Calculating the thickness of the slab

The calculation is carried out according to the joint venture "Design and arrangement of foundations and foundations of buildings and structures" and according to the manual "Guidelines for the design of slab foundations of frame buildings and tower-type structures" in two stages:

- collection of loads;

- bearing capacity calculation.

Collecting loads includes work to calculate the total mass of the house, taking into account the weight of the snow cover, furniture, equipment and people. Values for houses made of different materials can be taken from the table.

| Load type | Meaning | Reliability factor |

| Walls and partitions | ||

| Brick 640 mm | 1150 kg / m2 | 1,2 |

| Brick 510 mm | 920 kg / m2 | |

| Brick 380 mm with insulation 150 mm | 690 kg / m2 | |

| Bar 200 mm | 160 kg / m2 | 1,1 |

| Beam 150 mm | 120 kg / m2 | |

| Frame 150 mm with insulation | 50 kg / m2 | |

| Plasterboard partitions 80 mm | 30-35 kg / m2 | 1,2 |

| Brick partitions 120 mm | 220 kg / m2 | |

| Overlapping | ||

| Reinforced concrete 220 mm with cement-sand screed 30 mm | 625 kg / m2 | 1.2 - for prefabricated and 1.3 - for monolith |

| Wooden on beams | 150 kg / m2 | 1,1 |

| Roof on wooden rafters | ||

| Metallic coated | 60 kg / m2 | 1,1 |

| Ceramic coated | 120 kg / m2 | |

| Bituminous coated | 70 kg / m2 | |

| Temporary loads | ||

| Useful for residential buildings | 150 kg / m2 | 1,2 |

| Snowy | Depending on the area of construction, according to clause 10.1 of the Joint Venture “Loads and Impacts”. The snow region is determined by the joint venture "construction climatology". | 1,4 |

Important! The table already takes into account the thickness of the structures. To calculate the mass, it remains only to multiply by the area

In addition, each load must be multiplied by a safety factor. It is necessary to provide a margin for the bearing capacity of a concrete structure and to prevent problems with minor mistakes by builders or changes in operating conditions (for example, a change in the purpose of a building). All coefficients are accepted according to the joint venture “Loads and Impacts”.

For different loads, the coefficient is different and is in the range of 1.05-1.4. The exact values are also shown in the table. For concrete foundations for monolithic technology, a coefficient of 1.3 is taken.

Important! If the slope of the roof is more than 60 degrees, the snow load is not taken into account in the calculation, since with such a steepness of the slope, snow does not accumulate on it. The total area of all structures is multiplied by the mass given in the table and the coefficient, after which, adding up, the total weight of the house is obtained without taking into account the foundations

The total area of all structures is multiplied by the mass given in the table and the coefficient, after which, adding up, the total weight of the house is obtained without taking into account the foundations.

The basic formula for calculations is as follows:

P1 = M1 / S,

where P1 is the specific load on the soil without taking into account the foundation, M1 is the total load from the house obtained when collecting the loads, S is the area of the concrete slab.

Next, you need to calculate the difference (Δ) between the obtained value and the number given in the table above, depending on the type of soil.

Δ = P-P1

where P is the tabular value of the bearing capacity of the soil.

M2 = Δ * S,

where M2 is the required mass of the foundation (it is impossible to build a foundation more than this mass), S is the area of a concrete slab.

The following formula:

t = (M2 / 2500) / S,

where t is the thickness of the concrete pouring, and 2500 kg / m3 is the density of one cubic meter of the reinforced concrete foundation.

Further, the thickness is rounded to the nearest higher and lower multiple of 5 cm. After that, a check is performed, in which the difference between the calculated and optimal pressure on the ground should not exceed 25% in any direction.

Advice! If in the calculation it turns out that the thickness of the concrete layer exceeds 350 mm, it is recommended to consider such types of structures as strip foundations, columnar or slab with stiffeners.

In addition to the thickness, you will need to select a suitable reinforcement diameter, as well as calculate the amount of reinforcement for concrete.

Important! If, as a result of the calculation, you get a slab thickness of more than 35 cm, this indicates that the slab foundation is redundant in these conditions, you need to calculate the strip and pile foundations, perhaps they will be cheaper. If the thickness is less than 15 cm, then the building is too heavy for this soil and an accurate calculation and geological research is needed

Do-it-yourself slab foundation construction.

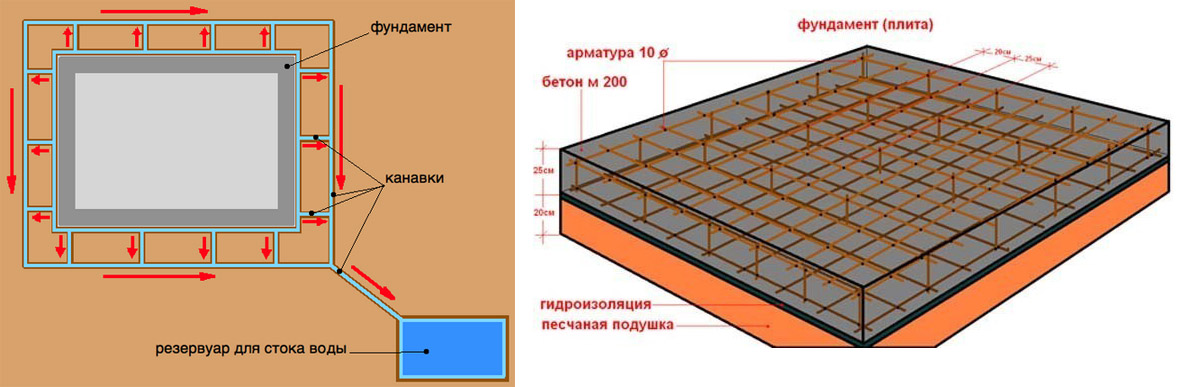

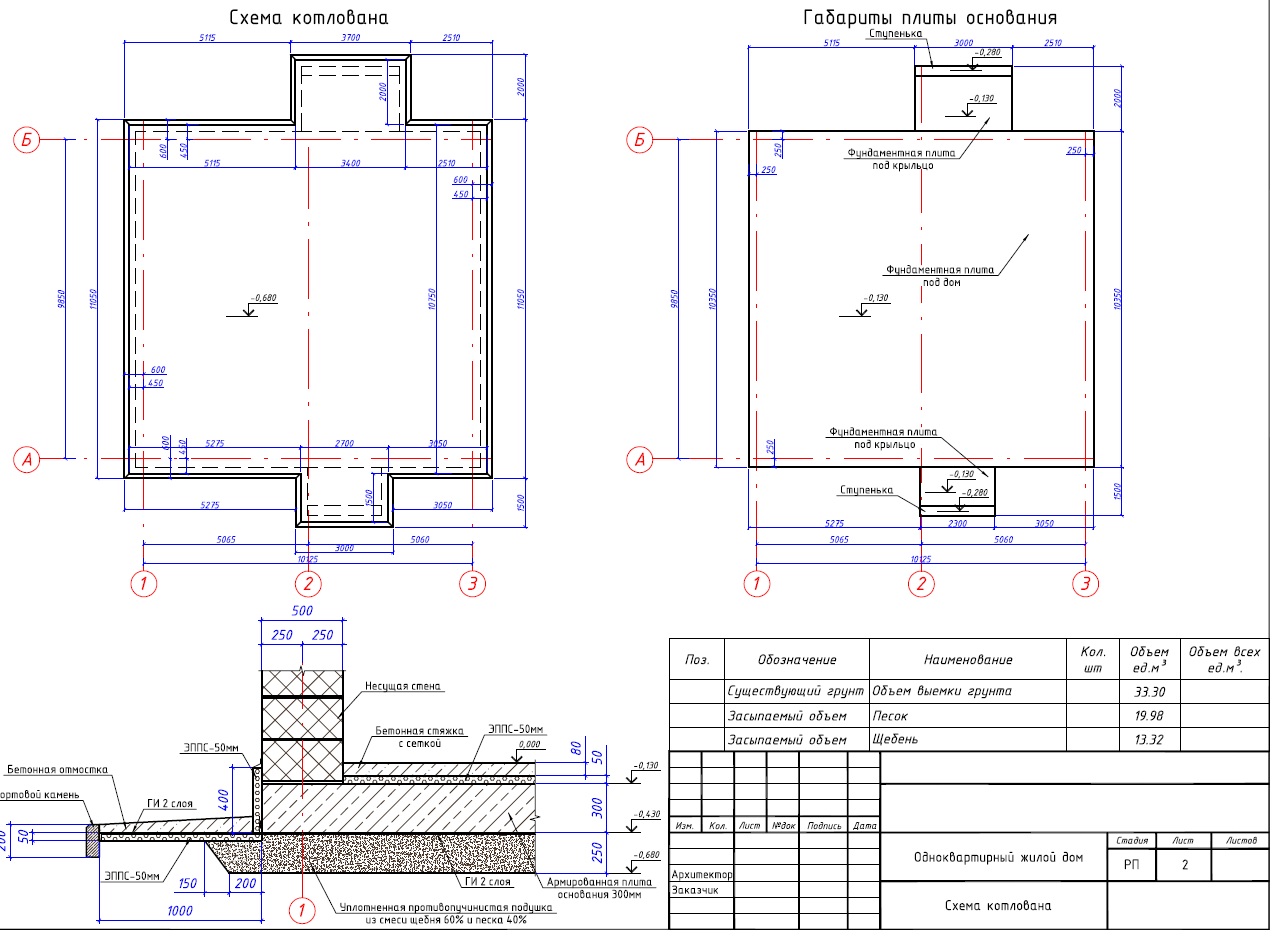

To begin with, you need to prepare the site, this is perhaps the most time-consuming operation for the construction of a slab foundation. For this, the top soil layer is completely removed to the depth established by the calculation. The last layer is recommended to be removed and leveled by hand; this is done in order to avoid irregularities and holes. The pit itself should exceed the dimensions of the foundation by 1-2 m from all sides for the convenience of work.

