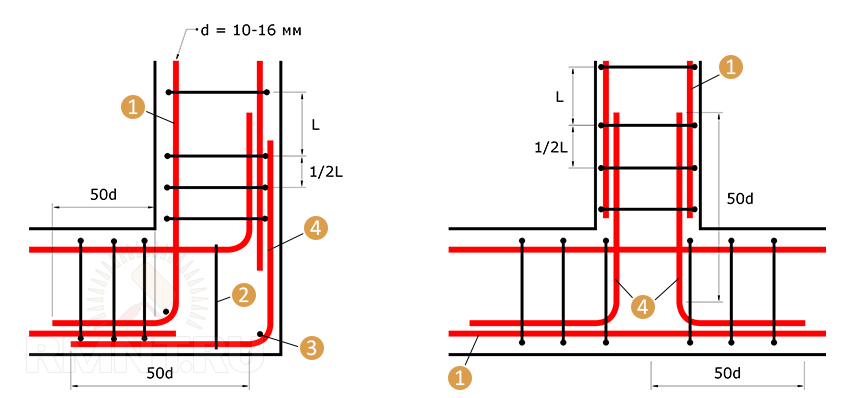

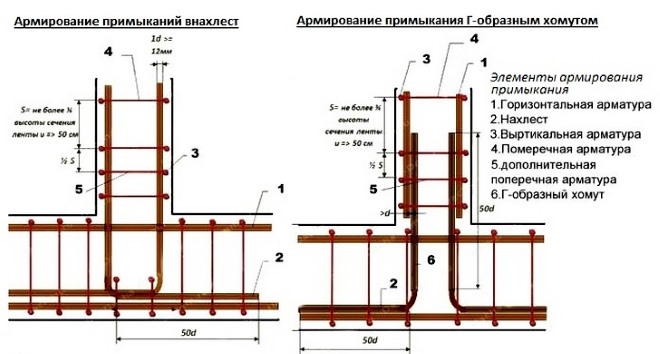

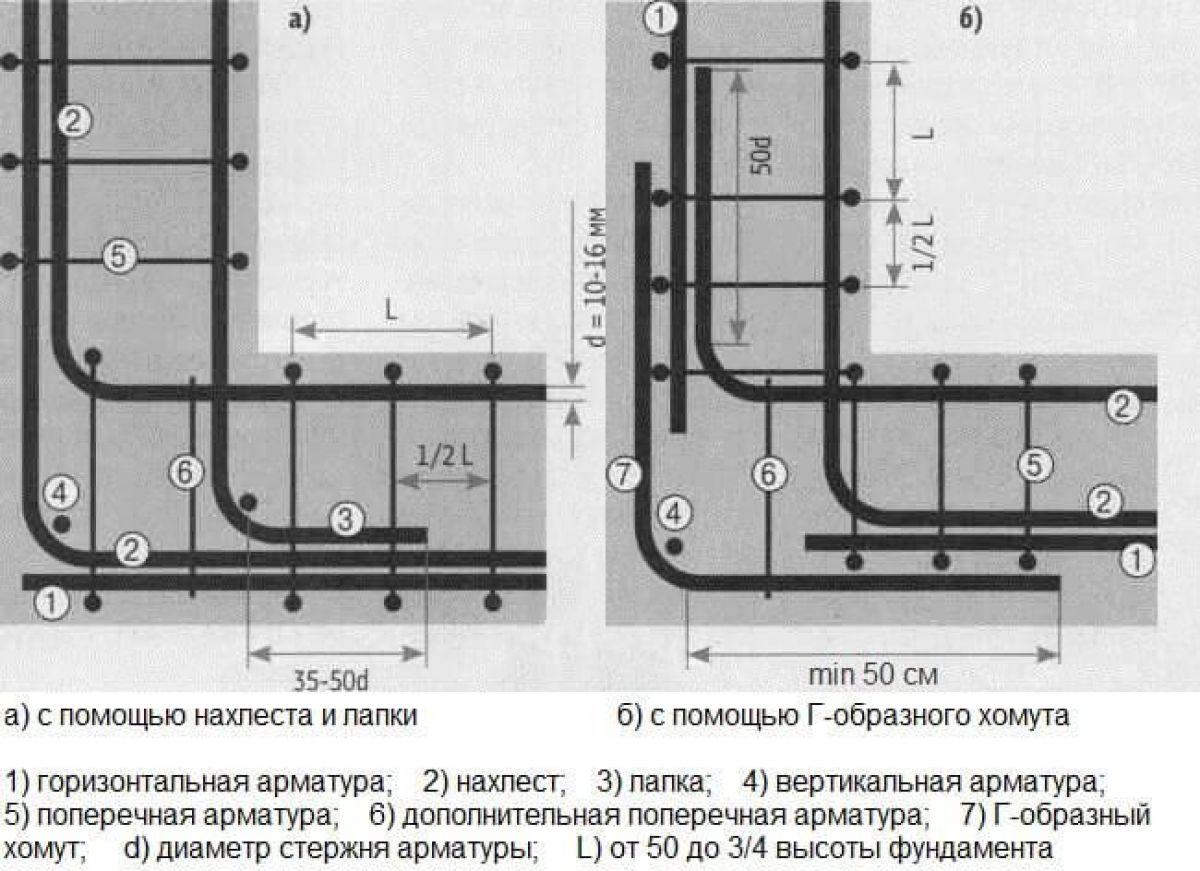

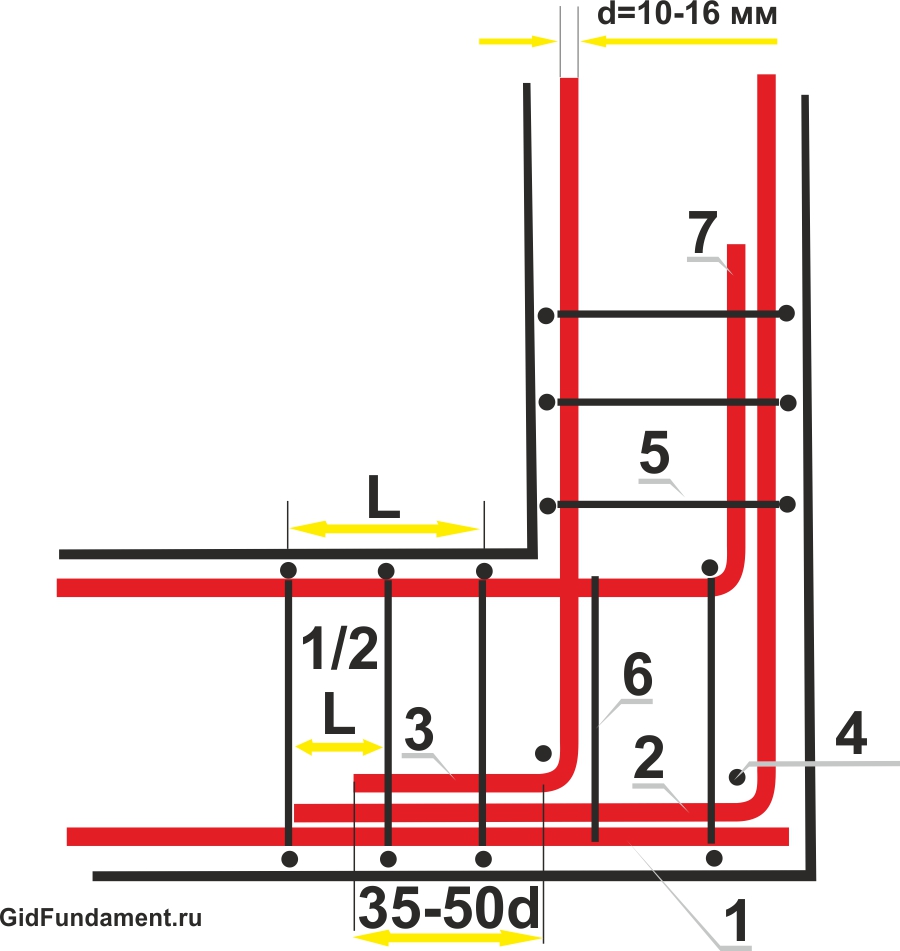

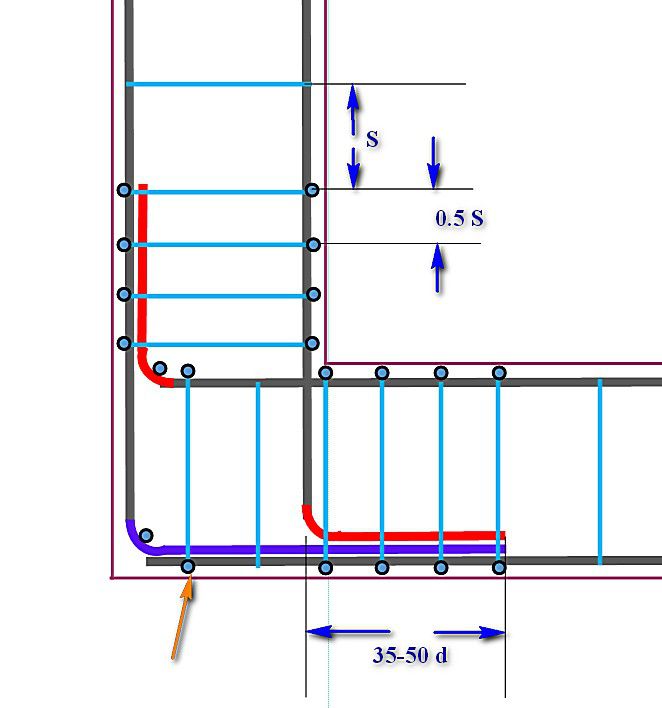

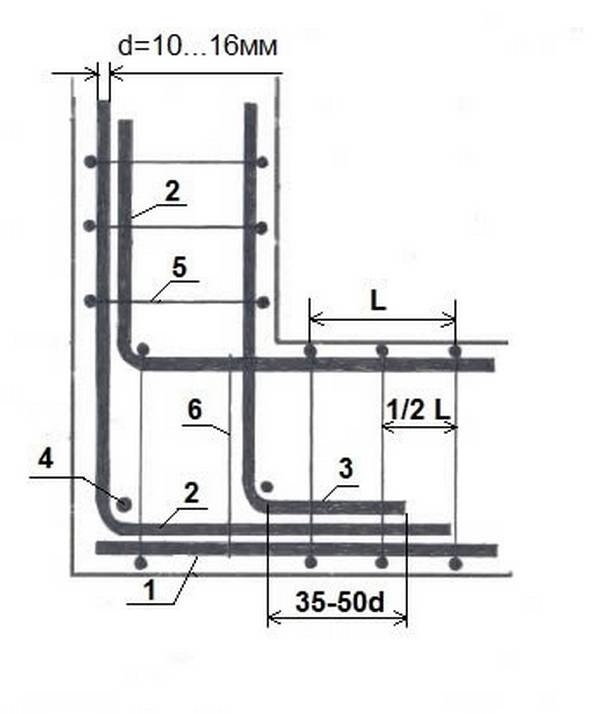

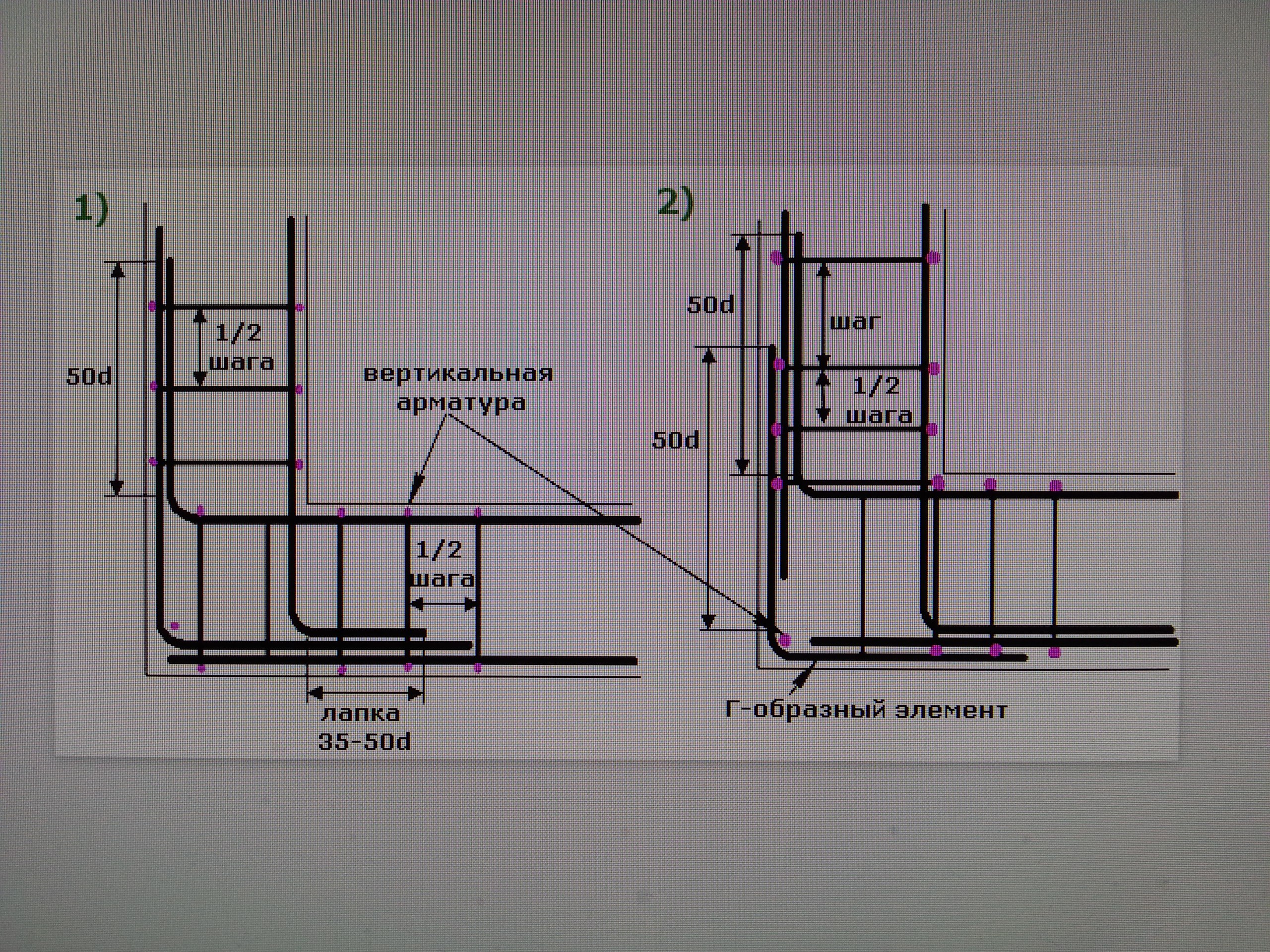

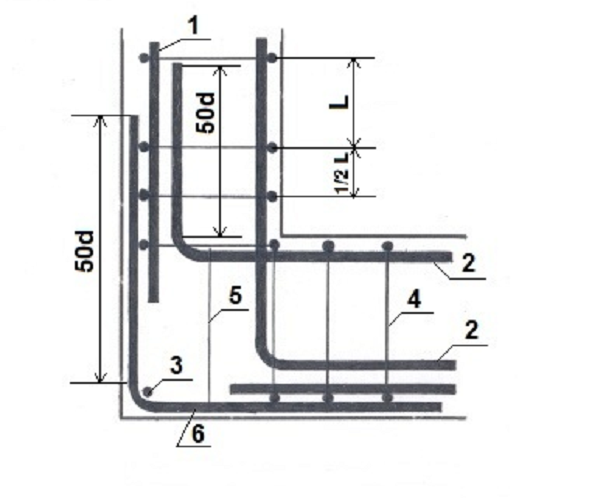

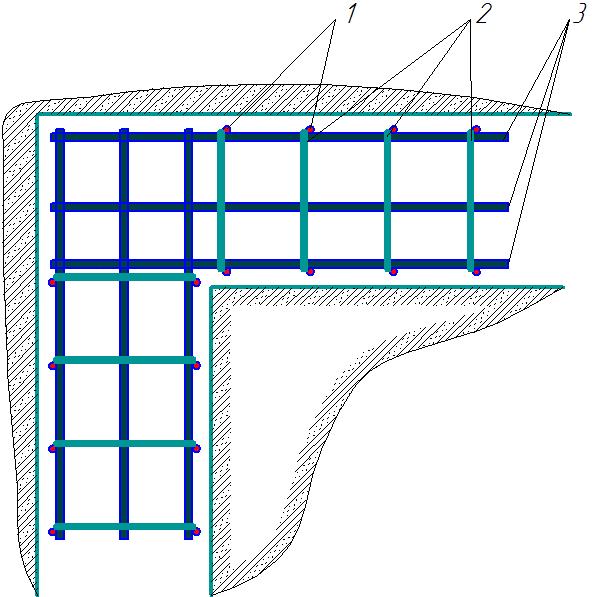

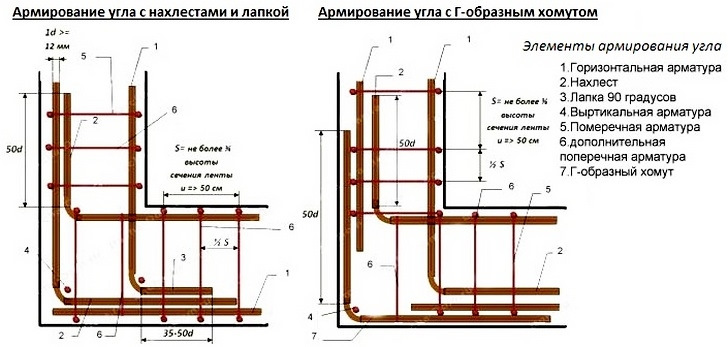

The same requirements apply when reinforcing corners and abutments with L-shaped and U-shaped additional reinforcing elements.

Tying the metal frame from the reinforcement for the strip foundation can be done not only in the formwork being equipped, but also in separate fragments (made in a place convenient for you), which are then lowered into the box.

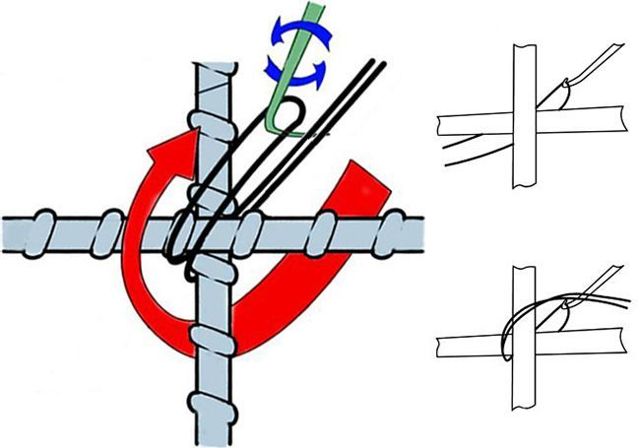

