The specificity of the leakproof type

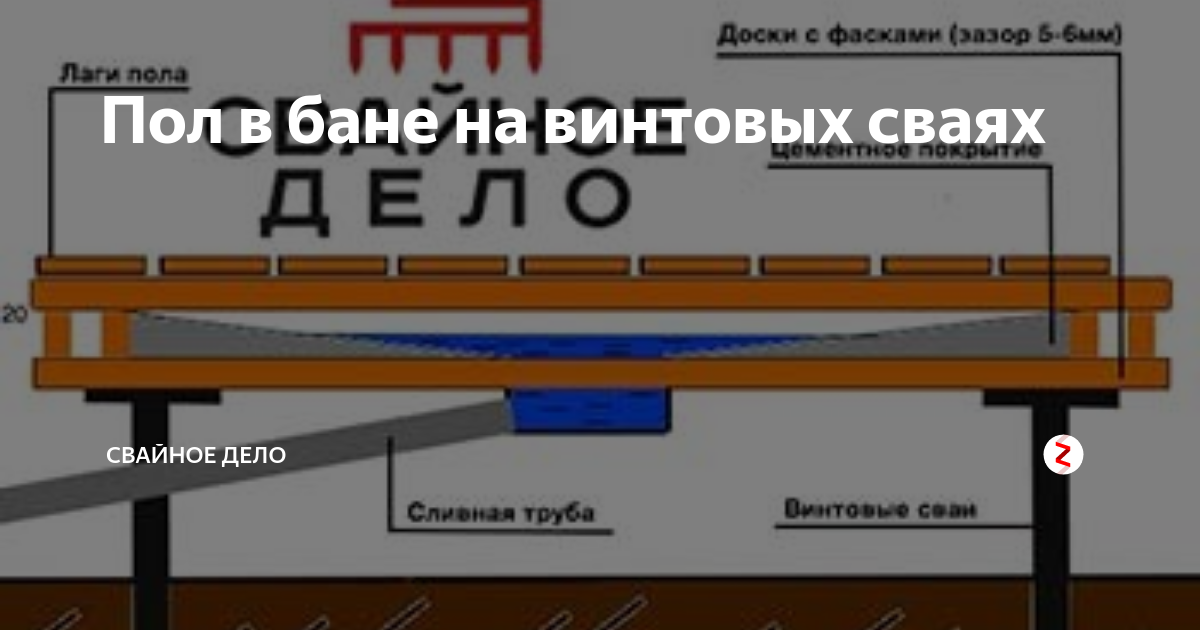

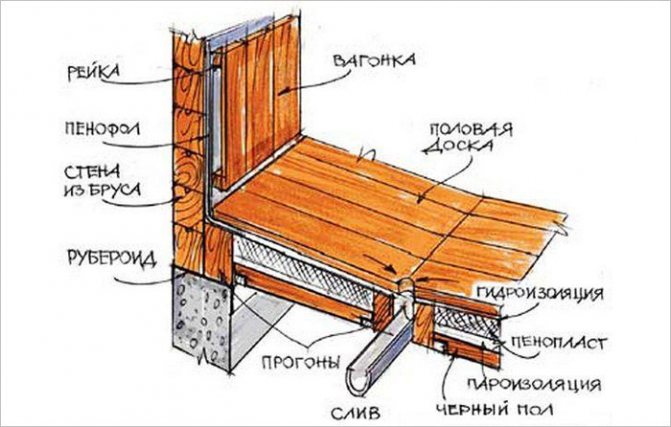

Example of a timber dry floor frame with a slope for water drainage This floor system resting on a foundation or standing on piles has its own challenges. Here you need to install two rows of boards. For the upper flooring, which goes over the log, a grooved pine or larch board is used, which is installed without gaps. Below, the presence of rough floors is required. This is the so-called "dry" floor, it is advisable to install it in the steam room and here it is necessary to insulate the space between the boards. It is advisable to place the floorboards on the final flooring with a slight slope towards the wastewater collection. At the lowest point, you need to make a hole to which a siphon is connected to drain the drains.

