Production of houses from block building materials

There are two technologies for erecting buildings from expanded clay concrete - monolithic filling and in the form of blocks. The first method is too expensive and not convenient to use, therefore it is not used in private construction. Block elements are in demand among developers, so they should be considered in more detail.

Block making

For the preparation of porous block building materials, a solution is used in a ratio of 1: 2: 3 - cement (it is better to use the M400 brand, which has good binding qualities), sand, expanded clay.

The production of porous bricks has a number of nuances:

- expanded clay has properties to absorb moisture well. When producing blocks, you should first make a small batch of the solution in order to determine the required amount of water to achieve the optimal consistency of the mixture;

- one of the peculiarities of porous stones is that they are light and float to the surface of the water. The solution should be mixed thoroughly so that all the granules are well covered with a sand-cement slurry;

- to perform the elements of the blocks, a fine-grained breed is used;

- the molded material hardens within 3 weeks.

When the porous building material dries well, you can move on to laying out the walls.

Features of buildings made of expanded clay concrete

The inexpensive cost of the material provides a reduction in the cost of constructing low-rise buildings and high-rise buildings with a monolithic-frame structure. Expanded clay concrete is chosen due to its advantages:

- low thermal conductivity, thanks to which you can build thick wall structures that do not create stress on the sole;

- vapor permeability, contributing to a comfortable microclimate inside the home;

- good soundproofing and soundproofing performance;

- the strength of clay elements, excluding the load on the base;

- environmental safety, fire resistance and durability.

The use of expanded clay concrete material reduces the cost of building residential buildings. Blocks are used for finishing facades, interior work and organizing a fundamental structure.

Cons of houses made of expanded clay concrete blocks

- The porosity of expanded clay concrete blocks is both a plus and, in turn, a minus for the house. Because of it, they absorb water very well into themselves, and when the temperature drops below zero, this water begins to crystallize, destroying the structure of the block, thereby harming the whole house as a whole. Therefore, you should not use expanded clay concrete blocks without additional protection from environmental influences, facing bricks, for example. Almost all materials of this type suffer from this disadvantage.

- Due to its small size, there will be a lot of seams in the masonry, which, in turn, very well let the cold inside the house. Therefore, additional insulation of the walls from the outside is indispensable. But this is a minus of most wall materials.

- If we compare a house made of expanded clay concrete blocks and, say, from gas silicate blocks, then the second one will have less thermal conductivity, with the same wall thickness. And this can also be written as a minus.

- Another minor disadvantage is that manufacturers of expanded clay concrete blocks do not have much choice in size, there are only ordinary ordinary 390x190x188mm and half blocks, which differ only in thickness of 90 and 120 mm, respectively. This does not allow you to particularly choose the thickness of the walls of the house, either 19 cm or 39 cm.

Recently, more and more often a marriage appears on the construction market, this applies not only to expanded clay concrete blocks, but, given that these blocks can be made in any "garage", in our case this problem becomes even more urgent, and this is possible set off as cons. To avoid such cases, before buying, it is advisable to come to the place where these blocks are produced, and personally make sure that they are manufactured with exact observance of the technology. Only then will you be 100% secure.

Conclusions and advice on building a house from expanded clay concrete blocks

From all of the above, I think we can conclude that houses made of expanded clay concrete blocks have a right to exist. In such a house it will be possible to live in warmth and comfort, with proper wall insulation. Plus, in general, it will cost you relatively little money, and all the disadvantages inherent in this material can be minimized or even completely nullified, observing the technology and features of the masonry.

Here are some tips from experts to help you avoid blunders:

Do not leave the walls of a house made of expanded clay concrete for a long time without external finishing, as I already said, their structure will collapse, and the strength of the whole house as a whole will largely decrease.

Pay special attention to waterproofing the walls of the house, without proper waterproofing, the walls will get wet in the house, especially the lower outer corners, which is fraught with mold.

Despite the fact that this is an easily accessible material, it is still necessary to calculate the expanded clay concrete blocks at home so as not to overpay for delivery.

In the central and northern regions, you should not use expanded clay concrete blocks to build a house without additional wall insulation. Though they are warm, but not so much.

Although in some cases it is possible to do without an armored belt, all the same, if funds allow, it is better to provide its device over expanded clay concrete walls.

You should not build any foundation from expanded clay concrete blocks, no waterproofing will help you there, blocks in the ground collapse in a very short time

In some cases, they are used to erect a basement, but even then they are full-bodied.

