Factors affecting the durability of screw piles

Advertising assures that the foundation on screw piles can last at least a century. Is this really so, or is this just another trick of marketers? Practice shows that this is quite possible, because some of the lighthouses erected under Mitchell are still standing. However, we are more interested in the fate not of some lighthouse in distant Europe, but of a small country house somewhere in the Moscow region, in the Urals or on the banks of the Yenisei. How long will it stand, being erected on a foundation of screw piles, produced not somewhere and once, but here and now?

On the basis of experimental data, the service life of steel screw piles in soils with different electrical resistance was estimated. According to these estimates, in soils with low corrosiveness (for example, dry shale or dry sand), piles made of non-galvanized metal will last at least 300 years, and those of metal with a protective coating - 800 years or more. Impressive, isn't it? However, this is a soil that is ideal in terms of its ability (or rather inability) to corrode metal.

Consider another limiting option for comparison. In soils with very high corrosive activity (sea soil, silt, wet clay, peat), the average predicted service life of a steel screw pile is only 30 years (if the pile is made of galvanized metal, this figure will increase to 70-75 years).

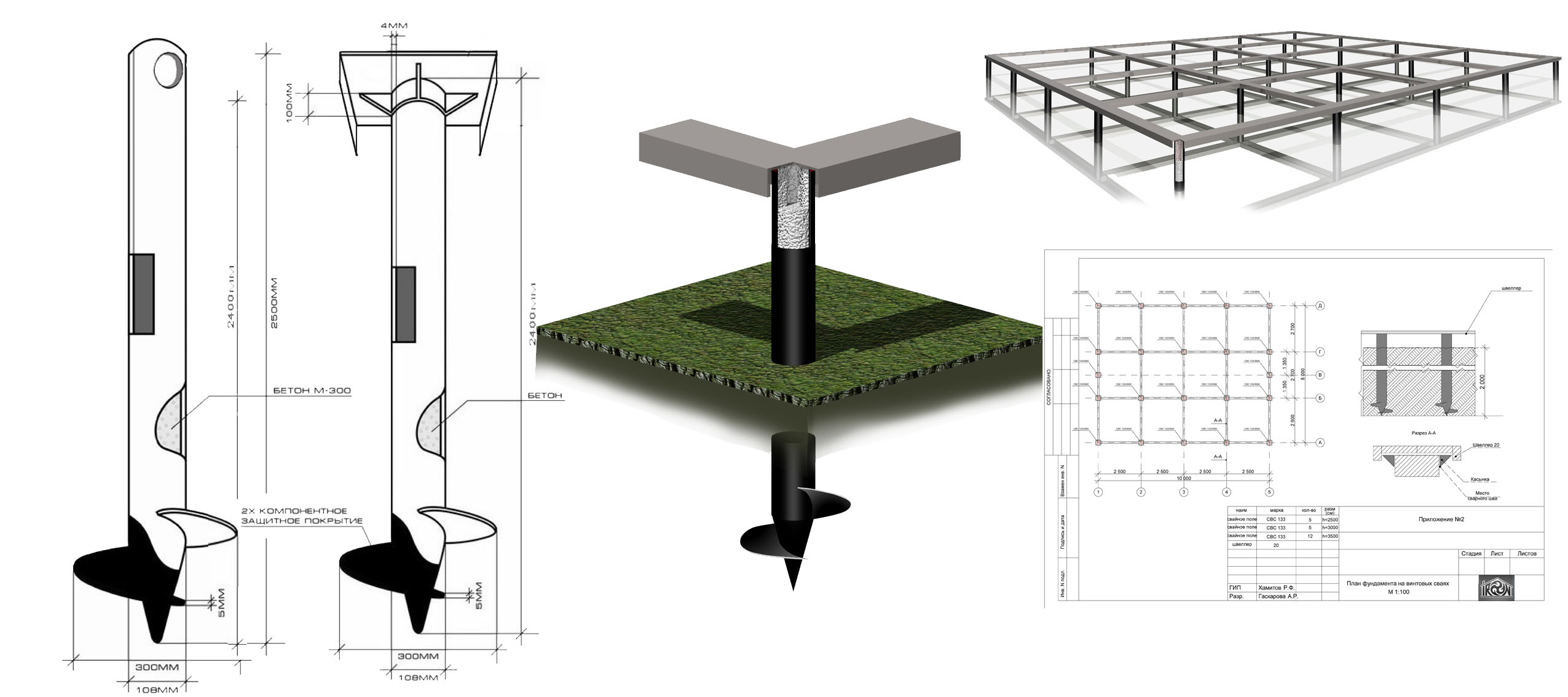

One important caveat should be made. When carrying out all these calculations, it was assumed that the pile was produced in accordance with the ICC AC358 standard used in the West, i.e. the wall thickness of its trunk is 8 mm. But it is almost impossible to find screw piles made of hot-rolled steel pipes with such a wall thickness on the Russian market. How long will the "standard" of domestic production hold out in an aggressive environment, i.e. a pile made of a welded pipe with a wall thickness of 3-4 mm - no one knows, but clearly significantly less than 30 (75) years.

From all of the above, it follows that the advertised 100 years of foundation service on screw piles are nothing more than empty words. Piles can last much more and much less - it all depends on the quality of the products and operating conditions, which is not said in the advertisement.

In general, the service life of screw piles depends on three main parameters:

- the thickness of the steel used to make the trunk and blades of the pile,

- the thickness and quality of the protective anti-corrosion coating,

- chemical activity of the soil in this area.

Without knowing these characteristics of piles and operating conditions, one cannot even make assumptions about how long they will last.

The widespread practice of welding screw piles with bundles of metal channels or corners, which is widespread among our builders, also contributes to a decrease in the service life of screw piles. Of course, the arrangement of such ties between the piles is justified when installing the foundation in the ground with weak lateral support. However, the connection of steel piles with conductive bridges leads to an acceleration of electrochemical corrosion of the metal.

In order to avoid the occurrence of stray currents that contribute to the acceleration of corrosion processes, steel piles should not have a galvanic connection with each other, as well as with other building elements made of steel. To connect the piles into a single system, a wooden strapping or metal strapping should be used, the elements of which are connected to the piles by means of clamps isolated from the piles with a dielectric material.

That's actually all we wanted to tell you about today.Now you know all the pros and cons of screw piles and, we hope, have understood the main idea that we were trying to convey to you. Screw piles are an excellent choice for creating a foundation, but they are not always and everywhere possible. Only a professional can determine the admissibility of using screw piles in each specific case. Believe me, the cost of hiring a specialist is incomparably less than the cost of eliminating mistakes made in the process of designing and building a foundation.

Disadvantages of the foundation on screw piles

The use of screw piles has a number of limitations, which, unfortunately, many manufacturers try to keep silent about. In conditions when companies involved in the installation of foundations easily violate technological standards, you, as a customer, need to have at least a general idea of when it is undesirable or completely unacceptable to use screw piles.

Impossible to use in areas with seismic activity

The erection of structures on foundations of screw piles is allowed only in areas with absent or, in the limit, with moderate seismic activity.

