Calculation of a bored foundation with a grillage

Before starting to mount the foundation of bored piles with a grillage, everything must be very carefully calculated. Only the correct parameters and numbers will allow you to achieve the desired result and ensure the strength, reliability, long service life of the future building.

Calculation of bored piles

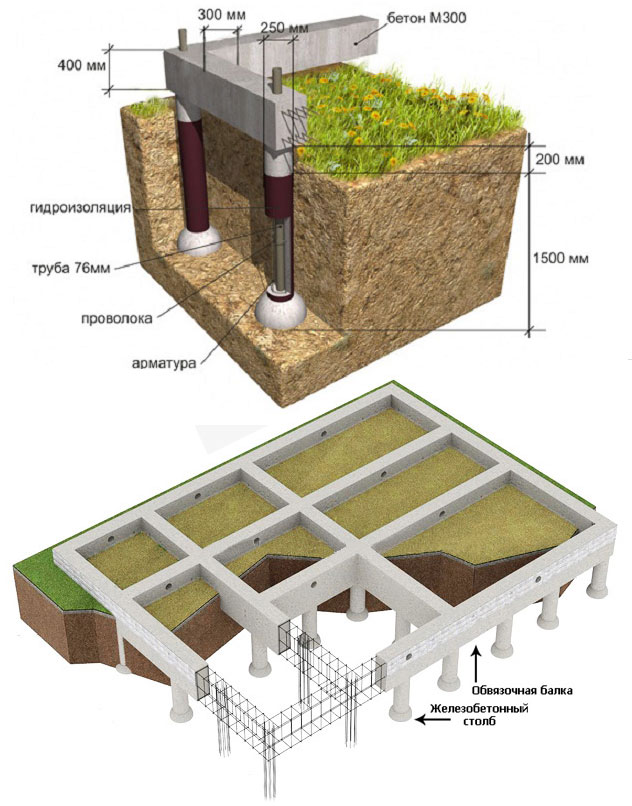

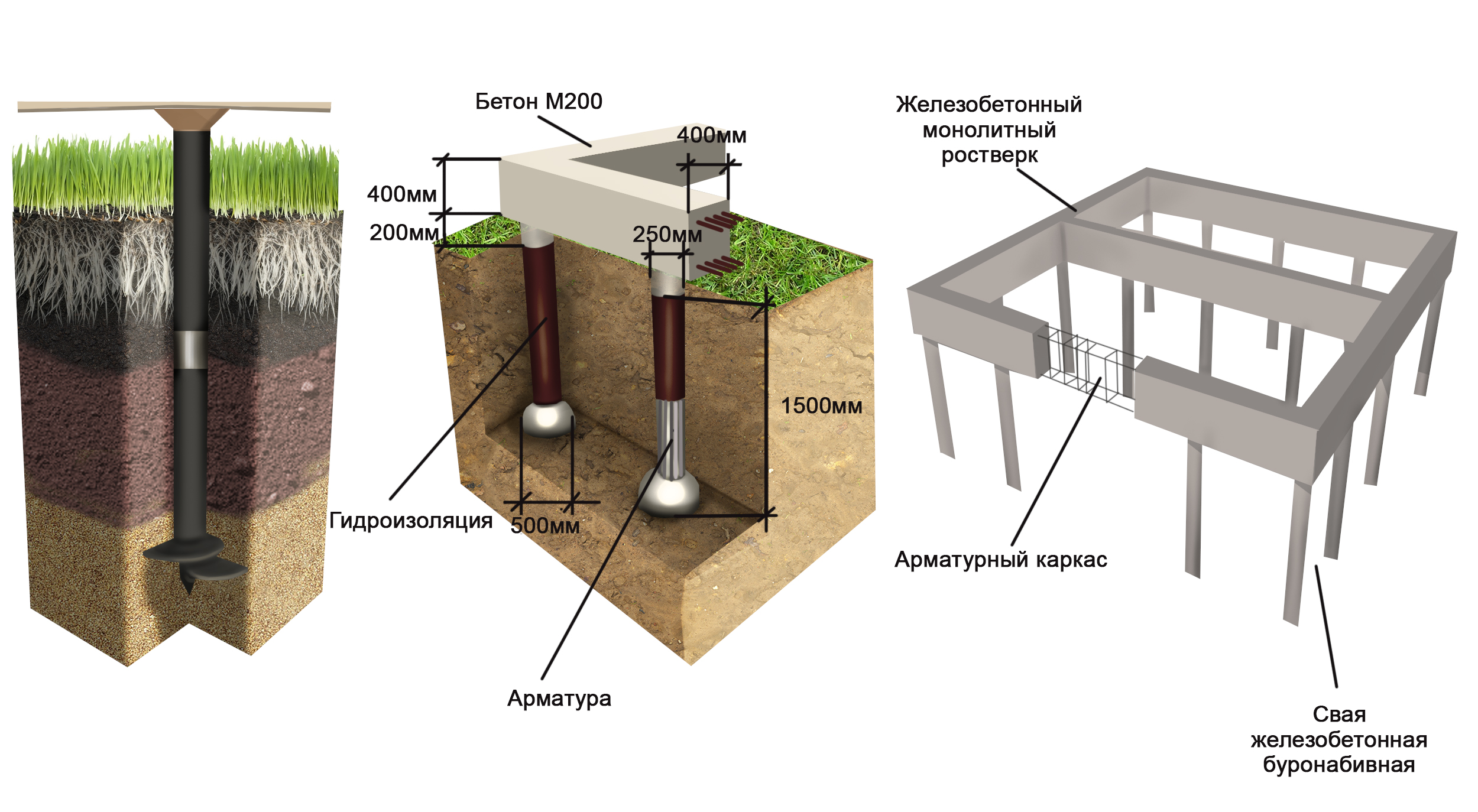

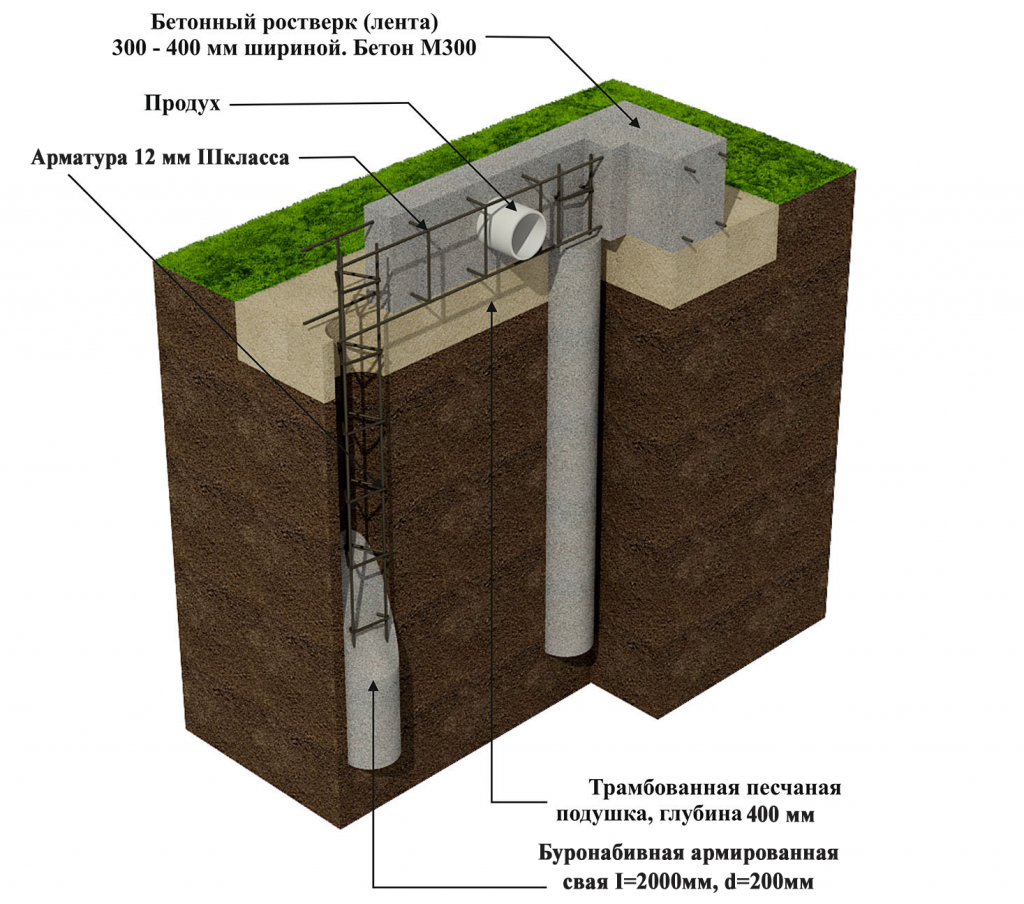

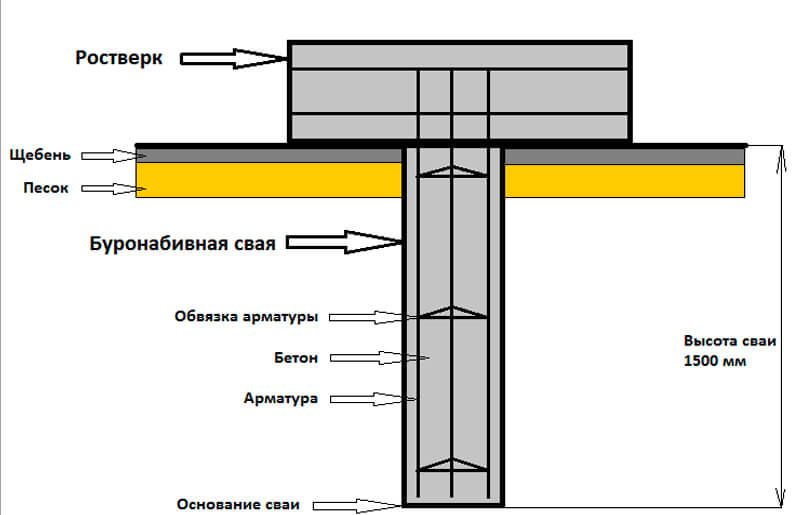

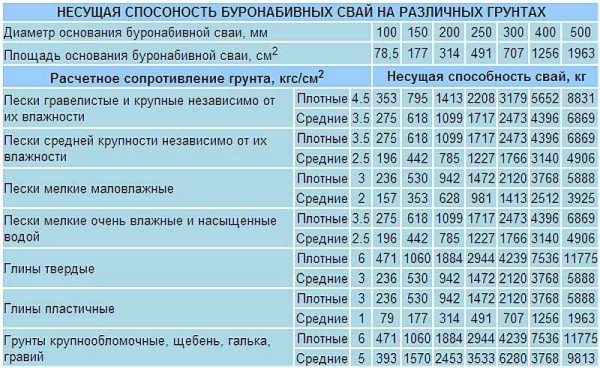

In the process of calculating the piles, the following values are determined: the length of the supports, the diameter, the number and the layout. The diameter is usually taken in the range of 15-40 centimeters, a section of 20 centimeters is considered optimal. For more accurate calculations, you can use special tables indicating the diameter of the supports and their bearing capacity, which is relevant for different materials.