In addition to everything, it is worth noting that a house made of expanded clay concrete blocks becomes a warm and cozy home for you, it is not enough just to find high-quality material, it is necessary to carry out its high-quality installation. Therefore, if you are not able to do it yourself, then you need to hire highly qualified and proven specialists.

The main advantages of houses made of expanded clay concrete blocks

Let's start with the main advantage of houses made of expanded clay concrete blocks - the thermal conductivity of the walls. Houses built from such blocks keep heat inside themselves very well, if, of course, the technology of both production and installation of blocks is followed.

This is due to the porous filler - expanded clay.

The second, but no less important advantage is the low weight of the expanded clay concrete block. In addition to the fact that expanded clay itself is a very light material, hollow claydite concrete blocks additionally have some voids, the size and number of which depends on the manufacturer, and make up about half of the volume

Given this, the walls of the house will be light, which will have a very good effect on the foundation under the house as a whole.

Despite the fact that expanded clay concrete is a relatively light material, most modern and expensive building materials will envy its strength and durability, proven over the years. And do not look at the fact that each block individually looks fragile, and breaks at the slightest fall or impact. In the wall of the house, blocks of expanded clay concrete are so strong that they can withstand almost any load of low-rise construction, be it floor slabs, various kinds of girders, lintels, etc.

One of the most important advantages of houses made of expanded clay concrete blocks is the cost compared to other materials, both the cost of the blocks themselves and their masonry. Thanks to this, such houses will never lose their popularity among developers.

During the operation of the house, if its walls were lined with high-quality material, the appearance of cracks and microcracks in the walls is unlikely, unlike aerated concrete, for example. This is because blocks made of expanded clay concrete are not very susceptible to shrinkage.

The main advantages of operating a house include the fact that the walls of the house, built from expanded clay concrete blocks, do not emit any harmful substances, because all the components from which they are made are environmentally friendly.

Expanded clay has very good soundproofing properties, thus the whole house as a whole will be well insulated from extraneous outside noise (not counting, of course, windows).

Due to their lightness and small size, expanded clay concrete blocks are very easy to assemble, which has a positive effect on the cost of building a house as a whole. By the way, laying walls made of expanded clay concrete blocks is not difficult to do with your own hands.

Plastering a house built of expanded clay concrete blocks, even with an ordinary cement-sand mixture, is a pleasure. The solution sticks to them very well, which not all wall materials can boast of. This will also save a little on finishing work.

The advantage, albeit insignificant, can be attributed to the fact that thanks to a simple and low-cost manufacturing technology, as well as popularity, expanded clay concrete blocks can be purchased in almost every city and even a small village, which will save on delivery.

So we examined the main advantages of houses laid out of expanded clay concrete blocks, as we can see, there are a huge number of them, which makes them very popular. But, as you know, they have not yet come up with an "ideal" material, they all have their disadvantages, and expanded clay concrete is not deprived of them, although he does not have so many of them.

The use of expanded clay concrete for the construction of a block base

The coefficient of hygroscopicity of expanded clay concrete is only 3% of the total mass. For example, the hygroscopicity of ordinary bricks is 6-10%, concrete is up to 15%, and foam and aerated concrete is up to 22%. Accordingly, this material is ideal for prefabricated foundations.

