Varieties of foundations and methods of their thermal insulation

Depending on the method of support on the ground, the following types of foundations can be distinguished, used for wooden buildings:

- columnar;

- monolithic;

- tape;

- pile.

For the construction of wooden and frame houses, in most cases, shallow foundations are used. They are made of concrete or brick in the form of a strip or slab structure. It is better to insulate such a foundation from the outside. The thermal insulation layer is located at a distance of about 1.5 m, behind which a frost-free soil layer is created.

Columnar base

This type of foundation is equipped with pillars that are dug in below the freezing line by about 2 m.

The pillars are located at all corners and intersections of the building structure, as well as in places with maximum load.

Pile structures

When making a screw base, instead of monolithic pillars, piles are used, which are screwed into the ground.

It is insulated in the same way as a columnar foundation.

Monolithic foundation

Monolithic is made in the form of a slab under the base of the house, the basement is not provided in this case.

To equip its buried version, they dig a pit; for a small one, the top layer of soil is simply removed. Such a foundation can be insulated with any modern materials only from the outside.

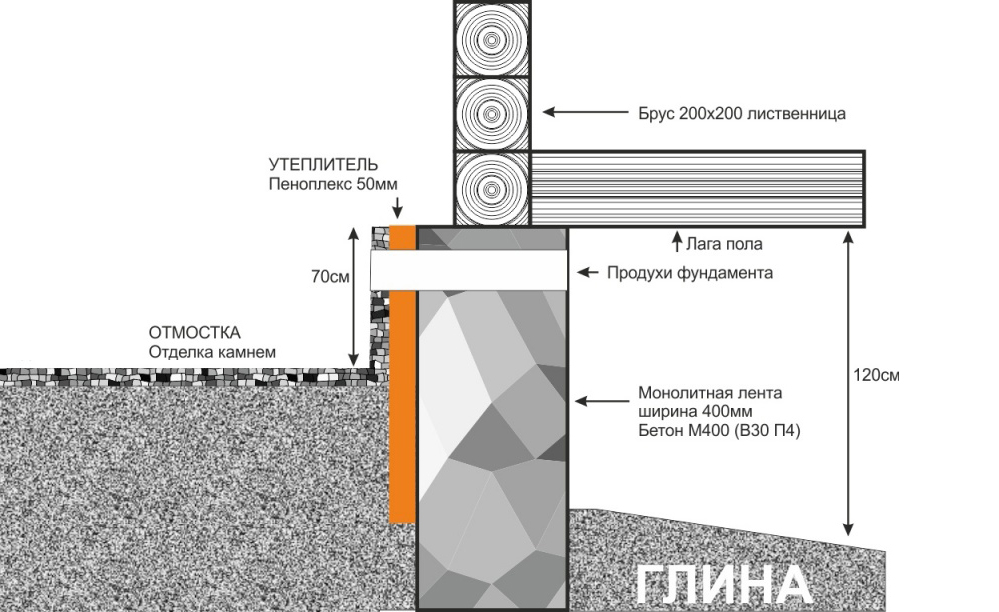

Tape

A tape-type foundation is created under the walls along the perimeter of the building, provides for a basement, it can be made of concrete blocks.

It can be insulated from the outside and from the inside without any problems.

Preliminary worries before insulation work: what needs to be done before the main installation

The preparatory stage is needed the same for any type of insulation. All work is carried out sequentially, taking into account the correct calculations and indicators for a specific climatic zone and type of material.

Clearing the perimeter and repairing the basement walls for further work

To insulate the basement, you need to walk around the perimeter and release it to the depth of the beginning of the foundation. The width of the trench should be about half a meter.

You can start repairing chips, potholes and leveling the surface.

The entire perimeter must be cleaned: construction dust, clay, adhered soil and other debris are considered contamination. For this, any hard brush is taken, it is convenient for it to walk around the house and thoroughly brush off the dust from it.

Irregularities on the walls must also be eliminated, especially if the basement is insulated with foam or extruded polystyrene foam. Depressions larger than 10 mm in diameter deserve special attention, they will eventually ruin the foam sheet.

You need to level the walls using plaster: first, the curvature of the surfaces is taken into account. They recognize her by placing the building level vertically and determining the difference between the indicators at the upper and lower points. If the difference is less than 1 cm, then the wall cannot be corrected.

Any defect should be removed, a layer of primer and plaster will also help in this. Alignment is carried out on beacons and plumb lines. Beacons must be installed on the tags, and then the beacon rails.

