Choosing the type of foundation

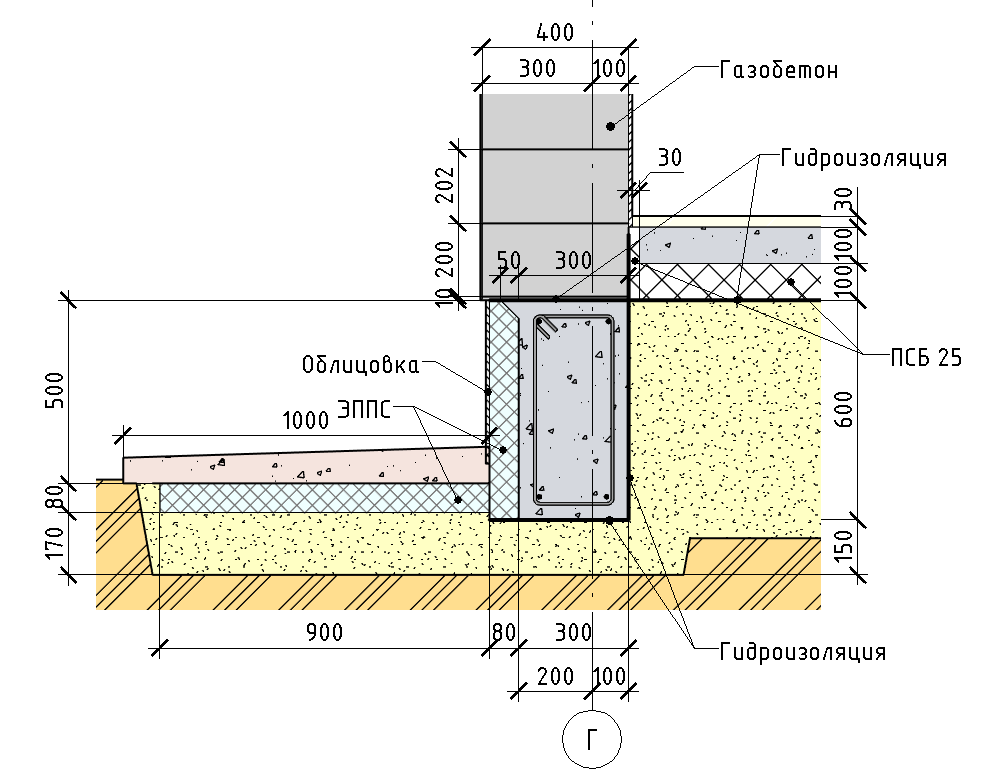

Since the construction of foam blocks is almost fifty percent lighter than a stone one-story house with walls of the same thickness, the bearing capacity of the foundations, and hence the amount of work and the estimated cost of the supporting structure, will be much lower. The minimum thickness of the foam block wall without cladding is 300 mm, and if the house is not supposed to be faced with brick, the width of the foundation can be taken in accordance with the size of the transverse dimension of the foam blocks.

Home construction

Home construction

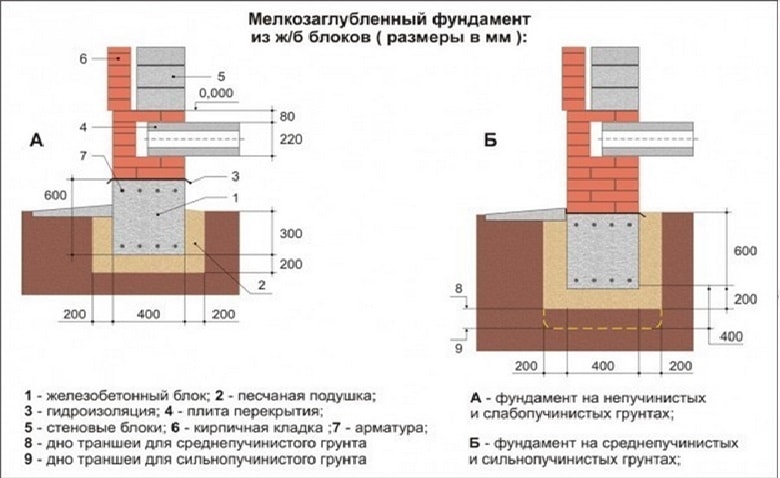

Depending on the type of soil, an appropriate foundation should be selected. For slightly heaving and non-subsiding soils, it is rational to use strip foundations, since it is enough to lay the foundation of the foundation slab below the freezing mark. Watered, weak soils require deeper laying of supports, and pile foundations successfully cope with this task within a reasonable budget.

When erecting pile foundations, it is necessary to take into account the features of the installation of the strapping structure. Pile foundations can be arranged under the walls of foam blocks, both with a low and a high grillage. For the installation of a grillage on the heads of metal piles, reinforced concrete and steel rolling profiles should be used, since it is not recommended to support walls made of foam blocks on wooden straps, as well as an unreinforced metal profile.