If there is a value for the bearing capacity of an individual pile, the distance between them is calculated using the formula:

l = P / Q - here:

- l - optimal distance between supports

- P - indicator of the bearing capacity of the pile

- Q is the load per linear meter of the base (the mass of the building is divided by the length of the grillage itself)

So, for a house weighing 50 tons, which is being built on clay soil on supports with a cross section of 20 centimeters, 27 supports are needed (50,000 kilograms / 1884 kilograms = 26.53). They also remember the rule: the distance between the piles must be equal to at least three of their diameters. That is, if piles are taken with a cross section of 20 centimeters, the distance between them should be at least 60 centimeters. For dense soil, the figure is increased by a quarter.

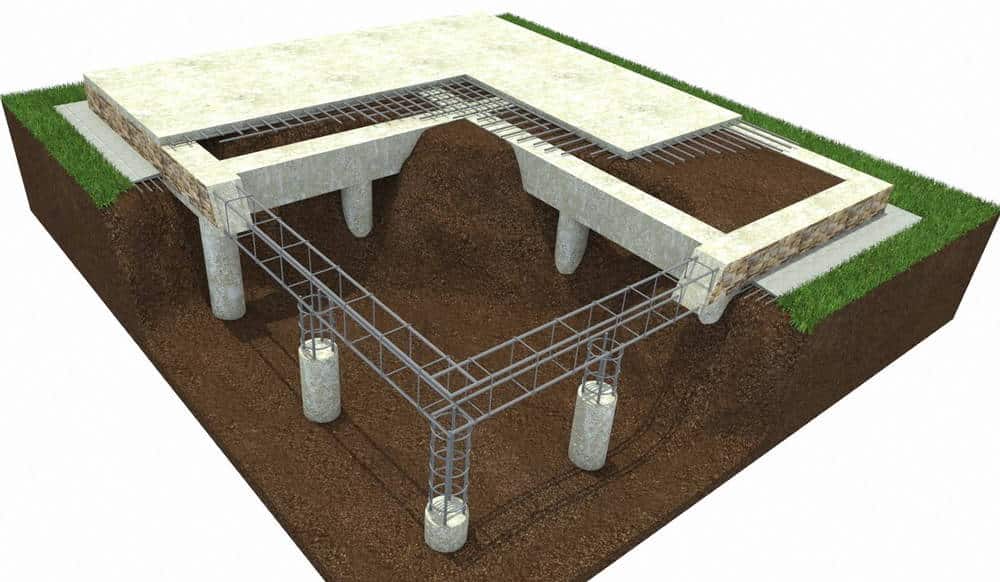

It is necessary to mount the base under the house according to a previously drawn up scheme, which is based on SNiP, which requires the implementation of such rules: the piles must be in the corners of the building, along the load-bearing walls and under the entrance group.

It is also advisable to install supports under heavy elements (stove, fireplace, boiler room, etc.). The drilling depth depends on the depth at which the bearing soils are found, on the level of soil freezing in the region. Usually drilled to a depth of 1.5-3 meters.

Calculation of a monolithic grillage

When it is created with a grillage, the technology assumes an accurate calculation of the very: its height and width. To get the width value, use the formula:

B = M / L * R - here:

- B - belt width

- M - building weight

- L - indicator of the length of the grillage

- R - the exact value of the bearing capacity of the topsoil

The formula is used for both a shallow foundation and a zero-height grillage. The hanging grillage is considered according to a different technology, rather complicated - in this case, it is better to leave the calculations to professionals.

The width of the grillage is usually 35-50 centimeters. For a medium-sized cottage, a width of 40 centimeters and a height of 30-50 centimeters will be sufficient, depending on the expected depth.

Reinforcement calculation

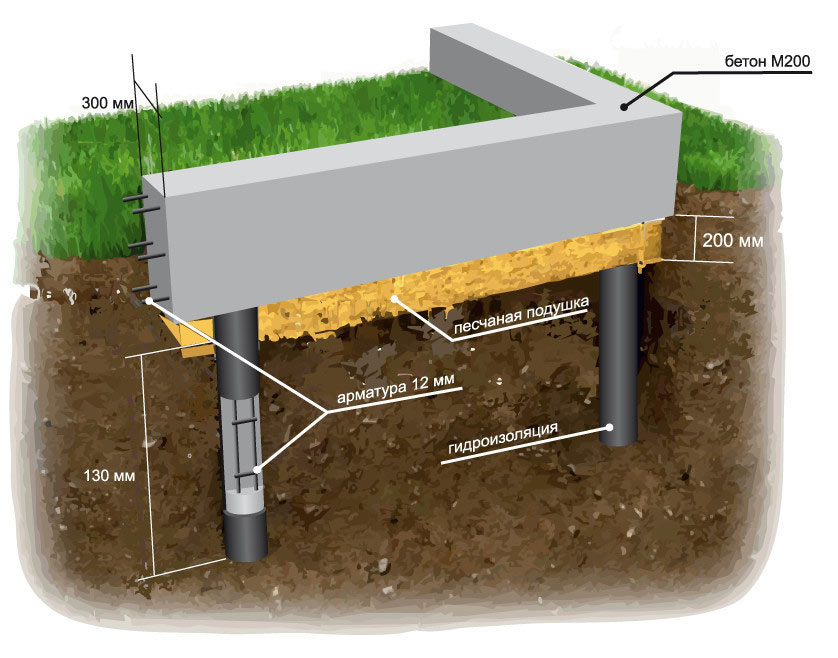

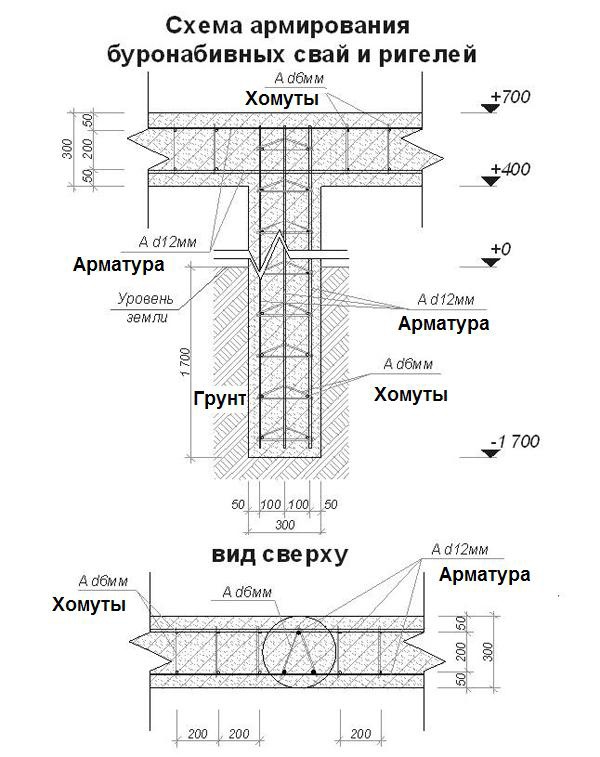

When the foundation is being created, the bored piles with the grillage must necessarily be combined with a reinforced frame. Reinforce with corrugated steel rods with a diameter of 10-12 millimeters, knit with a smooth knitting wire with a cross section of 6 millimeters.

The provisions of SNiP are dictated by the following rules:

- The number of rods in the longitudinal belt - at least 4 with a distance of up to 10 centimeters

- The step between the transverse jumpers in the longitudinal belt is up to 30 centimeters, between the connecting vertical ones - up to 40 centimeters

- The concrete cover is at least 5 centimeters thick on all sides to avoid metal corrosion.

To understand how to calculate the amount of reinforcement, you can take a simple example. So, if a monolithic grillage is created with a perimeter of 9x7 meters, and the conditional dimensions of the strapping are 40x40 centimeters, two longitudinal belts with three rods with a diameter of 14 millimeters each are used for reinforcement. The value of the step between the rods is 10 centimeters, the belts are united by jumpers made of rods with a diameter of 11 millimeters with a step of 20 centimeters.

Calculation:

- Determination of the total length of the rods in the upper longitudinal chord: 9 + 9 + 7 + 7 = 32 meters (perimeter of the grillage), 32x3 = 96 (length of three rods) 96 x 2 = 192 (length required for two chords).

- The jumpers are used with a length of 30 centimeters, located at a distance of 20 centimeters. For both grillage belts you need: 2x (32 / 0.2) = 320 pieces of 30 centimeters each = 96 meters.

- Length of vertical bridges connecting both frames. Their length is the same, 30 centimeters, for a square grillage = 96 meters.

It turns out that in this case it is necessary to purchase 192 meters of reinforcement with a cross section of 14 millimeters and 96 + 96 = 192 meters with a cross section of 11 millimeters for lintels.

The knitting wire is calculated as follows: 40 centimeters of material is spent on one connection. The number of connections is: 4x (32 / 0.2) = 640 pieces of 40 centimeters each = 256 meters.