The slats are fixed from the edge, not forgetting to check the vertical level. Then the intermediate profiles are mounted. After they start applying the plaster layer. The mixture is leveled with a rule and the wall is allowed to dry completely.

Padding

The primer is applied to the dried layer of the plastered wall. It is better to give preference to a ready-made composition that will be optimal for this work. The primer is applied with a brush, it at the same time removes the remains of debris and dust adhering to the process.

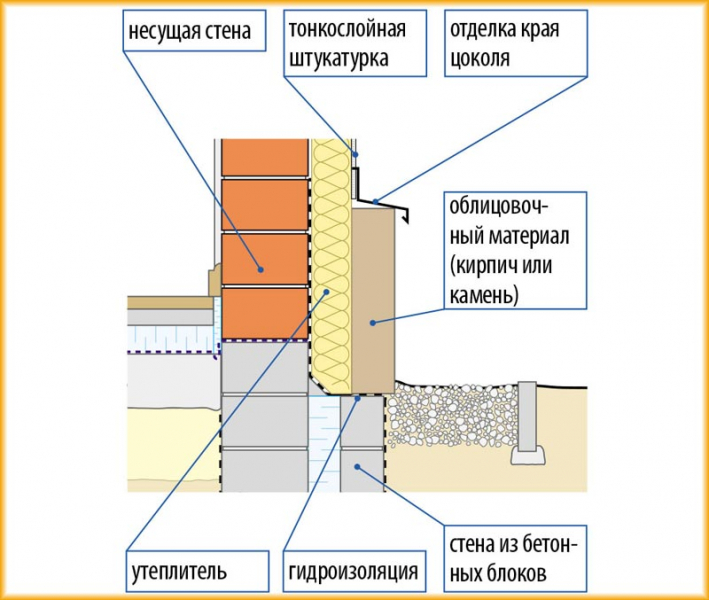

Waterproofing

In order to insulate the basement correctly, it is required to coat it with a waterproofing mixture. This will protect the house from dampness and mold.

Bituminous mastic or a special composition is used as a waterproofing material. Application is carried out with a roller or brush.

The preparation process can be considered complete, after which the basement insulation procedure itself is carried out.

Base insulation technology

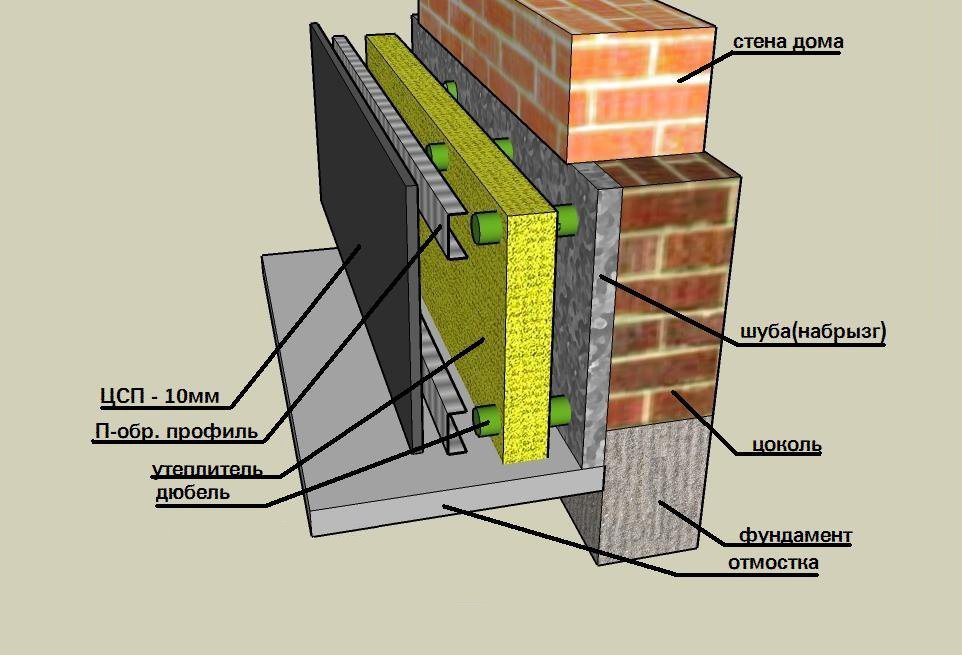

The basement insulation technology differs depending on the type of base and the heat-saving materials used.

Insulation of the foundation is divided into external and internal. It is necessary to insulate the outer part of the base before the construction of the basement and walls.