How to make a strip-pile foundation

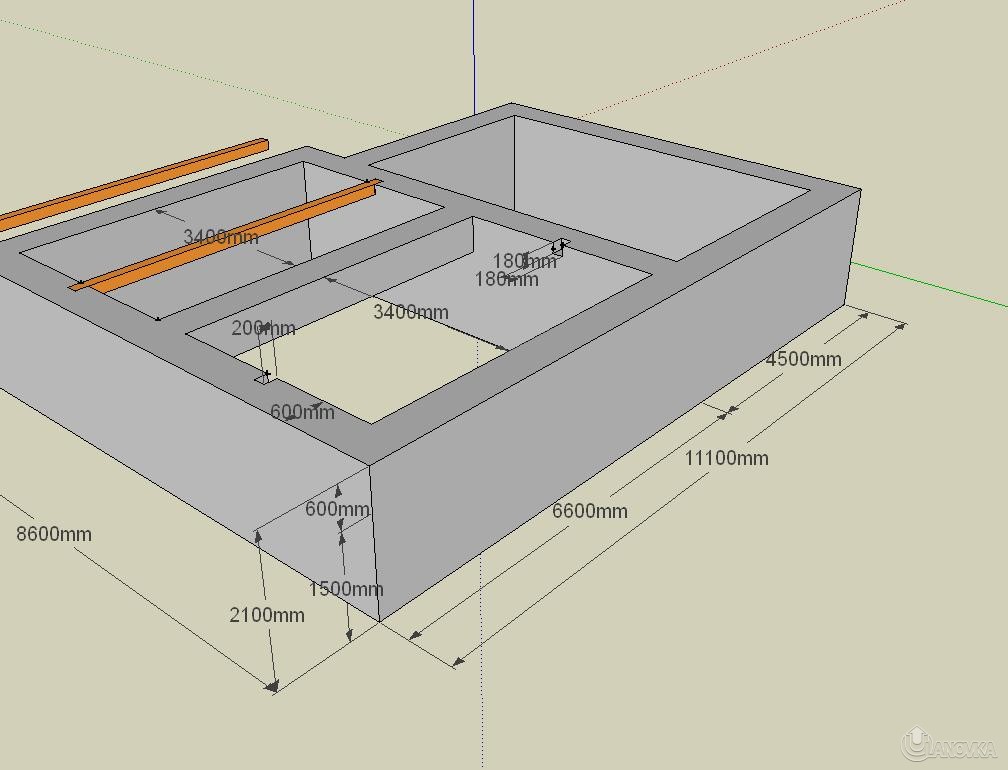

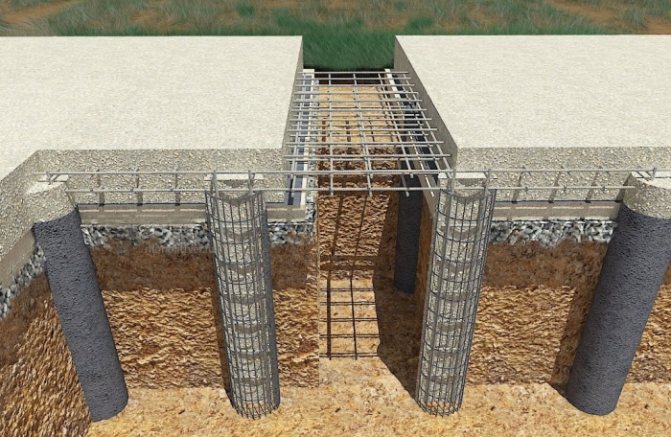

A pile foundation for a house can be erected on screw, bored, driven piles. In private construction, the first two types are more often used, since special equipment is needed to drive concrete piles into the ground. Supports are placed in the corners of the foundation, under the intersection of the load-bearing walls, and between these points at a calculated distance, which depends on the material and size of the house.

First of all, you need to prepare the site: clean it of plants, remove the fertile layer, level it. Next, markup is done. To do this, first the base axes are transferred to the terrain, the width of the tape is noted, the places where the wells will be drilled.

The next stage is earthworks. A trench is dug equal in width to the tape if the soil is dense, and wider if the soil is loose. The depth of the trench is equal to the thickness of the pad plus the depth of the foundation. Then wells are drilled.

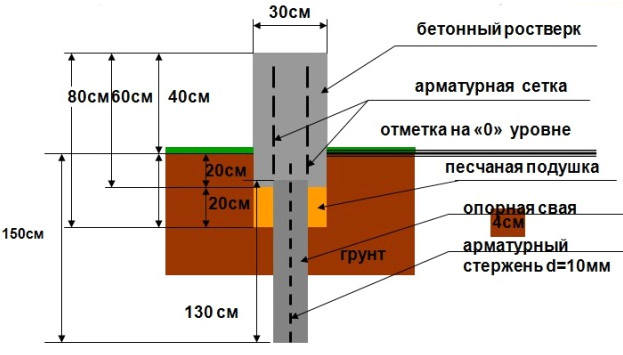

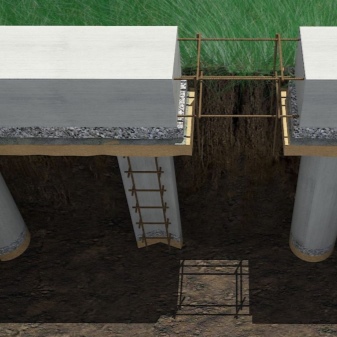

Bored piles are made by drilling holes in the ground and pouring concrete into them. For this, formwork is used from asbestos-cement or PVC pipes, or rolled into a tube of roofing material or polyethylene. The formwork not only gives the support its shape, but also makes its surface smooth, which helps to resist heaving due to the fact that the soil slides along the pile during shear. Fittings are lowered into the pipes. Most often, piles are made with a diameter of 20-25 cm, but not less than 1/3 of the width of the tape, they are placed in increments of 2 m. The depth of the well should be at least 0.5 m below the level of soil freezing, of which 20 cm is a sand cushion, 30 cm - the pile itself.

Before placing the formwork in the well, sand or gravel cushions with a thickness of 20-30 cm are poured, tamping them. Next, pipes are inserted into the wells.

The reinforcement of the piles is done so that it is possible to tie their frame to the frame of the tape. To do this, for each support you need 3-4 bars of reinforcement and small cuts as jumpers. They are tied together with knitting wire. The frame is made so that the reinforcement protrudes from the well by 15-20 cm.

If bored supports are made for a foam concrete house, then the entire foundation is poured under the foam block in one step, starting with the piles. Concrete is poured into the pipes, tamping it every 20 cm to avoid voids.It is advisable to use a vibrator for this; in its absence, you can do with an ordinary stick. After pouring the first 30 cm of concrete, the pipes are lifted so that the concrete flows out and provides a good connection of the pile to the ground.

For concreting the tape, formwork is constructed. It is made from planks, plywood, and other materials. Boards are knocked down into shields, connected together with self-tapping screws. Additionally, they are reinforced from the outside with props and connected with wooden planks or clamps.

The reinforcing frame for the tape is made of four longitudinal ribbed bars arranged in two rows. Between them, vertical and horizontal jumpers are made from thinner reinforcement, it can be smooth, tying with a knitting wire.

Also, the frame of the tape is connected to the frame of the piles. The reinforcement is installed in such a way that it is at a distance of 5 cm from the edges of the tape. Next, concrete is poured, be sure to compact it with a vibrator or manually with a metal rod. After that, the surface of the concrete is leveled, covered with polyethylene from the rain. In hot weather, concrete is periodically watered.