Impossibility to use in soils causing rapid metal corrosion

Steel screw piles should not be used in soils with an electrical resistance of less than 10 Ohm * m, in soils with a pH of less than 5.5, or in soils with a high content of organic compounds. The reason for these limitations is the high rate of electrochemical corrosion of steel under these conditions. A responsible developer, who is not indifferent to the issue of the durability of the structure he is building, is simply obliged to determine all the necessary soil characteristics at a given construction site before deciding to use steel screw piles. If it is not possible to determine the aggressiveness of the soil, one should adhere to the requirements adopted for piles installed in soils with very high corrosive activity.

Burial of screw piles into rocky ground is not allowed

Slag dumps and landfills for construction waste can be attributed to the same category of soils. Any solid inclusions can damage the blades or even the screw pile shaft during installation.

Plinth installation

Experts recommend not to neglect the device of the false base. It performs not so much an aesthetic role as a protective one. The space between the screw piles in the foundation must be closed from animals, snow, water, debris. The appearance and installation of the base depends on the selected material. The perimeter can be finished with corrugated board, vinyl or metal siding, brick, decorative plaster.

In some cases, the base is additionally insulated. This is necessary if the flooring of the house does not have high-quality insulation. Heat insulators for the pile-screw base must be rigid (with a density higher than 50 kg / m2). Most often, foam or extruded polystyrene foam is chosen.

Selection of pile parameters

When choosing screw piles, you need to consider everything:

- Dimensions and material of construction.

- Foundation load.

- The pile must be made with high quality and using quality materials.

- Anti-corrosion treatment is required.

- The tip, blade must be securely welded to the barrel (pipe).

- The minimum pipe wall thickness is at least 3.5 mm. As a rule, a maximum thickness of 5 mm is applied.

The pile length depends on the following factors:

- The type of soil.

- Freezing depth.

- The level of the solid formation.

The pipe for piles can be either solid-drawn or with a seam. The former are noticeably more expensive.

The pile diameter is selected based on the load to which it will be subjected. The most common piles are 57-133 mm. When building the foundation for a small frame house, as a rule, a diameter of 89 mm is used. The bearing capacity of such piles is 4000-5000 kg.

Large two-story houses are placed on 108 mm piles, the bearing capacity of which is 5000-9000 kg. with a pile weight of 30 kg. (2.5 meters).

With an uneven building site, piles are combined - the diameter and length may be different.

The correct selection of piles is the key to the reliability, stability and durability of the foundation. For this, all of the above parameters must be taken into account.

Pile material

The correct selection of the pile material is no less important - it is determined even during design, taking into account the expected load. For this, the data obtained in the study of the anticorrosive activity of soil layers are used.

Based on this, the thickness of the metal of the support blades is selected.

Blades made of metal up to 5 mm. used exclusively for light buildings. If it is massive, then the blade should not be thinner than 6 mm.

After the above studies have been carried out, you need to select the steel grade for the manufactured products. It directly depends on the chemical aggressiveness of the soil:

- Weak. It is enough to use steel Art. 3.

- Average. More expensive steel is already suitable here - Art. twenty.

- Strong. 09G2S and 30XMA are suitable here.

Anti-corrosion coating

Considering that the supports will be in a humid aggressive environment (soil), you need to take care of the metal's corrosion protection. Moreover, this coating should not be broken when screwing them in.

The compositions can be different - it all depends on the budget of the owner of the future home.

The simplest method is to cover the metal with two layers of anti-rust primer, which is done in two layers with drying after each according to the attached instructions. You can apply, for example, ship paint.

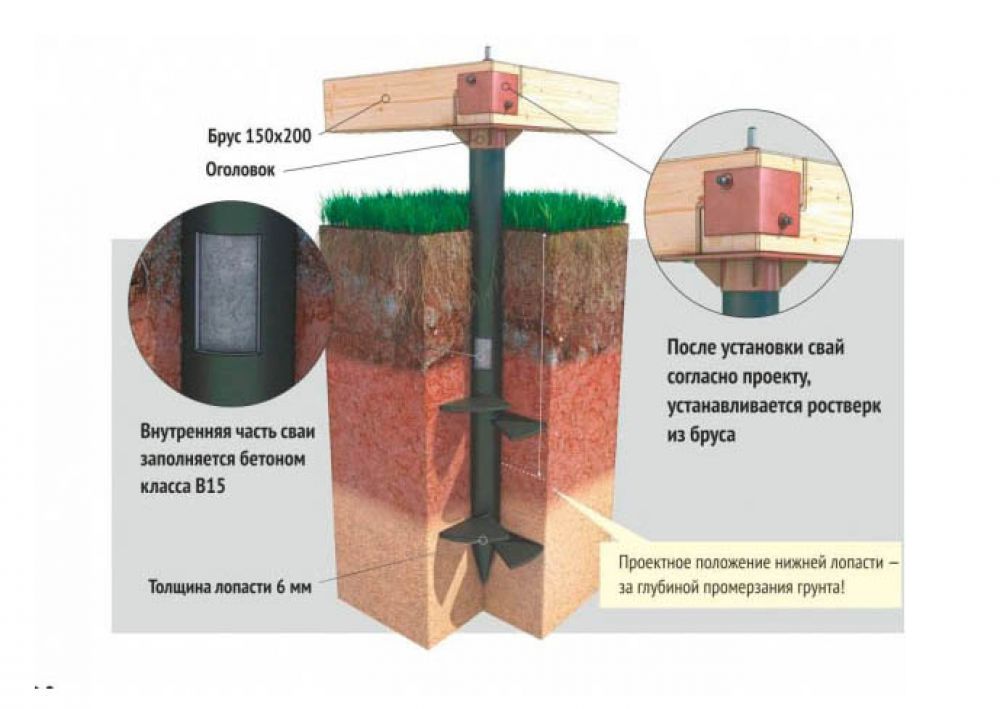

After the support is already screwed in, concrete must be poured inside it. This gives the following:

- Reduces corrosion - there is no condensation inside the barrel.

- Makes both the pile itself stiffer and the entire pile structure.

After all the piles are leveled by cutting with a grinder, you can weld the heads - the upper ends of the supports.

Homemade piles

For a 4x6 m bathhouse with a terrace, you will need about 20 piles. For the money - 40,000 rubles. the cheapest, this is not counting the grillage strapping. A fairly experienced home-builder will immediately realize that making them on their own, even if they require a lot of work, will cost at least three times cheaper, only a grinder and a welding machine are needed: on common soils in the middle lane for a disposable pile, a massive cast tip with a thick screw is not required.

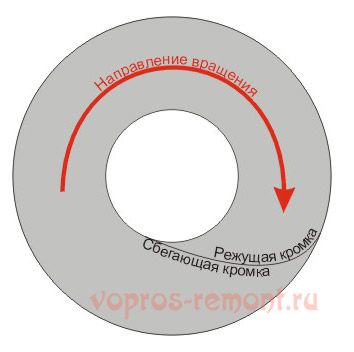

Indeed, screw piles for light soils up to 4-6 m long can be made by yourself without complicated calculations and calculations. For a bathhouse, a barn or a fence, this will be enough. For the sake of simplicity, let's take a pile with a single-turn screw located entirely on the trunk; its drawing indicating the required proportions is shown in Fig. on right. Pipes do not have to be taken from the standard range of pile diameters, any available will go; on fence posts - from 60 mm to the outside for picket or mesh fences or from 80 mm for solid wooden, profiled sheet or forged fences. Metal for the screw - steel from 4 mm thick.