If at the construction stage the measures for thermal insulation were omitted, they are insulated from the inside.

Thermal insulation of the strip base

Many people ask the question, why insulate the foundation in the house, if there is no basement there. Moisture, penetrating through the pores of concrete, increases in size during freezing, this often leads to the formation of cracks.

The strip foundation is insulated with a uniform layer along the entire perimeter.

Step-by-step instruction:

- A trench is dug along the entire length of the foundation. Its dimensions should be: in depth, like a foundation, in width 80-100 cm.

- They clean the concrete tape from dirt, earth and dust.

- If necessary, the surface is leveled by making a concrete screed.

- Laying waterproofing from roll materials or treating the surface with bitumen-based mastics.

- The slab insulation is fixed to a special glue.

When insulating the foundation with expanded clay, it is necessary to provide for a drainage system to drain water from the base of the house. Expanded clay due to its porous structure is characterized by high moisture absorption, while it loses its thermal insulation qualities.

For a drainage device, a trench is dug at a short distance from the base of the house. The bottom of the pit should be located deeper than the base of the foundation. The bottom is covered with geotextiles so that its edges go over the walls of the trench. Crushed stone is poured, pipes are laid, with a section of 10-20 mm. From above they are covered with rubble. The protruding edges of the geotextile are wrapped so that they cover the drainage structure. A layer of sand is poured on top.

Expanded clay is filled up to ground level. It must be dry and clean, free of foreign matter.

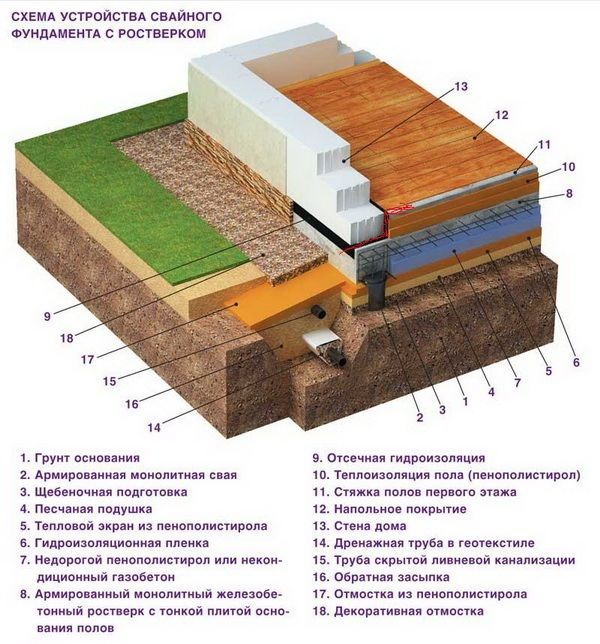

Pile base thermal insulation scheme

When using a material prone to increased moisture absorption as a heater, it is necessary to make a blind area. It will protect expanded clay from getting wet during rain or melting snow.

Thermal insulation of the pile foundation

In order to significantly reduce heat loss during the operation of the house, it is necessary to provide measures for its insulation at the stage of construction of the pile-grillage base.

This type of foundation is characterized by the fact that there is a gap between the ground level and the floor of the house. In winter, the floor in such a house will be cold and heating will be expensive. To reduce costs and create a favorable microclimate in the house, it is necessary to insulate the grillage.

The grillage is a structure made in the form of a tape, which unites the piles. It takes on the bearing load from the house and distributes it evenly through the piles to the dense layers of soil.

At the stage of installation of piles, they are isolated from moisture. Roofing material or other material rolled into a pipe (rough side inward) is laid in the well. After that, the reinforcement is laid and the well is poured with concrete.

After installation of the grillage, it is waterproofed and insulated. Most often, sheet polystyrene foam or polystyrene foam is used as heat-saving materials.

Insulation of the slab foundation

The slab foundation has a large area, so its insulation is quite expensive. There is a lot of controversy about whether it is necessary to insulate the foundation made in the form of a slab.

Heat-saving technologies allow to achieve a significant reduction in heat loss during the operation of the house. The invested funds pay off over time, and living in a warm house becomes more comfortable.

Insulation of the slab base is carried out after the leveling of the bottom and walls of the trench has been done.

Step-by-step instruction:

- Spread strips of roofing material with an overlap of 150-200 mm.

- Sheets of polyurethane foam are laid on top.

- The surface is poured with a cement screed.

- Reinforcement cage is mounted.

- The slab base is poured with concrete.

