Materials for making

The choice of material for making a grillage depends on several factors:

- type of foundation;

- foundation loads;

- type of soil;

- height of groundwater.

Reinforced concrete

The most convenient option for a grillage for concrete piles is a reliable, stable, durable and widespread material. They are made of steel reinforcement and concrete, which form a strong and wear-resistant structure. It is used in the construction of heavy multi-storey buildings and industrial facilities, less often for suburban housing.

Distinguish between prefabricated and monolithic reinforced concrete grillages. Prefabricated prefabricated and assembled on site.

- advantages - strength and ease of installation;

- disadvantages - the need to use lifting equipment and waterproofing of connecting nodes.

Reinforcement in the form of a flat or volumetric frame increases the strength many times over, hardened concrete tolerates compressive loads well.

Metal

An I-beam or channel is used. Profile rolled products provide rigidity and strength of the structure. The metal grillage is suitable for single-storey houses and in pile-screw foundations. The metal is attached to the pile heads by welding.

Metal piles and grillages require preliminary protective treatment, as they are susceptible to corrosion. Usually used on heaving soils.

- advantages - rigid and reliable construction;

- disadvantages - the need to use crane technology, treatment of seams due to the corrosion instability of welded joints.

Wood

A wooden beam or a box from a board for grillages is used for light wooden or frame-panel houses. A roofing or roofing material waterproofing should be installed between the beams and piles. To keep the wood from rotting, it is necessary to treat the elements with a special bioprotective impregnation.

The bars are attached to the piles with brackets or bolts. This material is now almost never used.

- advantages - structures are light and inexpensive, quick installation;

- disadvantages - low strength, the need for additional processing.

Concrete

Used for small buildings with a maximum number of supports. The pile heads should be buried into the concrete of the grillage by at least 10 cm. The absence of reinforcement does not allow such structures to be heavily loaded; bending loads are critical. Experts do not recommend using this type of grillage.

- advantages - simplicity and low cost;

- disadvantages - unreliability.

Calculation example

Initial data:

- Geological conditions of the area: at a depth of 2 meters from the surface of the soil, thick-plastic loams lie, then hard clays with a porosity coefficient of 0.5 are located at the entire depth of the study.

- Snow load - 0.18 t / m².

- It is required to design a foundation for a one-story house with an attic. The dimensions of the house in the plan are 4 by 8 meters, the roof is covered with a metal tile hip (the height of the outer wall is the same on all sides), the walls are made of bricks 0.38 m thick, the partitions are plasterboard, the floors are reinforced concrete slabs. The height of the walls within the first floor is 3 meters, on the attic floor the outer walls are 1.5 meters high. There are no internal walls (only partitions).

Collection of loads:

- wall mass = 1.2 * (24 m (house perimeter) * 3 m (first floor) + 24 m * 1.5 m (attic)) * 0.38 m * 1.8 t / m³ (brickwork density) = 88.65 t (1.2 - load safety factor);

- weight of partitions = 1.2 * 2.7 m (height) * 20 m (total length) * 0.03 t / m² (weight per square meter of partitions) = 2 tons;

- the mass of floors, taking into account the cement screed, 3 cm = 1.2 * 0.25 m (thickness) * 32 m² (area of one floor) * 2 (floor of the first floor and floor of the attic) * 2.5 t / m² = 48 tons;

- roof weight = 1.2 * 4 m * 8 m * 0.06 t / m² = 2.3 tons;

- snow load = 1.4 * 4 m * 8 m * 0.18 t / m2 = 8.1 tons;

- payload = 1.2 * 4 m * 8 m * 0.15 t / m² * 2 (2 floors) = 11.5 tons.

Total: M = 112.94 t. The perimeter of the building is Uhouse = 24 m, the load per linear meter is Q = 160.55 / 24 = 6.69 t / m. We pre-select a pile with a diameter of 30 cm and a length of 3 m.

By formulas for determining the distance between piles

All the necessary formulas are given earlier, you just need to use them in order.

1.F = 3.14 D² / 4 (round pile area) = 3.14 * 0.3 m * 0.3 m / 4 = 0.071 m², U = 3.14 D = 3.14 * 0.3 m = 0.942m; (pile perimeter in a circle);

2. Psn = 0.7 * 90 t / m² * 0.071 m2 = 4.47 t;

3. Rbok. surface = 0.8 * (2.8 t / m2 * 2 m + 4.8 t / m2 * 1) * 0.942 = 7.84 t;

In this formula, 2.8 t / m² is the design resistance of the lateral surface of the pile in refractory loam, 2m is the height of the loam layer in which the foundation is located. The resistance is found according to table 3. There are given values for the depths of 50, 100 and 200 cm suitable in this case. In the calculation we take the minimum in order to ensure the bearing capacity margin.

4.8 t / m² is the design resistance of the lateral surface of the pile in semi-hard clay, 1m is the height of the foundation located in this layer. The last number in the formula is the perimeter of the pile found in the first paragraph. The values 0.7 and 0.8 in items 2 and 3 are coefficients from the formulas.

4. P = 4.47 t + 7.84 t = 12.31 t (full bearing capacity of one pile);

5. L = 12.31 t / 6.69 t / m = 1.84 m - the maximum value of the distance between the piles (between the centers).

Assign a distance of 1.8 m. the length of our walls is a multiple of 2 m, it is more convenient that the distance between the piles is 2 m, for this you need to slightly increase the bearing capacity of the pile, for example, by increasing its diameter. If the obtained step value is large enough, it is wiser to find the minimum one, since the greater the distance between the piles, the more the grillage section will be needed, which will lead to additional costs. Calculations for a reduced diameter are performed according to the same principle. The applied amount of material is calculated for several options and the optimal value is selected.

Good publicity

What calculations are needed when installing piles

When calculating piles, the following values are determined:

- Length.

- Diameter.

- Number.

- Location.

The average diameters of the concrete structures to be installed are considered to be the range of 15-40 cm. The common type is with a section of 20 cm. For accurate calculations, you need to use tables indicating the diameter of the supports, the ability to withstand loads.