How to make a stove?

Now we will look at the process of making a monolith slab. Step by step it looks like this:

- First you need to install the waterproofing. It is necessary to keep the sole from getting wet. Use membranes, plastic films, roofing felt, etc. as waterproofing. If there is a cushion of fine gravel under the sole, the integrity of the waterproofing after lowering the sole may be compromised - punctures will appear. Therefore, it is worth taking care of a smooth surface - a foundation.

- After working with the waterproofing, start knitting the reinforcement. There are special pistols for this purpose, and if you don't have them, don't worry, you can handle it manually. The diameter of the reinforcing elements is selected based on the planned load. Place the reinforcement mesh on concrete supports - they are used to create a layer of protection.

-

Make sure that the surface is as flat as possible - for this, pre-install the beacons.

- Monolith formwork is made by analogy with pile formwork - it also consists of boards and beams. And outside you will need the same additional supports that will keep the formwork from collapsing at the time of pouring the solution.

- The difference in the manufacture of a monolithic slab is that after pouring, it is necessary to use a vibrator that shakes the concrete to eliminate cavities and increase the strength characteristics.

After pouring, it is customary to cover the concrete in two hours with a film. If it is very hot outside, then periodically remove the film and pour water on the concrete to avoid the formation of cracks on the surface.

When can it be used

It is recommended to install pile-grillage foundations in the following cases:

When unstable and weakly bearing soils go to a sufficiently large depth. These are karst, forest, peat soils, quicksands, plant and fertile soils of great thickness (more than 1.4-1.5 meters). In this case, the load must be transferred to dense soils located below with normal bearing capacity. It is not always possible to get to the bottom of them, and if it is possible, then the foundation turns out to be too expensive. Therefore, transferring the load with piles is the best choice.

In areas with large elevation differences. In this case, it is often much cheaper to use piles of different heights than to carry out work on leveling the ground or pouring a deep tape that can compensate for the height difference.

With a high level of groundwater. Pile foundations are the only ones for which the level of groundwater does not matter

It is important that there is a load-bearing soil under the heel. The level of the location of the waters affects only the type of grillage: if the water is close to the surface, the grillage is made high, if it lies deep, it can be made low.

When building in hard ground

In this case, small amounts of land work (in comparison with strip or slab foundations) have a positive effect.

If you decide to build a house using frame technology.To make a tape for it is a waste of money: it will turn out to be too large a margin of safety, which, in this case, is useless. In this case, a pile or pile-grillage foundation is the best choice.

With a large building mass (more than 350 tons). Then it turns out that the tape or slab must be very massive, and, therefore, expensive. In this case, the pile-grillage foundation is often cheaper.

Sometimes it's even simpler: they start from the lowest cost. But you always need to remember that any type of pile foundation is less reliable than slab and strip. And all because we cannot know exactly what kind of soil is under each of the piles. That is why, when calculating the parameters, an increased safety margin is laid in the design. Not 1.2, as is commonly believed, but 1.4. And still, no one can guarantee anything.