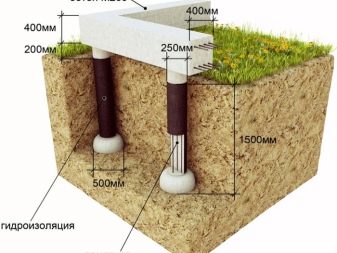

Screw piles are a metal tube with a blade at the bottom. The piles are screwed into the ground, and then a cement-sand mortar is poured inside. For the construction of foam block houses and buildings from other porous concrete, piles with a diameter of 108 mm are used. The distance between piles for a foam block house should be no more than 2 m.

Pile installation technology

After marking the construction site, the pile elements are placed in the corners, under the load-bearing walls with a step of 1.5-2 meters

After marking the construction site, the pile elements are placed in the corners, under the load-bearing walls with a step of 1.5-2 meters. A correctly installed screw-pile foundation can withstand a load of up to 25 tons per element. But the installation is not difficult at the same time, and we will do it with our own hands:

- The head of the finished element is equipped with a metal penny, firmly welded to the rod. The penny has holes for fastening equipment, where the gate is fixed;

- The rotation of the gate deepens the pile into the ground, and in the process of screwing in, the soil is compacted;

- The foundation requires the installation of a metal frame structure, which is attached to the pile heads by welding. This is a lattice base made either from rods or from channel cuttings.

Before starting the strapping, it is worth checking the level of the piles above the ground - an indicator of 15 cm is considered the norm. If the terrain has slopes, the pile heights will be different. In places where it is supposed to install load-bearing wall panels, a profile is placed, the width of the shelf of which is identical to the width of the block element.

Construction and concreting of bored piles

The arrangement of the basement also requires attention. Piles are constantly exposed to an aggressive environment, therefore all elements must be protected

It is especially important to prevent deformation of the structure during the cold season, otherwise damage to the frame will increase the risk of destruction of the structure.

Facing the piles does not take much time: the house is closed around the perimeter with shield sheets, then it is insulated with any available material and waterproofed with a film

The entire structure can be closed with siding, but it is important to leave small expansion joints between the fence and the bottom of the house, they will protect the structure from temperature deformations

Pile

The principle of operation of a pile foundation is similar to the operation of a columnar foundation. Individual piles are driven into the soil to pierce the weak layers and transfer the load to the solid soil. For a fairly heavy two-story house, the best base option is concrete or reinforced concrete piles. But they must be hammered with special equipment to a sufficiently large depth, equal to 4-6 m.

In individual construction, screw piles are most often used, which do not require additional costs for special equipment. The depth of their laying should be at least 20 cm lower than the amount of soil freezing.The downside is that the screw piles will not be able to carry the load from a building with reinforced concrete floors.

How to do it?

The foam block is a durable, lightweight and reliable material for construction, which is made from aerated concrete. Therefore, houses built from a foam block are characterized by a small static load, and for them you can choose lightweight foundation options. The foundation for the building can be laid with your own hands

In order for the work to be done correctly, it is important to follow all the installation steps step by step and adhere to a certain sequence. The laying of the foundation differs depending on its type