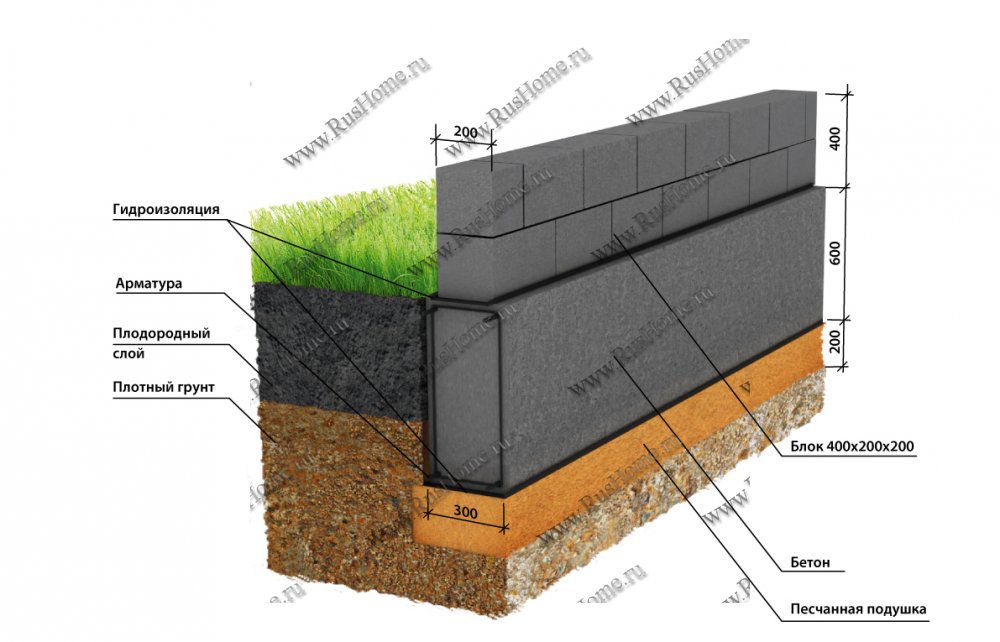

The foundation is made of expanded clay blocks, insulated with foam plastic and lined with bricks

Work on the geodetic reference of the house, soil sampling and the construction of a sand and gravel cushion are carried out by analogy with a flooded foundation. If the soil is sandy, then simply compaction of the bottom of the pit is allowed. The foundation is made in full analogy with the laying of walls from the same material. The blocks are placed on a conventional cement mortar with bandaging of the seams at 0.5 height. The permissible height of such a base should not exceed 5 rows.

Advantages and disadvantages of a strip prefabricated foundation made of expanded clay concrete blocks

Advantages:

- High resistance to groundwater;

- Resistance to sharp, significant and frequent temperature changes. The minimum coefficient of thermal expansion of the entire structure;

- Can be laid on any type of soil;

- High speed of production of works in comparison with pouring;

- The average specific weight of the blocks allows for installation without the use of heavy, specialized construction equipment.

Disadvantages:

- The shrinkage processes in the prefabricated base are more pronounced than in the monolithic foundation;

- A large sample of soil is required.

Such foundations are allowed as a base for a one-story building made of expanded clay concrete with an attic.

The foundation for a one-story house made of expanded clay concrete blocks

Is it possible to lay a foundation of expanded clay concrete blocks for a residential building? Theoretically - no, but in practice you can meet him much more often than you think.

The main problem of the expanded clay block is that it is a relatively light wall stone, and not at all a foundation material with high strength and wear resistance. Here is what the Cheboksary Stroykombinat, a large producer of lightweight aggregate concrete blocks, says about their application:

1.4. Wall blocks made of expanded clay concrete are intended for masonry of external and internal walls of buildings with a relative air humidity of no more than 75% in a non-aggressive environment.

1.5.The use of blocks made of non-hydrophobic expanded clay concrete, as well as blocks with voids for laying walls with a wet mode of premises, as well as in places where reinforced concrete moistening is possible, provided they are reliably protected from moisture by using high-quality steam and waterproofing.

Due to its low weight, a lightweight aggregate concrete foundation from blocks can be built in a short time. The construction technology is quite simple.

Before the start of construction, the site is freed from debris. Then they dig a trench 30-40 cm deep, at the corners of which support pillars are placed. A formwork consisting of reinforcement and wooden boards is placed in the trench. Then expanded clay concrete blocks are laid in the depth of the trench. It is better to lay them in layers, alternating expanded clay concrete with solid bricks. At this stage, it is necessary to take care of waterproofing the foundation - this will significantly extend the life of the entire structure. The expanded clay foundation must be reinforced with an armored belt, which is a tape of reinforced concrete: it is laid in several layers along the block base.

In the video below you can see a real review of the foundation laying from expanded clay concrete blocks.

Calculating the weight of the house

To calculate the weight of a house for choosing the optimal type of foundation, you need to find the area of the building itself, basement and attic floors, roof and multiply by the weight of the selected building materials.

For example, a one-storey house 5 × 8 m with a wall height of 3 m and one inner wall will have an area:

Foundation calculation

To calculate the concrete for pouring a monolithic foundation slab, it is necessary to multiply the building area by the desired foundation thickness, which can be at least 10-15 cm. Therefore, for a house with an area of 40 m², we need at least 400 m³ of concrete for the construction of a slab foundation.