Preparing a cushion for a sand and gravel slab foundation. Such a pillow is necessary to compensate for the forces of soil deformation, as well as to drain groundwater and exclude their capillary rise to the base of the foundation. The thickness of the pillow depends on the type of soil: on sandy soils it can be 15 centimeters, on saturated clayey or prone to strong heaving - at least 30 centimeters. The sand is poured into the pit, evenly and distributed over the entire area of the foundation, after which it is carefully compacted. For marshy or wet soil types, part of the cushion will consist of rubble, this improves the waterproofing of the concrete.

Formwork for slab foundations. The formwork for the slab foundation should consist of planed boards with a thickness of at least 20 mm, which are connected at the corners with self-tapping screws. From the outside, the formwork is reinforced with struts. Sometimes for a slab foundation, a permanent formwork made of fiberboard is used. It is attached to metal corners and screeds, and then braces are also arranged. After the above work, it is necessary to build penetrations for communications, along the way to install formwork around them. Pipes can also be laid and routed through penetrations before the foundation is poured.

Waterproofing of the slab foundation is carried out using a thick plastic film, geotextile or roofing material, it is overlapped to the bottom of the excavation, entering the formwork.

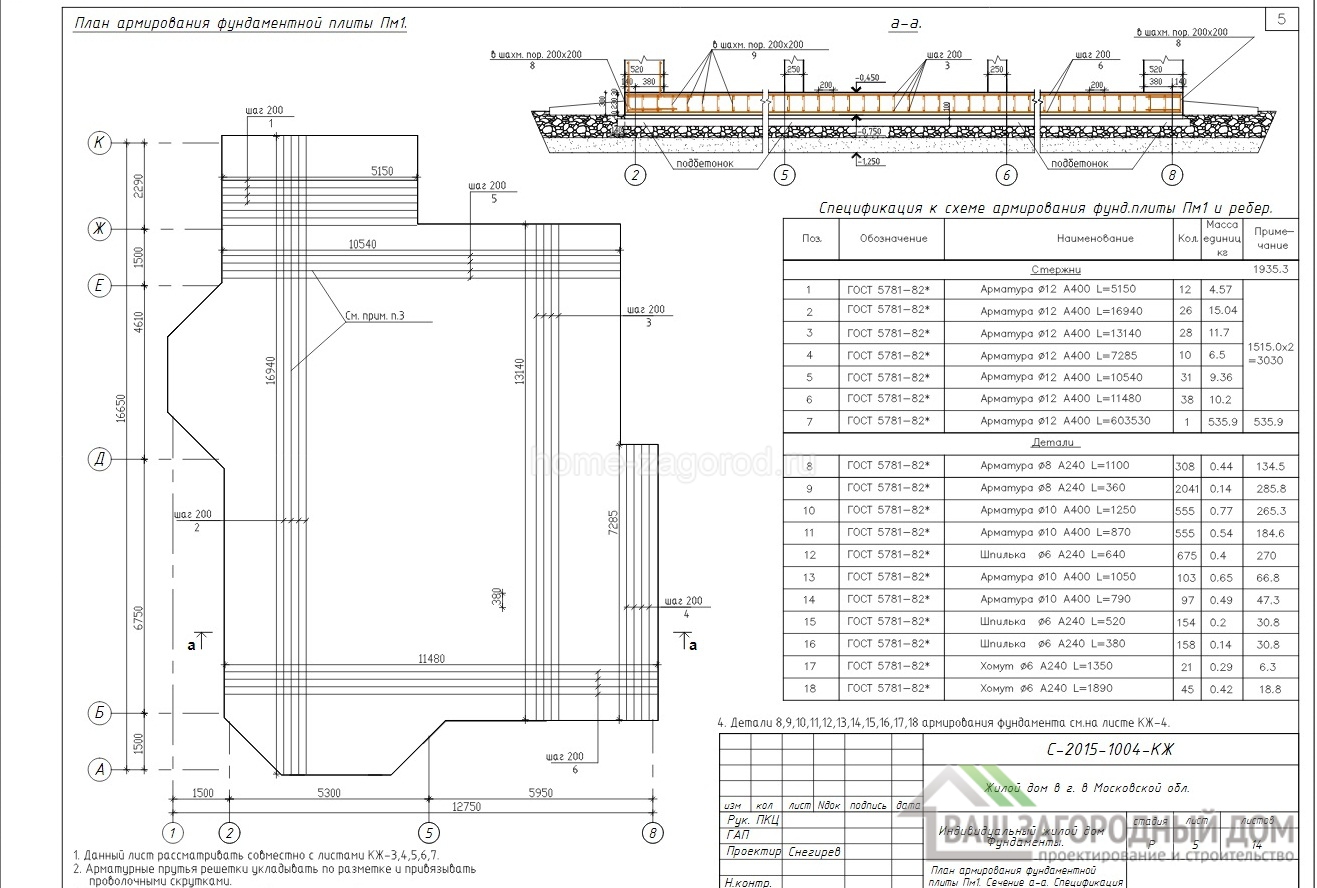

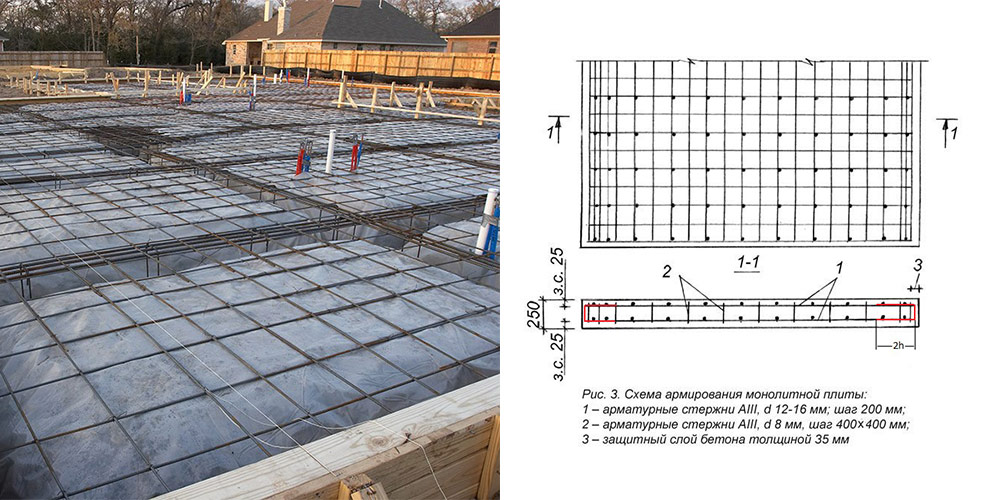

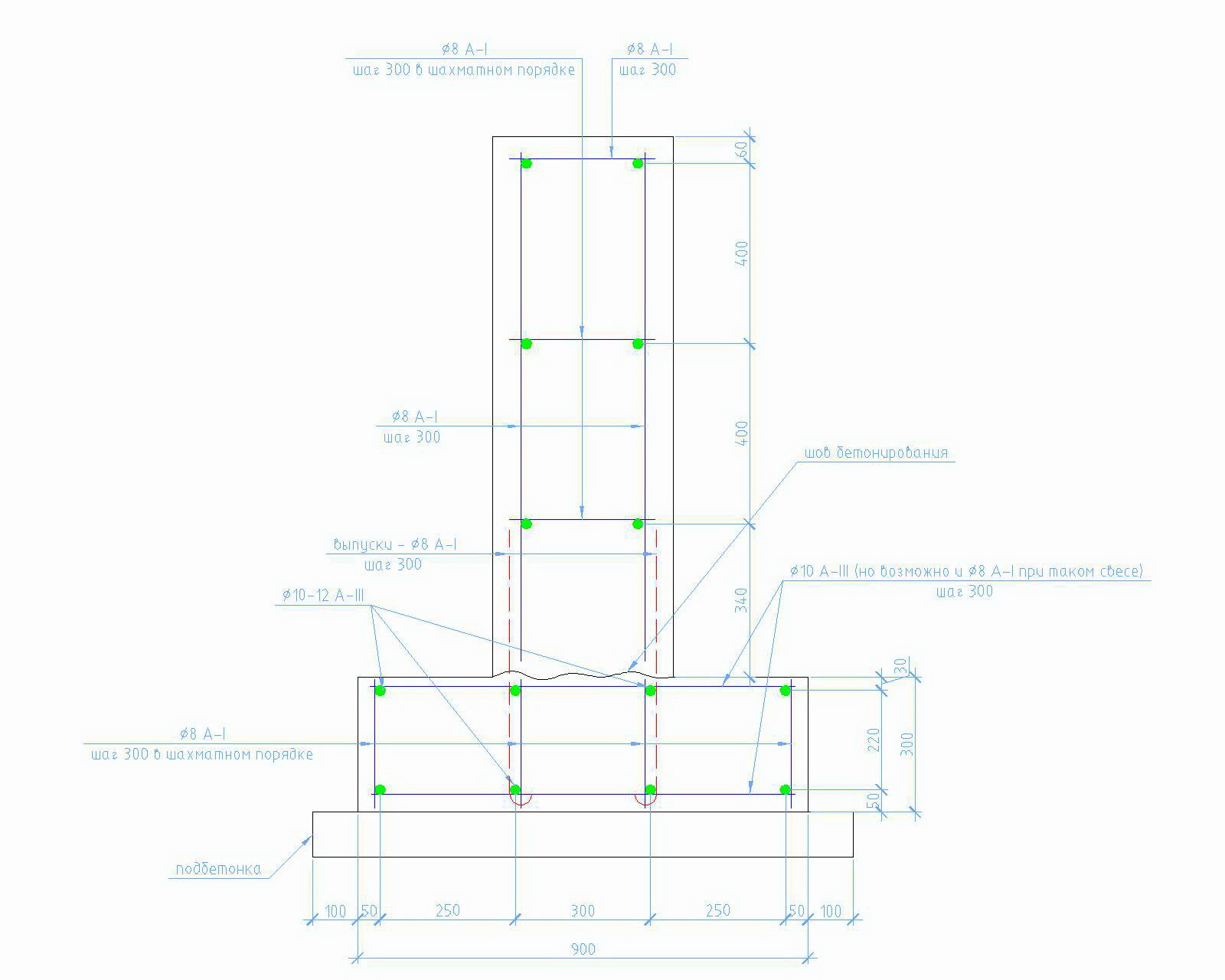

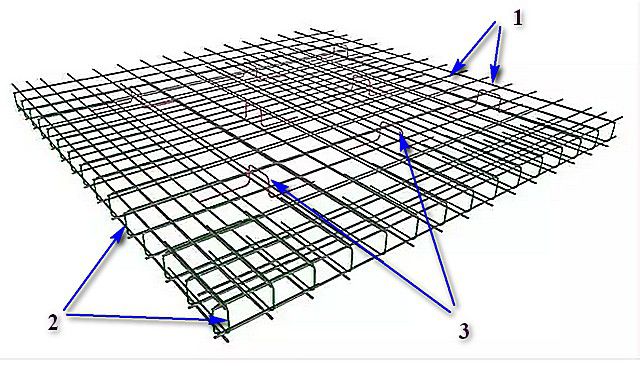

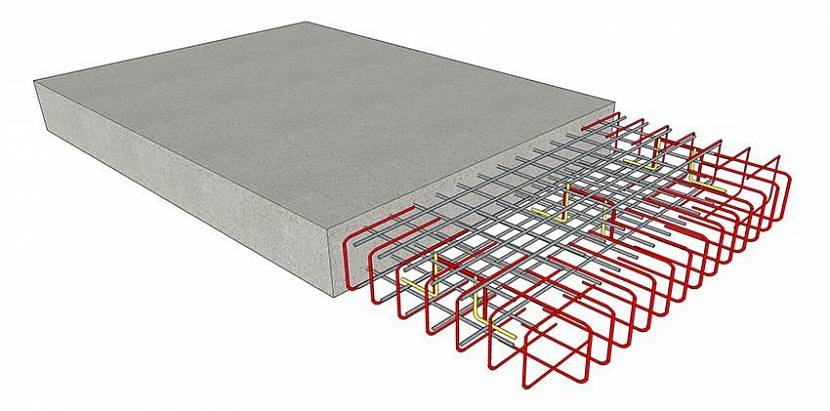

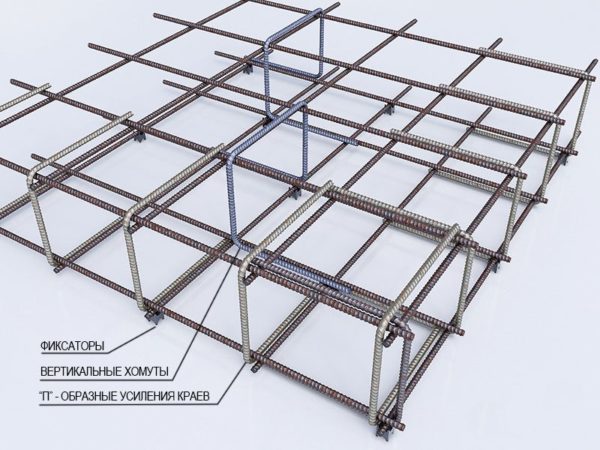