Important! It is necessary to tie the reinforcement of individual fragments together. Schematic representation of the methods of reinforcement knitting technology

Schematic representation of the methods of reinforcement knitting technology

Schematic representation of the methods of reinforcement knitting technology

To form the metal frame of the base, three strapping methods are used:

- Welding. At first glance, welding is the easiest and most effective way to connect fittings, but in practice everything looks different. During welding, the metal heats up to high temperatures and deforms, and this is a partial loss of rigidity. You also have to hire a professional welder who knows about the properties of the metal, can not burn it, and this is an additional financial cost. There is also a risk of destruction of the weld spot during the operation of the industrial vibrator. Difficulties arise if the metal is bent near the weld.

- Connection with bent wire or plastic clamps (ties). This method is popular with many developers as the connection can be done by hand in a matter of minutes. If flexible wire is used, then a special tool must be used to connect the links. Plastic clamps are more reliable than wire, but they are more expensive. The connection diagram is similar, only then you have to bend the rods at the required angle.

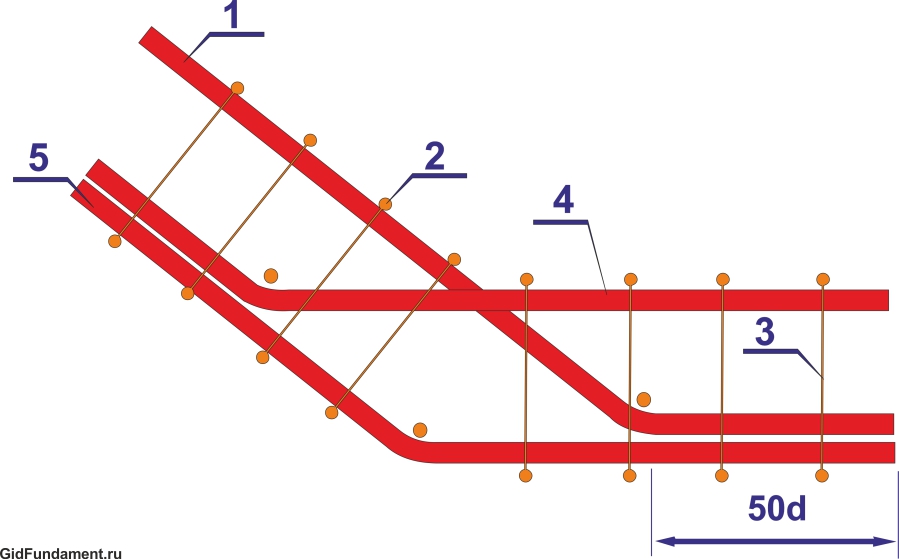

- Overlap. This method involves overlapping reinforcement with further wire fixation. It is more practiced for horizontal belts made of mesh, and a vertical smooth rod is used inside the joint.

Any of the above methods can be implemented by hand. In this case, it is necessary to bend the metal, which is quite problematic to do, given the stiffness of the reinforcement and its minimum diameter for horizontal belts from 12 mm.

Sketch of the technology for the correct creation of the connection of reinforcing rods and crocheting

Sketch of the technology for the correct creation of the connection of reinforcing rods and crocheting

It is quite possible to knit reinforcement using available tools. But it is worth noting that the correct binding of the rods to each other does not guarantee compliance with all building codes and high-quality installation. Since the knitting pattern of the frame depends on the type of foundation, its dimensions, thickness and the type of material used. Therefore, you need to consider a few key rules:

- If a mesh is used as a reinforcing cage, then the strapping must be overlapped.

- Taking into account the type and section of the reinforcement, it is necessary to calculate the length of the bypass at the joints.