Foundation diagram

Thermal insulation of a columnar foundation

Before insulating the columnar base, a basement is mounted, it will prevent heat loss due to the gap between the floor of the house and the ground.

A trench is dug along the perimeter of the house, with a depth of 200 to 400 mm. Sand and crushed stone are poured into it so that the height of the layers does not reach the ground level by 50 mm.

Bars are attached to the posts, the harness is mounted. After that, the surface is waterproofed and insulated.

Ways to insulate the foundation of a house with your own hands. Materials for insulation outside

The first method: a wooden formwork is arranged around the perimeter of the house, 30-40 cm from its walls. Between it and the basement of the house, the soil is poured and compacted to the level of the finished floor. From above it is sheathed with boards, the resulting ledge is used for domestic needs. For example, like a shop.

2nd method: A waterproofing agent - bitumen mastic is applied along the entire foundation into a prepared trench (1.5 m wide and deep to the bottom). With a high groundwater level, drainage works are carried out. The bottom of the trench is lined with polyethylene film with its output to the surface. Gravel is filled in. Its thermal conductivity is replenished by the air filling of the layer. The trench is closed from above with a concreted blind area, which has a slope from the wall.

3rd method: The method is similar to the second. The difference in the material used for backfilling in the trench is expanded clay (baked clay).

4th method: Sheets or plates of expanded polystyrene or polystyrene foam are used as insulation - the best materials for insulating the foundation from the outside. Their advantage: safety, durability, excellent heat and waterproofing qualities, the ability to create a seamless layer. A 10 cm layer of polystyrene foam is comparable in terms of thermal protection to 50 cm of brickwork.

The depth of laying the insulation is determined by the depth of freezing of the soil plus 5-10 cm. A trench is dug around the perimeter of the house 1 m wide. The walls are dried. A sand cushion is poured at the bottom of the trench, drainage pipes are laid and everything is covered with geotextile.

How and what is the best way to insulate the basement base from the outside? For this, the base is primed, tightened with a waterproofing film, to which polystyrene sheets are glued. The prepared glue is applied to the sheet, leveled and pressed firmly against the wall. The next, prepared in the same way, is connected with locks to the first. This is how the entire perimeter passes, placing the sheets in a checkerboard pattern. The laid sheets are re-coated with glue, joints and seams are sealed. The layer is allowed to dry.

The trench is covered with sand and gravel. From above, the insulation laid on the base is plastered using a reinforcing mesh. Expanded polystyrene has good opportunities for creating a decorative surface.

And here is a video on how to insulate the foundation from the outside with expanded polystyrene.

A gravel-sand cushion is used under the blind area, concrete is poured into the prepared formwork.

Method 5: Polyurethane foam as insulation has a significant advantage in terms of work performance. However, the toxic composition of the insulation requires the involvement of specialists in protective suits with special equipment.

Spraying polyurethane foam is carried out on the concrete surface of the foundation, open to the level of freezing. A layer of 5 cm reliably covers the surface, filling up all cracks and voids.

The material is moisture resistant, creates a seamless coating. Neutral to bioinfluence. Completion of work on the 4th method of external insulation.

Recommendations:

- lay the first row of slabs on a flat surface to avoid heat leaks;

- the efficiency of the work done depends on the choice of insulation;

- remember that "cold bridges" are formed at the corners of the house;

- when backfilling, in order to preserve the integrity of the insulation surface, it is worth using smooth asbestos-cement slabs;

- polystyrene slabs successfully resist the load of heaving soils.

Operational features of modern heaters

The modern market of insulation materials offers a wide range of required products. However, despite the large assortment of goods, among consumers, foam plastic, expanded clay, polystyrene and polyurethane foam are most often in demand. Often, foam glass is also used for insulation outside.

| Insulation | Operational Features |

| Polyurethane foam | An expensive material, for the installation of which it is necessary to use special equipment. It is applied to the surface of the foundation by spraying. Differs in high thermal insulation capabilities. |

| Styrofoam | More affordable products in terms of price. The special structure of such a material contributes to the emergence of difficulties during installation - during cutting, the foam crumbles very strongly. During the work, additional waterproofing may be required. |

| Expanded clay | The expanded clay layer is capable of absorbing moisture very well, due to which this material is positioned as a very good heat insulator. It creates a kind of pillow around the base of the house and prevents the penetration of cold air. |

| Foam glass | Used relatively recently. It is easy to process and prevents moisture penetration. |

| Polystyrene | Given the flammability of such a material, it is strongly recommended to refrain from using it as a facade insulation. But for underground insulation, polystyrene is ideal. Its resistance to increased moisture deserves special attention. |

Earth as insulation

The simplest way to insulate the foundation of a wooden house with your own hands is to backfill with earth. However, there are many questions to this method. It is advisable to use this method only before the start of the construction of the walls.