Reinforcement of a slab foundation is a very important stage, the strength of not only the foundation itself, but also the building as a whole will depend on it. For small structures, reinforcement can be performed using a reinforcing mesh with a mesh of 10-15 centimeters, and the places in which the load-bearing walls will be installed must be reinforced with a metal bar. If the structure of the structure is more massive, for reinforcement it is necessary to use a rod with a diameter of 10-12 mm, laid in the form of a grid. Cross rods are knitted together using wire. Welding of reinforcement is rarely used, since excessive stresses arise in the welding places during movement of the structure. The reinforcement mesh must be completely immersed in concrete; for this, it is installed on special guides. If the thickness of the foundation is large, then several layers of reinforcement are installed.

Filling the slab foundation with concrete is carried out at once, so the concrete will either have to be ordered or mixed very quickly with your own hands. Therefore, the filling must be carried out by a team of 4-5 people. The concrete is poured into the prepared formwork with the laid reinforcement, after which it is compacted first with the help of a deep vibrator, and then with the use of a vibrating lath. After punching concrete and removing voids and air from it, it is smoothed and the surface is leveled.

Drying of the slab foundation takes place within 4-5 weeks. During this time, concrete gains the required strength, after which it is ready for further use.During drying, you need to carefully monitor that the top layer of the foundation does not dry out and is not exposed to excessive moisture, for this you can use a material with which the concrete can be covered. After the concrete dries, to improve the thermal insulation properties, the slab foundation can be insulated with polystyrene boards.