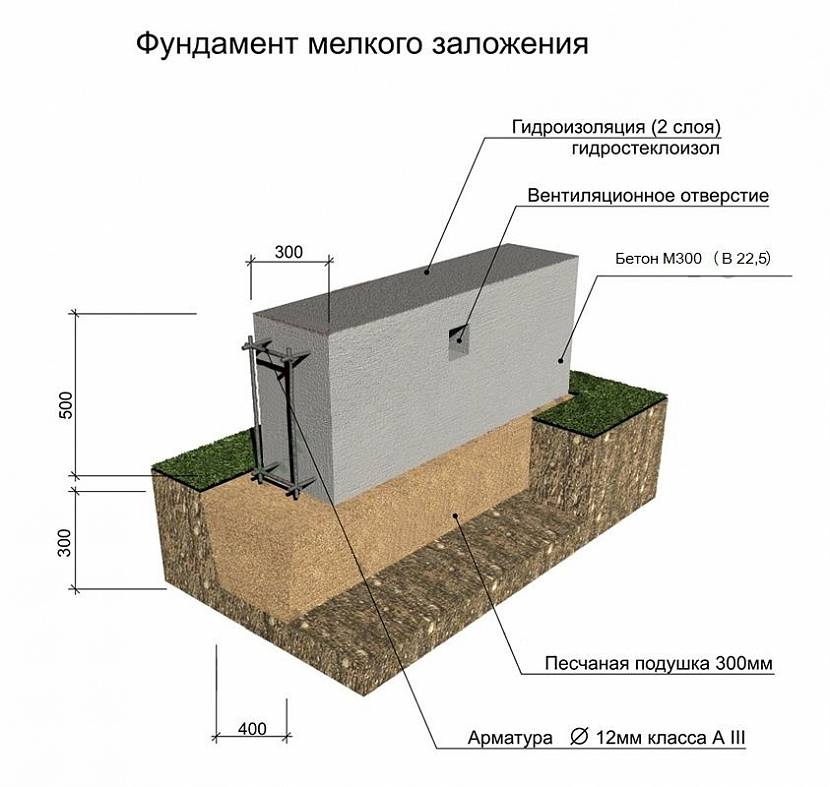

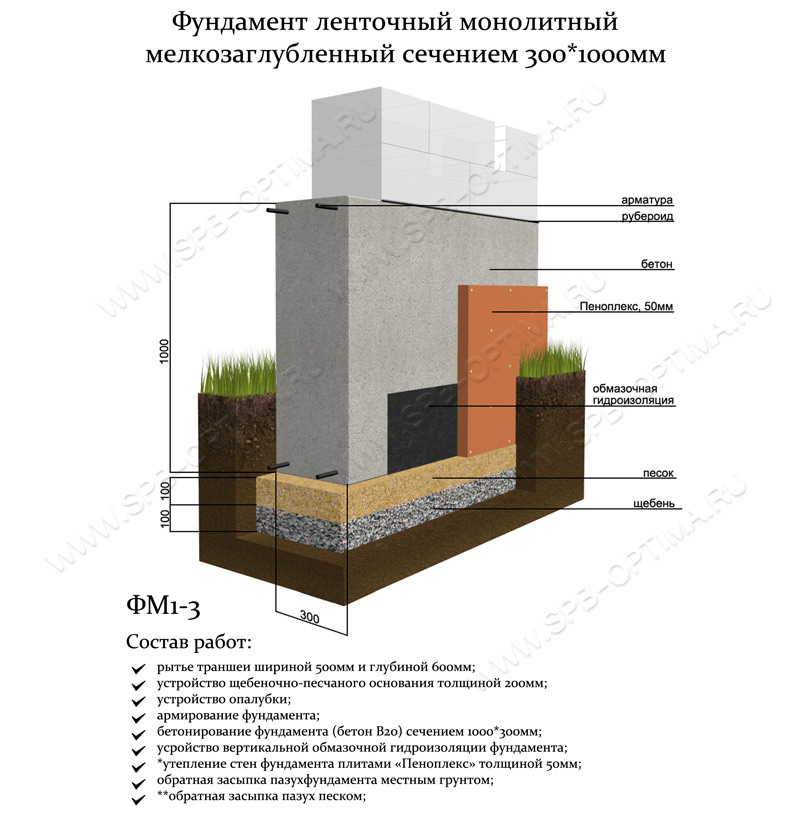

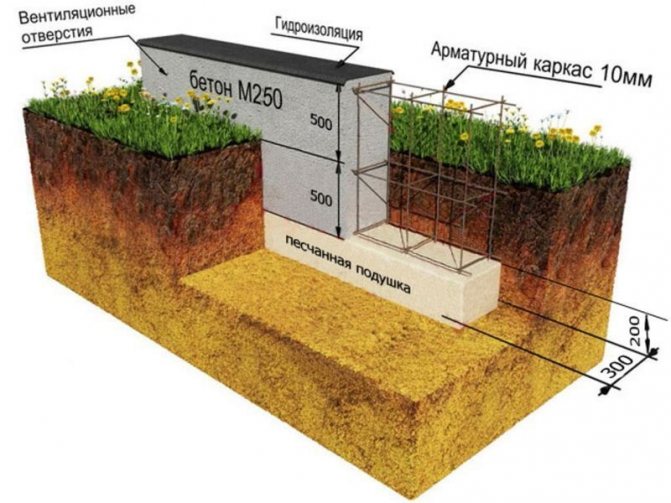

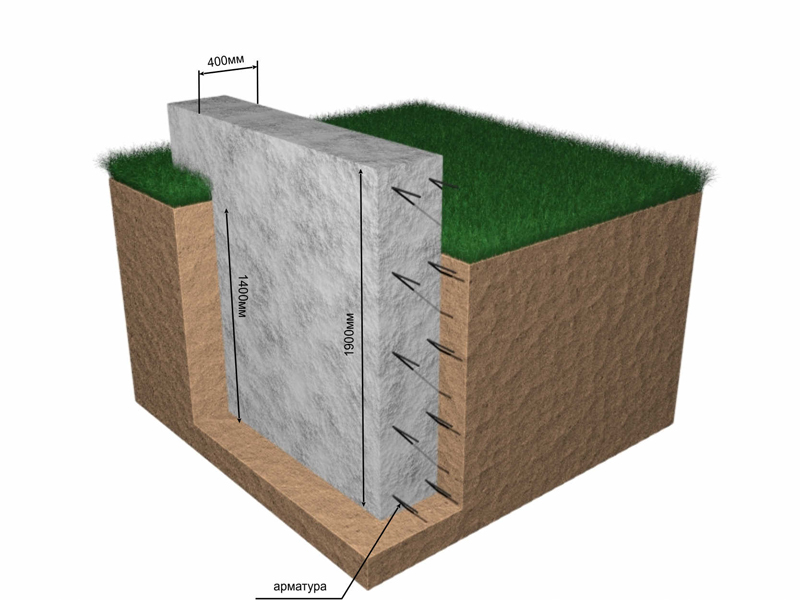

Strip foundation

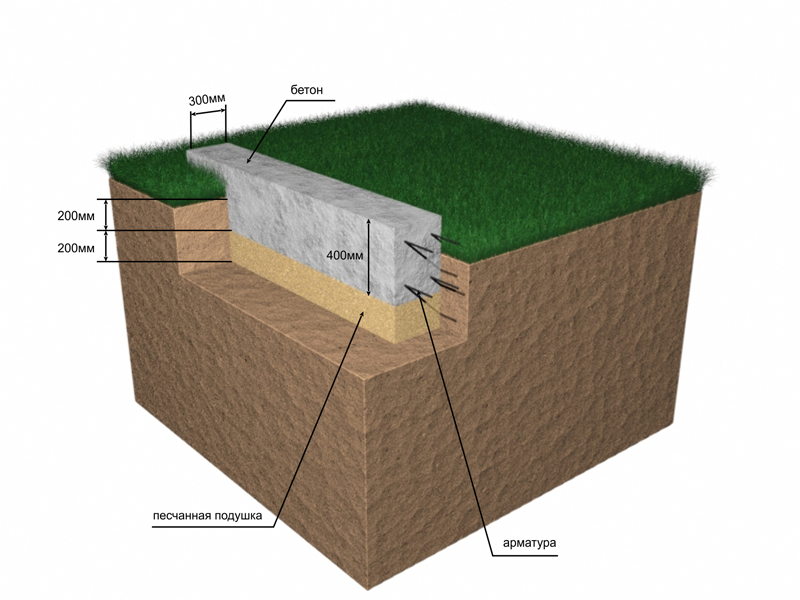

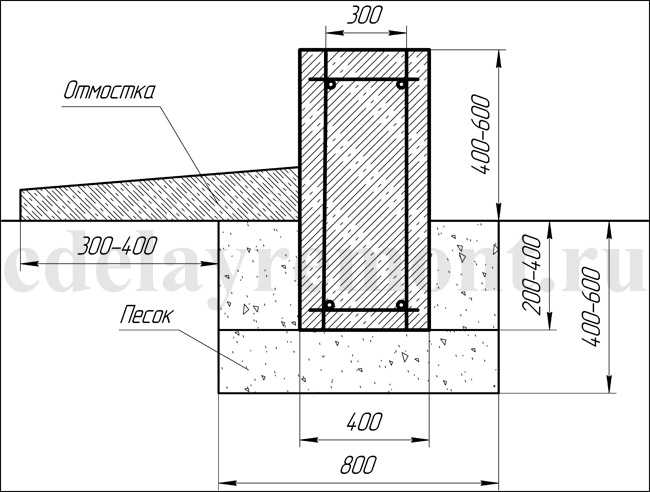

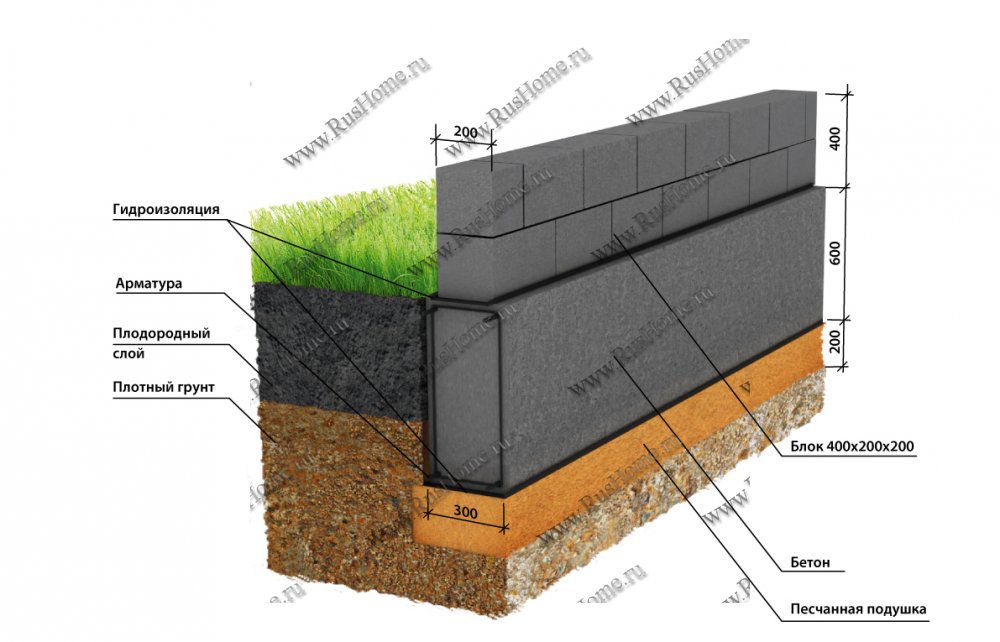

First, you need to dig a trench no more than 50 cm deep. The soil should be dug both under the future load-bearing walls and around the entire perimeter of the house. The base is made according to preliminary calculations, and it should be 10 cm wider than the walls.

A sand cushion is placed at the bottom of the trench and filled with additional rubble. The thickness of each layer is approximately 10 mm. After the pillow is carefully rammed, the formwork is prepared and the reinforcement cage is installed. For the frame, it is best to use rods with a diameter of 10 mm. Then the trench should be poured with concrete, the solution is evenly distributed over the entire working area. In the event that construction is carried out in the summer, then the concrete dries quickly. To prevent cracking, the surface should be periodically watered and covered with a film.

As a rule, the construction of a house can be started 10 days after the foundation has completely dried, the base within this period of time becomes strong and ready to withstand the loads of the structure. If the groundwater level is high, then the foundation should be protected from flooding. On the inside of the formwork, waterproofing in the form of hydroglass or roofing material is attached and the formwork is given additional time to solidify.

Column foundation

This type of foundation is chosen when the foam block house is built on soft soil, consisting of loam, peat and clay. Such a foundation reliably protects the structure from freezing and heaving of soils. The pillars for the base are chosen from reinforced concrete, they must be placed in places where large loads, load-bearing walls and facade corners are located. The pillars are buried 1 m deep at a distance of 1.5-2 m.

For houses with 3 floors, the columnar foundation is additionally reinforced with special reinforced concrete grillages. The formwork in this case is distinguished by a bottom, which is supported by supports installed in the ground. After the formwork is ready, the reinforcement cage is attached to it using knitting wire and mounting loops.