Single-turn pile screw pattern

How to cut a metal ring for a screw is shown in fig. left. The cutting line should smoothly pass from the tangent to the inner diameter of the ring to the same to the outer one. Then the cutting edge will be convex and easier to go into the ground. And the "horn" of the running edge will press the loosened soil against the pile shaft, to some extent compacting it. It is advisable to sharpen the cutting edge with a simple wedge.

When stretched into a spiral, the inner diameter of the ring will decrease. With the screw pitch indicated in the drawing above, it must be increased in the workpiece by 10%, plus 3-4 mm of technological margin. For example, for the most common 108 mm piles we get 121-122 mm. Piles are assembled together, the assembly technology is as follows:

- Prepare a screw pattern;

- Put it loosely on the pipe;

- At the end of the pipe, triangular scallops are cut out with a grinder, 3-6 depending on the diameter of the pipe;

- With a sledgehammer, bring them into a cone and boil the joints;

- The blank of the screw is brought to the resulting tip and the inner edge of the cutting edge is welded to the pile shaft;

- Use a pry bar to stretch the screw blank into a spiral until its inner edge rests on the pipe. At the same time, the pitch of the screw will "play around", but its value is not critical;

- Holding the screw with a pry bar, grab the inner edge of the running edge;

- The entire inner edge of the propeller blade is welded.

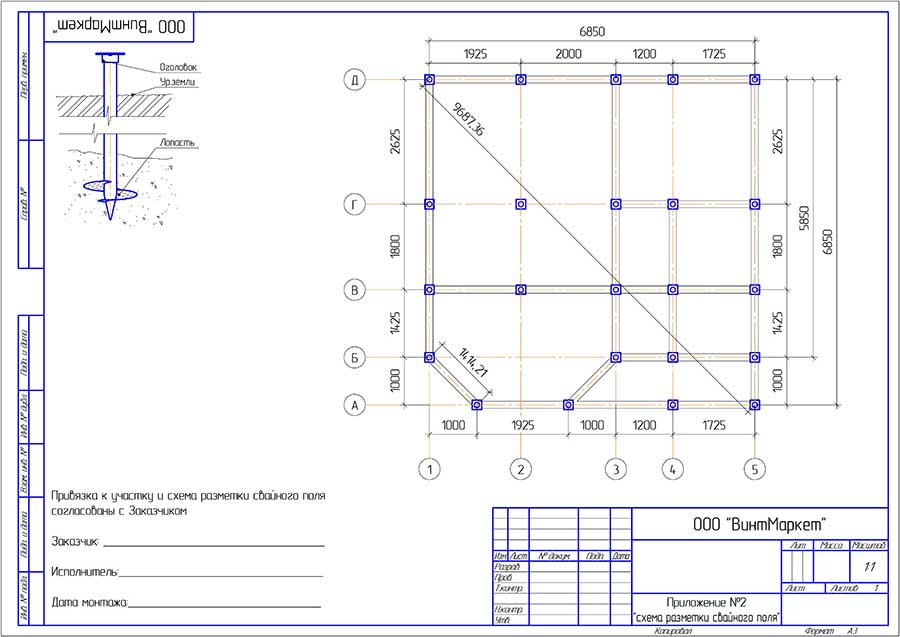

Design stages

The first stage of any structure is design. It determines the implementation of the structure, as well as the quantitative indicators of the materials used, financial investments, time. If you do not take care of the project first, there are risks of negative consequences. Sometimes they are even associated with the destruction of the house.

Design consists of the following main stages:

- Collection and detailed study of initial data.

- Development of drawings.

- Calculation of the load that will be applied to the foundation.

- Determination of the type of base.

- Calculation of the depth of arrangement of piles, as well as the choice of materials from which they will be made.

- Calculation of the bearing capacity.

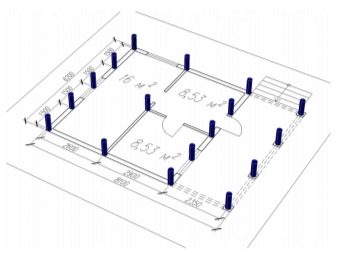

- Determination of the required number of piles, as well as calculating the distance between the supports.

Before proceeding to the design itself, it is necessary to decide what types of piles will be used to create the foundation.

Calculation features

Certain essential criteria must be considered when calculating the pile spacing. This will avoid placing the elements too close, wasting money, and not placing them too far, exposing the foundation and the entire house to the danger of subsidence.

In the calculations of professional builders, the following points are taken into account:

- the mass of the structure (frame, roof, decoration, etc.);

- the mass of internal content (equipment, furniture, things and residents);

- dynamic factors (wind load, weight of snow on the roof in winter);

- bearing capacity of the soil;

- technical parameters of screw piles;

- safety factor.

To determine the payload when calculating the pile spacing, the corresponding SNiP is used. For example, for a one-story residential building, the load is set at 150 kg per 1 sq. m. area. Wind and snow load indicators are reference and are set for each region depending on local weather conditions. The safety factor is on average from 1.1 to 1.25.