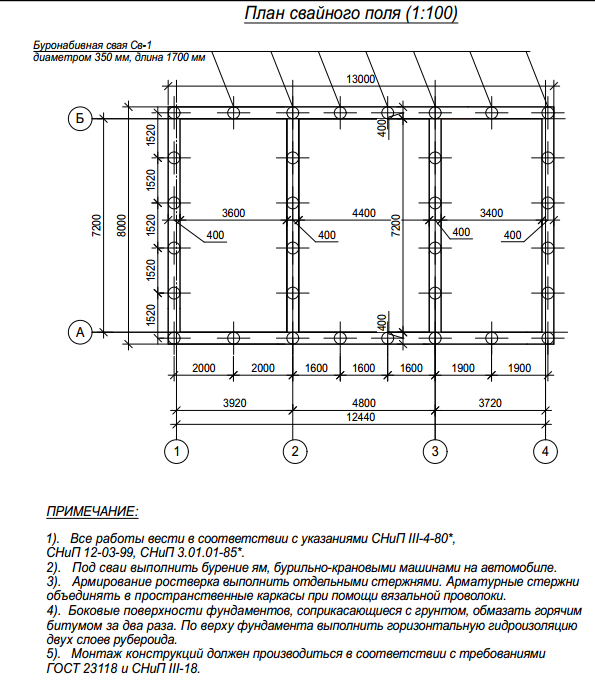

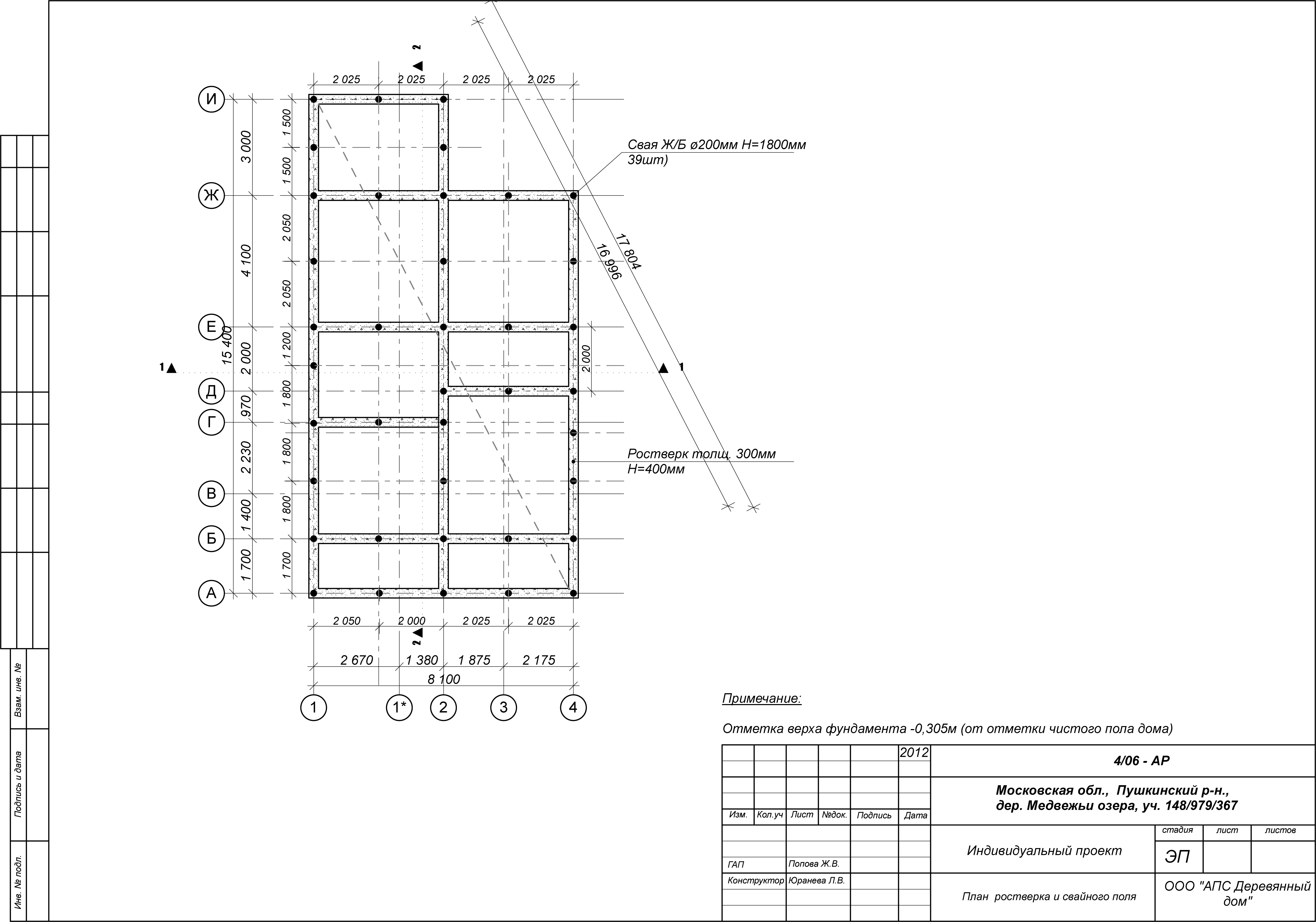

Approximate location of piles

Approximate location of piles

Having learned what bearing capacity one unit of a concrete structure has, you can calculate the distance between them:

I = P / Q:

- I - Suitable step between structures.

- P - What kind of load one unit can withstand.

- Q - Load applied per square meter of the base (you need to find out the mass of the building, divide by the total length of the grillage).

Calculation: building, total mass - about 50 tons. Installed on tight loam. The diameter of one pile is 20 cm.We get the following calculation:

The mass of the building is 50,000 kg / for the load exerted by the base of the building 1884 kg = 26.53 (round up to 27). To erect a building weighing 50 tons, it is necessary to place 27 supports around the perimeter of the base.

If you plan to install heavy structures inside the house, piles are also placed under them. The depth of the well depends on the bearing soil, the level of freezing. In central Russia - 1.5-3 meters.

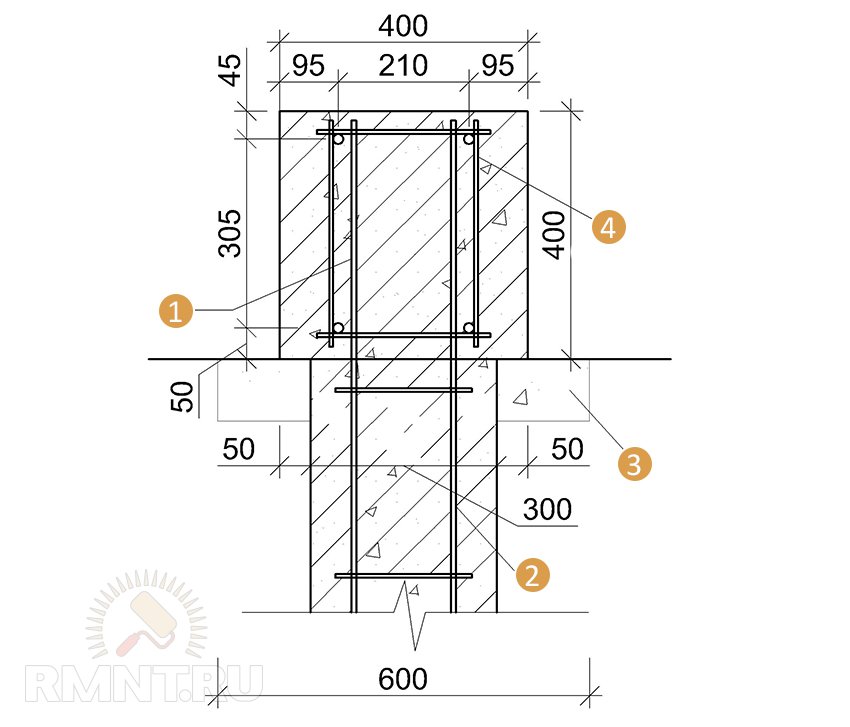

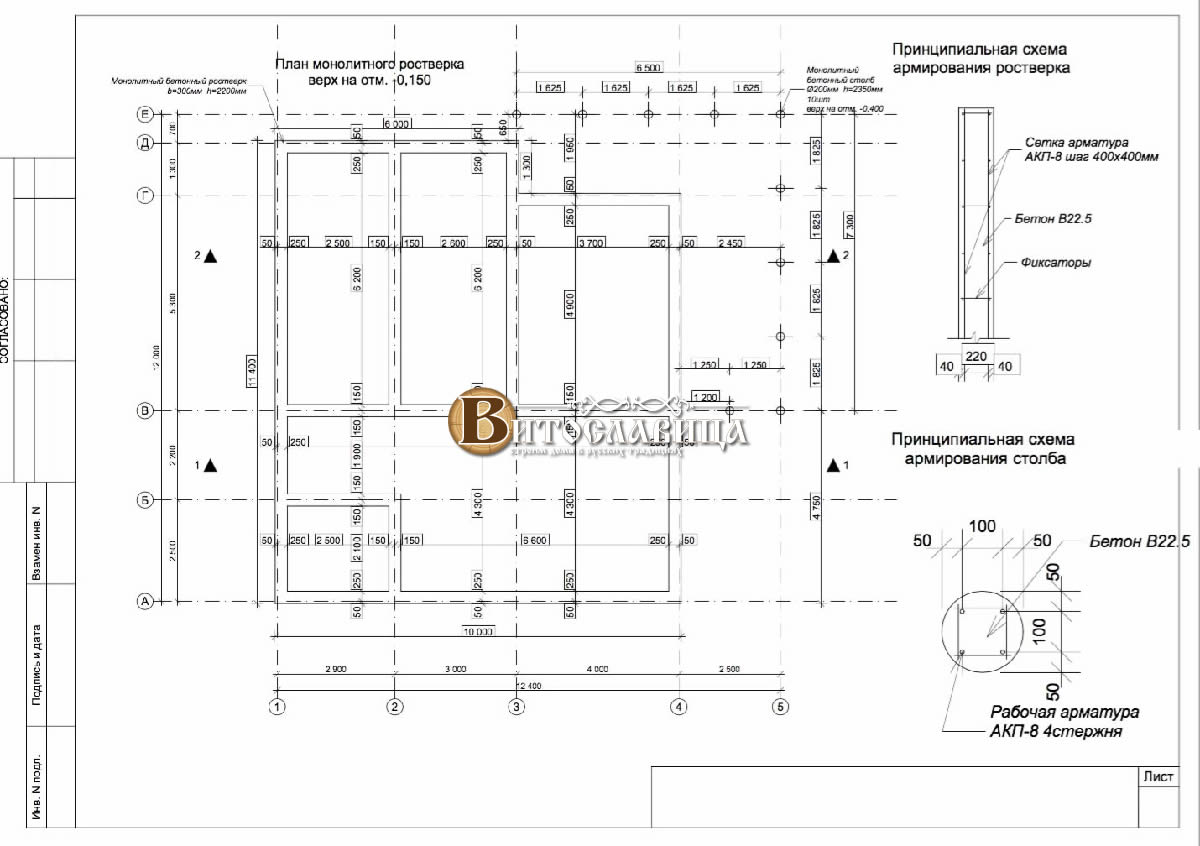

Calculations for the installation of a monolithic grillage

To determine the width of a structure:

B = M / L * R:

- The width of the grillage.

- Building weight.

- The length of the concrete structure.

- What kind of load can the soil withstand?