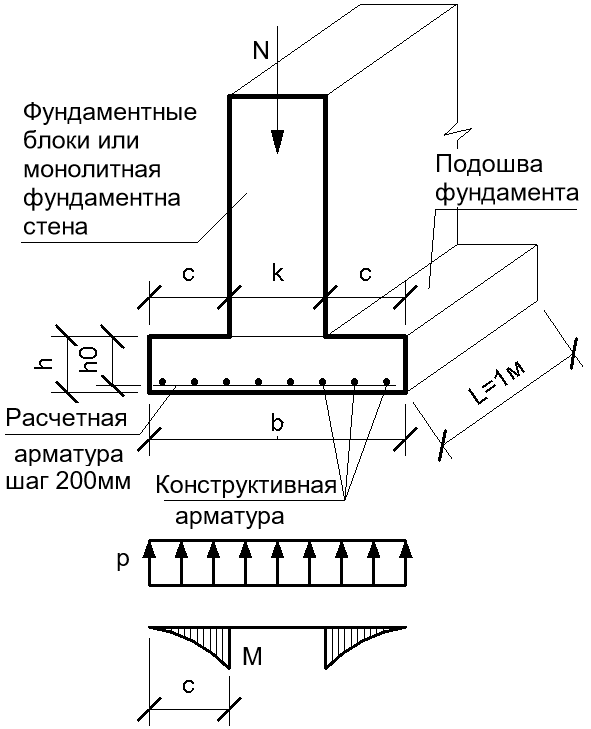

Calculation of strip and columnar foundation

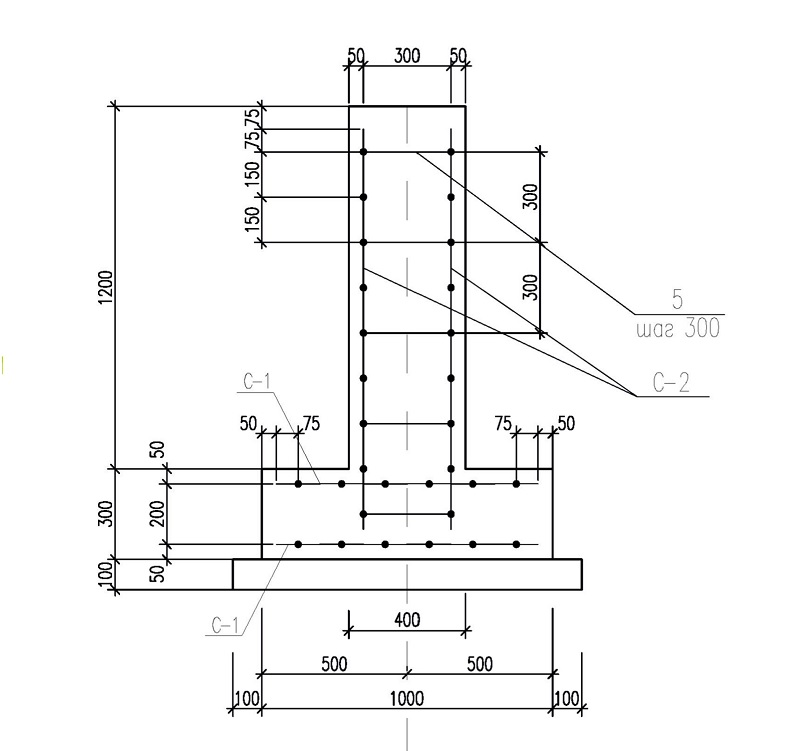

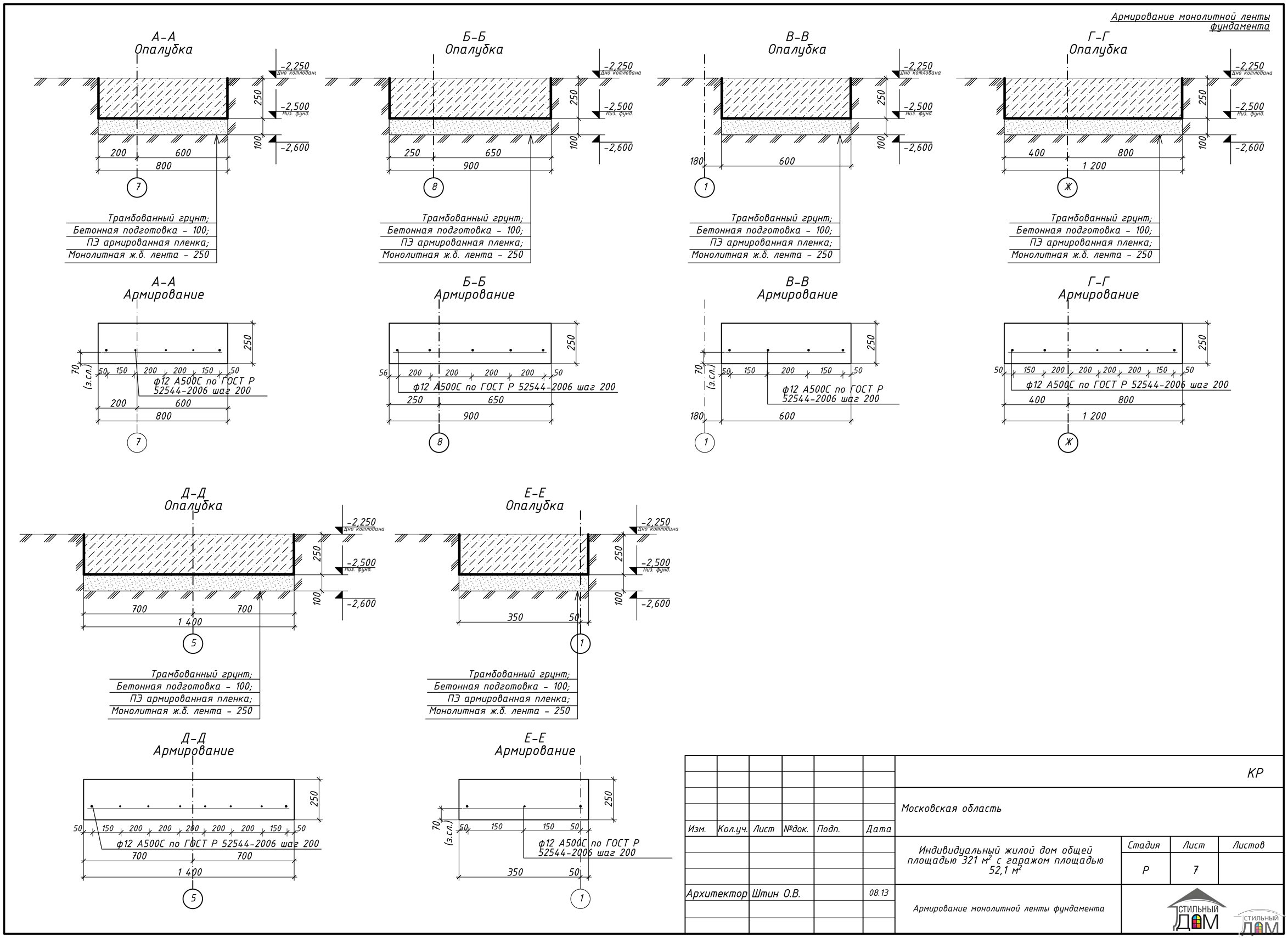

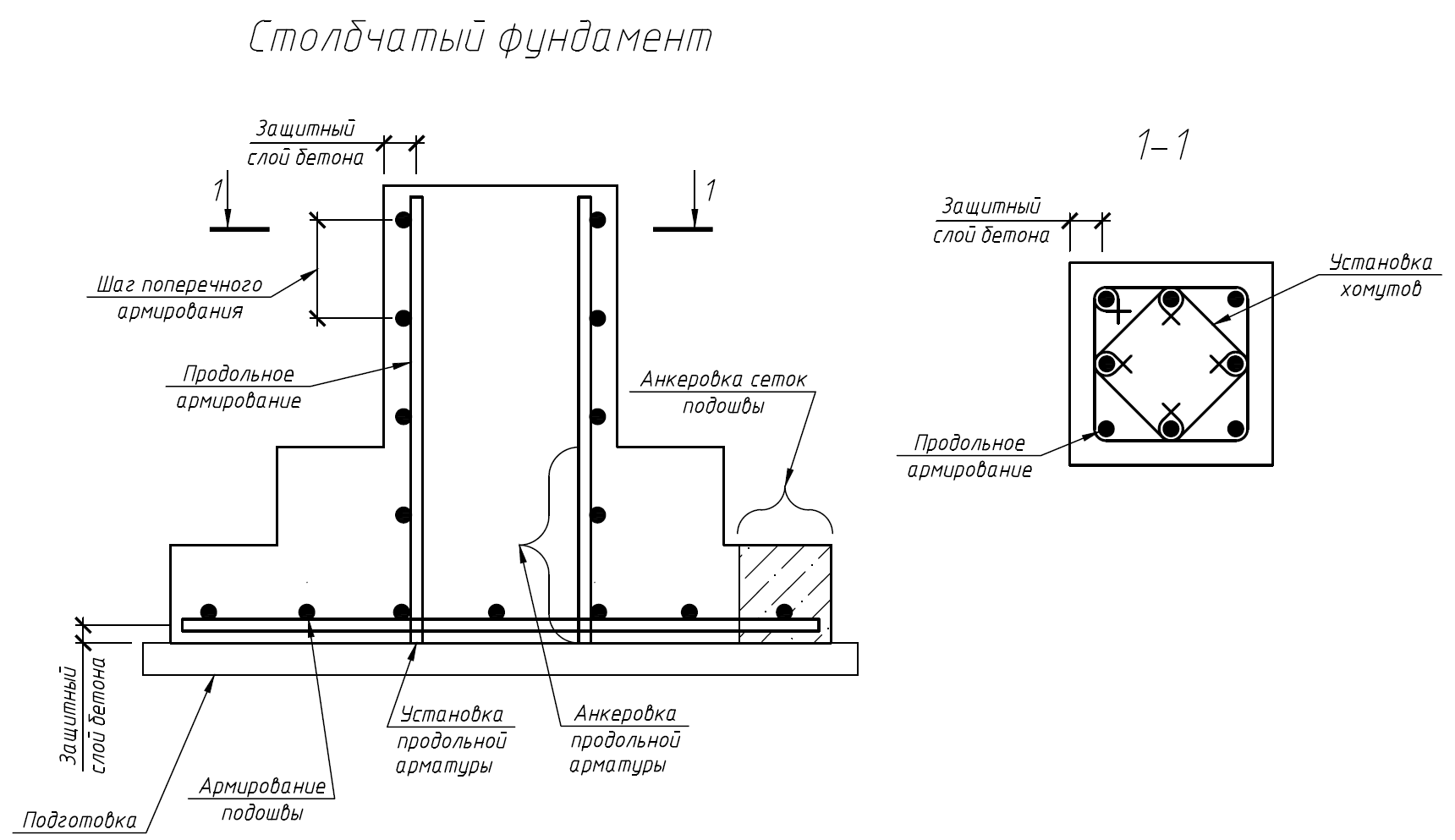

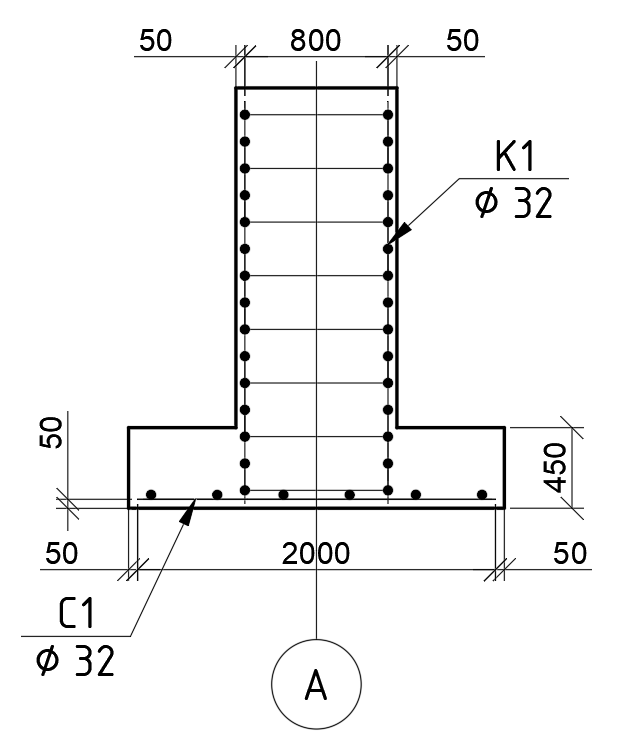

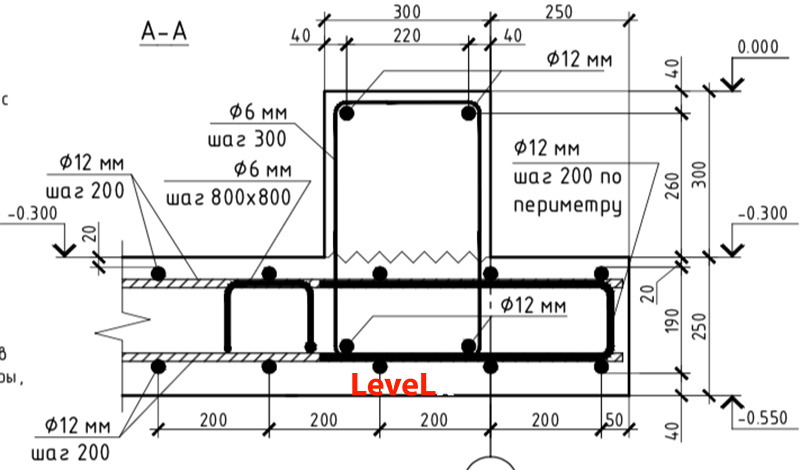

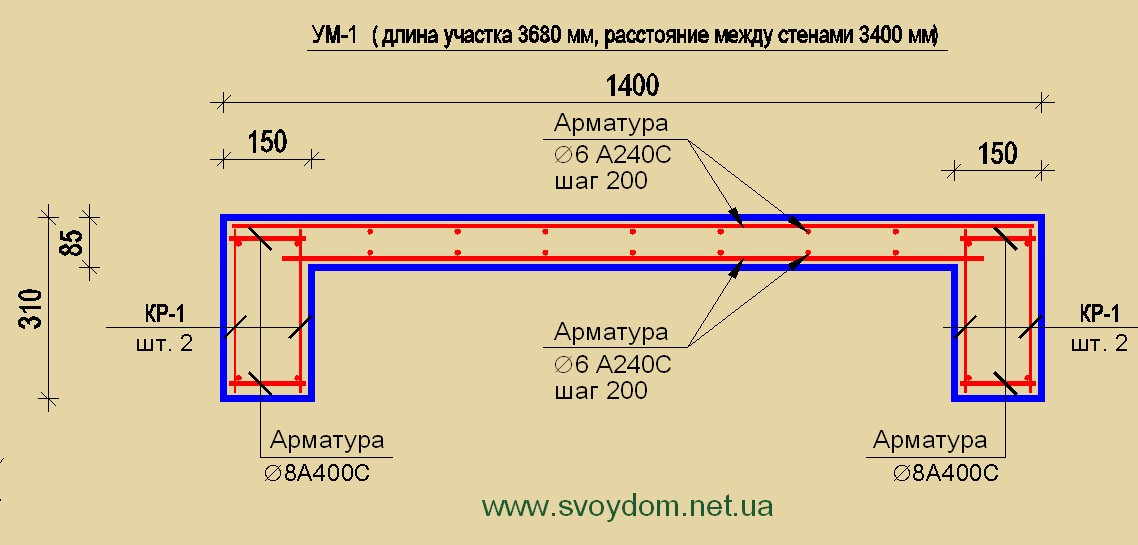

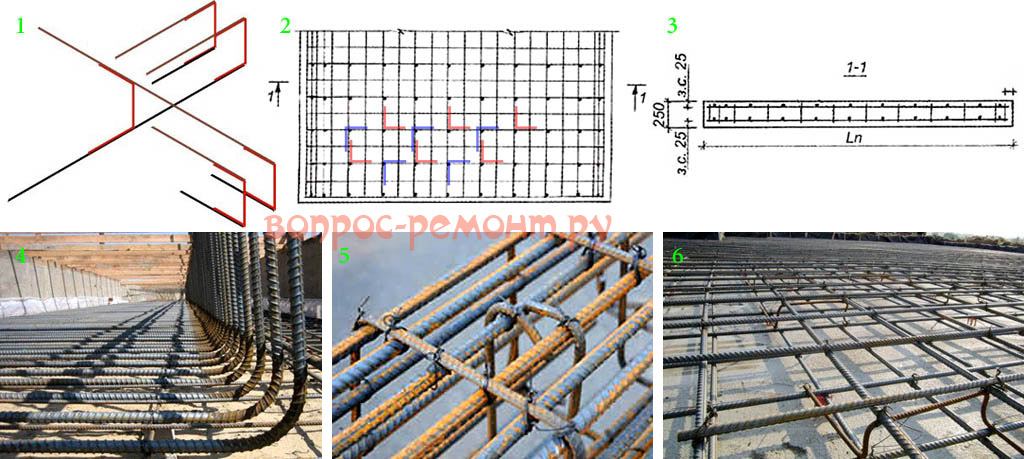

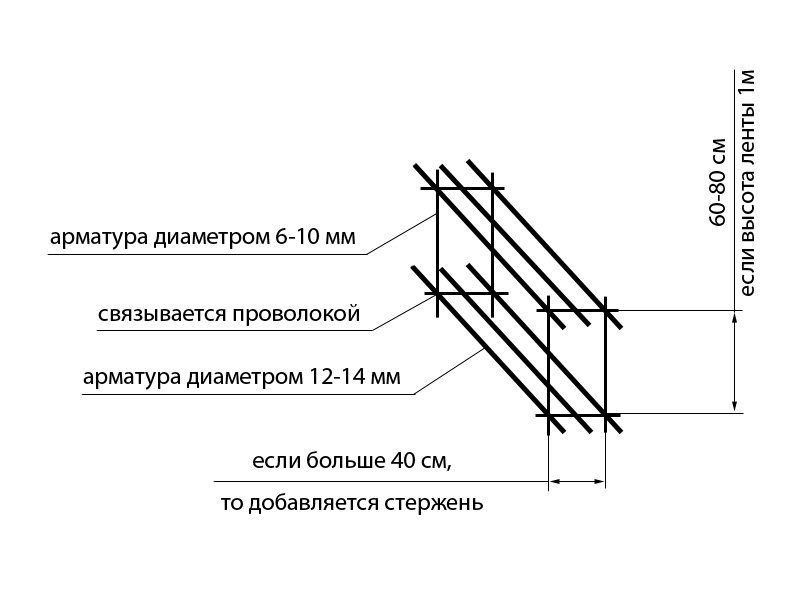

Reinforcement of the strip foundation, calculation of reinforcement, laying and knitting are carried out, in principle, in the same way. You just need to take into account that the reinforcement grilles in this design are not installed horizontally, but vertically. In this case, the length of the longitudinal rods depends on the length of the tape, and the transverse ones on the depth of the foundation.

The width of the tape determines the number of grids and the length of the rods connecting the grids together. For example, if the width of the foundation tape is 40 cm, then a distance of 25 - 30 cm is left between the gratings, this is the length of the connecting rods.