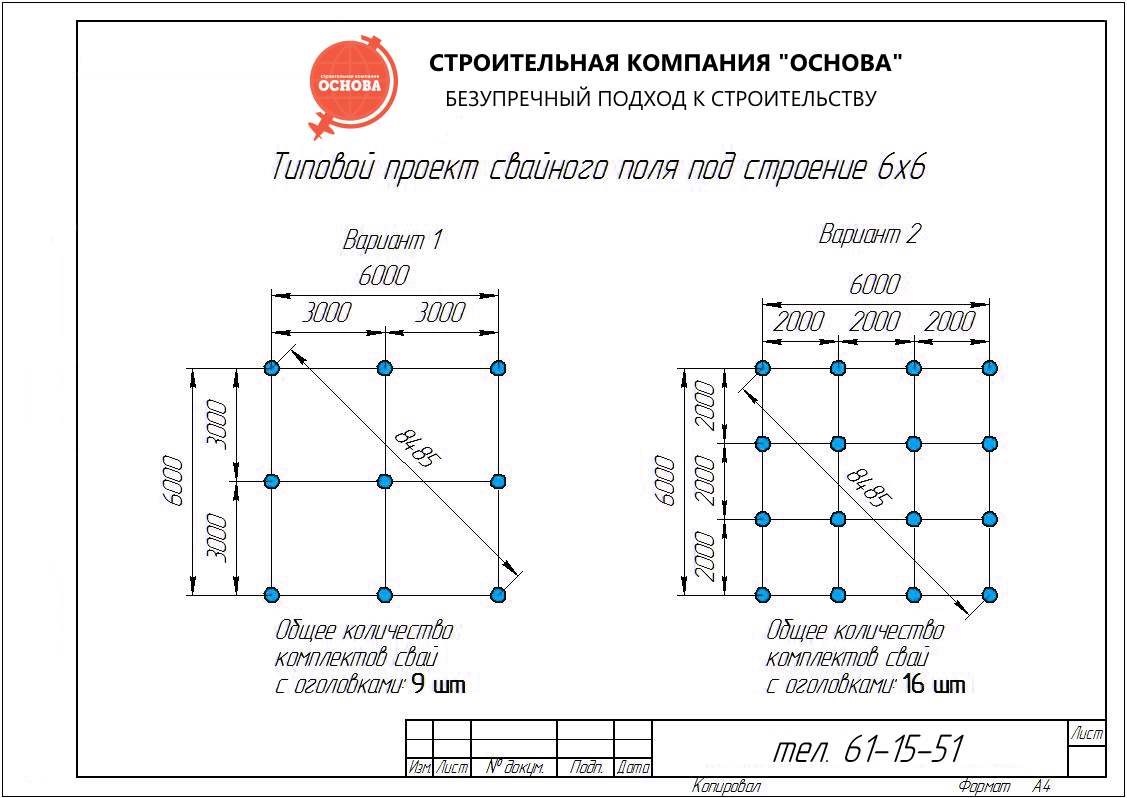

Before planning the location of the piles, it is necessary to calculate their number. It is determined based on the total support load. The total weight is divided by the bearing capacity of one pile, resulting in the exact number of supports. Further, they are placed at equal intervals along the perimeter of the building and under the supporting structures.

The second option is the placement of piles, planned based on the determination of the load per 1 running meter of the grillage. To calculate it, it is necessary to divide the total load of the building by the total length of all load-bearing walls, and then divide by the load-bearing capacity of the selected type of piles. The result is an indicator that determines the required number of supports to maintain 1 meter of the grillage. After that, the required pile spacing is determined, sufficient to support the foundation. This method is used for more massive buildings and is rarely used for low-rise frame houses.

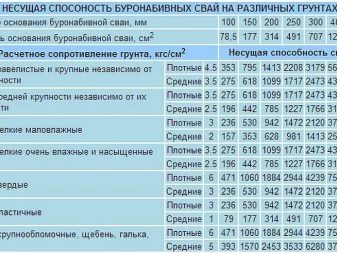

To determine the approximate bearing capacity of a specific type of pile, you need to look at the table with the corresponding indicators. More accurate information used in the final calculations is indicated by the manufacturer in the specification for a specific product. It should be borne in mind that the minimum distance at which piles for a house and a terrace are screwed in is 108 cm.

The actual service life of screw piles and what reduces it

The practical advantages of screw piles, which determine their distribution and widespread use, are possible only if all the rules for the production of supports and their subsequent installation on the ground are observed.

At the same time, there are many factors that significantly reduce the strength of the piles, and, consequently, the efficiency of the entire structure:

- the presence of a large volume of groundwater, which contains various chemically active compounds, leading to the destruction of the pile structure.

- The occurrence of corrosion due to the increased acidity of the soil into which the pile is immersed.

- A large temperature range also leads to the destruction of the integrity of the support.

- Stony soils lead to mechanical damage to the pile when it is immersed in the ground.

- Technological errors that occurred as a result of improper construction planning and negligent performance of work.

Anticorrosive pile processing

The service life of the pile foundation can be significantly reduced if the supports that will underlie the building are damaged during transportation or installation. Therefore, the actual service life of a screw foundation pile is unique in each case.

The main advantages of a foundation built on screw piles

We list the many advantages of screw pile foundations:

- This type of building a base for a home frees construction workers from such time-consuming and hard work as digging earth. Due to its design, a metal pile can independently make its own "path", easily reaching the desired depth. As a rule, a special working technique is used when installing piles. Some homeowners manually screw in a metal pipe in order to save money. It is not difficult, the strength of 2 adults will be enough;

- Lack of preparatory work. There is no need to clear the site itself, level the working platform, remove the topsoil. This type of foundation can be used absolutely on any soil. This fact pleases ecologists most of all, since the construction of a dwelling will not harm nature;

- Installation time is very short, maximum 3 days;

- Financial profitability. There is no need to order screw piles and wait a long time. Due to their popularity, they are always available for sale.

The screw foundation is actively used for the construction of both stationary and temporary structures. In general, the concept of "temporary construction" has nothing to do with flimsy and cramped trailers. The design of the capital and the temporary structure is practically the same. A significant advantage of the temporary construction, which has a screw base, is easy dismantling. Metal piles are easily pulled out of the ground and transported to the next installation site. This advantage is key for geologists, military, field builders, scientists, archaeologists.

The cost of this type of foundation is quite high, but it justifies itself with such qualities as reusability, quick assembly.

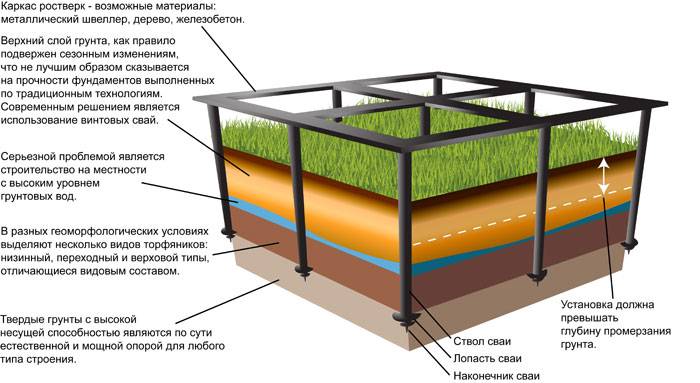

A foundation based on screw piles is most effective under the following conditions:

- Movable unstable type of soil. All unreliable, loose soil, the pile easily passes and is fixed in the hardest place. The pile is designed in such a way that it can easily withstand large lateral loads and gradual ground shifts;

- Rapidly changing climate. Metal tubes can be installed in any weather. They go well into very frozen soil;

- Water in the ground. Piles are perfectly fixed in swampy soil, in the depths of which are often subject to flooding. The screw foundation can be placed even in the middle of the reservoir.

Only rocky soils do not lend themselves to mounting piles, but even here you can find a way out, a solid and perennial rock in itself can serve as a good foundation for a structure.

Frame construction on piles

If you do not take into account the overall dimensions and load parameters, there remains only one type of classification of screw supports, namely, by the type of tip.

- With welded tip.

- With one-piece molded tip.

The first type is an economical solution. The tip is welded to the main bar. The disadvantage of these solutions is that they have only one drilling blade in their design, which means they are less stable than all-metal bearings.

On a note

Cast-tip piles are more durable and less prone to rust formation. Solid piles are produced from grades ST-25 and ST-35 - high quality carbon steels.

The basic depth of the supports in the soil is 1.5-1.8 meters. With such values, the minimum weight that one pile must withstand is 1 ton

Before building a frame house on piles with your own hands, it is necessary to take into account the number of piles in the calculations, while taking into account not only the overall dimensions, but also the approximate weight of the future structure

Frame houses on stilts are of different designs in the photo. It is imperative to take into account specific factors such as the expected snow load on the roof, soil characteristics at the points of screwing in the piles.

Frame with panoramic windows.

Distance between supports

During construction, it is important to observe the distance between the piles for the frame house, indicated in the project. An even distribution of supports around the perimeter will be a technological solution, since different parts of the house carry different loads on the foundation

For example: the part of the house in which the stove is located is much heavier than the space with the storeroom or utility rooms.

Building with a bay window.