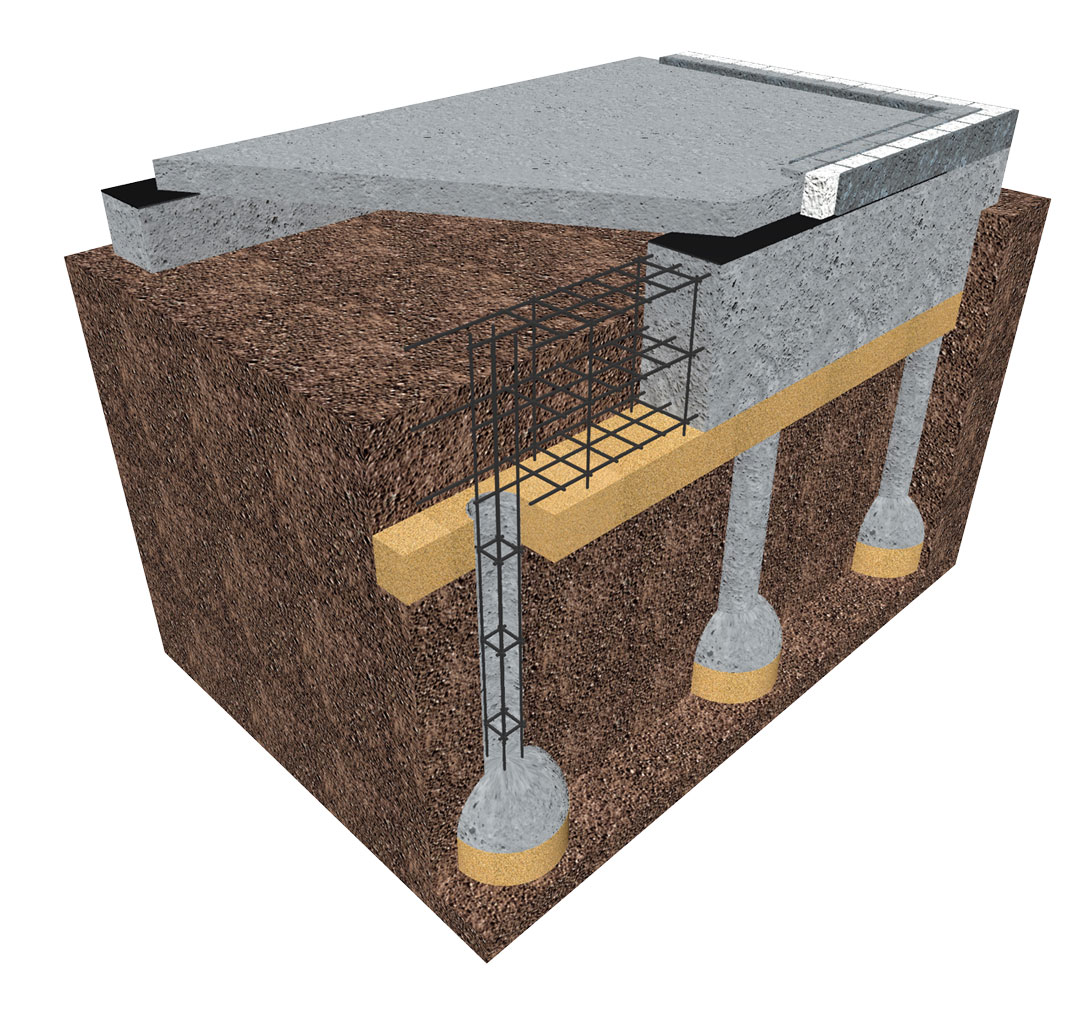

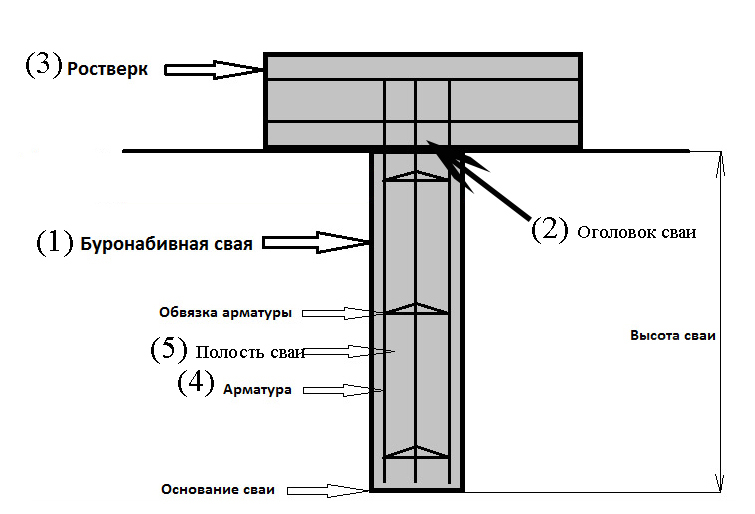

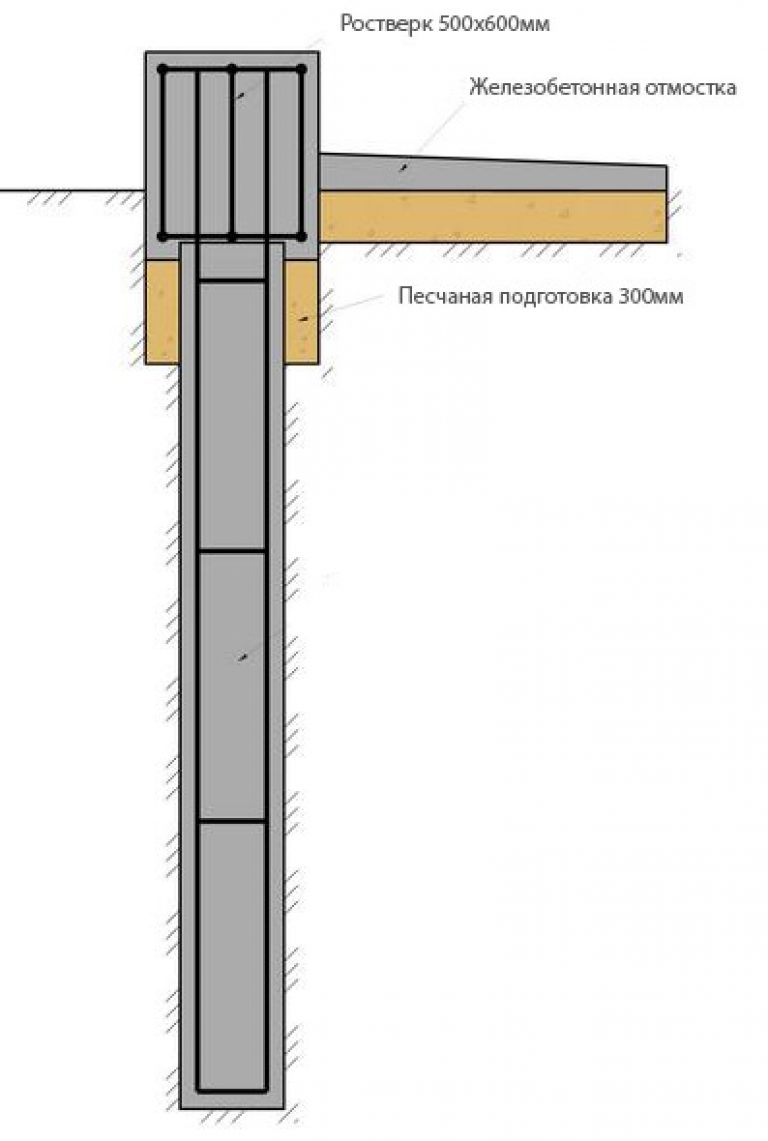

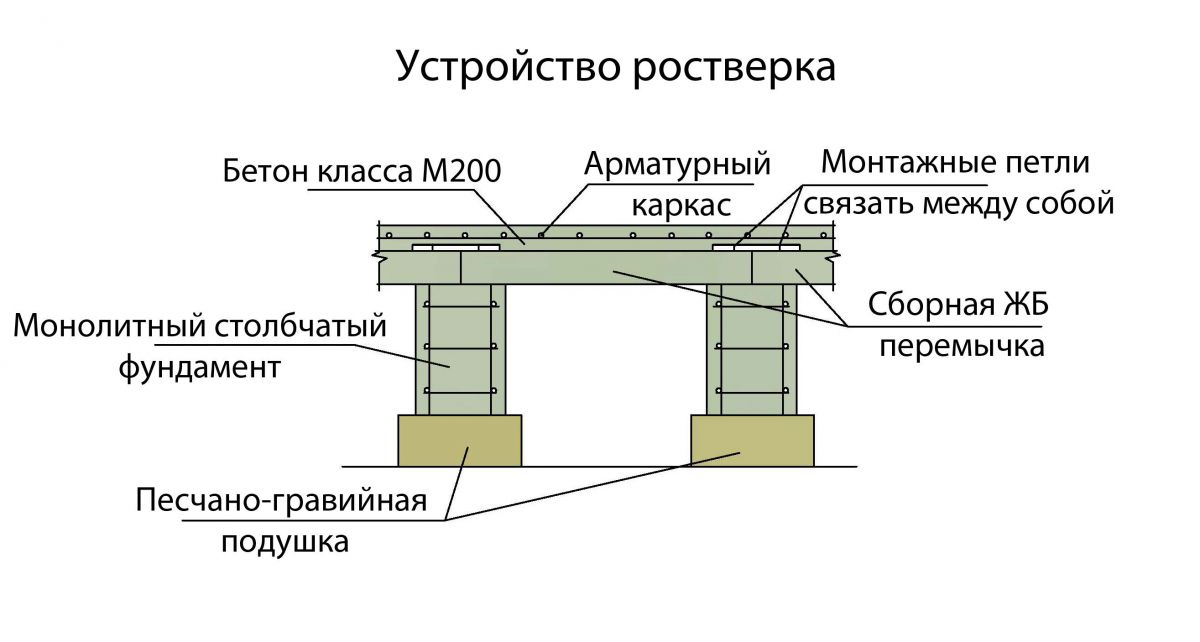

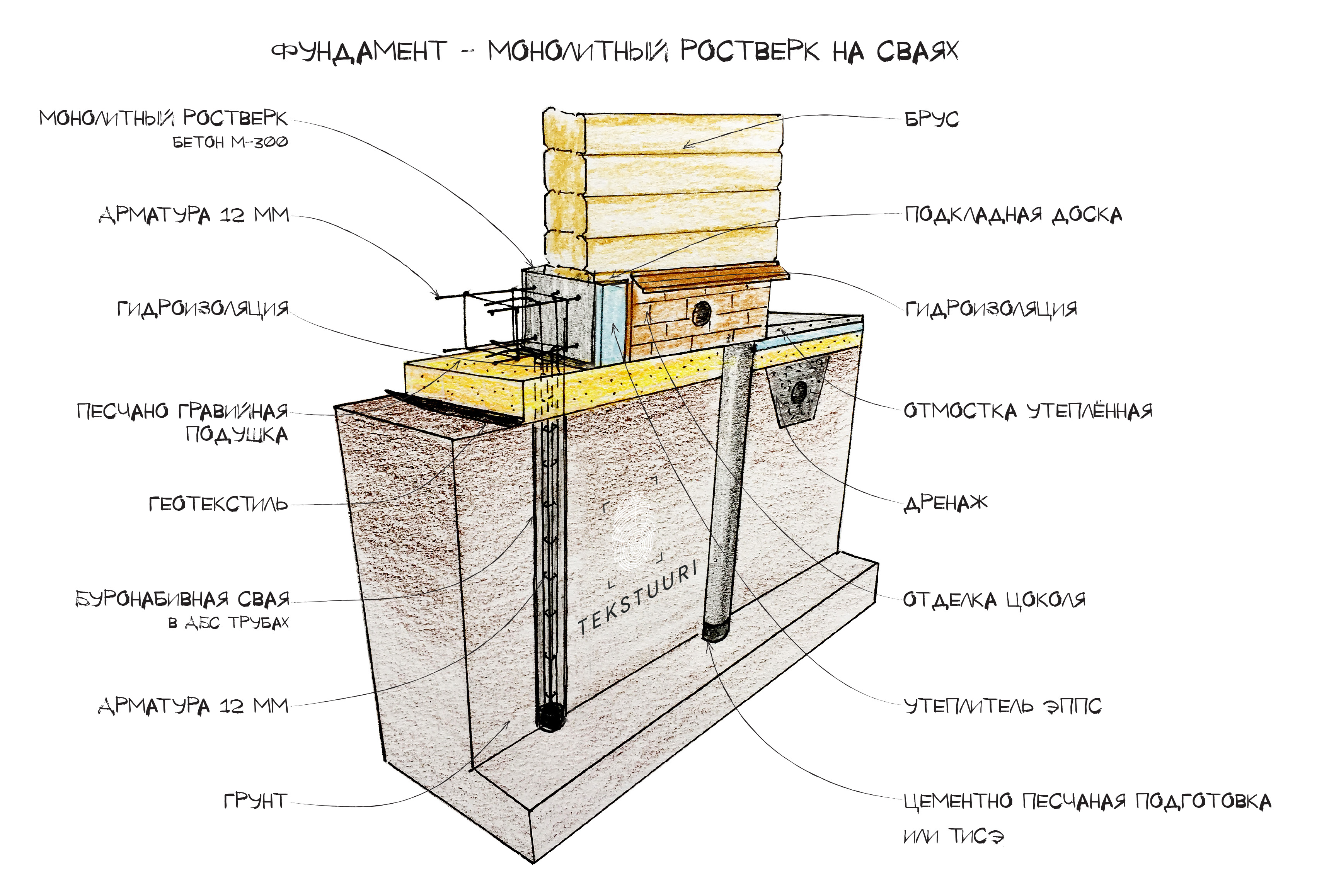

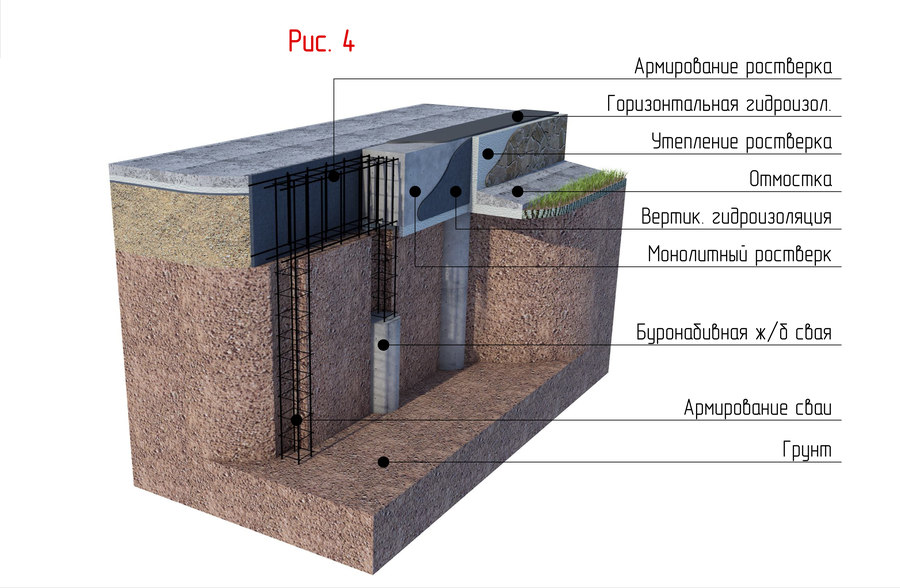

Monolithic grillage technology

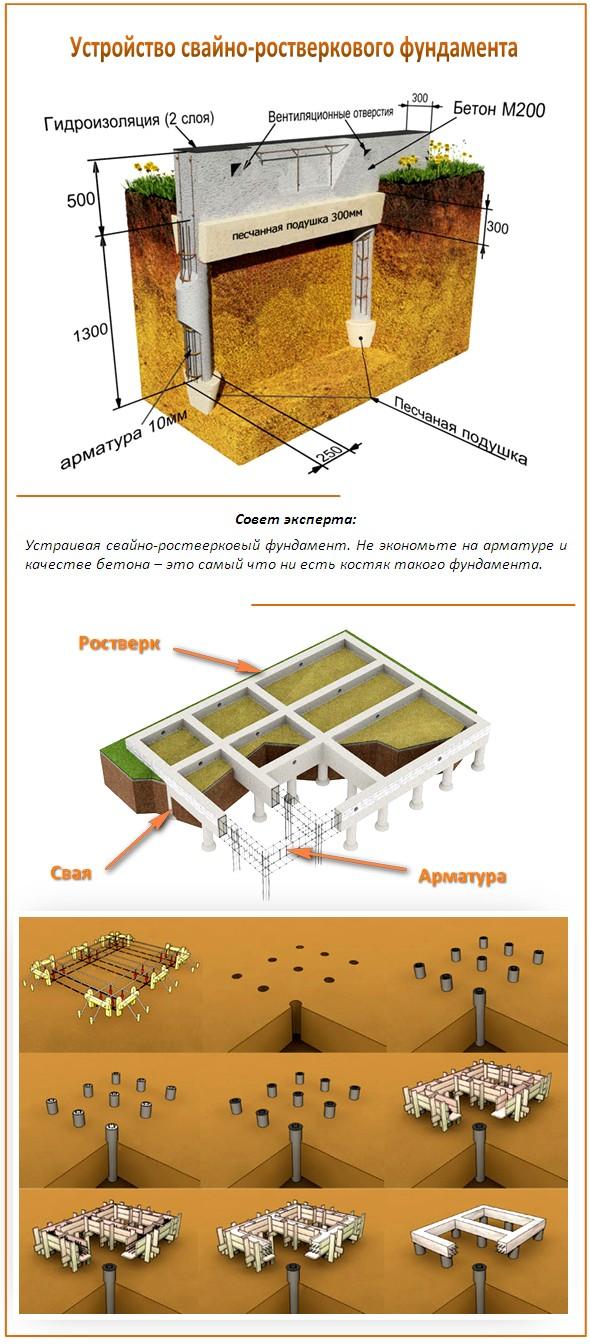

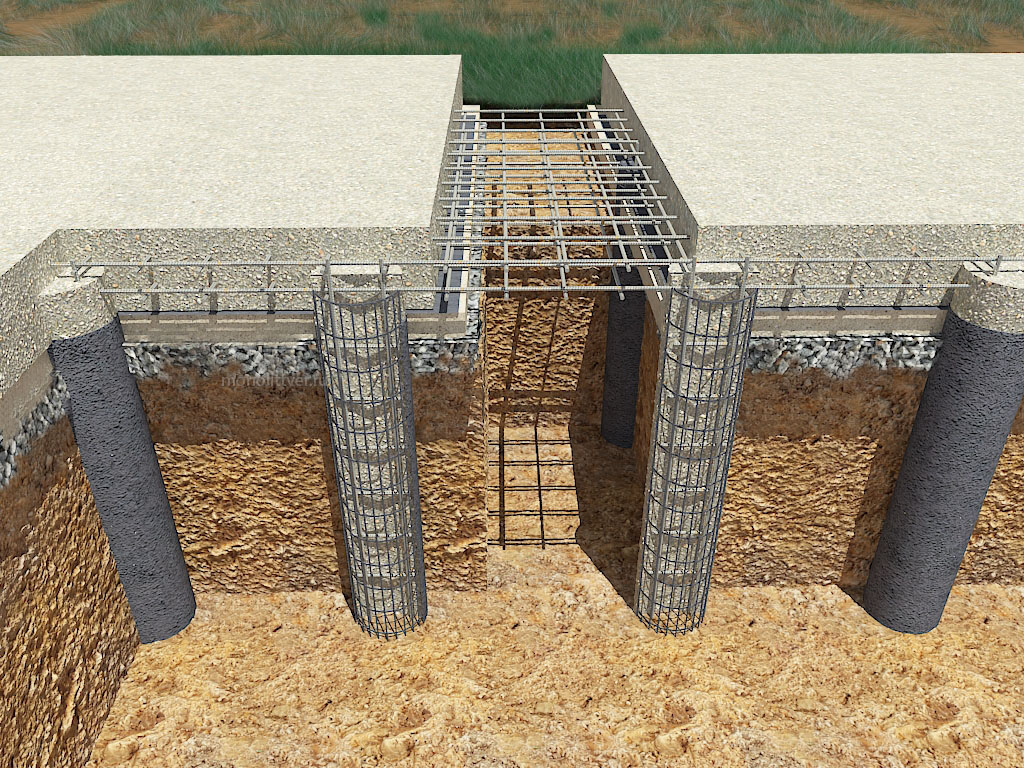

The device of a monolithic grillage consists of two main technological operations: laying of supports according to the principle of a columnar and pile foundation (except for wood) and pouring a foundation tape encircling all the heads of the pillars. However, there are some characteristic features. The sole under the pillars, as in a columnar foundation, is not laid, if this is not provided for by special design solutions. Backfilling to ground level is carried out immediately after the formwork is removed from the pillars, or in two stages (for low grillages): upon completion of the installation of the pillars and after the formwork has been removed from the monolithic foundation strip.

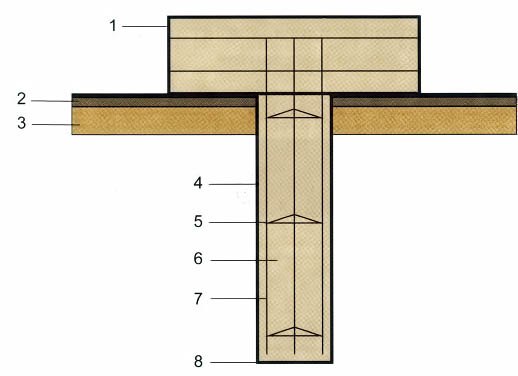

Having carried out measures for marking and determining the location of the pillars, they dig holes (Fig. A) and, where necessary, organize a sand or gravel cushion. Then reinforcement is carried out (Fig. B), the formwork is installed (Fig. C) and the concrete mixture is poured into the box (Fig. D). At this stage, after laying the first layer of mortar with a thickness of about 20-30 cm, the reinforcement cage is slightly raised so that the lower end does not touch the bottom (pillow), and the upper end is at least 5 cm from the marking line (Fig. E). Therefore, the length of the frame is made 10 cm less than the distance from the bottom (pillow) to the marking cord. After the concrete has hardened, the formwork is dismantled and backfilled (Fig. E).

The sequence of work when installing a pillar for a grillage:

- a - preparation of pits after marking;

- b - reinforcement;

- c - formwork installation;

- d - pouring the concrete mixture into the box;

- d - correction of the position of the reinforcing frame;

- e - dismantling of the formwork,

- where 1 - reinforcing cage; 2 - formwork; 3 - concrete solution.

Before starting the laying of the grillage tape, reinforced frames are installed, taking into account the distance from the bottom and the walls of the formwork at least 5 cm (Fig. A). Then the formwork is installed and concrete is poured (Fig. B). The installation of the formwork, the pouring of concrete, the dismantling of the formwork and the curing of the concrete mixture (Fig. C) is carried out according to the recommendations for the strip foundation.

The sequence of the device of the tape part of the grillage:

- a - installation of reinforced frames;

- b - installation of formwork and concrete pouring;

- c - dismantling of the formwork.

Payment

The installation process of any foundation is based on clear and dry numbers. No matter how much you would like to think otherwise, the slightest mistake in installing the foundation - and you can provide yourself and your structure with constant repairs with earthworks and a lot of financial costs. Avoiding this is simple - just take into account the widest possible range of factors that can affect the reliability of your foundation. This, of course, also applies to the foundation on bored piles.

Here is a complete list of parameters that, in one way or another, affect the safety of installing a bored foundation:

- the area and length of the foundation / grillage, as well as its height, the area of the lateral surface and the foot - this way you can calculate the average pressure from the building on a separate part of the foundation and the pile (do not forget to take into account the parameters of the internal partitions);

- the average costs of concrete or rubble elements - this will allow you to calculate the possibilities of rigidity and strength of an individual pile - here it is worth considering the presence or absence of siege pipes, formwork, waterproofing elements (do not forget that the initial planned costs of concrete in almost 100% of cases are slightly lower than the volume spent in the result);

- load and pressure on an individual pile, and load on rock from the weight of the building and foundation;

- the requirements and recommendations for the reinforced frame must be observed - this is a diameter of 1 cm, the number, length and weight of reinforcing bars, the diameter and pitch of the fastening clamps according to SNiP for your building;

- the characteristics of the formwork (depending on the material used for the formwork, these values according to GOST vary greatly);

- in addition to all this, take into account the external climatic conditions, which have already been mentioned above.

It often happens that some of the types of calculations cannot be applied to buildings erected by private developers, this can be justified by such factors as the installation of additional structures and elements on the territory (to which exact calculation operations cannot be applied before construction), the use of an individual type foundation (foreign, unpopular or not so widely known types of foundation) and some others. This is a common situation today, as the number of individual projects is increasing, and there are more and more bold design solutions in the construction of buildings. In this case, the developer must use the norms, rules and tables with data in SNiP 2.02.03-85, SNiP 3.03.01-87, SNiP 52-01-2003 and GOST R 52086-2003. Studying these documents will allow you to determine the optimal number of pile elements, calculate the depth of piling, the load on the soil and foundation in your area, and will certainly be useful for novice builders.

The process of calculating a bored foundation is simple. First, you need to calculate the weight of all foundation structures, take into account the approximate weight of furniture, people, wall barriers, stairs, superstructures, loads from snow or rain. The next step will be to determine the bearing capacity of an individual pile, it will depend on such parameters as the diameter and length of the pile, the characteristics of the reinforcement cage, the loads of soil rocks and their properties. You can calculate the bearing capacity of the piles from the data obtained from the punch tests

After the calculated measures, the builder carries out corrective work, which includes optimizing the number of piles (if the number is odd, it is usually rounded to an even number) and checking the entire structure for damage and cracks. The number of piles, as well as the distance between them, is determined by the weight of the building and the diameter of the piles themselves. When placing piles, keep in mind that their installation in the corners and at the junction of the walls near the building is required. Otherwise, the load and pressure on certain sections of the foundation may be close to the critical value.

