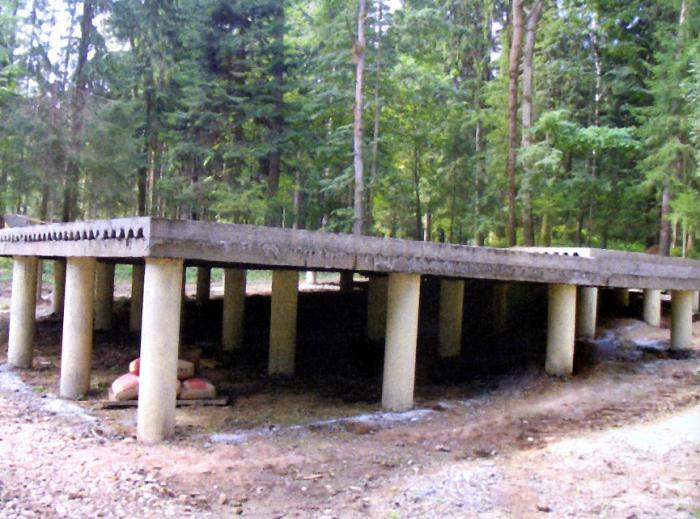

Construction of a pile-screw foundation with a concrete strapping

Before starting the construction of the building, the channel is primed with an anti-corrosion compound. This prevents the formation of rust and premature wear of the foundation. Concrete grillage on screw piles is used when erecting buildings from aerated concrete blocks.

options for tying screw piles

Despite the fact that the types of piles themselves may differ, the use of combined materials increases the strength of the foundation. Therefore, most often in construction, a reinforced concrete grillage is used. To build a foundation you need:

- Screw piles;

- Iron fittings;

- Special knitting wire;

- Concrete mortar;

- Formwork boards.

First, the piles are screwed. A screw pile is a metal pipe with a sharp tip and a special spiral blade, thanks to which the pile is screwed into the ground like a self-tapping screw. In addition, the blade reduces the pressure on the ground and eliminates the possibility of pulling out the pile due to heaving of the soil in the cold.

Under normal conditions, piles are screwed to a depth below freezing. In the Moscow region, this depth is one and a half meters. Screwed-in piles must be cut to level.

Reinforcement is knitted on the installed piles. Its diameter should be in the range of 12-18 mm. The distance between the individual reinforcing rods is 15-35 cm. The reinforcement strapping is done along the perimeter of the tape.

Holes are drilled in the upper part of the installed screw piles. Embedments pass through them, where longitudinal whips of reinforcement are attached.

After the installation of the reinforcement, the formwork is installed. Then concrete is poured. In this case, it is necessary to ensure that the upper edge of the pile does not go beyond the concrete base. When pouring concrete, the inside of the screw pile is poured first. In order to avoid the formation of voids, the casting is subjected to vibration using metal pipes. After that, the final filling of the place between the edges of the formwork is made.

A concrete strip foundation with piles is the best option for the construction of relatively light structures on difficult sloping landscapes. Piles in this case are also anchors that hold the base of the house when the seasons change. In turn, the tape provides an even distribution of the load over the entire area of the foundation.

Video with an example of the construction of a concrete foundation on screw piles for a fence:

Installation of the foundation on screw concrete piles

The process of installing a pile foundation on screw concrete supports includes conducting an engineering and geological survey, drawing up a project, calculating the required amount of materials, installing a pile field in accordance with project documentation.

Engineering and geological surveys

Engineering and geological survey includes the following activities:

- Drilling wells with soil sampling and description of traversed soils.

- Conducting laboratory studies of the physical and mechanical properties of soils, groundwater.

- Static and dynamic sounding of soils.

- Soil tests with dynamic and static loads.

- Installation in soils of reference or full-scale supports.

- Research work to determine the impact of the installation of a pile foundation on the environment and on structures and structures located near the future building.