The construction practice made it possible to calculate the average number of piles for frame houses of various sizes:

- for houses 6x6 meters - 9 piles;

- for home 8x8 meters - from 12 to 16 piles;

- for houses of 10x10 meters - at least 23-25 piles.

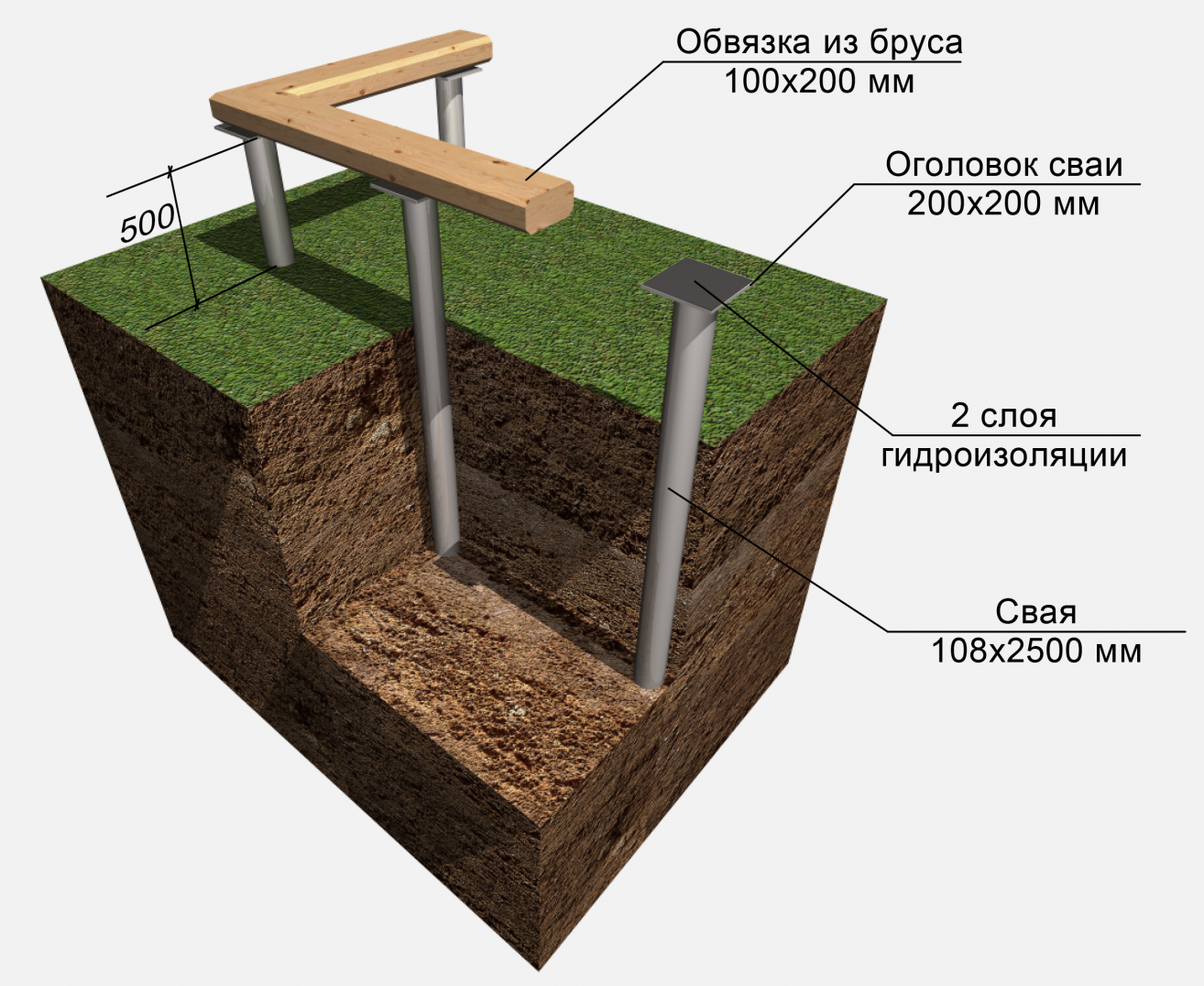

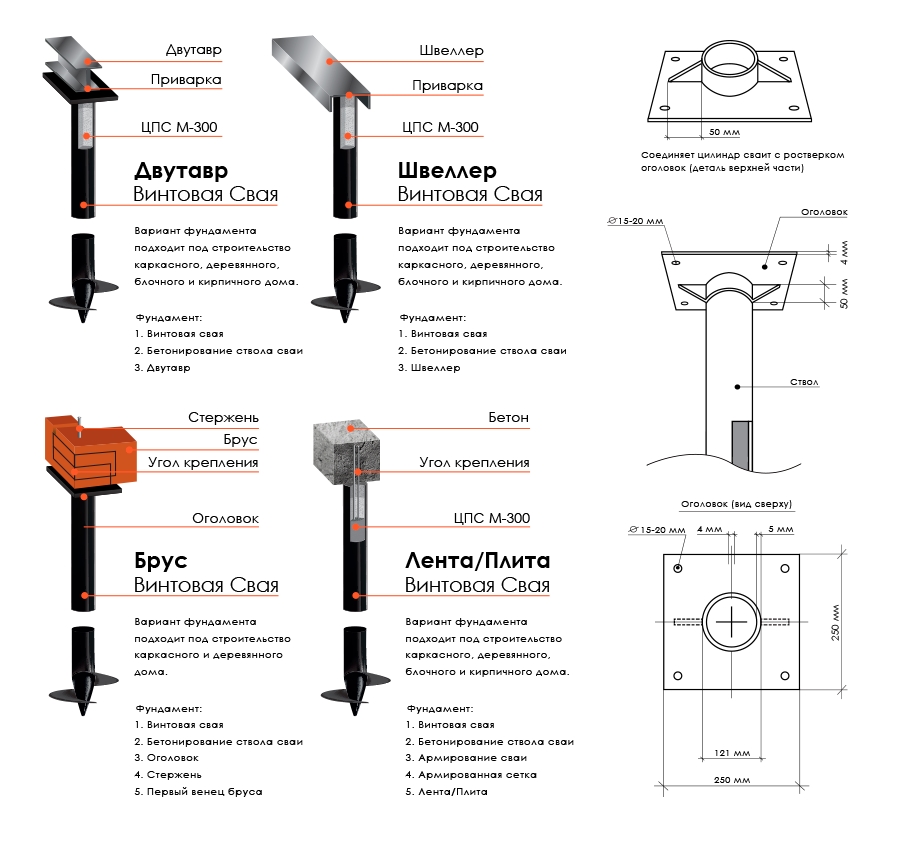

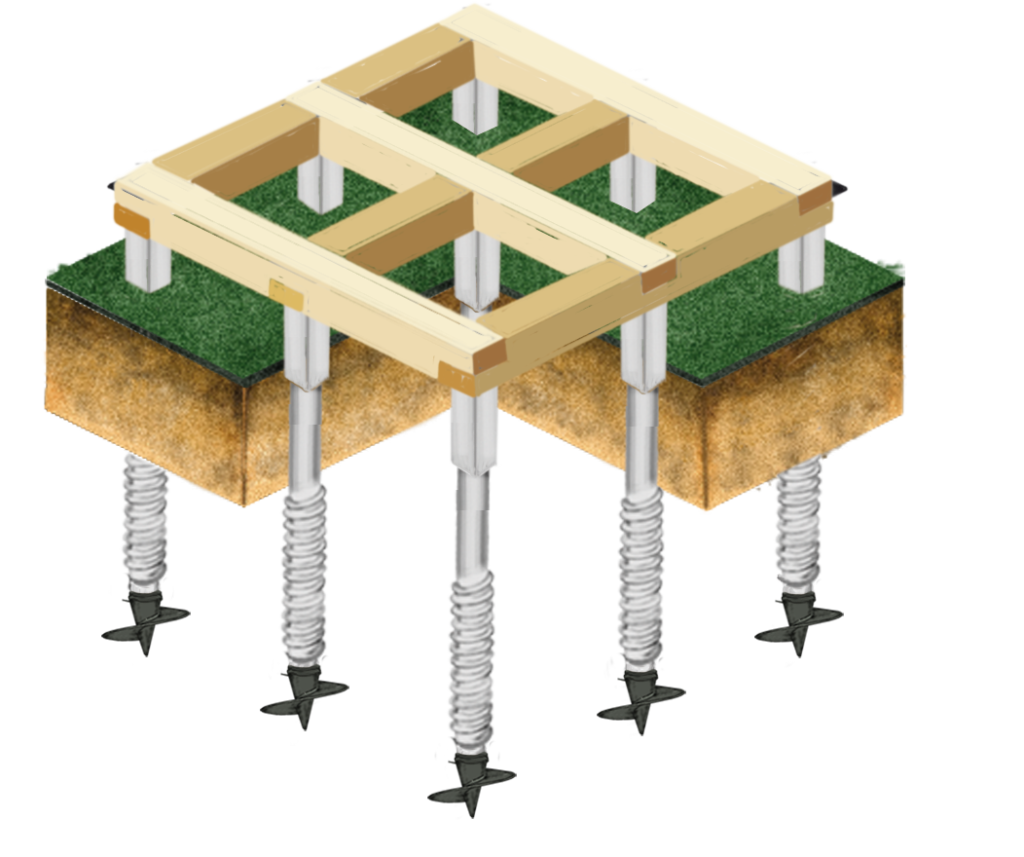

Supports strapping

After plunging the piles into the ground, it is necessary to connect their upper platforms to each other - to carry out the so-called strapping. The strapping will allow you to form a foundation grillage and subsequently mount the cake of the floor of a frame house on piles. The strapping can be carried out using metal beams, wooden beams, I-beams - synthetic perforated material.

Strapping with a bar on a pile-screw foundation.

A frame house on piles, the video demonstrates the main points that must be taken into account when tying piles with a bar.