As for the quantity, then again, everything will depend on the size of the cells of the reinforced foundation belt. For example, if the depth of the laying is 1 m, and the frame is laid inside the concrete mass, then the distance from the upper surfaces is set at 10 cm on each side. Therefore, the length of the transverse rods will be 80 cm. And the number of longitudinal guides will be equal to 100/20 = 5 rows.

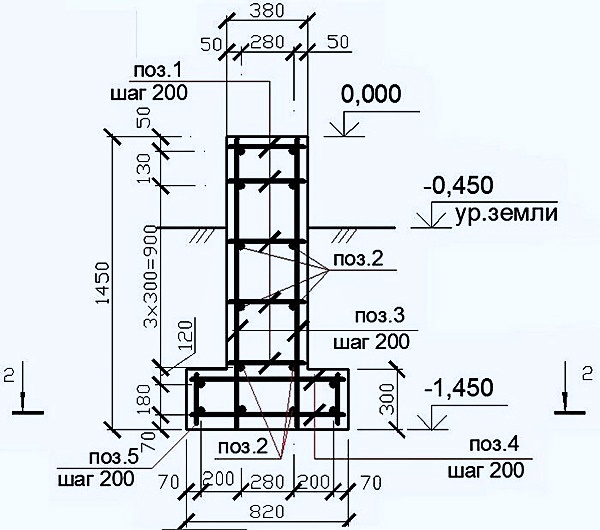

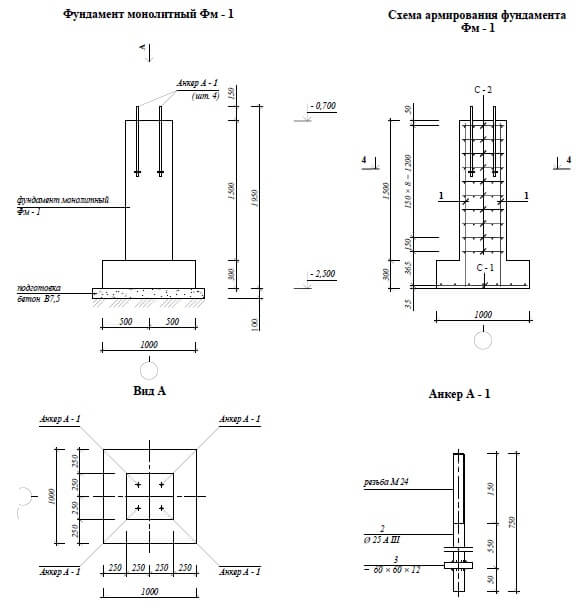

The rules for reinforcing columnar structures are very different from the two previous options. Firstly, these are vertically installed rods, tied with wire rod with a diameter of 6 mm or small reinforcement. It all depends on the size of the pillars themselves. Secondly, the section of the frame is either a square, or a circle, or a triangle.

The length of the main rods depends on the depth of the foundation. In this case, there is no need to take into account the distance from the bottom of the well to the reinforcement, because the finished reinforcing structure is installed directly on the prepared pad. But you will have to take into account the protrusion of the rods in the amount of 10 - 70 cm, which will stick out from the posts. They will be connected to the grillage reinforcement mesh.

