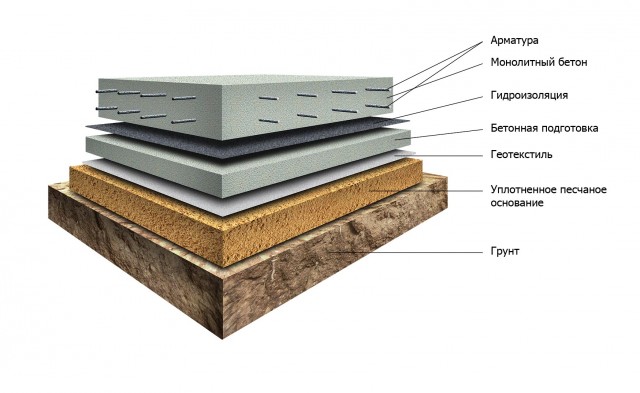

How to properly pour a monolithic foundation slab - a diagram of the future foundation

The technology proven in practice, in accordance with which a monolithic reinforced concrete slab is poured, guarantees the reliability of the foundation

It is important to build a multi-layer structure in the correct order. When thinking about how to pour a concrete slab, you should study the order of the foundation layers.

Ensures the reliability of the foundation - proven technology

Consider how the slab is arranged, starting from the soil level:

- geotextile fabric. It is laid on a horizontal surface of compacted soil. The material acts as a dividing layer between the sand-crushed stone cushion and the soil;

- damper cushion. Constructed from a mixture of sand and gravel. Backfill is designed to smooth out ground movements and level the base. Drainage lines are located inside the massif;

- foundation layer. Formed from concrete mortar. The concrete allows you to plan the surface and increase the load characteristics of the foundation slab;

- waterproofing. It restrains the penetration of ground moisture to the sole of the base and allows you to maintain the required moisture concentration in the concrete solution;

- friable or sheet insulation. The thermal insulation layer reduces heat losses, which helps to ensure a comfortable indoor temperature;

- non-separable or composite formwork. The formwork is erected along the contour of the foundation slab, gives it the necessary shape, and also prevents moisture seepage from the concrete during hardening;

- reinforcing lattice. Does not allow the concrete base to crack under the influence of loads and soil reactions. The power frame extends the life of the foundation;

- concrete layer. After gaining operational strength, concrete takes up the weight of the structure and evenly distributes the load over the area of the foundation surface.

Advantages and disadvantages

The main advantages of a monolithic foundation are:

- Low, in comparison with other types of bases, the cost of construction. The slab is poured directly from the concrete mixer without the involvement of highly qualified specialists and the use of expensive equipment.

- Good bearing capacity of this type of foundations due to the large area and structural integrity.

- Thanks to the common slab on which the walls of the structure are located, their integrity is ensured, even with seasonal swelling of the soil.

- The construction of a monolithic slab ensures the absence of large labor costs for earthwork.

The absence of large volumes of earthworks significantly reduces the cost of the estimated cost of the foundation being erected due to the uselessness of heavy equipment on the site (bulldozer, excavator, etc.).

One of the main disadvantages of a monolithic slab is the inability to combine the structure of this foundation and the basement.

For those who have groundwater close to the site, this is not necessary, but for summer cottage construction in the absence of groundwater, such a disadvantage can be critical.

The second disadvantage of this design is its high material consumption. A lot of concrete and reinforcement is required.

The reinforcement mesh needs to be knitted, and in large volumes of the slab base, this is a big time investment.

And the third drawback of a monolithic slab is that pouring can be done only under favorable weather conditions.

But comparing all the pros and cons, we can conclude that when erecting this type of foundation, there is a lot of savings on other materials and work, so such a foundation cannot be called particularly costly.

Device

How to make a foundation slab? A slab for this type of base is not just some kind of concrete product. Due to its characteristic features, it is called differently - a pie plate, because it consists of several layers of different materials.

During pouring, as the technology of a monolithic foundation-slab says: the thickness of each layer must be calculated separately.

The composition of the "pie" is as follows:

|

Layer |

Appointment |

| Geotextile | It is necessary to ensure the strength of the slab base. It is an obstacle to mixing the pad and soil. |

| Pillow | It is intended to make the support for the slab even, serves as drainage and creates a layer that is prone to heaving. |

| Concrete base | Provides waterproofing properties and also increases the level of load-bearing capacity. |

| Waterproofing | Considering that any structure in the soil is exposed to moisture, such a layer is necessary to prevent this effect. In addition, the waterproofing layer prevents the concrete from leaking, which preserves the strength of the material after hardening. |

| Thermal insulation | Not every slab is equipped with this layer. It is necessary if a warm basement room is designed in the building or the slab is located close to the soil surface. |

| Formwork | To preserve the shape of the concrete at the time of hardening. It can be built removable or remain in the structure. |

| Reinforcement | Due to the high compressive strength of concrete, it is necessary to create reinforcement with metal rods so that the material does not subsequently undergo cracking and can serve as long as possible. |

| Concrete | Thanks to this layer, all loads from the building are absorbed. In most cases, reinforced concrete is used, since it has more durable characteristics. |

How to calculate a reinforced concrete slab yourself?

How to calculate a reinforced concrete slab yourself?

To calculate a monolithic foundation slab, you need to know:

- Groundwater level;

- The parameters of the soil on which the foundation will be placed;

- The amount of soil freezing;

- The total weight of the building, it includes the weight of the box, roof, furniture installed in it, household appliances and residents;

- The size of the snow and wind load;

- The weight of the plate itself.