Drafting a project

Based on the geotechnical surveys carried out by a specialized organization, a project is drawn up containing the following information:

- foundation plan (pile field);

- specification of foundation elements (piles) with indication of their grades and quantity;

- binding the foundation to the terrain;

- pile screw-in depth;

- type of grillage used for tying piles.

The project also contains the signatures of the contractor (engineer of the design organization) and the customer.

Figure 3. Design of a pile foundation on concrete screw supports

Figure 3. Design of a pile foundation on concrete screw supports

Installation of the pile field

The process of mounting screw supports made of concrete includes the following operations:

- Drilling the leader (guide) hole to a depth equal to half the length of the support - for this operation, a manual motor-drill with a screw of the required diameter is used.

- Screwing in the screw support manually with a special wrench or using a hydraulic screw.

- Backfilling the leader hole with soil - the cavity around the pile can be filled both with soil extracted during drilling of the leader and with non-porous soil (river sand or loose sandy loam).

- Trimming piles one level at a time using a powerful gas saw with a diamond blade for concrete.

When installing a foundation from this type of support, the question may arise: is it necessary to pour concrete into the screwed-in screw piles? The answer to it is unambiguous - pouring concrete into the screw piles is impractical for several reasons.

First, the concrete poured into the pile does not significantly increase its strength and rigidity. Secondly, all metal elements of the support are reliably protected by a concrete layer from moisture and do not need additional protection, as in the case of steel counterparts. And finally, such a filling, although slightly, but still increases the weight of the supports, which are already heavy to carry and transport.

You can more clearly see how the process described above occurs in the following video:

Advantages and disadvantages

Before installing the structure, you should familiarize yourself with the positive and negative aspects of the issue and study the important performance characteristics.

The pluses of the foundation made of reinforced concrete piles should include

- A positive result of construction in problem areas (with the exception of rocky ground)

- Rapidity. The structure can be installed within a day, while the traditional method of erecting a foundation requires at least 7 days. After that, you can immediately carry out the construction of load-bearing structures (the monolithic base allows you to continue work only after 3-4 weeks).

- Minimizing construction and earthwork materials.

- All-seasonality. It is possible to form a foundation on driven reinforced concrete piles at any time of the year, regardless of climate and weather.

- Duration of use. Reinforced concrete piles under the foundation are very wear-resistant and are able to withstand any weather disasters. The term of their suitability can be about one and a half hundred years.

- Strength. Reinforced concrete piles for the foundation, in the construction of which metal rods are used, are characterized by the ability to transfer multidirectional loads, which is a necessary quality in unstable areas.

The foundation on driven reinforced concrete piles has only a few drawbacks.

- The possibility of subsidence or curvature of the foundation. There is always the possibility of an unreliable characteristic of deep soil, since it is not possible to consider a multi-meter layer.

- The obligatory use of expensive specialized equipment for the installation of piles.

- The lack of a basement and basement room is a real inconvenience that people who have decided to build a foundation on reinforced concrete piles will have to face.

Durability

If we talk about concrete, then according to the unchanged GOST 27751-2014, if everything is done in accordance with the technology, then such a foundation will stand for at least 50 years. In this case, it is imperative to take into account the operating conditions, the quality of materials, the negative effects of the environment, waterproofing and much more. Only with an ideal balance of all characteristics, the concrete base will last the declared period.

At the same time, 1 mm of steel (St20), which is usually used for the manufacture of piles, without any coatings will serve for at least 40 years, even if it is in loam. But the piles are made with a wall thickness of up to 6.5 mm. But you need to take into account the loads and other parameters. But in any case, piles certainly cannot last less than concrete. Even if the piles are installed in the so-called aggressive soil (where there is slag, ash, etc.), the structure will still fully meet the requirements of GOST.

Healthy! Do not install galvanized piles. Even in the best conditions, they serve no more than 15-20 years.

DIY pile foundation installation

For the installation of reinforced concrete piles, you will need certain materials, tools, pre-calculated calculations and a project. If it is difficult to calculate the parameters yourself, you can use online calculators or the services of professionals.