The difficulty of this method of warming lies in the need to use a large volume of soil. Otherwise, it will be very difficult to achieve a positive final result. Moreover, even if you insulate the foundation from outside with earth, you may not get the expected effect. This is due to the low thermal insulation potential of the material.

It should also be added here that warming the foundation with earth with your own hands will be associated with great difficulties. In this case, it becomes necessary to use specialized equipment, the rental of which is not cheap.

The benefits of thermal insulation

When the base of the building is not insulated, the currents of cold air penetrate into the house from the outside through the flooring, which is why the floor level is made raised in relation to the soil. Without external thermal insulation, the basement will be constantly damp.

Insulation of the foundation in the house prevents the appearance of mold, mildew

Insulation of the foundation in the house prevents the appearance of mold, mildew

In addition, the cold floor in the house reduces the level of comfort. The main advantages of thermal insulation:

- Heat losses in the building are significantly reduced, therefore, the financial costs of the family budget for heating are reduced.

- The effect of the forces of heaving of the earth is equalized.

- Prevents mold and condensation.

- The service life of the foundation is increased.

- The waterproofing is protected from mechanical damage.

- It is much easier to get rid of cold bridges.

Read also: insulating the basement base from the outside: how to do the installation yourself.

How to insulate the foundation yourself, this video will tell you:

2> Slab foundation

Another common type of shallow foundation is slab. A flat reinforced base is made over the entire plane of the surface on which the building structure will be located. This is an excellent option for protection against soil heaving and an ideal surface for further work.

There are also options for insulating a tiled foundation. It is possible to carry out basement insulation, while the plate is located on the heat insulator. But for residential buildings, it is preferable to place the insulating layer not under the foundation, but under the screed. Any material from the simplest foam to extruded polystyrene is suitable here as a heater. A layer of thermal insulation with a thickness of 50-100 mm must be applied to the ends of the slab.

There are also options for insulating a tiled foundation. It is possible to carry out basement insulation, while the plate is located on the heat insulator. But for residential buildings, it is preferable to place the insulating layer not under the foundation, but under the screed. Any material from the simplest foam to extruded polystyrene is suitable here as a heater. A layer of thermal insulation with a thickness of 50-100 mm must be applied to the ends of the slab.

It is possible to insulate the slab foundation from the outside only at the first stages of construction work. If the builders miss this moment, the situation can only be corrected by internal insulation.

A logical continuation will be the laying of insulation under the blind area, which is created around the building and will create a barrier to freezing of the walls and protect against frost heaving of the soil.