As a result of calculating the specified parameters, it is possible to determine what pressure the entire structure will exert on the ground. Then you need to refer to SNiP 2.02.01–83 and determine the maximum ground pressure at the site of the building. Let's consider an example:

- The building weighs 19 tons;

- Roof weight 3 tons;

- The weight of the foundation slab is 20 tons.

Possible snow and wind load will add 7.5 tons from above, for a total total load of 49.5 tons.

With a building size of 6x6 meters, the basement surface area will be 36 square meters or 360,000 square centimeters. The load on the ground will be the difference between the weight of the structure and the area of the foundation, as a result we get 0.13 kg per sq. centimeter. This load is permissible for any soil.

When calculating the thickness of a monolith, it is imperative to take into account the following parameters:

- The distance between the layers of the reinforcement mesh;

- The height of the concrete layer on and under the outermost layers of the reinforcement mesh;

- Reinforcement dimensions.

Practice shows that the traditional thickness of the slab is 200-300 millimeters. If we consider that under it there should be a compacted sand cushion up to 300 mm high, the total thickness is 600 mm. It must be understood that this parameter varies depending on the type of soil, the weight of the building.

The volume of concrete is equal to the product of the perimeter of the foundation by its height, and the required volume of sand or crushed stone is also considered. Based on the calculations carried out, the required amount of waterproofing, reinforcement, etc. will be known.

general information

The essence of the slab base is a reinforced concrete slab, which is placed on a soil layer up to 300 mm.Crushed stone or sand is mixed with the soil. The do-it-yourself monolithic foundation slab itself is 20 - 40 cm thick.

For the construction, monolithic slabs or prefabricated ones can be used, which are poured on the construction site. A slab foundation on heaving soils, as well as a slab foundation on filled sandy soil, show themselves to be the most effective in comparison with other types of structures.

Despite the fact that the monolithic type of slab is considered more reliable, when choosing how to make a slab foundation, it is preferable to pour the slab in place. This is due to the fact that the process of transporting and laying a monolithic base is quite laborious and expensive, and it is very simple to build a pie plate.

This type of foundation is suitable not only for the construction of large industrial or residential buildings: it is also suitable for small outbuildings, for example, a foundation for a bath-house can be made, and a foundation for a garage is a monolithic plate with your own hands.

In a separate article on our website, all the pros and cons of the slab base are considered.

Sometimes, in addition to the slab, combined types are used, for example, a pile-slab base or universal ones, for example, from road slabs.

Tools and building materials required for pouring a foundation slab

As with any construction work, in order to fill the foundation slab, you will need tools and materials for manufacturing:

- devices for measuring the area;

- tools or equipment for digging a foundation pit;

- cement, water, gravel, sand;

- lumber, nails, hammer (for formwork construction);

- materials for waterproofing, thermal insulation;

- reinforcing rods, wire;

- concrete mixer or other equipment for mixing concrete;

- vibratory rammer;

- polyethylene or roofing material.

With such a set of tools and building materials, you can build a high-quality tiled base.

Pouring with a concrete pump

This is the most expensive and most convenient foundation pouring. Concreting is carried out as follows - a specialized machine with the help of a sliding boom can deliver concrete mixture at a distance of 30 to 50 meters, which allows pouring even in places with difficult or impossible access to the formwork. Due to the high cost, concrete pumps are mainly used only in construction at large facilities.

DIY pouring

You can fill the slab under the foundation with your own hands. This is the cheapest filling method, but rather laborious and time consuming. To do this, you can use one or more concrete mixers, it all depends on how many people are involved in pouring the foundation slab. You can do without them, mixing the concrete mixture with shovels in a trough, but the concrete will not have the same quality as when using a concrete mixer, and the time costs will increase significantly.

If you use a small concrete mixer with an operating volume of up to 50 liters, then it will take about 20 completed cycles to pour one cube of the finished mixture. Mixing of concrete takes about 3 - 5 minutes. But in order to make a batch in a concrete mixer, it is necessary to put sand, cement, water and crushed stone, and then deliver the ready-made concrete to the formwork. Then the approximate cycle will be 10-15 minutes. It follows from this that one cube is filled in 5 hours of work. The whole process can be speeded up with more people using a larger concrete mixer.

Sand, gravel, water and cement, as well as the concrete mixer itself, should be located next to the formwork. This will save time and effort spent on the delivery of building material and ready-mix, which will be poured into the formwork.

Advantages and disadvantages

The main advantage of a monolithic foundation is its strength and ability to withstand significant load forces.Such a foundation can withstand seasonal soil displacements, the effects of precipitation, temperature changes.

In addition, the pluses include:

- speed of work and their efficiency. As a rule, the construction of a monolithic foundation for a small house does not require the use of special construction equipment;

- a large selection of monolithic foundation schemes. As a rule, due to the solid base, it becomes possible to use frame configurations that fully correspond to the design drawings, up to non-standard shapes;

- tightness. If the monolithic foundation slab is poured in accordance with non-joint technology and hydrophobic additives are added to the concrete mixture, a foundation can be created that can withstand moisture.

Unfortunately, a monolithic foundation is not a 100% guarantee of success, since it also has certain drawbacks. These include:

- significant consumption of concrete;

- rather laborious construction work;

- the need for preparatory activities.

If you compare the pros and cons of a monolithic slab foundation, you will come to the conclusion that an effective result requires good preparation.