Rebar diameter calculation

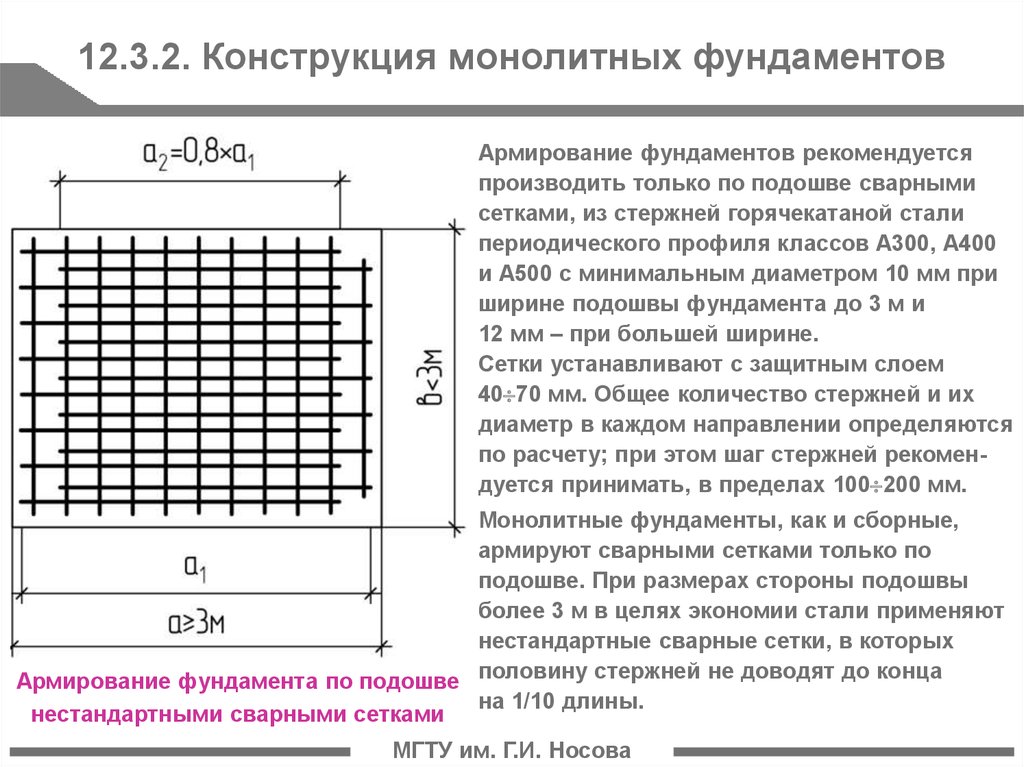

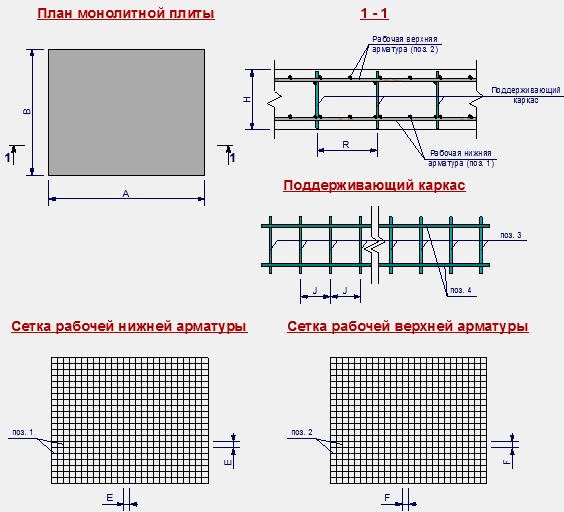

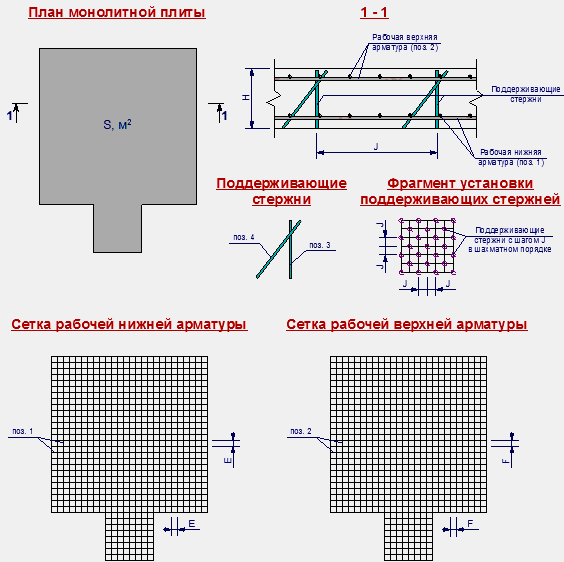

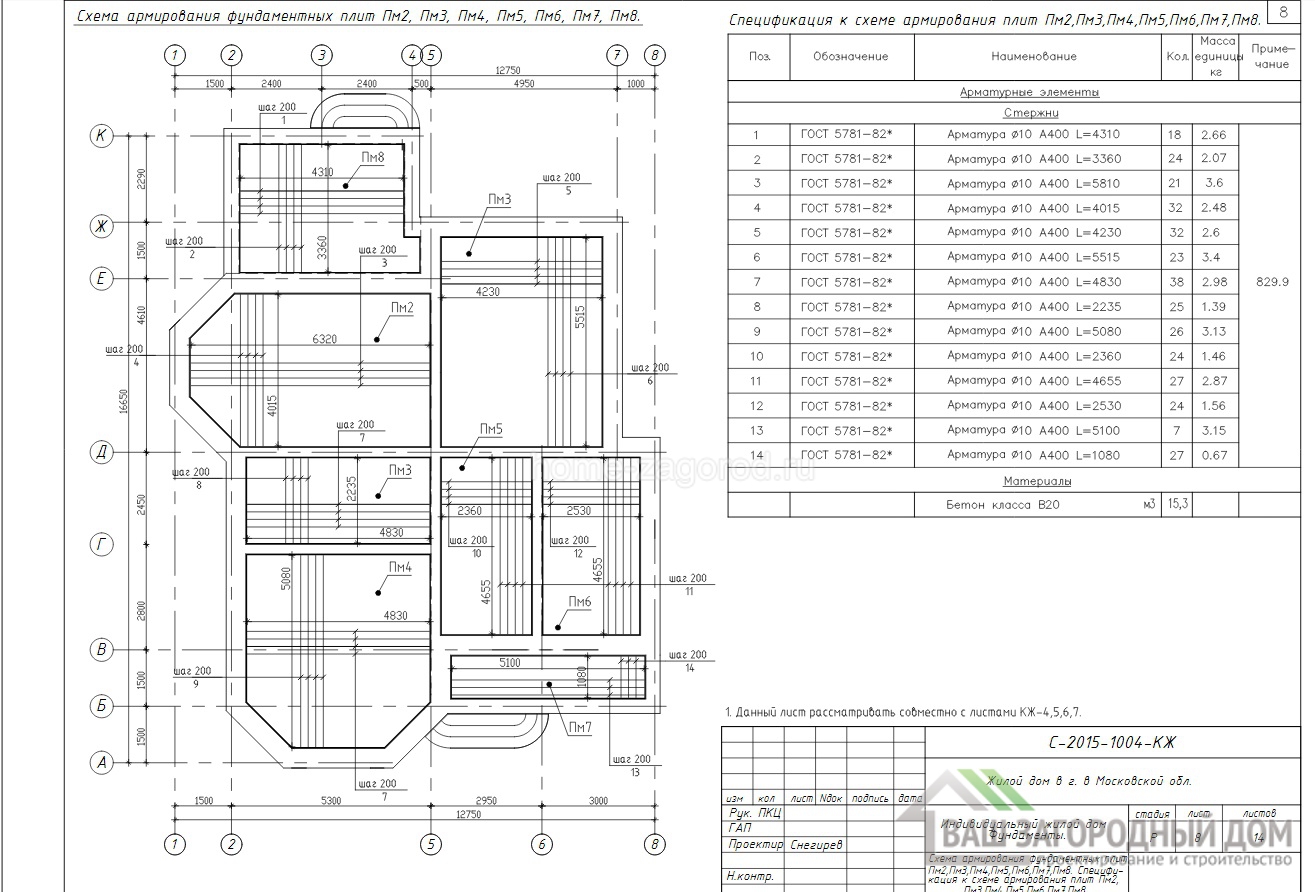

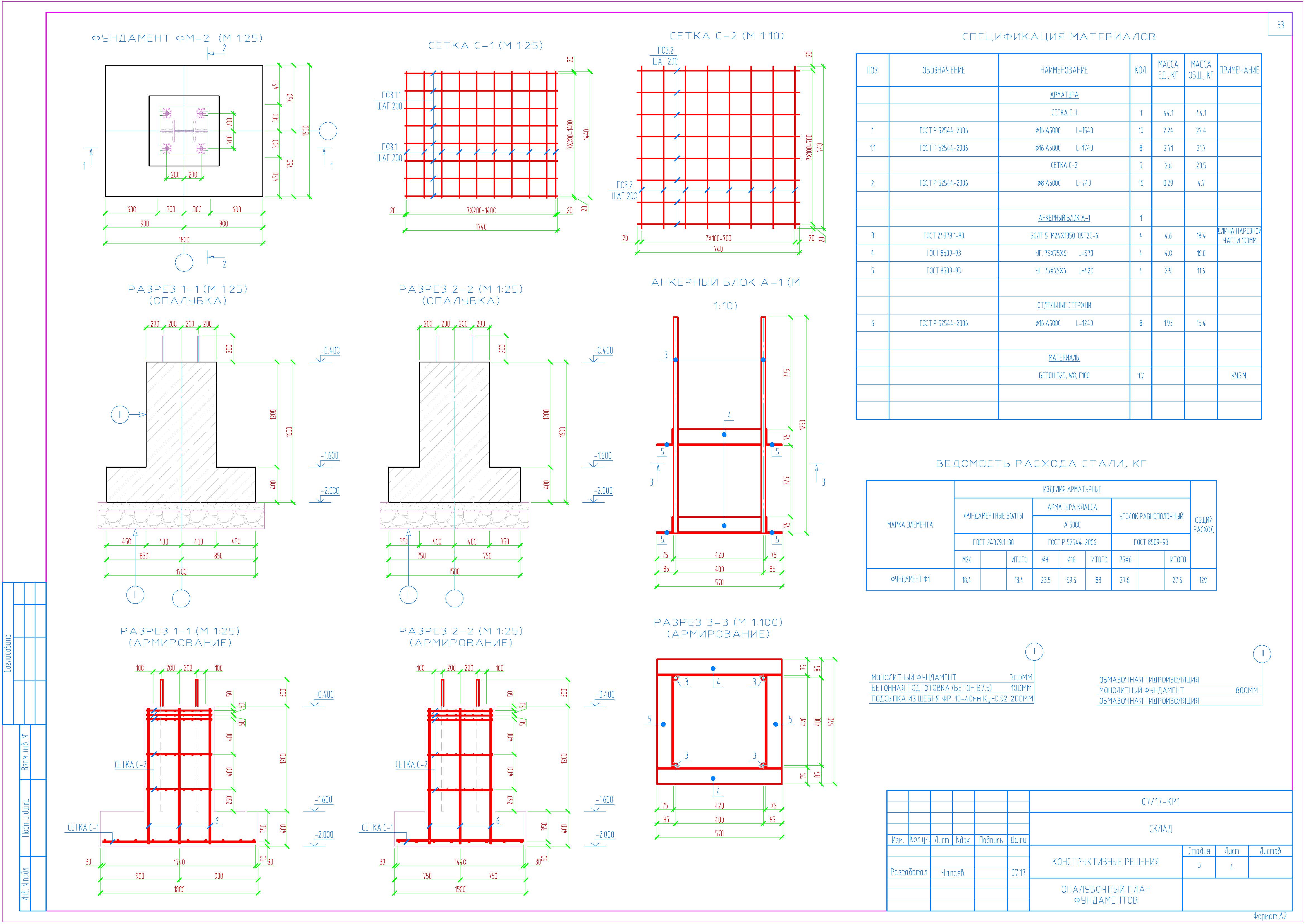

Calculations associated with a monolithic slab are quite complex and require special knowledge. Not every constructor can execute them correctly. For individual construction, you can be guided by the minimum values adopted according to the manual "Reinforcement of elements of monolithic reinforced concrete buildings".