- You need to bend the rods strictly at a certain angle and evenly.

- The grade of concrete and working conditions at the junction are taken into account. The minimum overlap is at least 25 cm.

If the reinforcement is carried out at a height of 3 meters or more, then one cannot do without scaffolding or a scaffold. The strapping technology turns out to be more complex, due to the existing safety rules for high-altitude work. The strapping is carried out in three stages:

- First, prepare the reinforcement, tie the slings to it.

- Raise to the required height, align and place in the plastic guides.

- Tie the rods using any of the listed technologies.

The cost of strapping is relatively low, since the craftsmen can process several square meters of the frame in an hour. And even faster when using special knitting tools. And they guarantee the quality of the knitting of the rods and compliance with all building codes, especially since the bending of the rods will be with special tongs.

Video instruction

Scheme

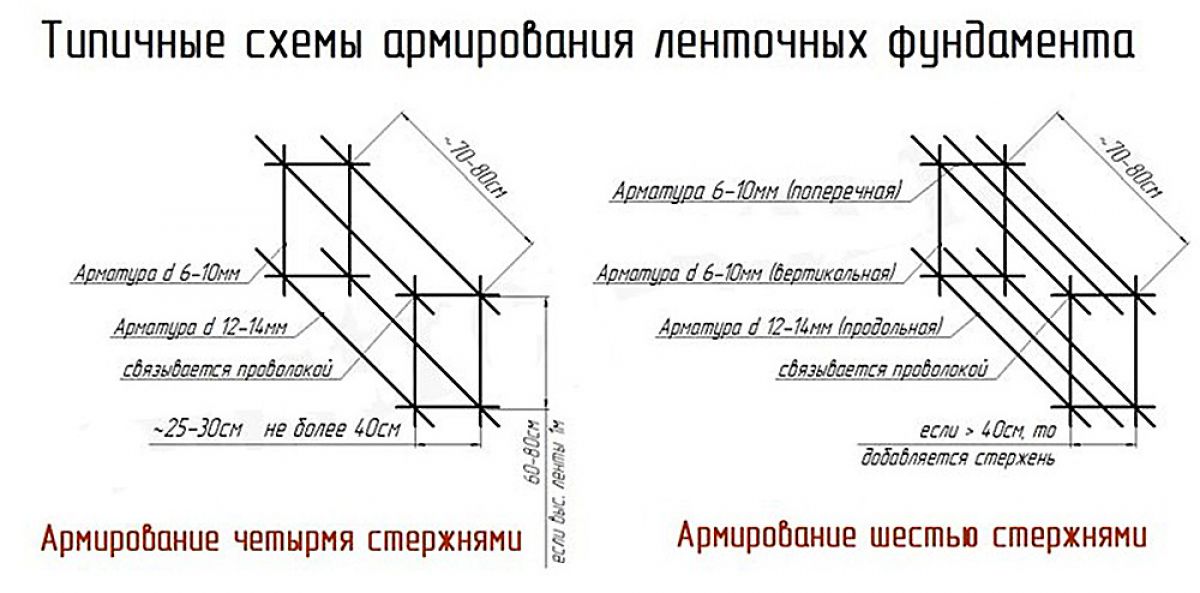

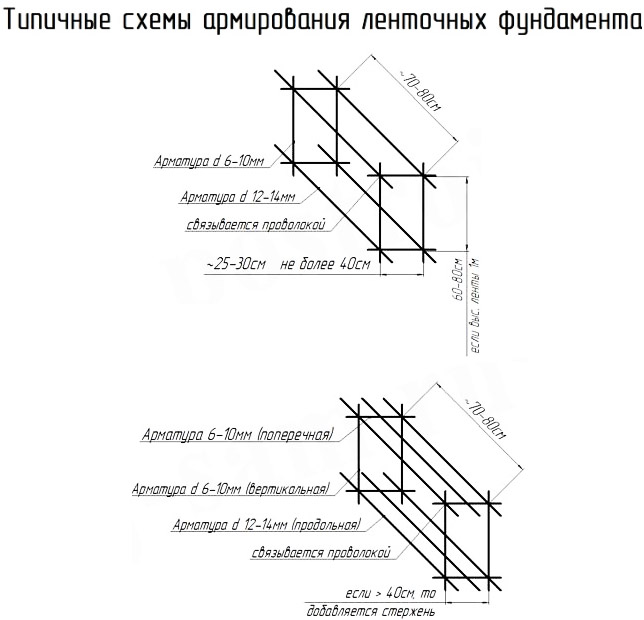

The constant movement of the soil puts the most serious pressure on the strip foundation. In order for it to firmly withstand such loads, as well as to eliminate sources of cracking at the planning stage, experts recommend taking care of the correctly selected reinforcement scheme. The foundation reinforcement scheme is a specific arrangement of axial and perpendicular bars, which are assembled into a single structure.

SNiP No. 52-01-2003 clearly examines how the reinforcement materials are laid in the foundation, with what step in different directions.

It is worth considering the following rules from this document:

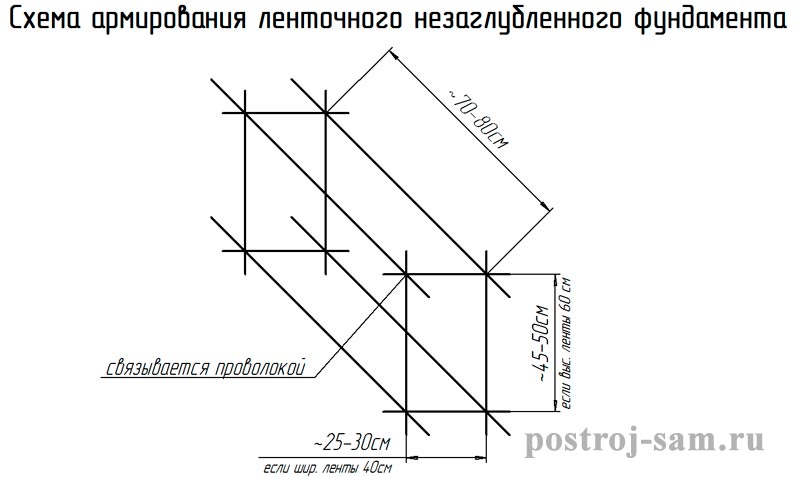

- the step of laying the rods depends on the diameter of the reinforcing product, the dimensions of the gravel granules, the method of laying the concrete solution and its compaction;

- the step of working hardening is a distance that is equal to two heights of the cross-section of the hardening tape, but not more than 40 cm;

- transverse hardening - this distance between the rods is half the width of the section itself (no more than 30 cm).