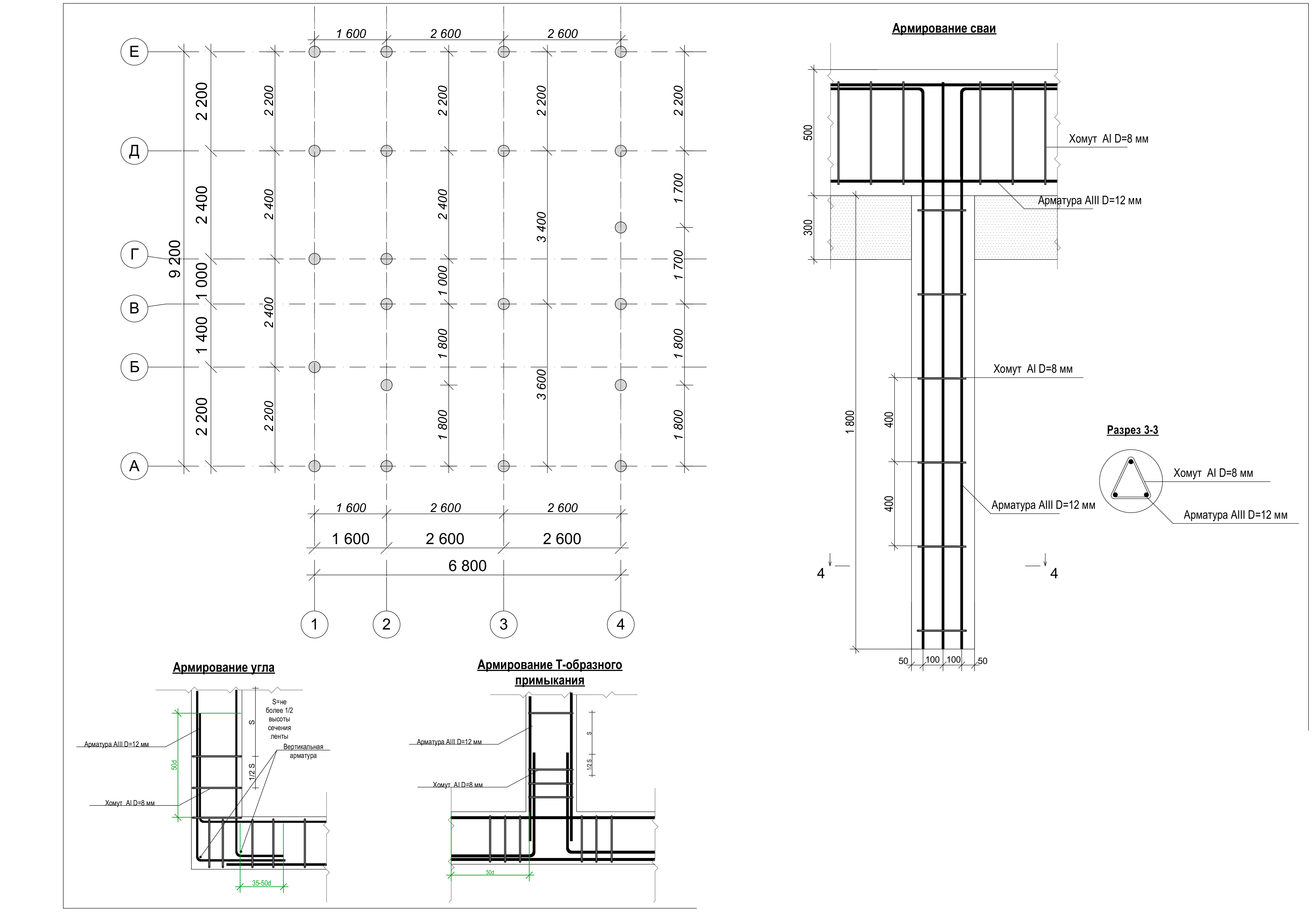

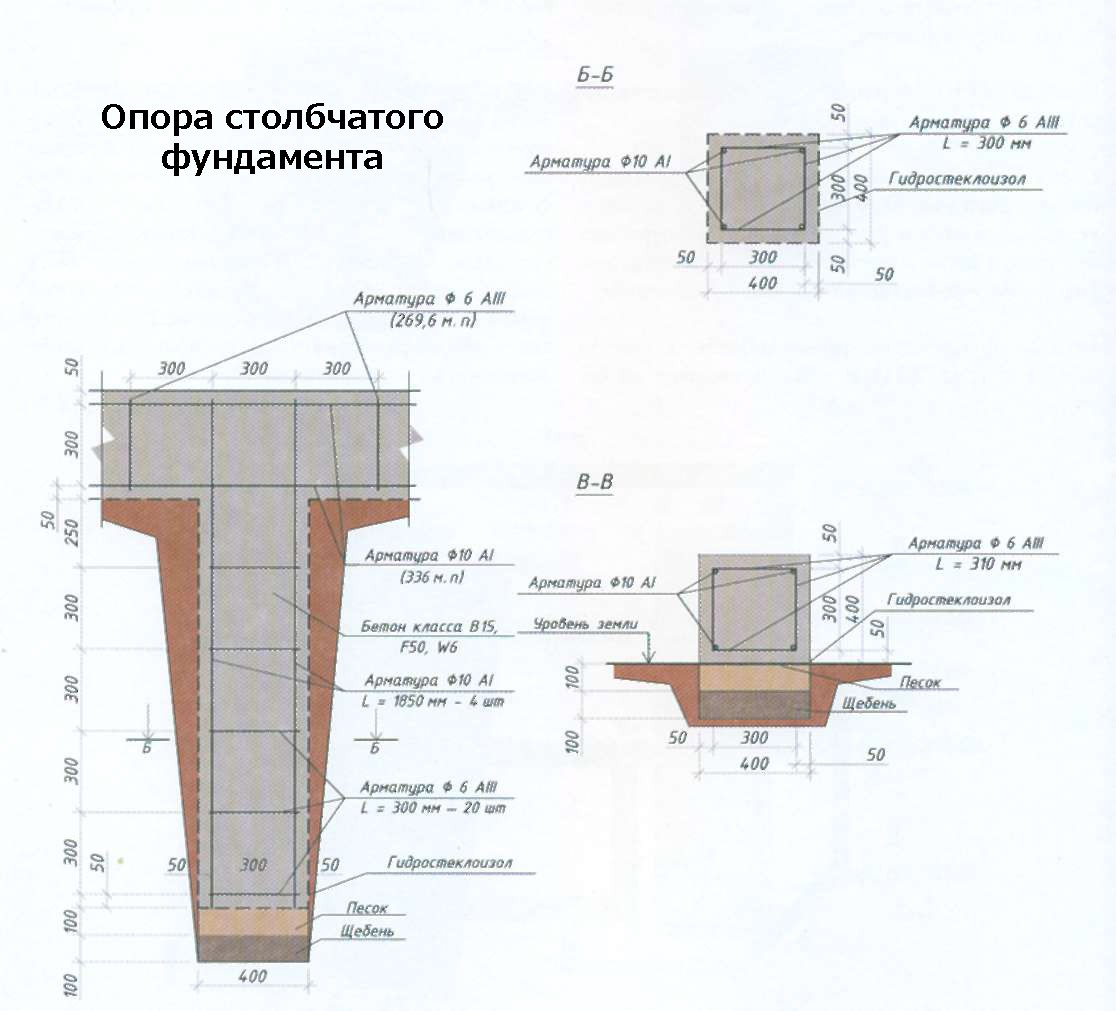

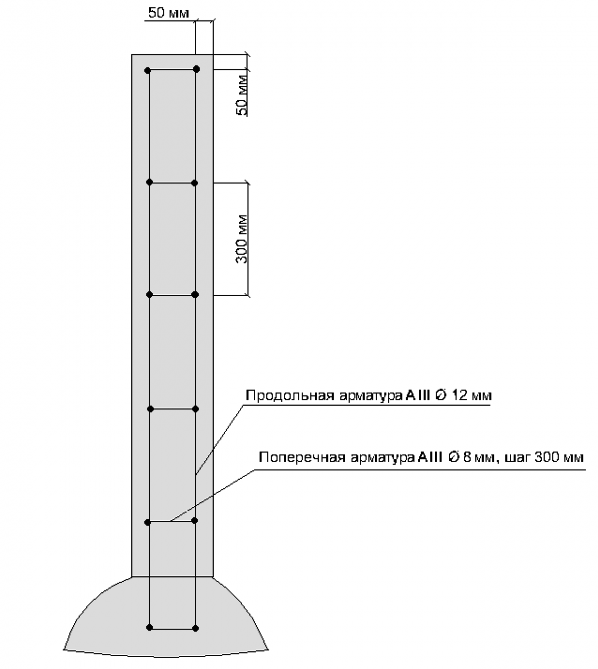

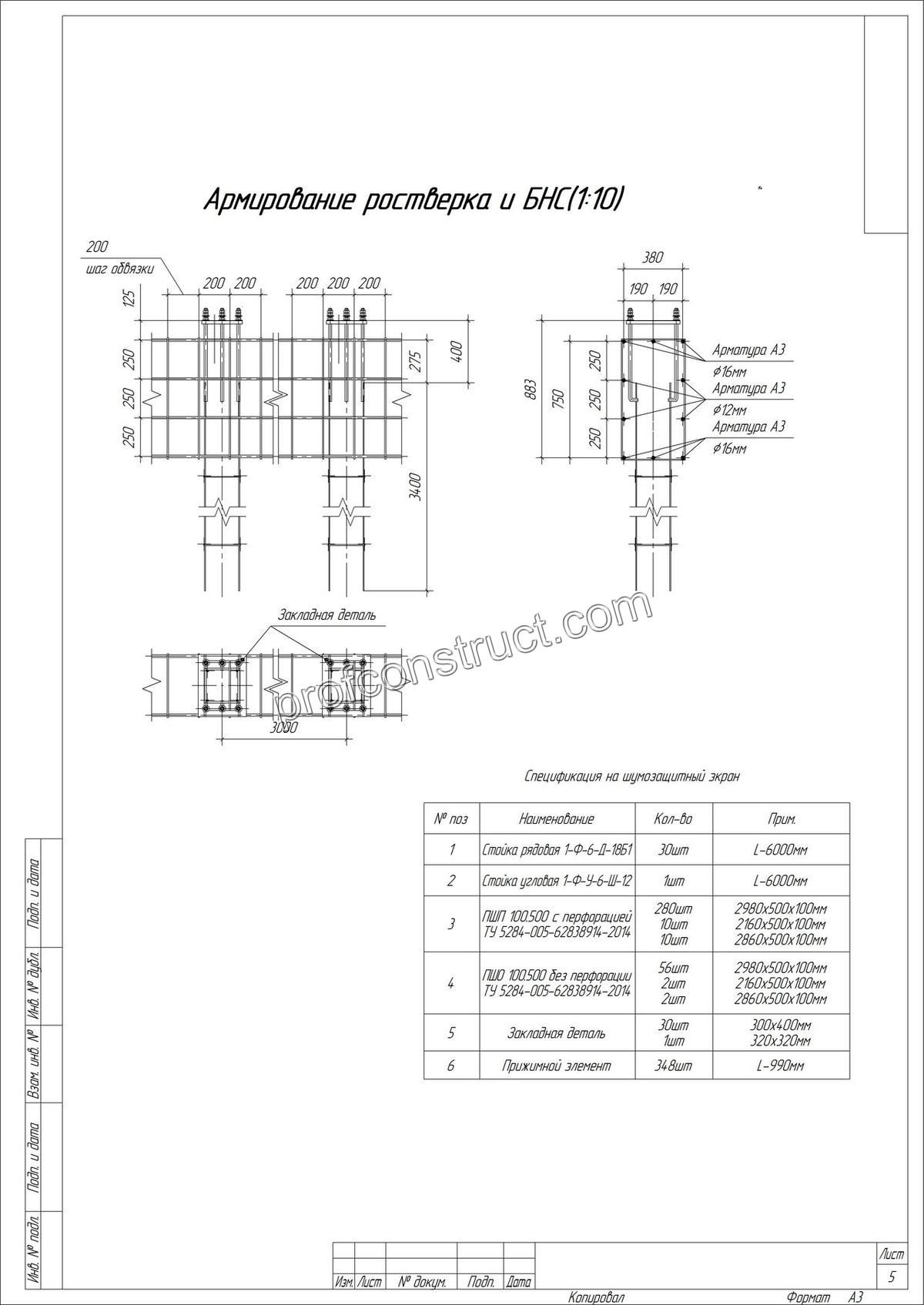

Reinforcement calculation

Before pouring the piles, reinforcement is carried out to strengthen the base. The size of the reinforcement depends on the mass of the building, weight foundation loads... Common fittings are corrugated, 12 mm in size.