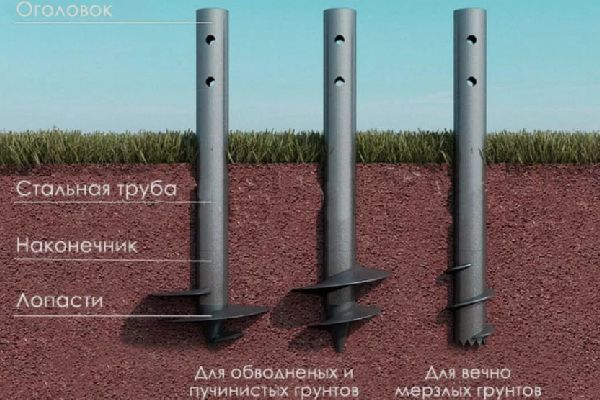

Screw pile foundation

If weak soils lie on the building site, there is a high level of groundwater and deep freezing of the soil in winter - it is best to erect a pile foundation made of screw support elements under the frame of the bathhouse.

The screw pile base is great for heaving soils

The helical support is a hollow metal rod with welded (or cast) blades and a pointed end.

The piles are easily screwed into the ground with their own hands using a special device threaded into the hole in the upper part of the rod, so this foundation for the bath can be built without the involvement of expensive installation equipment and qualified specialists.

A log house for a bath can be erected on an area with a difficult terrain, by immersing the screw supports to a considerable depth. The rod of screw piles can be easily extended to the required length, so the support can be easily screwed in deep enough so that the ends of the piles rest against the soil with high bearing capacity.

The use of piles in wet soils is also possible, but in this case it is necessary to treat the supports with anti-corrosion compounds before screwing in, because any scratch on the metal can cause rapid corrosion.

Screw pile foundation technology

Before you start screwing the screw supports into the ground, you should clear the area of debris, uproot trees and shrubs, carefully choosing the roots

It is very important that the trees growing next to the building do not damage the root system of the piles immersed in the soil. Removing trees and shrubs is usually easy to do with your own hands.

Competent markings are one of the keys to the reliability of the foundation

Competent markings are one of the keys to the reliability of the foundation

Then they begin to mark the places where the piles are screwed in, for which the perimeter of the future bath is marked on the site, for which pegs are driven in the corners of the building, along which the cords are pulled. It is absolutely not difficult to do this work with your own hands.

After marking the pile field (screw supports are installed under the outer and inner load-bearing walls, under furnaces, boilers and hearths that have significant weight, it is worth arranging separate foundations), proceed to screwing the piles. Two people plunge the pile into the ground by rotating the device clockwise in the lug.

The piles are screwed: what to do next

When all the piles are submerged to certain heights, outlets of supports of different heights with lugs remain above the ground. It is necessary to cut all piles to the same height, controlling this process with the help of measuring instruments. Hollow supports are easy to cut with your own hands using a specialized power tool.

The inner cavity of the screw piles is filled with concrete mortar, which should harden within a few days. Until the mortar inside the bar has gained strength, it is best to pause other work on the foundation supports.

After the concrete has completely solidified, you can start installing the headrests, which are welded to the upper part of the supports, they serve to protect the metal rods from moisture penetration. The piles are strapped from a bar or channel - the grillage combines the supports into a single foundation belt, which guarantees a more even distribution of the load on the ground.

Watch a video of how a log house looks like on a screw base.

Tape supports for a log house

The blockhouse of a bathhouse is allowed to be installed on strip foundations made of monolithic reinforced concrete, natural stones (cobblestones, rubble). It is allowed to arrange a bath on prefabricated tape bases, for which reinforced concrete blocks are used. Do not assemble precast concrete with your own hands - you will have to call lifting equipment.