Tying reinforcement strip foundation - DIY foundation

The foundation is the main part of any home. Its operational life largely depends on what the foundation will be, which means the comfortable living of its residents. You can build a solid and reliable house only by knowing how to knit reinforcement when building the foundation of a building.

Step-by-step instruction

The beginning of the correct reinforcement of the strip foundation

Hot-rolled steel of periodic profile of A3 classes and high-strength wire Вр are used to perform the work. The choice of diameters depends on the expected (design) load on the base. Installation work is carried out directly at the construction site.

After the purchase and delivery of the material to the construction site, the following must be done with it:

- expand by diameter;

- clean from dirt;

- align the rods (if required);

- cut workpieces of a given size.

Laying the finished reinforcement cage

Before proceeding with the installation of blocks from reinforcement, it is necessary to install the formwork. Next, two belts are installed: the lower one (above the ground) and the upper one. Each layer is poured with concrete.

The process of performing work itself consists of the following stages:

- drive the retainers (pieces of rods) into the ground at the bottom of the foundation to form a protective layer of concrete;

- sequentially, lay all the blocks of the frames;

- connect all joints of the knots with a knitting wire;

- reconcile the installed elements.

Steel frame knitting

The best option is a strip foundation, reinforced in a rectangle or square. This is due to the ability to easily identify and install the axle. Knitting is a laborious process, but it is considered effective.

The work is done by hand using a special hook or pliers.

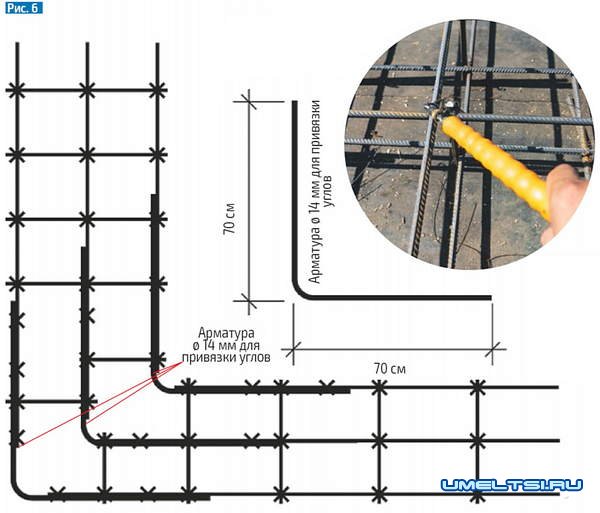

For greater stability, the reinforcing frame is connected with a cell, while the corners are placed at an angle of 90 degrees.

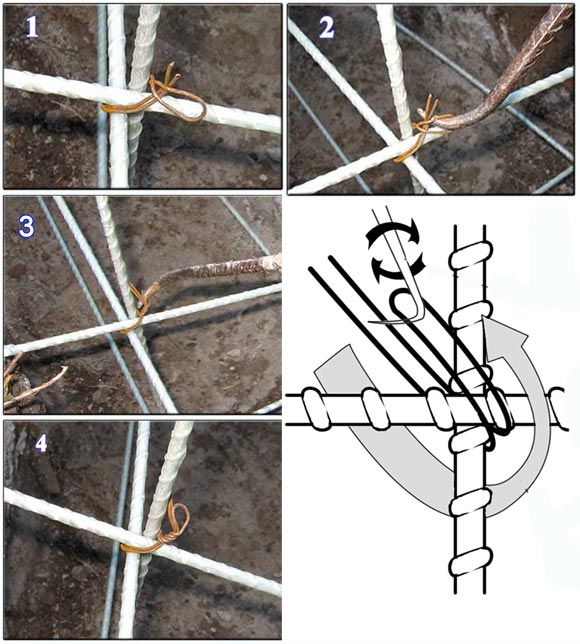

A piece of wire, up to 30-50 cm long, is cut, folded in the center and applied to the junction. Then, a hook is threaded into the formed loop, the ends of the rods are inserted into it, which are subsequently turned out all the way, forming a strong bond.

There is another way of knitting - with the help of mechanical tools: a screwdriver (special attachment) and an electric hook. In this case, the technological process is significantly accelerated.

It is more difficult to carry out reinforcement work at the ends of the foundation. Here it is advisable to use bent rods that reliably connect the adjacent ones. The workpieces are fastened to the block by means of bundles (clamp), and reinforcements (P or L-shaped) are mounted at the joints.

Useful tips and tricks on how to knit reinforcement in a strip foundation

Particular attention should be paid to the reinforcement of the corners of the building, i.e. in these areas, the base carries the load in several directions.

To avoid moisture ingress, the rods should not come into close contact with the formwork and the ground.

For the manufacture of products, high quality metal is used, without rust and not used.

It is not recommended to "grow" a ready-made frame

Any addition must be calculated.

Practical skills are required for tying reinforcement.

In the process of work, you can alternate different ways of connecting the nodes of the frame.

Knit reinforcement only if there are overlaps.