Requirements for a monolithic slab are presented in Appendix 1, Section 1. The total cross-sectional area of the working reinforcement in one direction is taken to be at least 0.3% of the total cross-section of the foundation. The minimum diameter of the rods is assigned 10 mm for the side of the slab less than 3 m and 12 mm for the longer side length. The diameter of the vertical rods must be at least 6 mm, but the conditions of weldability must also be taken into account. The maximum size of the working reinforcement is 40 mm, in practice 12, 14 and 16 mm are more often used.

Calculation example

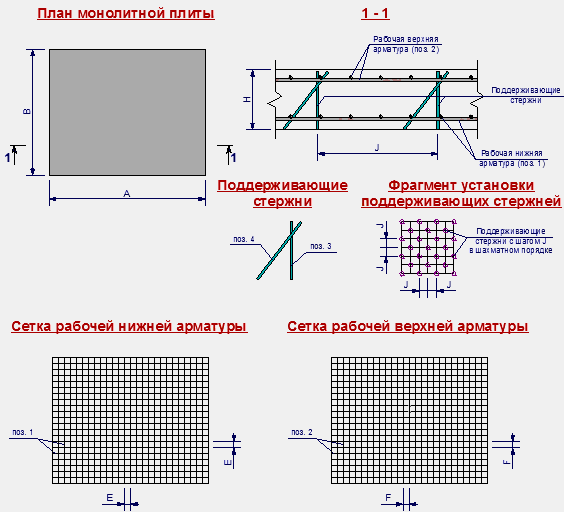

As the initial data, there is a 6 by 6 m reinforced concrete slab. The thickness for a private house is taken 200 mm. It is necessary to properly reinforce the structure. The example does not consider the reinforcement of reinforced concrete in the areas of support of the walls.

Determination of diameters

First of all, it is determined that the meshes will be laid in two rows, since the thickness of the structure is more than 150 mm. Next, the required area of steel rods is calculated.

- Cross-sectional area of the foundation = 6 m * 0.2 m = 1.2 m²;

- The minimum area of all reinforcement = 1.2 m² * 0.3% = 0.0036 m² = 36 cm²;

- Minimum reinforcement area in one direction for one row = 36 cm² / 2 = 18 cm².

Next, you need to use the assortment of reinforcing bars, which is given in GOST 5781-82 *. This document shows the cross-sectional area of one rod. For convenience, you can find an extended version of the assortment. It determines that for a given section in one mesh, one of the following options must be used:

- 16 rods with a diameter of 12 mm;

- 12 rods with a diameter of 14 mm;

- 9 rods with a diameter of 16 mm;

- 8 rods with a diameter of 18 mm;

- 6 rods with a diameter of 20 mm.

We choose the option with the twelfth diameter. To correctly lay out the elements, a diagram is needed. The drawing will help you calculate the pitch of the rods. For a side with a length of 6 m, the pitch of 16 rods is approximately 400 mm. We assign a maximum distance of 300 mm based on the condition of SP 63.13330.2012 clause 10.3.8.

For reliability, vertical reinforcement is assumed to be 8 mm with a step of 300 mm.

Quantity calculation

Recently we have a slab foundation calculator, for convenience you can use it.

In order not to be mistaken when purchasing materials, it is necessary to calculate their quantity in advance. If there is a plate layout, this is not difficult to do. When calculating the lengths of the rods, it is necessary to take into account the concrete cover thickness of 20-30 mm on each side.

Calculation of working reinforcement.

- Length of one rod = 6000 - 30 * 2 = 5940 mm;

- The number of rods in one direction = 5940/300 = 19.8, we take 20 pieces;

- The number of rods in both directions for the upper and lower net = 20 * 2 * 2 = 80 pcs;

- The length of one rod for U-shaped clamps = 200 mm + (200 mm * 2) * 2 = 1 m;

- Number of rods for U-shaped clamps = 20 * 2 = 40 pcs;

- The total length of reinforcement with a diameter of 12 mm = 80 * 5.94 m + 40 * 1 m = 515.2 m;

- The mass of rods with a diameter of 12 mm = 515.2 * 0.888 kg (according to the assortment) = 457.5 kg.

Calculation of vertical reinforcement.

- Length of one rod = 200 - 20 * 2 = 140 mm;

- Number of rods = number of horizontal rods in one direction * number of rods in the other = 20 * 20 = 400 pcs;

- The total length of rods with a diameter of 8 mm = 400 * 0.14 = 56 m;

- Weight of rods with a diameter of 8 mm = 56 * 0.395 = 22.12 kg.

It is convenient to summarize all the resulting values in a table.

| Diameter | Length | Weight |

| 12 mm | 515.2 m | 457.5 kg |

| 8 mm | 56 m | 22.12 kg |

When calculating costs, it is worth considering the standard length of one rod - 11.7 m, which means that, for example, rods of 8 diameters will need 5-6 pieces with a small margin. And with a large length of the working reinforcement, it is required to increase the total length by 10-15% to connect the rods with an overlap.

A competent choice of diameter, pitch and adherence to the installation technology will ensure the reliability and durability of the foundation at the lowest possible cost.

We recommend: Technology of building a slab foundation.

Good publicity

Calculation of the consumption of reinforcement when reinforcing a slab foundation

The calculation of the number of reinforcement for a monolithic foundation is carried out on the basis of generally accepted norms and rules. All calculations are performed in strict accordance with SNiP 51-01-2003 and SNiP 3.03.01-87. The instructions of GOST R 52086-2003 are also taken into account without fail.

Watch the video on how to choose the right fittings (metal or composite).

Even before starting work on reinforcement, it is necessary to establish:

- How many rods are required and their surface quality.

- Minimum diameter of vertical rods. It is determined in accordance with SNiP.

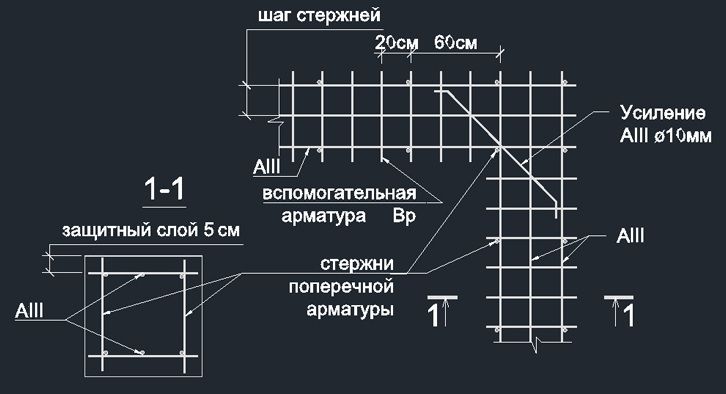

- Reinforcement mesh cell size. The step corresponding to the standard size should not be less than 20 centimeters.

- Overlap level when laying individual pieces of overlapping reinforcement.

- Total length of all reinforcement including overlap.

- The length of the wire used for knitting.