The main way is to tie piles with a bar. The strapping bar is impregnated with a special compound, which increases the service life of the bar several times. The beam is laid on the pile heads strictly in the center. The docking of the strapping bar in the corners of the foundation is made in a paw and is additionally fastened with staples.

On a note

In the second version, the strapping of the piles of a frame house is carried out using sections of a profiled pipe. Moreover, the pipe is not laid on the top of the piles, but is attached to the rod itself, thereby acting as a spacer. The strapping elements are attached to the piles using anchor bolts or rigid metal pins.

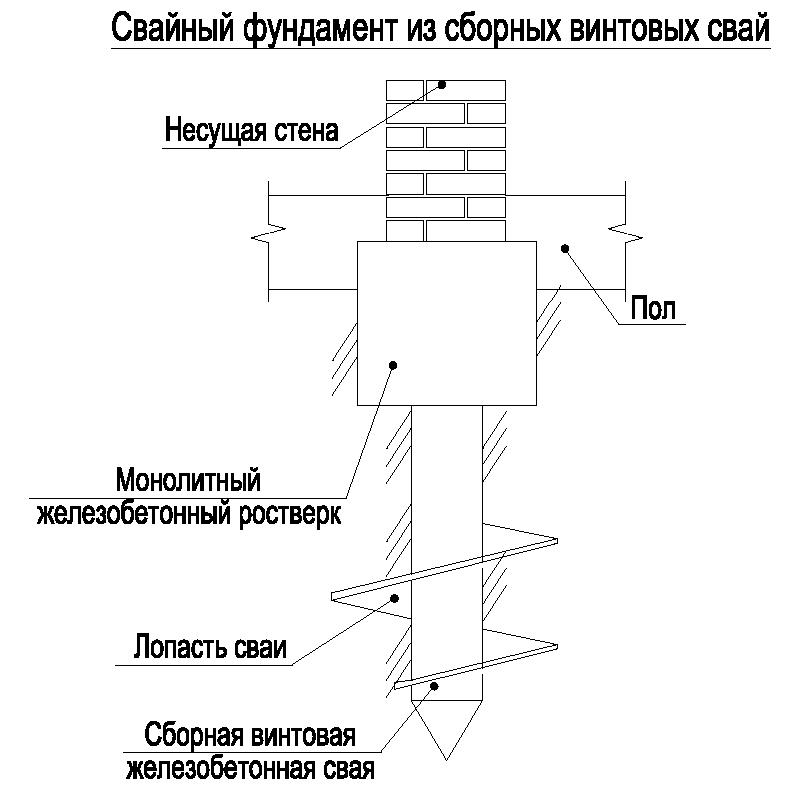

Types of pile foundations

The pile foundation is a field of individual piles. Their number, the distance between the piles, the method of distribution and strapping are calculated individually for each house project. At the top, each pile can have a small platform or rebar. This is necessary for the subsequent installation of the piping.