The cross section of the slab will be 0.1 × 0.1 = 0.01 meters. We find the required volume of concrete mix equal to, multiplying the value of the cross-section by the length of the edge of the slab - 47 m, we get:

Briefly about the main

What is the best foundation for a house made of expanded clay concrete blocks? There is no single answer to this question: houses made of the same building materials can be radically different from each other, as well as the opinions of developers about their characteristics, purpose or appearance. One thing is indisputable - the strength of the building depends on the quality of the foundation. For example, full-bodied expanded clay concrete blocks with a strength of M100 and higher, of course, can be used to build the foundation of a small one-story house, provided that a high-quality product was selected and the laying technology was followed. This option is beneficial in terms of budget and time: you do not need to wait for ripening, as is the case with a flooded foundation. Nevertheless, expanded clay wall blocks are categorically not suitable for the foundation when it comes to building a house with several floors - the expanded clay block is simply not designed for such a load, and in this case it is much more profitable to lay a strip foundation or buy FBS blocks and it is safer for residents ...

In addition, at the stage of designing a building and selecting a foundation, it is necessary to take into account such accompanying factors as the quality of the soil, its features, the presence and degree of aggressiveness of groundwater, the climate of the area, the type of building and its purpose. The cost of construction work is also an important factor. Evaluate your requirements and capabilities sensibly, choose trusted manufacturers and suppliers of building materials. Only in this case, the construction will not turn into a disaster, and as a result you will receive a full-fledged house for a comfortable stay.

Construction technologies

So, depending on the type of construction of the house made of expanded clay concrete blocks, a foundation is selected.

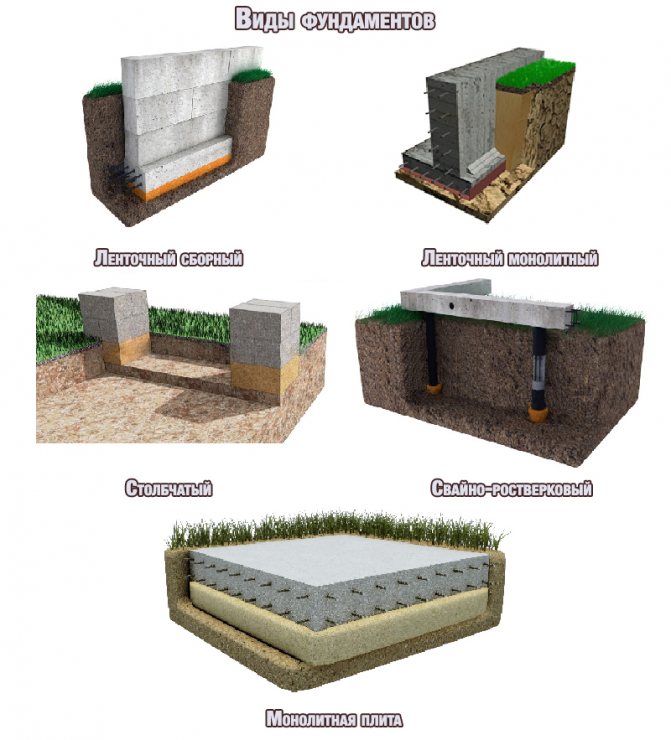

Tape

The strip foundation can be either prefabricated or monolithic

It can be both prefabricated and monolithic. Monolithic has many advantages, since it minimizes the need for the use of special equipment. In this case, the width of the tape should not be less than the thickness of the wall panels to create a solid support and prevent the axis of the blocks and the base from shifting.

The material requirements are as follows:

- concrete grade B20-25;

- reinforcing rods A400;

- bedding from sand of medium fraction;

- provide insulation materials for tape with low or deep immersion.

Columnar base

It can be made of concrete blocks or monolithic. A mandatory grillage is provided, providing an even distribution of the load on all elements.

Slab base

Equipped with reinforced concrete monolithic slabs. For private buildings, slabs with a cross section of up to 300 mm, concrete of class B20-25, reinforcement A400 are taken. Reinforcement cages are required, as well as pouring in one pass, which will increase the reliability of the entire structure.

Piles

To build a house from blocks with your own hands, it is better to choose bored piles

They can be screw or bored. To build a house from blocks with your own hands, it is better to choose bored piles, which increase the strength of the entire structure, however, screw pile elements will reduce earthwork and deepen them much faster and easier. It is imperative to arrange a grillage, which is better made of reinforced concrete, but you can also use an ordinary metal one.

When choosing a foundation for a block structure, it is necessary to very clearly understand the features and capabilities of the soil. Only with correct calculations will it be possible to avoid mistakes and make the foundation really solid. Do not forget about insulating the underside of a house made of blocks, if the choice fell on pile or slab foundations. Experts recommend stopping at the last option, however, tape types of bases can be used, with acceptable soil qualities at the construction site.