In central Russia, it is enough to equip a shallow foundation for a log house

Distinguish between shallow and conventional strip foundations. A shallow tape will require digging trenches with a depth of 0.3 m to 0.7 m. Conventional tape bases are buried to a distance of 1.7 m.

What foundation to choose for a log bath? To answer this question, it is worth determining such indicators of the site as the depth of freezing, the composition of the soil and the level of groundwater.

If the site contains weak soils with a low bearing capacity, it is best to choose the option of a conventional strip base, but it is worth remembering that work on arranging a strip under a frame will require a lot of labor and time. After marking the foundation on the site, you will need to dig a large volume of trenches, install the formwork, make a reinforcing cage, after which you can start pouring the concrete solution.

The finished foundation-tape made of monolithic reinforced concrete is gaining strength for about a month, so you should not plan the start of construction in the autumn period or the beginning of winter, so that you do not have to perform a set of additional work to preserve the foundation for the winter.

Watch a video on how to make a tape base and a concrete sub-floor for a bath with your own hands.

Guidelines for choosing a design

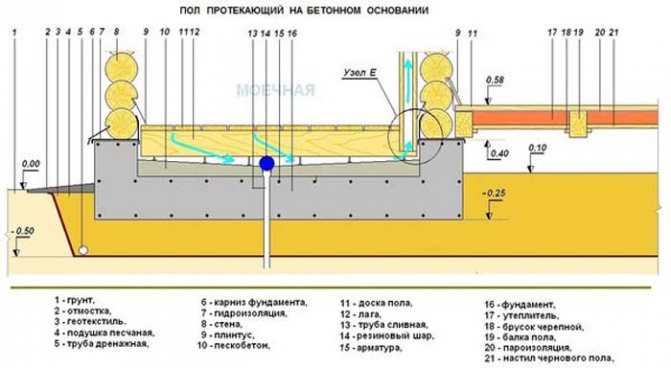

Diagram of a concrete floor with ventilation in a bath. Starting to build your own bathhouse, you must initially think over the type of water drainage and decide on the choice of material for the floor. In most cases, the floor is concreted or planks are laid on the joists. A concrete foundation is labor intensive, financial and time consuming. However, its service life can last up to half a century.

A simpler and cheaper option is the device of lumber floors. It is not difficult to make it. There are enough videos and photos of materials on this topic on our site. But this design is designed for 7-8 years. After this period, many elements will have to be replaced. According to the type of water drainage, and the associated complexity of the device, structures made of wood are divided into leaking and "non-leaking" types.

Features of installing wooden floors

When constructing a floor in a steam room according to a leak-proof type, the installation of the log should be in a perpendicular direction relative to the water flow. One of the main structural elements of a wooden floor is strong logs, which can be supported by a bar in the columnar method of arranging the foundation. But it must be remembered that all contact points must be carefully insulated with roofing material with an intermediate coating with preheated bitumen. If the floor is installed on piles, it is advisable to use an insulating material with more effective properties.

After fixing the logs, boards treated with special compounds against rotting are laid on them. If a leaking floor is supposed to be installed, then a gap of 3-4 mm between the boards is required for ventilation and water drainage. And along the perimeter of the area, a technological gap of 2 centimeters is made.

Protection and prevention for the floor in the bath

The main enemy of the bath is high humidity, constant evaporation and dampness. And here you can not do without waterproofing. But materials will also need to be processed with appropriate antiseptic compounds. Otherwise, mold and mildew can destroy wood and even concrete substrates. All elements during construction are imperatively impregnated with antiseptics, which are sold in abundance in hardware stores. And here the main thing is not to be lazy and carry out the processing several times. In addition, it will not work to insulate the bathhouse without the use of waterproofing. These measures will increase the service life of all elements and extend the life of the structure as a whole.