Methods and methods of knitting reinforcement for the foundation

When creating a strip base for a private house, reinforcement for the foundation plays a very important role, it excludes the possibility of its deformation during seasonal ground movements and ensures integrity.

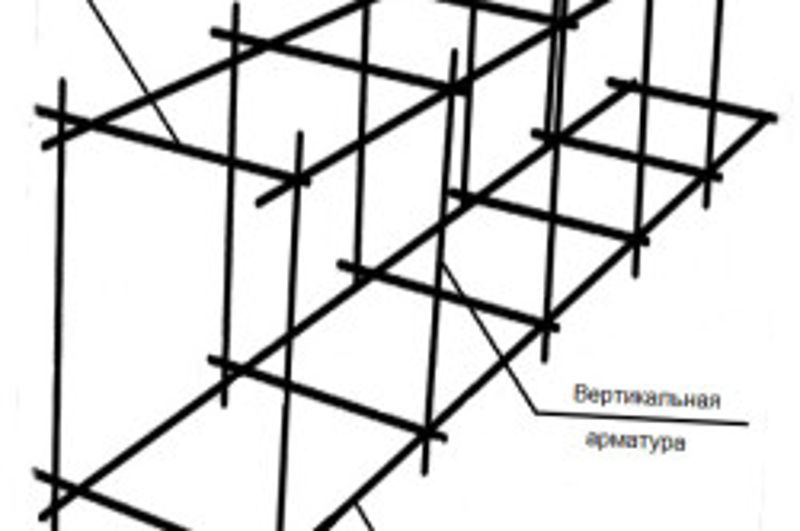

Each metal frame in a strip foundation consists of two or more horizontal tiers, which are fastened together with transverse rods (crossbars). All elements of the frame are connected to each other using electric welding or wire for tying reinforcement.

Reinforcement calculation

Before purchasing the required amount of reinforcement for the frame, it is necessary to carry out some mathematical calculations that will help determine the amount of material.

It is also important to consider some features, such as:

- Corrugated reinforcement (metal rods with ribs) withstands a greater load on horizontal structures than smooth ones and provides a better quality of adhesion to concrete;

- When calculating, it must be borne in mind that the frame should not rest against the formwork, but is located at a distance of 5-10 cm from it. This will protect the metal from exposure to air and moisture. For example, if the width of the concrete foundation tape is 60 cm, then the frame width will be 45-50 cm;

- Smooth bars can be used as crossbars to support longitudinal tiers.

If it is planned to build a one-story house, then the distance between the transverse and longitudinal bars is approximately 50-55 cm.But if the building has two floors or a massive attic, then this distance is reduced to 20-30 cm, which significantly increases the material consumption.

Rebar bundle options

In order to connect all the elements of the metal structure with each other, a mounting wire with a diameter of 0.8 or 1.2 mm is used, which is pre-cut into small pieces of 20-25 cm. The installation of reinforcement for the foundation can be done in several ways, depending on the tool used:

- crochet hook for reinforcement, this knitting method is described below;

- special clamps. In this version, special plastic or metal disposable clamps are used. This is how fiberglass reinforcement for the foundation is usually knitted.

Before knitting the reinforcement for the foundation, you must provide yourself with protective gloves and use only serviceable tools.

Step-by-step hand-twisting process

The fastest and most common method in private construction is to knit reinforcement under a strip foundation using a special crochet hook for reinforcement.

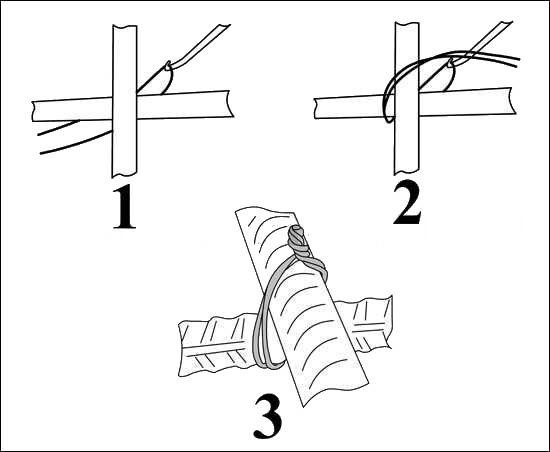

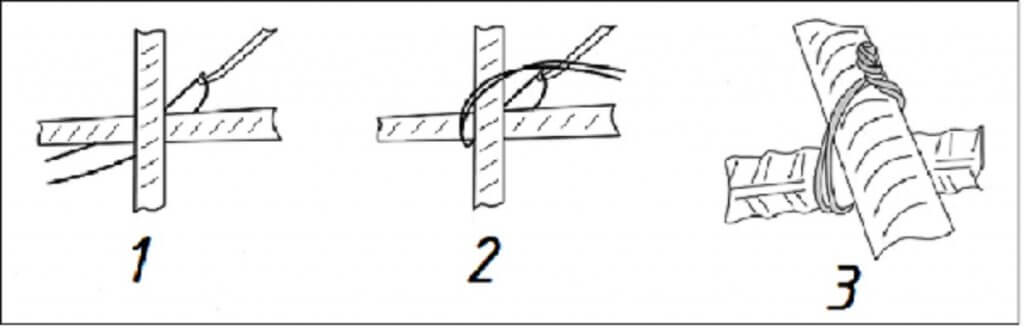

In order to do everything correctly and quickly, you must strictly follow the procedure below:

- the wire for tying reinforcement is cut 20-25 cm long and folds in half;

- we start the wire under the junction of the rods and insert the hook for knitting the reinforcement into the loop;

- with the second end of the wire we tie the reinforcement connection and put it on the hook;

- then we rotate the crochet hook for the reinforcement clockwise, holding the other end of the wire so that the ends are intertwined;

- remove the hook from the loop and bend the ends of the wire into the frame.