Device technology

The foundation for any building is an important part, the construction of which must be taken with the utmost seriousness. To make a supporting structure from expanded clay concrete with your own hands, you need to stock up on strength, time and certain knowledge. You can put KB blocks on a ready-made adhesive solution purchased at a hardware store, or on a mixture of cement, sand, expanded clay and water made with your own hands. Novice developers are advised not to use block masonry, but simply fill the formwork with ready-made mortar. To carry out the work, you will need the following materials and tools:

- reinforcing mesh;

- wooden boards;

- roulette;

- roofing material;

- shovel.

Having drawn a drawing and determining the parameters of the future structure, you need to clear the area of debris and carry out the markup. Next, pegs are put down and a rope is pulled between them. The next stage is digging a trench around the entire perimeter of the future foundation, at least 30 cm deep, and installing wooden formwork. After that, the reinforcing mesh is laid out, fastening it with wire, and the insulating material is laid out along the walls.

Filling and shrinking

Expanded clay concrete is evenly distributed and leveled, not forgetting to vibrate it with reinforcement or a special vibrating device. If you need to lay the blocks, then the masonry starts from the corners, carefully pouring the prepared solution between them. In this case, the armopoyas is laid on top of the laid expanded clay blocks, and the waterproofing is attached to the outer side wall of the foundation tape. In order for the foundation of the building to be strong and serve for many decades, it is necessary to ensure that the newly laid mortar is completely solidified. The design bureau acquires its maximum strength characteristics after 30 days.

Characteristics of expanded clay

Expanded clay block is the end product of processing low-melting clays by firing. As a result, a porous building material is formed, which has a number of unique properties that are in demand in the construction industry.

Material technical qualities

Expanded clay block is characterized by the following indicators:

- high strength - 50-150kgf / cm²;

- good noise and heat insulation. Block walls made of expanded clay concrete do not require additional insulation;

- resistance to aggressive environmental influences;

- increased fire resistance and resistance to moisture.

The bulk density of the porous material is commensurate with wood, for this reason the building is erected on various types of foundations.

Expanded clay fractions

Loose expanded clay is divided into the following fractional types:

- expanded clay sand - fractions from 2-5 mm. It is used in construction work - laying a sand cushion, for filling aquariums, for constructing drainage.

- crushed stone - large multifaceted pebbles ranging in size from 0-5 mm, 5-20 mm, 20-40 mm, 40-70 mm, 40-200 mm. It is used in expensive construction, equipment for playgrounds, landscaping, decoration of premises.

- gravel - elongated granules from 5 mm to 70 mm. Natural material is taken for the construction of the foundation, backfilling of sites, for the manufacture of roofing materials, and the construction of routes.

The raw material has various variable sizes, which ensures its wide application in various fields.

Filled strip foundation

Filled strip foundations occupy leading positions in low-rise private construction. Their arrangement is a rather laborious and time-consuming process, but if there is access to specialized construction equipment (rent), the construction time can be significantly reduced.

The main stages of the production of work on the construction of such a foundation are:

- Geodetic works. The type of soil, the level of occurrence of groundwater and the depth of freezing are determined;

- Binding to the site and marking of trenches;

-

The sampling of land is made, the width and depth correspond to the norms of SNiP -87 "Earthworks, foundations and foundations";

Pit for a strip foundation

- If the depth of the groundwater is below 2 m from the freezing horizon, then the sufficient depth of the monolithic foundation is 0.6-0.7 m. If it is less, then it is necessary to make a trench 20 s more deep than the freezing level.

- Collapsible wooden or metal panels can be used as formwork.

- Reinforcement is made of 10-12mm reinforcement, welding or tying it in such a way that the spatial frame comes out 3-5cm narrower than the outer wall.

- The filling is carried out with a cement-sand mixture of the M250-300 brand, on a previously poured and compacted sand-gravel pad.

Advantages and disadvantages of a tape filler base

Advantages:

- Great reliability, long service life. This is the only acceptable option if a two-story house is being built from expanded clay concrete blocks;

- Allows you to create a garage on the basement floor, a spacious basement or a full room;

- It is built on clayey soils with a high level of freezing. Does not squeeze out, gives minimal shrinkage.

Wall-ready strip foundation

Disadvantages:

- Large material costs;

- Long device time;

- High labor intensity and large volume of earthworks.

This is interesting: How to choose an electrical panel for an apartment - what you need to know

Material features

Expanded clay concrete has been used in the field of construction for a long time. Most of the domestic housing stock is an example of this. During the construction of typical panel buildings, the external elements were made of this material in order to keep the heat in the apartments. Another question is that the thickness was assigned insufficient (according to the old norms), and in such houses it is cool in winter.