Pile type selection

In accordance with the method of driving the piles into the ground, several types of supports are distinguished. It is necessary to choose a specific type taking into account the characteristics of the soil, the depth of the supports, the availability of the necessary equipment and tools. So, for example, if the foundation for a heavy house is being created, the supports will be alone. When it is designed on piles, completely different options are chosen.

Types of pile foundations:

- Driven-in - immersion of usually solid square supports into the ground with different indents, plungers, hammers

- Shell piles - hollow piles, which are buried with a vibratory driver and then poured with concrete

- Screw - steel supports are screwed into the soil thanks to special blades on the surface

- Rammed - the simplest option, when a concrete solution is poured into a pre-drilled hole in the ground with reinforcement installed in it (or without it)

Piles can be positioned in the ground in different ways: individually at important nodes of the base, ribbons around the perimeter of the walls, bushes at points for massive structures, in the field in order to support the grillage.

The piles themselves can be made of metal, wood, concrete, reinforced concrete. According to the presence of a void inside, the supports are solid and hollow, in diameter - square, round, complex shapes, according to the presence of a support - hanging and supporting.

In private construction, reinforced concrete rammed, screw steel piles are usually used. The most common types of foundations are pile-screw and bored.

Site marking

After the geological survey is completed and the project is ready, it is necessary to prepare the object. The construction site is thoroughly cleaned of debris, leveled and marked. The design position of the piles is brought to the object using geodetic instruments (level, theodolite), marked with wooden stakes and a rope (outer perimeter, grillage dimensions).

Drilling holes

They dig trenches as you like - you can use a small drill (especially if the supports are installed at a considerable depth). The trench must be at least 1.5 meters high and 15 to 40 centimeters in diameter. In order to increase the level of resistance of the building to heaving, the diameter of the well is expanded in the process (the bottom is 40-60 centimeters, on the surface - 20).

If the foundation is drilled with your own hands, a level is tied to the drill - the vertical must be controlled after each turn.

The minimum distance between the supports of the house is the sum of three sections of the supports: for example, if the diameter of the piles is 40 centimeters, the minimum step is 120 centimeters. But all these calculations are performed before drilling is performed, piles are driven in, etc.

Formwork installation

Formwork is made from cement pipes or wooden planks. The design is carried out on loose and soft soils to prevent the destruction of the walls. If the soils are dense, it is enough to perform the formwork only above the ground to make the head.The frame can be a waterproofed asbestos-cement pipe or a roll of roofing material.

Reinforcement cage manufacturing

Before pouring concrete into the piles, they need to be reinforced. For this, steel rods with a cross section of 12 millimeters are used. The rods are connected every meter with transverse rods or a knitting wire with a cross section of 8 millimeters. To provide a connection with the grillage, the frame is made at least 10 centimeters longer than the pile (then the edges are tied to the reinforcing frame of the grillage).

Pouring concrete

Do-it-yourself piles are easy to make. The material can also be prepared independently or ordered ready-made from the factory. The piles are filled with concrete in layers, necessarily vibrated or compacted with a piece of reinforcement. After the concrete has hardened, the formwork for the monolithic grillage is mounted.

Concrete piles and the foundation created on their basis are an excellent opportunity to build a solid, reliable, durable building. Subject to a correctly executed project, adherence to technology and certain knowledge, all work can be done independently.

Technology for erecting a foundation from bored supports

In frequent construction, piles with a non-removable shell are most often used.

When installing a foundation base from bored supports, several options for a pile rod device are used:

Casting of supports without shells - this option is used only in stable soils with a minimum level of groundwater

For the construction of pits for supports without shells, it is important that the edges of the wells do not crumble, are not washed away by groundwater, and do not change their geometric shape. To strengthen the well, during drilling, clay or concrete mortar can be used, which reliably strengthen the walls of the prepared holes.

Installation of pile rods with a retrievable shell - this technology is used in water-filled soils

The upsetting pipe, made of steel in the form of a cylinder, prevents the collapse of the borehole walls and the erosion of concrete during the filling of the cavity. After filling the pipe with concrete, the casing is pulled to the surface.