Types and calculation of the load-bearing element of a brick building

Monolithic base, as well as FBS blocks are able to withstand the load of a brick structure

Monolithic base, as well as FBS blocks are able to withstand the load of a brick structure

Many people do not know which foundation is best for a brick house, for this reason they start to panic. Before you start calculating the foundation for a house, you need to decide on its appearance.

Nowadays, there are many types of load-bearing elements of a building.But not all of them can withstand the direct impact of heavy loads from a brick building.

The foundation should be chosen correctly, based on the level of climatic influences in a particular region. It is also necessary to determine the structure of the soil structure, the location of groundwater types and the level of loads that will arise from the residential building itself.

According to experts, a monolithic foundation is considered good, since its bearing capacity is quite large. The downside of this type is the high cost, which is unacceptable for the device of a private country house.

You can make a foundation from blocks, it also has many positive characteristics, but the FBS device is expensive due to delivery. For this reason, the block type of construction is omitted. The best option would be a foundation on piles, since in addition to a large number of advantages, this type of foundation is cheaper than the previous types.

You can make a foundation from blocks, it also has many positive characteristics, but the FBS device is expensive due to delivery. For this reason, the block type of construction is omitted. The best option would be a foundation on piles, since in addition to a large number of advantages, this type of foundation is cheaper than the previous types.

In order to properly perform the foundation for a brick house, it is imperative to perform a detailed calculation of the supporting structure. Such actions can be performed according to such principles as:

- a complete calculation of the mass of the structure is carried out, taking into account: partitions, roof structure, bearing walls made of bricks, and also the weight of finishing materials should be added;

- the mass of the base is calculated, while its variety should be taken into account;

- the total value of the mass must be divided by the area that is used for the future foundation, as a result, a weight number is formed that affects the soil. For more information on calculations for a brick house, see this video:

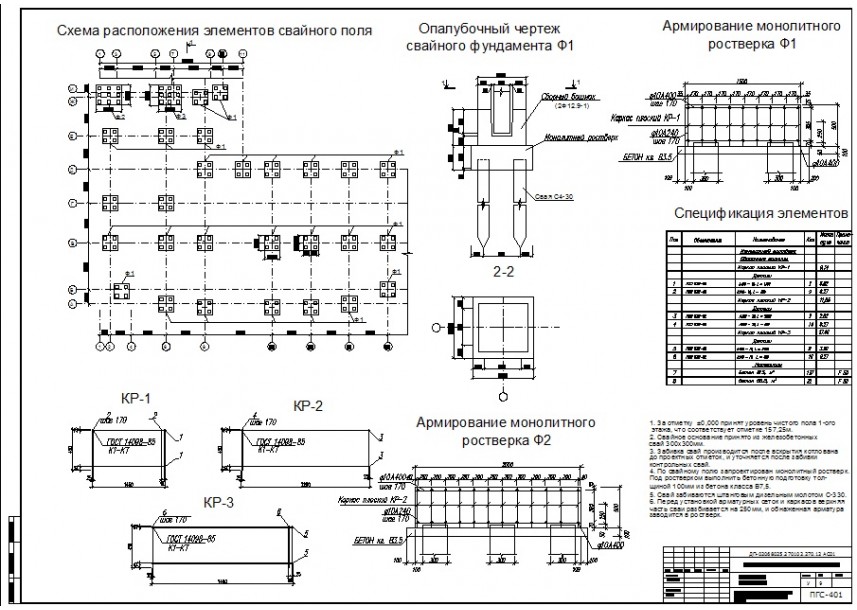

Collecting loads

Before calculating the bored foundation, it is also necessary to collect loads from all overlying structures. It will take two separate calculations:

- pile load (taking into account the grillage);

- load on the grillage.

This is necessary because the calculation of the grillage of the pile foundation and the characteristics of the piles will be carried out separately.

When collecting loads, it is necessary to take away all the elements of the building, as well as temporary loads, which include the mass of snow cover on the roof, as well as the payload on the floor from people, furniture and equipment.

To calculate the pile-grillage foundation, a table is drawn up, in which information about the mass of structures is entered. To calculate this table, you can use the following information:

| Design | Load |

|---|---|

| Frame wall with insulation, 15 cm thick | 30-50 kg / sq.m. |

| Wooden wall 20 cm thick | 100 kg / sq.m. |

| Wooden wall 30 cm thick | 150 kg / sq.m. |

| Brick wall 38 cm thick | 684 kg / sq.m. |

| Brick wall 51 cm thick | 918 kg / sq.m. |

| Plasterboard partitions 80 mm without insulation | 27.2 kg / sq.m. |

| Plasterboard partitions 80 mm with insulation | 33.4 kg / sq.m. |

| Interfloor ceilings on wooden beams with insulation laying | 100-150 kg / sq.m. |

| Reinforced concrete floor slabs 22 cm thick | 500 kg / sq.m. |

| Roofing cake using a coating of | |

| sheets of metal tiles and metal | 60 kg / sq.m. |

| ceramic tiles | 120 kg / sq.m. |

| bituminous shingles | 70 kg / sq.m. |

| Temporary loads | |

| From furniture, people and equipment | 150 kg / sq.m. |

| from snow | determined by table. 10.1 JV "Loads and Impacts" depending on the climatic region |

The dead weight of the foundations and grillage is determined depending on the geometric dimensions. First, you need to calculate the volume of the structure. The density of reinforced concrete is assumed to be 2500 kg / m3. To get the mass of an element, you need to multiply the volume by the density.

Each component of the load must be multiplied by a special factor that increases reliability. It is selected depending on the material and manufacturing method. The exact value can be found in the table:

| Load type | Coefficient |

|---|---|

| Constant for: - wood - metal - insulation, backfill, screeds, reinforced concrete - manufactured at the factory - manufactured at the construction site | 1,1 1,05 1,1 1,2 1,3 |