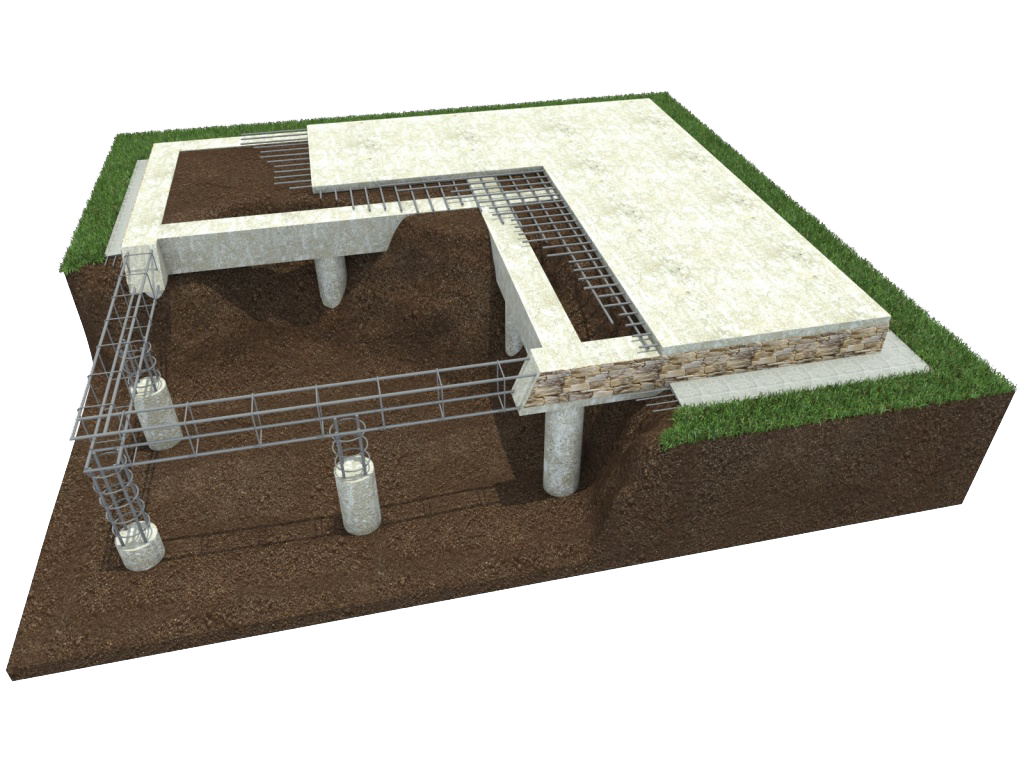

Creating a pile-grillage foundation with your own hands

It is quite possible to do the construction of a pile-grillage foundation with your own hands. For the construction of small buildings (gazebos, country houses), a grillage on a columnar base is chosen, the pile option is suitable for buildings of permanent use. Work is best done in late spring, early summer or early autumn. First, the site is prepared, clearing it of vegetation and debris, then further stages of the work are carried out.

First, you need to prepare materials and tools, order concrete of strength class B17.5-22.55, or purchase ingredients from which it will be prepared in a concrete mixer. If necessary, it is necessary to add gravel or fine crushed stone under the future strapping.

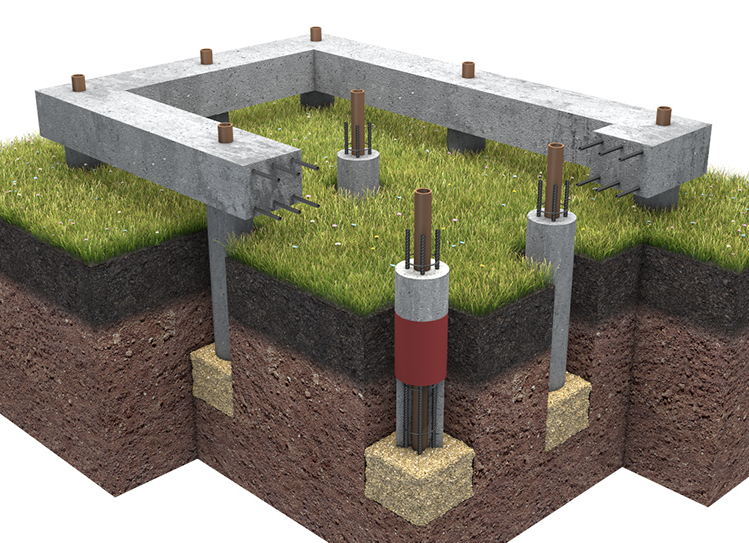

Formwork

The formwork is mounted 10 centimeters higher than the height of the band grillage.The formwork is made of wooden boards or boards of a sufficient level of strength in order not to crack and not to disperse under the weight of concrete.

How is reinforcement done

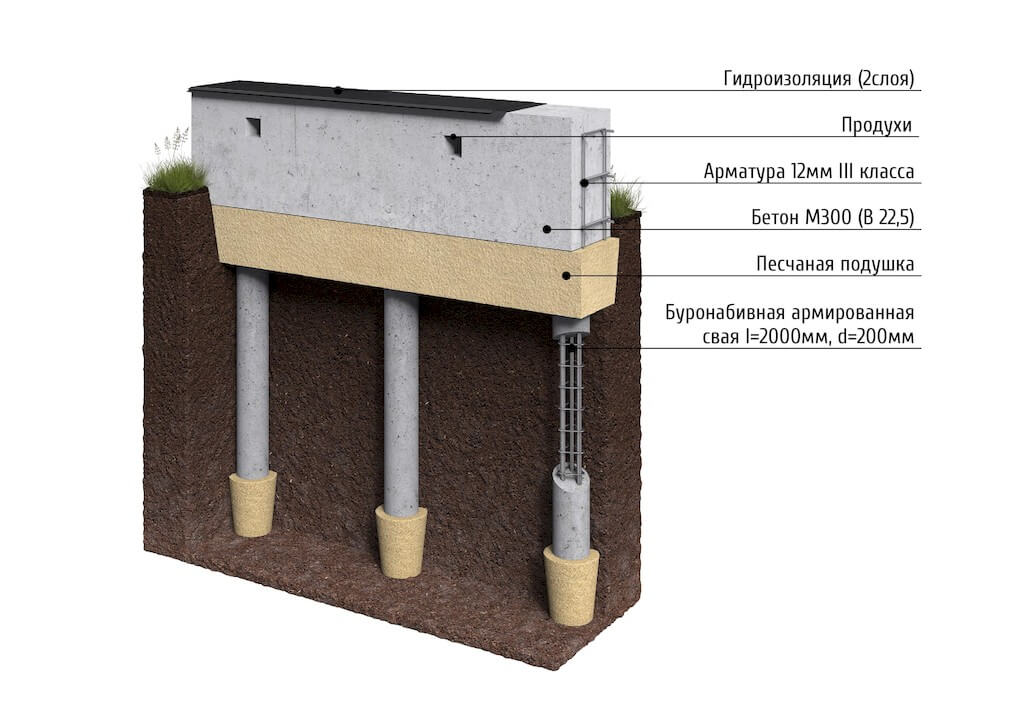

The prefabricated monolithic grillage must be reinforced. For reinforcement, steel rods with a cross section of 12-18 millimeters are chosen, the depth depends on the project, but the mesh is laid evenly, in increments of 15-30 centimeters. The harness is mounted around the entire perimeter of the tape base.

The wire is cut in advance, the frame is installed in the mounted formwork, there they are tied to the reinforcement of the piles as rigidly as possible. Holes are drilled in the upper part of the piles protruding above the soil level, mortgages are passed through them, longitudinal whips of reinforcement are attached to them. Steel rods are driven inside the piles, the whips are tied together, with the upper whips. Inside the piles, the reinforcement is laid in a layer of 2-3 rods.

Concrete

The concrete is poured in equal horizontal layers, the thickness of which should be 10-15 centimeters. After pouring, each layer is sequentially rammed with a vibrating tool, then only the next one is poured.

For pouring the grillage, concrete grade M300 or M350 is suitable.

Rostwerk: weather and temperature-humid conditions

The grillage device is carried out in hot weather, preferably calm, no precipitation. Direct sunlight should not hit the surface either. If the air temperature is negative, the concrete must be provided with minimal heat loss at all stages - from preparation to laying. If work is carried out on heaving soils, the ground is first warmed up to a positive temperature, protected from freezing.

Dismantling the formwork

After completing the pouring of concrete, the formwork is dismantled, first removing the fasteners and spacers, only after that the boards. The formwork panels should easily move away from the frozen monolith, if such a situation is not observed, this indicates that the solution has not yet frozen and has not gained the required strength.

Drying and care

When a concrete grillage is poured, proper care of the monolith must be ensured. The design is reliably protected from sunlight, wind, precipitation. The surface is covered with plastic wrap, periodically moistened with water if the air temperature exceeds + 22C.

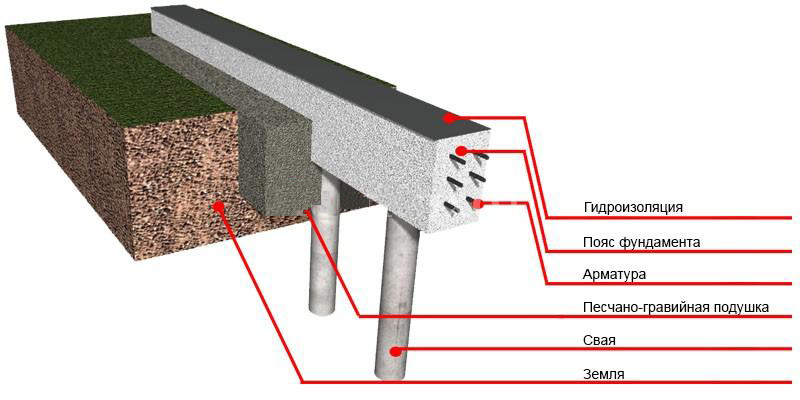

Waterproofing

The concrete grillage must be waterproofed, this is especially important when building pile-grillage foundations of a buried type. It is also advisable to isolate elevated grillages from moisture.

Waterproofing options:

- Penetrating - a special mortar with excellent adhesion characteristics covers the foundation.

- Coating - the strapping is covered with bituminous mastic.

- Sprayed - liquid formulations with high water-repellent properties are applied using a spray bottle.

- Roll - the tape is coated with mastic, roll material is placed on top.

The choice of method and material for waterproofing depends on the type of soil, groundwater level, type of grillage, financial capabilities and other factors.