Filling of piles with a bored method with a permanent shell (not removable) - this method is practiced when installing foundation supports on soils with a high level of groundwater, composed of rocks with a low bearing capacity, which can be washed out by groundwater during concreting.

We recommend that you see how the work on the device of bored supports is going on.

Issue price

Suppose we decided to build a small 8x10 wooden house. To organize a structure from screw piles, we will need to spend money on the delivery of materials, installation, geological expertise and on the piles themselves. As a result, about 70,000 rubles will be spent on a foundation made of screw piles. The most impressive graphs of expenses will fall on 16 piles (each about 2,250 rubles) and their installation (about 38,000).

Well, if we go to build a strip foundation, then we will have to double the list of everything needed. If engineering and geological surveys for piles will cost 2,500 rubles, then 55,000 rubles will have to be paid to calculate the strip foundation. Added:

- Reinforcement (about 7,000). And the fittings for our house will cost about 40,000.

- Pouring with concrete (another 33,000 rubles). Well, of course, the solution itself is needed. It will cost another 50,000 rubles.

- Waterproofing (without it anywhere, so you have to spend at least 12,000).

- Plywood and burs (this is at least 15,000 more).

The list can be continued longer. Ultimately, such a foundation will cost not just a pretty penny, but 270,000 rubles or more.

And that is not all. Can you determine the quality of concrete "by eye"? And how to catch the moment when the reinforcement starts to fit? Contractors almost always use cheaper materials. Therefore, such a concrete base will be too expensive.Piles are much easier to check. And their installation is usually carried out without problems in front of the customer.

Features of the foundation on piles

In this case, screw piles are used as supports, each of which is equipped with a kind of blades, which in turn fit tightly into the ground to a selected depth. Such structures are becoming more and more popular due to their high load-bearing capacity. In addition, modern elements of this type are produced even more durable.

The thickness of the metal wall of a typical pile is 4-6.5 mm. This means that such a foundation can also be built on problem ground. It is in such an area that they are given the greatest preference.

Pros and cons of such a foundation

If we talk about the advantages, then it is worth highlighting:

- Fast installation.

- No need to use heavy construction equipment. The piles are driven by hand.

- The possibility of building a house in a marshy or loose area. This is the best option for unstable soils. Also, piles are suitable for areas with large differences in soil height.

- Long service life.

- No need to carry out numerous preparatory work (digging trenches, etc.).

- Possibility of installing piles at any time of the year.

But no one is perfect, therefore, such designs have disadvantages:

Risk of purchasing material of inadequate quality. In fact, there is a similar disadvantage when building a concrete base. If you purchase not steel piles treated with a protective compound, but made of other metals, then the structure will corrode.

Healthy! When selecting piles, be sure to check all welds. They must be neat and of high quality. The reliability of the entire building will depend on this.

Piles are very difficult to install on rocky ground. Since these products are equipped with blades, they are the ones that are damaged during the installation process. Because of this danger, it becomes impossible to install the structure to the desired depth. As a result, the finished foundation turns out to be extremely unstable.

Also, the disadvantages often include the lack of a basement. But if desired, it can be organized without problems by sewing up the structure.

Of course, there are fewer minuses to piles than pluses, but the usual concrete structures of the tape type also have them.

Classification of concrete piles

It is customary to subdivide piles depending on the material of manufacture, therefore, concrete support rods include reinforced concrete supports and concrete piles.

Reinforced concrete driven supports are usually made industrially, concrete ones can be poured directly at the construction site, while work on the construction of a pile field for a building can be done with your own hands. The installation of the driven supports cannot be done manually; in order to immerse the rod into the ground, the use of expensive piling equipment will be required, which greatly increases the cost of building the facility.

The disadvantage of driven piles is that they are mounted using special equipment.

Depending on the method of installation, concrete supports can be divided into two groups: rammed and driven.