Schemes of the device of floors of different types in the sauna

If, for some reason, these measures were not taken during construction, then a number of fairly simple procedures must be followed to avoid the destruction of the wooden components of the floor and walls. You can disassemble the structure, dry it thoroughly, remove the foci of decay, and clean up the lesions with a fungus with a metal brush and sandpaper. Then soak the wood with an antibacterial solution and dry again. It is advisable to cover the boards with wax or varnish with water-repellent properties after finishing work.

Principles of installation of screw piles

To install the supports, you can use a specialized machine, a portable motorcycle tool, or manually wrap the pipes. The larger the diameter and number of screw piles, the more arguments in favor of the mechanized method.

To tighten the support you will need:

- Construction plumb line;

- A collar pipe with a shoulder length of at least two meters;

- Ballast cargo;

- Several tens of liters of clay solution in water.

Each pile is placed on the ground in the place where it is wrapped, loaded with ballast and plumbed in a strictly vertical position. While one worker holds the screw support upright, two assistants use a steel lever to screw the pipe into the ground, adding mud.

After installing all the screw piles on the foundation field, the marking cords are pulled and the pipe heads are cut so that the cutting line of all supports is in one strictly horizontal plane. Support pads made of steel plates or metal strips are welded onto the cut racks.

Making a frame

Before assembling the walls of the bath from a profiled bar, screw piles must be laid on the strapping. The base frame is sewn from a massive oak bar of 150-200 mm or polished sleepers with a length of 220-250 cm.

The strapping material is attached to screw piles with undercut anchor bolts to hide the nut in the wood. Before fixing on screw piles, each section of the strapping is checked with a building level and, if necessary, leveled with a lining of washers or thin metal. One of the strapping options bath foundation on screw piles shown in the video

We collect the log house

Installation of bath walls on screw piles practically does not differ from the process of laying profiled beams. The first beam is mounted on a glue or mastic base, the steel rims of the bath are laid out "dry", with jute or synthetic fiber lining.

If the bath box is assembled from a profiled bar, then the remaining gaps between the crowns are caulked with linen thread with the addition of wood glue. After assembling the strapping frame on the screw piles, the subfloor logs are laid on the timber with the help of metal corners and "moths". You can use a board with a section of 150x40 mm and even an inch, since the rough base does not experience a special load.

The advantages of a columnar foundation on piles for a bath

- You can use materials at hand: metal pipes, concrete and reinforcement. After all, the construction of the bath is light, it is not built from natural stone or concrete, but, in most cases, from wood. However, it will be quite difficult to make the floor insulation due to the relief of the base.

- An open drainage space can be laid between the piles or a protective grid with porous insulation can be installed;

- The design is perfect for buildings built on swampy soils and subject to seasonal movements through freezing of soils;

- Floor insulation is done directly during the installation of the second floor;

- Pipe communications can be laid at different depths. Additionally, pipe insulation can be provided, but it is still not recommended to install them at a depth below the lower edge of the screw piles;

- The bathhouse can be built on a steep slope;

- The supporting structures are installed directly on the upper horizontal aligned edge of the foundation, which can become a second floor with insulation.

Drain device

Due to the fact that panel, frame baths or buildings from a log house are mainly built on the pile foundation, the grillage is arranged mainly from timber or rolled metal.

Organization of drainage with tilted tiles

Organization of drainage with tilted tiles

In this case, the drain can be done in several ways at once:

- Filling the slab grillage;

- Laying an asbestos-cement sheet on the beams with a screed or cladding on it with flat slate tiles, and ensure the required slope due to the difference in the thickness of the glue;

- Fixing the galvanized sheet on the grillage with a slope towards the drain (for wooden floors);

- Laying a membrane attached to both sides of the walls on the subfloor (for wooden floors).

Membrane drainage device

Membrane drain

Membrane drain

The most economical option is to drain through EPDM membranes. In this case, the construction will be as follows:

- Sub-floor logs, fixed by metal holders;

- Subfloor, which can be made from densely laid boards 25-30 cm;

- Insulation, which is used as an EPSP with a thickness of 80-100 mm;

- Ladder, arranged in the subfloor and in insulating material, and inserted into the drain with a dry odor trap;

- Full-length membrane. Also, it should be brought to the walls on the sides, taking into account the elevation of the finished floor;

- Finishing floor joists, fixed by means of holders from the profile;

- Finishing cover in the form of an edged board, which is not recommended to be rigidly fixed, but attached to 10 mm dowels.