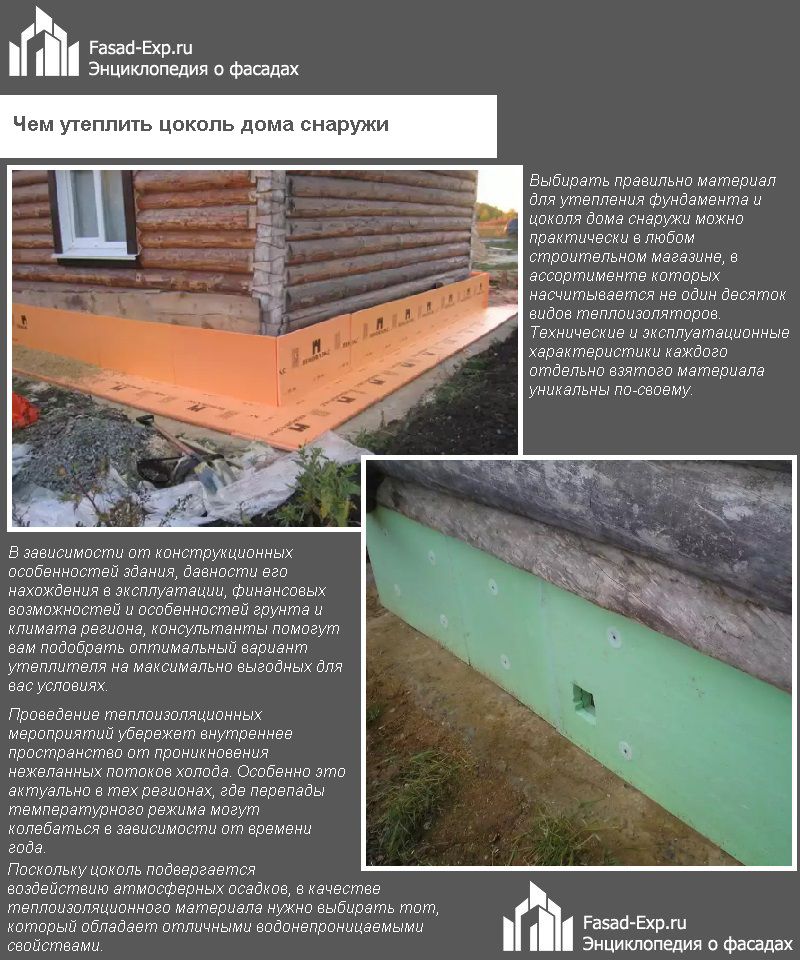

The choice of insulation for the basement

Among the wide variety of modern heaters, only polymer-based plate and spray materials fully meet the above requirements. Let's consider their characteristics in more detail.

Expanded polystyrene foam

Expanded polystyrene foam

Warming with expanded polystyrene

Expanded polystyrene (polystyrene) has been used as a heater for a long time, and still does not give up its positions. It retains heat excellently, does not accumulate moisture, is easy to cut and is lightweight for effortless installation. In addition, polystyrene has the lowest cost among other polymeric heaters, and this is a weighty argument in its favor for thermal insulation of large areas or a limited budget.

Insulation of the basement with foam

To insulate the basement, it is necessary to choose PSB-S 25 or PSB-S 35 foam plastic, which is characterized by increased density and resistance to mechanical stress. The thickness of the slabs varies between 20-100 mm, and depending on climatic conditions, the insulation can be laid in 1 or 2 layers. The material withstands temperature drops from -60 ° C to + 80 ° C without changing its characteristics, so it is not afraid of the most severe frosts and summer heat. The service life, on average, is 25 years, and with a high-quality arrangement of the heat-insulating pie, it will be 10 years longer.

Styrofoam characteristics

Despite all the advantages, foam plastic also has disadvantages: it has low bending strength, that is, it is quite fragile, and is often damaged by rodents.

Mice gnaw through the insulation

In addition, in the absence of waterproofing, moisture penetrates into the upper layers of the material and, freezing, provokes crumbling of the slabs.

Extruded polystyrene foam

Extruded polystyrene foam

EPPS has a denser structure than foam, and the size of its cells does not exceed 1 mm. This results in almost zero water absorption and greater mechanical strength. Extruded polystyrene foam is also more resistant to chemical attack, microorganisms, shrinkage deformations. Due to its low vapor permeability, this insulation is not recommended for use on wooden surfaces, but it is ideal for thermal insulation of plinths.

Penoplex

EPS is in high demand, the most popular are Penoplex, TechnoNIKOL XPS, Styrofoam, TEPLEX, URSA XPS heaters. They are produced in slabs of various thicknesses and densities, standard sizes - 1200x600 mm and 2400x600 mm. The material can withstand temperatures from -50 to + 75 ° C without loss of characteristics, is easy to assemble and lasts for about 50 years, subject to the laying technology.

TechnoNICOL extruded polystyrene foam

Thermal insulation Ursa XPS

The disadvantages include the flammability of the insulation - almost all EPPS brands have a flammability class G3 and G4. When melted, the material releases toxic substances.

Penoplex burning

Another disadvantage is the high cost. However, properly executed thermal insulation quickly pays for all the costs with the beginning of the heating season.

Sprayed insulation

Insulation of the PPU base

Polyurethane foam is at the same time heat, sound and waterproofing of a house. It is suitable for insulating all parts of a building, from roof to foundation, and has excellent adhesion to all types of substrates. Its main advantage is the absence of seams, since a continuous coating is formed during spraying, strong and durable.

Seamless insulation of the base

The insulation process takes very little time, the material hardens in seconds and you can immediately start finishing.

The only difficulty is that a special installation and skills to work with it are required to apply the insulation. The services of a specialist, like renting an installation, are not cheap, but if you take into account the durability of such thermal insulation, then there is still a benefit. A layer of polyurethane foam with a thickness of 50 mm at a density of 36 kg / m3 replaces an EPSP layer with a thickness of 120 mm, and it lasts at least 50 years.

PPU spraying

External insulation of the foundation and basement