| From furniture, people and equipment | 1,2 |

| From the snow | 1,4 |

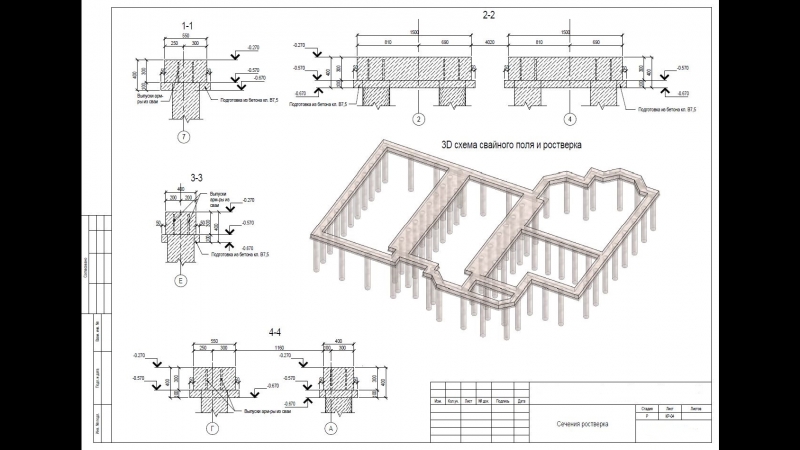

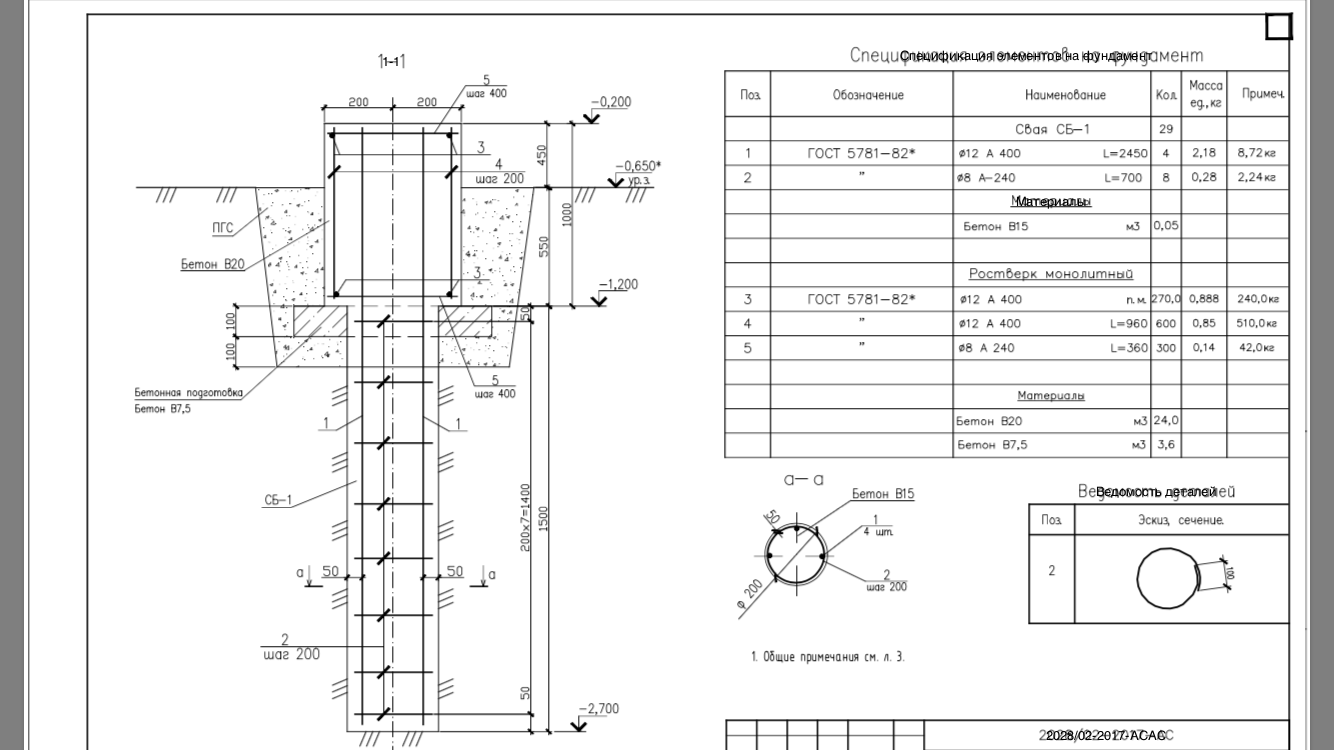

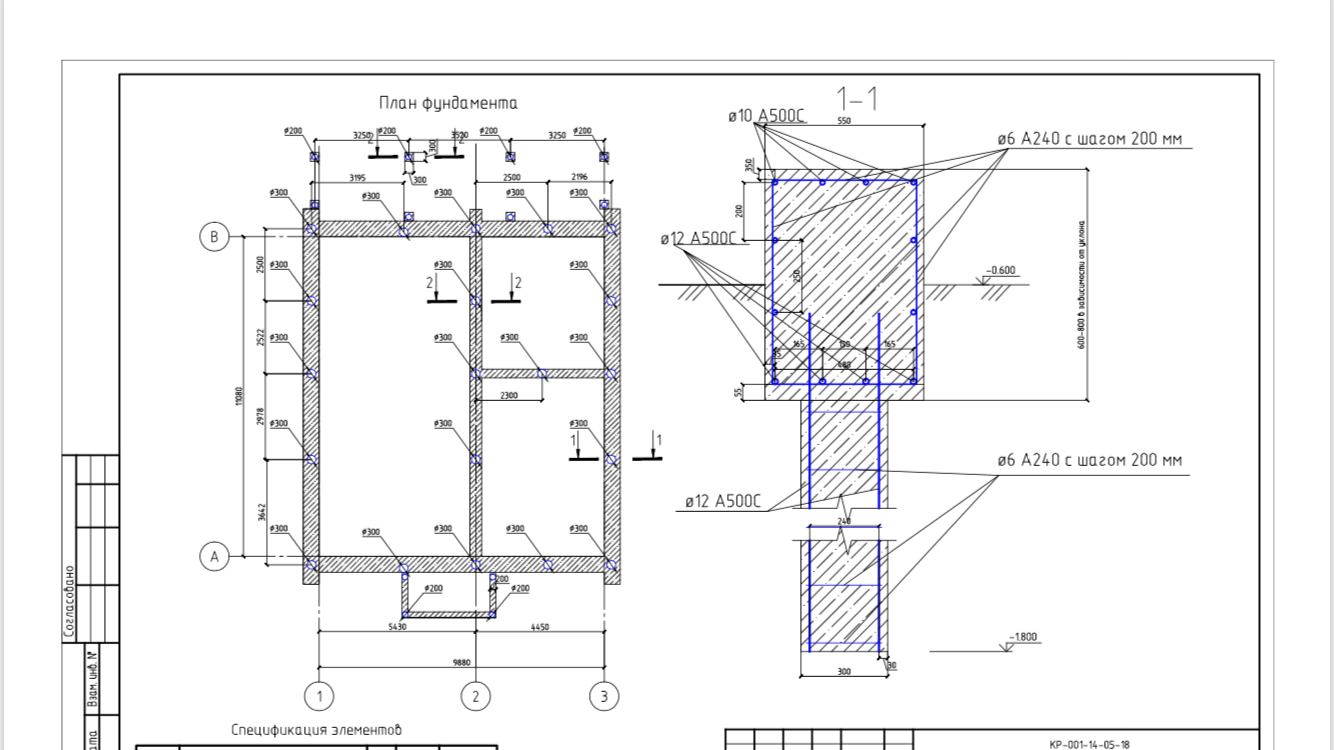

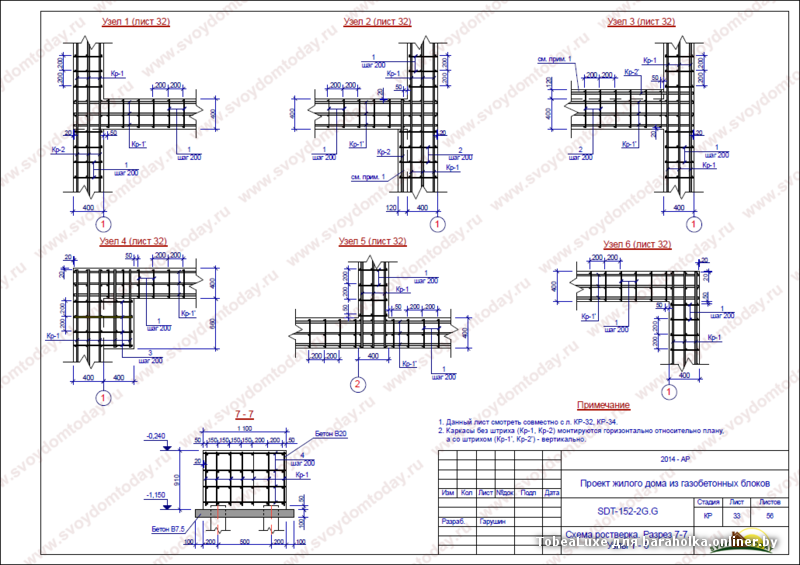

Installation of a monolithic grillage

After the installation of the piles, the installation of the grillage is started. His device includes:

- installation of formwork;

- laying of reinforcement according to the design indicators;

- filling the mold with concrete mortar;

- dismantling of formwork;

- waterproofing works.

The design of the formwork depends on how the grillage is located above ground level.

Formwork installation

The strength and appearance of the grillage will depend on the correct installation of the formwork. The removable form is most often assembled from boards, sometimes plywood is used.

The lower part of the formwork for the hanging grillage.

It is imperative to control the vertical level of installation of the side walls. The corners should be set at 90 degrees, unless other parameters are set in the project. The walls are reinforced with struts so that the concrete solution does not destroy the formwork.

If the grillage is located above ground level, you need to calculate the load from the reinforcement and concrete mortar on the bottom wall of the mold. If the bottom falls out, work will need to start over.

After the installation of the formwork, a layer of sand 150 mm thick is poured into it. Moisten it, tamp it well. Laying waterproofing material.