Calculation of the number of piles

Piles transfer the load from the structure to the soil through the base and lateral surface. With a hanging grillage, the weight of the aboveground part is transferred pointwise to the buried supports. Foundations of this type are used in the construction of timber and frame houses, since the bearing capacity of the anchors is sufficient for the perception of small stresses.

The recessed structure of the grillage unloads the piles, distributes the load to the area of the foundation foot. This type of foundation is preferable when building houses made of brick or aerated concrete, since the mass of the walls is quite significant and requires additional reinforcement of the pile-grillage structure.

To find out the required number of supports, the piles are calculated according to the algorithm:

- They carry out engineering and geological surveys and find out the bearing capacity of the soil with the help of SNiP “Soils. Classification ", VSN 5-71.

- Determine the total constant load from walls, floors, roofs, finishes, interior equipment. Summarize it with temporary ones - from people, furniture, filled tanks, snow (SNiP "Loads and Impacts").

- Find the linear load per meter of the grillage, dividing the total weight (clause 3) by the length of the foundation under the supporting structures.

- According to the formulas, tables of SNiP 11-17-77 or using an online calculator, the bearing capacity of one pile is determined. Consider the geometric characteristics of the support, the depth of the laying and the resistance of the soil.

- The minimum number of supports required for a pile-grillage foundation is found by dividing the total load by the bearing capacity of one pile. A safety factor of 1.4 is recommended, increasing the number of anchors by 40%.

The actual number of piles may differ upward, since there are rules for placing them under the base:

- in the corners of the building;

- at the intersection of walls, partitions;

- for heavy, over 300 kg, equipment, for example, a furnace;

- the distance between the piles should not exceed 3 m.

- The mass of the house is calculated (all materials and the approximate weight of the "filling" are taken into account).

- Based on the weight and safety factor, the required support area is determined.

- Since the piles have already been placed, we can count their number.

- Next, we select the cross-sectional area of the piles. Since we know their number, multiplying by the selected area, we find out the total.

- The obtained result is compared with the previously calculated (point 4) support area.

- If the area found at step 4 is larger than that calculated at step 2, the selected pile parameters are suitable for us.

- If less, we increase the planned cross-section of the piles, multiply and compare again. So we find the required pile area.

Sometimes it is more profitable not to increase the area of the piles, but to install them more often. In this case, the calculation method does not change.

Bearing capacity of piles of different diameters in different soils (to enlarge the picture, right-click on it)

Where H is the bearing capacity of the soil (it can be taken from the table). The coefficient 1.4 was applied due to the fact that the pile foundations require a greater margin of safety: we do not know what kind of soil is under all the piles. Therefore, it is better to play it safe.

For more information on calculating the support area and calculating the mass of the house, see the video.

How to equip a pile foundation at home?

The pile one differs from other types of foundation in the relative simplicity of its construction. To build such a foundation, a certain sequence of actions is required:

- The first step is to study the soil in the selected area. This is necessary in order to determine the bearing capacity of the soil, its ability to withstand the weight of the proposed structure. In addition, the length of the piles is also determined by the nature of the soil, as well as the degree of their burial into the soil.

- Further, after engineering searches, the main drawings of the future foundation are drawn up, on which the locations of the supports, their length, driving depth and other parameters are precisely determined. The drawing is a full section of the future base.

- After that, according to the markings on the drawings, the soil is drilled at the locations of the piles. If the supports are already ready-made, then they can be inserted into the ground by hammering them using special construction equipment.

- After installing all the supports, it is the turn of the formwork. In this case, a removable formwork is used, or a wooden structure is made directly on site.

- If you plan to install a built-in monolithic grillage, then in this case a special trench is prepared for further pouring concrete mortar.

- After preparing the concrete solution, the grillage and supports are poured.

- The poured solution is left for exactly one month until it dries completely and becomes strong enough.

You can make a pile base for a house with your own hands. This may require the following materials:

- Reinforced concrete supports of the required dimensions, depending on the type of soil and the characteristics of the territory.

- Sand or rubble for arranging pillows at the bottom of the drilled hole, if necessary.

- Special equipment and equipment, if it is planned to arrange trenches and wells.

- Concrete mortar for pouring the base.

- Planks and nails for formwork construction.

In general, the process of building a pile foundation is not so difficult. If the arrangement of the base is carried out for a future small private house, then the piles, as a rule, are not too large. Therefore, they can be easily installed without the involvement of additional large equipment. In fact, the construction of a pile foundation turns out to be simpler than the arrangement of a strip or monolithic foundation.

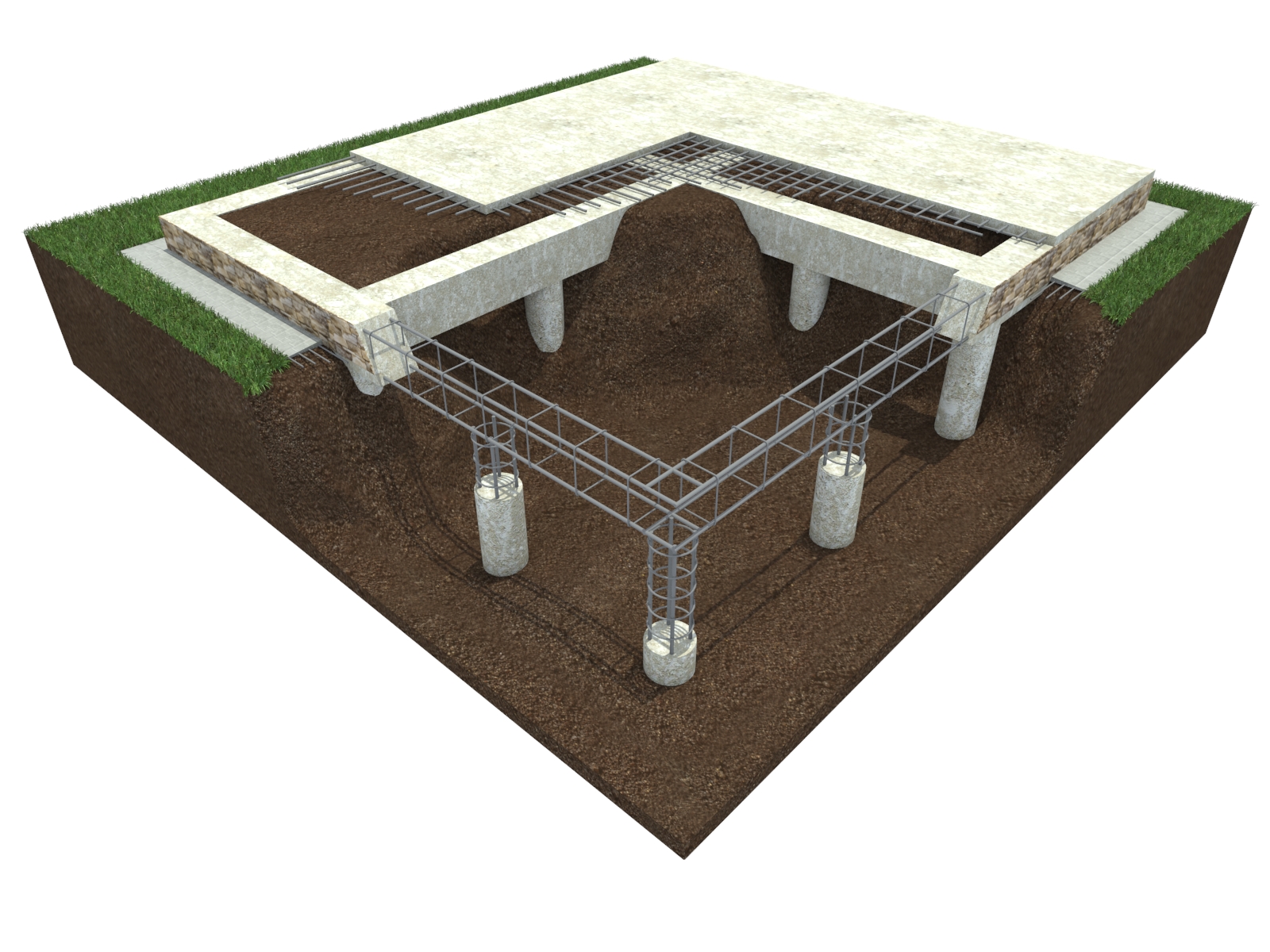

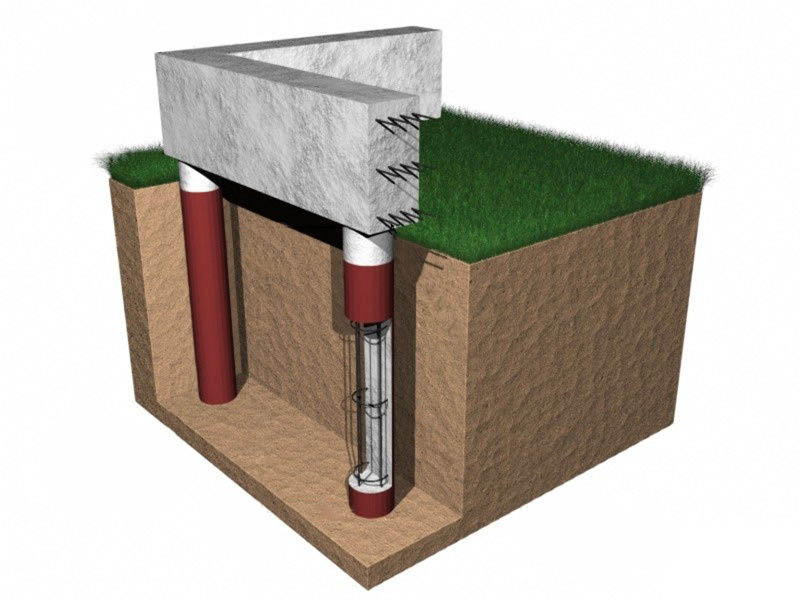

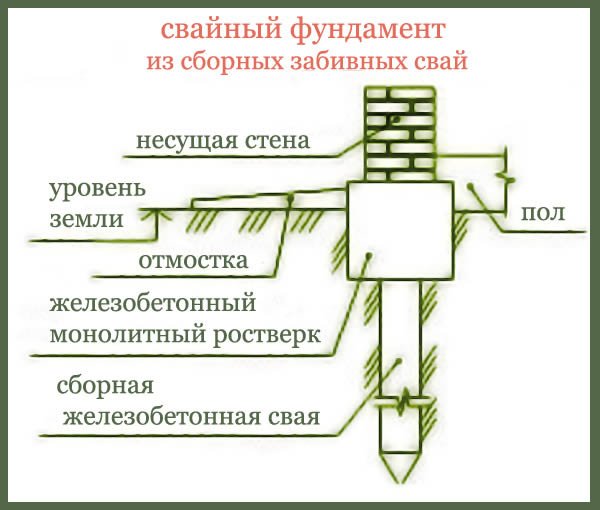

What is a pile-grillage foundation

A pile foundation is probably imagined by everyone: it is a certain number of piles buried in the ground to the level of the bearing layer or below the freezing level. In its pure form, this type of foundation is rarely used. This is due to the peculiar design, which does not allow redistributing the load from the house between the piles. Therefore, the pile foundation is mainly made for log houses from logs or beams, sometimes - for frame buildings. These types of building materials, due to their characteristics, redistribute the load themselves. They are poorly compatible with houses made of other materials.