This fixing of the topcoat allows you to remove the boards at any site for garbage collection and drainage drain cleaning. For the water drainage device, the slope is arranged directly in the membrane during installation. The lower part of the EPDM is pressed down, then the waterproofing is slightly lifted to the top and secured with a slight tension.

Watch the video on how to waterproof a drain using a membrane and install a drain cover.

For frame baths, in order to clad the walls from the inside, a vapor barrier is required, while the scheme will undergo some changes:

- First, the subfloor is laid, and its insulation is done in the same way as in the first solution;

- The membrane is fixed on the walls with a small start using a stapler, a tightness is created for the drain device;

- The frame of the walls is sheathed with a vapor barrier material, while its lower edge is laid on top of the EPDM - when moisture accumulates, it will flow onto the membrane without destroying the wooden elements of the load-bearing frame.

Application of sheet materials

Creating a slope from porcelain stoneware or tile using sheet materials will cost a little more, but it is quite possible to do it yourself.

Watch a video on how to slope a drain using tiles.

In this case, it is necessary to observe the following technology:

- The rough floor is arranged from edged boards on logs;

- Extruded XP5 expanded polystyrene is used as a heater;

- Dry screed is made of asbestos-cement sheets or DSP;

- For waterproofing, an EPDM membrane and coating with polymer mastic are used;

- The drain is arranged only in the form of ladders with dry water locks;

- For cladding, tiles or porcelain stoneware are used, laid with an inclination towards the ladder.

Drainage device when making a screed

Dry seal design

Dry seal design

Uncoated screed is performed in order to save on finishing. In this case, you will need wooden ladders that are laid when using the bath, and are removed at the end of the bath procedures for drying.

In this case, the drain is arranged after the implementation of a two- or three-layer waterproofing of the screed with mastics, penetrating substances or by means of hydroglass insulation. Sewer drains are embedded in the foundation, for which it is best to use dry locks.

Drain device when pouring the slab

The slab is poured during the construction of the foundation grillage. In this case, the slope of the drain is set directly along the slab, and the sewer hole is arranged by installing a pipe of the required diameter into the formwork.

What is the best foundation to choose?

The foundation is located in the underground part of the building. The whole support of walls, roofs and ceilings presses on him, so it all depends on your choice. Even if the groundwater is close, you will find a suitable foundation here.

1. Screw foundation for a bath:

Screw piles will be the best solution for any kind of soil, and most importantly, they can even be done in winter. The installation of such screws is carried out using a special technique or a long pipe attached to the pile. But first, markings are made on the site along the perimeter. They can be installed at different distances, it all depends on the soil.

If the bath is a light construction, then piles can be installed at a distance of 2 - 3 meters. The depth is done to a dense soil layer of 1.5 - 2 meters.

When all the piles are leveled and screwed in, 250 x 250 mm heads are put on for each screw and welded. The diameter is selected from the pile itself.

Further, the lower crown of the bar is attached to the head. The most important thing is to do it right cuts, only on the site of the heads, otherwise they made in another place will weaken the beam.

2. Monolithic (slab floating) foundation:

I'll tell you right away this type of base, for very powerful structures and for a bath it is rarely used. It is the most expensive base. It is not difficult to do it, but it will take a lot of time. Such a foundation reliably protects from groundwater, and a rigid reinforced structure is not afraid of shrinkage and deformation of the soil, since the slab will protect the bath from destruction even if it moves. The monolith is mainly used on homogeneous, heaving, including clayey soils, as well as peat and swampy places.