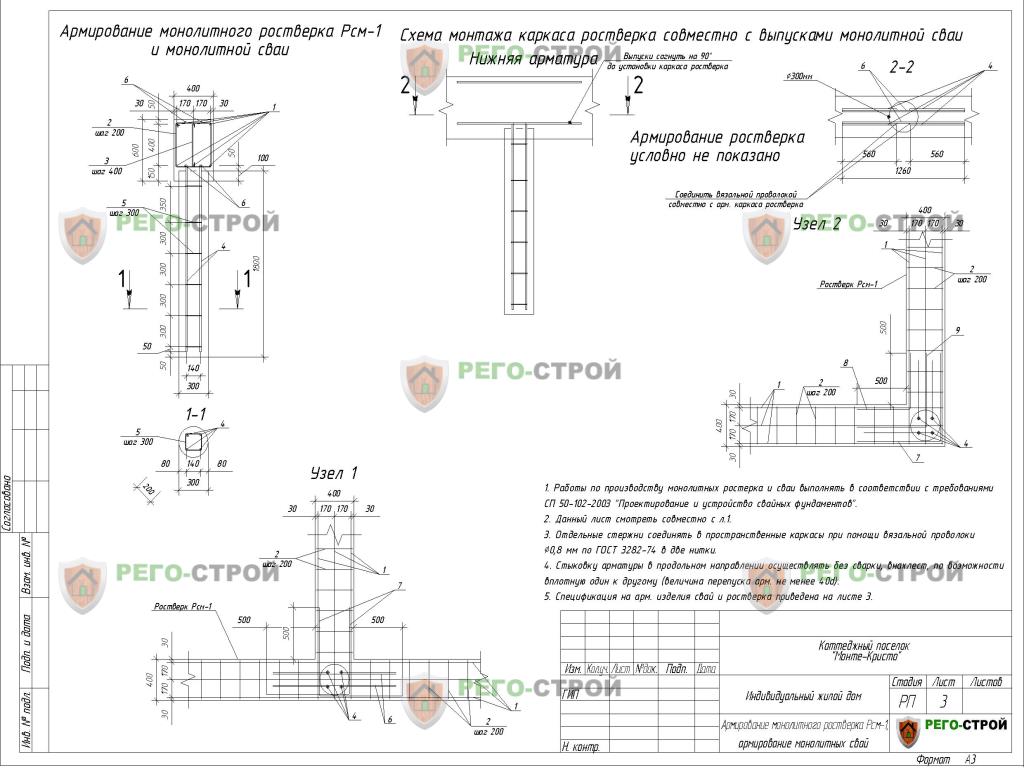

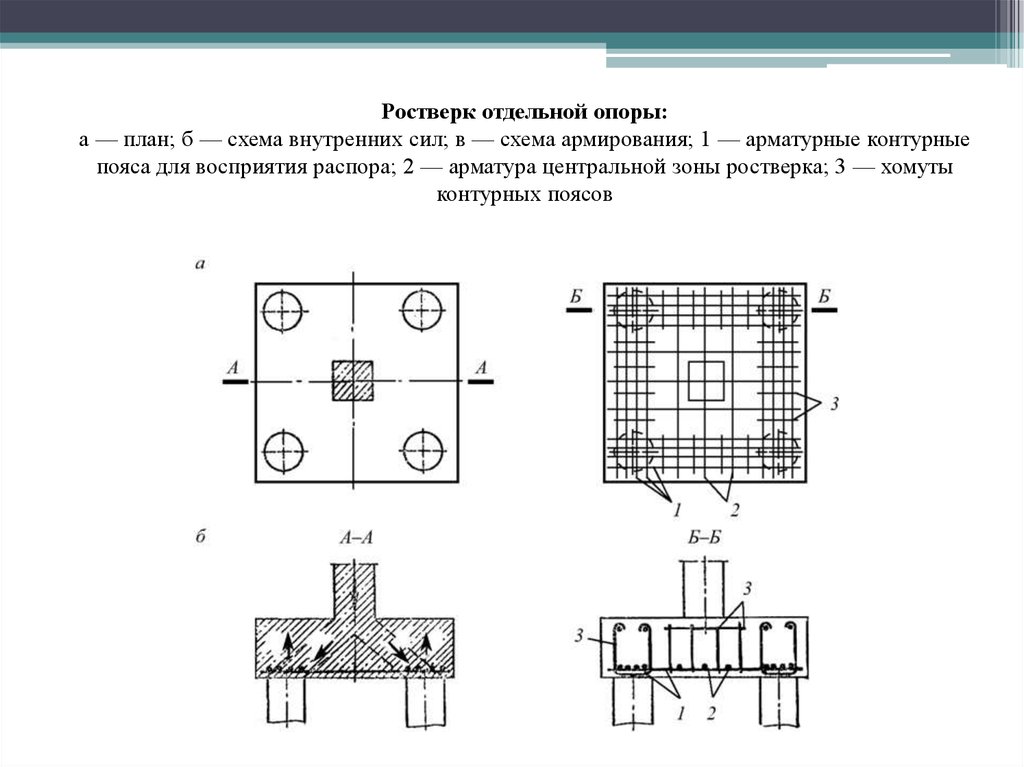

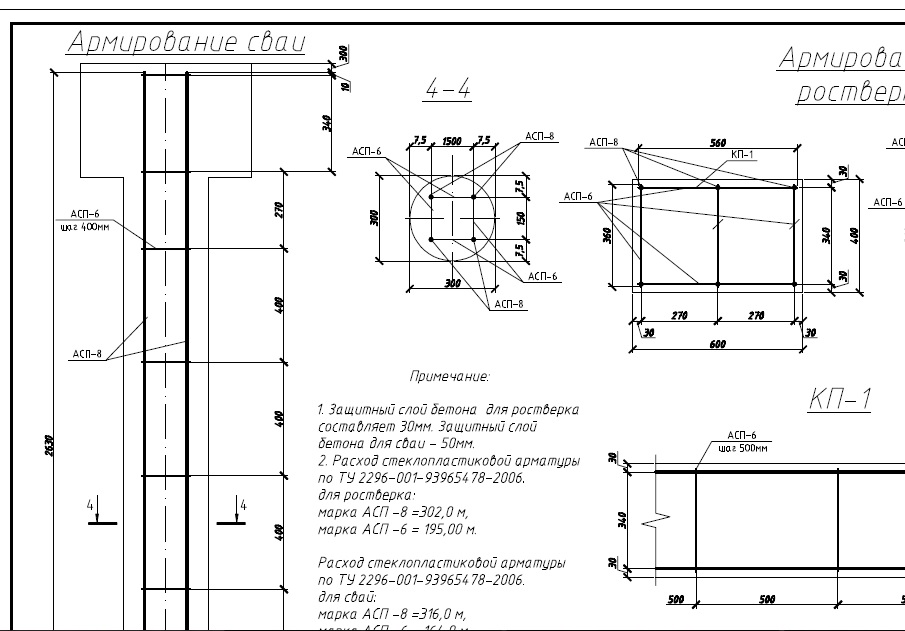

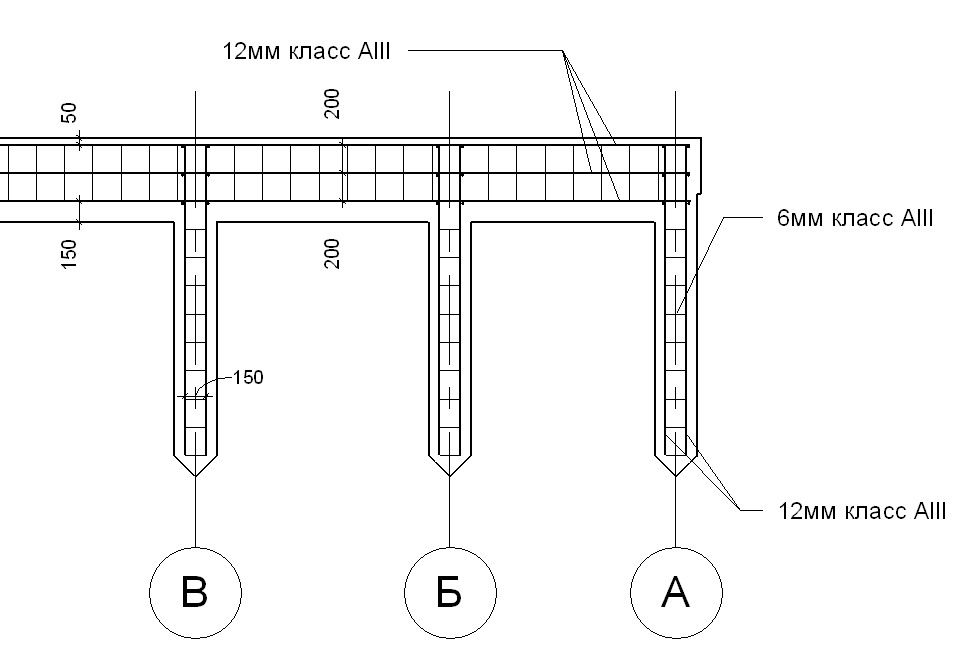

Reinforcement

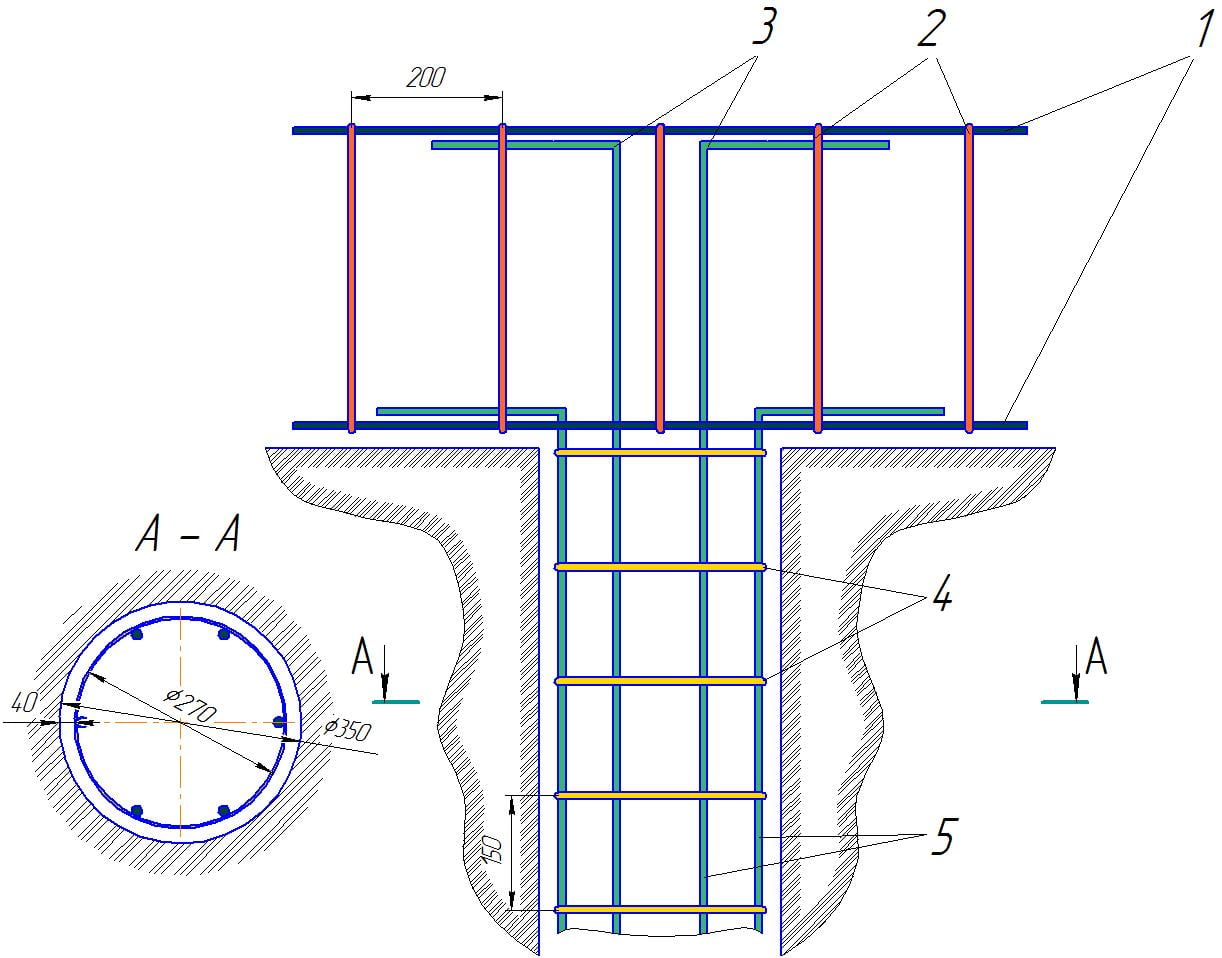

Reinforcement of hanging grillages is performed with metal rods. Experience has shown that fiberglass reinforcement is good when it rests on the ground. The type of reinforcement and the type of beams for the grillage device are determined at the design stage of the house.