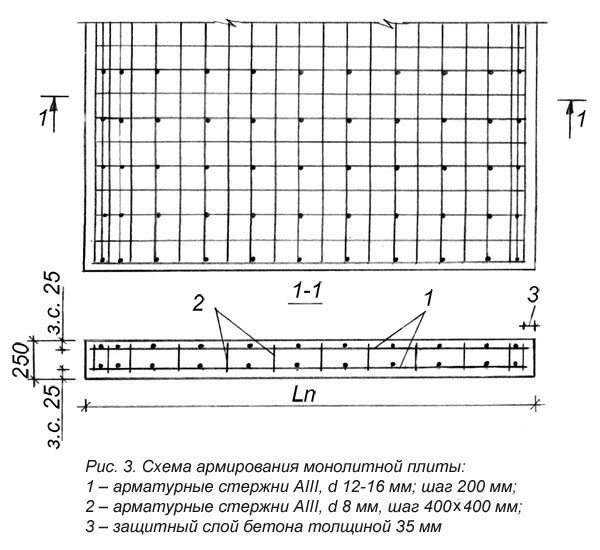

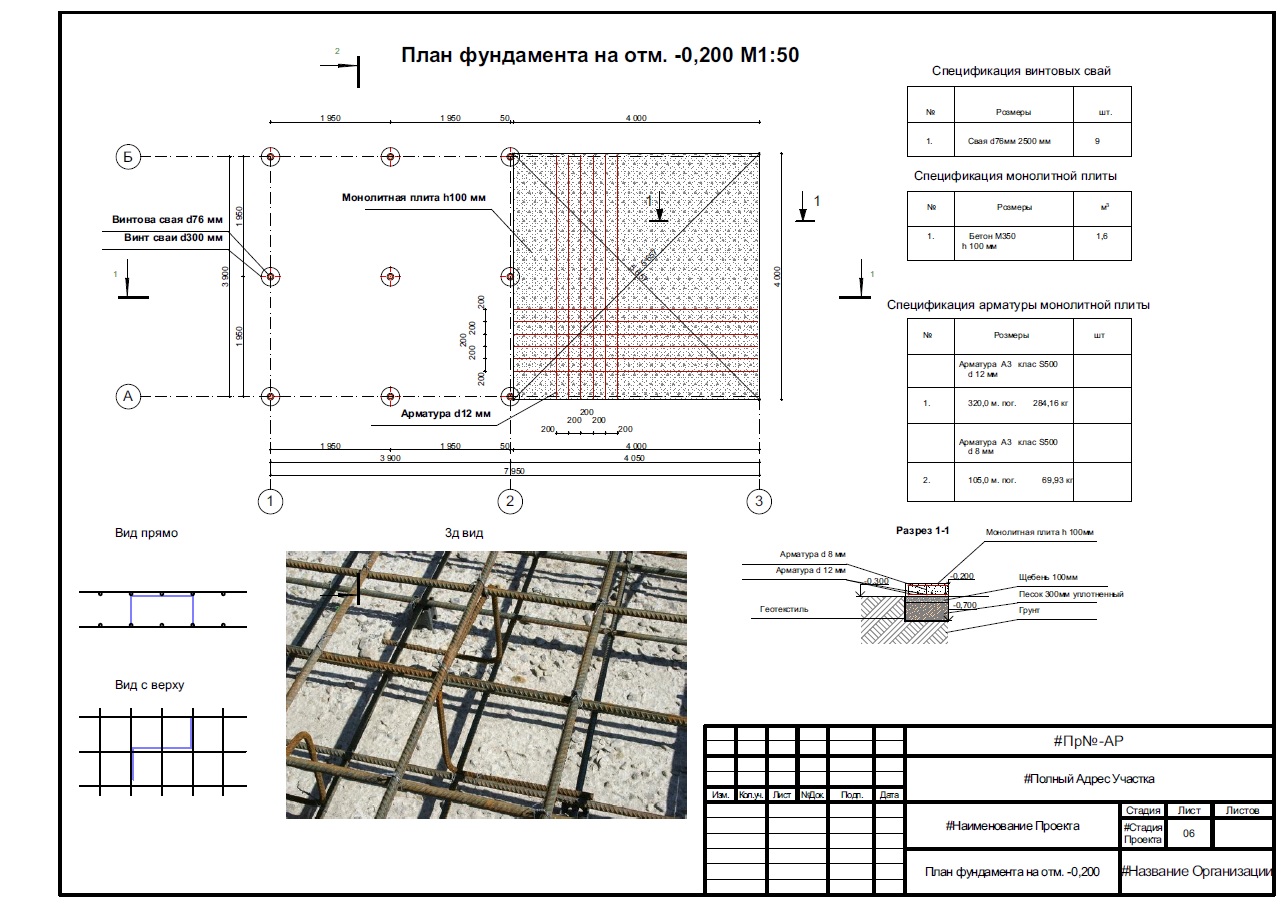

An example is the calculation of the reinforcement of a monolithic base, the slab size of which is 8x8 m. A rod with a diameter of 10 millimeters is ideal for reinforcement. In some cases, rods are used for longitudinal reinforcement, the diameter of which is 14 millimeters, and for transverse - 8 mm.

Monolithic reinforcing mesh

Monolithic reinforcing mesh

As for the rules according to which the reinforcement is laid, the step between the bars of the reinforcing mesh is 20 centimeters. Knowing this distance and the thickness of the rod, you can accurately calculate the number of rods required to complete the work. It is enough to divide the width of the slab by the step width and add one bar. In this case, you get 8: 0.2 + 1 = 41.

If in our case the length and width of the slab are equal, then we can multiply the resulting number by 2 to calculate the number of longitudinal rods. Otherwise, the calculation can also be carried out using the size of the slab length. Therefore, 41x2 = 82 rods.

This means that after calculating the number of rods for the first layer, you can multiply the result by 2 and get the total number. 82x2 = 164 rods.A reliable connection is required to ensure communication between the layers of the mesh. To do this, use special mounts. The total length will be 164x6 = 984 meters, since 164 is the total number of rods, and 6 is the standard length of one rod.

The reinforcement mesh is knitted using a special knitting wire. Welding contributes to structural failure due to the effects of corrosion. To determine the number of points at which the rods intersect, it is enough to multiply the number of rods used by the same number. 41x41 = 1681. Each knot will need at least 30 centimeters of wire, which means 1681x30 = 5043 m of wire.

Watch the video on how to correctly knit the reinforcement.

The calculation of the reinforcement for the slab foundation can be done independently. In such calculations, knitting, packing, and mesh spacing are taken into account. But specialized organizations will perform such a calculation with higher accuracy thanks to software developed for designers.

How to work with a calculator

The calculator allows you to roughly calculate the amount of building materials for a slab foundation - reinforcement, concrete, boards for formwork, waterproofing, sand and crushed stone for a pillow, in order to check the construction estimate or quickly calculate how many materials to order if you are building without a project. Do not have the illusion that with the help of an online calculator you can calculate the foundation by loads; for this, at least you need to do geological surveys and have a house project on hand. For such calculations, please contact the designers.

Reinforcement

In parameters:

House material - the choice of material does not affect the calculation, but only displays the recommended step of the slab reinforcement cell in the calculation table. In any case, the cell pitch must be calculated by the house designer, this value is given for reference.

Working reinforcement diameter - the diameter of the main working reinforcement (mesh) of the foundation from your project.

The cell pitch of the working reinforcement is the distance between the rows of the working reinforcement.

Grid step

Shear reinforcement diameter - the diameter of the reinforcement that serves to separate the lower and upper layers of the reinforcement (spider).

Rebar spider

In counting:

Recommended diameter of working reinforcement - depends on the larger length and width of the slab. 0 to 3 meters, recommended diameter = 10 mm, 3 to 10 meters diameter = 12 mm, 10 to 20 meters diameter = 14 mm. This value is for reference only.

Recommended diameter of transverse reinforcement - if the height of the slab is less than 30 cm, then the diameter = 8 mm, if the height of the slab is more than 30 cm, then the diameter = 10 mm. The value is for reference only.

Recommended cell size of working fittings - depends on the selected material at home. The value is for reference only.

The number of layers of working reinforcement - if the height of the slab is less than or equal to 15 cm, then the number of layers (nets) = 1, if the height of the slab is more than 15 cm, the number of layers of working reinforcement = 2.

The minimum overlap of the working reinforcement when connected in one row = 40 multiplied by the diameter of the working reinforcement.

The length of the working reinforcement is calculated taking into account the reinforcement under the walls - one row of reinforcement is added at the edges of the foundation (the cell pitch is two times less than the specified one), the reinforcement under the inner walls must be taken into account independently.

The number of coasters is calculated with a density of 2 pieces per m².

Reinforcement for reinforcing the ends is understood as U-shaped clamps for reinforcing the ends (see the figure below):

Formwork

Here, only the height (width) of the boards is set for the formwork itself and for vertical supports with a step of 0.5 meters. The length of all boards is taken equal to 6 m. The thickness of the formwork boards is taken to be 40 mm, the thickness of the boards for the supports is taken to be 50 mm. The length of the spacers is not calculated because not everyone uses them.

Pillow

Release of the pillow behind the foundation - the pillow is always made slightly wider than the slab itself, usually by 20-30 cm, sometimes the pillow is made immediately under the blind area - about 1 meter wider than the slab.

Cost of materials

The cost does not include concrete for foundation, geotextiles and waterproofing, since these elements are not strictly required in the construction of a slab foundation, and not all of them do.

Good publicity

Features of foundation reinforcement

In contrast to the reinforcement of floors, the laying of reinforcement in foundation slabs should be carried out in an uneven order. To ensure the maximum reinforcement of the zones under increased load, the rods should be laid taking into account the level of punching in one place or another of the slab. An exception is a thin foundation base (no more than 150 mm), laid under light structures - in such cases, the layout is carried out in the form of a grid.

In residential construction, the thickness of the foundation, as a rule, varies in the range of 20-30 cm and depends on the mass of the structure and the properties of the soil. To ensure the maximum possible reinforcement, the reinforcement should be laid in two layers, on top of which a protective concrete layer should be provided to prevent corrosion.

Useful Tips

Before proceeding with the calculation of the amount of materials and the base itself, you need to study all the features of the soil. Loose soil can rise and fall several centimeters throughout the year. If this is not taken into account, then over time, the foundation will begin to burst under stress, and cracks will go throughout the house.

The reinforcement is connected with a wire, which makes it mobile and because of this, frozen concrete, under the influence of soil deformations, will also be mobile, which will preserve its structure and guarantee the absence of cracks.

Related videos:

Payment

Let us analyze how the calculation of materials is made for a plate of 8 by 8 meters. Reinforcement will be carried out with a step of 20 centimeters, rods with a diameter of 14 in two layers, for vertical rods 8 millimeters, the step is the same. We take the concrete used for the slab of class B20 (the strength corresponds to the grade M250) for preparation of class B7.5. We take the thickness of the slab 25 cm.

- Concrete for slab B20: 8.2 x 8.2 = 67.24 m²;

- Let's calculate the cubic capacity, that is, the volume of the required concrete: 67.24 m² x 0.25 m = 16.81 m³;

- Consumption of the amount of material for reinforcement, taking into account the provision of the protective layer of the slab: 8200 - 60 = 8140 mm rod length. Based on a step of 20 cm, we calculate their number for 1 direction, divide 8200 by 200 = 41 pieces x 2 sides = 82 pieces x 2 layers of the entire plate = 164 rods;

- Let's calculate the total length: 164 x 8.14 = 1334.96 meters. The mass of 1 meter of reinforcement 14 with a diameter is 1.2 kilograms. Thus, the mass of the entire working reinforcement: 1334.96 meters x 1.2 = 1601.252 kilograms;

- Let's move on to the vertical reinforcement rods, its length will be equal to the difference of 25 cm and 6 cm = 19 cm.Take a step of 40 centimeters, we get 21 pcs x 21 pcs = 441 units, we get the mass from the expression 441 x 0.19 x 0.395 = 33, 1 kg;

- Consumption of class B7.5 concrete for preparation is calculated as: 8.2 x 8.2 x 0.05 (specified thickness) = 3.3 meters³;

- Geotextile and slab waterproofing are considered as slab area adding a little margin: 67.24 meters²;

- We consider the sand cushion by multiplying the sides of the slab and the height of the cushion, taking into account that it goes beyond its boundaries by 0.1 meter on each side, that is, 8.4 x 8.4 x 0.5 = 32.5 cubic meters of sand.

Note that for two-story houses made of aerated concrete (gas silicate), frame and garages (made of bricks), the thickness of the slab will be 20-25 centimeters. For heavier buildings, as well as two-story houses made of brick, concrete, timber, the thickness must be taken from 25-30 cm. For light structures, for example, garages and gazebos, it is enough to take foundation slab thickness 10-15 centimeters.

Reinforcement of the foundation with a thickness of 10-15 cm is made in one layer, with a thickness of 20-30 cm - in two layers (volumetric).