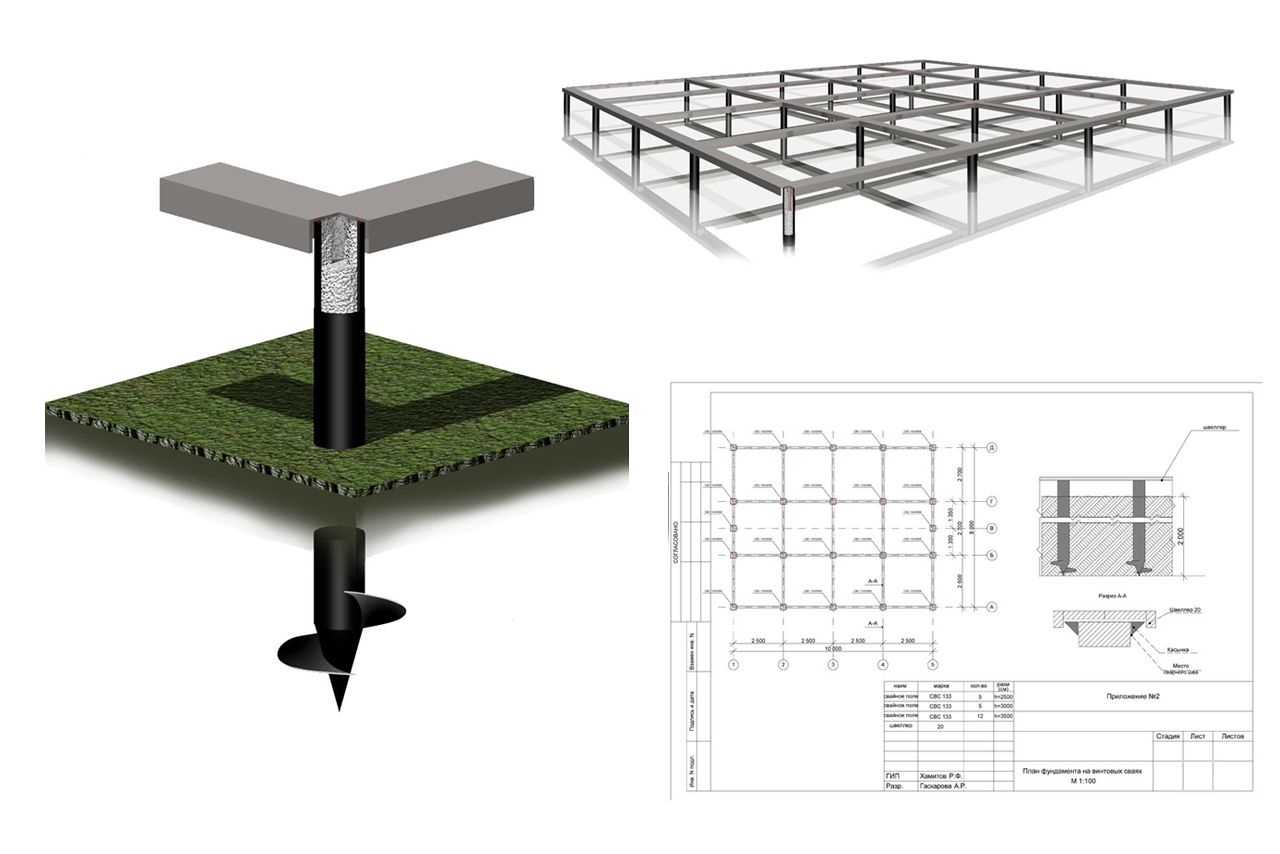

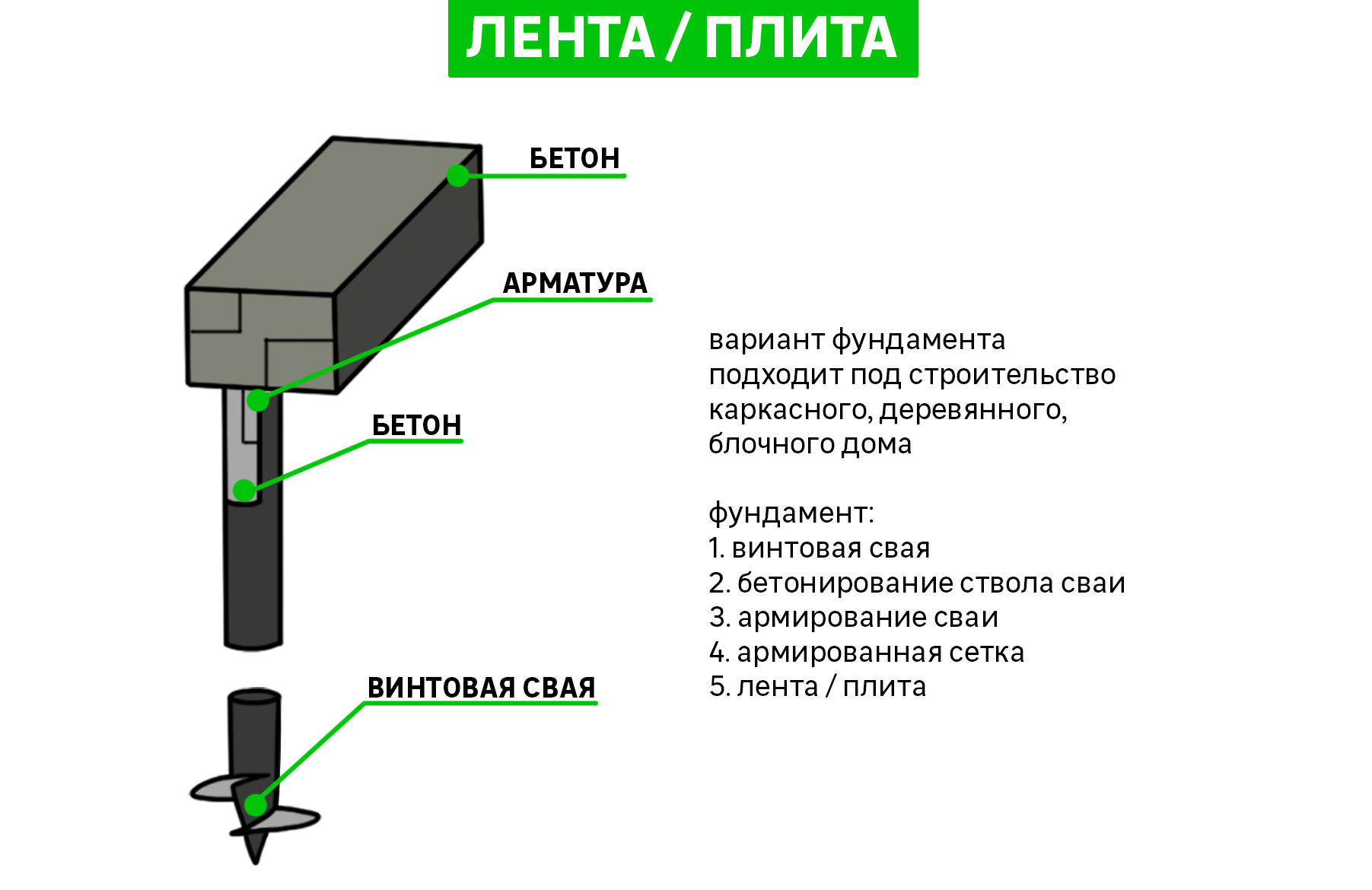

Foundation on screw piles

Screw piles are the undisputed leader in the field of private construction. Most of the frame projects are based on a foundation on screw piles. The pile is a metal pipe, pointed at the bottom and with a welded helical blade.

In fact, this is nothing more than a large self-tapping screw, only without a cap. Such a pile is simply screwed into the ground.For this, construction equipment can be used, or it is possible to equip the pile foundation with your own hands. One of the most budgetary and labor-intensive technologies.

Finished foundation on screw piles

Screw piles can be combined. If the classical screw pile is a hollow metal pipe, then the combined one involves filling the void with concrete or reinforced concrete mortar. The pluses of the foundation on screw piles include its low cost, the ability to install without the use of heavy equipment, use in permafrost conditions and on swampy soils.

The disadvantages of such a foundation are fragility, according to reviews, it can stand for about 70 years. Another drawback is that the foundation on screw piles without a grillage can only withstand lightweight structures, for example, wooden or frame houses. For stone, brick or block buildings, it is better to use other, more solid foundations.