After cutting the supports to the desired size, reinforcement will protrude from them. It will be used as a connecting element between the grillage and the support.

Before performing the reinforcement, draw a drawing of the location of the metal rods. All work is performed, focusing on this scheme. If the reinforcement is incorrectly laid, the structure may not withstand the load and deform.

The metal frame is set strictly according to the level.

Metal rods, connected to each other by 3-4 pieces of wire, are lowered into the formwork. The reinforcement should not touch the edges of the wooden mold under the concrete, so that later it would not turn out that its edges protrude from the concrete base.

To ensure ventilation of the space under the floor of the house, air vents are left in the structure, inserting pipes with a diameter of 100 mm into the formwork.

After installing the metal frame, all construction waste is removed from the formwork using an industrial vacuum cleaner with high power.

Pouring with concrete

They check the geometry and reliability of the fastening of the formwork and the reinforced frame so that the structure does not collapse during the filling with concrete.

A cement mortar is prepared. It should be homogeneous, without lumps. The solution is mixed at the construction site using a mixer or ordered from the factory in a concrete mixer.

The filling is carried out in one pass. It is not recommended to take a break for more than a few hours. It is poured in layers, each layer is compacted with a mixer or a shovel bayonet so that all air bubbles come out and there are no voids left.

Waterproofing

Hanging grillage can be insulated from moisture by coating the structure with bituminous mastics.

When installing a buried concrete tape and before pouring concrete, roofing material is placed on the bottom of the formwork, and after dismantling the formwork, the entire grillage is covered with roll insulation.

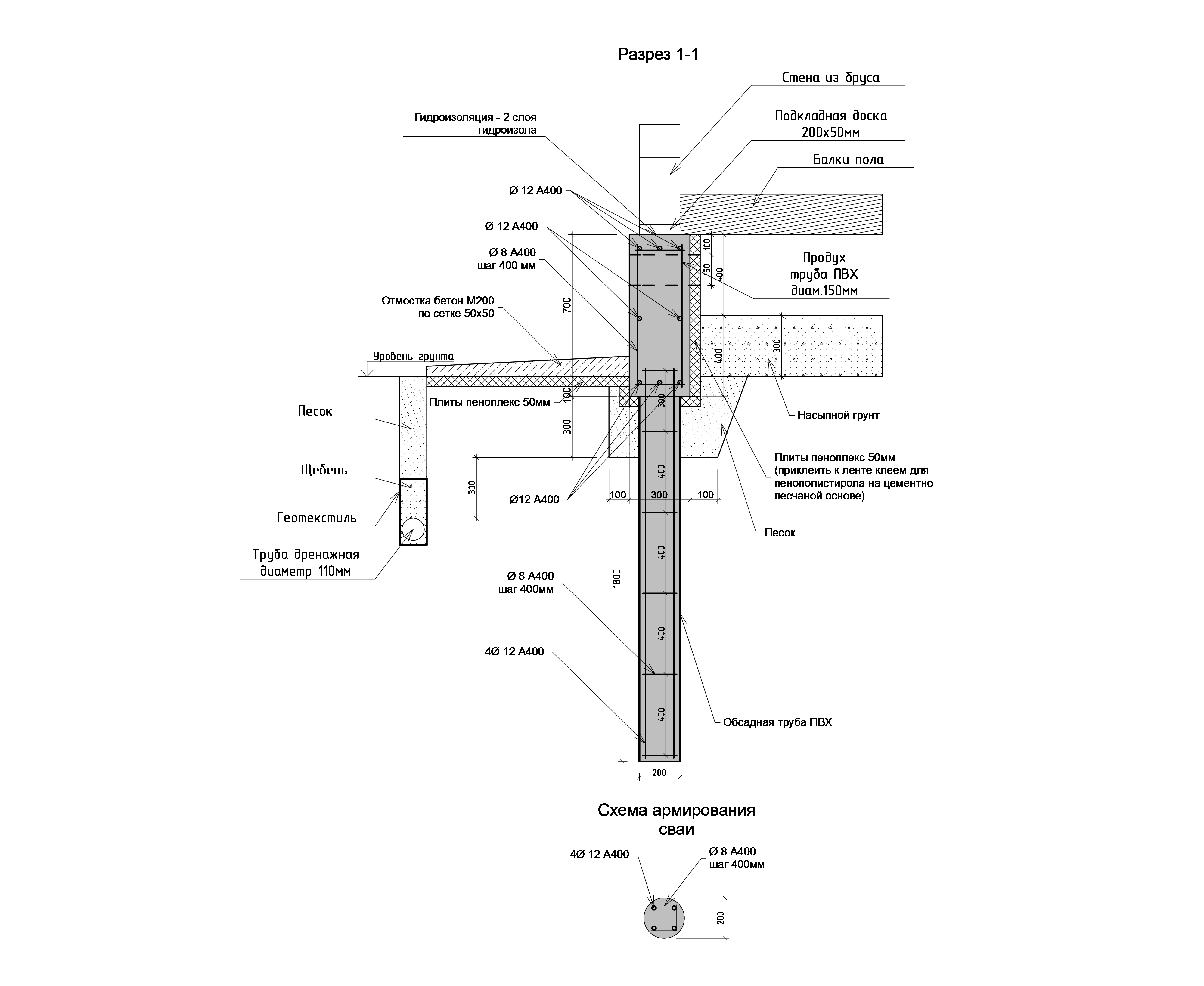

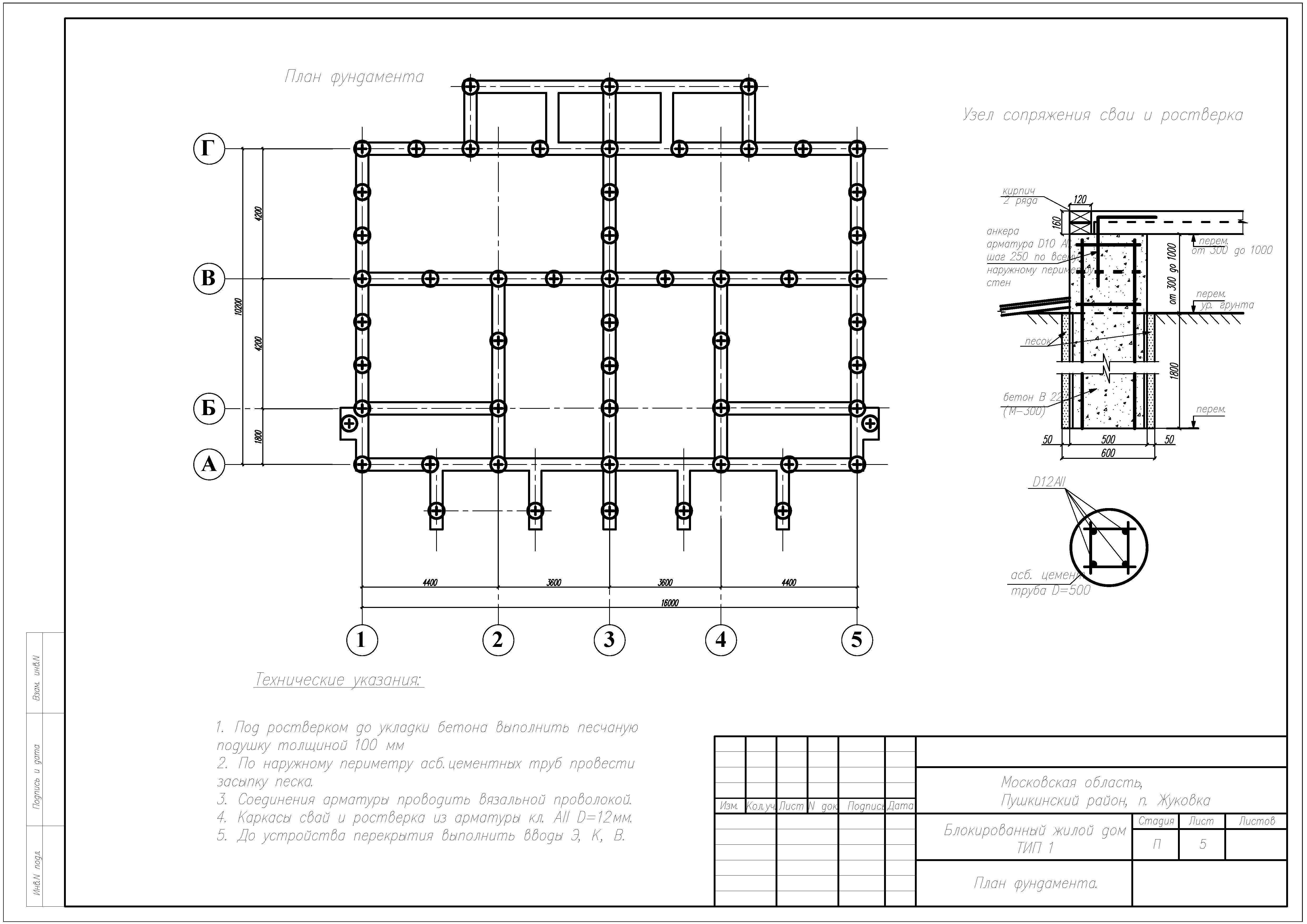

Diy bored pile foundation

The step-by-step instructions presented below provide for the independent construction of a pile foundation in a bored version with a grillage on top. This is the most popular option among private traders, since it is not difficult to implement it. For work, only asbestos-cement pipes, concrete mortar and steel or fiberglass reinforcement are needed.