According to the technology of work execution, rammed supports are mounted in pre-prepared wells (pits), which are performed using special drilling equipment. Driving rods are immersed in soil (sandy or clayey) without preliminary preparation.

It is customary to subdivide piles depending on the shape of the cross-section; there are reinforced concrete supports with round rods, as well as square and rectangular. Round-section supports are used on weak, heaving soils, the basis of which is clay; for more rigid soil bases, rods with a square or rectangular cross-section are used.

What materials will you need?

When setting up your foundation, you may need some tools.We recommend stocking up on a level, tape measure, hammer, shovel and welding device. In addition, you may need a concrete mixer and lacing.

Before starting the process, it is necessary to lower the frames made of reinforcement. Asbestos-cement pipes may also be suitable for their role.

- The use of asbestos-cement pipes is important if the soil is rather loose and characterized by crumbling.

- Provided that the soil is dense, concrete can be poured directly into the borehole. It is also required to backfill sand at the bottom of the well. The layer thickness is about 25 centimeters. From above it should be covered with rubble material with a layer of 10 centimeters.

All these operations help in protecting the base of the LF foundation from hazardous actions caused by washing away excess moisture. In addition, with their help, other factors that negatively affect the design will be excluded.

Installation of a fence using a pile foundation is carried out as follows:

- Along the entire perimeter, the base is tied with reinforcing materials. Formwork is placed in a circle.

- The armature can be scalded or tied with wire. The best option would be to use fittings, an average of 13 millimeters in diameter.

- You should not skimp on the thickness of the reinforcement. This entails a deterioration in the reliability of the piles. They simply cannot withstand the entire weight of the building and cracks are likely to occur on them. The consequences are disastrous for the entire building, because if water gets into the pile cracks, then the foundation will collapse.

One of the newest materials in this area is fiberglass reinforcement. Its main advantage is cost and light weight. As for the width of the LMF foundation, it is determined based on the parameters of the building itself. Usually it is about four hundred millimeters.

Do I need to concreted screw piles

The question of why concrete is poured into screw piles haunts many craftsmen. Someone argues that this is not necessary, while others do not imagine the arrangement of the pile foundation without concreting the trunk.

Competent opinions of the supporters of this technology

The technology makes it possible to build reliable houses with foundations with a sufficiently high bearing capacity without destroying neighboring buildings, which is especially important in densely built-up facilities. Pouring a pile with concrete increases its bearing capacity by 30-35%, making it stronger and more rigid.

It is also important that concreting reliably protects the pile shaft from moisture ingress, which can destroy the structure. And when ice appears in an unpoured pile during thermal expansion, it can change and deform its trunk .. When considering whether screw piles should be poured with concrete, it is worth considering such an advantage as reducing the cost of work

Piles can be installed with a smaller diameter, since the cost of concrete for pouring is much less than the cost of a pile, and the strength in the end is the same

When considering whether screw piles should be poured with concrete, it is worth considering such an advantage as reducing the cost of work. Piles can be installed with a smaller diameter, since the cost of concrete for pouring is much less than the cost of a pile, and the strength is the same in the end.

Justification of uselessness

Some masters in Moscow and other cities doubt whether it is worth pouring concrete into the piles, arguing that the contact between concrete and metal implies a difference in the coefficient of expansion. This can lead to cracks in concrete, accumulation of moisture, corrosion, and pile destruction.

Modern manufacturers offer new thick-walled pipes that can withstand serious loads, and their cost is approximately equal to the price of conventional pipes, taking into account concreting. But in this case, you can save time and effort on filling the supports with mortar.

Concreting is inappropriate when performing a foundation for a certain period of time - for example, under a construction trailer. The question of whether it is possible to unscrew the screw piles filled with concrete is not even worth it - it is very difficult. In this case, it is easier to install the hollow supports, and then unscrew them with a special mechanized technique for re-installation.

Concrete screw piles will help create a reliable and solid foundation for the construction of a durable house. Subject to adherence to technology and the choice of quality materials, all work is done quickly and easily.