Floating foundation

Such a foundation is suitable for all types of soil, the only exception is clay. The base consists of monolithic slabs that can move with the ground, protecting the walls of the structure from destruction and cracks.

To make such a foundation, first, under the entire area of the structure, dig a pit with a depth of at least 60 cm, then lay a pillow consisting of a layer of sand (25 cm) and rubble (15 cm). After that, be sure to arrange a reinforcing frame and waterproofing. For the frame, rods with a diameter of 8 cm are used and a step of 25 cm is observed between them.

As for the foundation for houses, in the project of which a basement is provided, it requires special implementation technologies. The main feature of such a foundation will be depth, therefore, for the foundation, they dig a deep pit and create a space around the perimeter of the foundation, which will press on the walls from the outside with the thickness of the soil.

The evenness of the trench must be checked with a laser level, after which you can fill in gravel, sand and lay waterproofing. Formwork is installed along the walls of the trench; it can be made of any building material: polymer, metal or asbestos pipes.

A metal belt made of rods with a diameter of 16 mm is mounted inside the formwork for reinforcement. As a result, a structure resembling a cage is obtained, its walls should not touch the upper surface and the bottom of the future fill. The frame rods must be overlapped, and bend in the corner sections of the foundation without mixing. It is best to fix the frame with electric welding or knitting wire. The final stage of the work will be the filling of the solution, it must be carried out in layers. After each filling of the layer, the surface is leveled.

In addition, screw piles are often used as supports for the foundation, which are screwed into the soil below the freezing level of the soil. The installation of piles must be carried out accurately, therefore, the correctness of their fixation is checked with a laser level. After the piles are twisted, concrete is poured into the inside of the pipes, and the upper part is closed with heads.