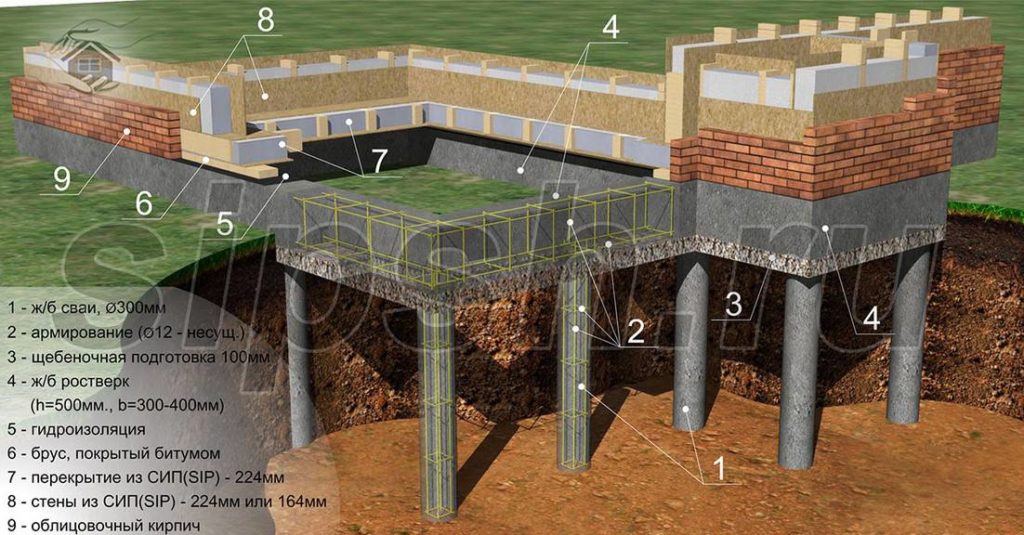

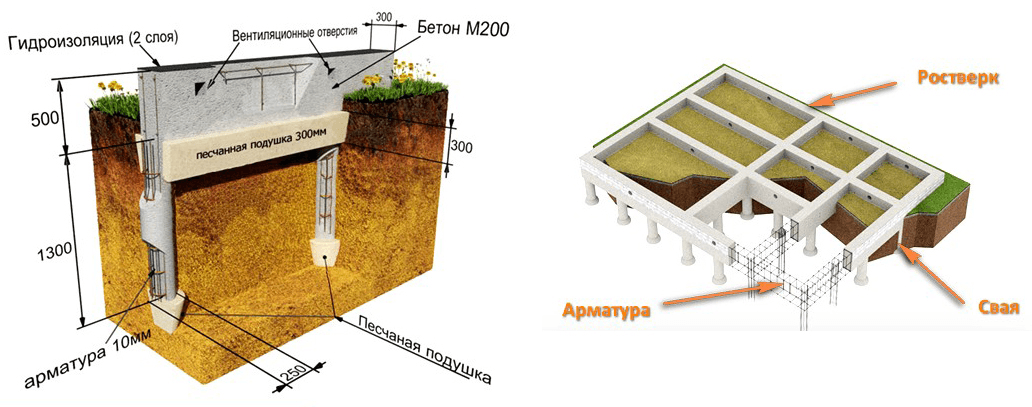

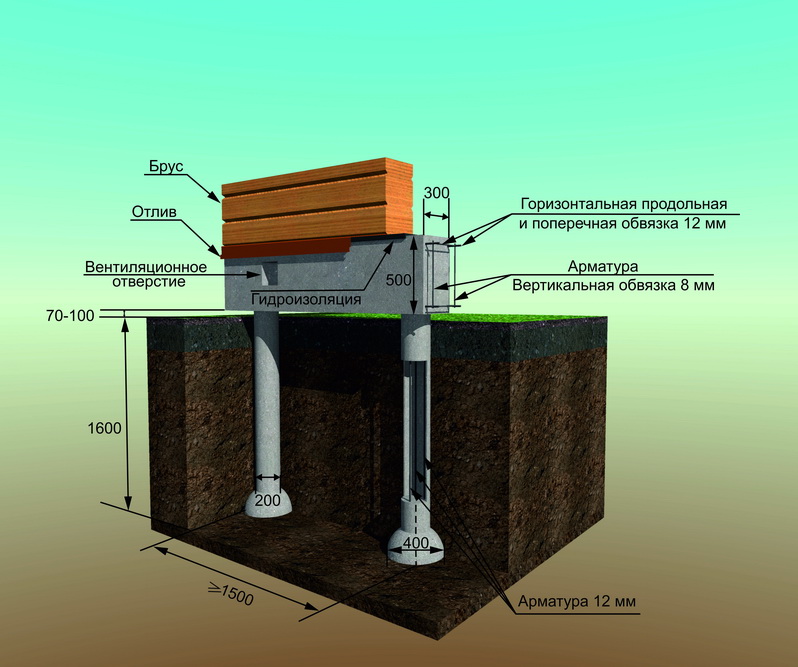

Foundation on bored piles

Bored piles are a type of pile that is made on site using concrete or reinforced concrete mortar and reinforcement. To begin with, wells are drilled on the construction field, marked out according to the drawing. Vertical shafts are reinforced with reinforcement and then filled with mortar.

Depending on the type of soil on which the foundation is being installed on bored piles, various casing materials can be used.

For example, in the case of loose and sandy soils, a special hollow pipe can be lowered into the shaft. The technology allows the wall to be insulated with roofing felt, roofing felt, and plastic wrap. Depending on the material used, the casing can be removed after pouring, or it can be left in the mine, performing the function of waterproofing.

Installation of bored piles

Piles made according to the latter scheme, using casing and insulating materials, last longer than simple bored piles.

The advantages of such a foundation are ease of installation. One of the varieties of bored foundation is columnar. Such a foundation can be equipped without the use of special equipment. Dig or drill holes for the piles by hand, make a mortar yourself and pour the base.

Another advantage is the ability to put the house even in a place that is hard to reach for technology, almost right next to other buildings.

However, such a foundation will be short-lived and less durable. Without special waterproofing, fill piles quickly collapse. The disadvantages include the impossibility of their operation in regions where horizontal ground movements are observed.

Scheme for the construction of a bored pile foundation

Disadvantages of a pile foundation

- Pile-screw foundations are applicable only for light buildings, for example, a country house.

- Despite the protective zinc coating, screw piles, even those treated with anti-corrosion protective agents, are easily corroded. This happens especially quickly in the places of welding, as well as in the underground part of the piles. Therefore, when choosing piles, it is necessary to give preference to solid piles without welded seams. This small detail will significantly extend the life of the piles.

- The disadvantage of the screw pile foundation is the rather high final price of the house. Yes, metal piles can be purchased inexpensively. Installation work will not be so expensive either. But if a solid house is being built, then such a foundation entails additional costs for the creation and insulation of the basement and the external decoration of the basement, because in our case it simply does not exist. And this threatens in the conditions of our winter frosts with the fact that the floor in the house will constantly be very cold. It's the same with communications. In an uninsulated room, the water in the pipes will constantly freeze and only well-organized insulation will eliminate this problem.

The sewerage system in winter will also not be able to function normally.

- Without insulation, the soil under the house will also freeze very strongly and, thus, the possibility of using an underground room for storing vegetables grown in your courtyard will be lost.

- The stilt house has one distinctive feature. It does not sit down, as it happens when a conventional strip foundation is destroyed, but, on the contrary, rises. After all, the soil pushes the incorrectly installed piles out of the ground.