Under this base, we first level the surface, then make the markings, and dig out a pit about 40-50 cm high. For a bath, this will be quite enough. Then we make the formwork with boards, 40 cm high above the ground. We cover the soil with a special material (geoxyl) in several layers, pour 30 cm thick sand and tamp it. We are laying the sewer pipe.

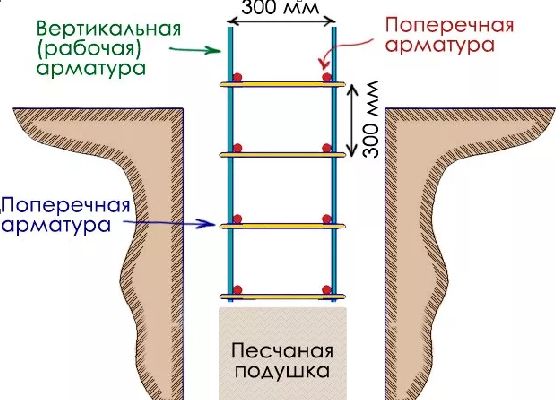

Since it is not concrete without reinforcement, so we lay the reinforcement. The first layer is placed at a distance of 5 cm. The second layer is 20 cm from the first. We make the reinforcement in two directions (mesh 30 x 30 cm), we tie it with wire.

Fill the foundation with a mixer and cover with foil for 8 - 10 days. Further, it will be possible to build a brick bath or from blocks, and of course from wood materials.

3. Columnar:

This foundation is more convenient when building small structures with low pressure on the foundation. Not suitable for bricks, concrete, cinder blocks. The easiest way is with an asbestos-cement pipe or iron pipe. To do this, first make markings, then dig holes 1.2 - 1.5 meters deep and if they do not collect water from groundwater, then this depth will be enough. By the way, you can dig it with a shovel, but there is still a faster way, drill with a cone-shaped drill. Then the holes are much smoother.

It is also important for pillars what hole diameters are needed, and they should be 5-10 cm larger than the material parameters

- For asbestos-cement pipe - 200 mm. in diameter.

- Brick - 50 x 50 cm.

- Rubble stone - 60 x 60 cm.

- Reinforced concrete - 30 - 35 cm.

Next, fill the hole with sand, about 20 cm, and spill it well so that the sand is well compacted. The next step is to wrap the pipe with waterproofing and insert it into the hole. We fill the gap between the wall with sand or crushed stone.

We stick a mesh of reinforcement with a diameter of 12 mm into the pipe. We link it as shown in the figure.

And fill it with a concrete mixer. Taking your time, tamping well and expelling the air.

You can also watch a video on how to quickly fill a columnar foundation with your own hands.

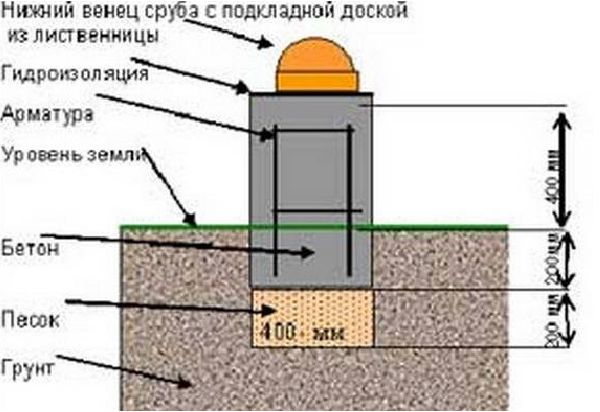

4. Strip foundation:

This type is the most versatile, it is suitable for any soil and will withstand any structure. You can even make a 2-floor sauna on it. It is made by pouring concrete around the entire perimeter. A strip foundation is being erected below groundwater in your area and above 30 cm from the ground. The advantage of the tape base is to evenly distribute the weight of the entire structure in relation to the ground.

Also, if you look at the severity of the bath and good soil, the foundation can be made shallowly buried. Accordingly, it will be cheaper, but it must be well reinforced. Look at the diagram for such a basis.