General installation diagram

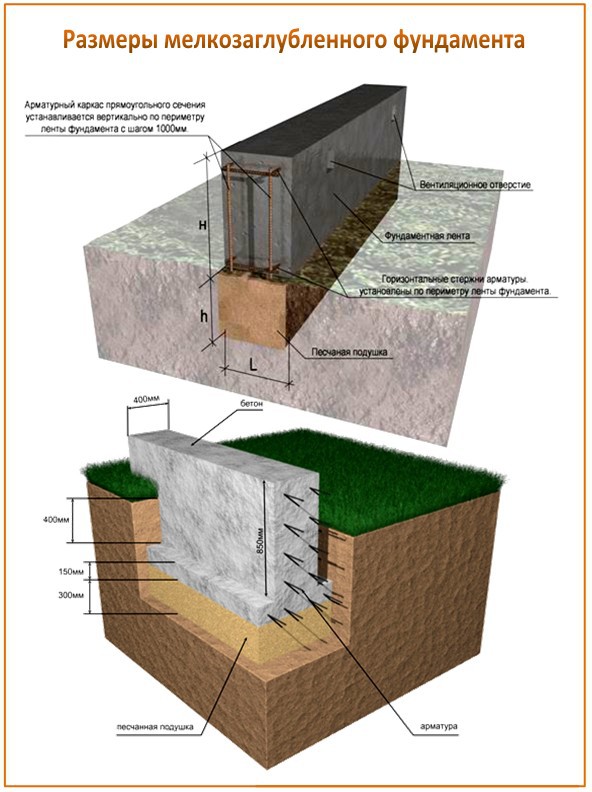

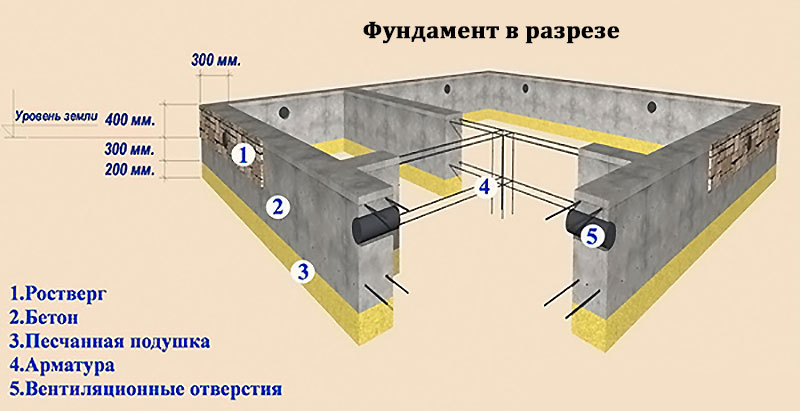

Procedure for the construction of a shallow strip base:

- Removal of the topsoil, leveling and marking of the site.

- Digging trenches to a specific depth and width.

- Creation of a sand cushion.

- Formwork assembly and installation.

- Arm-belt knitting.

- Pouring concrete, holding to the desired degree of hardening.

- Completion of work.

All steps, without exception, must be performed in the correct sequence.

IMPORTANT!

The depth of the trench should be increased by the thickness of the sand backfill layer, about 20 cm.

Foundation pillow

A layer of sand backfill is required to level the bottom of the trench and create a drainage effect

Sifted river sand is used (ideally), without clay admixtures (this is important!). Backfilling is done to a thickness of 20 cm

The pillow is checked for horizontal and carefully tamped. The possibility of slippage of the tape depends on the quality of the compaction. therefore it is necessary to achieve maximum density. The quality is checked by going over the pillow - if there are no traces left, then the rammer is of high quality.