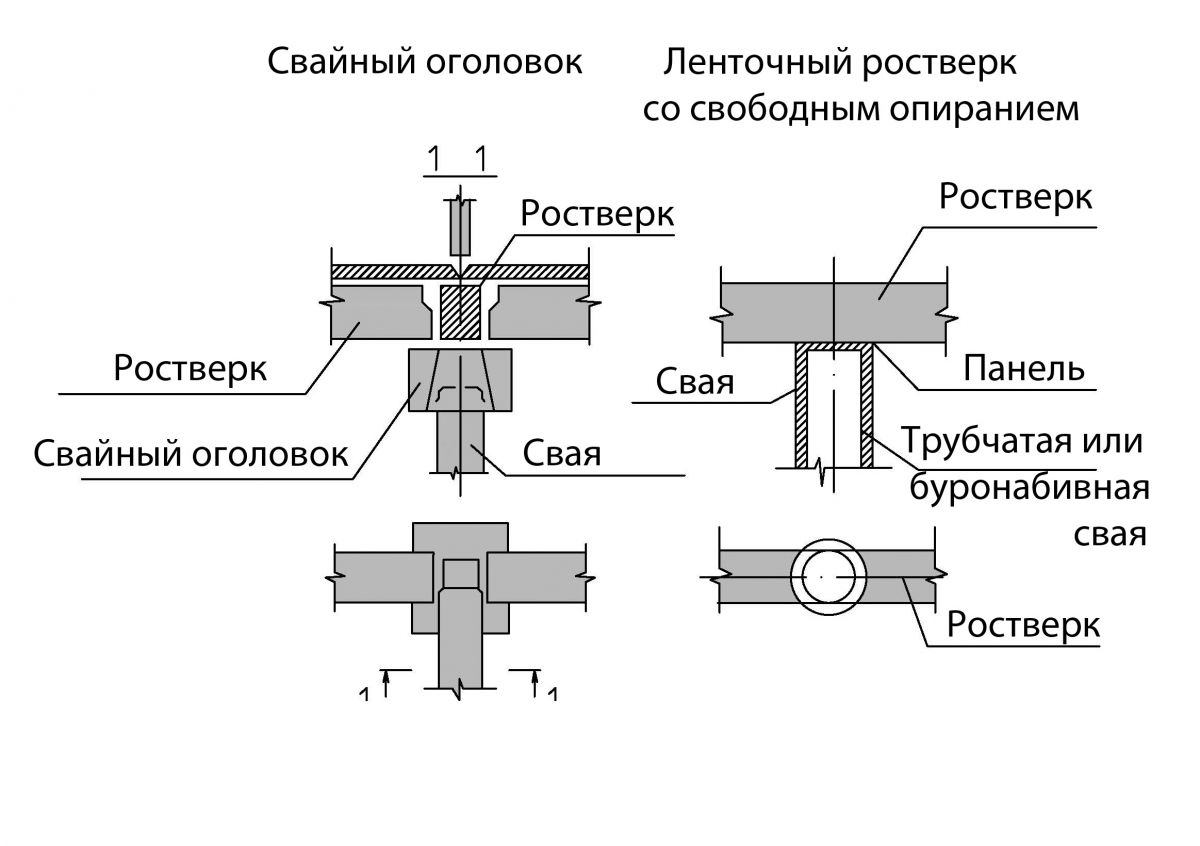

But their improved form - a pile foundation with a grillage - is devoid of many drawbacks and can be used both for brick and block buildings. In them, all the supports are tied with a tape made of metal or reinforced concrete (concrete) into a single structure. This tape is called the grillage.

It looks like a pile-grillage foundation taken out of the ground

A grillage is a part of the foundation that unites the pile heads and serves as a support for the walls. It is the grillage that accepts, and due to the closed structure, redistributes the load, transferring it to the piles. It can be metal, wood, concrete or reinforced concrete. By the type of execution, concrete (reinforced concrete) grillages are low and high.

Distinguish between pile foundations with a high and low grillage

The high grillage is above ground level. Most often it is made of metal - channels of large cross-section or square metal pipes. They also make such a grillage from concrete, but its structure is more complicated: you have to figure out how to pour the tape at a distance from the ground.

How does the grillage work and what does it give

Any house in different parts will give a different load: decoration, furniture, sanitary ware, other things are unevenly placed. Consequently, the load from different parts of it will be different. The grillage takes on these uneven loads and redistributes them. The “leveled” load is already transferred to the piles.

What is the difference between pile and pile-grillage foundations (to increase the size of the picture, right-click on it)

Why is this good? The fact that with the same loading of piles, there is less chance that they will shrink unevenly. And uneven shrinkage, as you know, leads to cracks in the foundation and walls. Therefore, the pile-grillage foundation is more stable. Although the main drawback of pile foundations remains: we cannot know what kind of soil is under each of the piles. Therefore, it is unrealistic to predict their behavior. That is why architects are not very fond of them: it is impossible to guarantee the long-term operation of the house.

Strip foundation on piles

Low grillages are more predictable in this regard. They usually start below ground level and are cast from reinforced (or not depending on the project) concrete. Moreover, the reinforcement of the piles is connected with the reinforcement of the grillage.

In this case, the grillage is a shallow strip foundation and it is made using the same technology. It differs in that it has a rigid connection with the piles, which significantly increases the reliability and stability of the structure. Such foundations are also called tape-based on piles or pile-tape. This design is almost ideal: it combines the advantages of the pile and strip foundations, largely compensating for their shortcomings.

The device of the pile-strip foundation (to increase the size of the picture, click on it with the right mouse button)

How does he work? The load from the house is transferred to the belt. Due to the presence of longitudinal reinforcement, it is redistributed over the entire area. Since the tape also rests on the ground, part of the load is transferred to it, the rest falls on the piles. In this case, the load and shrinkage are uniform: they are "aligned" by the tape.

In winter, when heaving forces begin to act on the foundation, all the advantages of the pile-strip foundation are manifested. If the house stands on heaving soils, their depth is below the freezing level, it is very difficult to imagine the conditions under which the house will be flexible or it will give uneven shrinkage.

When heaving forces act on the tape, the "heels" of the piles, and they themselves, do not allow the soil to move the foundation. Therefore, strip-pile foundations are an excellent choice on highly heaving soils. At the same time, the costs are much higher than in the construction of a conventional pile foundation, but much lower than in the construction of a tape below the freezing depth.

Calculation of a bored foundation with a grillage

To determine the required number of piles, their diameter and the pitch between them, it is necessary to proceed from the dimensions of the house and the material for its construction. For heavy and loaded houses, the calculations are quite complicated, therefore, to solve such a problem, you need to contact a special design bureau.

For lighter houses, calculations can be done on your own. To do this, you need to have data on the type of soil on the site and the approximate load from the structure. You can find out the type of soil yourself by sequentially making samples in different parts of the future site under the house.

The length of the piles depends on the depth of soil freezing in a particular region and averages 1.8-2.5 m. The most common diameter of bored piles in private construction is 20cm.

In order not to make long and complicated calculations, you can use a ready-made table, according to which you can find out the bearing capacity of bored piles, and, based on the mass of the house, calculate the required number. To do this, it is necessary to divide the mass of the house by the bearing capacity of one pile of the selected diameter.

When choosing the distance between the piles, the rule is that it should be no more than three diameters of the piles. On soils with good bearing capacity, another 25% can be added to this figure. It turns out that for piles with a diameter of 20cm, the distance between them will be 80cm.

The first on the plan of the pile field are corner piles and piles under the intersections of the bearing walls. Further, the remaining piles are evenly distributed with the selected step. At the last stage, piles are planned for entrance groups and annexes, as well as for heavy elements in the form of fireplaces and stoves.

Calculation of the width and height of a monolithic grillage is also a complex procedure, depending on the bearing capacity of the soil and the mass of the house. In most cases, for standard buildings, it is taken 40-50cm in width and 20-40cm in height. These dimensions are quite enough for the correct distribution of the loads from the building.

It is important to remember that if a monolithic grillage for bored piles is buried in the ground, it does not become a strip foundation and does not begin to take over the loads from the house. All loads are borne by piles

It is important to consider this at the stage of foundation design. This rule is also true when erecting a support-column foundation.

Conclusion

A monolithic slab with a grillage is by far the most popular type of foundation. It is installed on terrain with any relief and any type of soil - with this ensures high levels of reliability and durability. Design features make it possible to completely eliminate the likelihood of subsidence, which guarantees the reliability and safety of the building.

The technology of manufacturing a monolith with a grillage looks simple - even a beginner can do it. This allows the use of this type of foundation in the construction of private houses, thus reducing the monetary costs of the services of specialists.