The main characteristics of the material of the walls of the house, which are important in the design and construction of your own hands, are as follows:

- the mass of the walls (which depends on their width and density);

- resistance to movement of the base.

Each of them should be described in more detail.

Block mass

Everything is simple here, the less the load on the foundation of the house, the less money and effort will have to be spent on it. For each material, the optimal wall thickness is selected according to the joint venture "Thermal protection of buildings". It is in this document that formulas are given for the calculation based on the required resistance of the structure to heat transfer. To compare expanded clay concrete with other materials, you can see the table below.

| Material for building walls at home | Density | The width of the wall based on considerations of thermal protection (the average value, taking into account the decreasing coefficient mp = 0.63, adopted according to clause 5.2 of the joint venture "Thermal protection of buildings". | The mass of one running meter of a house wall with a height of 3 m (average floor height during DIY construction) |

| Solid ceramic brick | 1800 kg / m3 | 64 cm | 3456 kg |

| Foam concrete blocks (for load-bearing walls) | 900 kg / m3 | 50 cm | 1350 kg |

| Expanded clay concrete blocks | 1000 kg / m3 | 80 cm | 2400 kg |

| Wood | 520 kg / m3 | 30 cm | 470 kg |

It can be seen from the table that the use of expanded clay blocks does not significantly reduce the load on the foundation in comparison with the brick, therefore, when choosing and building with your own hands, it is worth focusing on supports specifically for brick walls. A similar situation is for cinder block walls. But, if there is a choice between these two materials, preference should be given to expanded clay, since it is more environmentally friendly. In the production of expanded clay blocks, a special fired clay is used, and wastes from various industries can be used for cinder blocks, and it is impossible to say with certainty (without additional research) that they are safe for humans.

Shrinkage resistance

A wall made of any small-piece materials does not accept movement of the base. Fastening the elements together with glue or mortar does not guarantee that a solid structure will be formed. Expanded clay blocks and cinder blocks are lightweight concretes that work perfectly in compression, but are not able to cope with bending, namely, it occurs when the foundation is displaced.

Shrinkage cracks are possible due to improper design of the foundation.

It is important during construction with your own hands to provide a reliable foundation that will work as a single structure and transfer the loads from the house to the ground

Expanded clay concrete support

Under the block house for the foundation, you can take expanded clay concrete porous building material. The budget option for the construction of a support has a number of practical properties:

- characterized by increased wear resistance. The porous structure of the material is strong, which guarantees the durability and quality of the structure.

- excellent thermal insulation properties of the building material. The structure does not need additional insulation.

- Expanded clay concrete bricks retain their shape during temperature changes, which guarantees the integrity of the base.

- completely safe for humans, environmentally friendly.

- the installation is carried out by hand, without the involvement of additional equipment.

Arrangement of a supporting structure made of a porous block is a good solution not only for one-story buildings, but also for buildings with several floors. A block foundation requires time and effort to lay out. But its use will provide a residential building with a reliable and durable foundation.

To build your country house using blocks of expanded clay concrete, you should solve the issue of arranging the foundation. The choice of a certain type of foundation is the key to the reliability of the entire construction.

vote

Article Rating

How to calculate the cost of a house made of expanded clay concrete blocks

The total cost is made up of a large number of factors. The construction of supporting structures is just one of them. For clarity, let's take the average prices. Suppose that we will carry out the work with our own hands without the help of a construction team. Let's say that we need to build a small one-story house with an area of 10 x 10 m without internal partitions.Let us take the height from floor to ceiling equal to 3 m.

The total area of the four walls in this case will be 3 x (10 + 10 + 10 + 10) = 120 m2.

For masonry, we will use products with dimensions of 0.4 x 0.2 x 0.2 m. We consider the area of the outer side: 0.4 x 0.2 = 0.08 m2. One square meter accounts for 1 / 0.08 = 12.5 pcs. This means that with a thickness of one layer, we need 120 m2 x 12.5 pieces. = 1500 pcs. We did not take into account door and window openings in our calculations. According to statistics, the emission goes exactly as much as is necessary to fill them. It can be a fight during transportation and rough handling, scrap, trimming, etc.

When the brand, size and consumption are known, it remains to study the offer from different suppliers and manufacturers. If 1 piece costs 65 rubles, the whole batch will cost 97,500 rubles. Plus transportation and mortar. You can safely add another 25,000 rubles.

In general, you can use calculators for calculations - online programs can be found on a variety of thematic sites.