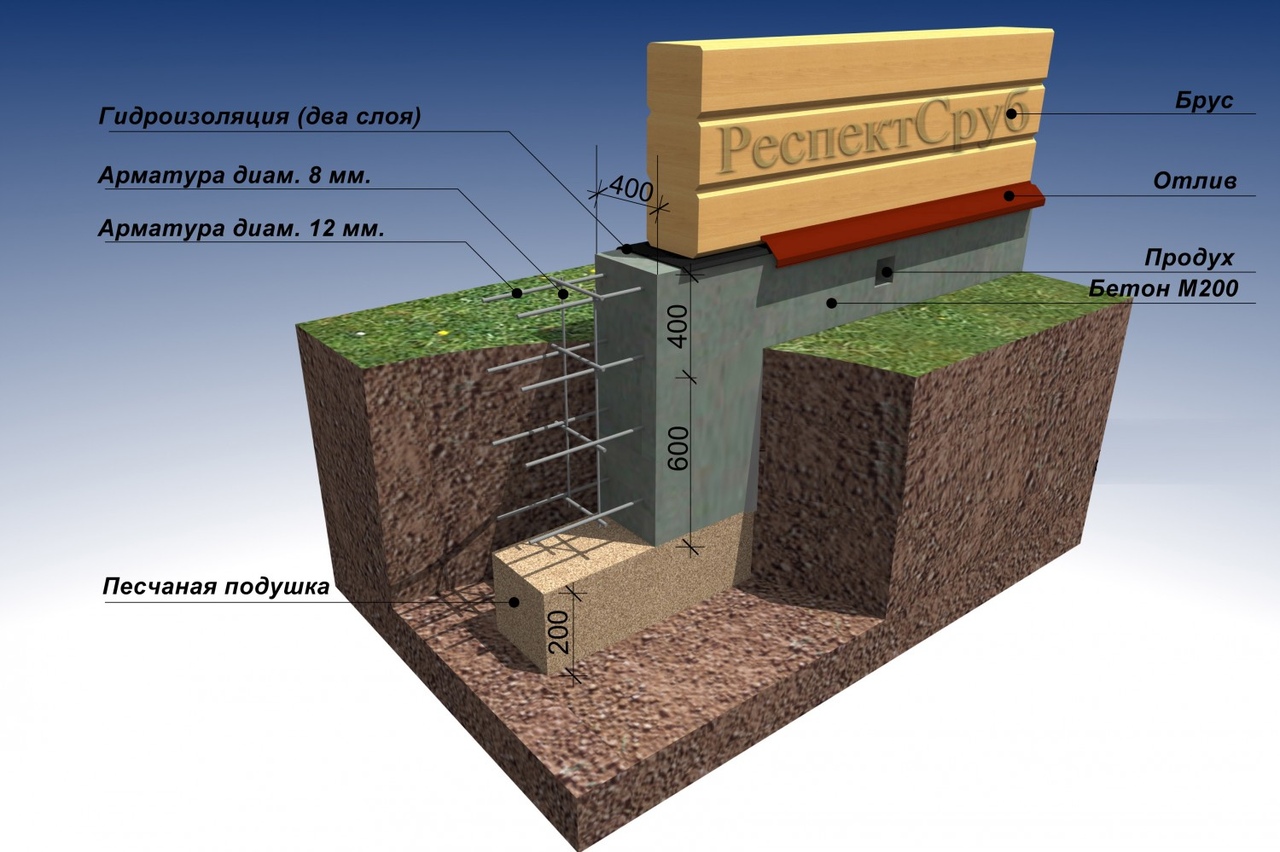

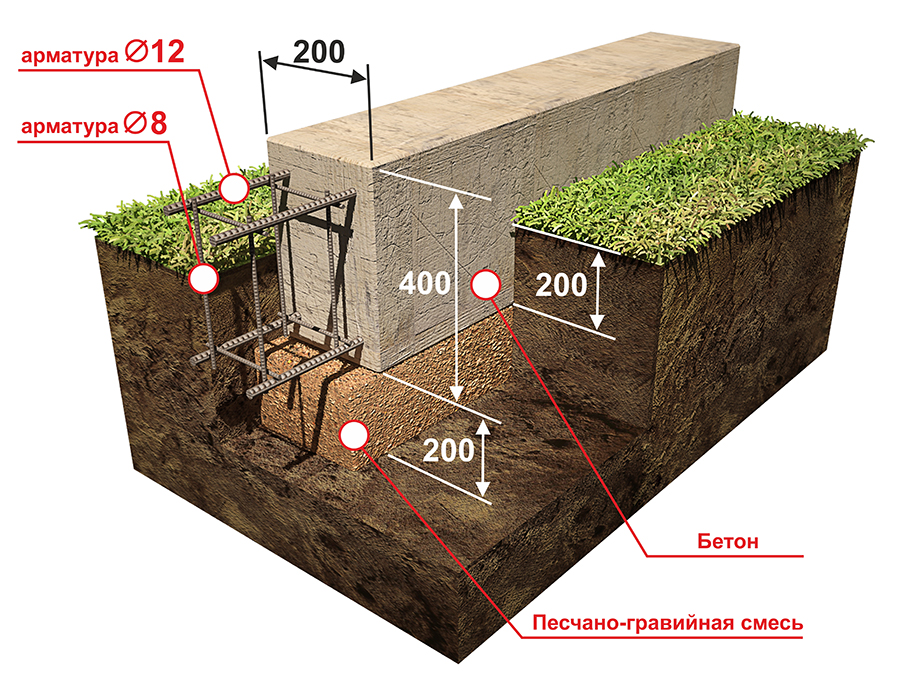

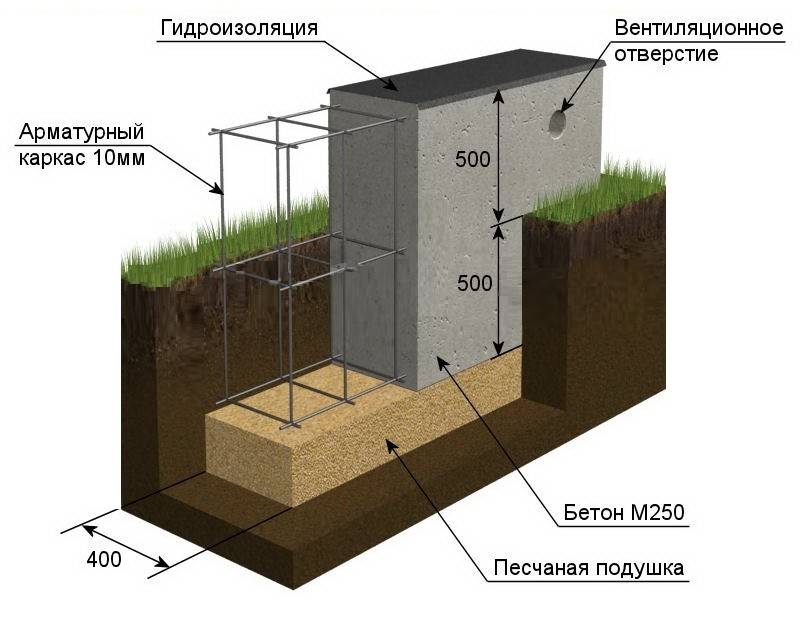

Concrete and reinforcement grade

For pouring the strip foundation, M200 concrete is mainly used. This material is strong enough to support even heavier structures, but the use of lower density concrete is not recommended.

The quality of the material is different, and a certain margin of safety in this case will not hurt.

The thickness of the working reinforcement rods for the strip for foam concrete is 12 mm, and for vertical (smooth) reinforcement, you can use 8 mm rods. This is quite enough, given the relatively small size of the tape.

When using composite (fiberglass) reinforcement, the same dimensions should be adhered to, since a decrease in the diameter of the rods can lead to deformations when pouring concrete.

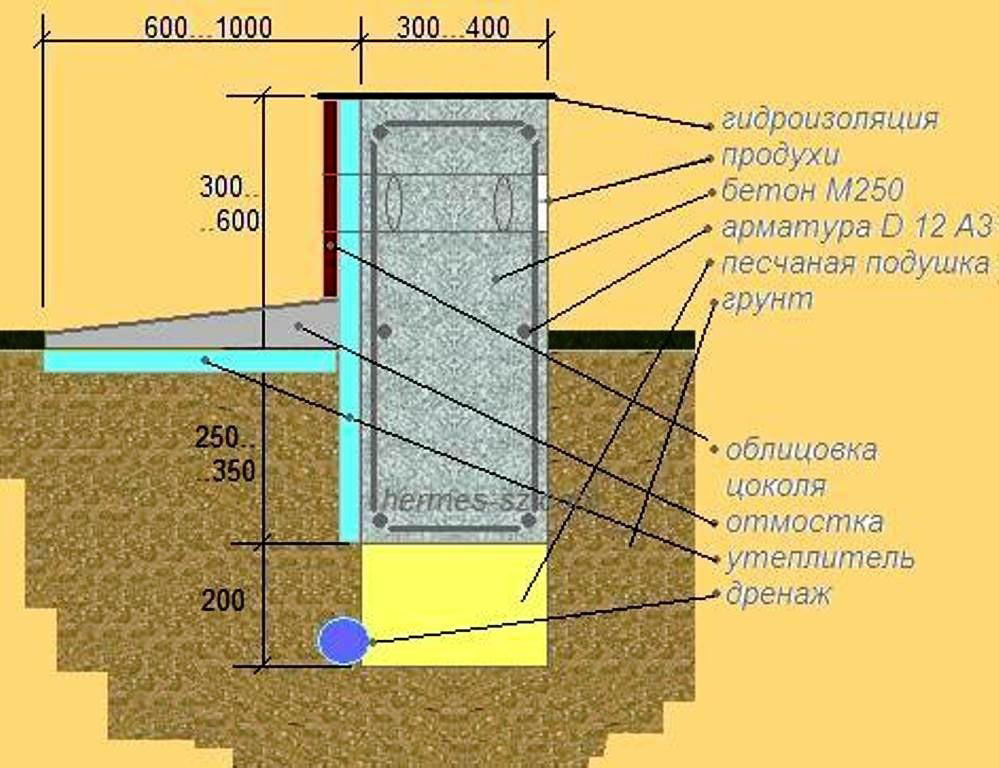

Formwork installation

To create the formwork, you need to stock up on wooden edged boards.