Using this simple procedure, tying strip foundation reinforcement with a knitting gun is much faster and more efficient.

P.S. And for dessert I suggest watching a video clip: We knit reinforcement cages with a screwdriver

How are the fittings connected?

Before getting interested in how to correctly knit reinforcement, it does not hurt to consider all the ways to connect the elements of the reinforcing frame. There are now three methods. It:

- welding;

- wire knitting;

- use of plastic clamps.

Each option has not only disadvantages, but also advantages, so they are used depending on specific conditions.

Welded connection

This method has been known for a long time. More often it was used (and is used) in the construction of super-strong foundations for multi-storey buildings. However, welding has several weaknesses.

- In order to bring the work to a high quality, you need experience in handling a welding machine. Since not every master who has conceived the idea of building a house with his own hands is familiar with such work, to perform the operation you will have to hire a professional welder, and this promises additional costs that you want to avoid during large-scale construction.

- Unreliability of the reinforcing frame. During welding, the metal heats up to temperatures that provoke a violation of the structure of the steel in the heating zone. In addition, the welded joint does not respond in the best way to bends, therefore material deformation is possible even at the compaction stage, when using vibrators. The result is a partial loss of stiffness by the framework.

It is not recommended to bend metal near the welding site. Complete destruction of connections during vibrator operation is another potential and serious problem, therefore this method is not recommended, despite the speed and relative simplicity of the solution.

Wire knitting

The biggest plus of this method is its simplicity, since there is no need for additional equipment, and no special skills are required from the builder either. In case of an error, it is very easy to fix it. The entire reinforcement process is easy to carry out in the formwork. The cost of the work is minimal, but the master still needs to know how to properly knit the reinforcement on his own.

The disadvantage of wire knitting is the relative instability of the created structure.

If the reinforcing frame is made outside the formwork, then during its subsequent installation, maximum care is required.

Using plastic clamps

The main advantages of the method are the highest speed of work, reliable fixation of the reinforcement, simplicity that does not require skills. Such plastic ties also have drawbacks. These include:

- the large amount that will be spent on the purchase of this material, if you compare these costs with the purchase of a practical, inexpensive knitting wire;

- possible marriage: if the clamp was incorrectly fixed, then it will have to be bitten off, and this promises unnecessary expenses, since the element will become unusable;

- negative impact on elements at low temperatures: such plastic clamps, especially inexpensive ones, can burst in frost.

If you make a choice, then either method of the last two options can be considered as the main contender. However, wire tying outperforms plastic competitors, since in this case the work will cost less. In addition, not all professional builders approve of plastic products. They say that good screeds are expensive, and cheap products simply do not stand up to criticism: they tear quickly.

Materials and tools for knitting reinforcement

Considering that the reinforcing belt gives stability to the entire structure, perceiving a significant share of the load, a lot depends on its high-quality performance.

How do you correctly knit reinforcement for a strip foundation? It is generally accepted that steel rods are needed to create a frame base. Builders prefer to use the following types of steel graded by:

- materials of manufacture. Iron rods are considered a classic option, repeatedly tested in practice. They are divided into six groups according to the level of strength, the material is bent and welded. Composite rods contain basalt, carbon, glass and aramid fibers. This type of material is lighter in weight, affordable, does not rust, does not bend or is welded;

- profiles. Smooth profile is more often used instead of jumpers for connections. Rod fat, which has a periodic profile, differs in relief, with the help of which the adhesion to the solution is improved.

For proper knitting, special tools are required. If you follow the rules of knitting, then you can achieve a more reliable connection than welding. The strength index in the connecting nodes will not decrease, the help of an experienced welder is not required, all work is carried out directly in the formwork structure or in the immediate vicinity.

Let's figure out how you can tie the reinforcement for the foundation. When carrying out such work, you can use:

- knitting gun. The fastest method. It is inconvenient to work with the device in hard-to-reach areas, and it consumes large quantities of wire intended for knitting. The main disadvantage of the tool is its high cost. If you use Chinese-made fixtures, then one pistol is enough for 1 base;

- crochet for knitting. It resembles a curved and sharpened nail with a handle instead of a head. On the Internet you can find materials on how to knit a reinforcement with a screwdriver, using such a hook as a nozzle. Industrial screw hooks work efficiently, but the process is slowed down, leaving long tails;

- folk remedies. With small working volumes and the absence of special tools, it is allowed to use pliers or a homemade hook prepared from a suitable nail. The quality of work will not be the best, such a scheme for tying reinforcement for a strip foundation will not give the proper strength.

Structural rods are distinguished by purpose:

- working rods. Longitudinal reinforcement elements located along the strip base;

- clamps. There are transverse, vertical and horizontal, I connect the frame structure into one whole.

To know how to properly knit reinforcement for building a base for a private house, you need to know a certain work pattern:

- use composite or greasy rods with a diameter of 11 - 14 or 12 - 18 mm, a profile of the periodic type;

- the rods are laid out with an overlap, connected by horizontal elements.For a shallow base, two layers of 2 - 4 rods are enough; in other structures, three layers are arranged. The gaps between the rods should not exceed thirty to forty centimeters;

- vertical elements support the upper and lower layers, place them in increments of forty to ninety centimeters. The load on them is small, material with a diameter of 6 - 11 mm is suitable for manufacturing;

corrosion protection is performed. The frame must be completely filled with concrete; at least six to eight centimeters must separate it from the upper edge of the formwork. When arranging the foundation for a private house, a hook is used to knit reinforcement.

We already know how to knit reinforcement correctly. And how much will it take to build the foundation? The volume of material is determined based on:

- dimensions of the foundation;

- a diagram defining how to tie steel bars. It includes the number of layers and longitudinally spaced rods along the entire width.