The device is performed in five stages:

-

Excavation.

-

Installation of asbestos-cement pipes and laying fittings in them.

-

Pouring concrete.

-

Grillage device.

-

Closing the plinth.

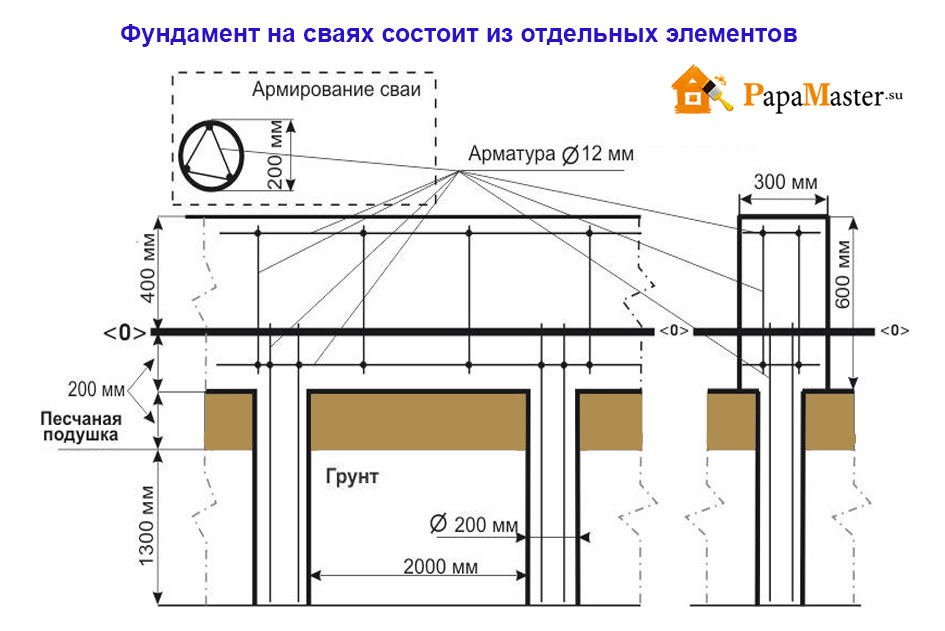

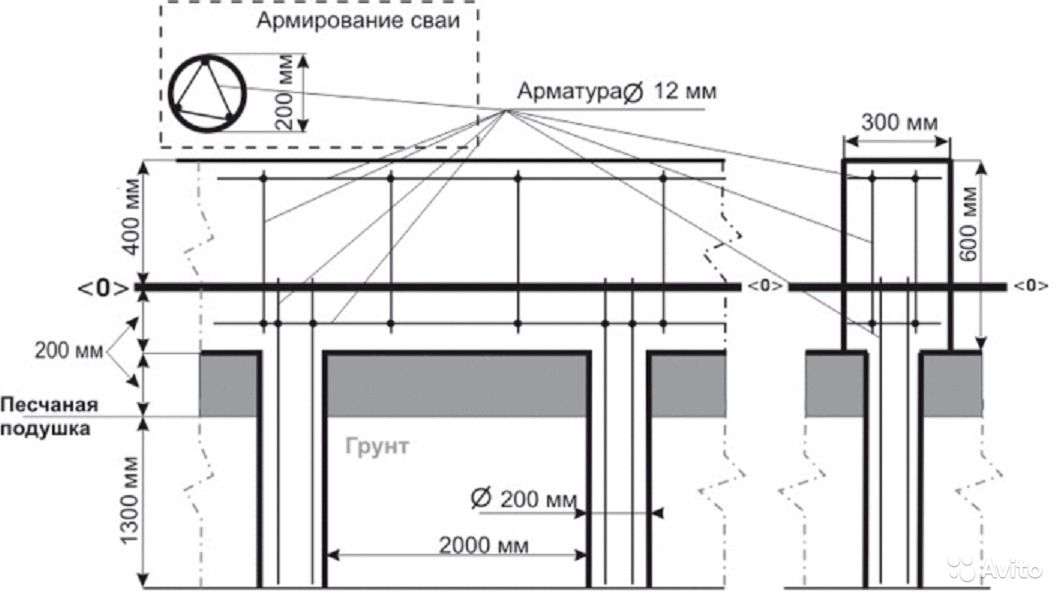

For the manufacture of bored piles, asbestos-cement pipes with a diameter of 300–400 mm are required. They will serve as a guarantee that the foundation will have a good bearing capacity both vertically and horizontally. And unlike the steel version, asbestos cement will not rust in the ground.

The wells for the supports are easiest to make with a hand drill with a gasoline or electric motor. The depth of these holes should end up being 30–40 cm below the freezing point of the soil.

Pile pillars are located along the perimeter of the building and under the load-bearing walls inside with a step of up to two meters. After drilling the wells, a sand cushion 10–15 cm thick is poured on their bottom. Then concrete is poured another 25–30 cm from above as a support under the piles. And already in this not frozen solution, pipes made of asbestos cement are installed. Moreover, they should protrude at least 30 cm above the ground.

In order for the pipes to remain strictly in an upright position, they are sprinkled with sand, which is thrown in the process of compaction. Next, the support pillars are reinforced. For this, 3-4 rods of steel or fiberglass with a cross section of 10-12 mm are used.

Reinforcement rods must be placed in the center of the pipe at an equal distance from each other. To simplify installation, they can be tied with wire crossbars while still on the ground. In height, these vertical rods should be higher than the upper edge of the pipe, protruding from the latter by 15–20 cm. After reinforcement, this fixed formwork should only be poured with concrete, making sure that no voids are formed inside the solution.

Already after 3-4 days on the resulting supports, you can mount a grillage made of reinforced concrete (with the laying of formwork, reinforcement and pouring a concrete mixture), a steel channel or a bar. As a result, there should be a gap of 25-30 cm between it and the ground. It is impossible to lay the grillage directly on the ground, it can simply be squeezed up when heaving and demolished along with the building.

At the end of the arrangement, it is best after the construction of the walls, the supports and the grillage structure should be closed with cladding on the sides. Corrugated roof or facade sheeting or decorative brick is perfect here. Only first you need to lay down all communications. Fortunately, water supply and sewerage in the house on piles are carried out between the supports without additional tweaks and drilling in concrete.

Grillage foundation construction

The grillage is a strip structure that connects freestanding piles to each other

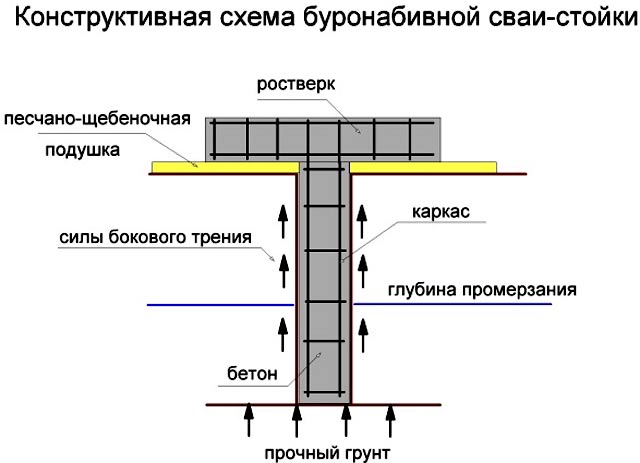

For the construction of the walls of buildings, various types of grillages are constructed, differing in their location relative to the zero mark:

- towering. The lower plane of the power circuit is at least 15 cm above the soil level. The high structure is constructed for lightweight buildings, the construction of which is carried out on all types of soil. It is indispensable for problematic soils and requires reliable reinforcement with steel reinforcement. This is due to the presence of free space between the soil surface and the concrete edging;

- located at soil level or ground grillage. It is formed on a sand-crushed stone bed without sinking into the ground. The main feature of the ground structure is that the concrete monolith touches the soil surface with zero clearance. This design is used on stable soils that are not subject to deformation as a result of frost heaving. When the soil freezes, there is a high probability of violation of the integrity of the concrete contour;

- not deeply buried. The support plane of the concrete reinforcement rests on a crushed stone-sand bed, located below the zero mark in the depth of the pit.Structurally, such a foundation is similar to a strip-type foundation, which is carried out on pile supports. The construction process is quite laborious and associated with significant costs. This structure is used on soils with reduced bearing capacity for the construction of large structures.

Pile foundations are constructed for the construction of lightweight buildings. The construction of the foundation grillage, which is a concrete edging, ensures the stability of such structures. The width of the tape corresponds to the thickness of the walls, and the height of the contour is no more than 0.4 m.

Also, the grillage acts as a supporting surface on which the walls of the building are erected.