The dimensions of the tape are small, so 25 mm thick lumber is suitable, but if the parameters of the foundation are large enough, you can use boards with a thickness of 30 or 40 mm.

The formwork is assembled in stages:

- Next to the trench, boards are assembled with a width of not 10-15 cm more than the height of the tape.

- The shields are lowered into the trench, aligned along the axes and connected with crossbars. Their size determines the width of the tape.

- Outside, the shields are fixed with inclined stops and vertical support strips.

When assembling panels, it is necessary to monitor the tightness of the connection. There should be no gaps larger than 3 mm, this will cause the concrete to flow out. If gaps are found, they must be plugged with tow or hammered with wooden slats.

Reinforcement and knitting

The reinforcement cage is assembled according to the standard scheme. It is necessary to form a spatial lattice of four working rods (two at the top and two at the bottom), with a depth of immersion in concrete of 2-5 cm. Vertical elements (clamps) are installed with a step of about 40 cm.

The corners are carefully formed, on which additional rods are installed to strengthen the joints.

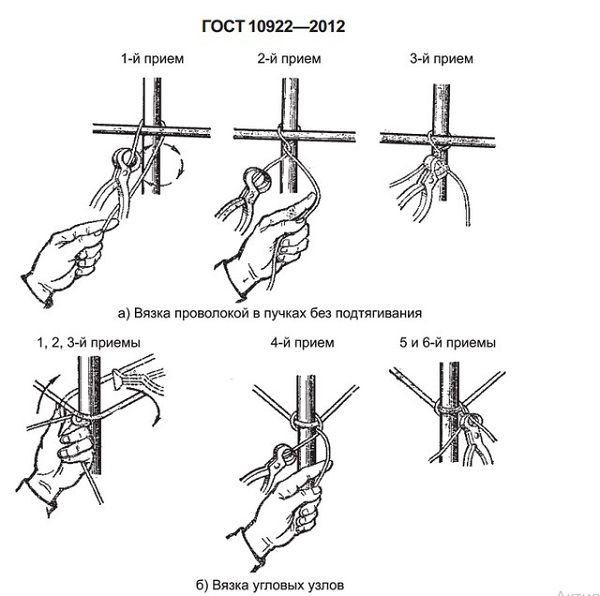

The connection of the rods can be done using electric welding, but for reinforcement of this size, tying with annealed steel wire (1-1.5 mm) is usually used. A piece of wire about 25-30 cm long is bent in half, then the connection of the rods is clasped from below in a diagonal direction.

The ends go up, grab the loop with a special hook and twist it by 4-6 turns, tightly pulling the rods to each other. The connection turns out to be strong, and the work skill is acquired very quickly.

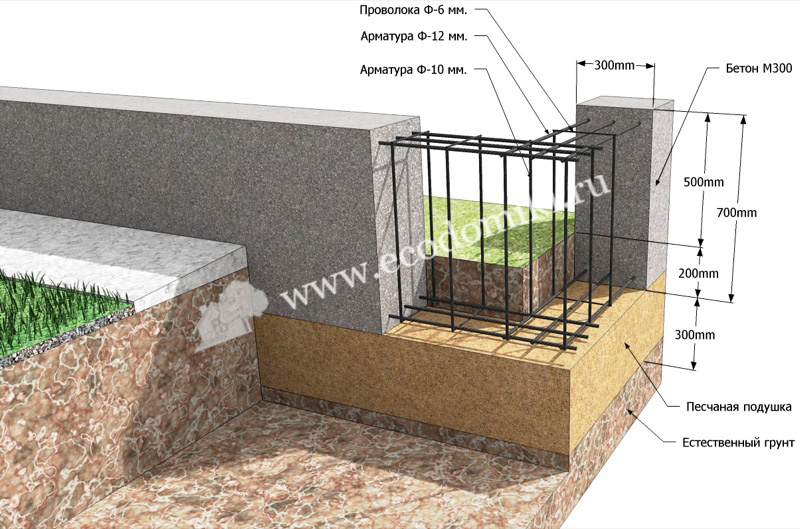

Fill

Fill must be done in one go

This is important, since the connection of concrete that has begun to set with a fresh pour cannot be strong enough; if a break occurs for more than a day, you will have to stop pouring and wait until the concrete completely hardens

At the same time, it will no longer be possible to create a full-fledged monolith, so it is necessary to organize the work in such a way as to fill it at a time.

It is recommended to order ready-mixed concrete, which will be delivered directly to the site, this will free up working hands and will help to get the material with guaranteed and uniform quality.

Pouring is done from different points so that the concrete spreads evenly over the entire length of the formwork. Vibrators or conventional forks are used to remove air bubbles.

At the end of the casting, the surface of the tape is smoothed, then the formwork is covered with polyethylene to protect it from sunlight or rain.

Peculiarities

The strip foundation is supposed to be arranged around the perimeter of the house, including under the internal load-bearing walls. Often, such a foundation is built under heavy houses made of natural stone, brick or concrete blocks. But it is also compatible with buildings with reinforced concrete floors. Another advantage of the tape is its suitability for placing basements and cellars. It is much more difficult to equip slab structures with such premises, and sometimes it is completely impossible.

Even a general description shows that the depth of the tapes is usually quite large. However, the simplicity of the technology used justifies its use in low-rise buildings and in the construction of ancillary facilities. In addition, tape bases work well even where there is a risk of uneven building shrinkage. This is usually due to the heterogeneous composition of the soil, which has different mechanical characteristics. When constructing a basement, you can use foundation structures in the form of ready-made main walls.

The service life is highly dependent on the material used. So, concrete and rubble stone can work up to two centuries in a row. But a lot depends on:

- the exerted load and its changes;

- the quality of the materials used;

- characteristics of the solution;

- soil properties and climatic parameters of the area.

For the manufacture of the foundation, in addition to concrete and rubble stone, their mixture or brickwork is sometimes used. The tape is made both in the form of a straight contour and with breaks, the geometric shape is a rectangle or a trapezoid. In any case, the width is taken no less than that of the supported wall, and ideally more by 100-150 mm. The wide variety of types of strip foundations does not mean that they can be chosen arbitrarily, there are quite strict building standards.